Viscose filament feeding device

A technology of feeding device and viscose filament, which is applied in the field of feeding device and viscose filament feeding device, can solve the problems of low coordination accuracy of conveying and sorting, inability to reel pulp feeding, and large space occupied by equipment, etc., to achieve Reduce the difficulty of equipment maintenance, simple structure design, reduce the effect of equipment occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

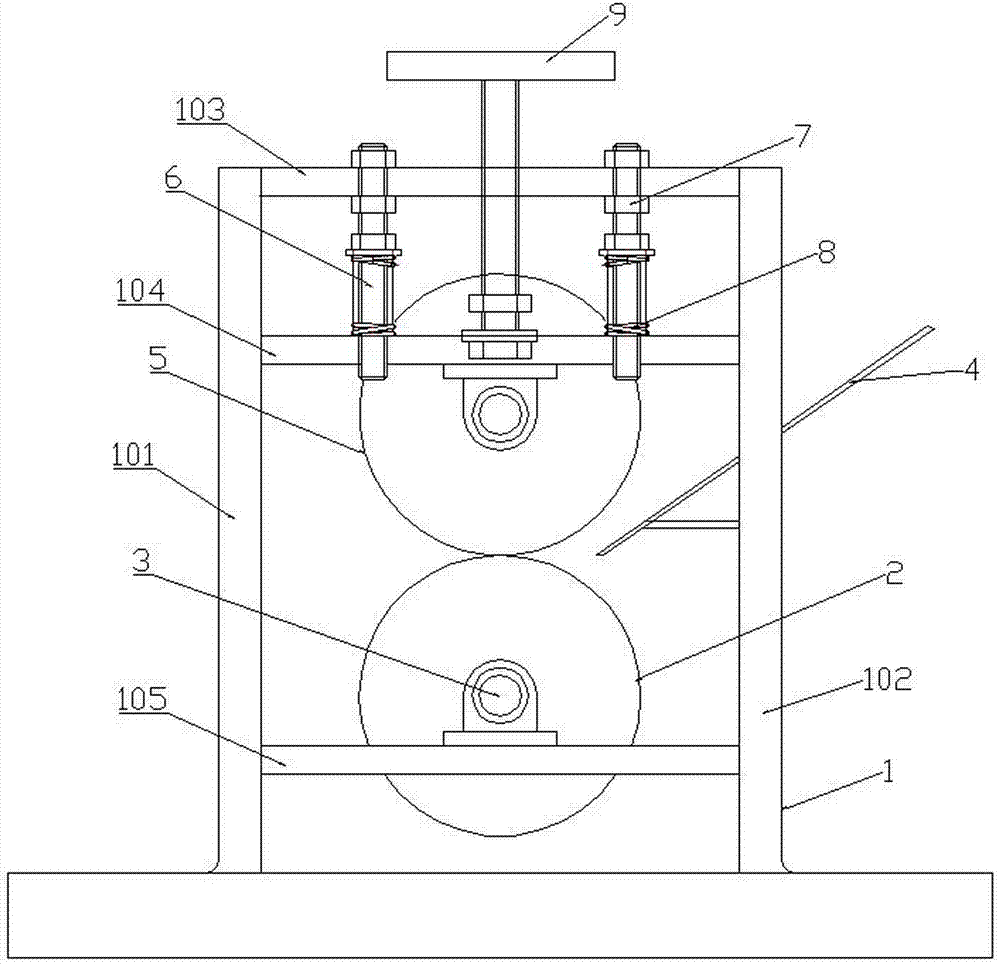

[0027] A viscose filament feeding device, comprising a frame 1 and a driving roller 2 and a driven roller 5 arranged on the frame 1, the driven roller 5 is arranged above the driving roller 2; the frame 1 includes a pole I101 , pole II102, pole III103, pole IV104 and pole V105, pole I101 and pole II102 are arranged vertically, pole III103, pole IV104 and pole V105 are arranged horizontally from top to bottom, pole III103 , support rod IV104 and support rod V105 are all set between the support rod I101 and the support rod II102; at the same time, the support rod I101 and the support rod II102 are equipped with chute, and the support rod III103 and the support rod V105 are fixedly arranged on the support rod I101 and the support rod II102, and one end of the support rod IV104 is set in the chute of the support rod I101, and the other end is set in the chute of the support rod II102, and the support rod IV can slide up and down between the support rod I and the support rod II; Th...

Embodiment 2

[0029] A viscose filament feeding device, comprising a frame 1 and a driving roller 2 and a driven roller 5 arranged on the frame 1, the driven roller 5 is arranged above the driving roller 2; the frame 1 includes a pole I101 , pole II102, pole III103, pole IV104 and pole V105, pole I101 and pole II102 are arranged vertically, pole III103, pole IV104 and pole V105 are arranged horizontally from top to bottom, pole III103 , support rod IV104 and support rod V105 are all set between the support rod I101 and the support rod II102; at the same time, the support rod I101 and the support rod II102 are equipped with chute, and the support rod III103 and the support rod V105 are fixedly arranged on the support rod I101 and the support rod II102, and one end of the support rod IV104 is set in the chute of the support rod I101, and the other end is set in the chute of the support rod II102, and the support rod IV can slide up and down between the support rod I and the support rod II; Th...

Embodiment 3

[0033] Such as figure 1Shown: a viscose filament feeding device, comprising a frame 1 and a driving drum 2 and a driven drum 5 arranged on the frame 1, the driven drum 5 is arranged above the driving drum 2; the frame 1 includes Strut I101, Strut II102, Strut III103, Strut IV104 and Strut V105, Strut I101 and Strut II102 are vertically arranged, Strut III103, Strut IV104 and Strut V105 are arranged horizontally from top to bottom, The support rod III103, the support rod IV104 and the support rod V105 are all set between the support rod I101 and the support rod II102; at the same time, the support rod I101 and the support rod II102 are equipped with chute, and the support rod III103 and the support rod V105 are fixedly arranged on the On the support rod I101 and the support rod II102, and one end of the support rod IV104 is set in the chute of the support rod I101, and the other end is set in the chute of the support rod II102, and the support rod IV can be between the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com