PCB potential connection point dotting device

A PCB circuit board and connection point technology, which is applied in the field of electronic equipment marking devices, can solve the problems of automatic solder feeding, spotting errors, and uncontrollable spotting temperature, etc., and achieves simple structure, reduced errors, and convenient spotting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

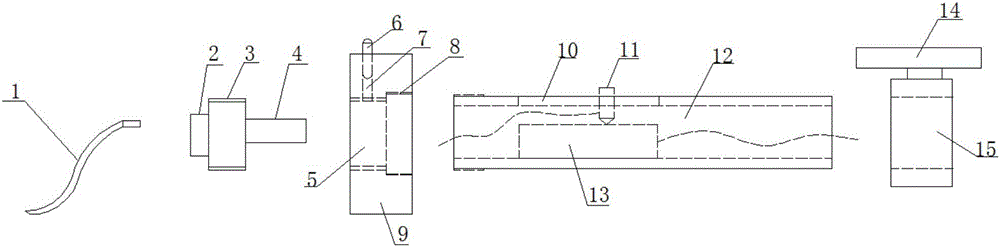

[0027] The present invention will be further described below in conjunction with the accompanying drawings. Embodiments of the present invention include, but are not limited to, the following examples.

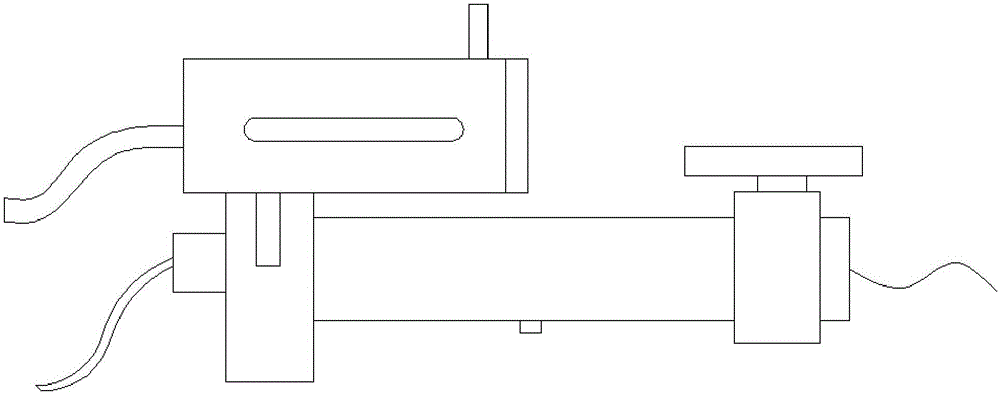

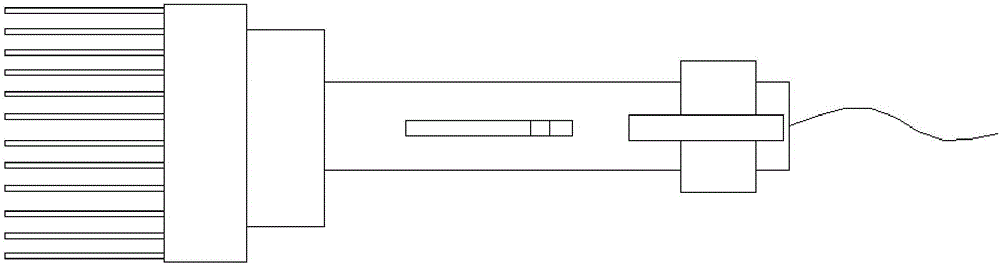

[0028] Such as Figure 1-Figure 6 As shown, the potential connection point dotting device of the PCB circuit board includes a multi-point dotting device and a solder feeding device clamped on the multi-dot dotting device;

[0029] in,

[0030] The multi-point dotting device is mainly composed of a detachably connected metal heat-conducting sheet 1, a resistance heat sink, a heat-insulating ring 9 and an internal hollow insulating handle 12; the metal heat-conducting sheet 1 is provided with a plurality of The cross-section of the metal heat conducting sheet 1 is an S-shaped curve structure and its end section is a sharp angle; A row of evenly arranged sockets 16 is arranged on the connecting plate 2, and the metal heat conducting sheet 1 and the sockets 16 are matched and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com