Method for high-frequency vibration assisted micro-deep drawing forming of foil boards

A high-frequency vibration and micro-drawing technology, which is applied to forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of foil plates that are difficult to deep-draw and form cylindrical parts, so as to improve the performance of micro-drawing and suppress the initiation and propagation, inhibiting crack initiation and propagation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

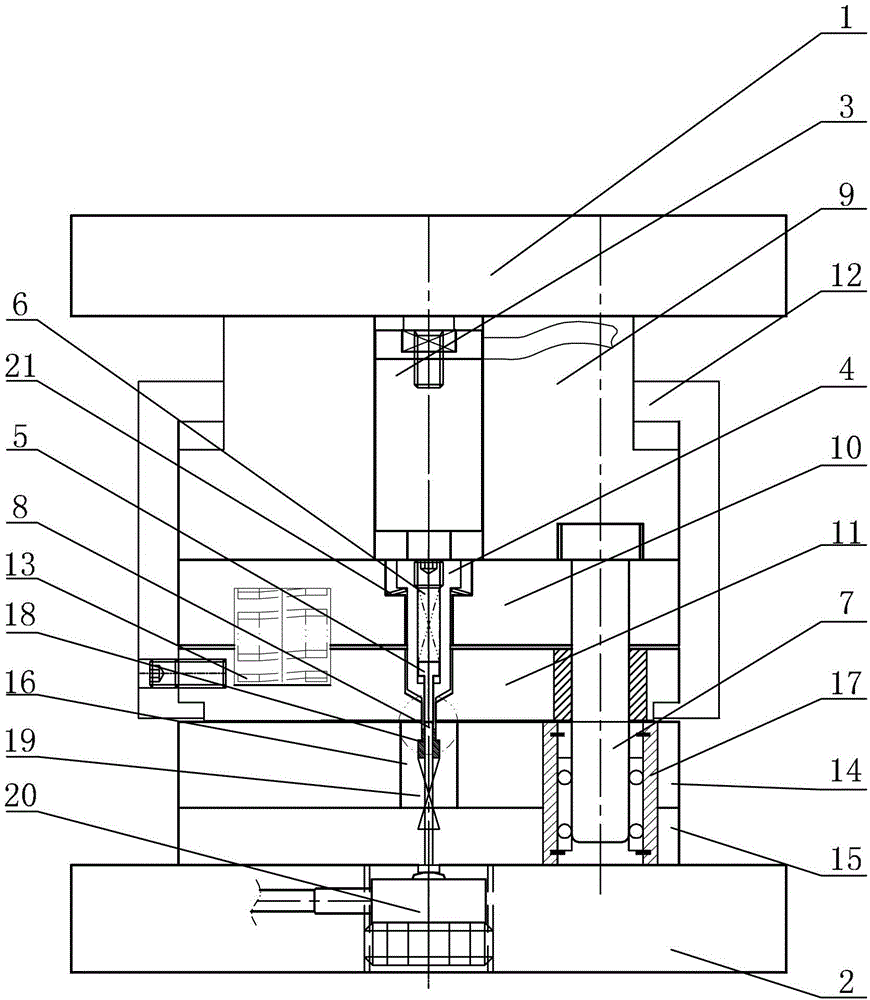

[0015] Specific implementation mode one: combine figure 1 Describe this embodiment, the high-frequency vibration assisted foil plate micro-drawing forming device in this embodiment includes an upper mold base 1, a lower mold base 2, a magnetic telescopic micro-driver 3, a punch 4, a back pressure ejector rod 5, a back pressure Spring 6, guide post 7, drawing punch 8, butterfly spring 21, upper die assembly and lower die assembly, upper die holder 1, upper die assembly, lower die assembly, lower die holder 2 from top to bottom The bottom is arranged in sequence, the upper end of the upper mold assembly is connected to the lower surface of the upper mold base 1, the lower end of the lower mold assembly is connected to the upper surface of the lower mold base 2, and the magnetic telescopic micro-driver 3 and punch 4 are arranged from top to bottom Set in the upper mold assembly in turn, the magnetic telescopic micro-driver 3 is connected to the high-frequency power supply, the po...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the upper mold assembly of the high-frequency vibration assisted foil plate micro-drawing forming device in this embodiment includes an upper mold plate 9, an upper mold fixing plate 10, a blanking blank holder 11 and a spacer sleeve 12. The template 9, the upper mold fixing plate 10, and the blanking blank holder 11 are sequentially arranged in the spacer sleeve 12 from top to bottom, and the upper end of the upper template 9 is connected with the lower surface of the upper mold base 1.

[0017] The technical effect of this embodiment is: the limit sleeve 12 has a limit effect on the internal structure of the mould, ensuring a good cooperation between the internal structures of the mould.

[0018] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the upper mold assembly of the high-frequency vibration assisted foil plate micro-drawing forming device in this embodiment also includes a first edge-holding spring 13, and the first edge-holding spring 13 is arranged on the upper mold fixing plate 10 and the falling plate. Between the binder ring 11.

[0020] The technical effect of this embodiment is: the blank-holding spring 13 can ensure a blank-holding effect on the material in the stage of blanking the disc, ensuring smooth blanking of the ring.

[0021] Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com