Patents

Literature

53results about How to "Constant friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

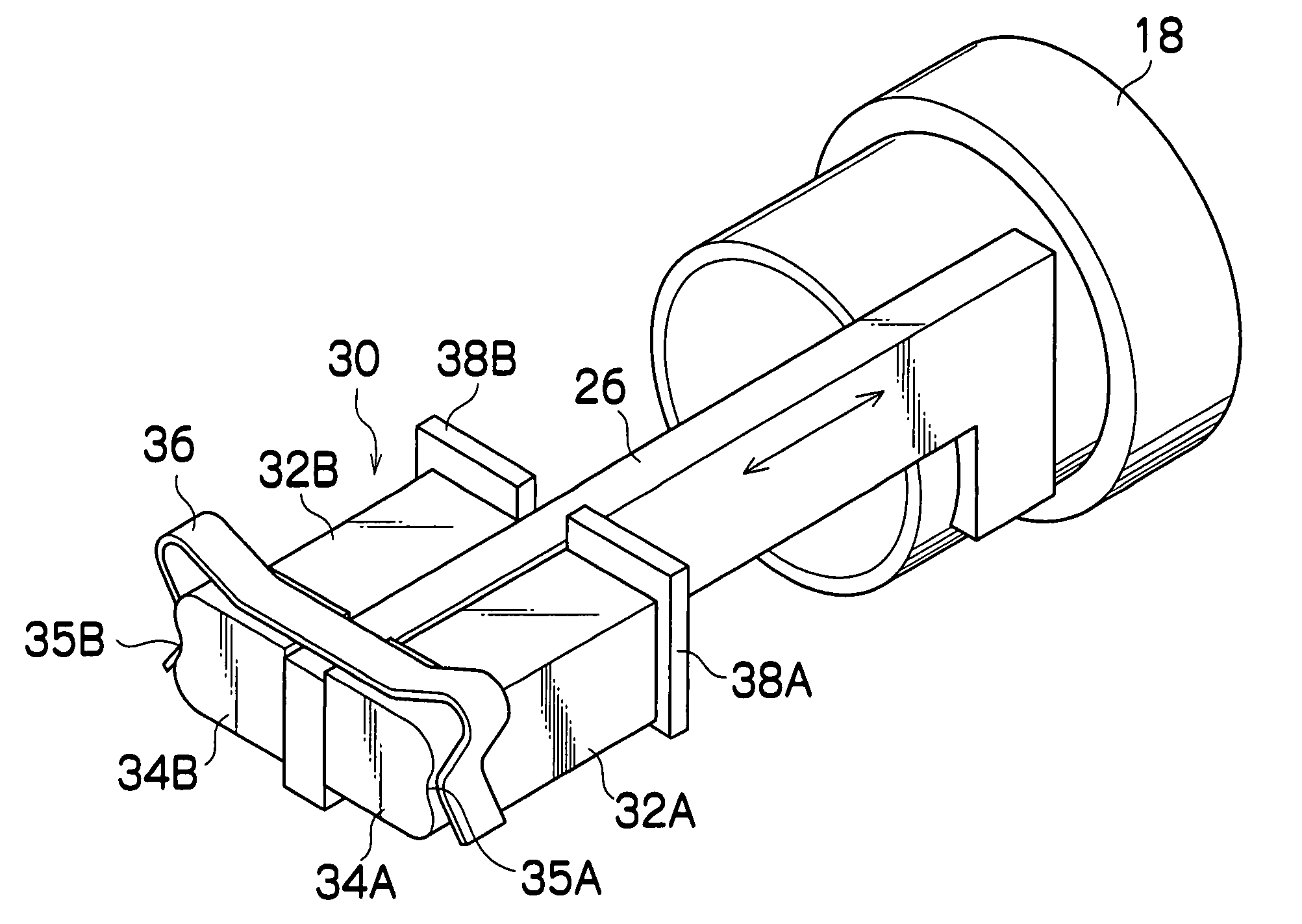

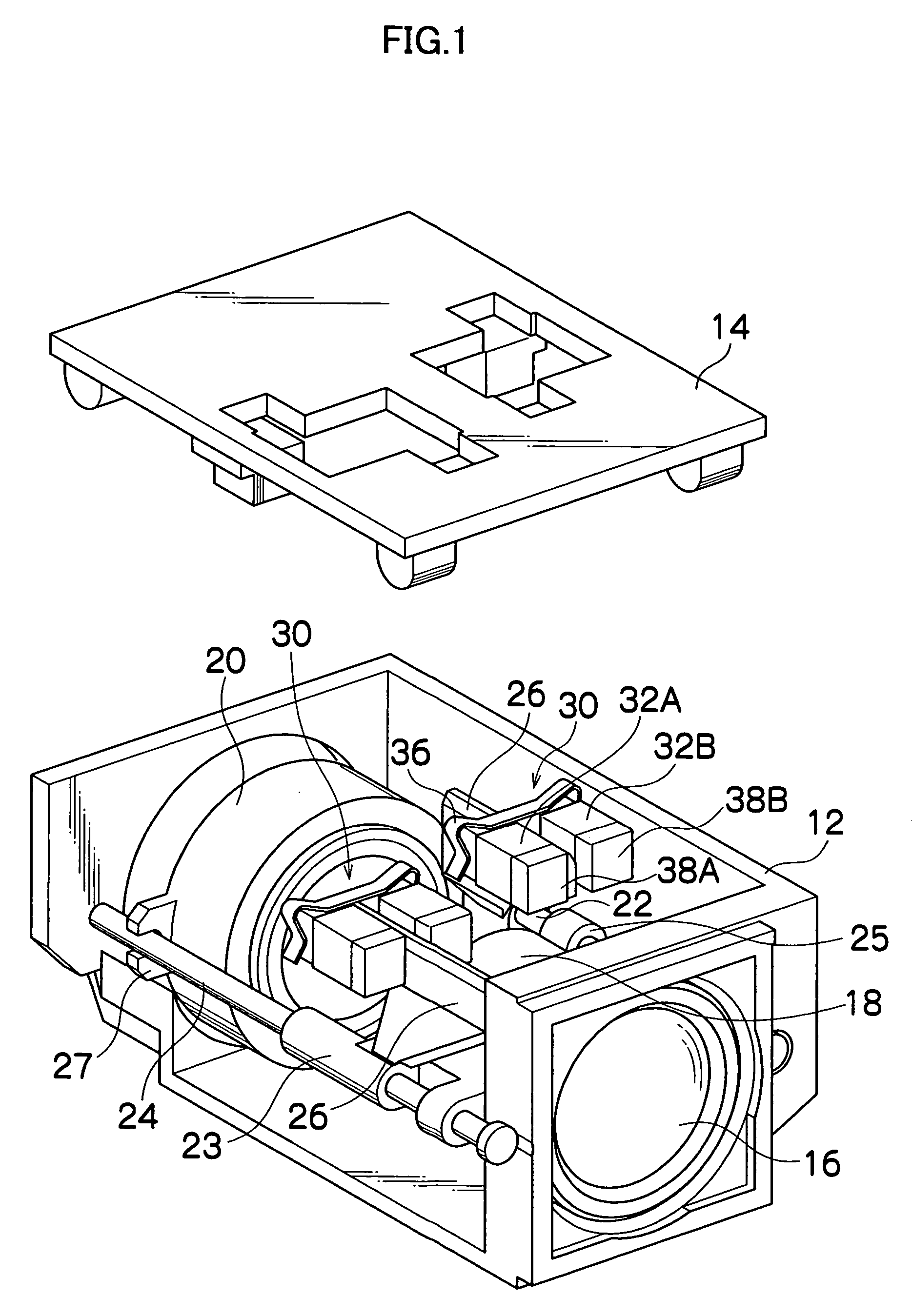

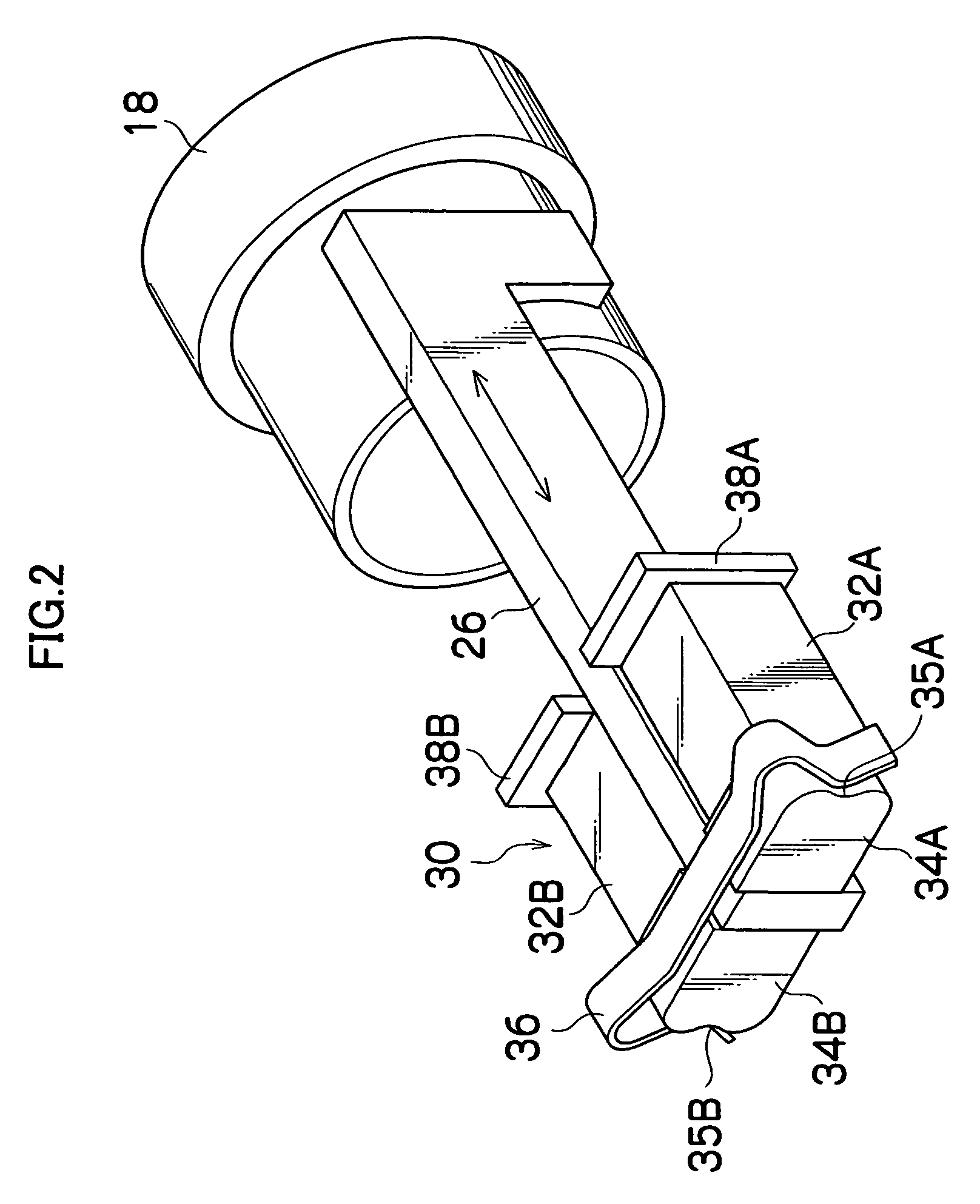

Actuator and its control method and lens device

InactiveUS20050275315A1Small installation spaceMove preciselyPiezoelectric/electrostriction/magnetostriction machinesMountingsOptical axisActuator

An actuator which drives a lens frame in an optical axis direction is constructed by piezoelectric elements, driving members, and a pressing spring. The piezoelectric elements are placed at opposite sides with a driven plate therebetween, and the driving members are fixed to the respective piezoelectric elements. The driving members are pressed against the driven plate from both sides by the pressing spring.

Owner:FUJI PHOTO OPTICAL CO LTD

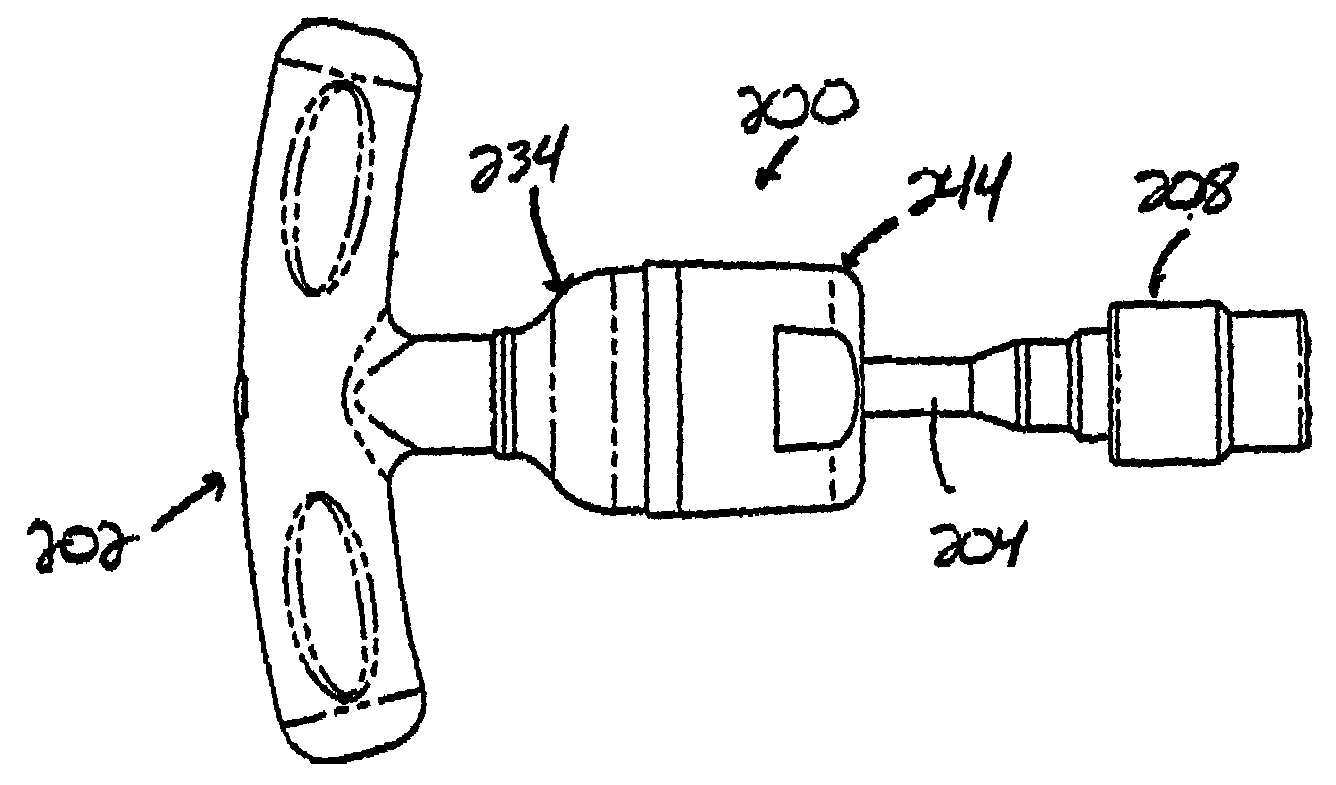

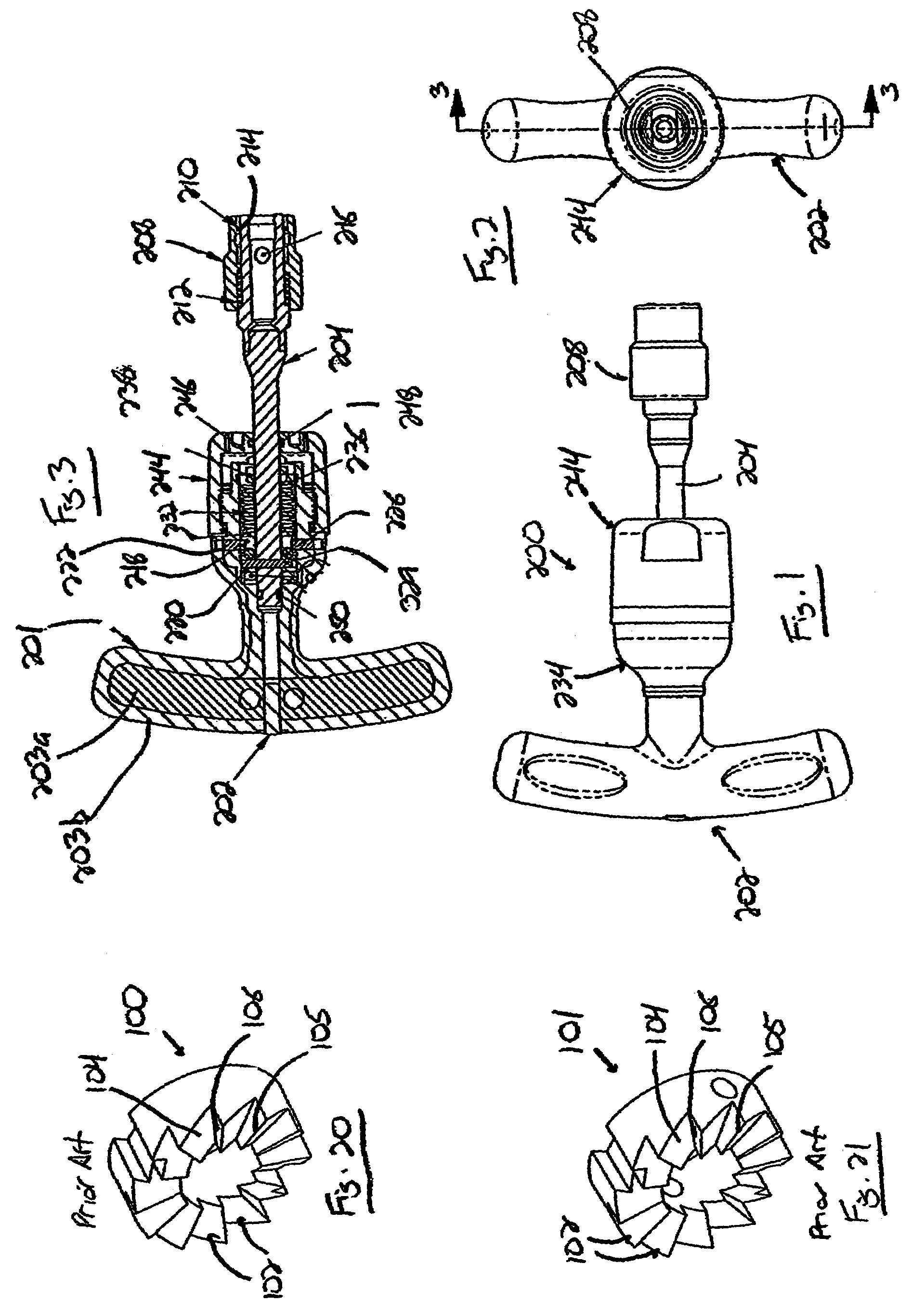

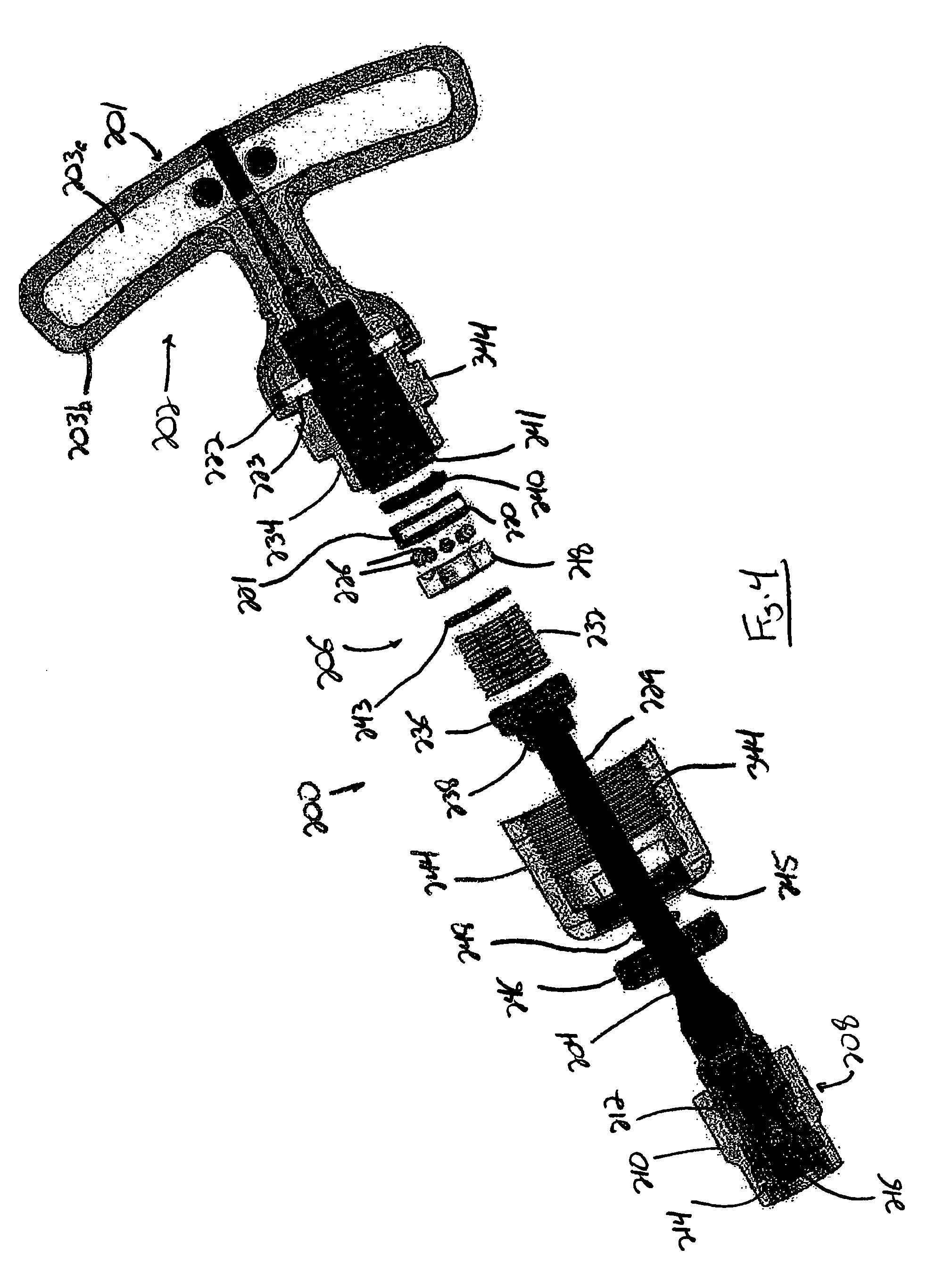

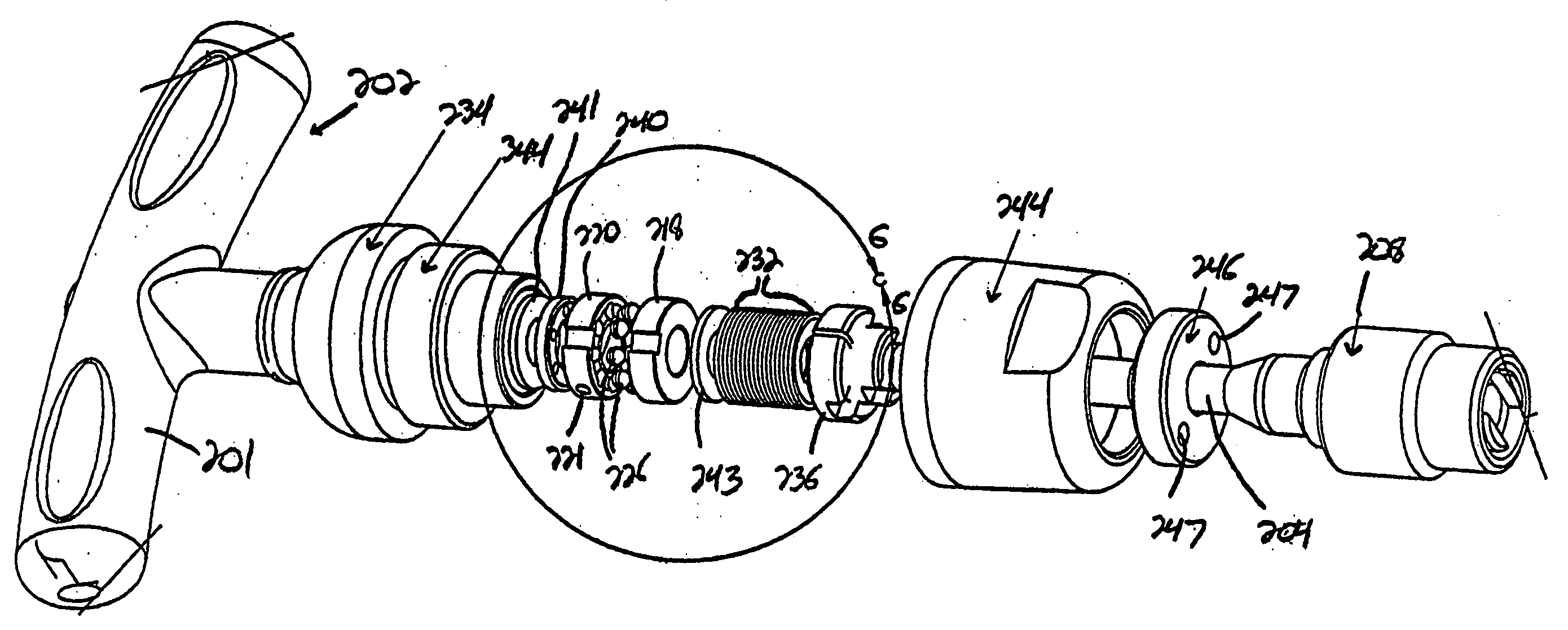

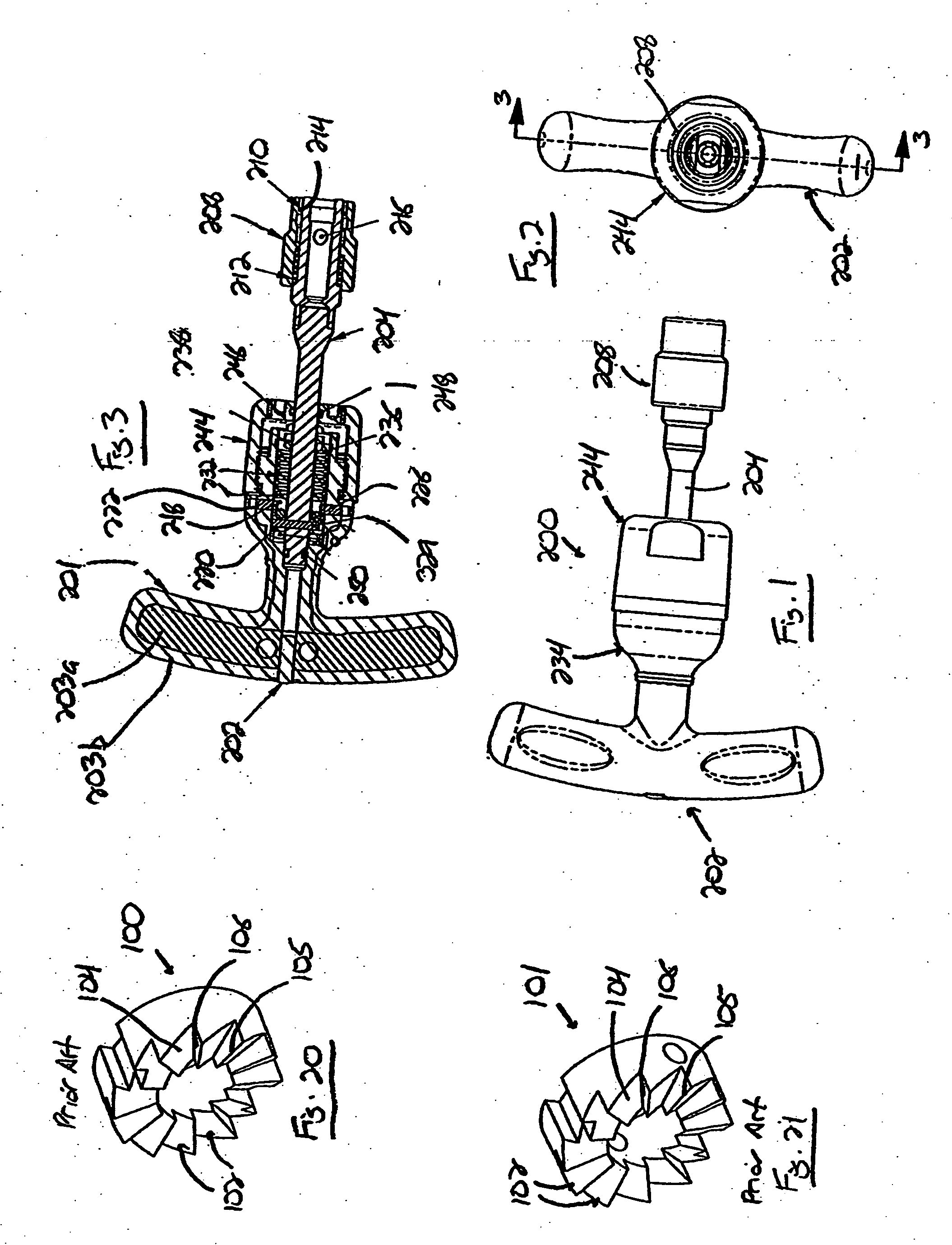

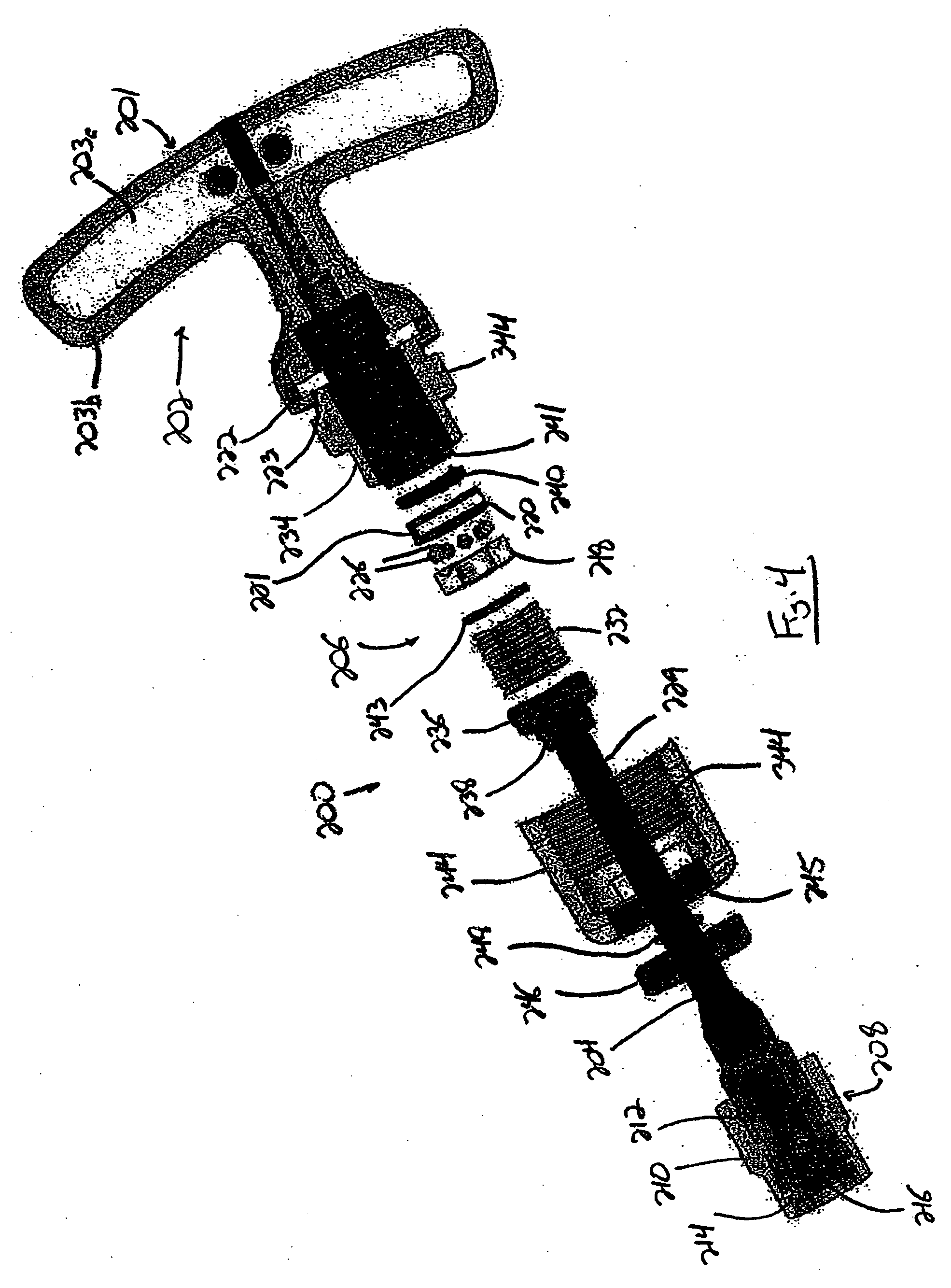

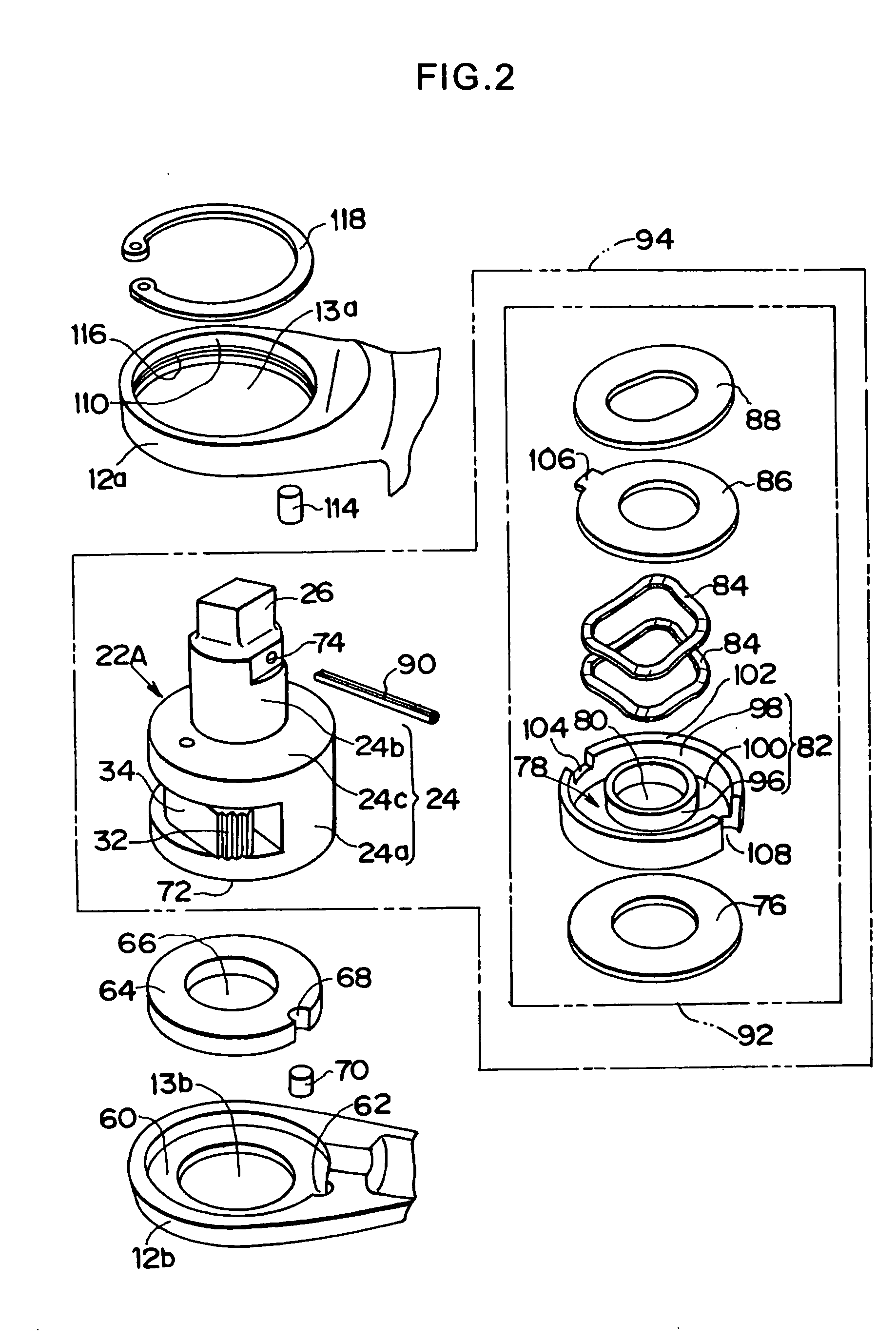

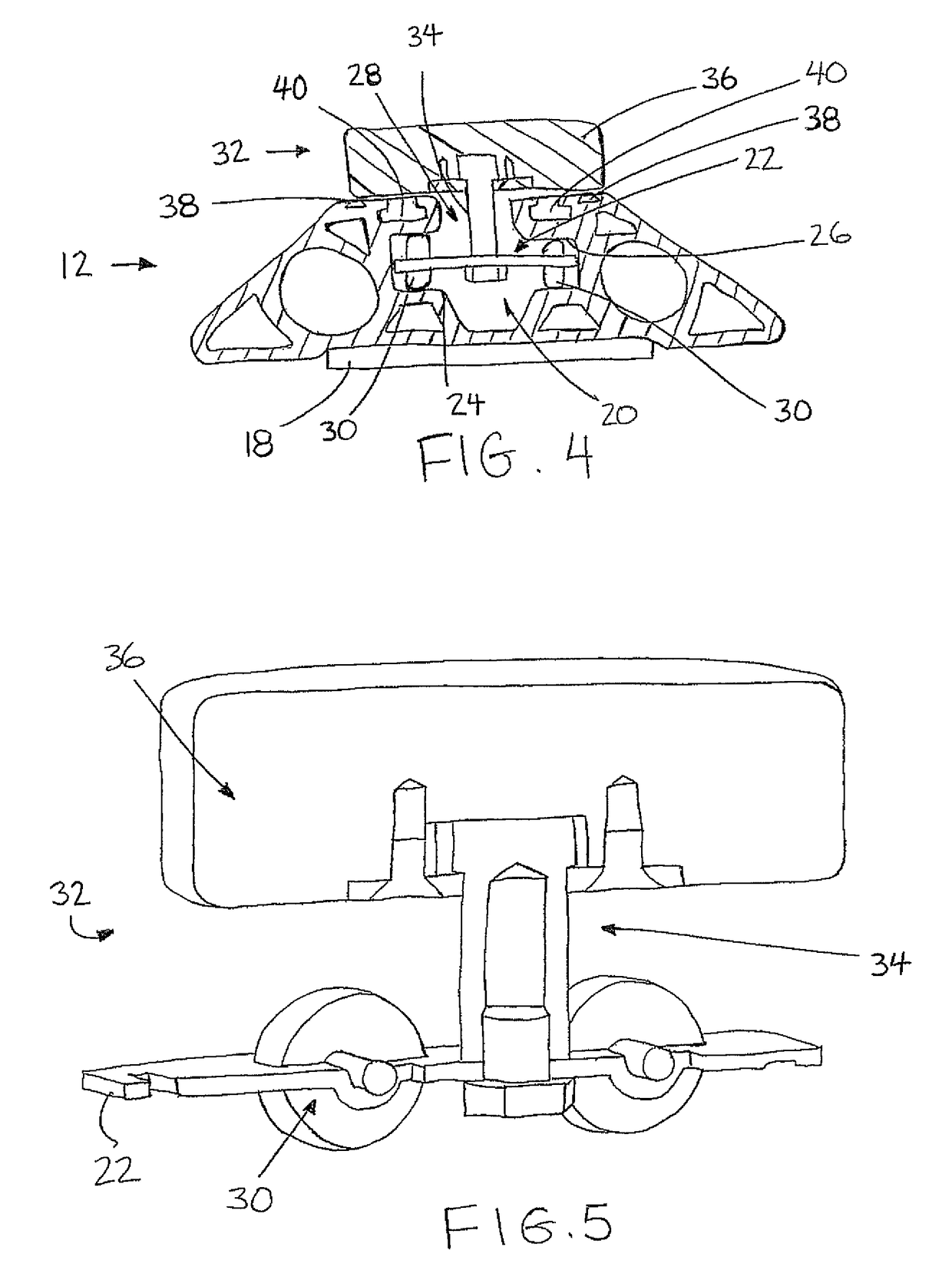

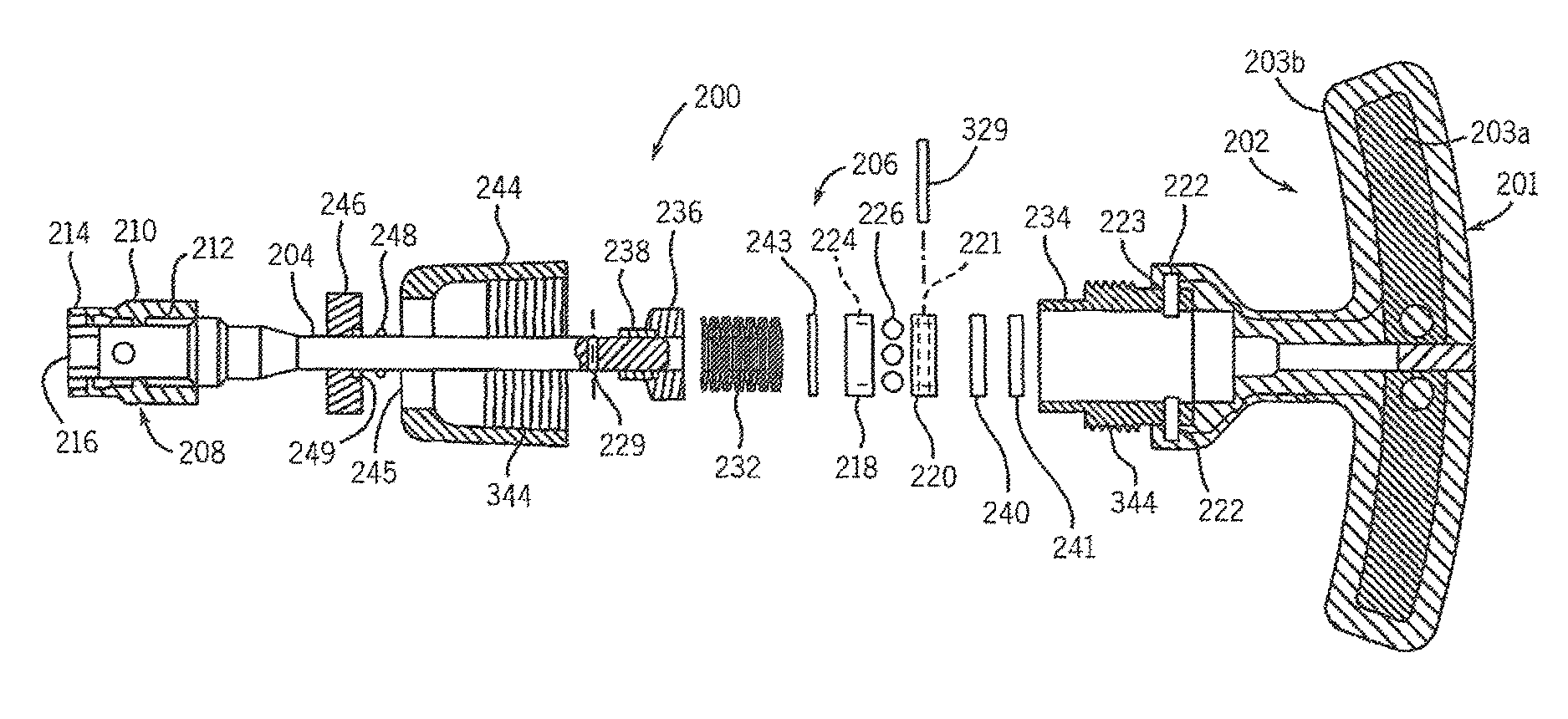

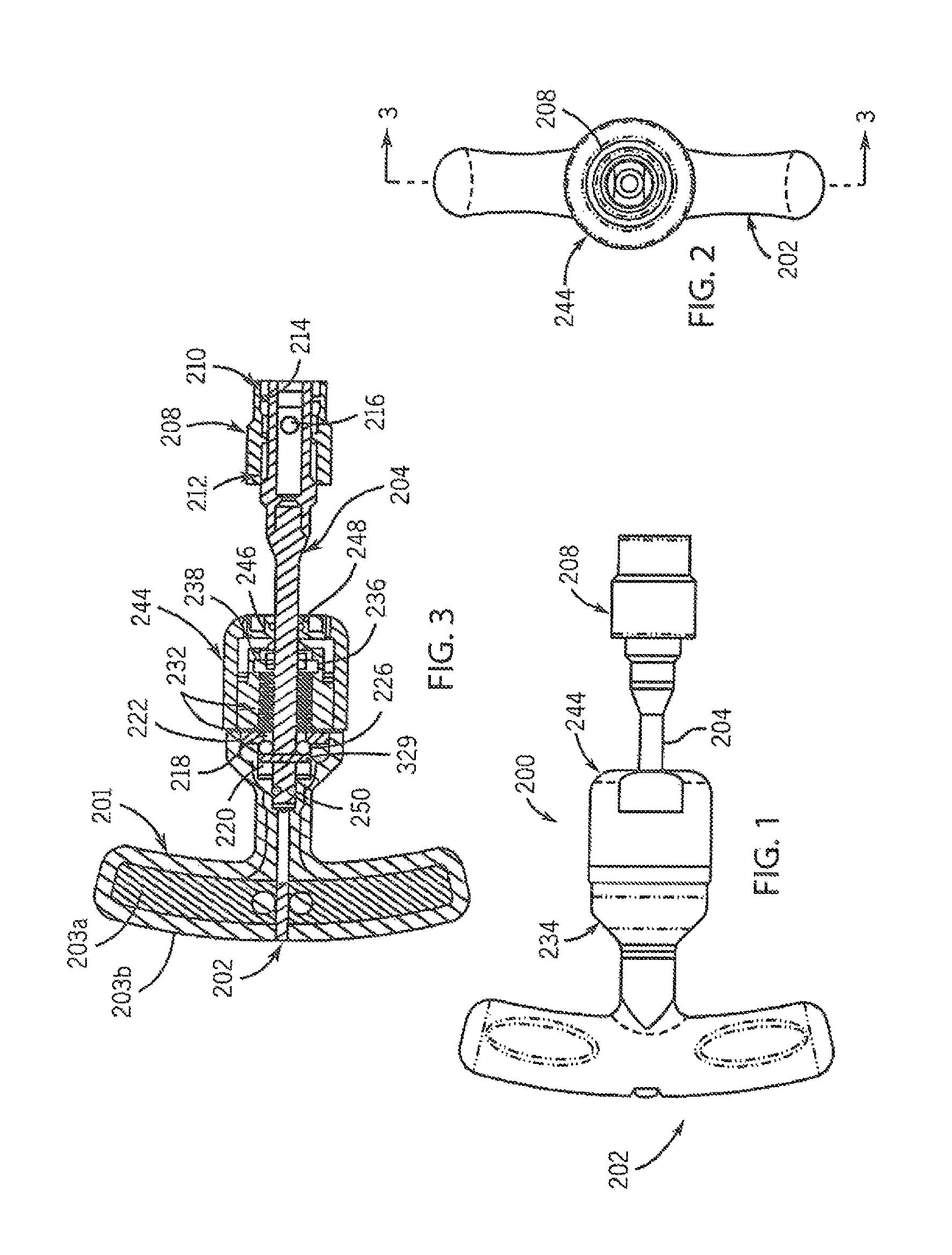

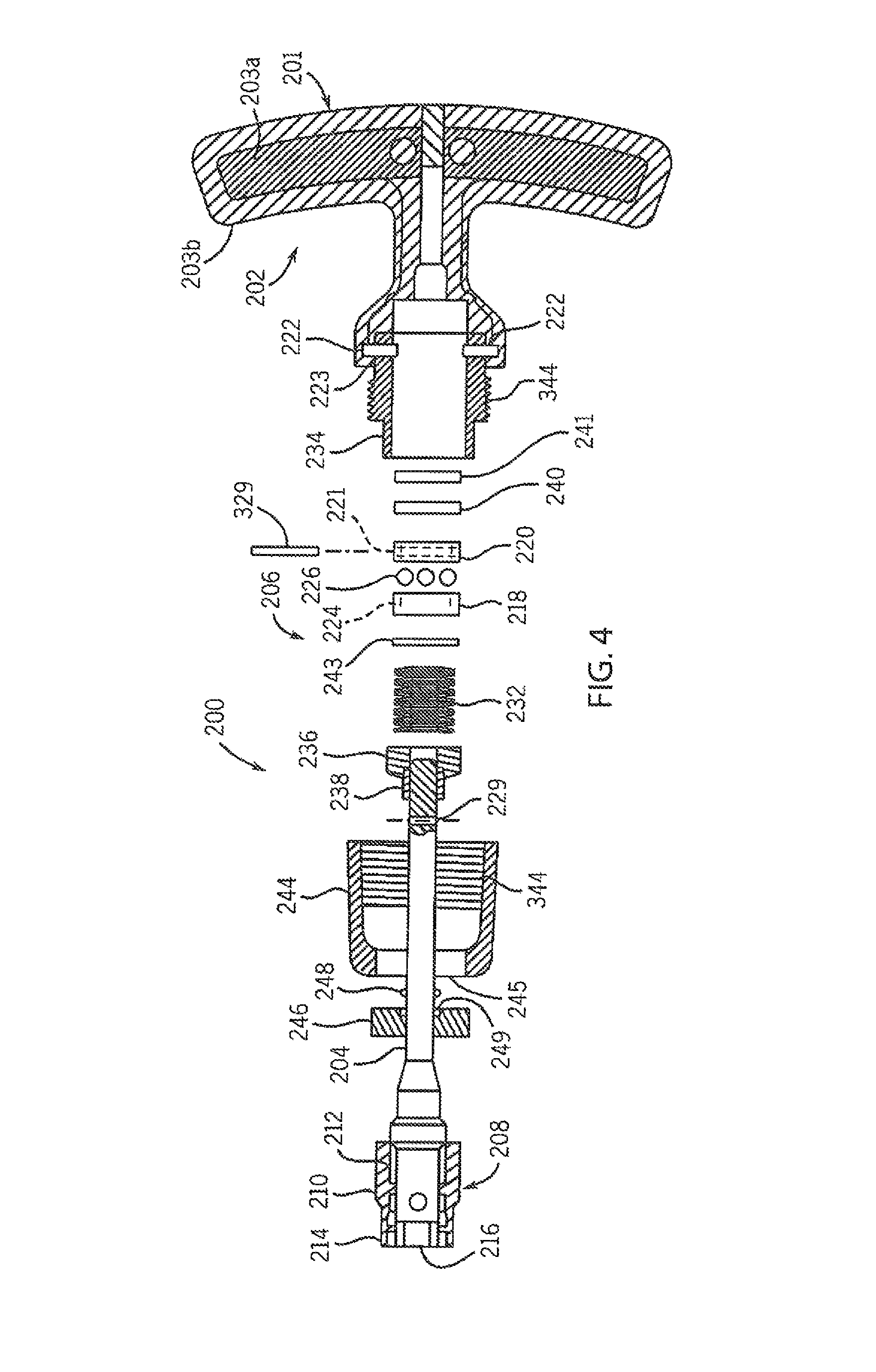

Torque-limiting mechanism

A torque-limiting mechanism is provided for use in a variety of torque-applying tools. The mechanism includes a handle defining a housing in which are disposed a slip gear and a fixed gear. The fixed gear is attached to the housing while the slip gear is attached to drive body extending outwardly from the housing and engageable with an item to be turned utilizing the tool. The slip gear and the fixed gear are connected by ball bearings disposed within recesses located on each gear that are pressed into the recesses by a force exerted on the gears by a number of spring members disposed between an enclosed end of the housing and the fixed gear. The amount of force exerted by the springs on the gears can be varied as necessary, thereby allowing the amount of torque required to enable the slip gear to move with respect to the fixed gear to be set where desired. The use of the ball bearings as the engagement members between the fixed gear and the slip gear provides a smooth transition between positions when the slip gear rotates with respect to the fixed gear, and greatly reduces the amount of friction forces acting on the torque-limiting mechanism, such that the force controlling the operation of the mechanism is solely provided by the springs and easily predictable and controllable.

Owner:GAUTHIER MICHAEL T

Torque-limiting mechanism

ActiveUS20060278051A1Reduce the amount of variationReduce frictionSpannersWrenchesBall bearingGear wheel

A torque-limiting mechanism is provided for use in a variety of torque-applying tools. The mechanism includes a handle defining a housing in which are disposed a slip gear and a fixed gear. The fixed gear is attached to the housing while the slip gear is attached to drive body extending outwardly from the housing and engageable with an item to be turned utilizing the tool. The slip gear and the fixed gear are connected by teeth disposed on each gear and by ball bearings disposed within recesses located on each gear that are pressed into the recesses by a force exerted on the gears by a number of spring members disposed between an enclosed end of the housing and the fixed gear. The amount of force exerted by the springs on the gears can be varied as necessary, thereby allowing the amount of torque required to enable the slip gear to move with respect to the fixed gear to be set where desired. The use of the ball bearings as the engagement members between the fixed gear and the slip gear provides a smooth transition between positions when the slip gear rotates with respect to the fixed gear, and greatly reduces the amount of friction forces acting on the torque-limiting mechanism, such that the force controlling the operation of the mechanism is solely provided by the springs and easily predictable and controllable. Further, the teeth, due to the angled locking surfaces formed in the teeth, enable the gears to only rotate with respect to one another in one direction.

Owner:GAUTHIER BIOMEDICAL

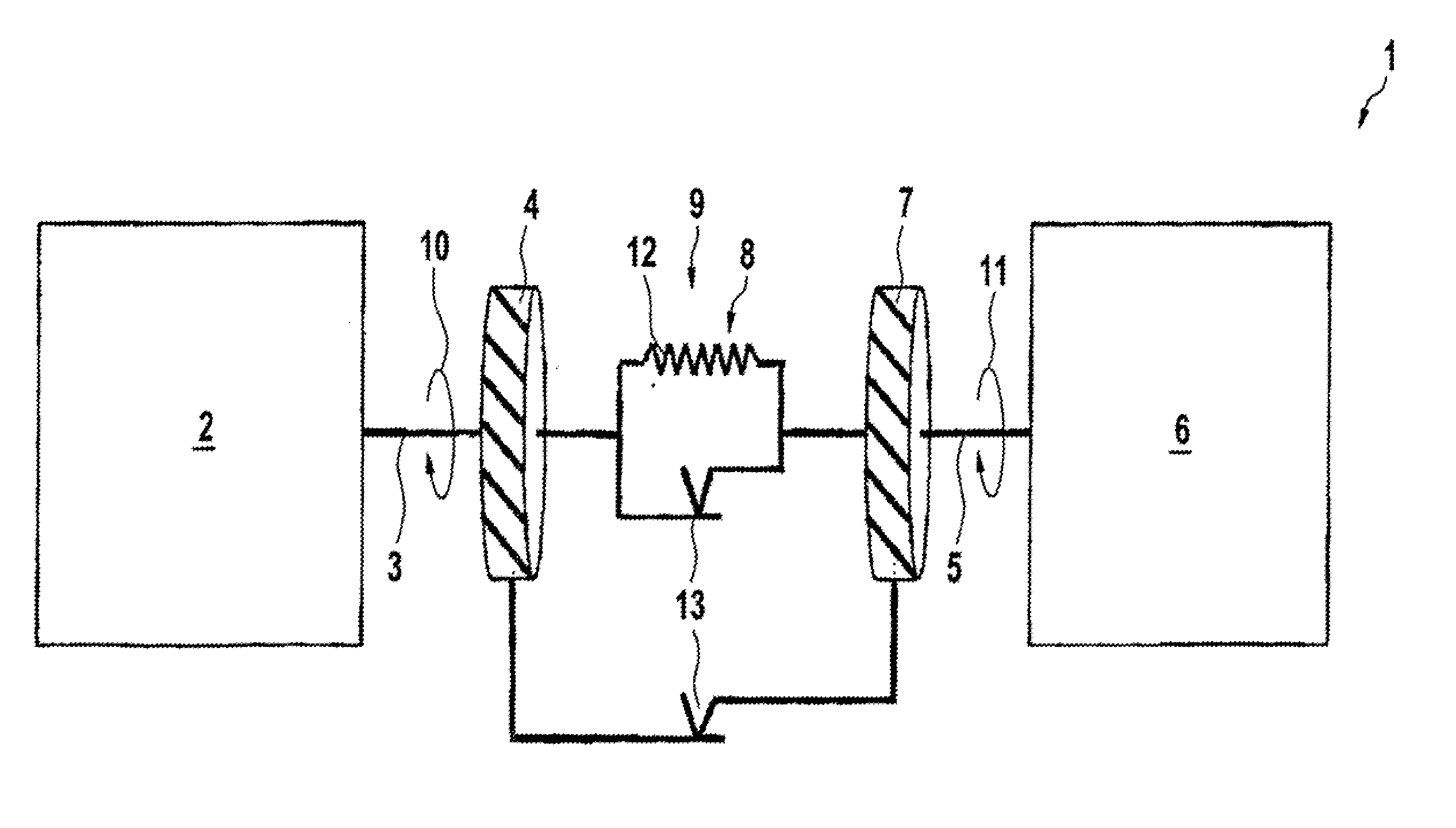

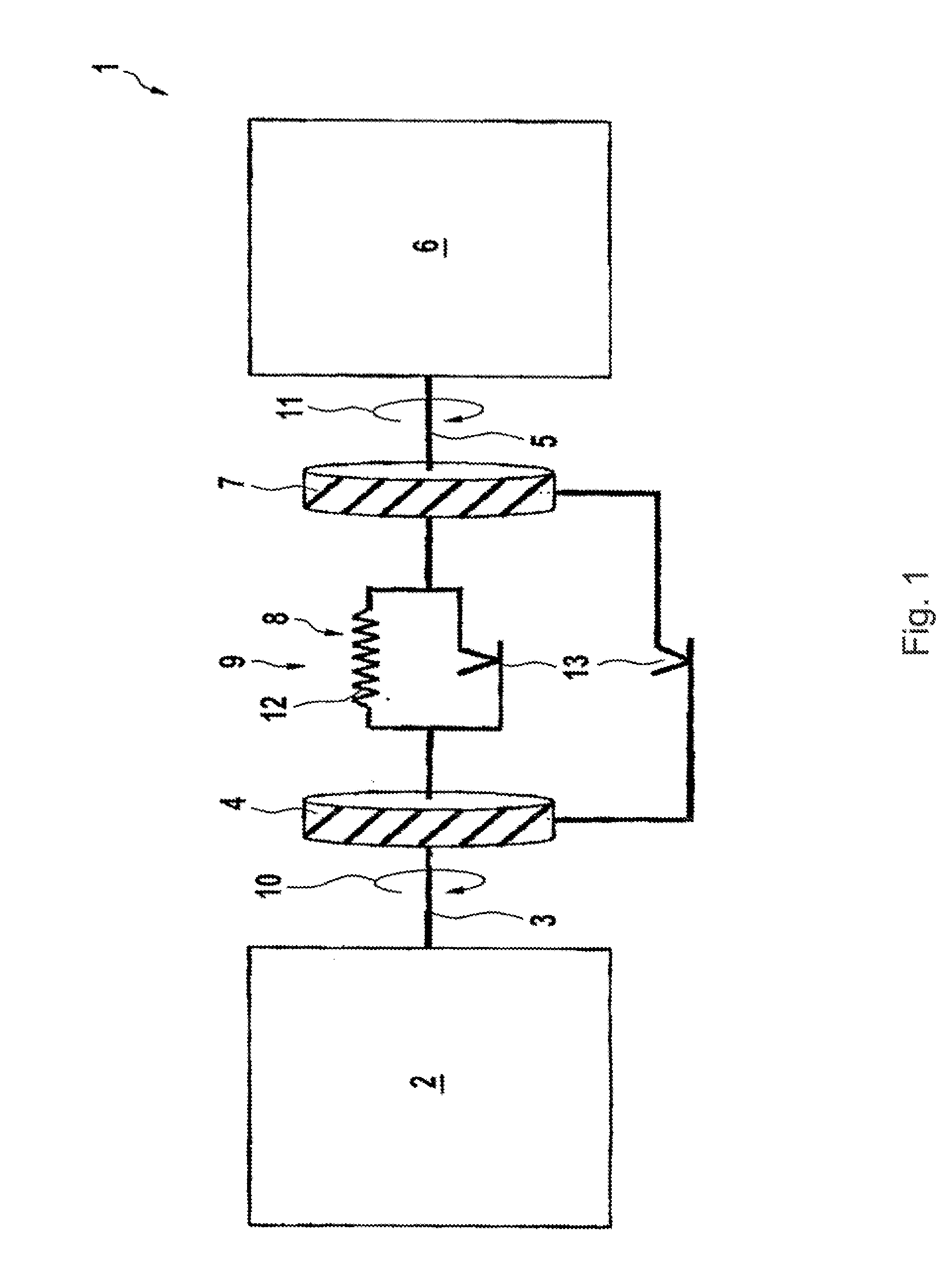

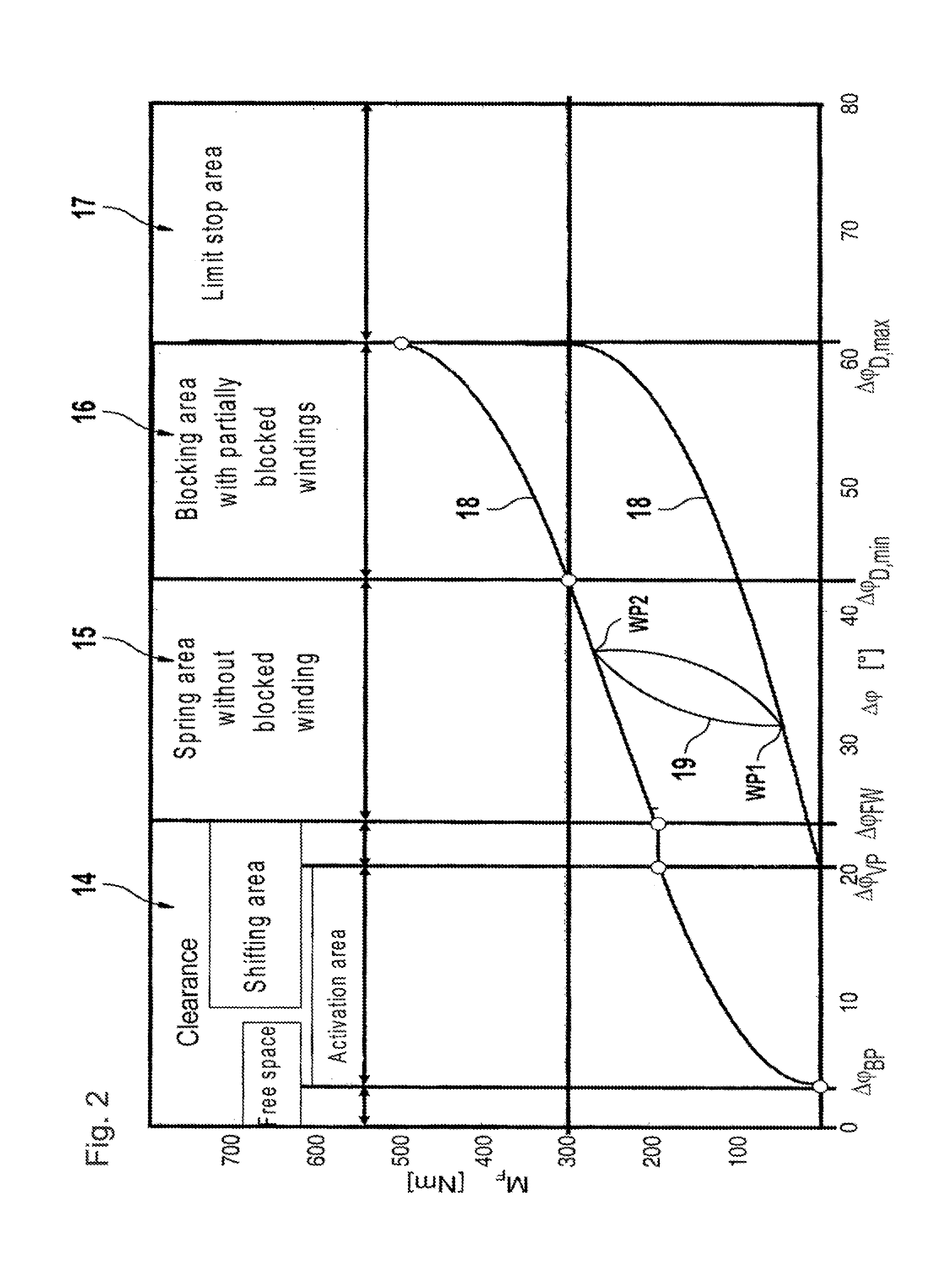

Method for operating a drive train

InactiveUS20100273607A1Constant frictionChange in stiffnessDigital data processing detailsEngine controllersRotation velocityVariator

A method for operating a drive train in a motor vehicle with a dual mass flywheel driven by an internal combustion engine via a crankshaft and at least a transmission input shaft of a transmission that can be coupled with an output part of the dual mass flywheel. Between the input part and output part a hysteresis-laden damping device is effective, which influences engine torque output from the internal combustion engine and load torque transmitted to at least a transmission input shaft through the hysteresis characteristic. To eliminate the disturbances caused by the dual mass flywheel a state model constantly determines rotation speeds of the input part and of the output part and depending on a differential angle determined from the rotation speeds and from the characteristic numbers of the damping device, a characteristic disturbance torque for influencing at least the load torque is determined in real time.

Owner:SCHAEFFLER TECH AG & CO KG

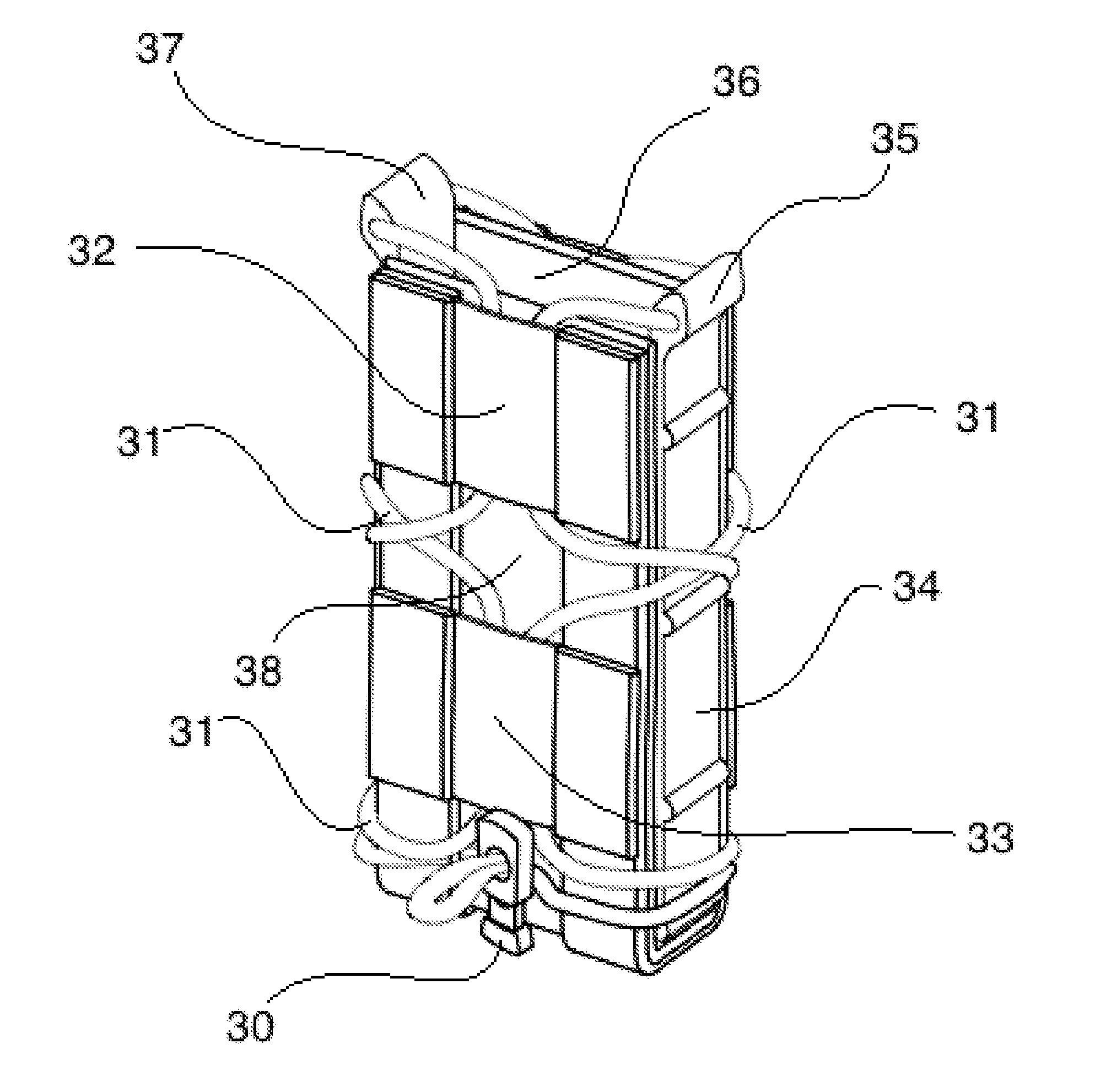

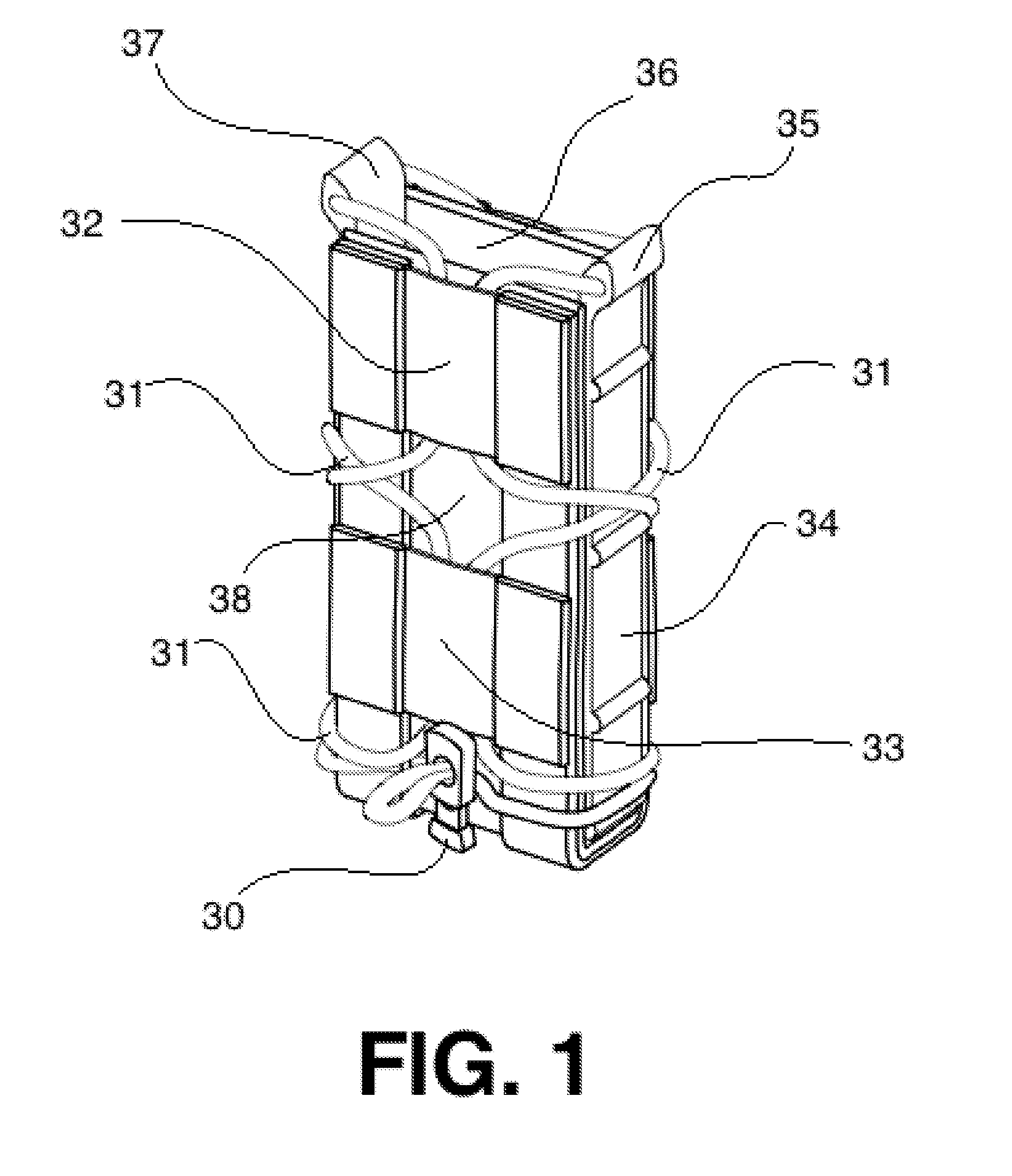

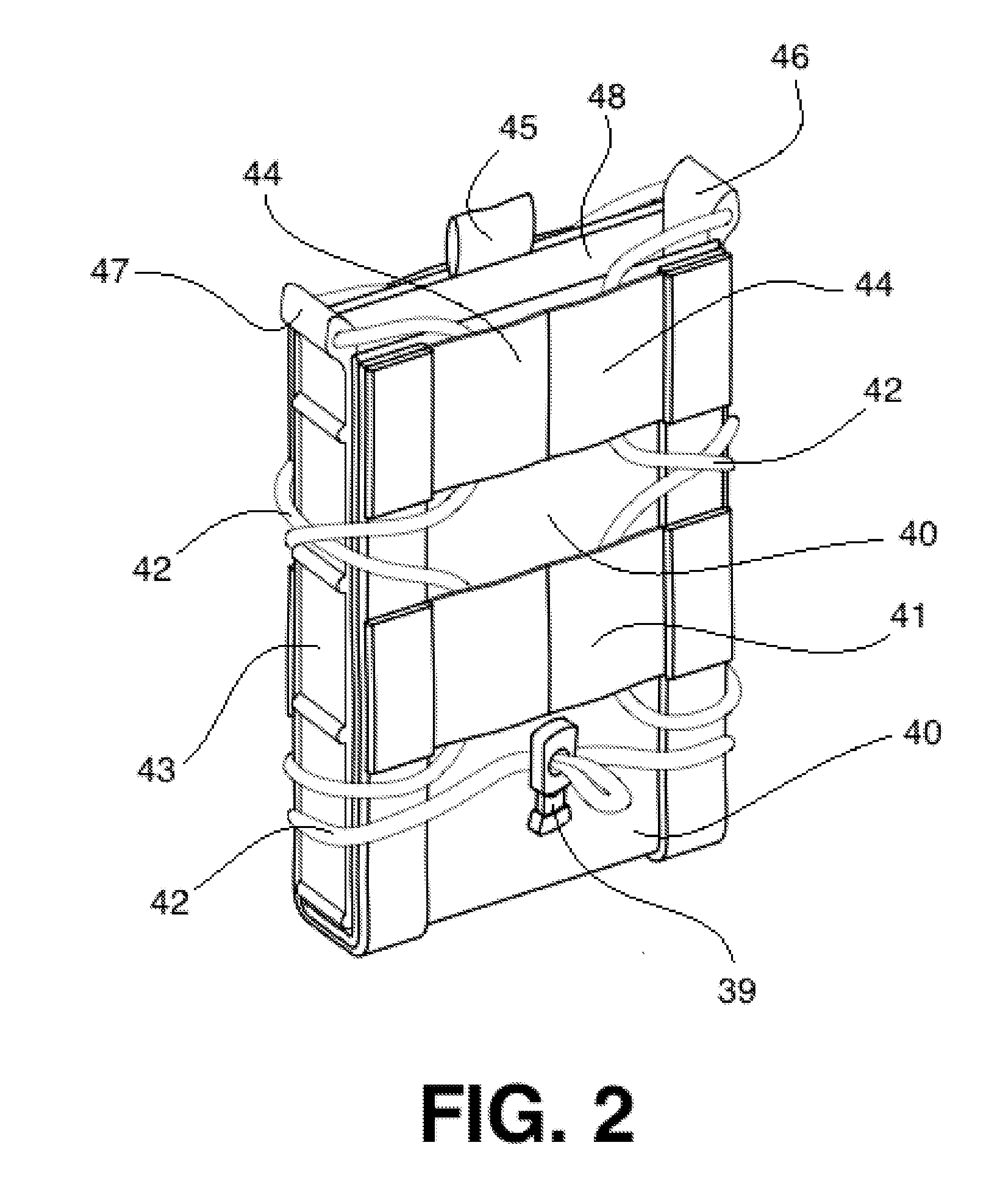

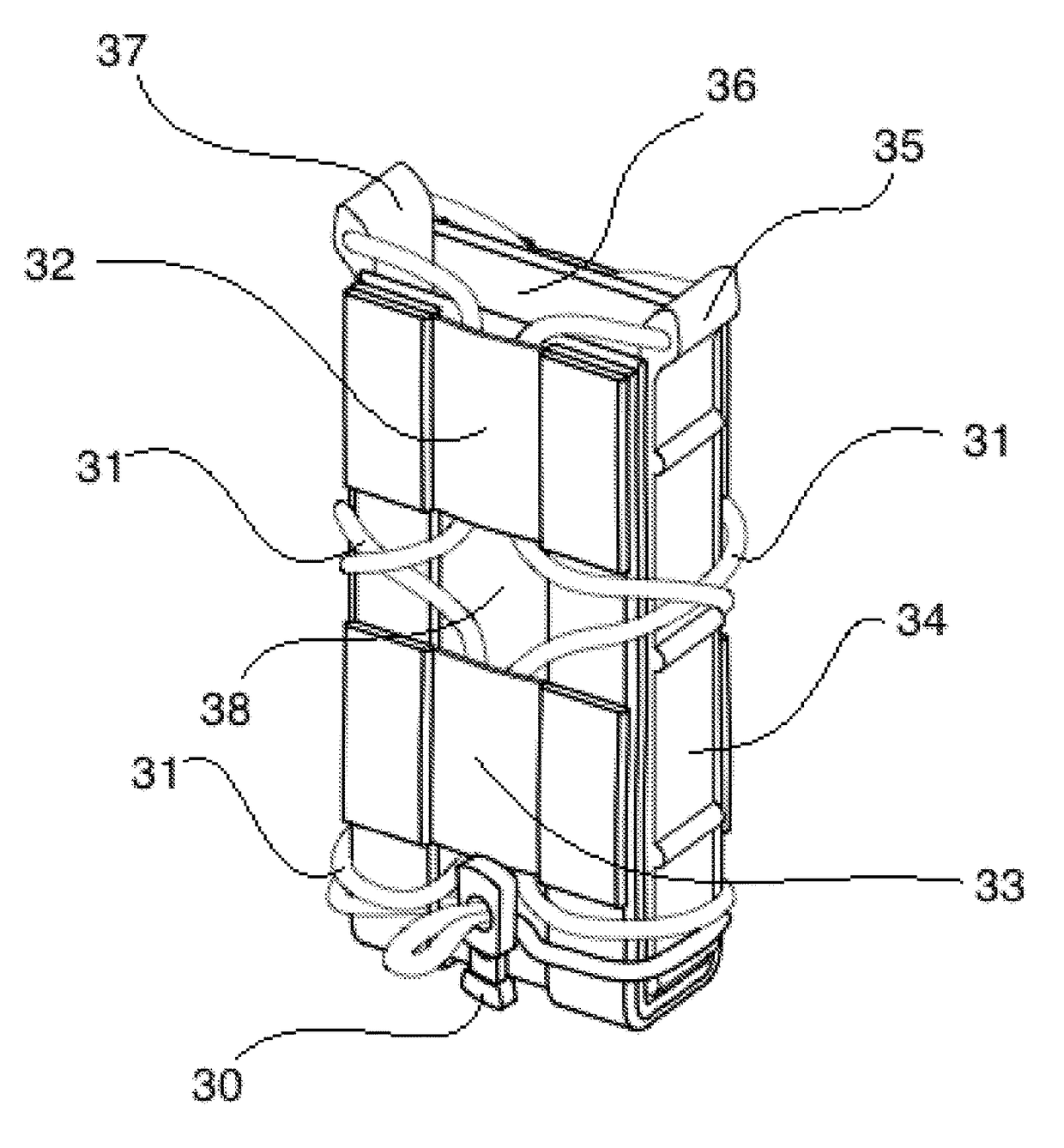

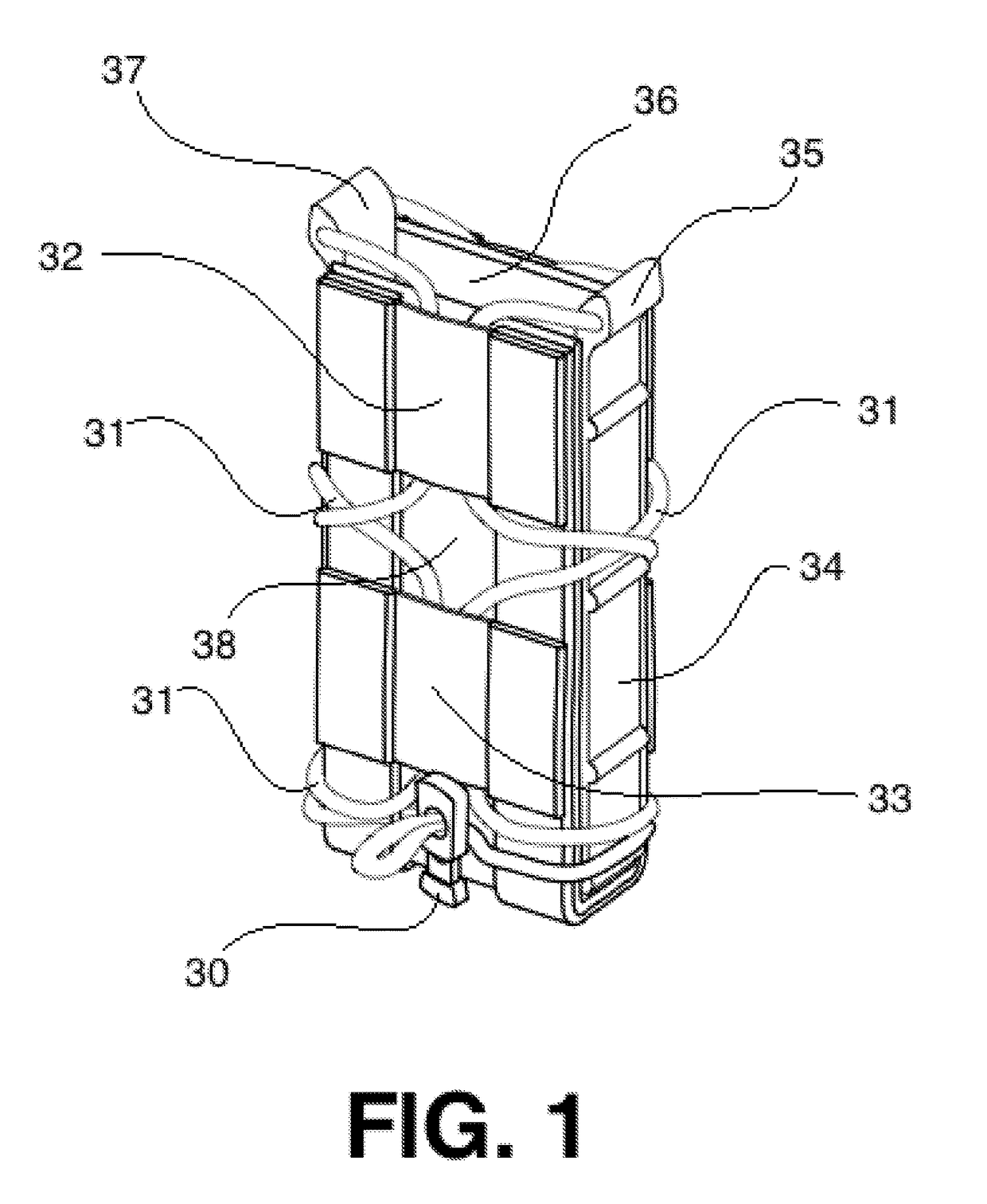

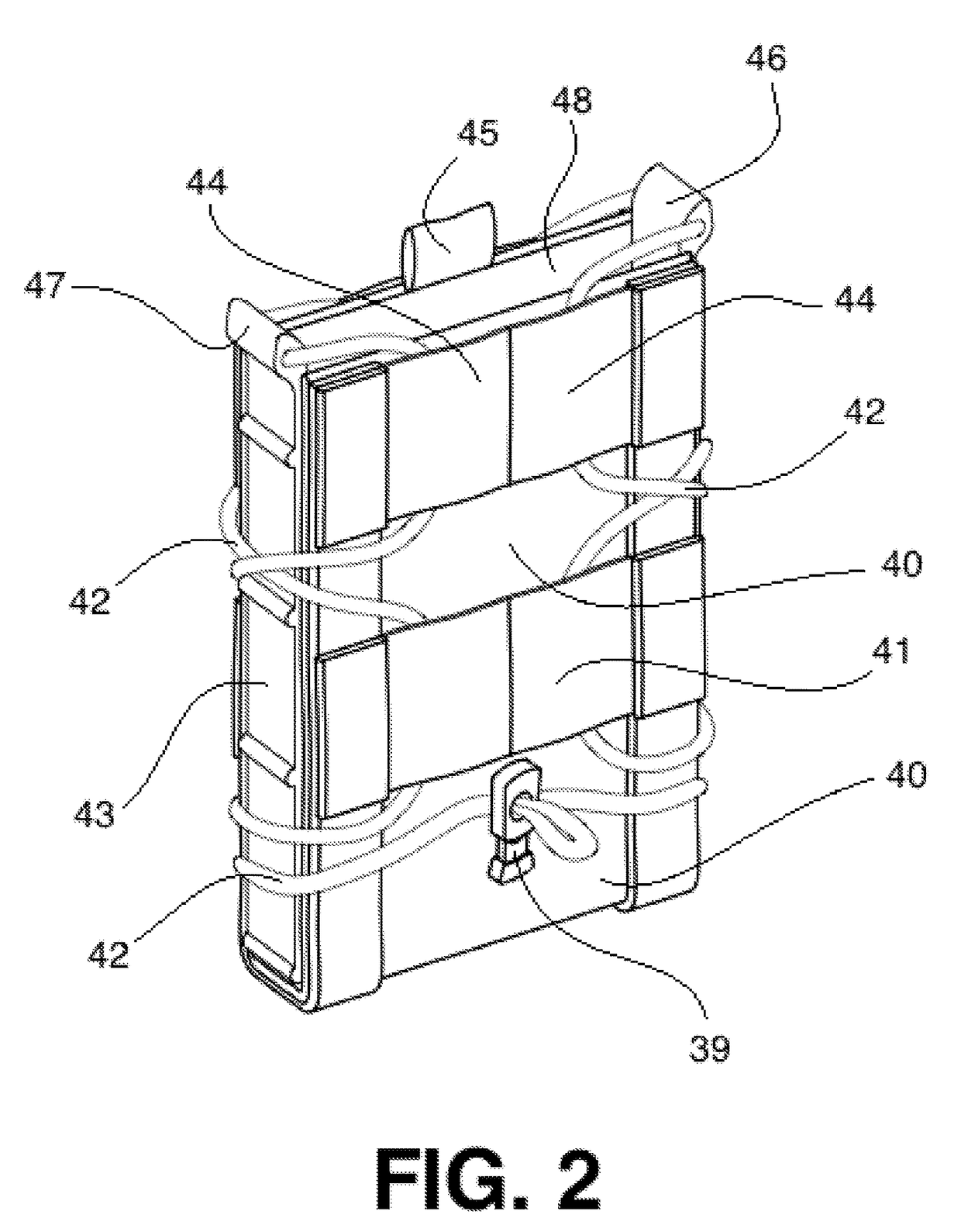

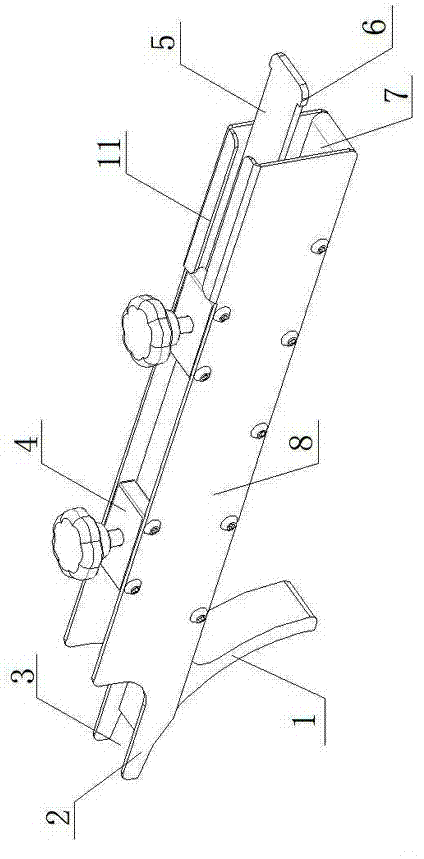

Magazine retention device

An apparatus for the secure stowing of a magazine, the apparatus comprising a pocket defined by a first pair of opposing side panels and a second pair of opposing side panels, the first pair of opposing side panels being in substantially perpendicular plane to the second pair of opposing side panels and the first pair of opposing side panels being shorter in height than the second pair of opposing side panels, a bottom panel, and a top opening; biasing means whereby at least one pair of opposing side panels are biased toward one another; and means of attachment whereby the pocket may be attached to a person or object.

Owner:HEAVEN SENT GAMING

Magazine retention device

ActiveUS9759536B2Constant frictionFlexible elementsAmmunition storageEngineeringMechanical engineering

An apparatus for the secure stowing of a magazine, the apparatus comprising a pocket defined by a first pair of opposing side panels and a second pair of opposing side panels, the first pair of opposing side panels being in substantially perpendicular plane to the second pair of opposing side panels and the first pair of opposing side panels being shorter in height than the second pair of opposing side panels, a bottom panel, and a top opening; biasing means whereby at least one pair of opposing side panels are biased toward one another; and means of attachment whereby the pocket may be attached to a person or object.

Owner:HEAVEN SENT GAMING

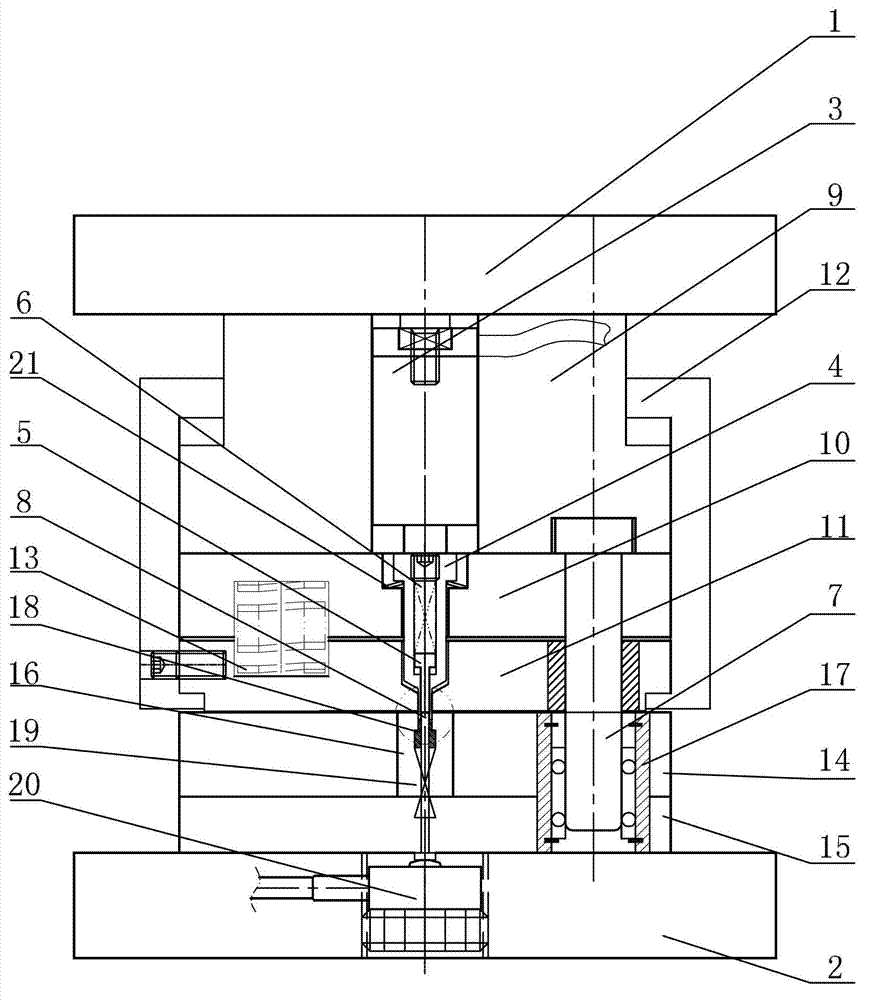

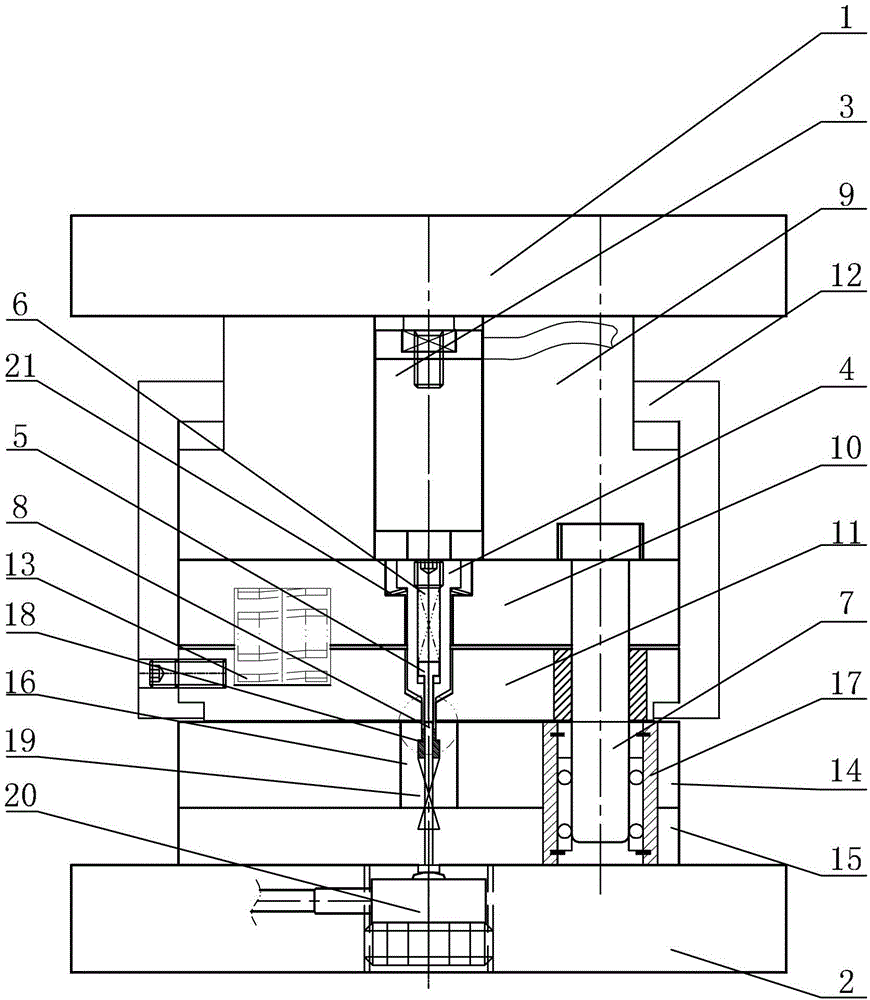

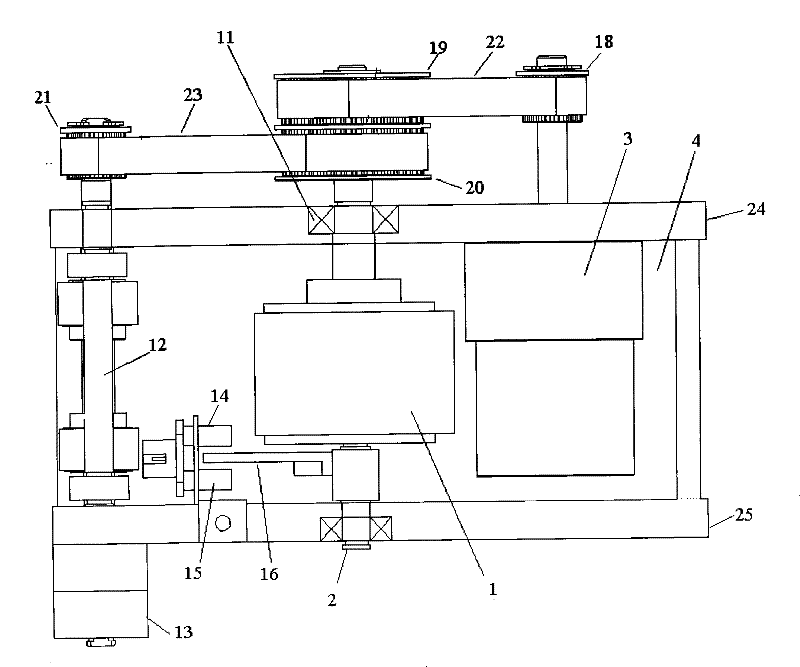

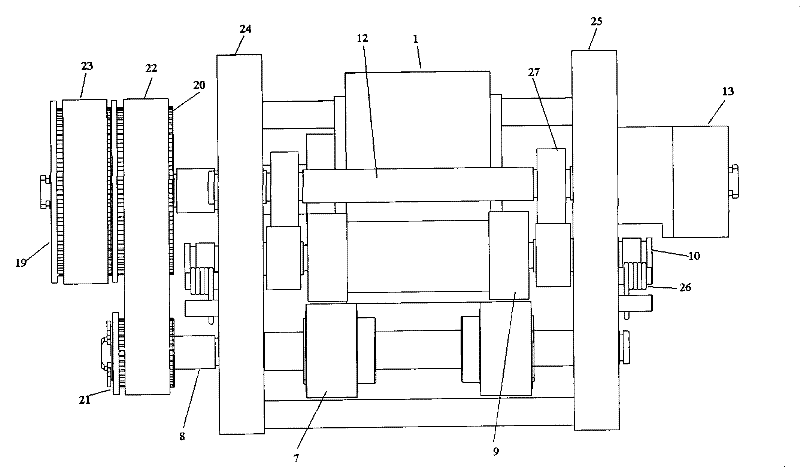

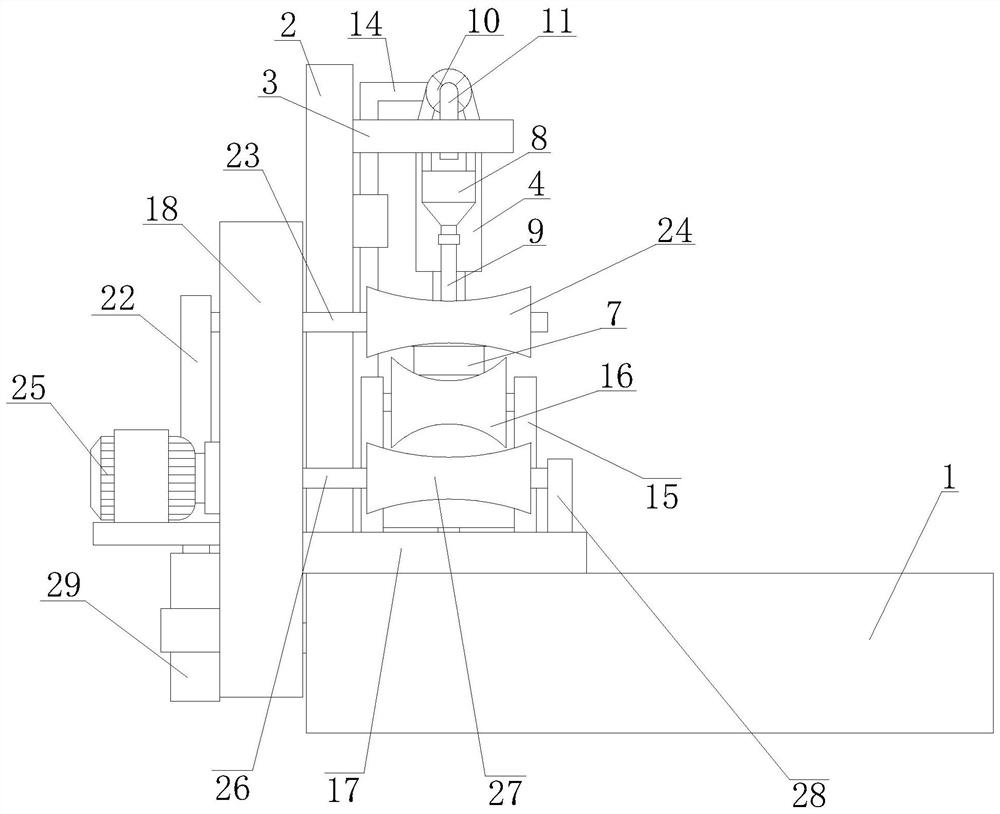

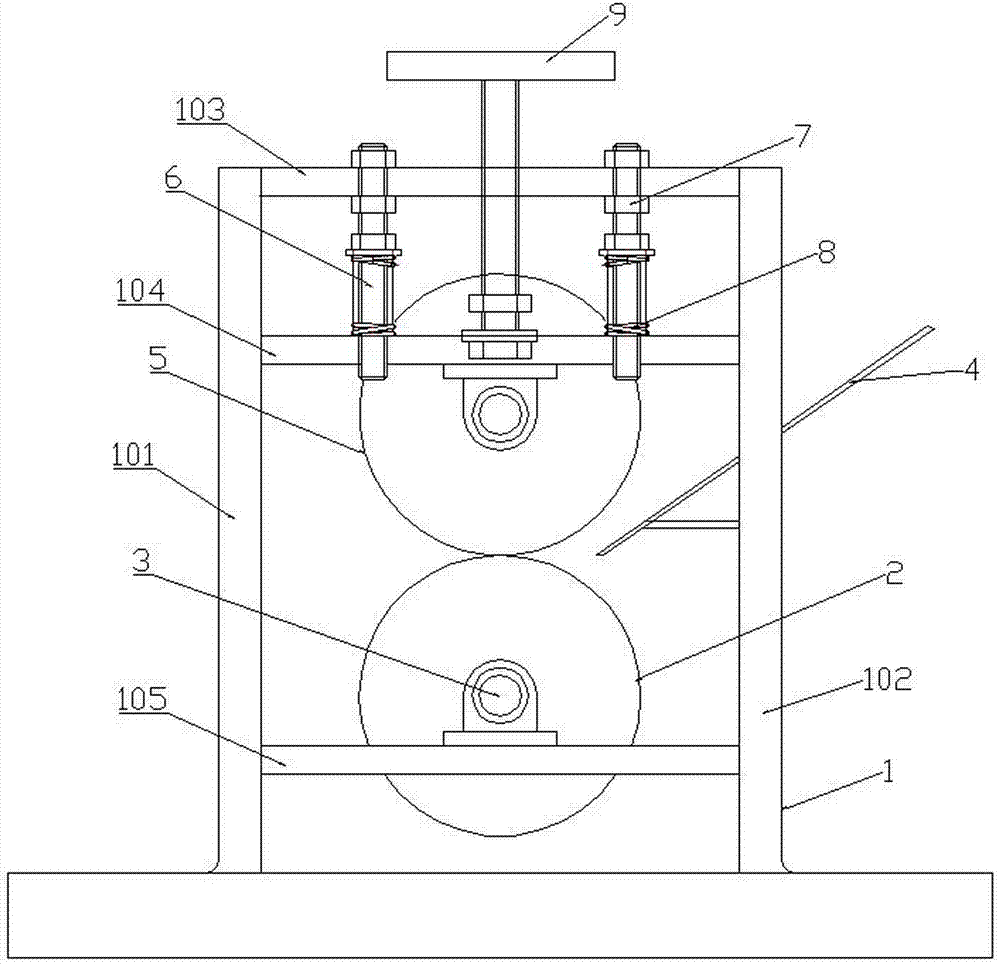

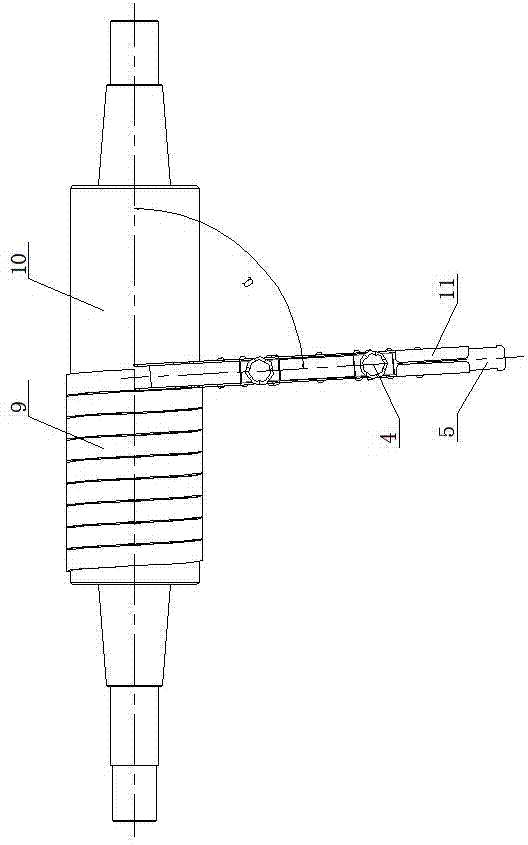

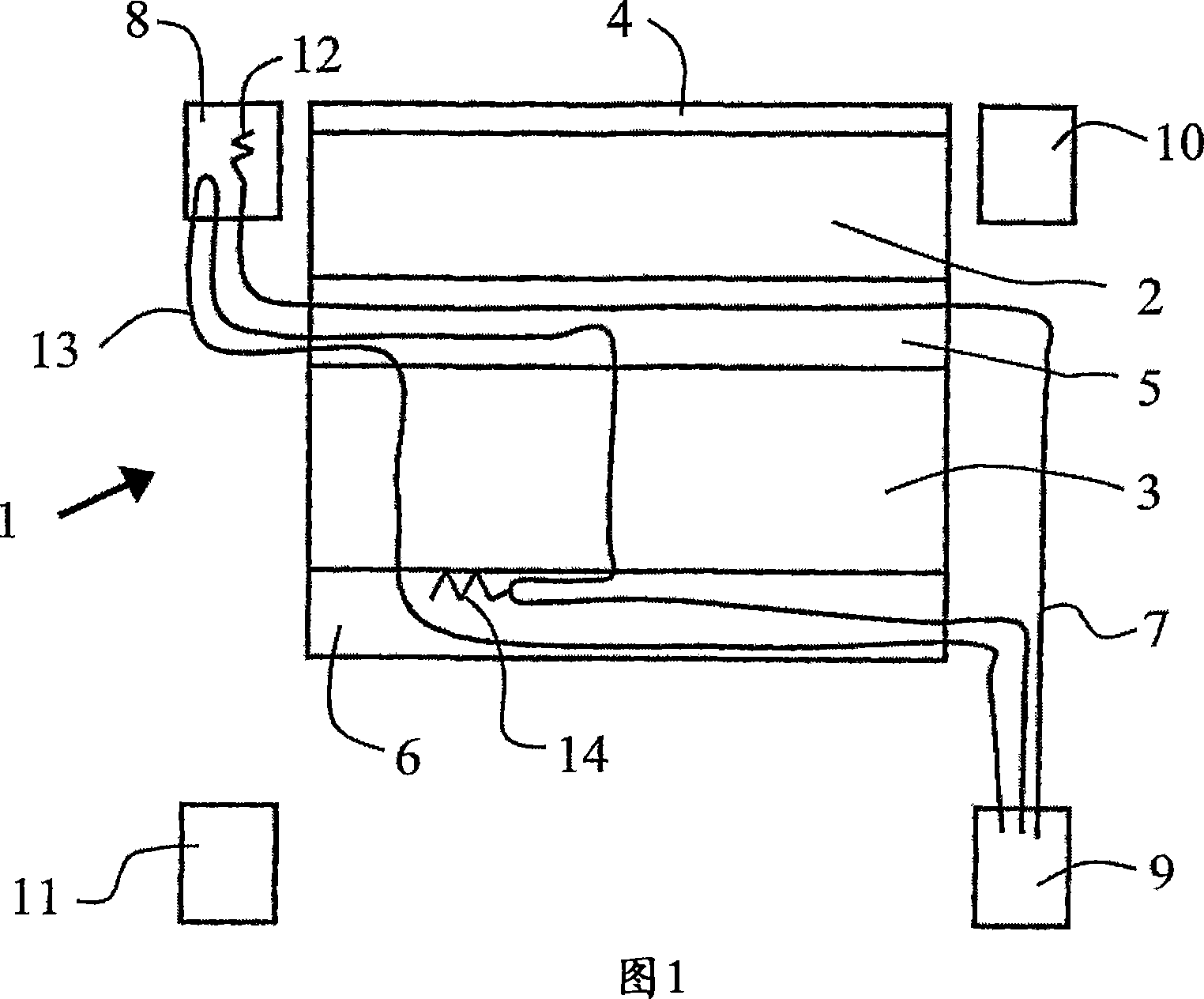

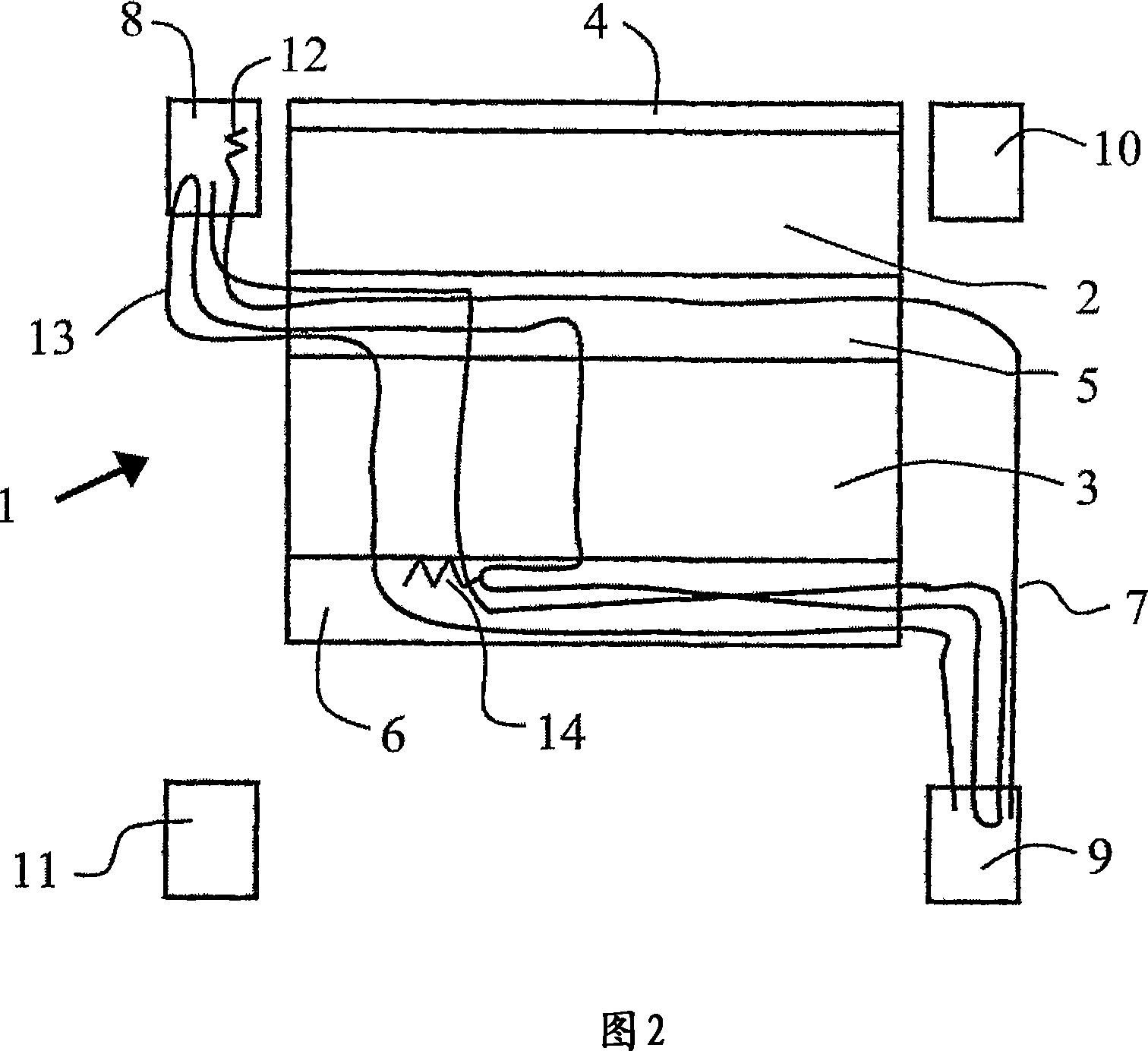

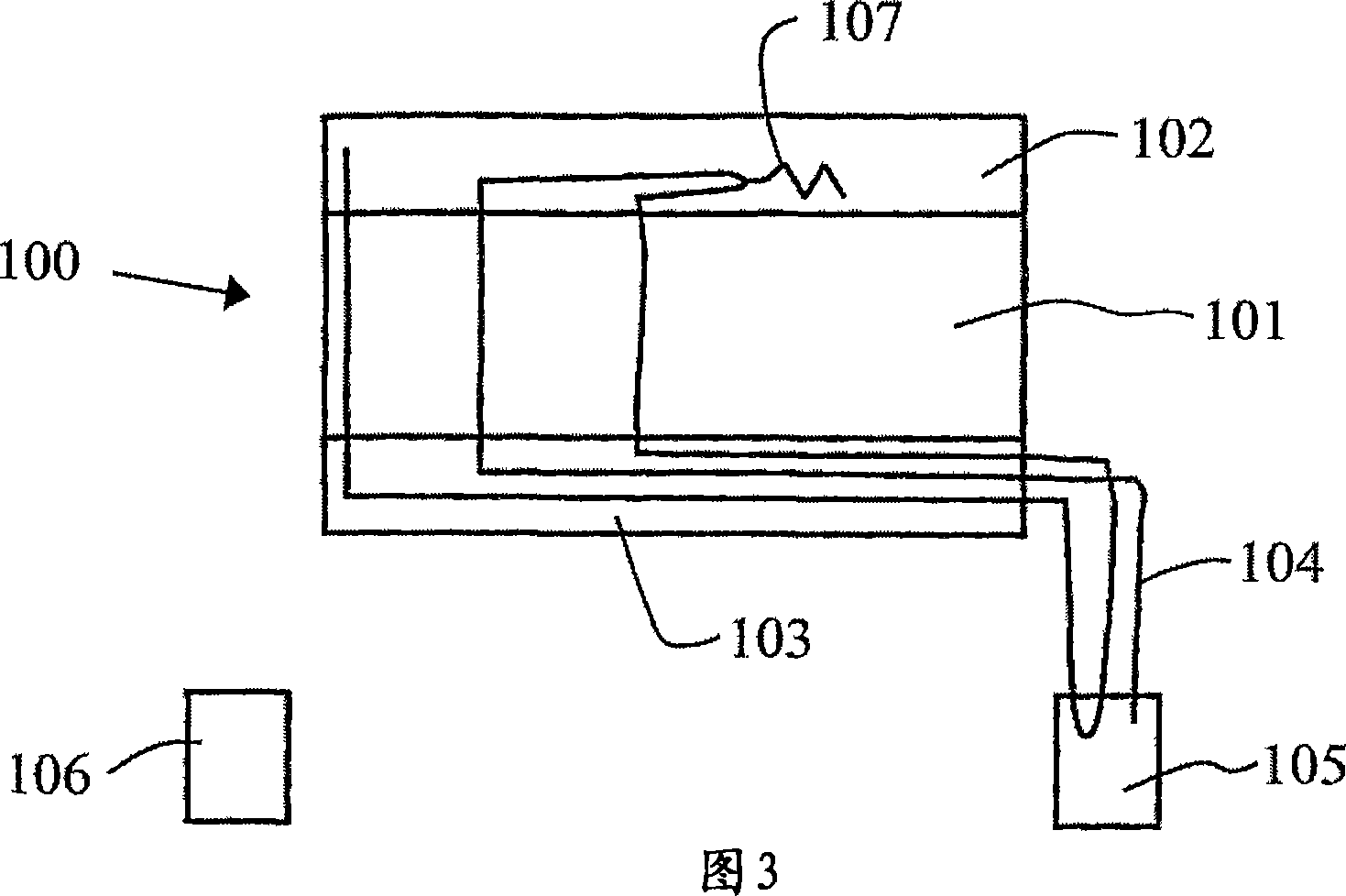

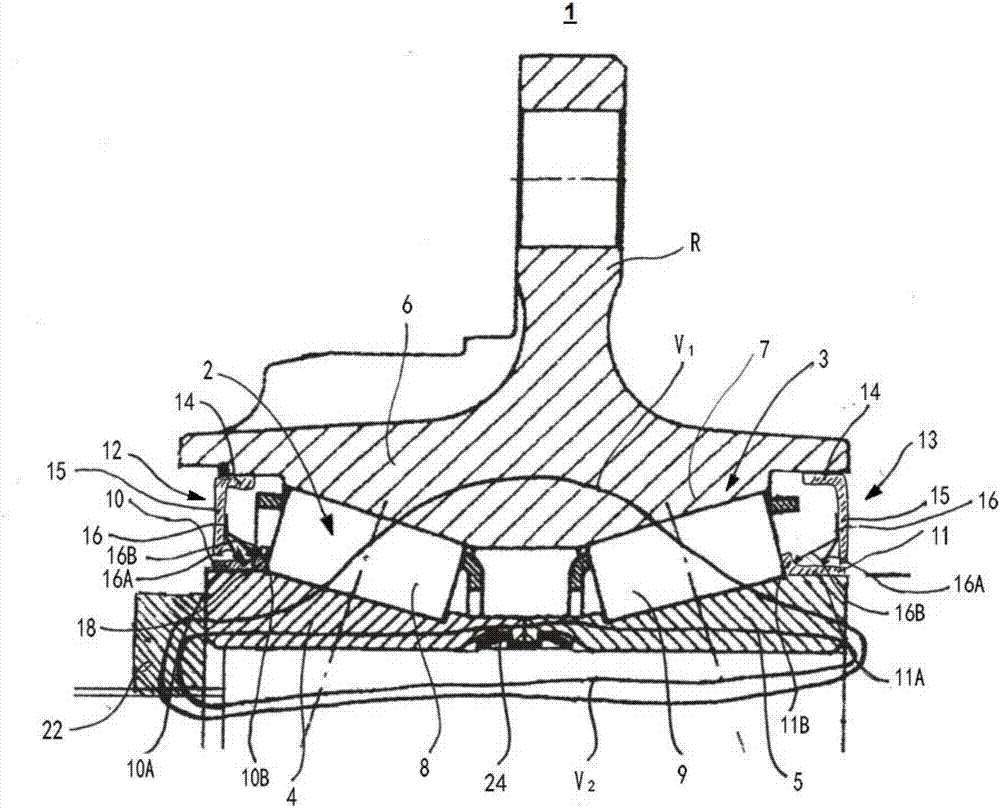

Device and method for high-frequency vibration assisted micro-deep drawing forming of foil boards

ActiveCN103042109AReduce frictionInhibition of germinationShaping toolsHigh frequency powerMicro actuator

The invention relates to a device and a method for micro-deep drawing forming of foil boards, in particular to a method and a device for high-frequency vibration assisted micro-deep drawing forming of foil boards and aims to solve the problem that low-strength foil boards are difficult to form small-diameter cylinder pieces by means of deep drawing. An upper die base, an upper die component, a lower die component and a lower die base of the device are sequentially arranged from top to bottom, the upper end of the upper die component is connected with the lower surface of the upper die base, the lower end of the lower die component is connected with the upper surface of the lower die seat, a magnetic extendable micro-actuator and a male die are arranged in the upper die component sequentially from top to bottom, the magnetic extendable micro-actuator is connected with a high-frequency power supply, a power output end of the magnetic extendable micro-actuator is connected with the upper end of the male die, a back pressure spring and a back pressure ejector rod are arranged in a cavity of the male die sequentially from top to bottom, a deep drawing punch is inserted on the upper surface of the lower die component, and a belleville spring is sleeved on the outer side wall of the upper end of the male die. The device and the method are used for micro-deep drawing forming of the foil boards.

Owner:HARBIN INST OF TECH

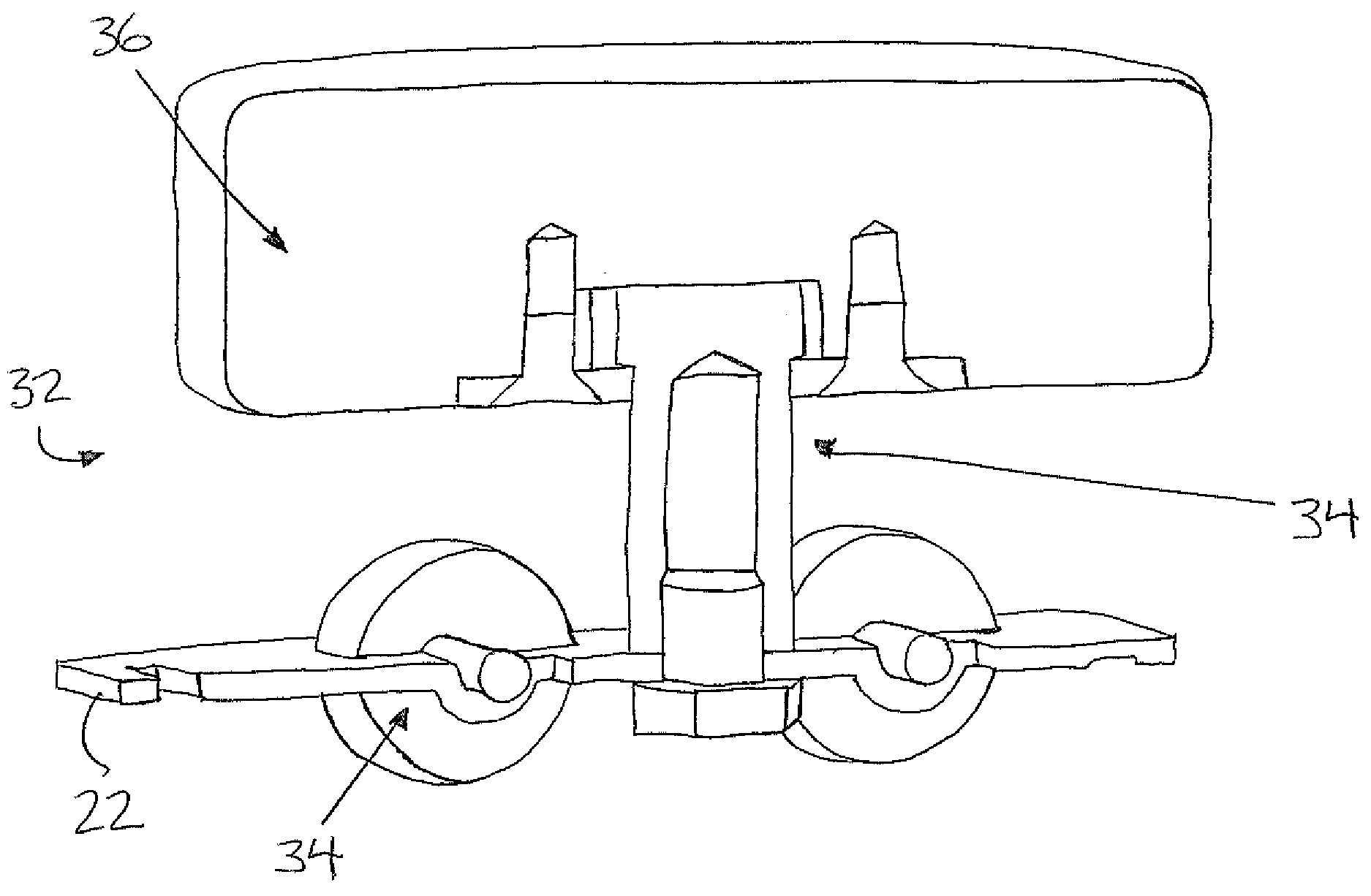

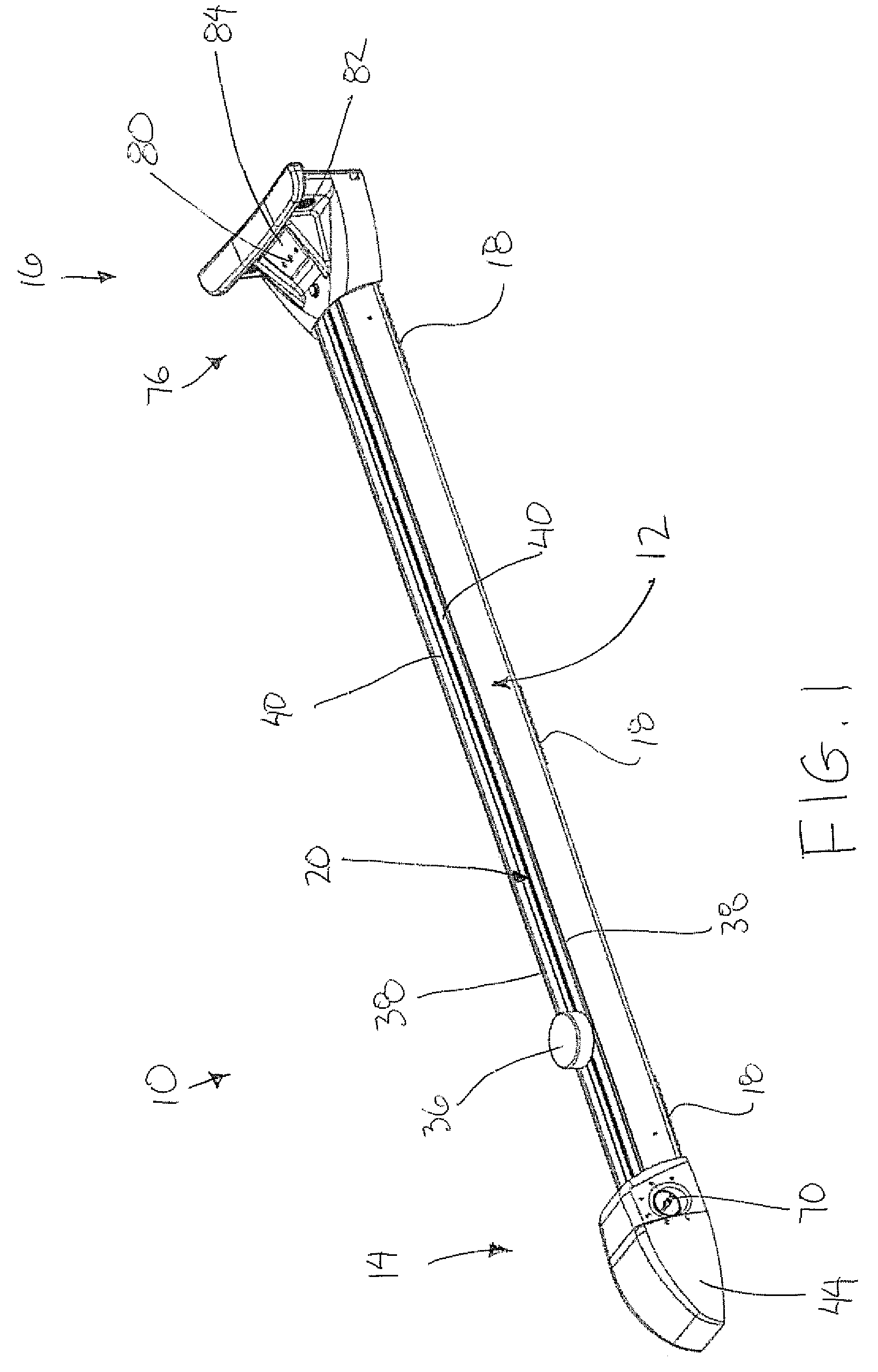

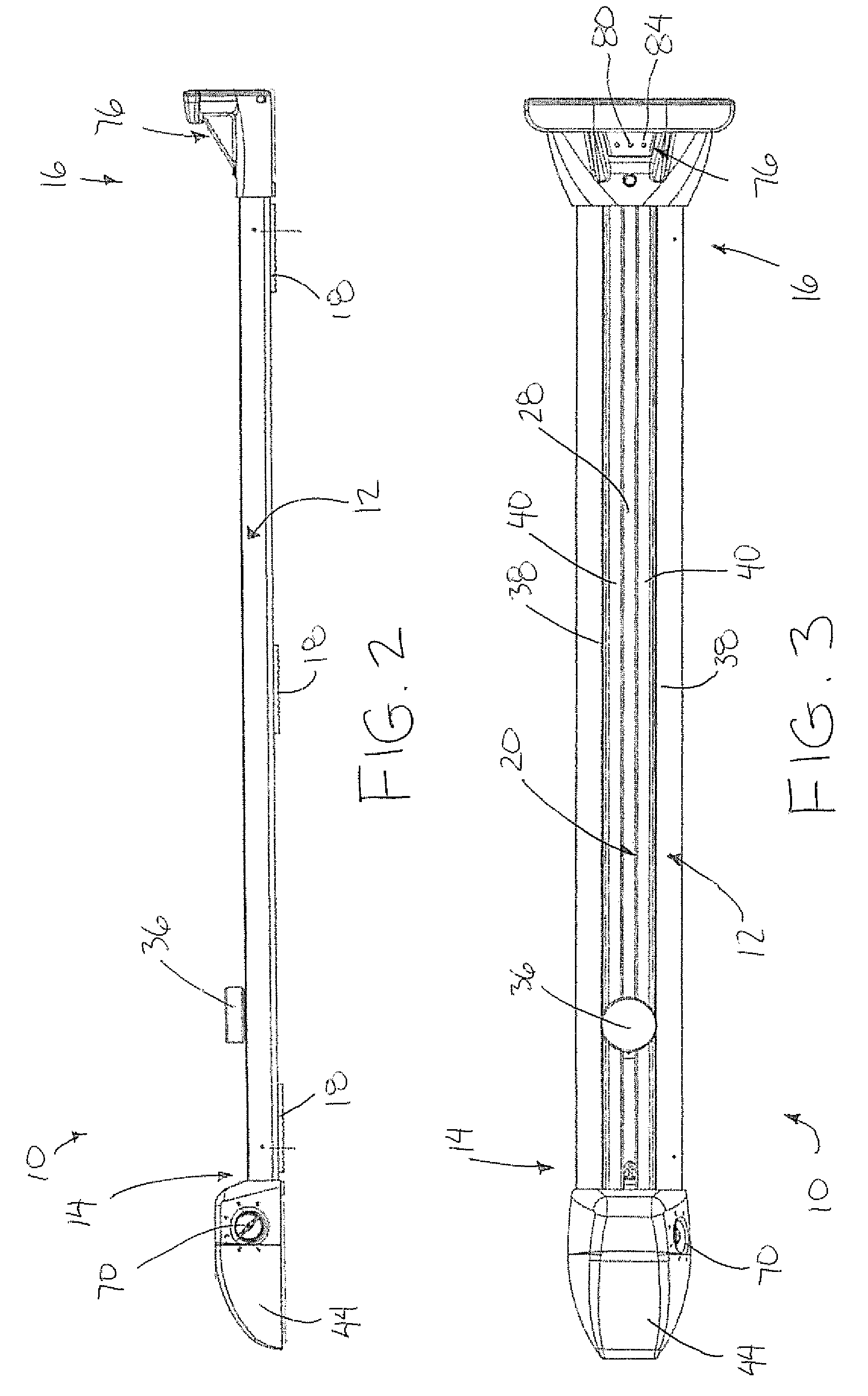

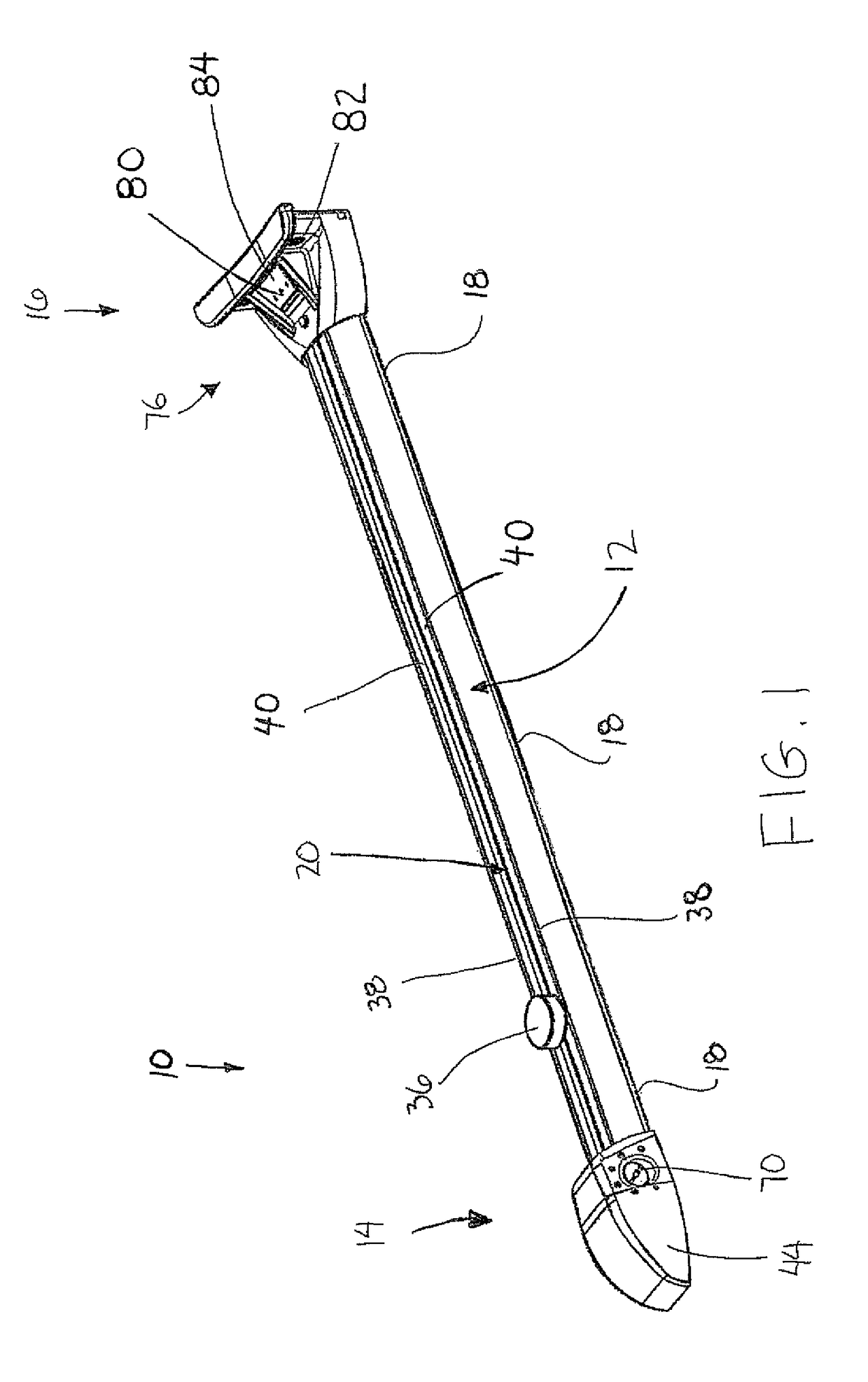

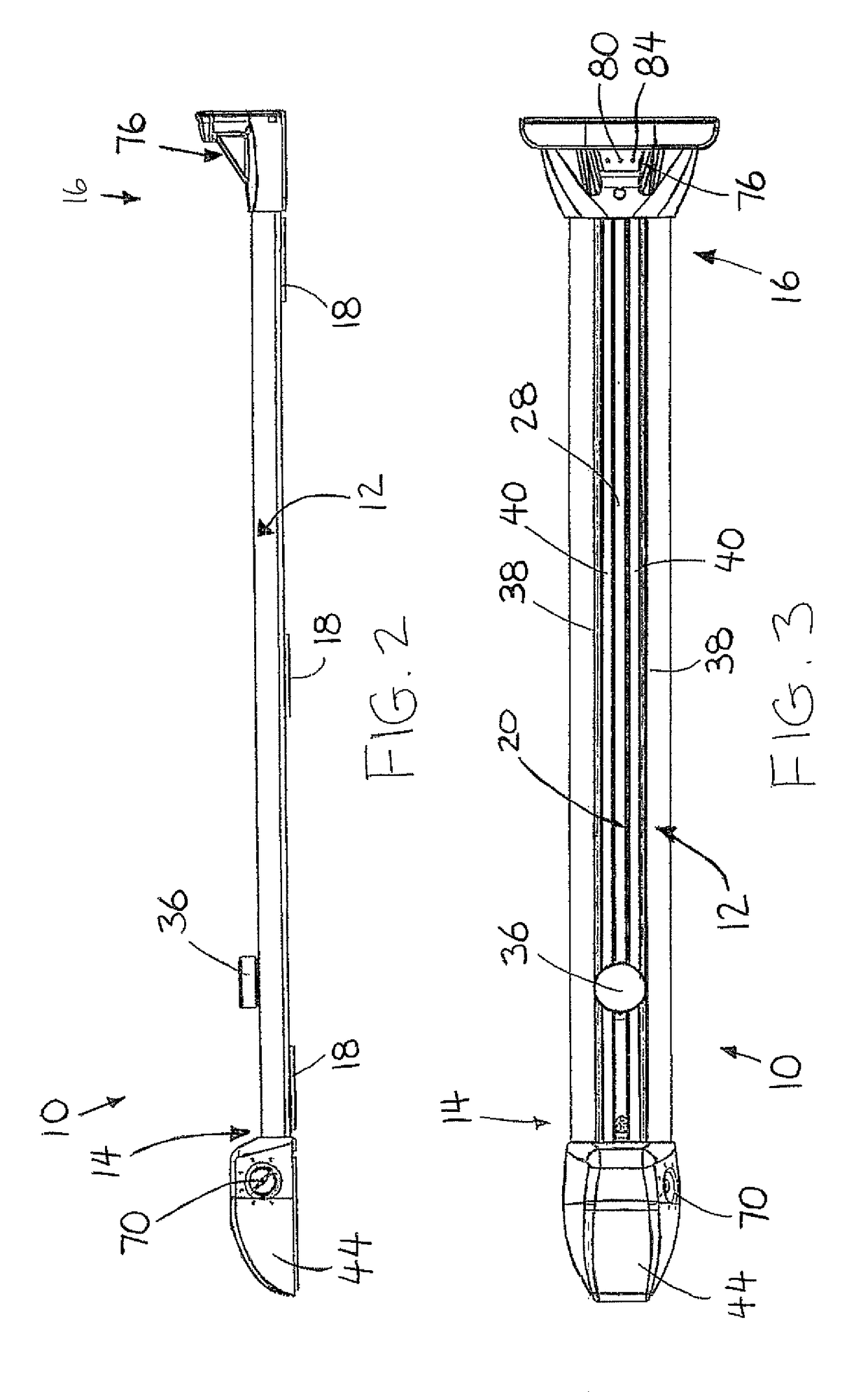

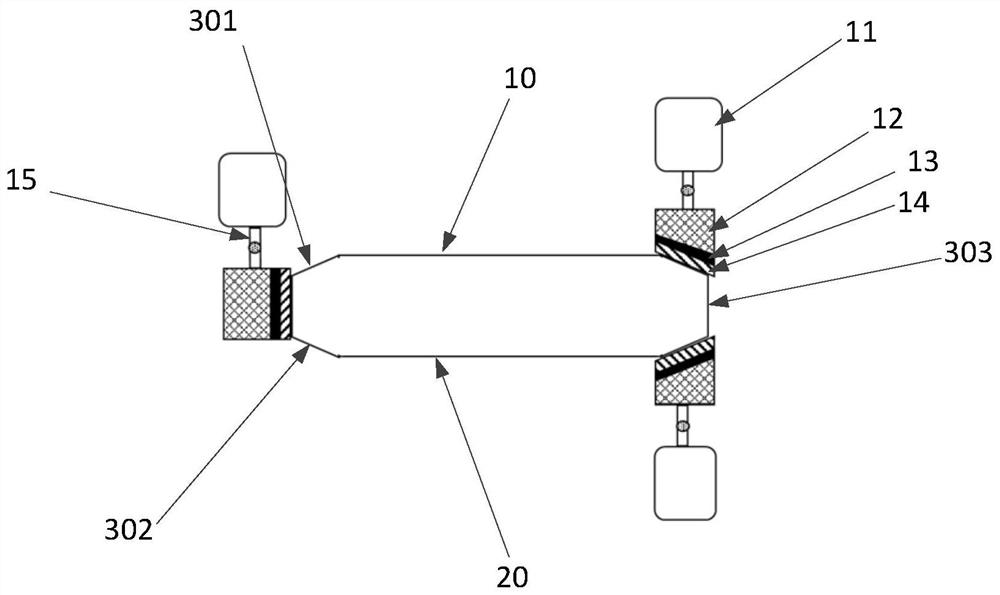

Hockey Shooting Training Device

InactiveUS20100160092A1Convenient amountTechnically accurateSport apparatusVisual guidanceHockey stick

A hockey shooting training device comprises an elongate track and a carriage having a puck shaped an engaging member supported thereon for engagement by a hockey stick to be displaced along the track with the carriage from a starting end to a target end. Wheels on the carriage have a resilient peripheral surface for rolling along the track. A tether coupled to the carriage is wound onto a spool at the starting end of the track. Constant frictional resistance is applied to the spool during displacement of the carriage towards the target end as the tether unwinds from the spool. A winding mechanism on the spool returns the carriage to the starting end. An illuminated indicator extends along the track to provide visual guidance of the path of the carriage. A further indicator may indicate an angular offset of the engaging member from a central position about an upright axis.

Owner:SHOT TEC

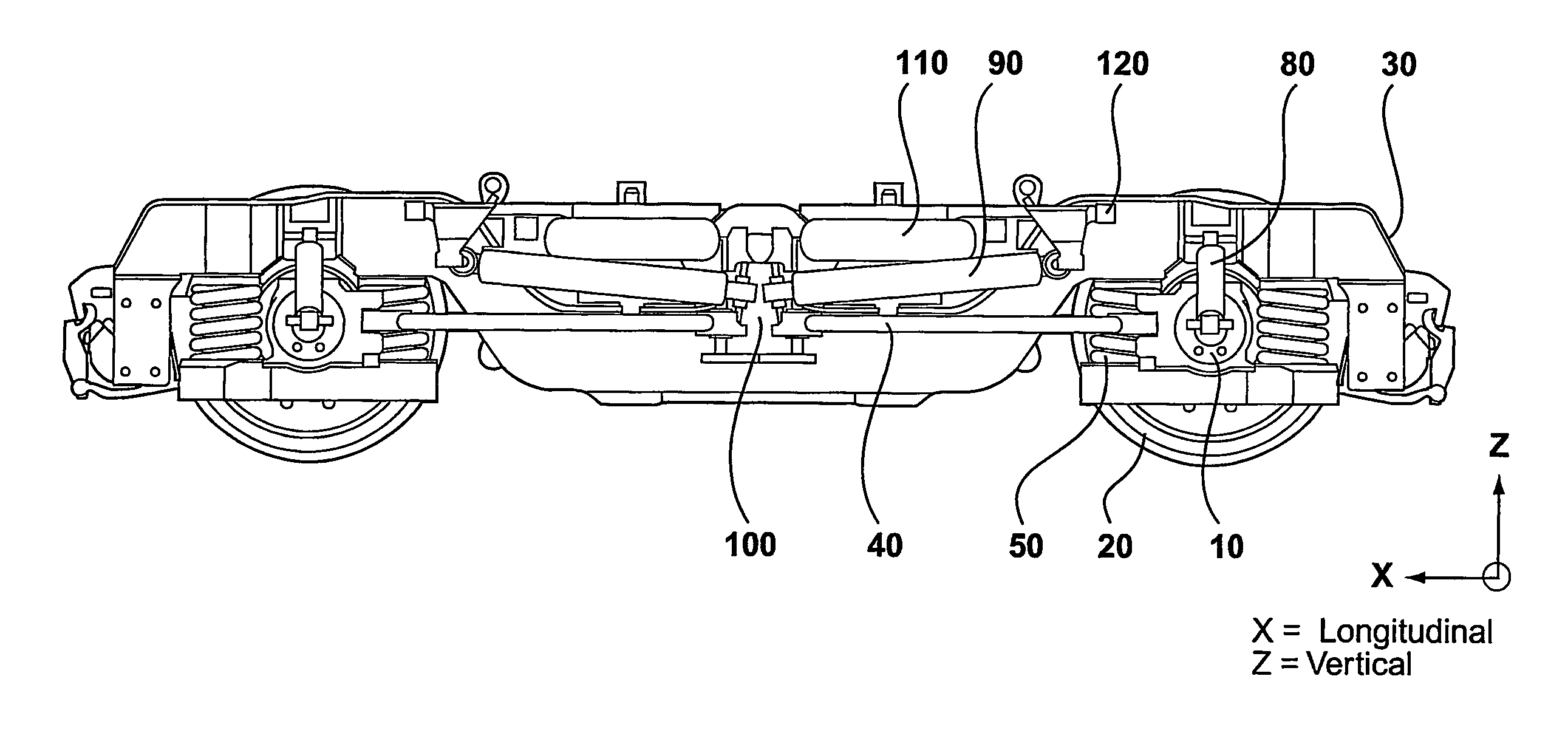

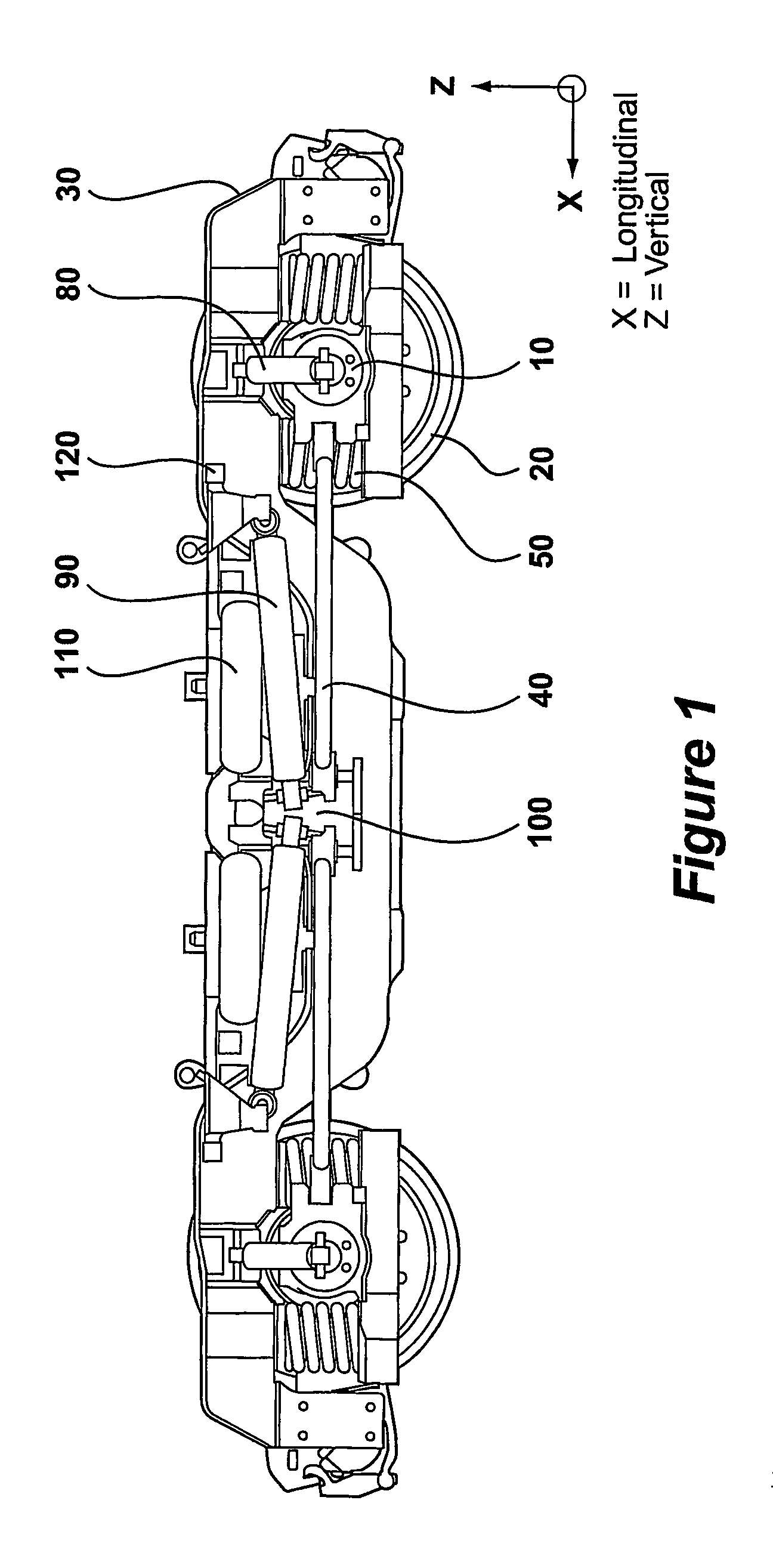

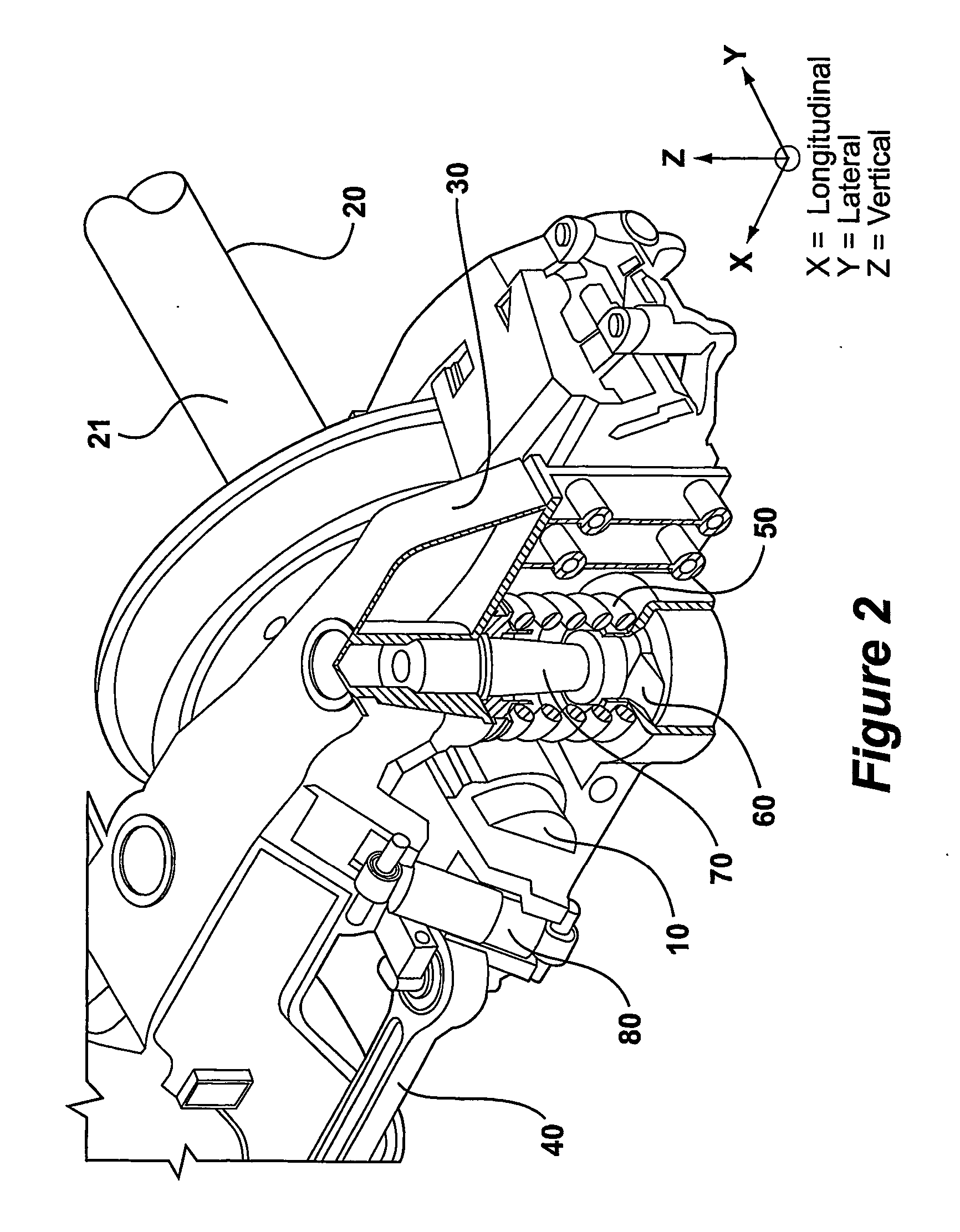

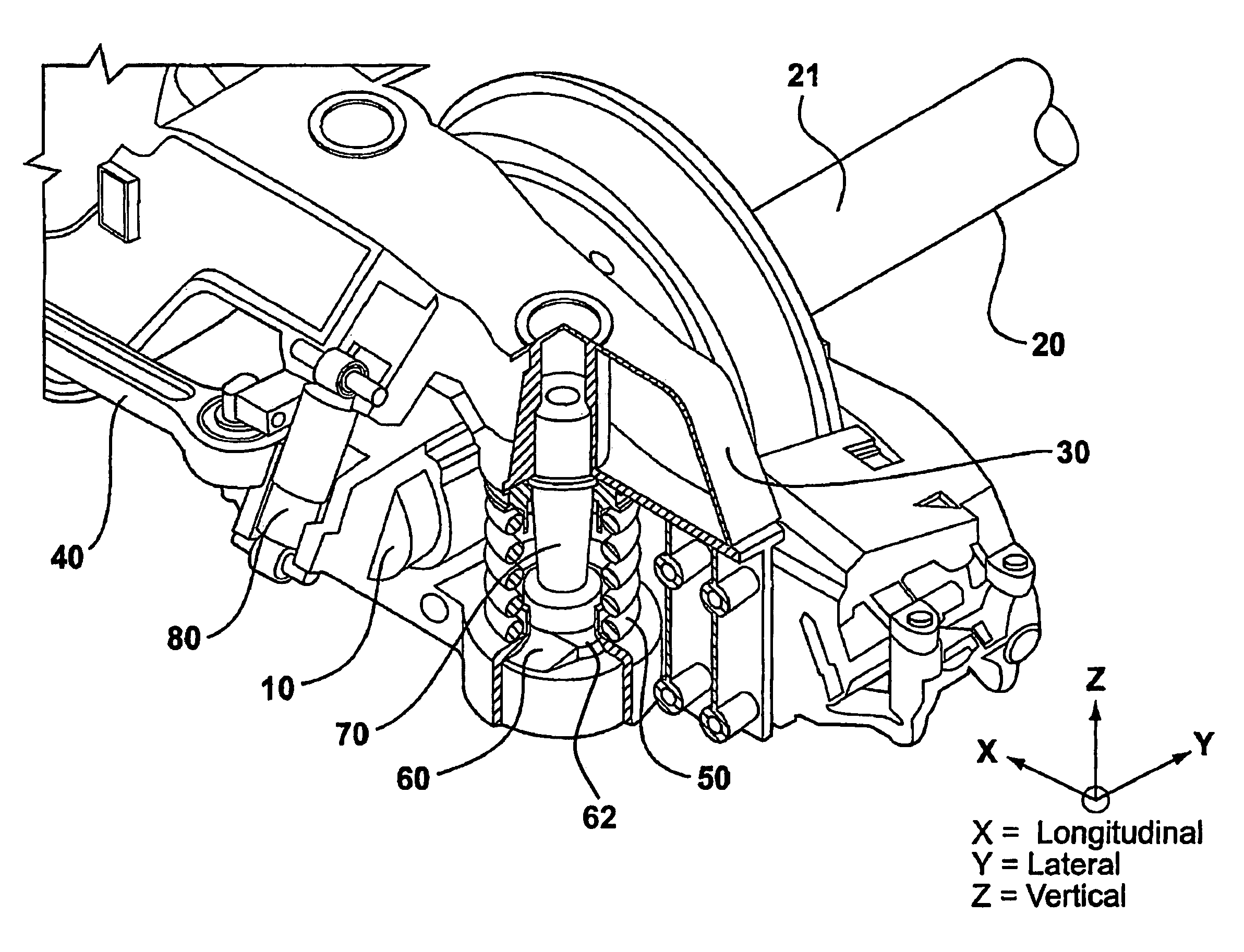

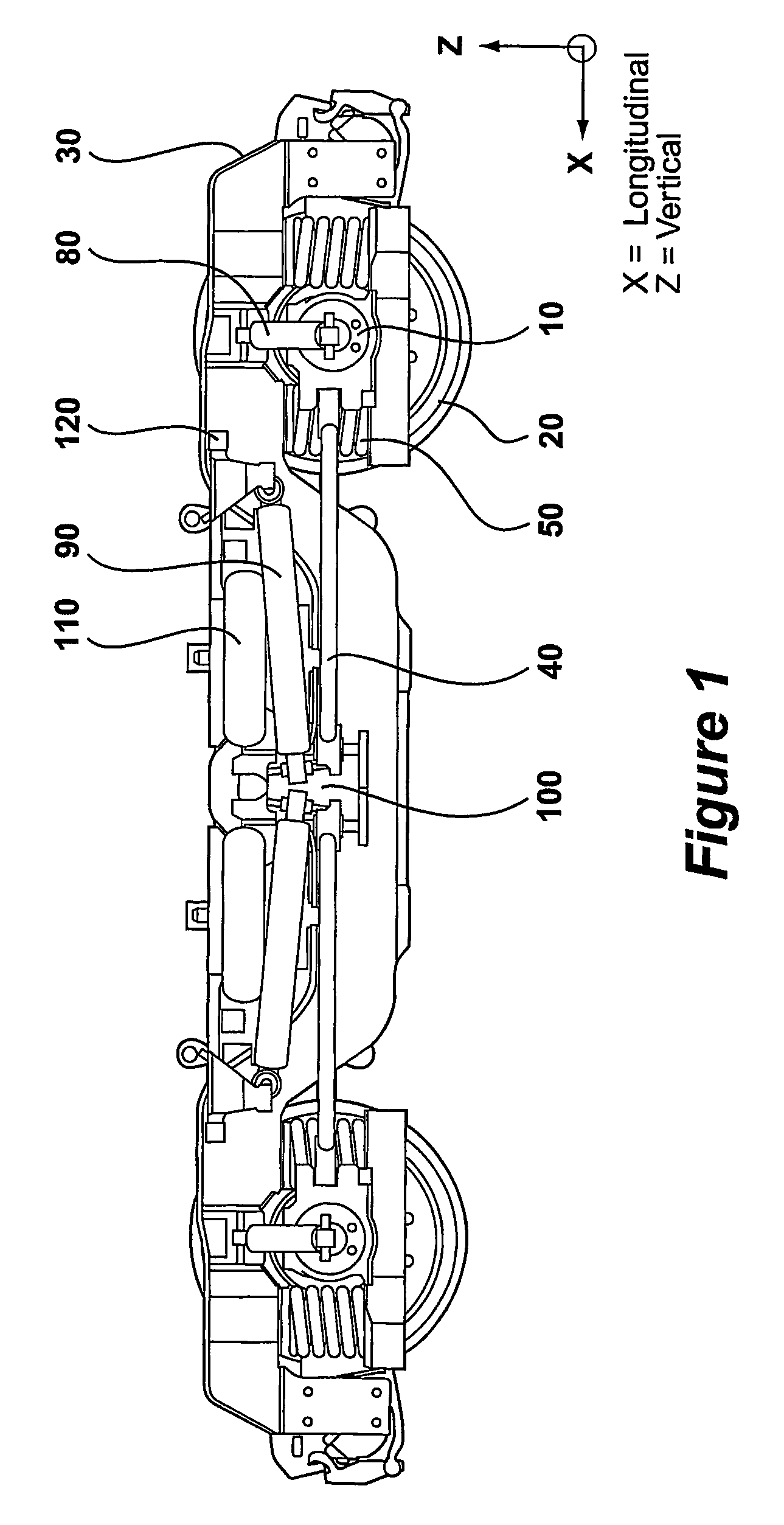

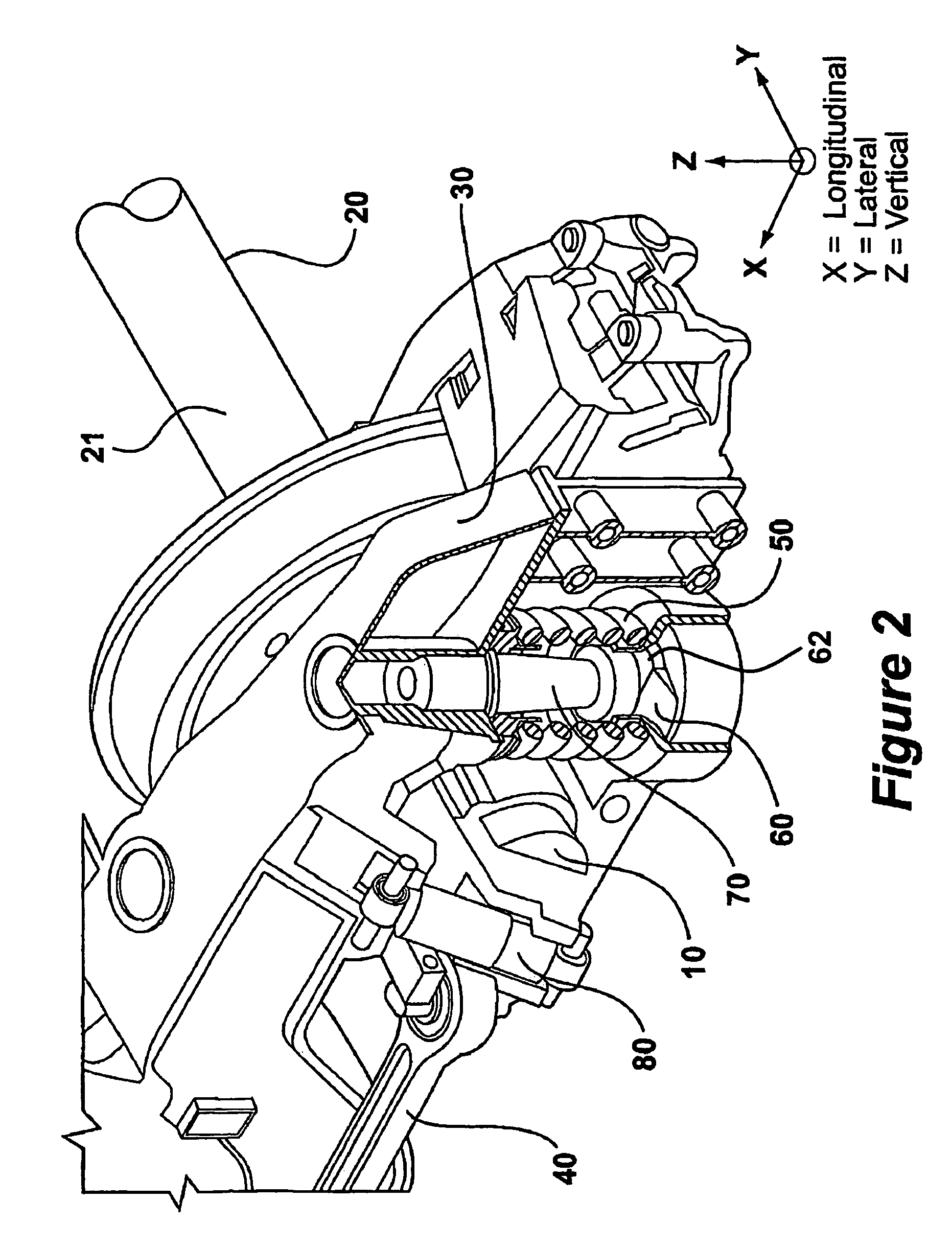

Wheel set guidance assembly

A wheel set guidance assembly is provided for suspending a wheel set bearing (10) of a wheel set (20) to a bogie frame (30), comprising separate vertical (50), lateral (70) and longitudinal (40) guidance elements for independent guidance of the movement of the wheel set in vertical, lateral and longitudinal directions wherein the stiffness of the guidance elements can be selected independently of each other.

Owner:BOMBARDIER TRANSPORTATION GMBH

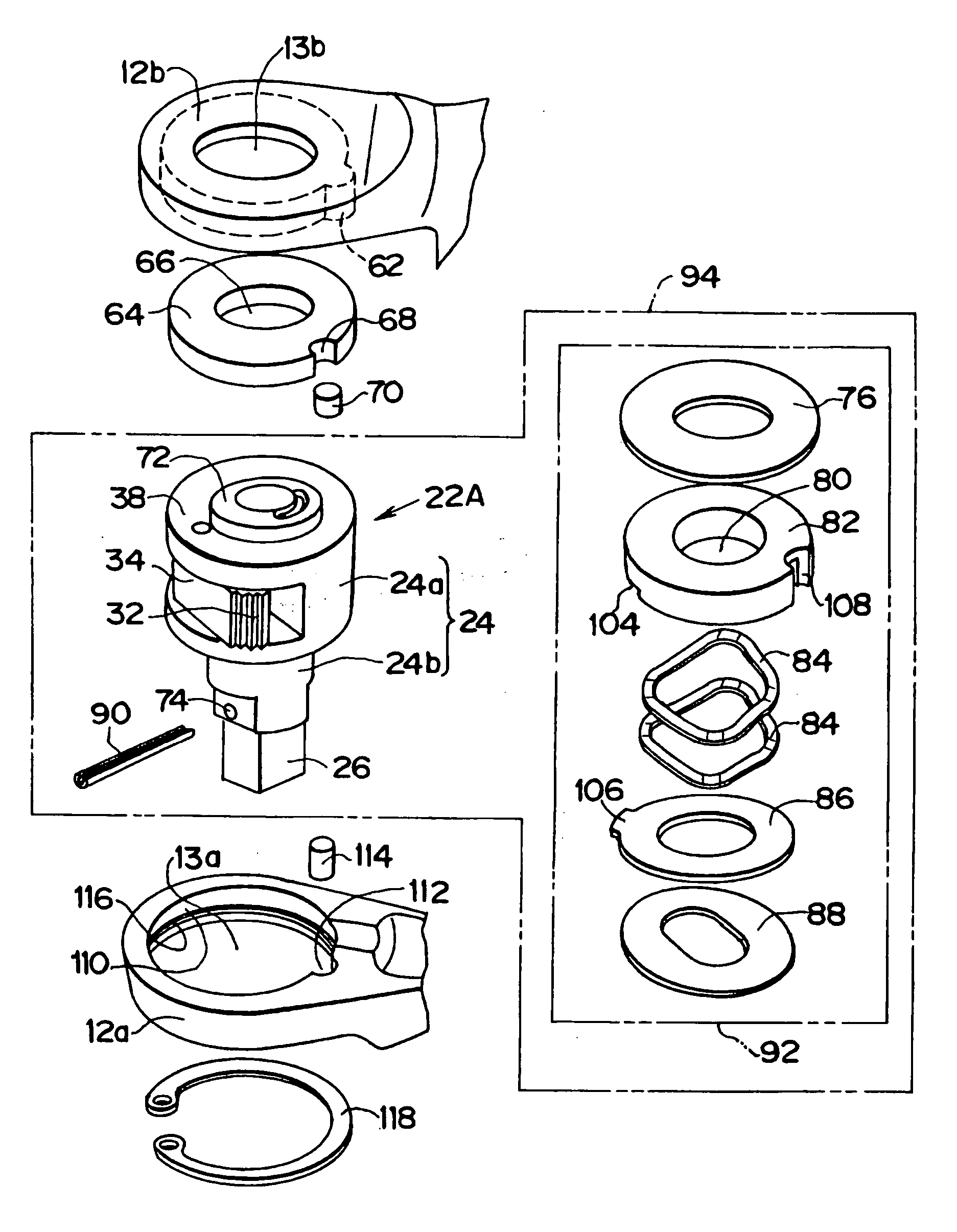

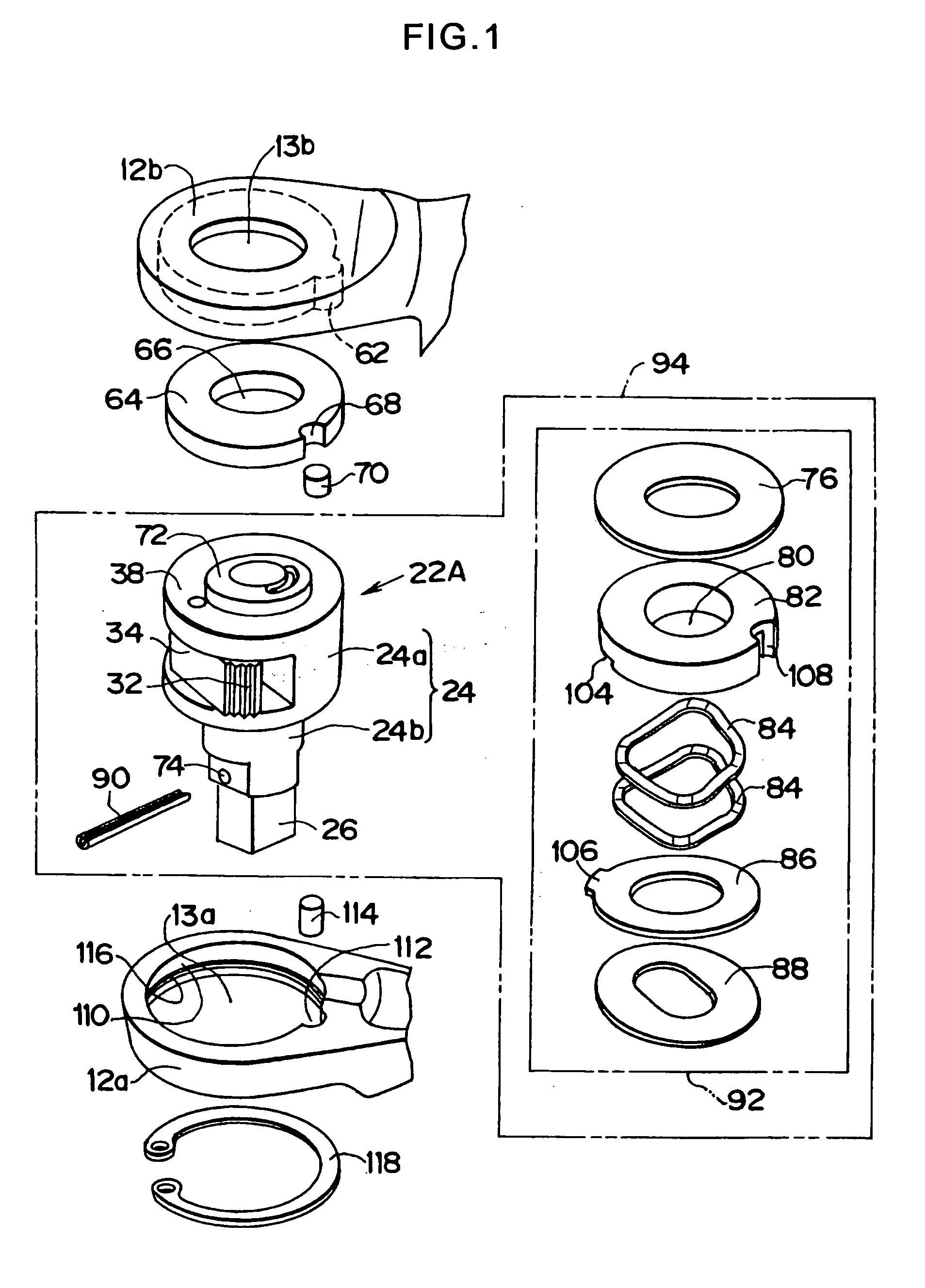

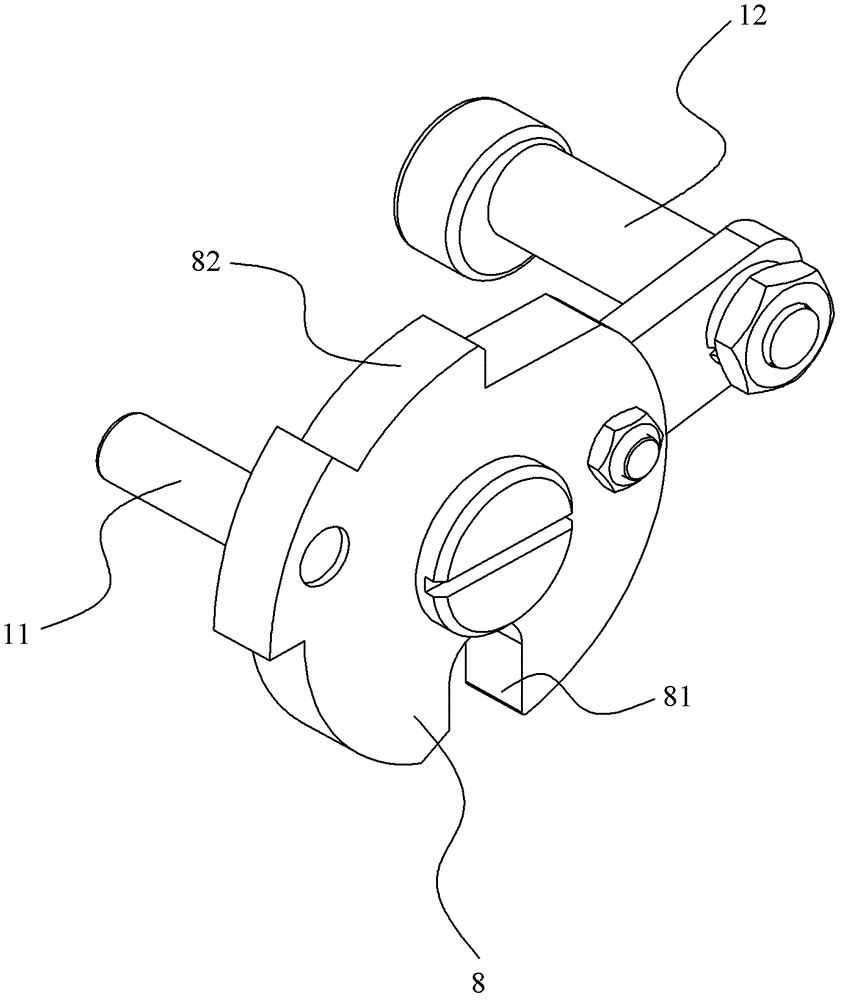

Ratchet wrench and method of assembling the same

The invention provides a ratchet wrench which can secure constant friction applied to a shank to generate a desired torque from start of an operation irrespective of an outward increase in distance between a pair of annular hold portions. A frictional force generation means 92 including a first guide bush 82 and a disc spring 44 is attached to a shank 22A with a locking pin 90 to form a shank assembly 94 as an assembly. Spring force of the disc spring 44 acts not on the outside of the shank assembly 94, but only on the inside thereof. The shank assembly 94 is inserted from a central space 13a of a first annular hold portion 12a toward a second annular hold portion 12b, and the shank 22A is held by an inner wall of the second annular hold portion 12b. In the back side on which the shank assembly 94 is inserted, the drop-out of the shank assembly 94 from the central space 13a side of the first annular hold portion 12a to the outside is prevented by a snap ring 118 attached to a groove 116 of the first annular hold portion 12a.

Owner:KEI TEII ESU

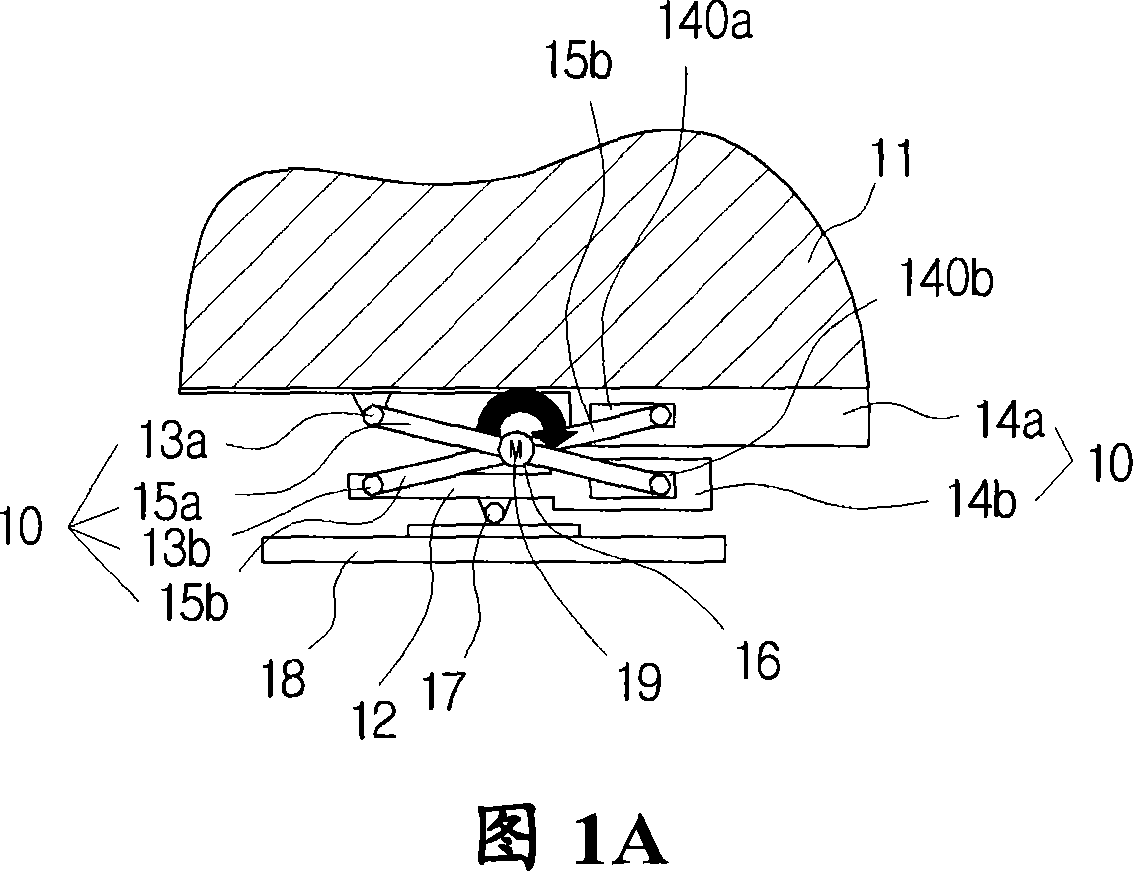

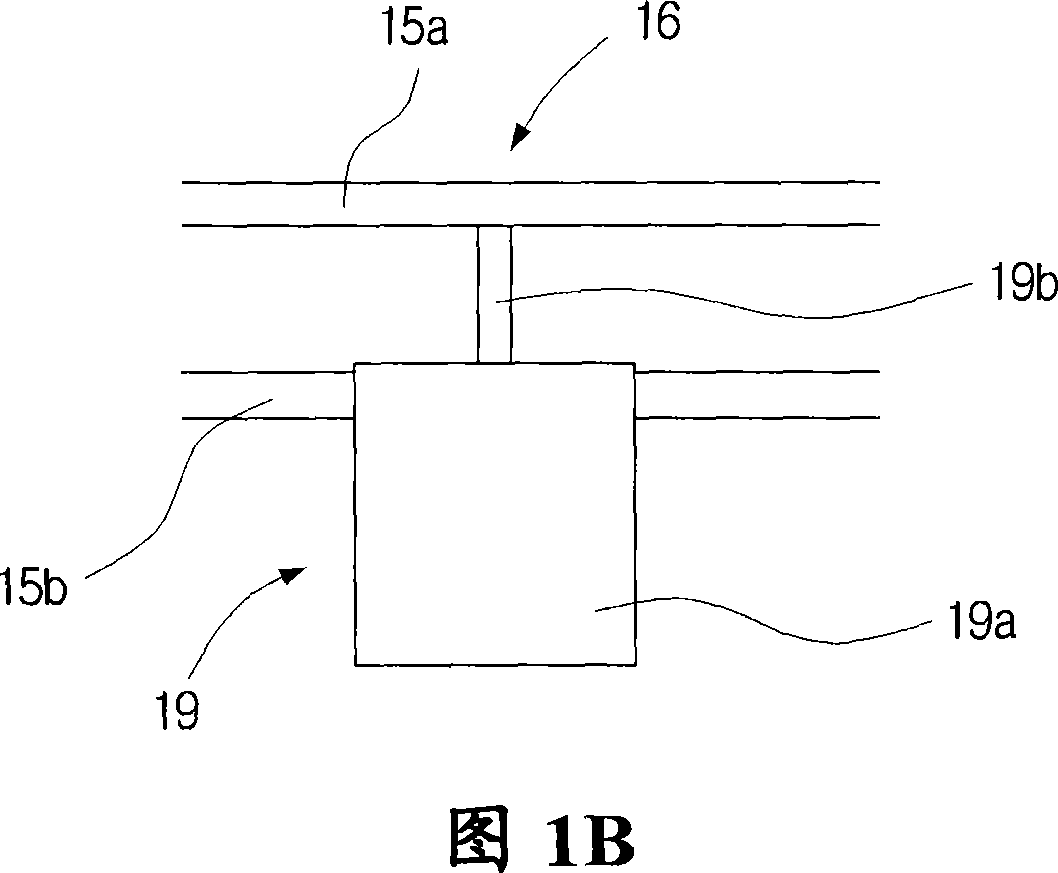

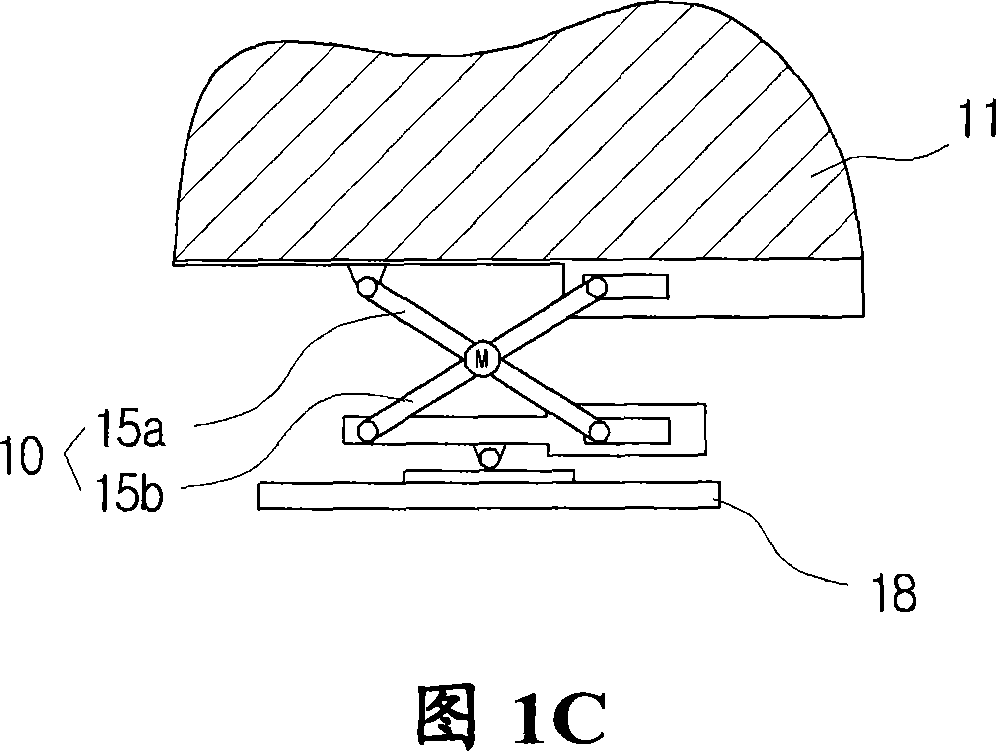

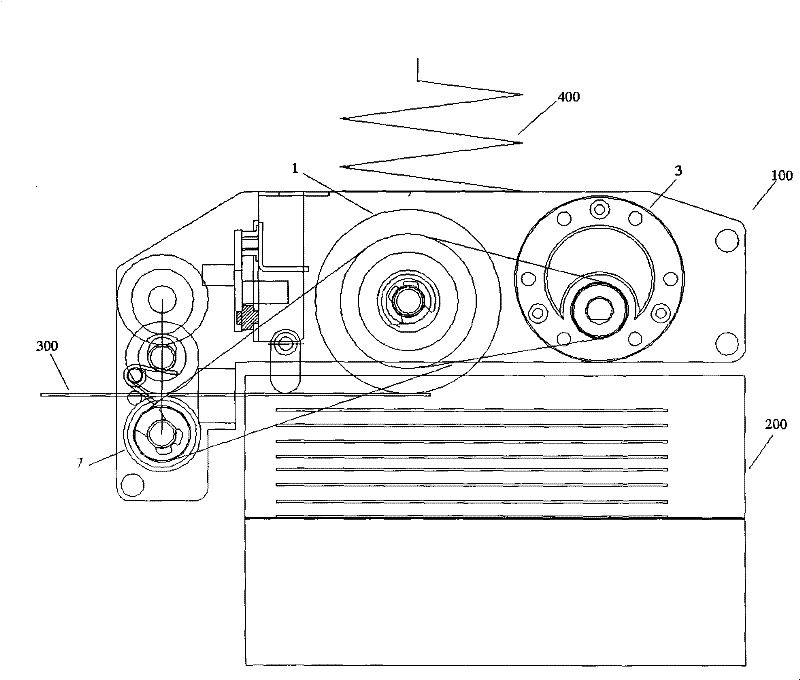

Display extension apparatus

InactiveCN101055774APrevent rotationConstant frictionTelevision system detailsInstrument housingDrive shaftDisplay device

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Wheel set guidance assembly

A wheel set guidance assembly is provided for suspending a wheel set bearing (10) of a wheel set (20) to a bogie frame (30), comprising separate vertical (50), lateral (70) and longitudinal (40) guidance elements for independent guidance of the movement of the wheel set in vertical, lateral and longitudinal directions wherein the stiffness of the guidance elements can be selected independently of each other.

Owner:BOMBARDIER TRANSPORTATION GMBH

Hockey shooting training device

InactiveUS7905800B2Constant frictionConstant resistance to a shooting actionRacket sportsEngineeringVisual guidance

A hockey shooting training device comprises an elongate track and a carriage having a puck shaped an engaging member supported thereon for engagement by a hockey stick to be displaced along the track with the carriage from a starting end to a target end. Wheels on the carriage have a resilient peripheral surface for rolling along the track. A tether coupled to the carriage is wound onto a spool at the starting end of the track. Constant frictional resistance is applied to the spool during displacement of the carriage towards the target end as the tether unwinds from the spool. A winding mechanism on the spool returns the carriage to the starting end. An illuminated indicator extends along the track to provide visual guidance of the path of the carriage. A further indicator may indicate an angular offset of the engaging member from a central position about an upright axis.

Owner:SHOT TEC

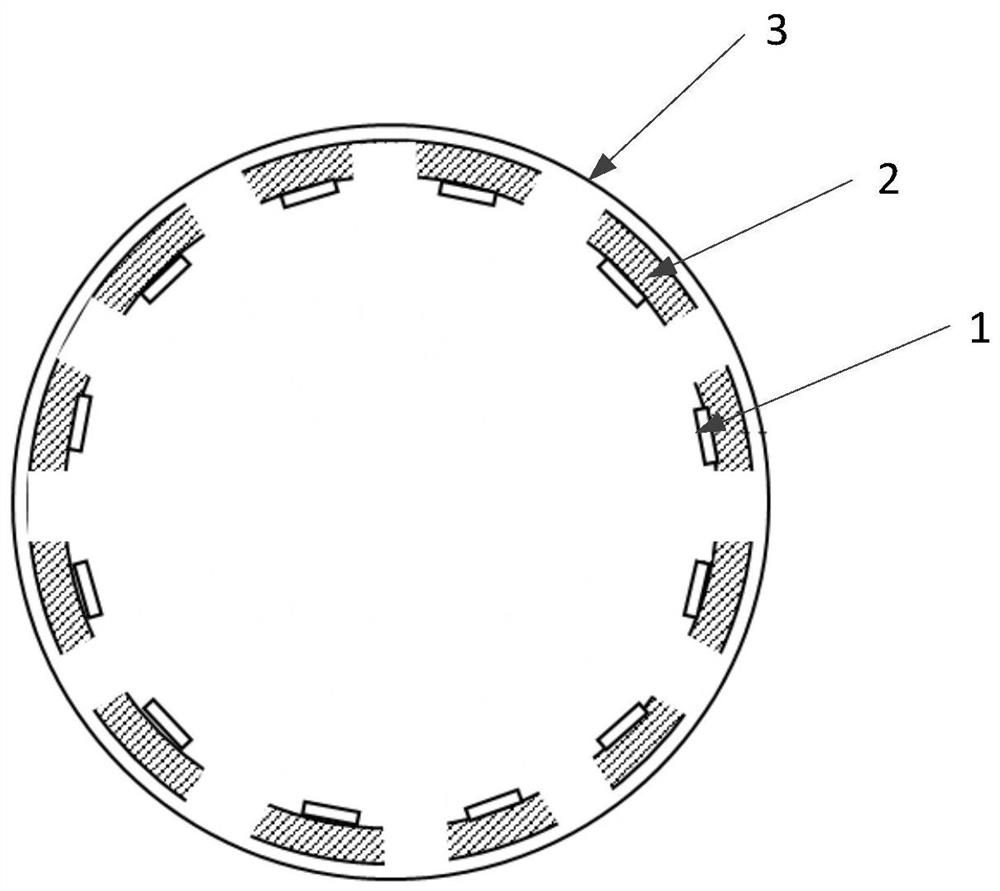

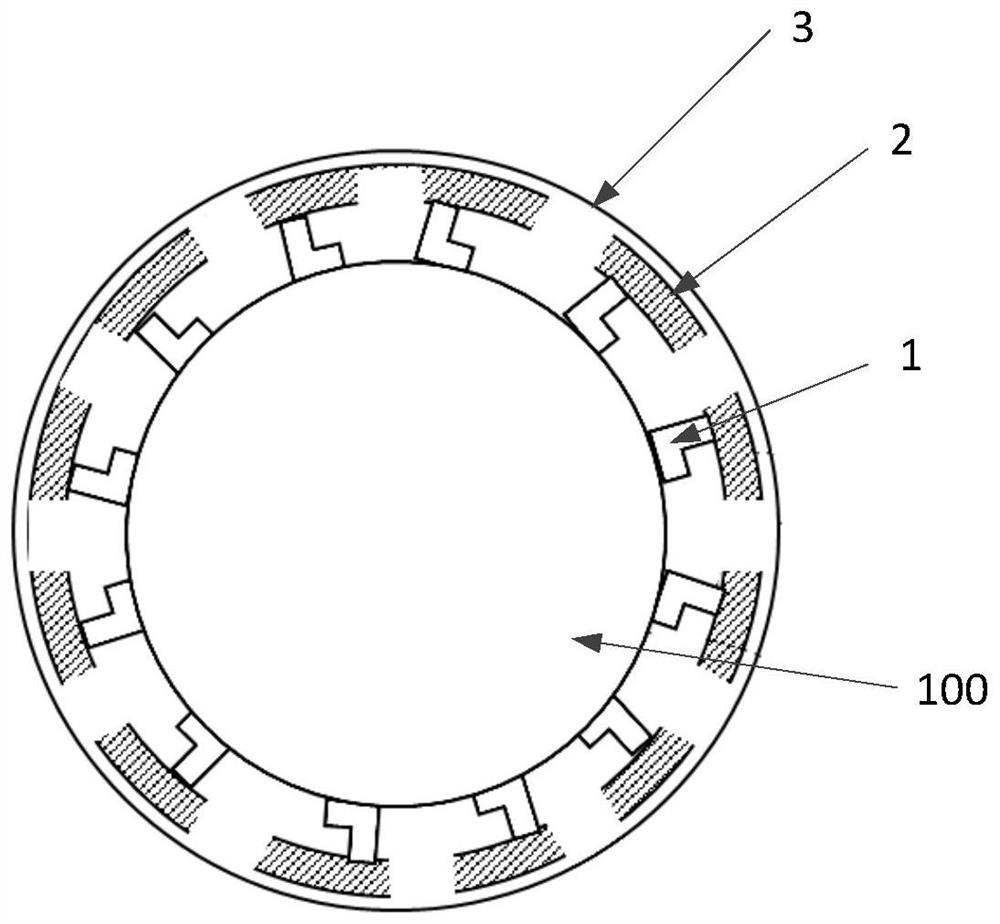

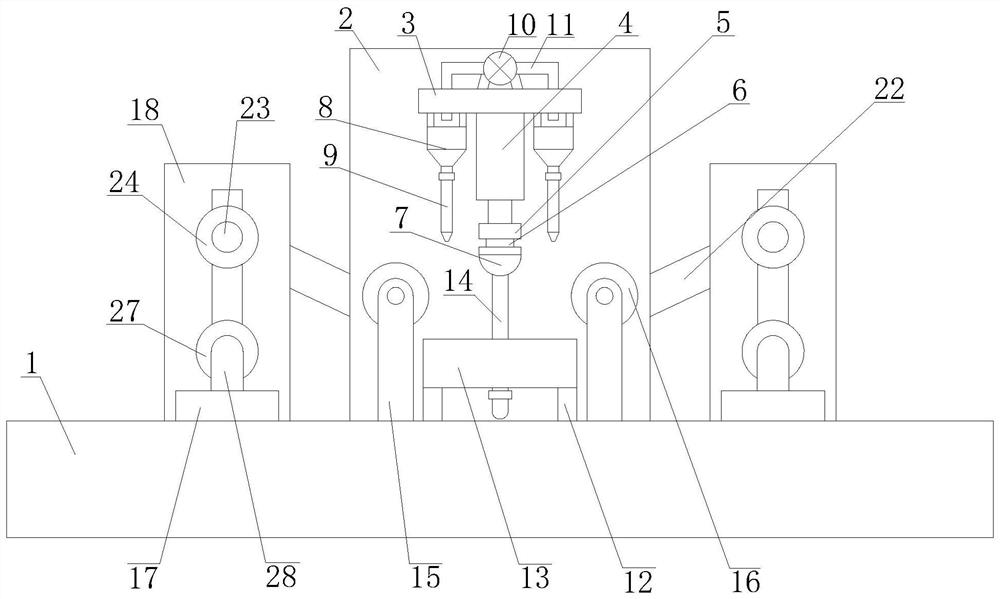

Edge polishing device and polishing method

The invention relates to an edge polishing device. The edge polishing device comprises a body, a driving component and polishing heads, wherein the body comprises a ring support; the polishing heads are circumferentially fixed to the ring support; the driving component is used for controlling rotation of the body to drive the polishing heads to rotate in order to perform polishing on the edge of awafer; each polishing head comprises a polishing disc; each polishing disc is connected to the ring support through a connecting structure; each connecting structure comprises a sliding rail extending in the circumferential direction of the ring support; each polishing head is movably arranged on the corresponding sliding rail; an elastic displacement sensor for sensing a displacement distance ofeach polishing head on the corresponding sliding rail is arranged between the polishing head and one end of the sliding rail; the driving component comprises a processing unit for acquiring the friction force between the polishing heads and the wafer according to signals of the elastic displacement sensors and sending a control signal; and the driving component further comprises an execution unitfor adjusting the rotation speed of the body according to the control signal in order to adjust the pressure applied to the wafer by the polishing heads to keep the polishing rate constant.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

Method for high-frequency vibration assisted micro-deep drawing forming of foil boards

ActiveCN103042109BReduce frictionInhibition of germinationShaping toolsHigh frequency powerMicro actuator

The invention relates to a device and a method for micro-deep drawing forming of foil boards, in particular to a method and a device for high-frequency vibration assisted micro-deep drawing forming of foil boards and aims to solve the problem that low-strength foil boards are difficult to form small-diameter cylinder pieces by means of deep drawing. An upper die base, an upper die component, a lower die component and a lower die base of the device are sequentially arranged from top to bottom, the upper end of the upper die component is connected with the lower surface of the upper die base, the lower end of the lower die component is connected with the upper surface of the lower die seat, a magnetic extendable micro-actuator and a male die are arranged in the upper die component sequentially from top to bottom, the magnetic extendable micro-actuator is connected with a high-frequency power supply, a power output end of the magnetic extendable micro-actuator is connected with the upper end of the male die, a back pressure spring and a back pressure ejector rod are arranged in a cavity of the male die sequentially from top to bottom, a deep drawing punch is inserted on the upper surface of the lower die component, and a belleville spring is sleeved on the outer side wall of the upper end of the male die. The device and the method are used for micro-deep drawing forming of the foil boards.

Owner:HARBIN INST OF TECH

Selectively lockable torque-limiting mechanism

ActiveUS9555526B1Reduce the amount of variationReduce frictionSpannersWrenchesEngineeringMechanical engineering

A tool including selectively operable torque-limiting mechanism is provided. The tool includes a housing, a torque-limiting mechanism disposed within the housing and including a first gear engaged with the housing and including a number of first recesses, a second gear rotatably disposed within the housing adjacent the first gear and including a number of second recesses, a number of bearings disposed between the first gear and the second gear partially within the first recesses and partially within the second recesses, and a variable force-applying assembly engaged with the first gear opposite the second gear, a drive body engaged with the second gear and extending outwardly from the housing, and a cover disposed around the housing and selectively engaged with the drive body to control the operation of the torque-limiting mechanism.

Owner:GAUTHIER BIOMEDICAL

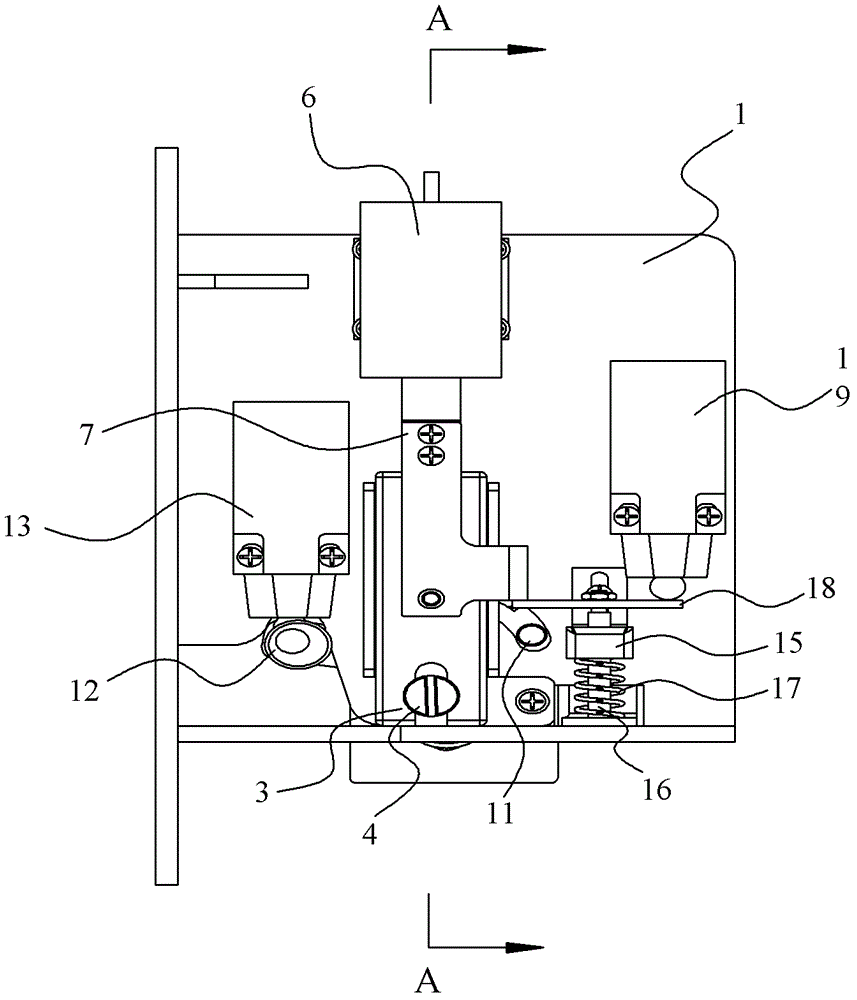

Safety door locking device and safety door adopting same

The invention discloses a safety door locking device and a safety door. The safety door locking device includes a main support, an auxiliary support and a unlocking slideway sliding block mounted on the main support through a slideway, a locking wheel mounted on the main support through a torsional spring and including a guide groove and a plurality of teeth-shaped objects, a lock pin fixed on the auxiliary support and accommodated in the guide groove, a stop pin matched with the teeth-shaped objects to limit the rotation of the locking wheel and fixedly connected with the unlocking slideway sliding block, and a first unlocking mechanism arranged on the main support and fixedly connected with the stop pin through a connecting plate. The safety door locking device and the safety door can be used in low-temperature environment and are free from the influence of the environment change; the machining is rather simple, and the matching precision requirement is low; and the door opening / closing status signal feedback structure is simple, the reliability is high, and the device is convenient to mount and adjust.

Owner:JIANGSU SUBURBAN RAILWAY ELECTRICAL EQUIP

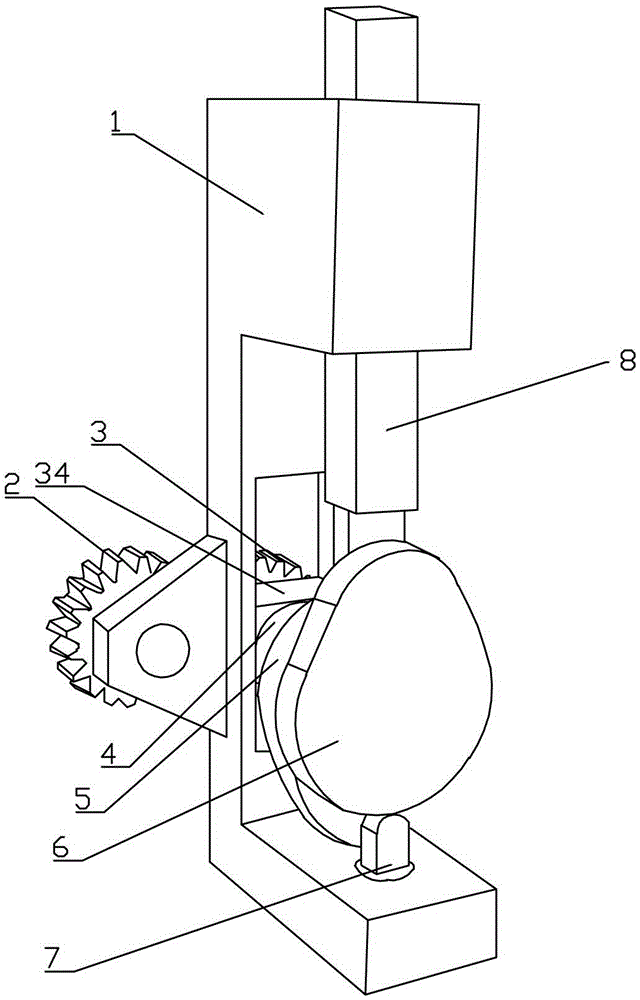

Hole digging device with adjustable hole depth

InactiveCN105409393ASolve the problem of mobile power transmissionIncrease the maximum strokePlantingFurrow making/coveringSeederGear wheel

The invention relates to a delivery mechanism of a seeder, in particular to a hole digging device with adjustable hole depth. The hole digging device comprises a fixed rack, a drive mechanism, a transmission cam group, an adjusting propping block and a driven slide bar, wherein the drive mechanism comprises a fixed gear, a sliding gear and a slider, the fixed gear is rotationally connected onto the fixed rack and meshed with the sliding gear, and the sliding gear is rotationally connected to the slider which is glidingly connected to the fixed rack; the transmission cam group comprises a camshaft, a transmission cam and an adjusting cam, the camshaft is fixedly connected with a shaft of the sliding gear, the transmission cam and the adjusting cam are both fixed on the camshaft, the transmission cam is propped against the driven slide bar above the transmission cam, the driven slide bar is glidingly connected to the fixed rack, the adjusting cam is propped against the adjusting propping block below the adjusting cam, and the adjusting cam is fixed on the fixed rack. The hole digging device capable of changing the hole digging depth is provided to solve the problems that a transmission mechanism of the conventional hole digging mechanism cannot change the maximum travel and the hole depth cannot be adjusted.

Owner:CHONGQING DONGYUAN AGRI DEV CO LTD

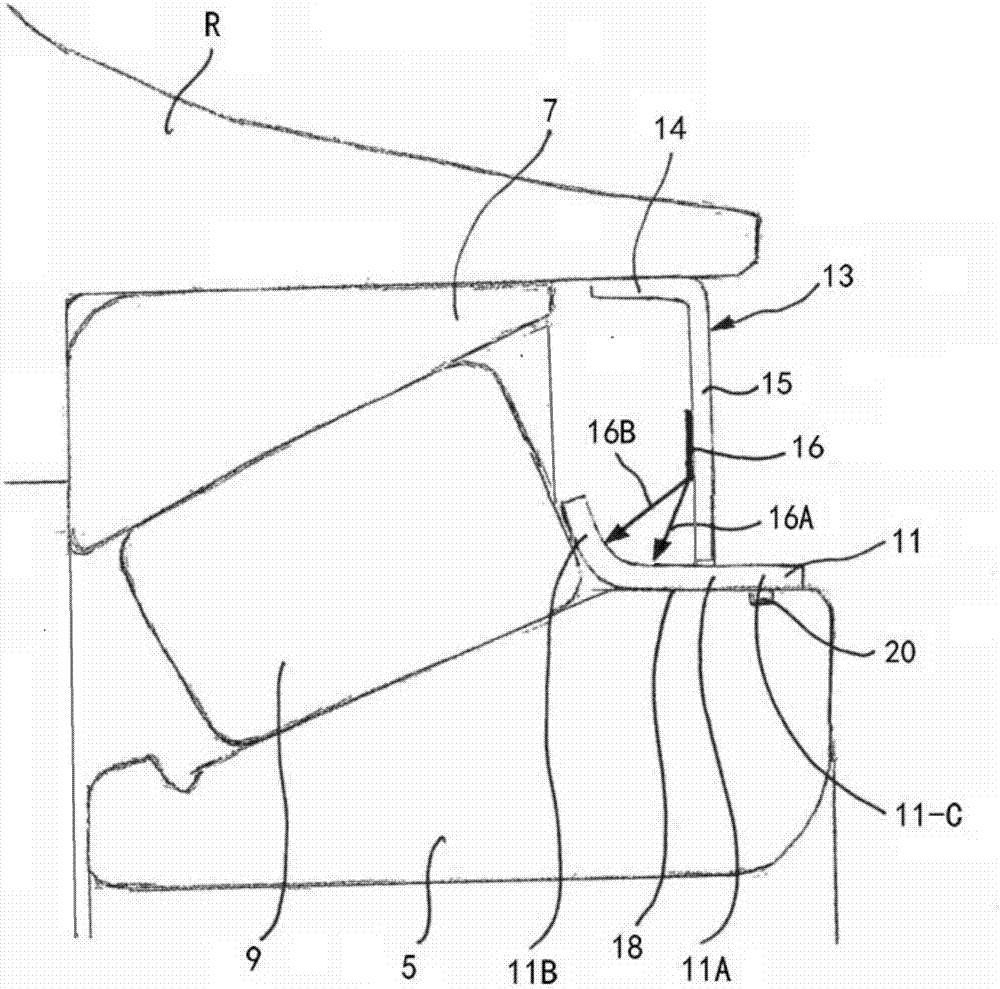

Automatic card dispatching device

ActiveCN101635064BConstant frictionFriction effectConveying record carriersAuxillary ticket-issuing devicesPull forceTransmission channel

The invention relates to an automatic card dispatching device, commonly referred to as a square card card-scratching device. The invention aims at solving the problem of inaccurate card dispatching because the friction force between a friction wheel and cards is affected by the quantity of the cards. The device in the invention comprises an elastic hoisting piece (400), and a transmission device (100) internally provided with a transmission channel, a friction wheel, a motor and the like and is hoisted at the lower part of the elastic hoisting piece; the upward tensile force of the elastic hoisting piece is smaller than the self gravity of the transmission device to cause the friction wheel (1) to exert normal friction force on the front surface of the uppermost card so as to send the uppermost card out. The invention can ensure that one single card is transmitted once and excess cards are blocked and returned into the card box by matching a reversing wheel (7) with a separating wheel(9) under the combined action of the friction wheel, the reversing wheel and the separating wheel. The automatic card dispatching device can greatly improve the reliability of the automatic card dispatching device.

Owner:GAOXIN MODERN INTELLIGENT SYST

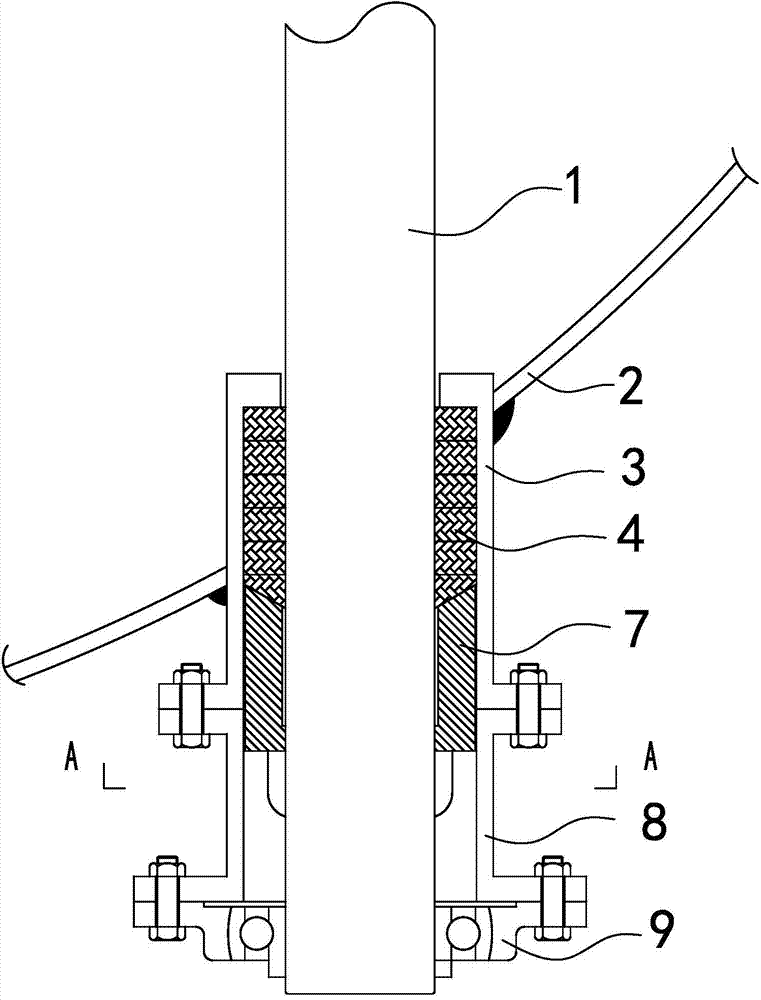

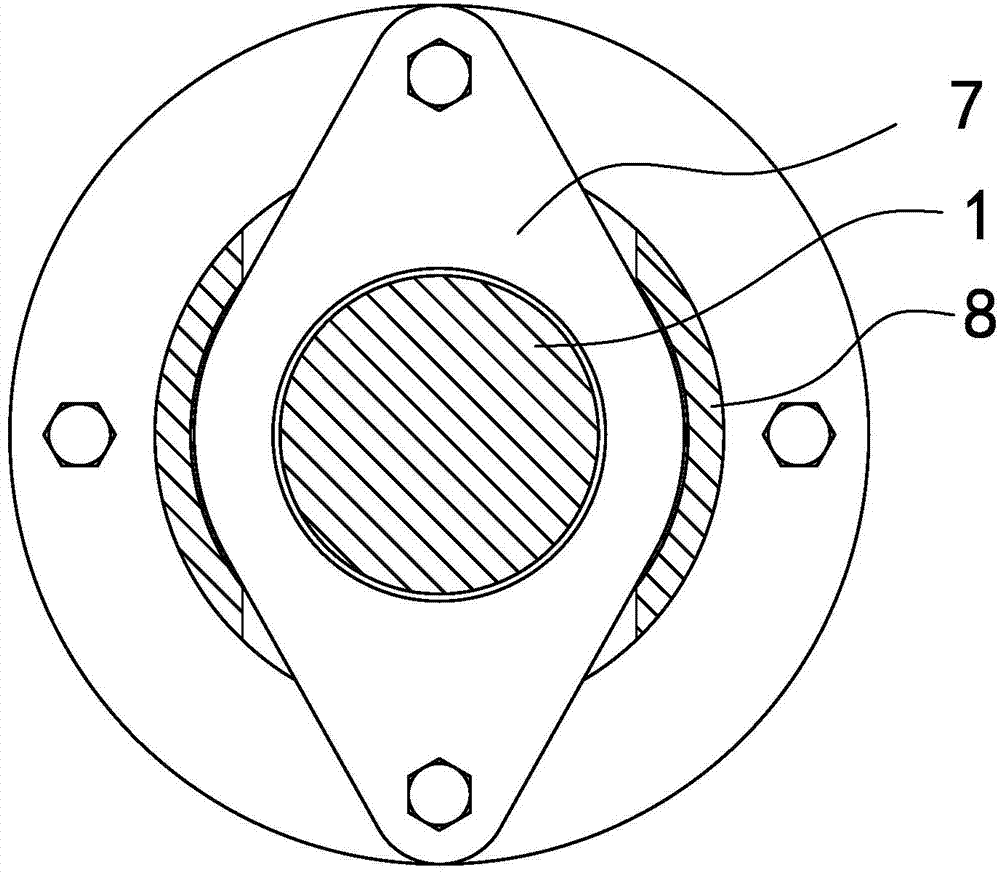

Sealing device for valve shaft of high-temperature butterfly valve

The invention relates to a sealing device for a valve shaft of a high-temperature butterfly valve. The sealing device comprises a valve shaft, a packing box, a composite sealing body, packing and a packing pressing cover, wherein the valve shaft is provided with an annular sealing lug boss; the packing box is arranged on the outer side of the valve shaft; the packing box is internally and sequentially provided with the composite sealing body, the packing and the packing pressing cover which are tightly connected from the direction close to the lug boss to the direction far away from the lug boss; and the packing pressing cover is fixed on the packing box, and the packing is pressed. The lug boss is in end face sealing with the composite sealing body, a gap with the size of 5cm or more than 5cm is formed between the lug boss and the packing box, and a gap with the size of 5cm or more than 5cm is formed between a pressing sleeve and the valve shaft. The composite sealing body can be finely adjusted when the valve shaft is deformed, even bent at a high temperature, so that the valve shaft is still tightly combined with the composite sealing body and the pressing sleeve, and the friction force is not changed. The sealing device is provided with a blowing opening 4, and an external wind force is introduced from the blowing opening to blow away a medium between the valve shaft and the sealing device, so that the sealing device is prevented from being blocked.

Owner:洛阳兴罡石化设备有限公司

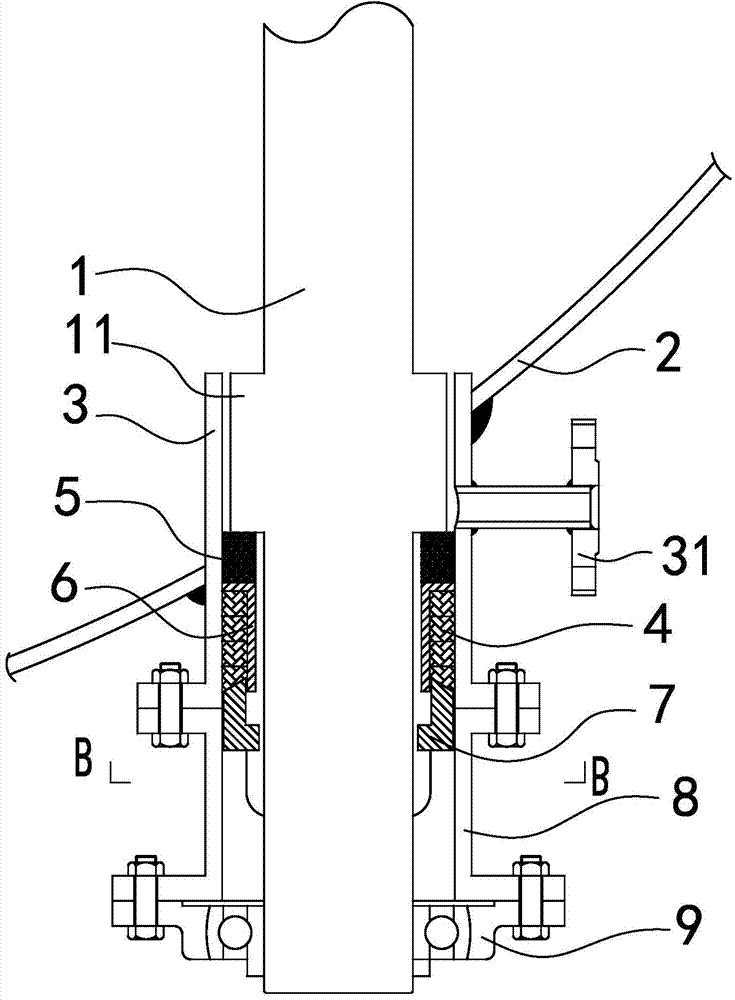

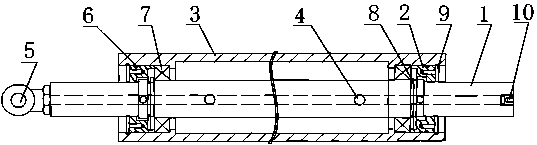

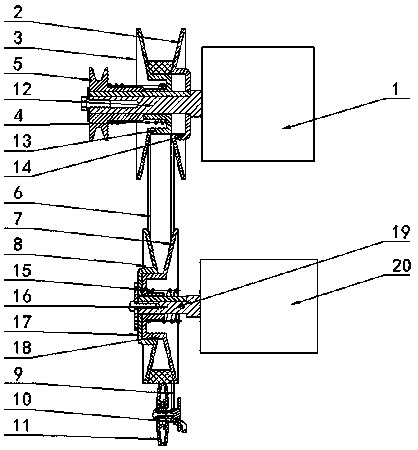

Ventilation carrier roller device of tipping paper laser perforating machine

PendingCN111250877AConstant frictionEasy to cleanLaser beam welding apparatusRetaining ringBearing (mechanical)

The invention discloses a ventilation carrier roller device of a tipping paper laser perforating machine. The ventilation carrier roller device of the tipping paper laser perforating machine comprisesa ceramic carrier roller with a shaft center through hole, a ventilation shaft with a shaft center through hole, a sealing bolt, an APBT-type threaded tee joint, two high-speed bearings, elastic retaining rings for shafts, two sealing glands, O-shaped rings and elastic retaining rings for holes; the ventilation shaft is arranged in the shaft center through hole of the ceramic carrier roller in asleeved mode; ventilation holes are formed in the ventilation shaft; the sealing bolt is arranged in one end of the ventilation shaft; the APBT-type threaded tee joint is arranged on the other end ofthe ventilation shaft; the two high-speed bearings are arranged between the inner wall of the ceramic carrier roller and the outer wall of the ventilation shaft; each elastic retaining ring for shaftsis arranged between the corresponding high-speed bearing and the ventilation shaft and can be used for fixing the high-speed bearing to be connected with and position the ventilation shaft; the two sealing glands are arranged on the two sides of the inner wall of the ceramic carrier roller and at the outer side of the high-speed bearings; each O-shaped ring is arranged between the corresponding sealing gland and the ceramic carrier roller; and the elastic retaining rings for holes are arranged on the inner wall of the ceramic carrier roller and are used for fixing the sealing glands. The ventilation carrier roller device of the tipping paper laser perforating machine has the advantages that dust adsorption on the surface of the carrier roller is effectively reduced, dust is effectively prevented from entering the inner structure of the carrier roller, the mechanical rotation stability of the carrier roller is ensured, and the service life of the machine is prolonged.

Owner:吉林长白山包装材料有限公司

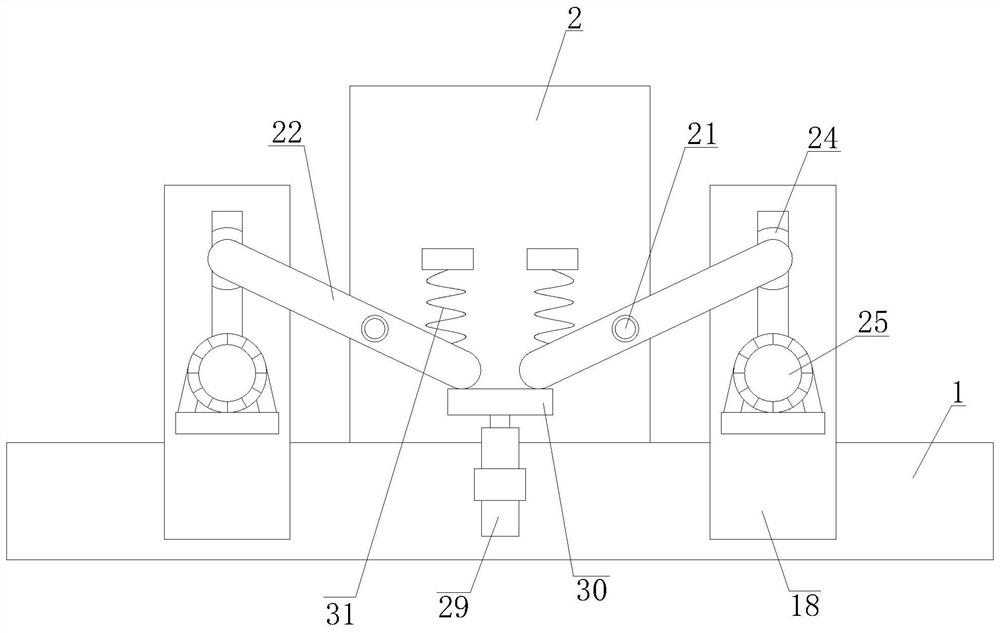

Cable character code wear resistance detection device

InactiveCN111795902AStrong tensionAvoid uneven forceInvestigating abrasion/wear resistanceHydraulic cylinderStructural engineering

The invention relates to the technical field of cable character code wear resistance detection. The invention further discloses a cable character code wear resistance detection device which comprisesa base, the top of the base is fixedly connected with a back plate, a top plate is fixedly connected with the front face of the back plate, a first hydraulic cylinder is fixedly connected with the bottom of the top plate, a transverse plate is fixedly connected with the output end of the first hydraulic cylinder, a pressure sensor is fixedly connected with the bottom of the transverse plate, and an erasing block is fixedly connected with the bottom of the pressure sensor through a connecting plate. The cable character code wear resistance detection device solves the problems that during the detection of an existing cable character code wear resistance detection device, the pressure between a wiping block and a cable character code cannot be accurately controlled, such that the detection result is not accurate, the quality of the cable is seriously affected, the clamping operation on the cable during the detection process is tedious, and the efficiency of the detection work is seriouslyreduced.

Owner:惠安县钗新汽车配件中心

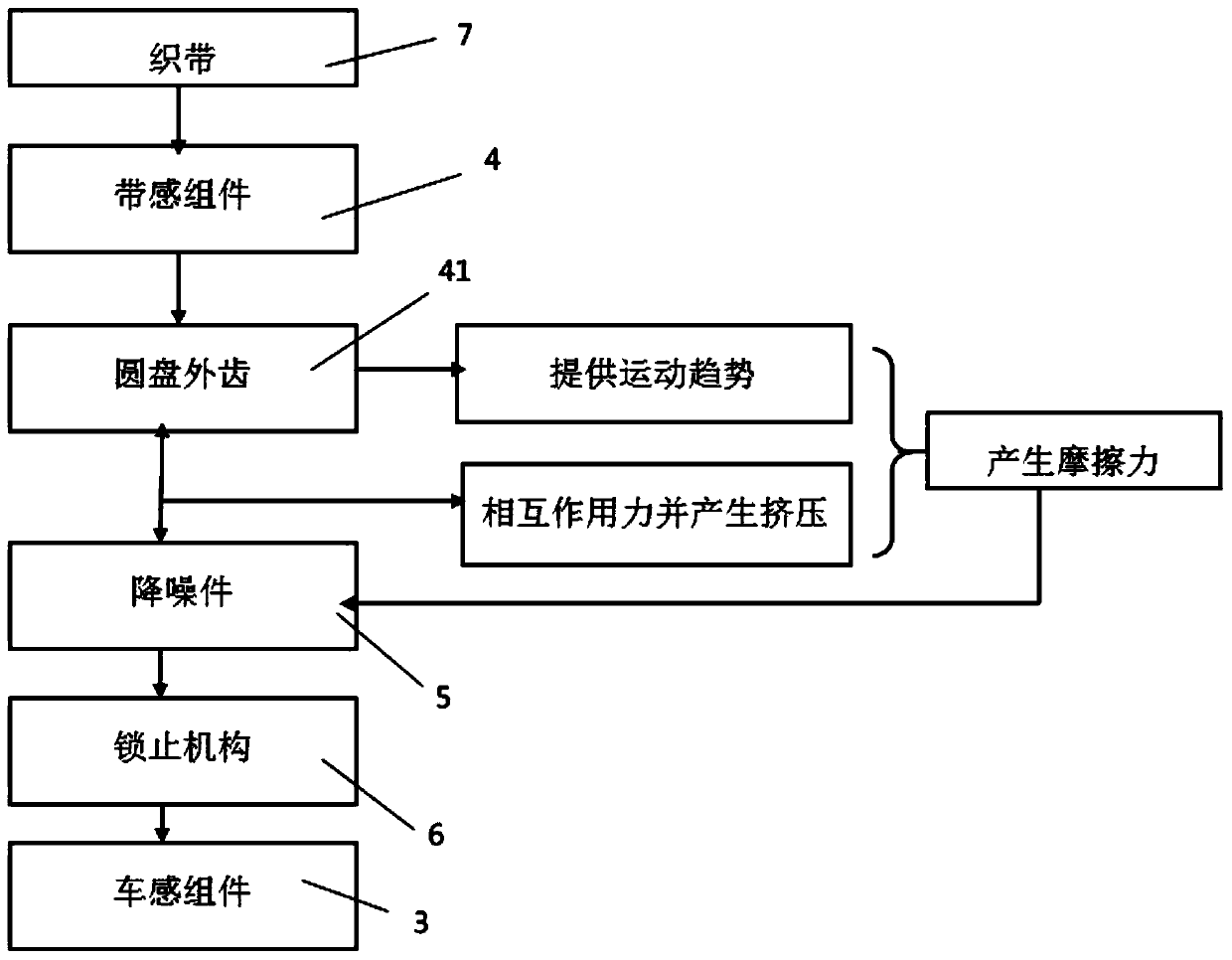

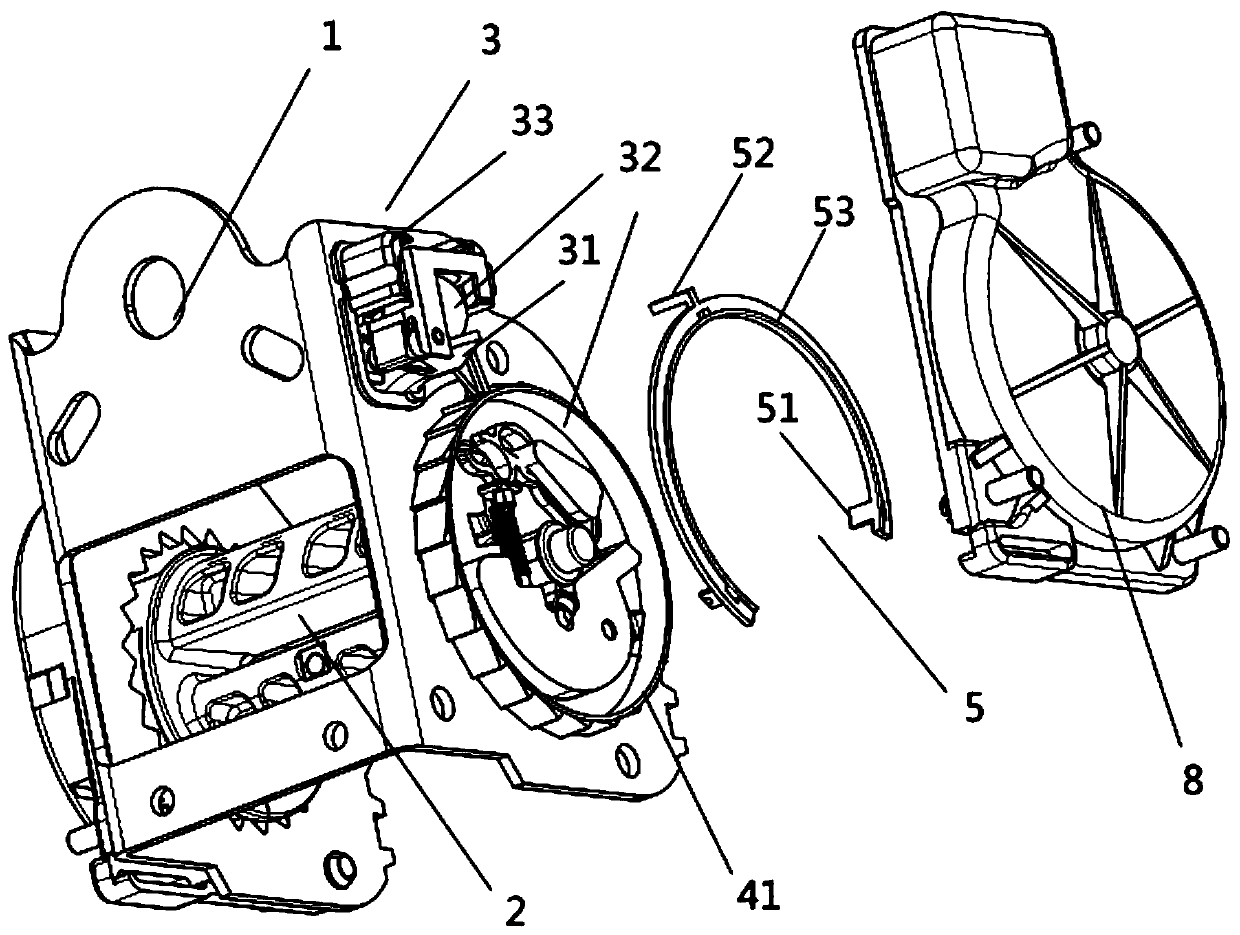

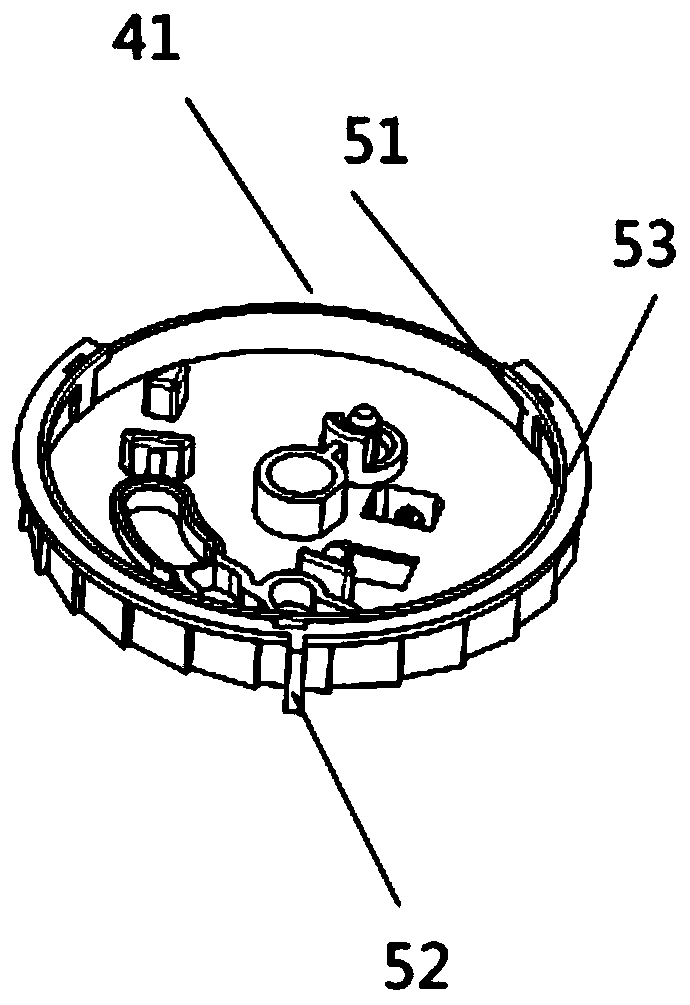

Emergency locking retractor for noise reduction on vehicle sensing assembly

ActiveCN109823303ACancel soundRestoration of locking functionBelt retractorsLocking mechanismSteel ball

The invention relates to an emergency locking retractor for noise reduction on a vehicle sensing assembly. The emergency locking retractor comprises a belt sensing assembly, a noise reduction piece and the vehicle sensing assembly; the belt sensing assembly is provided with a disc outer tooth, the noise reduction piece is arranged on the disc outer tooth, the interaction force exists and the extrusion is generated between the noise reduction piece and the disc outer tooth, and the disc outer tooth performs circular motion under the trigger of a ribbon and provides a movement trend for the noise reduction piece to generate friction force; when the ribbon is unreeled, the noise reduction piece rotates and squeezes a vehicle sensing arm of the vehicle sensing assembly from the front face or side face through a locking mechanism of the noise reduction piece, thereby limiting moving space of a steel ball of the vehicle sensing assembly; when the ribbon is pulled out, the noise reduction piece rotates reversely, and the noise reduction piece breaks away from the vehicle sensing arm of the vehicle sensing assembly. The emergency locking retractor for the noise reduction at the vehicle sensing assembly has the advantages that the steel ball state of the vehicle sensing assembly can be limited, so that after a passenger does not wear or wears a safety belt, the steel ball is in a specified position and cannot move due to vehicle running, thereby eliminating the sound made by the vehicle sensing assembly.

Owner:CHONGQING GUANGDA IND

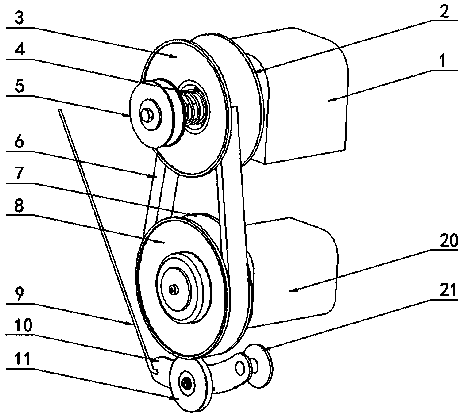

Viscose filament feeding device

The invention discloses a viscose filament feeding device and belongs to the technical field of chemical fiber production equipment. The viscose filament feeding device comprises a rack, a driving roller, a driven roller, a lifting rod playing an adjusting function, fixing units, elastic pieces and the like, wherein the driving roller and the driven roller are arranged on the rack. According to the viscose filament feeding device, by the adoption of the roller type feeding device, by using the friction force formed between the two rollers and pulp, roll pulp is continuously and uniformly conveyed into a pulp machine, and continuous and uniform feeding is achieved; and the elastic pieces are adopted for the two rollers, radial clearance compensation is achieved, the constant friction forcebetween two rotating wheels is guaranteed, and timing, quantitative and continuous feeding is achieved.

Owner:YIBIN GRACE +1

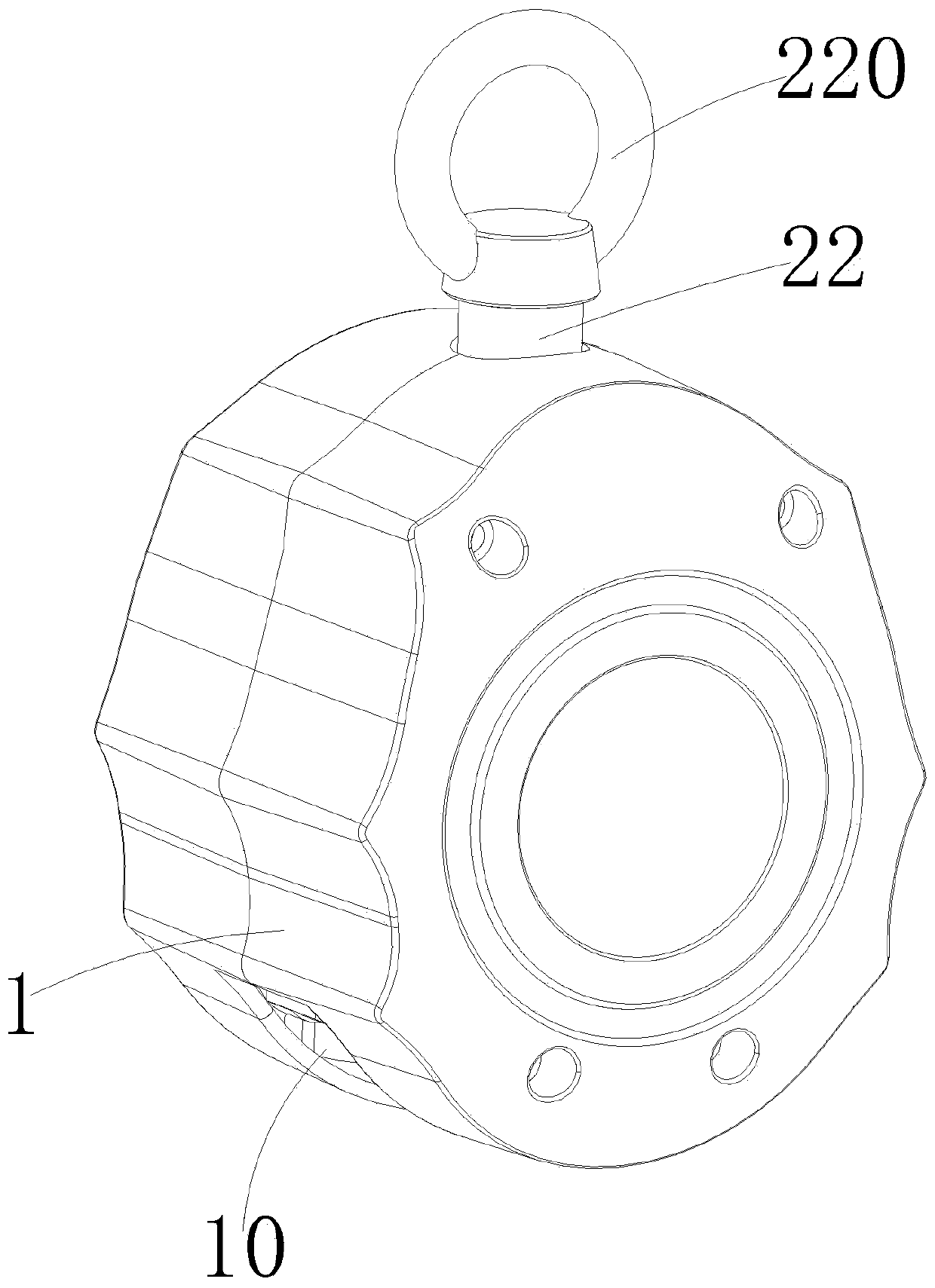

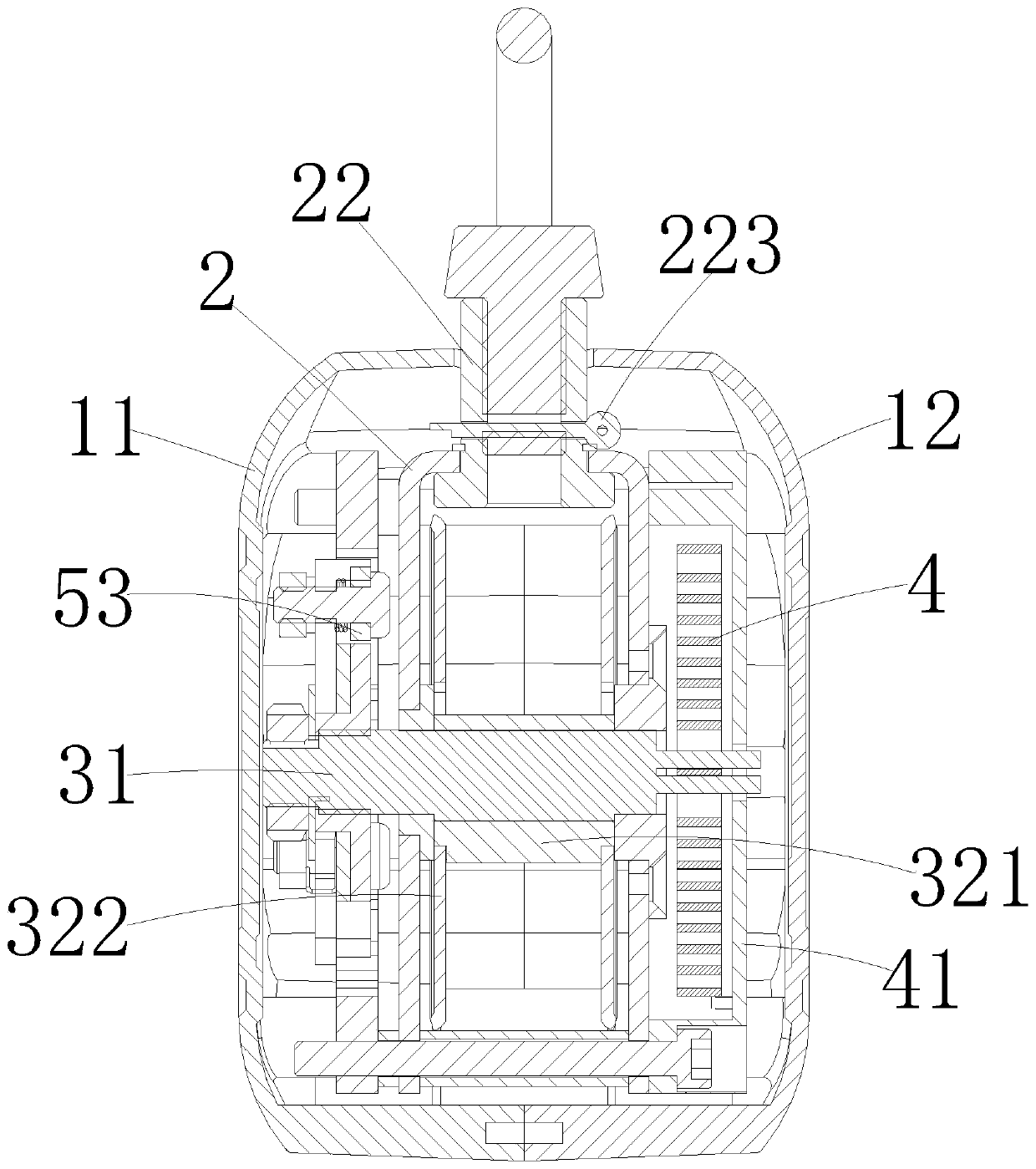

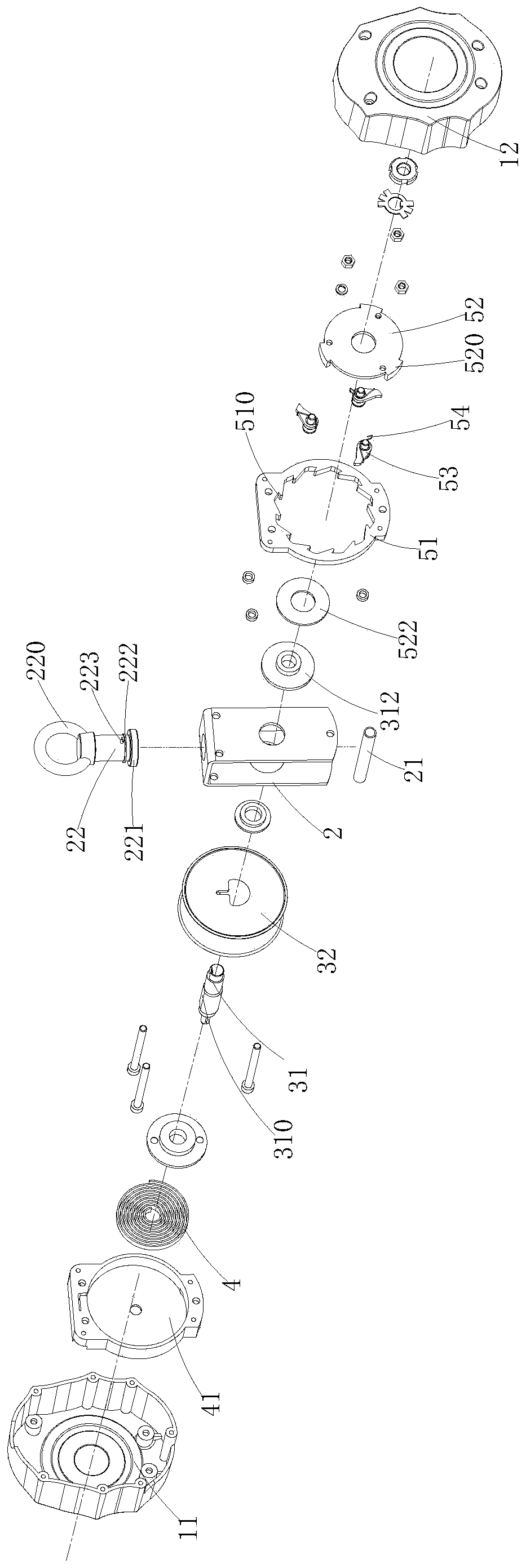

Buffer type differential anti-falling device

Owner:JINHUA JECH TOOLS CO LTD

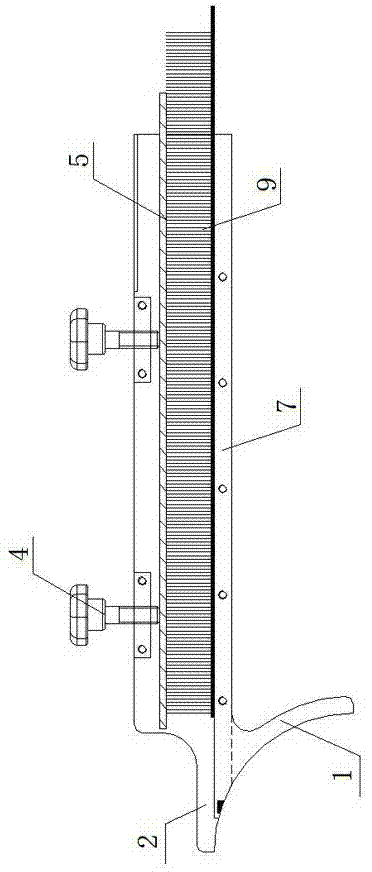

Portable rapid needle cloth wrapping device suitable for brushing roller

The invention discloses a portable rapid needle cloth wrapping device suitable for a brushing roller. The device comprises a base plate, two side plates are arranged on the base plate, a preload pressure adjusting device is arranged between the two side plates, a pressing plate matched with the preload pressure adjusting device is arranged below the preload pressure adjusting device, and a needle cloth channel is formed between the pressing plate and the base plate. A needle distribution groove is formed in the front end of the base plate, two needle cloth distribution guide plates are arranged on the two sides of the needle distribution groove, the rear ends of the needle cloth distribution guide plates and the side plates are connected into a whole, an arc abutting plate attached to the roller face of the brushing roller is arranged on the lower portion of the front end of the base plate, and an included angle alpha formed between the needle distribution channel and the axis of the brushing roller ranges from 83 degrees to 90 degrees. The portable rapid needle cloth wrapping device is light, handy and convenient to carry, the needle cloth is pressed by the pressing plate, constant pressure is applied to the needle cloth in the needle cloth wrapping process, the friction applied to the needle cloth by the needle cloth wrapping device is constant as well, and therefore the constant tension of the needle cloth can be ensured in the wrapping process; needle cloth gaps are constant at the high wrapping speed due to the fact that the needle cloth distribution guide plates are arranged on the needle cloth wrapping device.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

A screening arrangement for a window

InactiveCN101057057AEffective and reliable parallel guidanceEasy to attachDoor/window protective devicesEngineeringMechanical engineering

Screening arrangement for a window, said screening arrangement comprising a first screening element and a second screening element arranged end to end, the first screening element being arranged between a first bar element and a second bar element. To provide a versatile screening arrangement, which is easy to install and provides high degree of user friendliness regarding positing of the screen, the second screening element is a blind, arranged between the second bar element and a third bar element, the screening arrangement further comprising a cord system having a set of guide cords of which one is extending from a position at a wing corner along the second or third bar element to a diametrically opposite wing corner, and a set of holding cords of which one is extending from a position at a wing corner, along the nearest of the second or third bar element, threaded through a first set of apertures of the blind, and along the other of the second or third bar element to a diametrically opposite wing corner and return to the starting point through a second set of apertures of the blind.

Owner:VKR HLDG AS

Bearing assembly with preload

ActiveCN107013568AAvoid enteringPreload is simple and fastRolling contact bearingsBearing assemblyRolling-element bearingEngineering

In the following a bearing assembly, in particular a wheel bearing assembly for a vehicle, with at least one rolling-element bearing, in particular with two tapered roller bearings, is presented, wherein the at least one rolling-element bearing includes a bearing outer ring and a bearing inner ring that define a bearing interior between them in which rolling elements are disposed. Furthermore, the bearing assembly includes a seal assembly for sealing the bearing assembly, wherein the seal assembly includes a carrier element that is connectable, for example, via an axially extending ring arm, to one of the bearing rings of the bearing assembly such that they rotate together, and includes a radially extending annular flange, wherein the radially extending flange carries a radially encircling seal with at least one seal lip. The seal lip in turn extends toward the other bearing ring and sealingly abuts on a sleeve-shaped element that is connectable to the other bearing ring of the bearing assembly such that they rotate together, and the sleeve-shaped element is configured to form a flange of an axial stopper of the rolling elements.

Owner:AB SKF

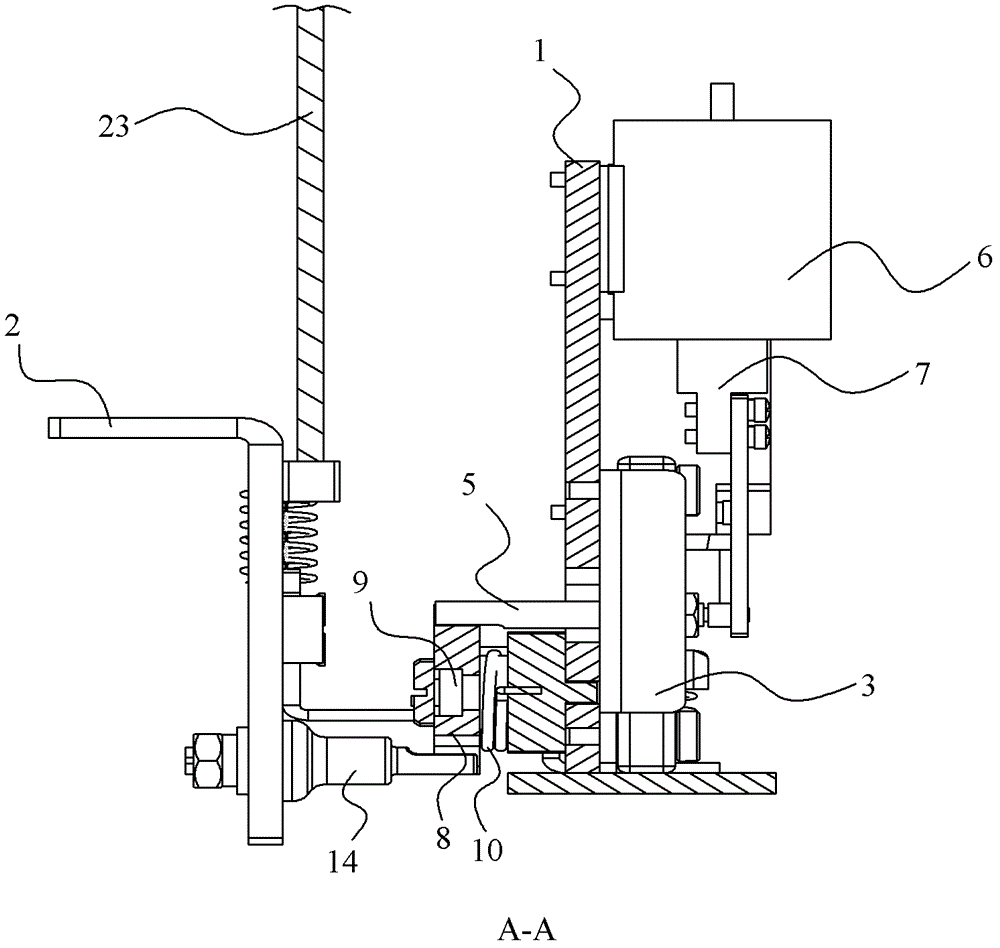

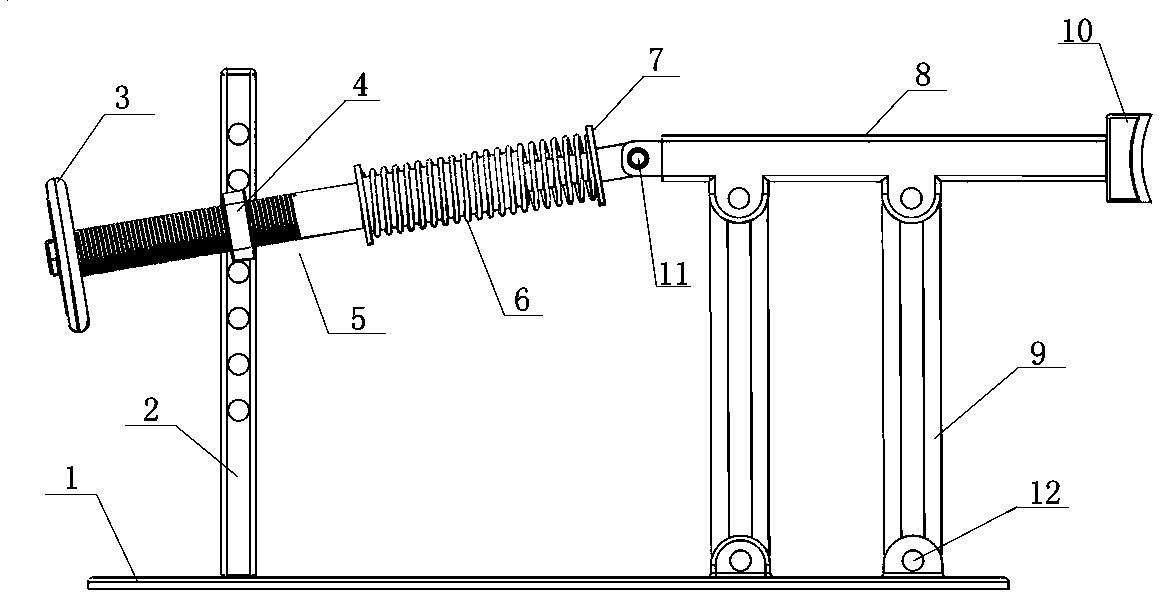

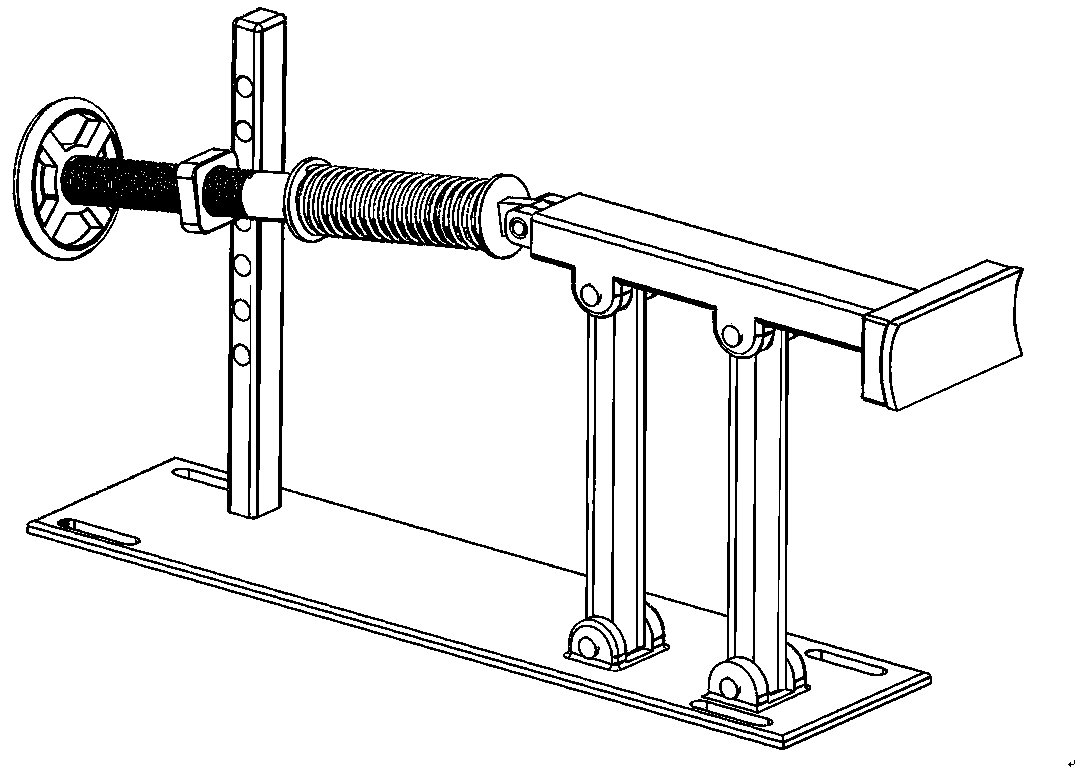

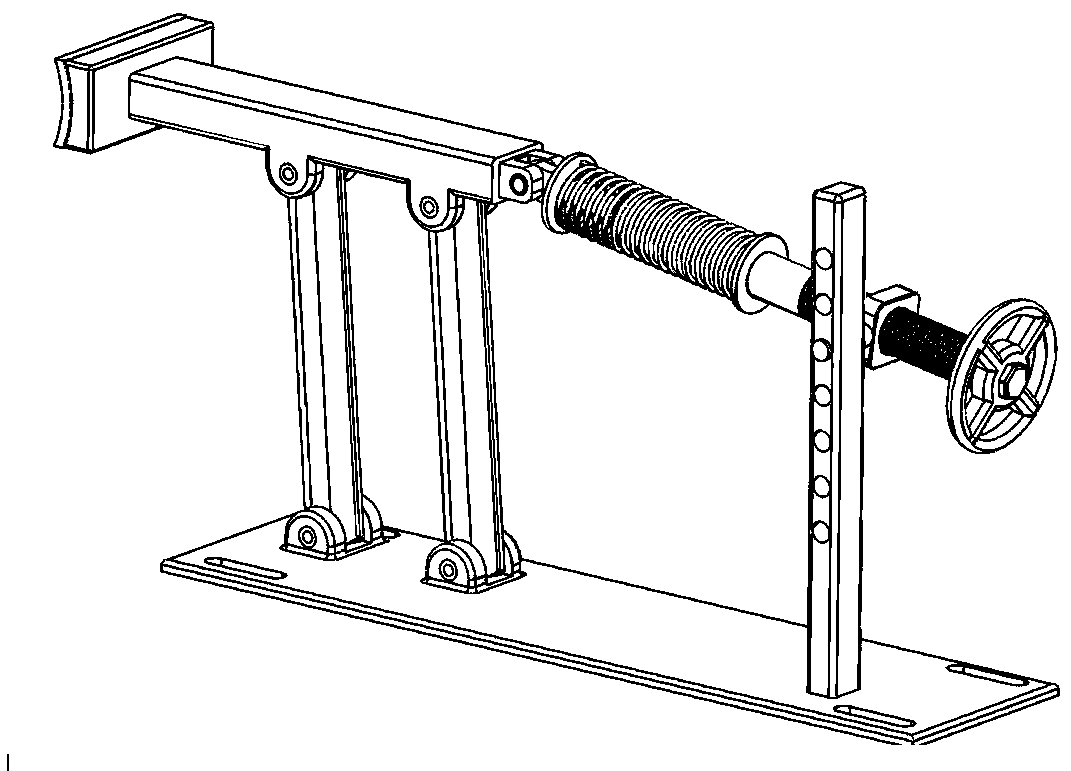

Constant tension paying-off brake device and using method thereof

PendingCN110668250AReduced precision requirementsAdvanced technologyFilament handlingInsulating conductors/cablesEngineeringAir compressor

The invention relates to a constant tension paying-off brake device and a using method thereof, and belongs to the technical field of production of enamel-cover winding wires for large-sized power transformers. According to the technical scheme, a height-adjustable supporting column (2) is provided with one or more placement holes, and a twistable nut (4) is arranged in the position holes of the height-adjustable supporting column (2); one end of an adjusting screw (5) is connected with the twistable nut (4) through a thread, the other end of the adjusting screw (5) is opened, the adjusting screw (5) is internally provided with a slide way communicated with the opening, one end of a slide rod (7) is slidably arranged in the slide way, the other end of the slide rod is hinged to a brake rod(8), and a spring (6) sleeves the adjusting screw and the slide rod; a brake sheet (10) is arranged at the top of the brake rod, the tops of two connecting rods are hinged to the brake rod, and the bottom of the two connecting rods are hinged to a base (1). According to the constant tension paying-off brake device, there is no need to provide compressed air for an air compressor, meanwhile, the requirement for the precision of a paying-off bobbin tool is not high, and a large amount of expenditure is reduced.

Owner:BAODING TIANWEI WIRE MFG

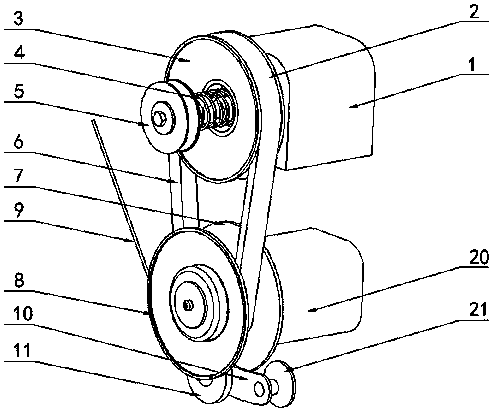

Variable-diameter stepless speed changer

The invention discloses a variable-diameter stepless speed changer. The variable-diameter stepless speed changer comprises a driving wheel set, a driven wheel set and a speed changing belt (6). The driving wheel set comprises a driving wheel static disc (2), a driving wheel moving disc (3) and a driving wheel compression spring (4). The driving wheel static disc (2) is fixed to an output shaft (12). The driving wheel moving disc (3) is arranged on the output shaft (12). The driving wheel compression spring (4) ejects the driving wheel moving disc (3) to clamp the speed changing belt (6). The driven wheel set comprises a driven wheel static disc (8), a driven wheel moving disc (7) and a driven wheel compression spring (15). The driven wheel static disc (8) is fixed to an input shaft (16). The driven wheel moving disc (7) is arranged on the input shaft (16). The driven wheel compression spring (15) ejects the driven wheel moving disc (7) to clamp the speed changing belt (6). The elasticforce of the driven wheel compression spring (15) is much larger than that of the driving wheel compression spring (4). The variable-diameter stepless speed changer has the advantages of simplicity and reasonability in simple, convenience in operation and use, wide speed change range, good speed adjustment effect, stability, reliability, low production cost and the like.

Owner:浙江大邦电动工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com