Ventilation carrier roller device of tipping paper laser perforating machine

A laser punching machine and tipping paper technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of product quality and mechanical rotation instability, affecting the technical indicators of paper tape, and reducing the service life of the machine. , to achieve the effect of preventing the destruction of dynamic balance, ensuring stability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

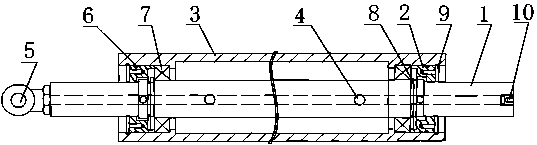

[0011] Such as figure 1 As shown, the ventilation idler device for tipping paper laser punching machine provided by the present invention includes a ceramic idler roller 3 with a shaft center through hole, and an shaft center hole shape ventilation shaft 1 sleeved in the shaft center hole of the ceramic idler roller 3 The ventilation shaft 1 is provided with a ventilation hole 4 capable of connecting the inner cavity formed between the central through hole of the ventilation shaft 1 and the inner wall of the ceramic idler 3 and the outer wall of the ventilation shaft 1, and a sealing bolt arranged in one end of the ventilation shaft 1 10. Set on the other end of the ventilation shaft 1, an APBT-type threaded tee 5 that can connect the through hole of the ventilation shaft 1 axis and external compressed gas, and two high-speed connections between the inner wall of the ceramic idler 3 and the outer wall of the ventilation shaft 1. The bearing 7 is arranged between the high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com