Bearing assembly with preload

A technology of combining units and bearings, applied in the direction of bearing assembly, bearing components, bearings in rotating motion, etc., can solve the problems of time-consuming installation, box seals can no longer be used, expensive, etc., and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

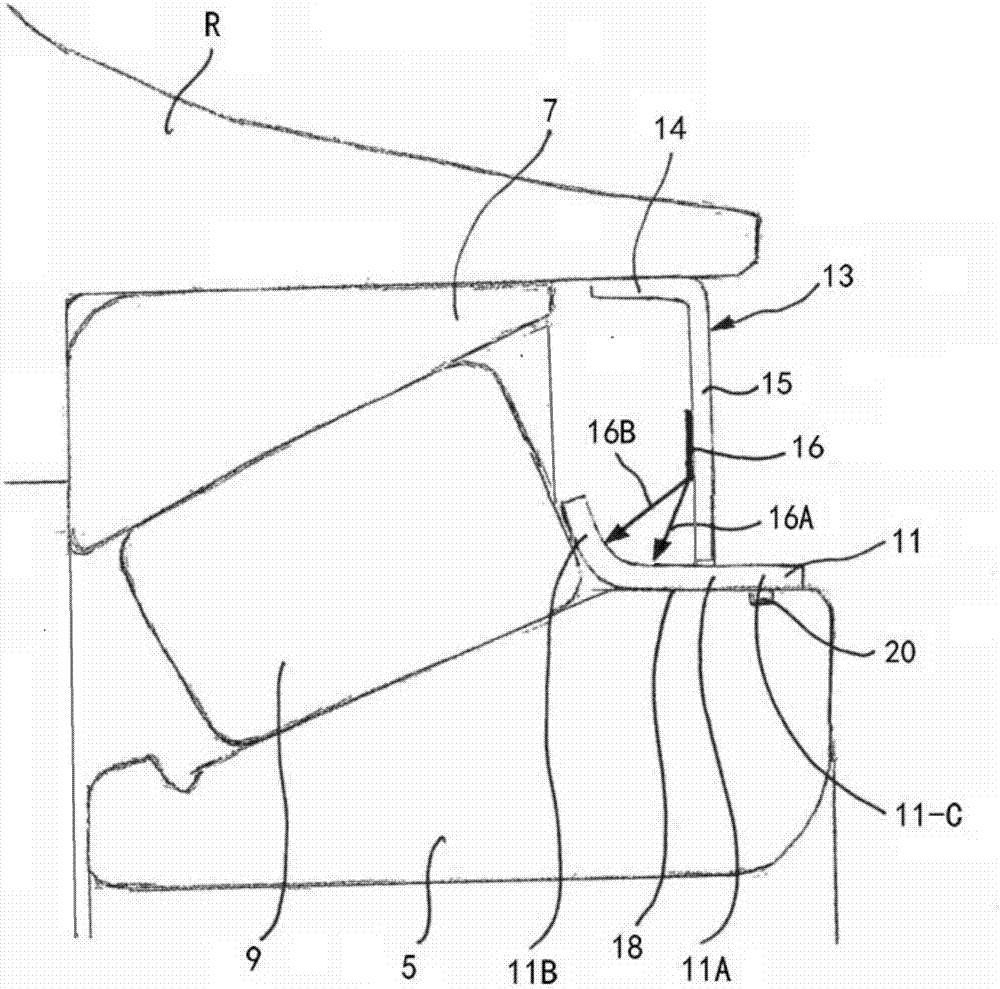

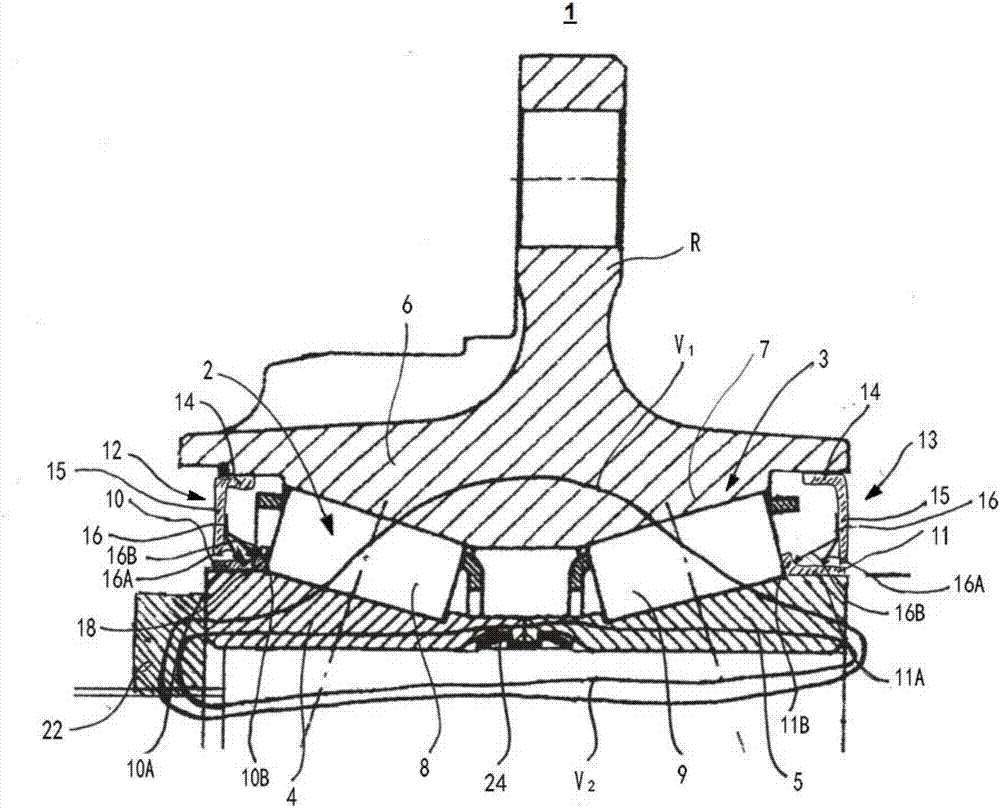

[0059] exist figure 1 In , a bearing combination unit 1 is depicted comprising two tapered roller bearings 2 and 3 . Each of the two tapered roller bearings 2, 3 has an inner ring 4 or 5 but shares an outer ring 6, or as figure 2 As depicted, each tapered roller bearing has its own outer ring 6 , 7 . The rolling elements 8 or 9 are arranged between the bearing rings. Such a bearing combination unit may especially be found in a wheel bearing unit, wherein the bearing combination unit is mounted to the hub R of the wheel.

[0060] The depicted bearing combination units are embodied in a back-to-back configuration. Ribs 10 and 11 on the inner rings 4, 5 limit the axial mobility of the tapered rollers 8, 9.

[0061] Here, the ribs 10 , 11 are designed as sleeve-shaped components (rib sleeves), which are pushed onto the bearing rings 4 , 5 . Although the sleeve-shaped member 11 of the inner ring 5 is fixed on the inner ring 5 as a fixed rib, this does not apply to the sleeve-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com