Emergency locking retractor for noise reduction on vehicle sensing assembly

A retractor and component technology, applied in the field of retractors, can solve the problems of unstable friction and inability to achieve, and achieve the effects of stable performance, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

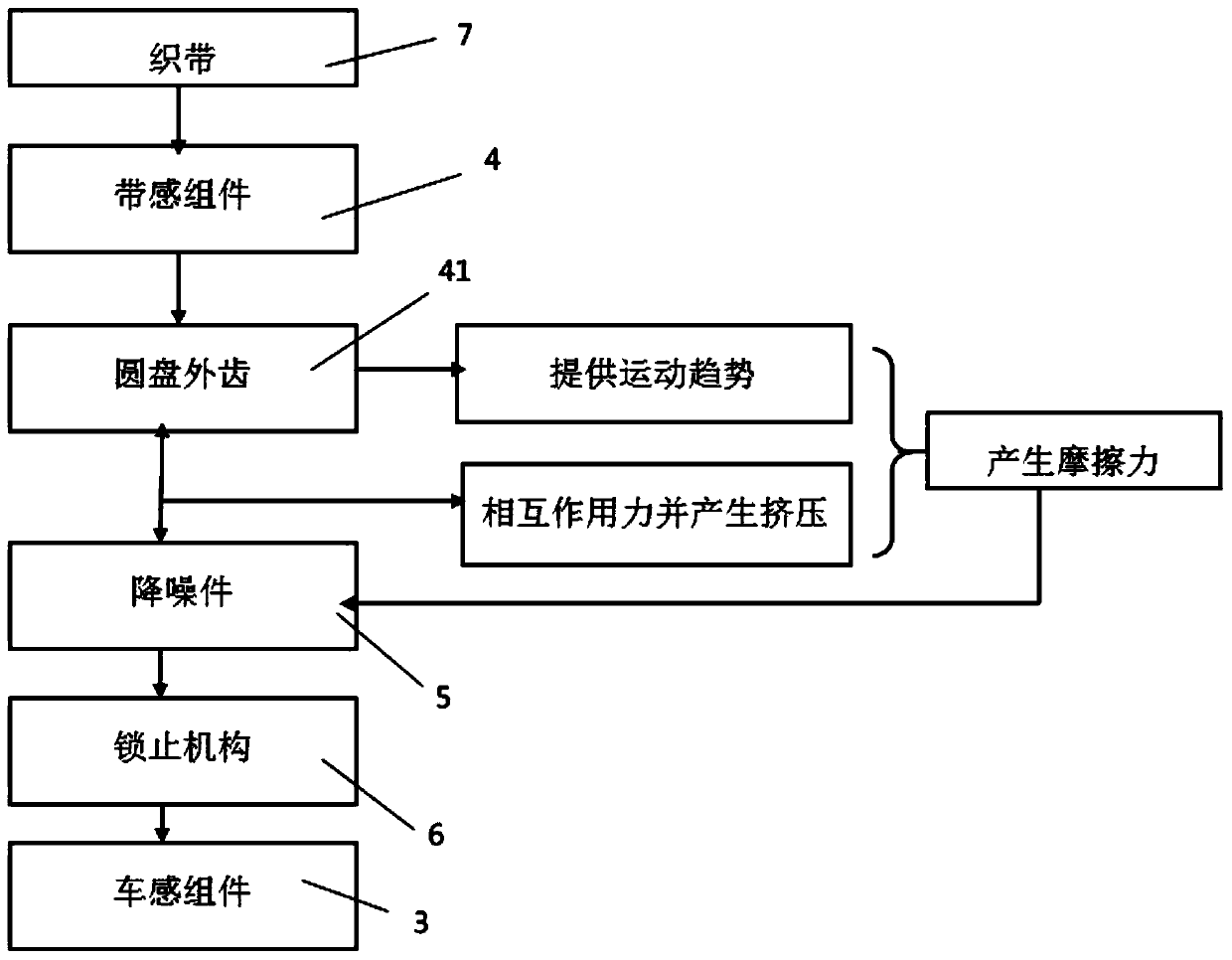

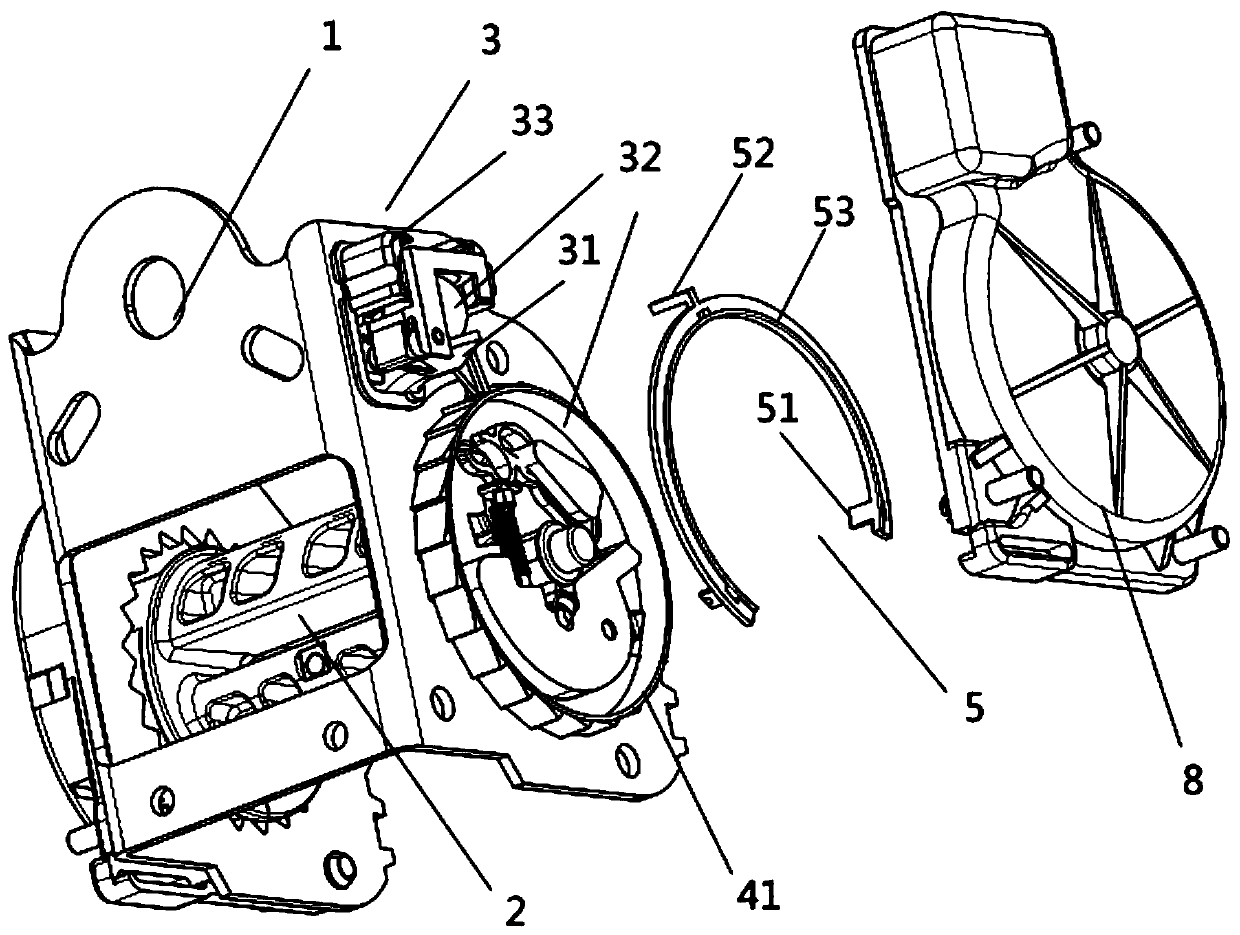

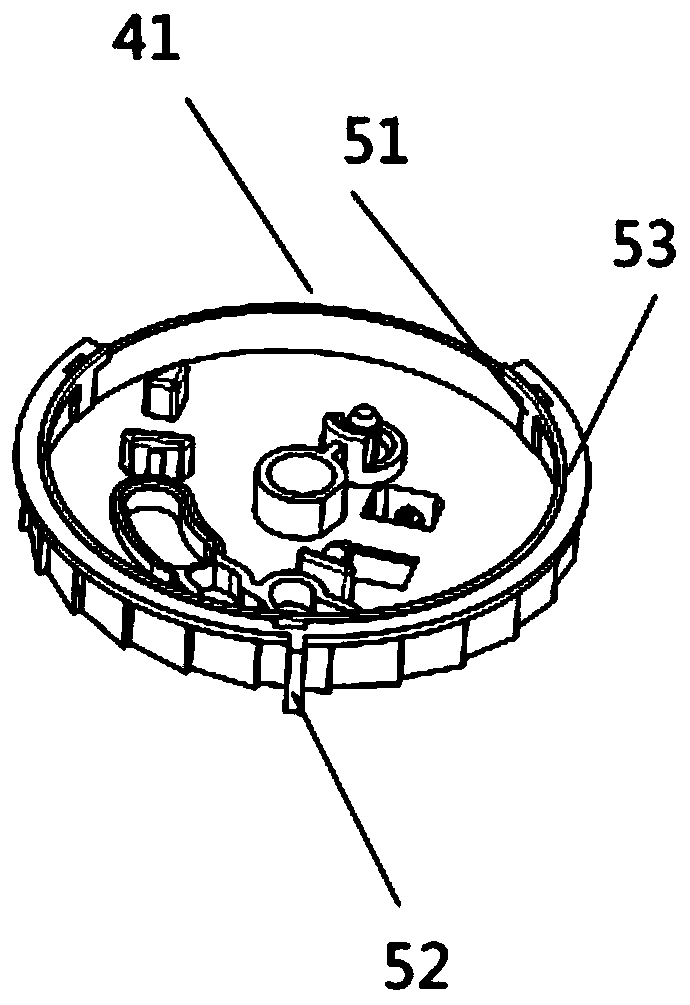

[0055] Please refer to figure 2 with image 3 , figure 2 It is an exploded schematic diagram of a retractor for noise reduction at the position of the vehicle sensing component 3 of the present invention. image 3 It is a schematic diagram of the assembly of the noise reducing part 5 and the outer teeth 41 of the disc. A retractor for noise reduction at the position of the vehicle sensor component 3, the retractor includes a bracket 1, a mandrel component 2, a vehicle sensor component 3, a belt sensor component 4, a noise reduction component 5, and an end cover 8 ; The mandrel assembly 2 is installed on the bracket 1; one end of the mandrel assembly 2 is installed with a sense assembly 4; The sense assembly 4 includes disc outer teeth 41; the noise reduction member 5 is docked on the outer end surface of the disc outer teeth 41, and utilizes the friction generated when the noise reduction member 5 moves outwardly with the disc outer teeth 41 The force drives the noise re...

Embodiment 2

[0067] Please refer to Figure 4 with Figure 5 , Figure 4 It is an exploded schematic diagram of a retractor for reducing noise at the position of the vehicle sensing component 3 according to Embodiment 2 of the present invention. Figure 5 It is a schematic diagram of the assembly of the noise reducing member 5 and the outer teeth 41 of the disc in the second embodiment. This embodiment is basically the same as Embodiment 1, the difference lies in that the structure of the noise reduction member 5 in this embodiment is different, and correspondingly the generation of frictional force that promotes the reciprocating rotation of the noise reduction member 5 is different. The noise reduction member 5 in this embodiment includes a snap-in sheet 54, a carrier sheet 53, and a locking sheet 52; the snap-in sheet 54 is arranged on the inner wall of the carrier sheet 53; the locking sheet 52 is arranged on the carrier The outer peripheral surface of the sheet 53.

[0068] In thi...

Embodiment 3

[0071] Please refer to Image 6 with Figure 7 , Image 6 It is an exploded schematic diagram of a retractor for noise reduction at the position of the vehicle sensing component 3 according to Embodiment 3 of the present invention. Figure 7 It is a schematic diagram of the assembly of the noise reducing member 5 and the outer teeth 41 of the disc in the third embodiment. This embodiment is basically the same as Embodiment 1, the difference lies in that the structure of the noise reduction member 5 in this embodiment is different, and correspondingly the generation of frictional force that promotes the reciprocating rotation of the noise reduction member 5 is different. The noise reduction member 5 in this embodiment includes a carrier piece 53 and a locking piece 52; the locking piece 52 is arranged on the outer peripheral surface of the carrier piece 53; the upper end or lower end of the outer tooth 41 of the disc An end slot 55 is provided; the outer diameter of the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com