Sealing device for valve shaft of high-temperature butterfly valve

A technology of sealing device, butterfly valve valve, applied in the direction of shaft sealing, valve device, valve details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and structure of a sealing device for a high-temperature butterfly valve shaft proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , features and their effects are described in detail below.

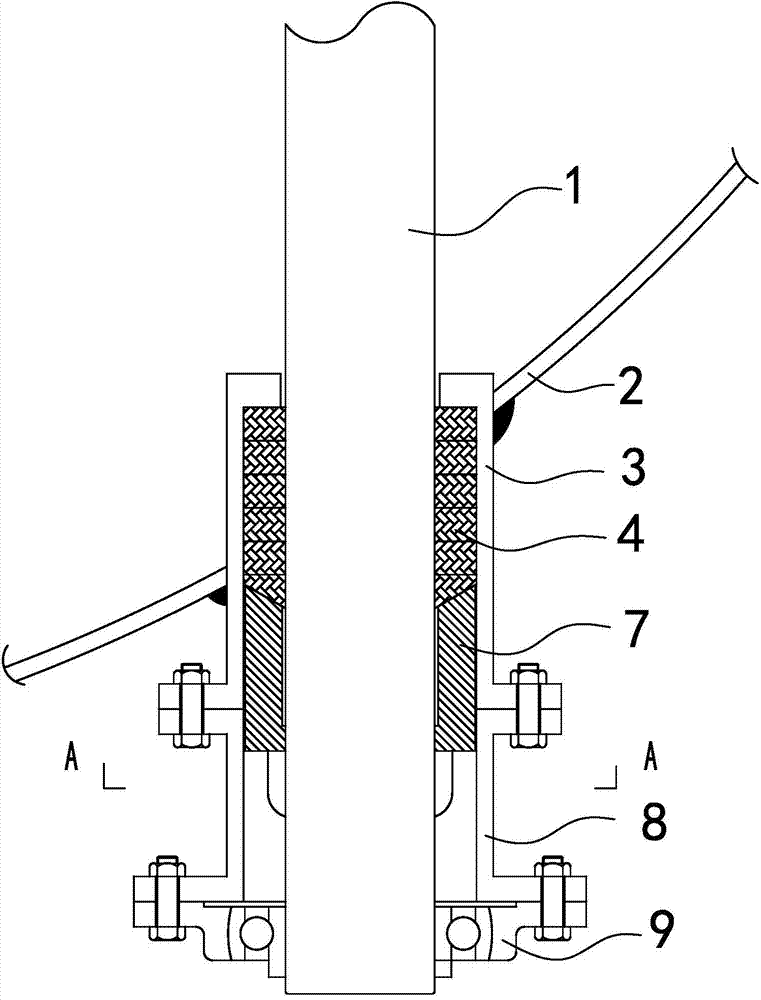

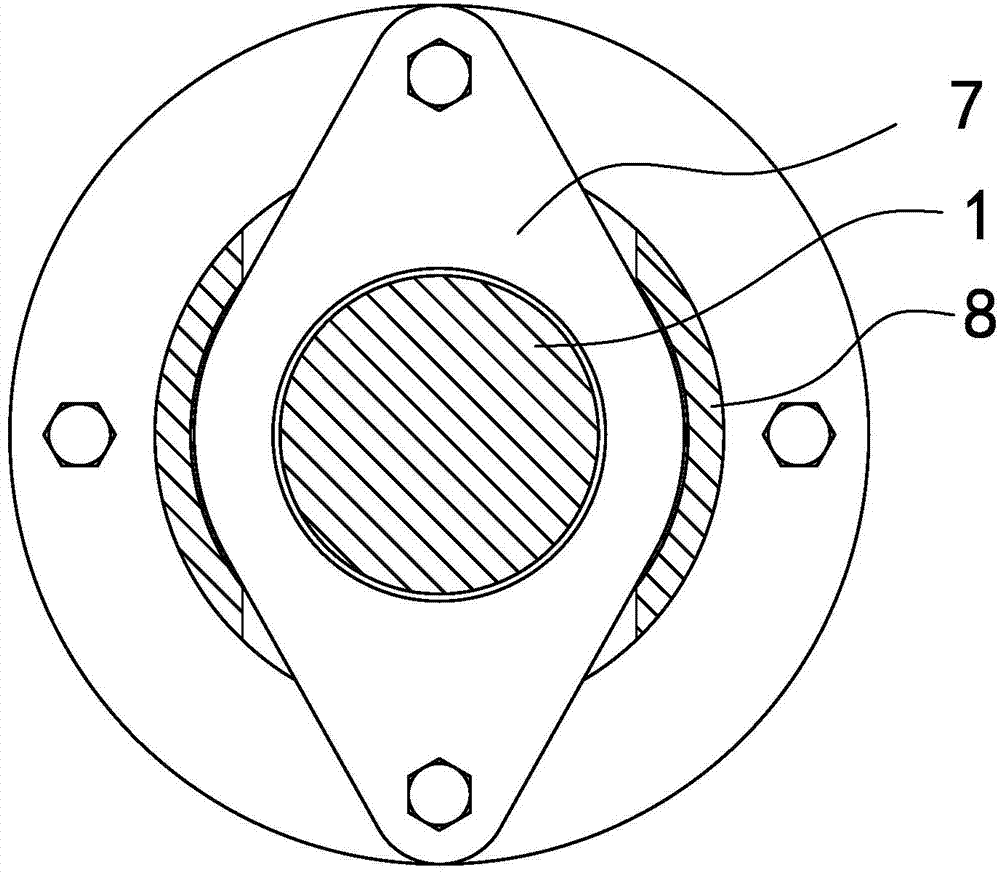

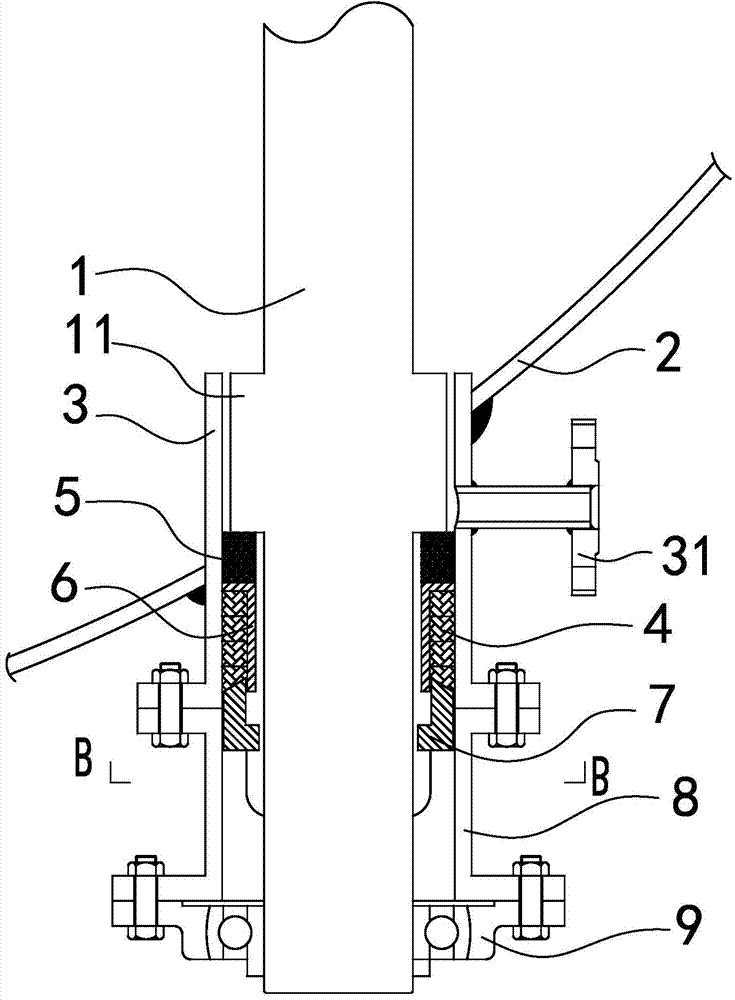

[0034] see image 3 and Figure 4 , which is a cross-sectional view of a sealing device for a valve shaft of a high-temperature butterfly valve and a B-B cross-sectional view thereof according to an embodiment of the present invention. It can be seen from the figure that the embodiment of the present invention is a valve shaft sealing device for a high temperature butterfly valve, including a valve shaft 1 , a stuffing box 3 , a composite sealing body 5 , a packing 4 , a compression sleeve 6 , and a packing gland 7 .

[0035] Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com