Variable-diameter stepless speed changer

A continuously variable transmission and variable diameter technology, applied in the field of variable speed transmission, can solve the problems of low snow removal cost, large space occupied by friction wheels and friction discs, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

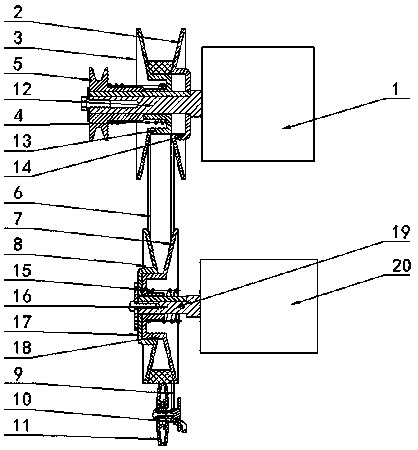

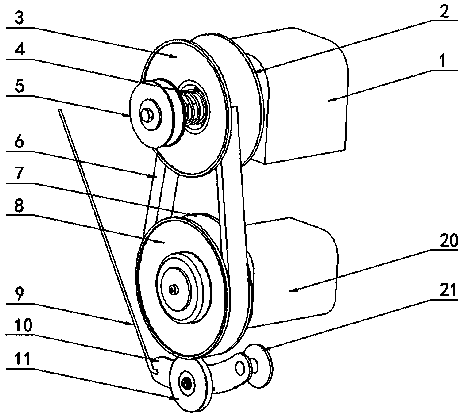

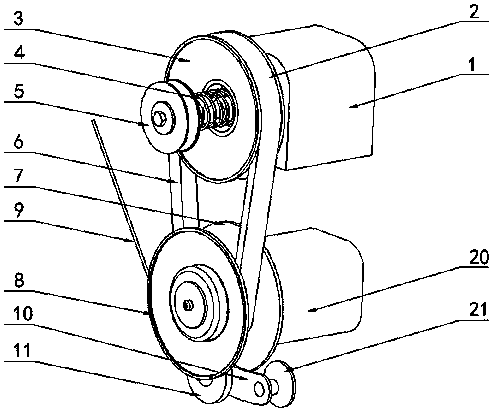

[0015] Figure 1 to Figure 4 Shown, for the present invention creates the specific embodiment of variable-diameter continuously variable transmission, and it comprises engine 1, driving wheel set, driven wheel set, transmission box 20 that drive machine advances, speed change belt 6, tension speed regulating device, so The driving wheel group described includes the driving wheel fixed plate 2, the driving wheel moving plate 3, and the driving wheel pressing spring 4. The driving wheel fixing plate 2 is fixed on the output shaft 12 of the engine 1, and the driving wheel moving plate 3 can be rotated through the spline. It is arranged on the output shaft 12 to move, and the driving wheel fixed plate 2 is provided with a driving wheel fixed plate outer ring 14, and the driving wheel driving plate 3 is provided with a shaft movable relative to the driving wheel fixed plate outer ring 14 through a spline. The inner ferrule 13 of the driving wheel driving disc can ensure the stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com