Patents

Literature

95results about How to "Precise and stable movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

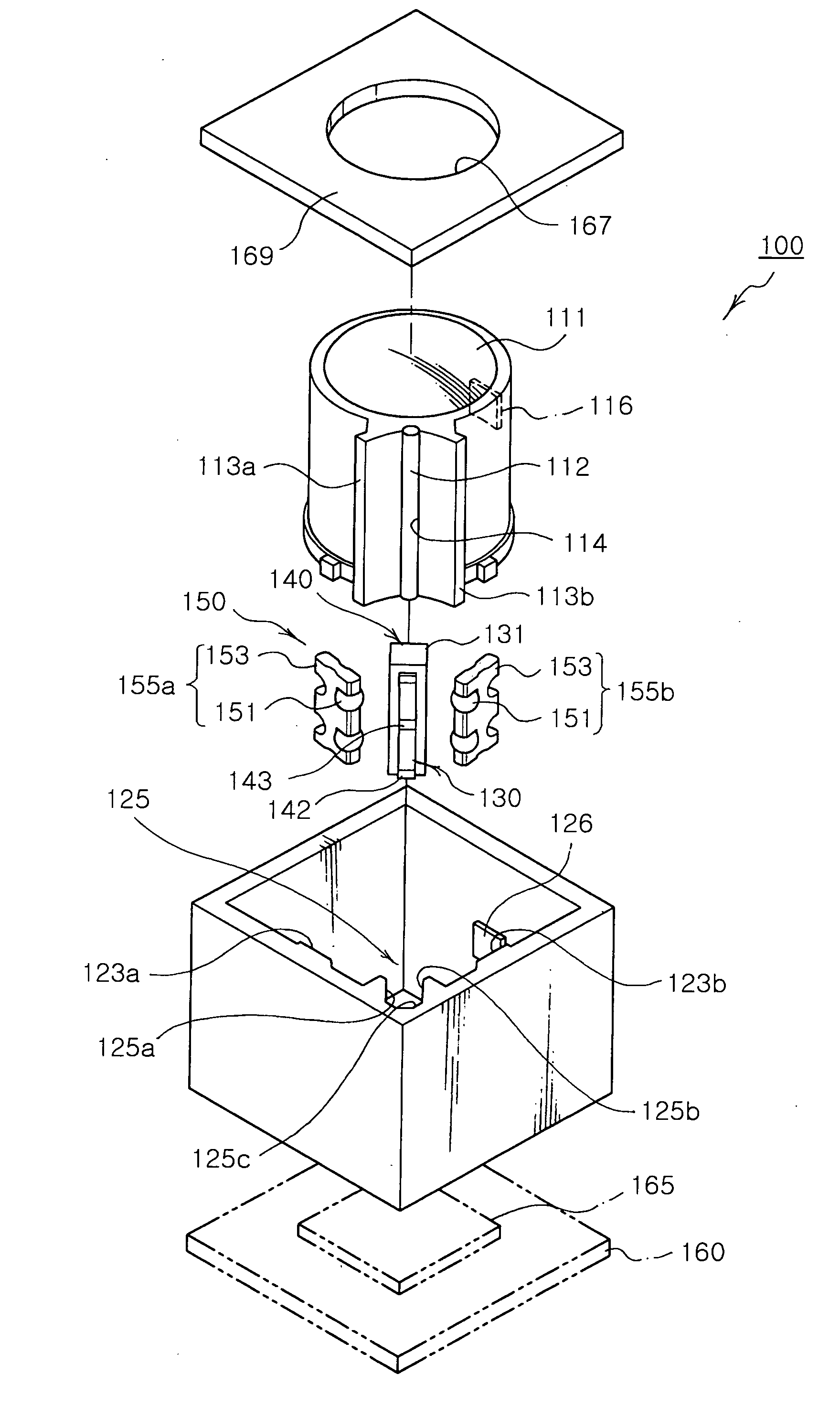

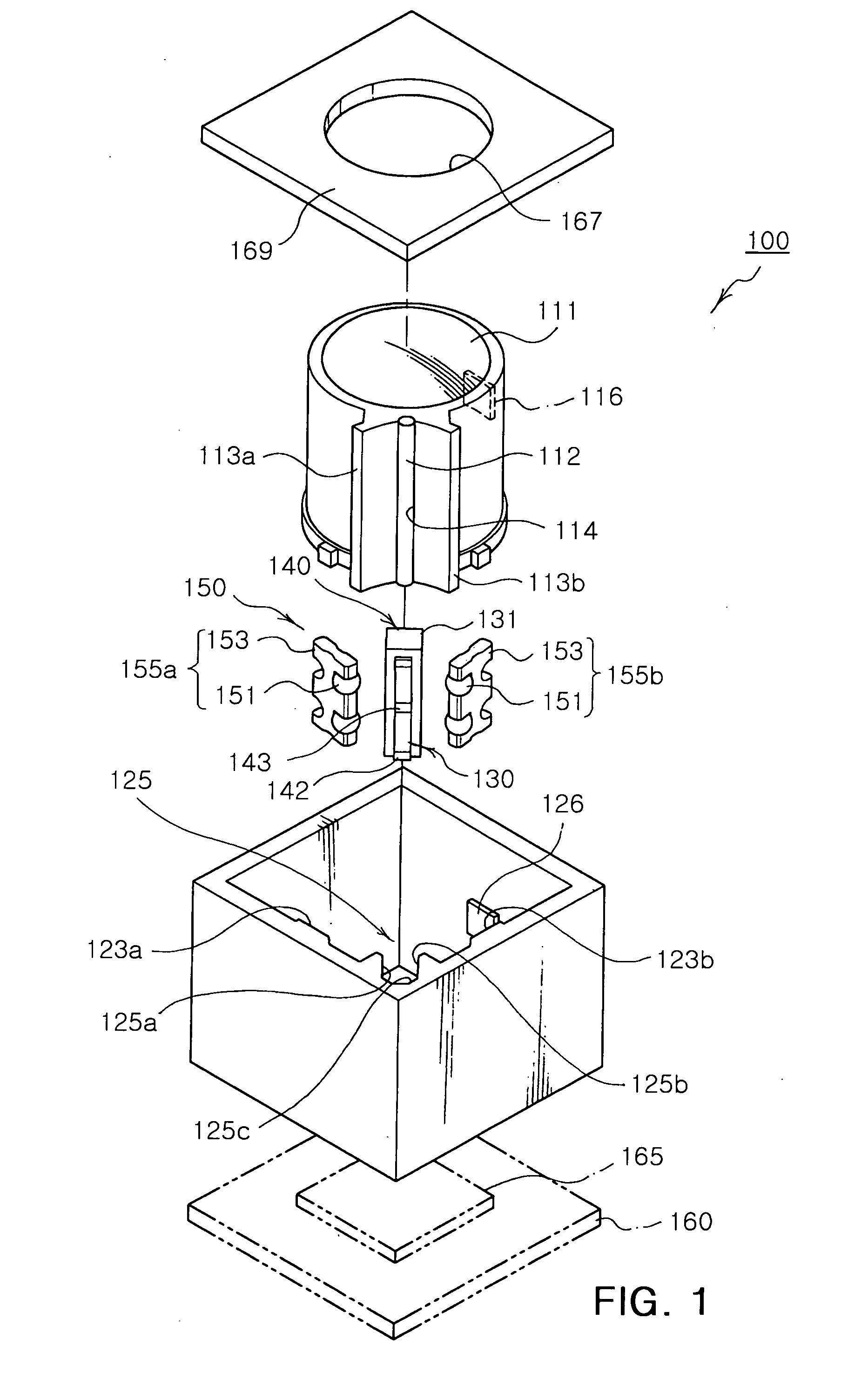

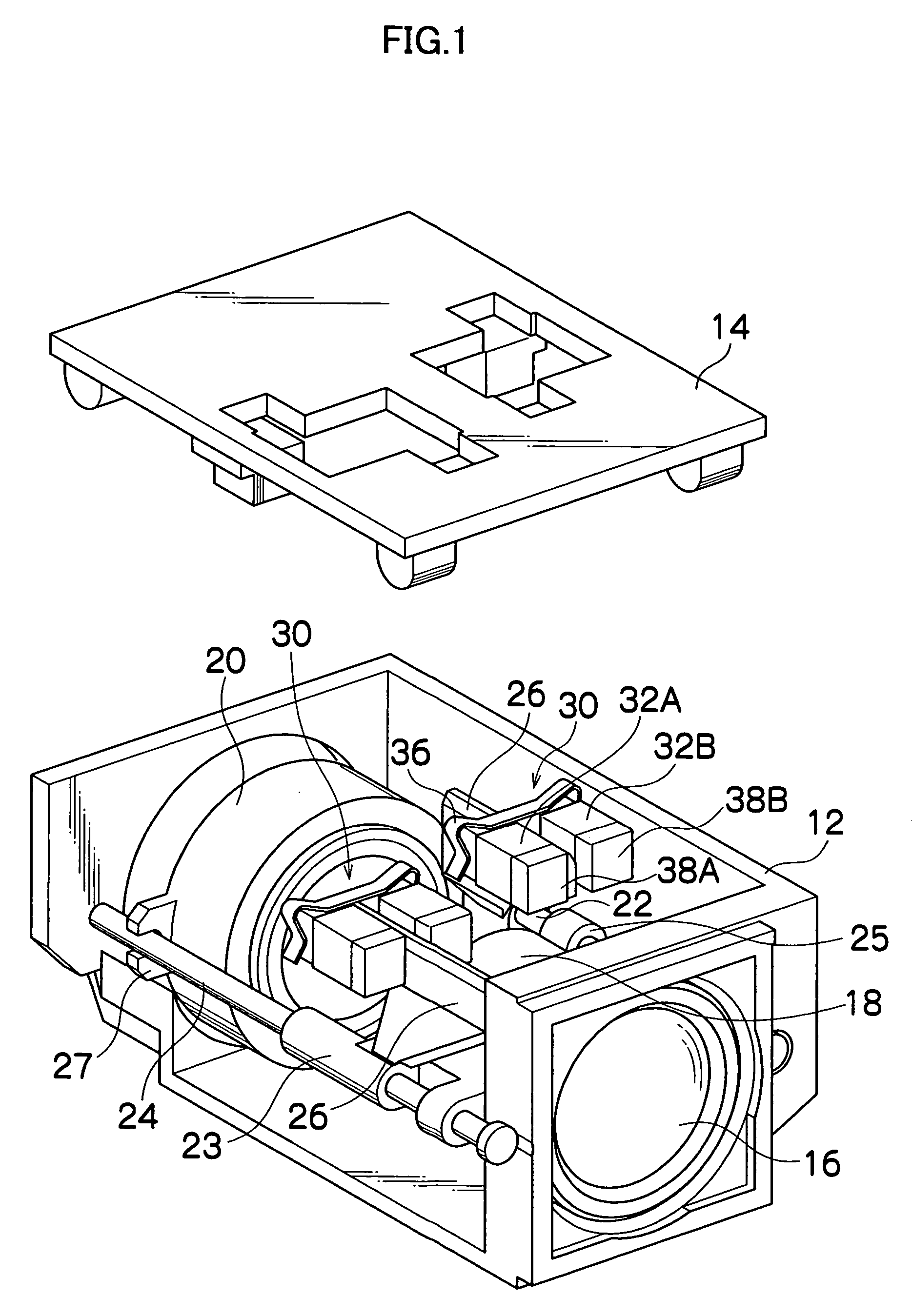

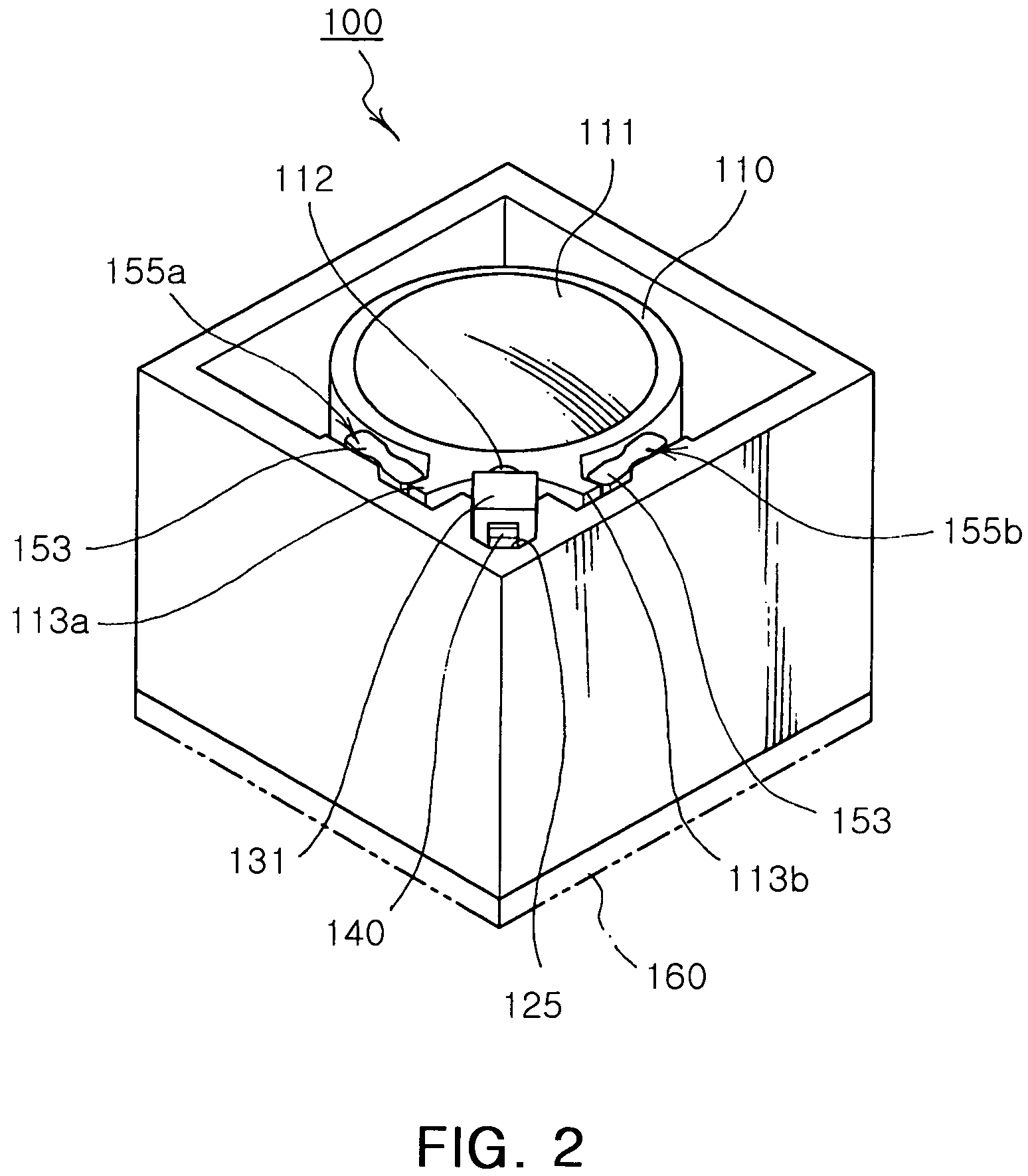

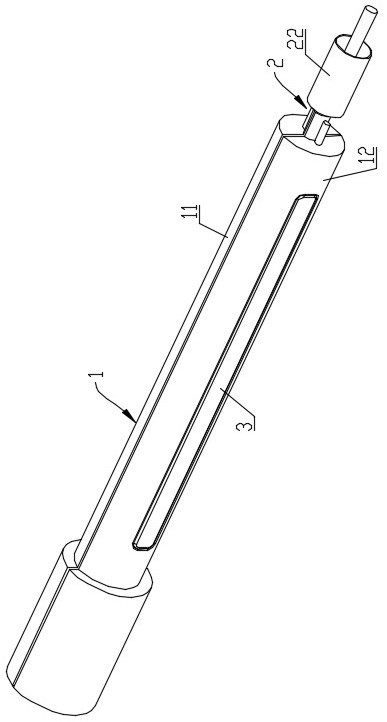

Lens driving device

InactiveUS20080144201A1Simple structureBig distanceMountingsPiezoelectric/electrostrictive/magnetostrictive devicesCamera lensOptical axis

A lens driving device including: a lens barrel having at least one lens therein and provided with a friction member; a housing for housing the lens barrel therein; an actuator having a piezoelectric body disposed at an edge of the housing to apply a driving force, the piezoelectric body having at least one output member provided at one side thereof to be in contact with the friction member; a preload member disposed between the edge of the housing and the actuator to apply an elastic force toward the lens barrel; and a guiding part disposed between the housing and the lens barrel to guide the lens barrel to move in an optical axis direction. The lens driving device is simplified in a driving mechanism and thus reduced in size, while experiencing minimum loss of a driving power and ensuring more accurate and stable movement of the lens.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

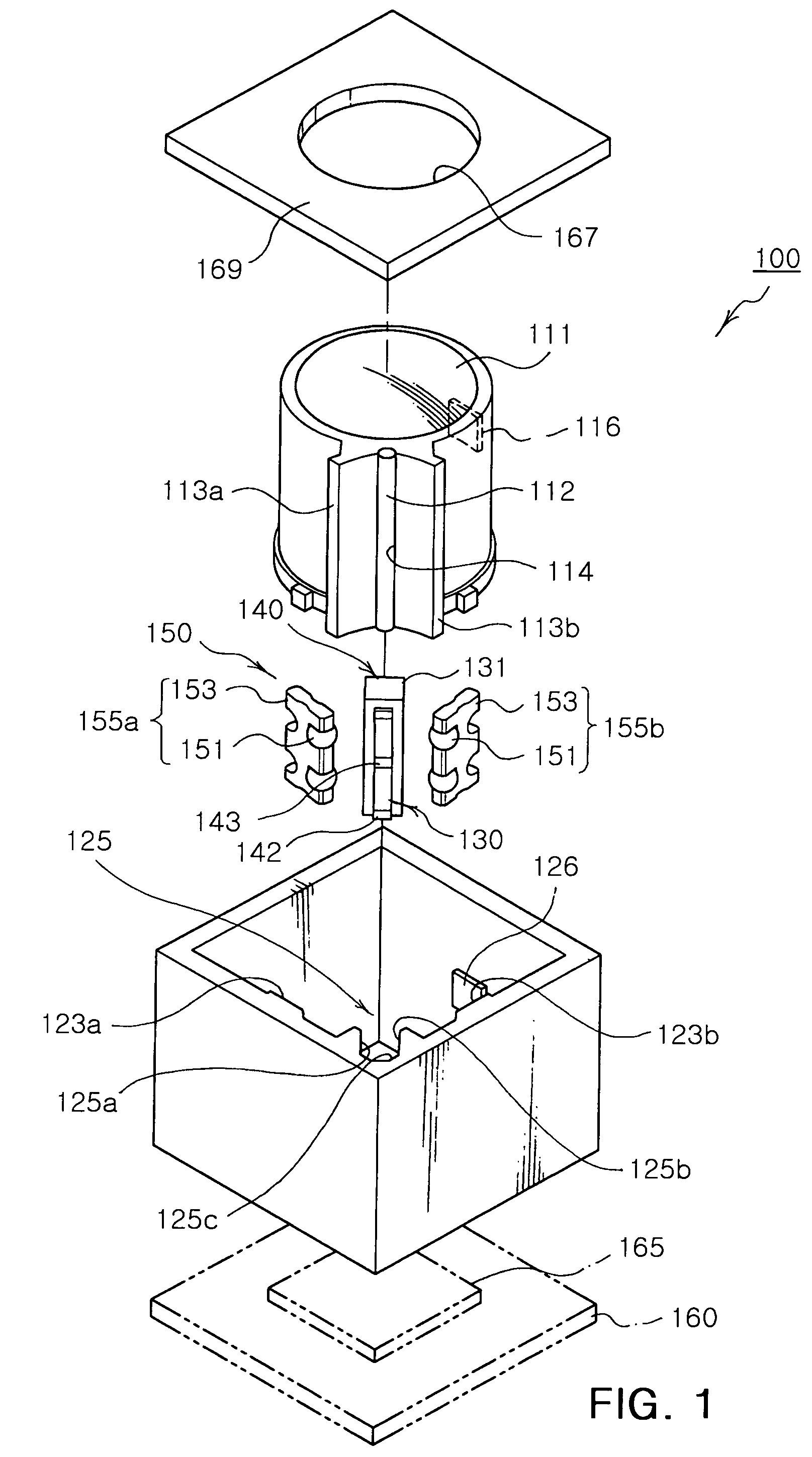

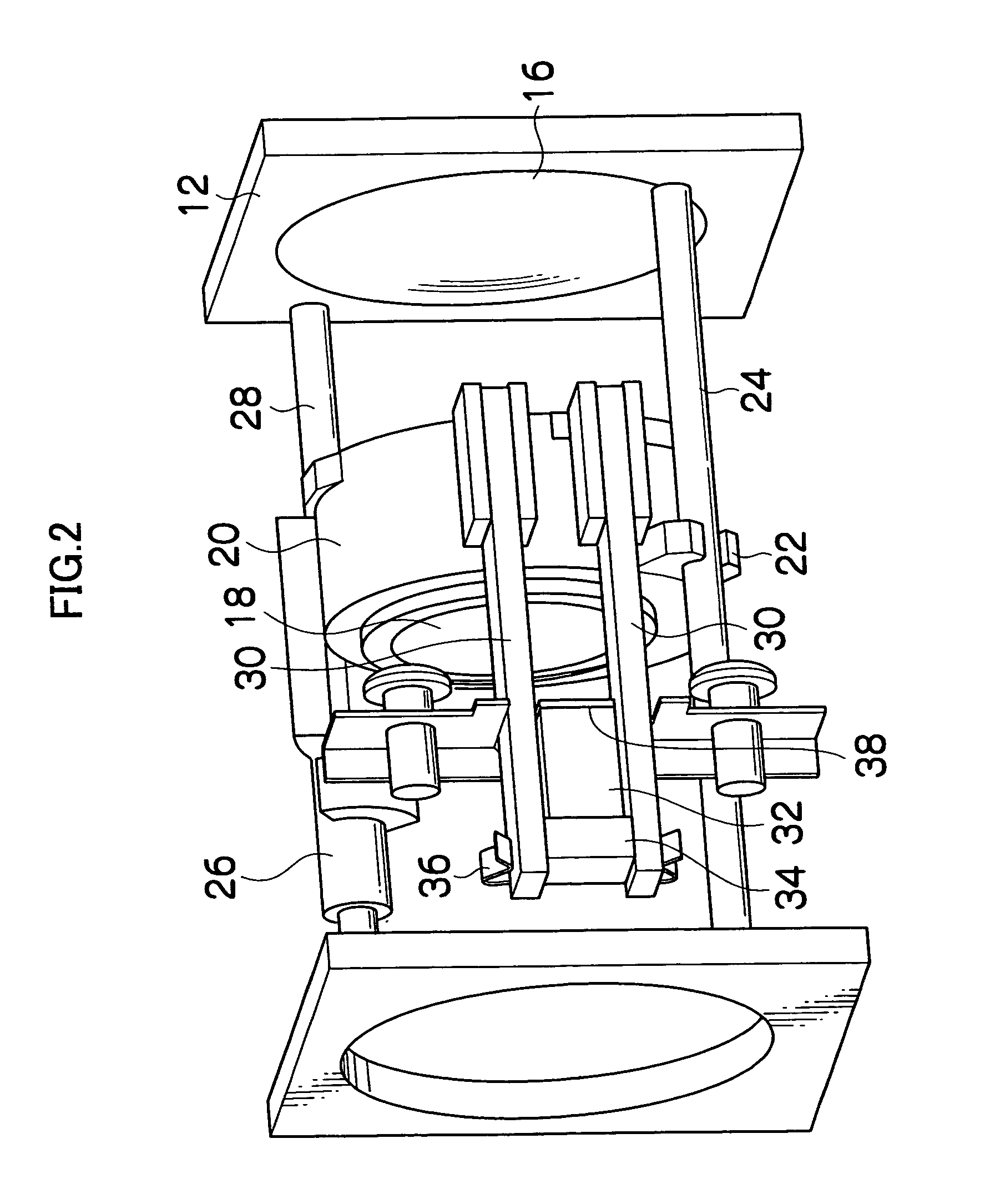

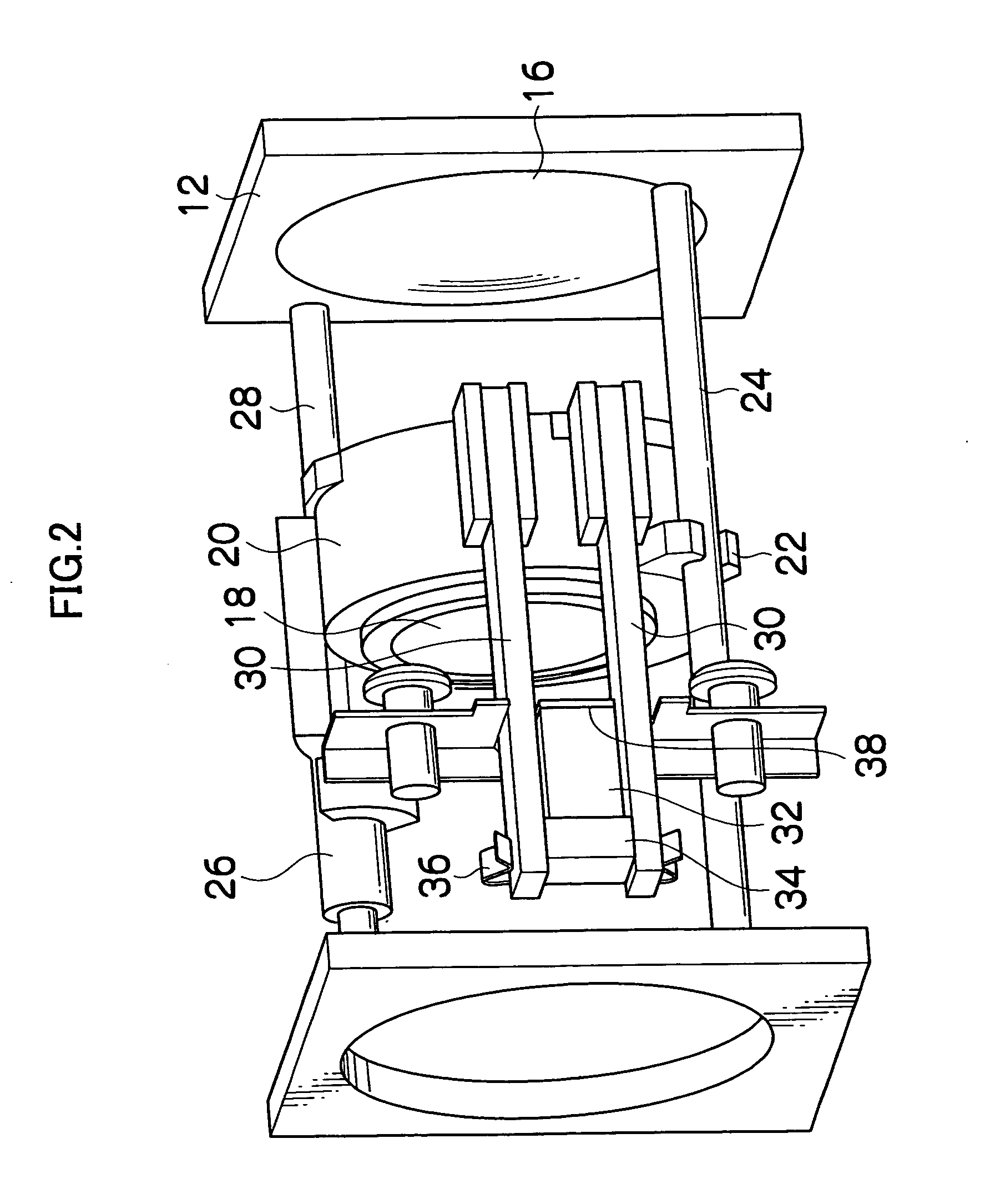

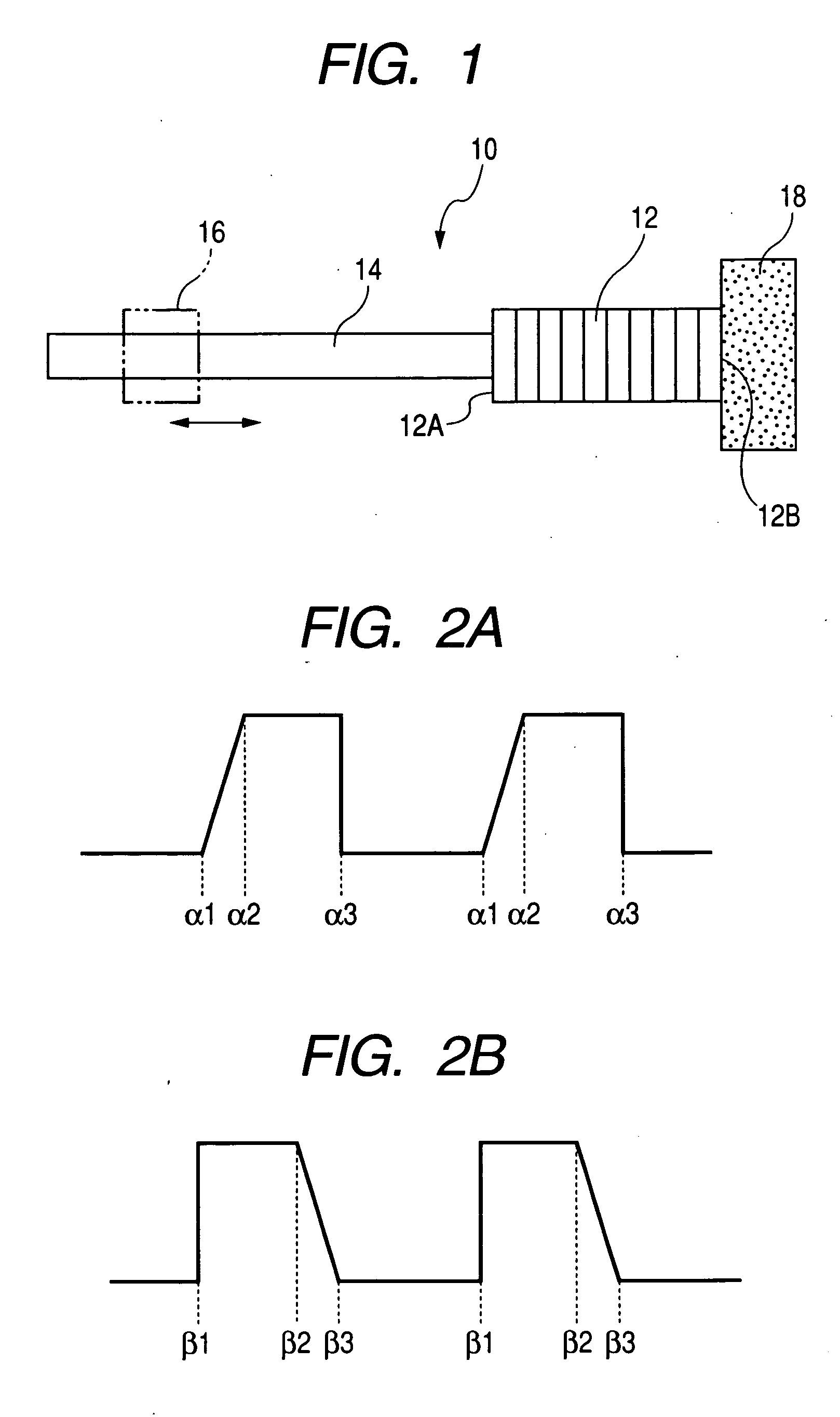

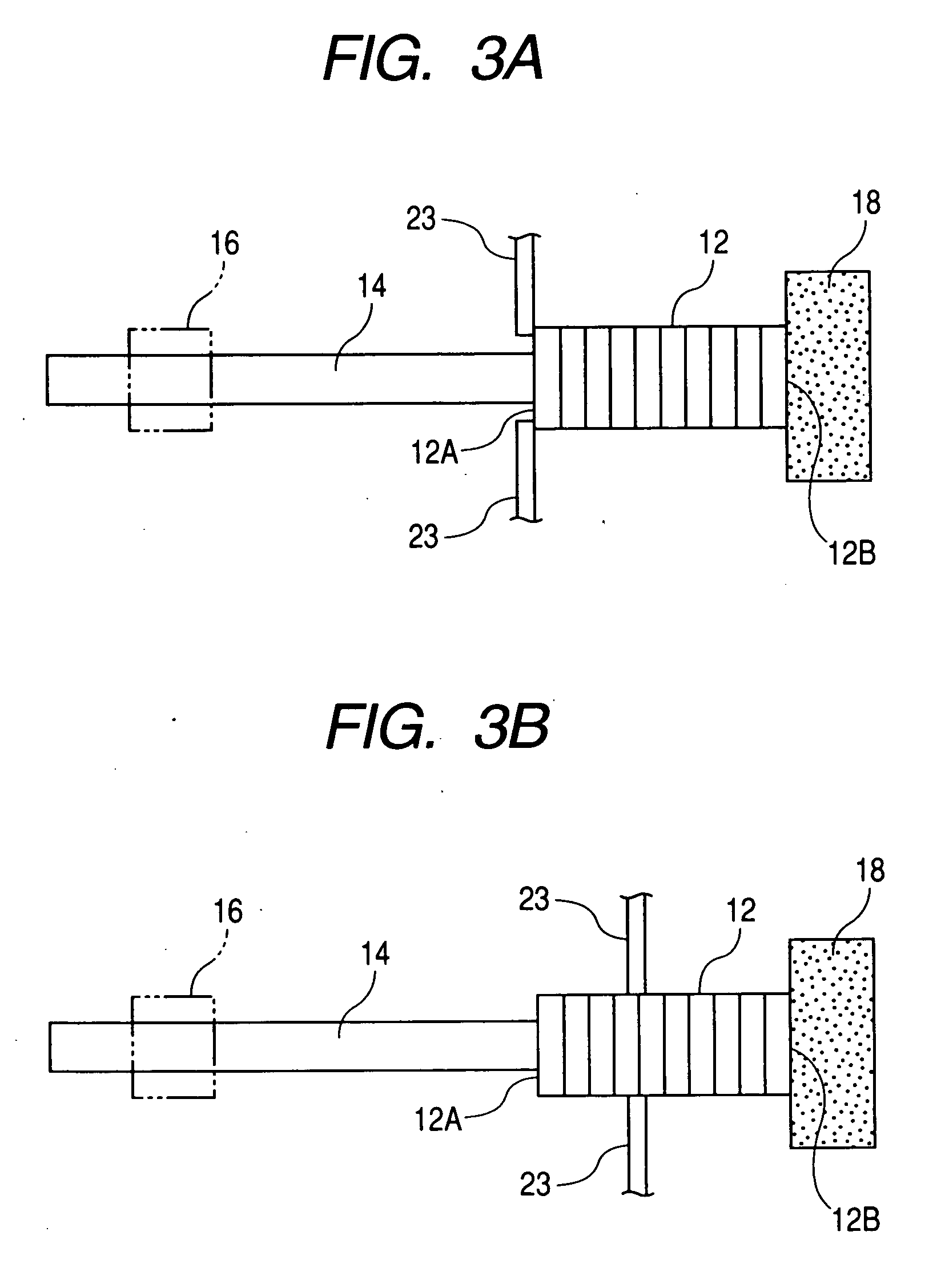

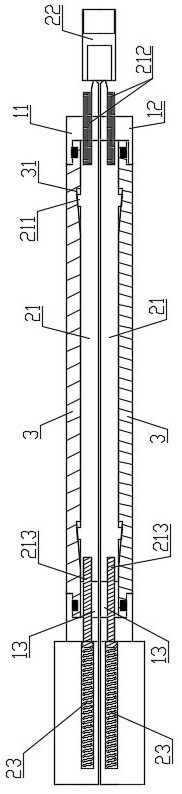

Actuator and its control method and lens device

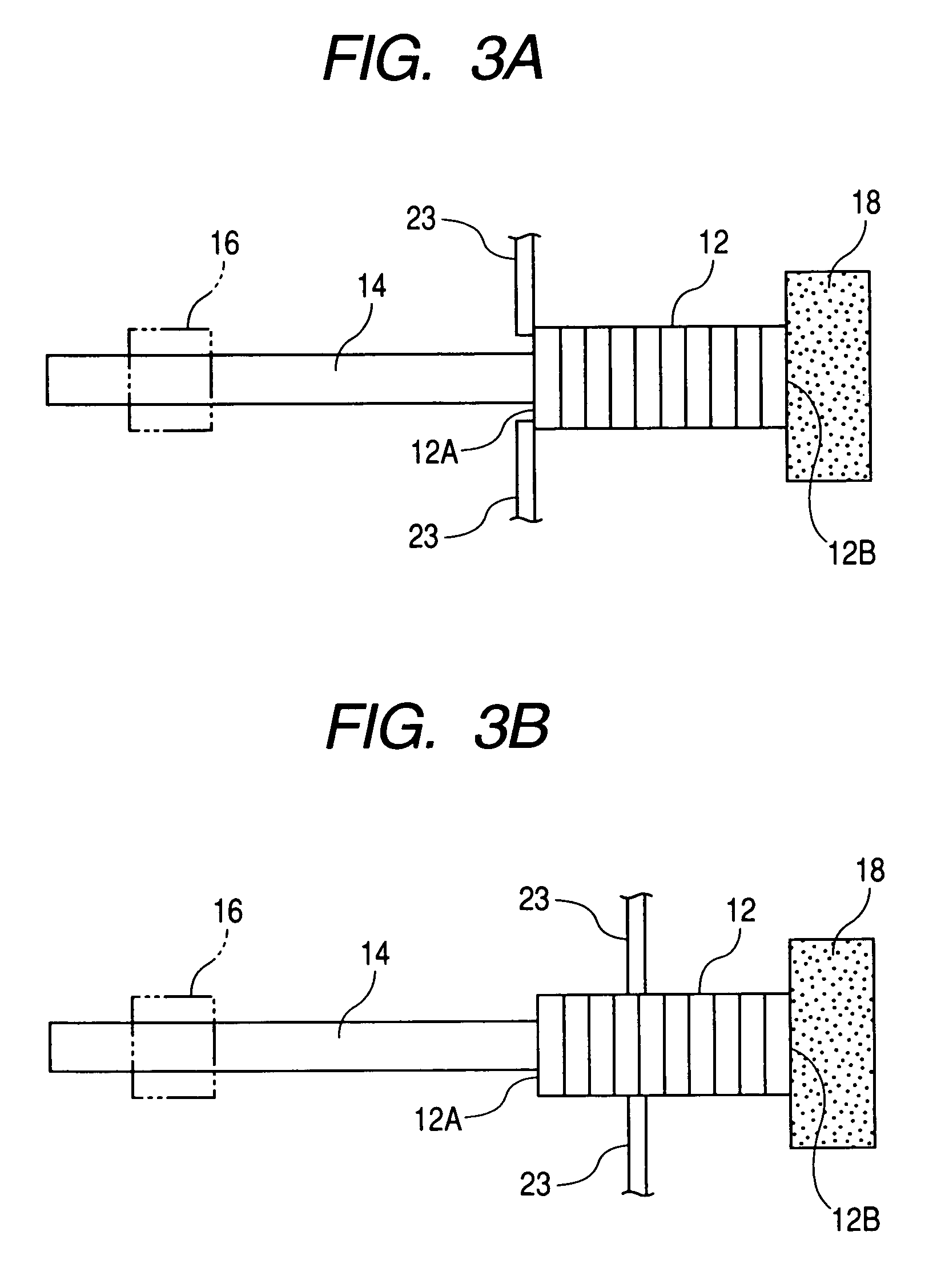

InactiveUS20050275315A1Small installation spaceMove preciselyPiezoelectric/electrostriction/magnetostriction machinesMountingsOptical axisActuator

An actuator which drives a lens frame in an optical axis direction is constructed by piezoelectric elements, driving members, and a pressing spring. The piezoelectric elements are placed at opposite sides with a driven plate therebetween, and the driving members are fixed to the respective piezoelectric elements. The driving members are pressed against the driven plate from both sides by the pressing spring.

Owner:FUJI PHOTO OPTICAL CO LTD

Lens driving device

InactiveUS7706089B2Simple structureBig distanceMountingsPiezoelectric/electrostrictive/magnetostrictive devicesCamera lensOptical axis

A lens driving device including: a lens barrel having at least one lens therein and provided with a friction member; a housing for housing the lens barrel therein; an actuator having a piezoelectric body disposed at an edge of the housing to apply a driving force, the piezoelectric body having at least one output member provided at one side thereof to be in contact with the friction member; a preload member disposed between the edge of the housing and the actuator to apply an elastic force toward the lens barrel; and a guiding part disposed between the housing and the lens barrel to guide the lens barrel to move in an optical axis direction. The lens driving device is simplified in a driving mechanism and thus reduced in size, while experiencing minimum loss of a driving power and ensuring more accurate and stable movement of the lens.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

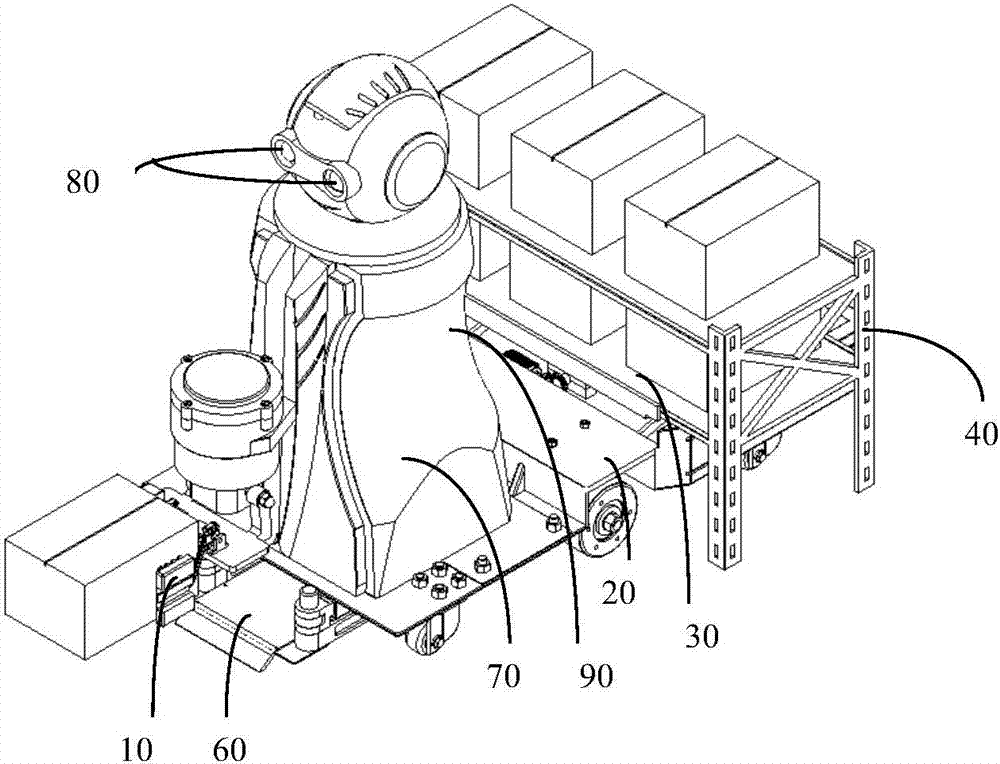

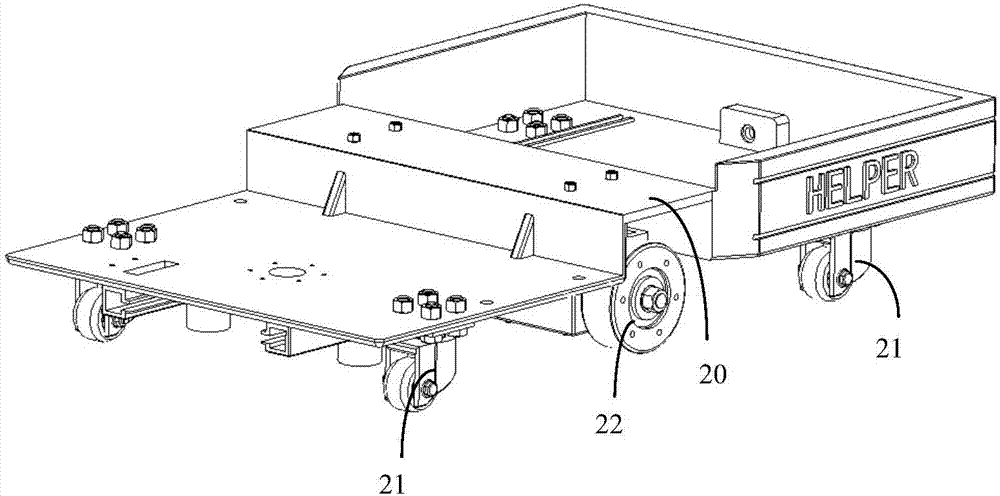

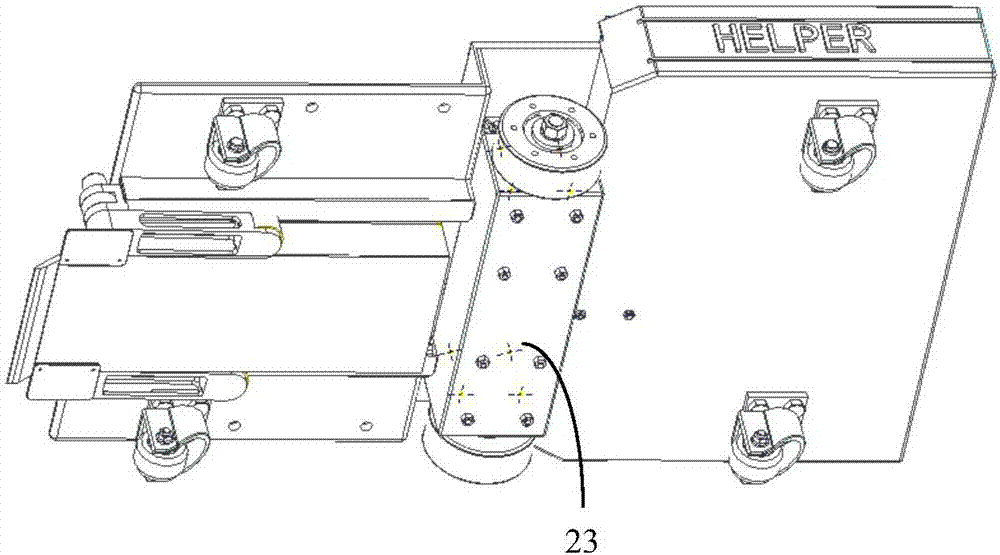

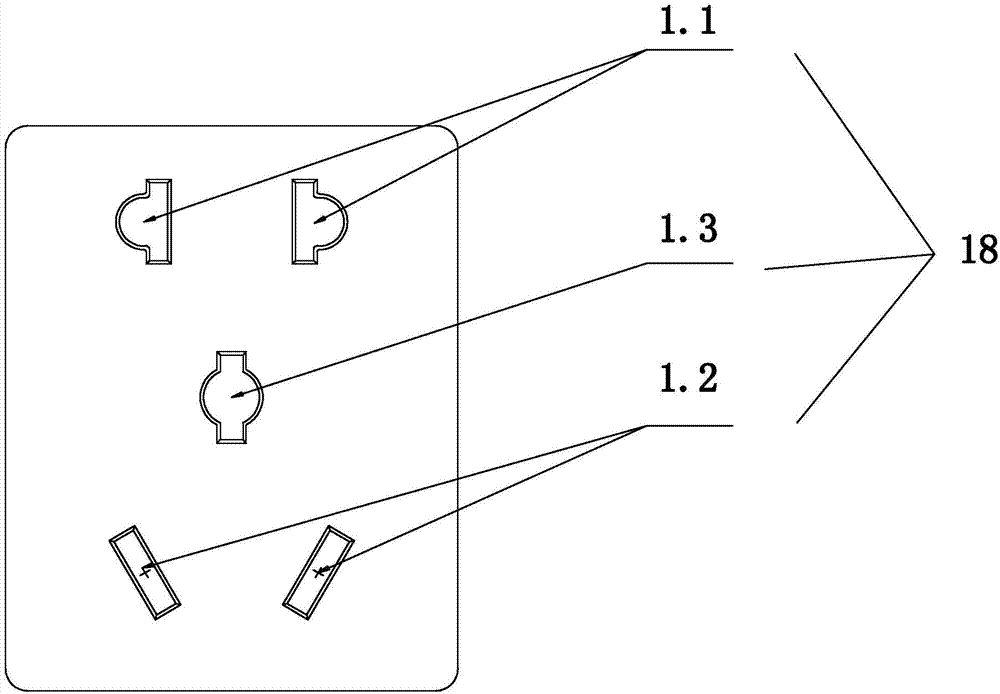

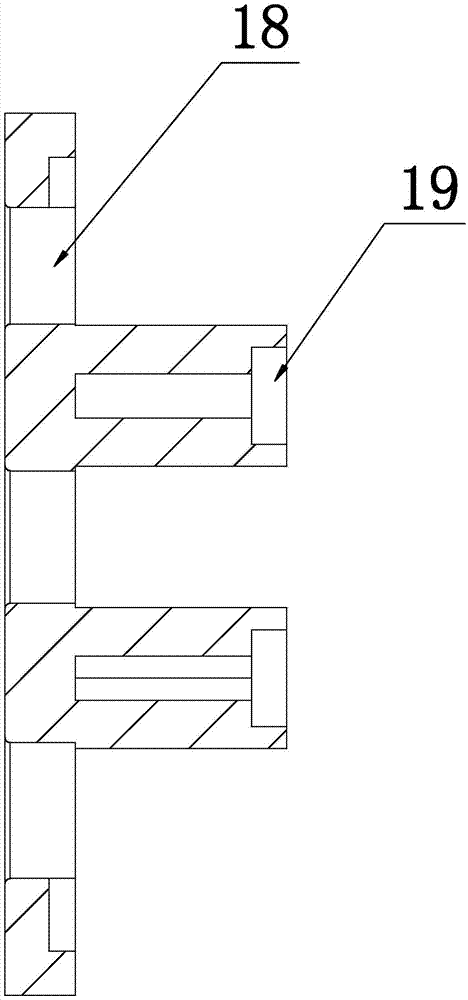

Carrying and conveying robot

ActiveCN106985145AAdapt to different working conditionsAdapt to working conditionsProgramme-controlled manipulatorMagnetic tapeComputer module

The invention relates to a carrying and conveying robot comprising a bearing table, execution mechanisms and a control module. The bearing table is provided with a drive device. The drive device regulates the speed and direction of the bearing table on the basis of control information of the control module so that the bearing table can be used in cooperation with the execution mechanisms for carrying goods on the basis of the control information of the control module. The robot further comprises a magnetic belt guide unit and a vision guide unit. The control module determines at least one route on the basis of a first position parameter and a second position parameter of a carrier in an assigned area and indicates the drive device to move along the at least one route preset according to guidance of the magnetic belt guide unit so that the carrier in the unloaded state can be carried to the first position from the second position, and the control module controls the bearing table to carry the carrier, fully loaded through the execution mechanisms according to placement morphological parameters of the goods in a corresponding movement manner, to the assigned second position according to the preset at least one route. By means of the dual manner of magnetic belt guidance and vision guidance, positioning of the robot can be more accurate, and efficiency can be higher.

Owner:HEFEI UNIV OF TECH

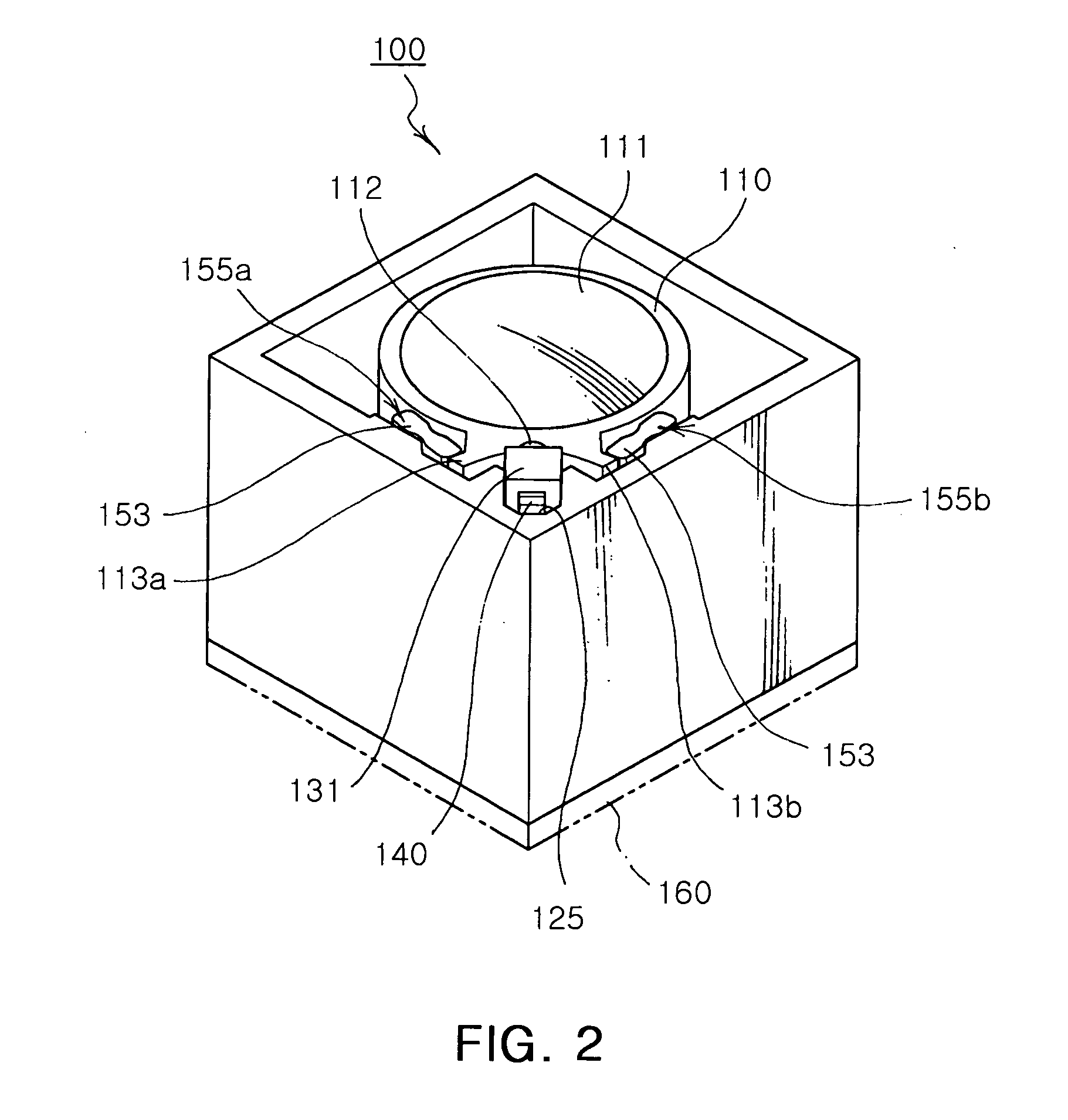

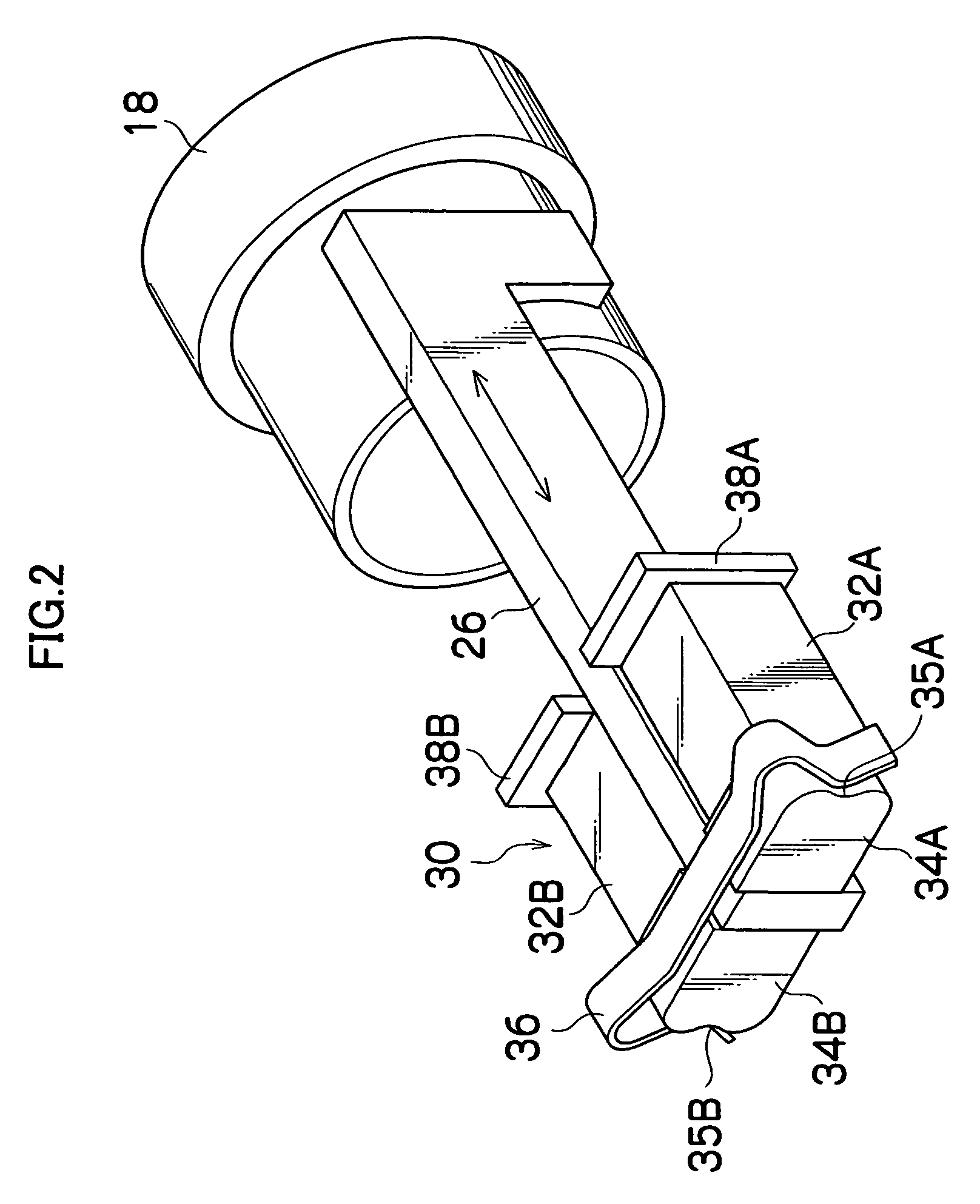

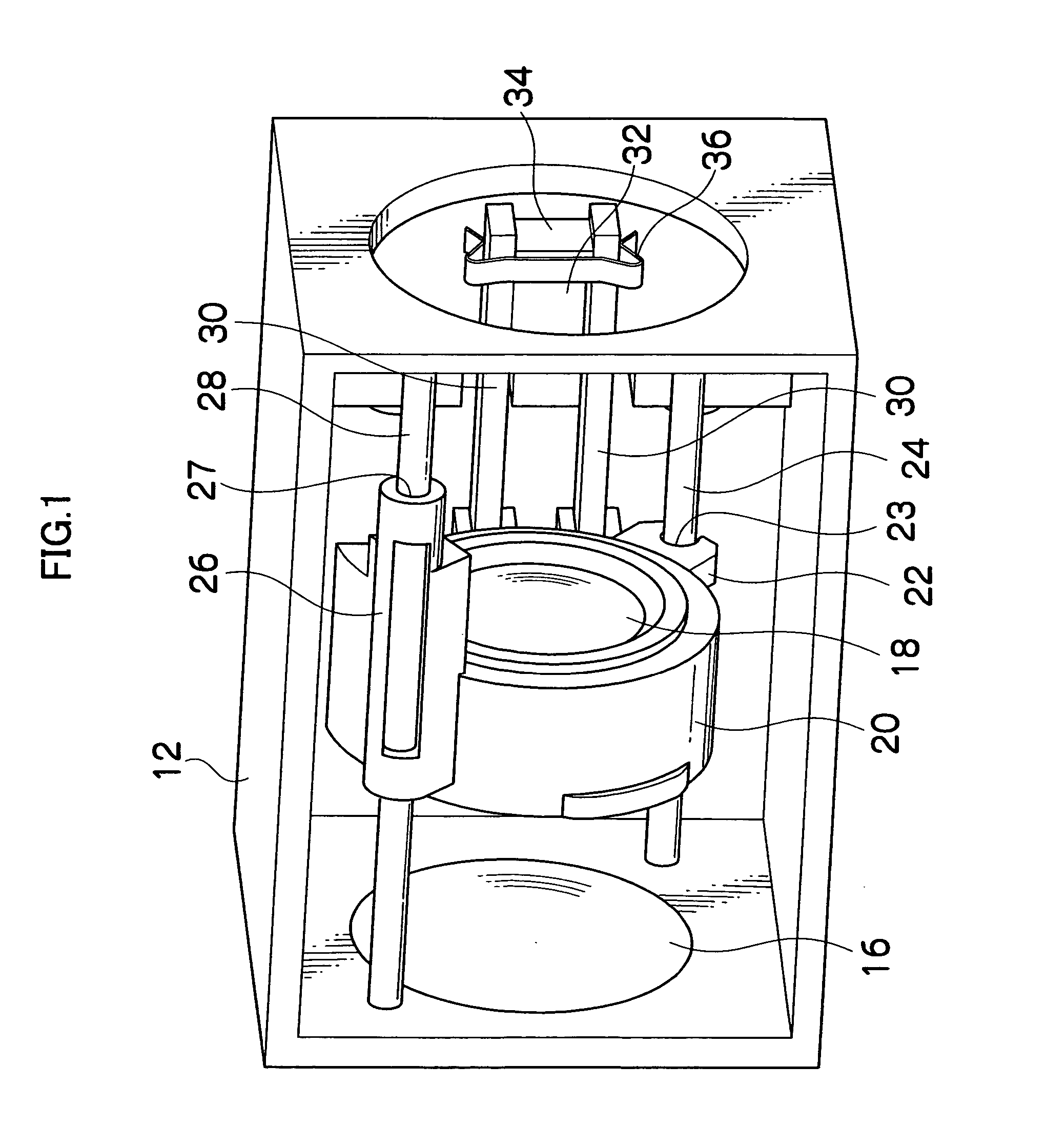

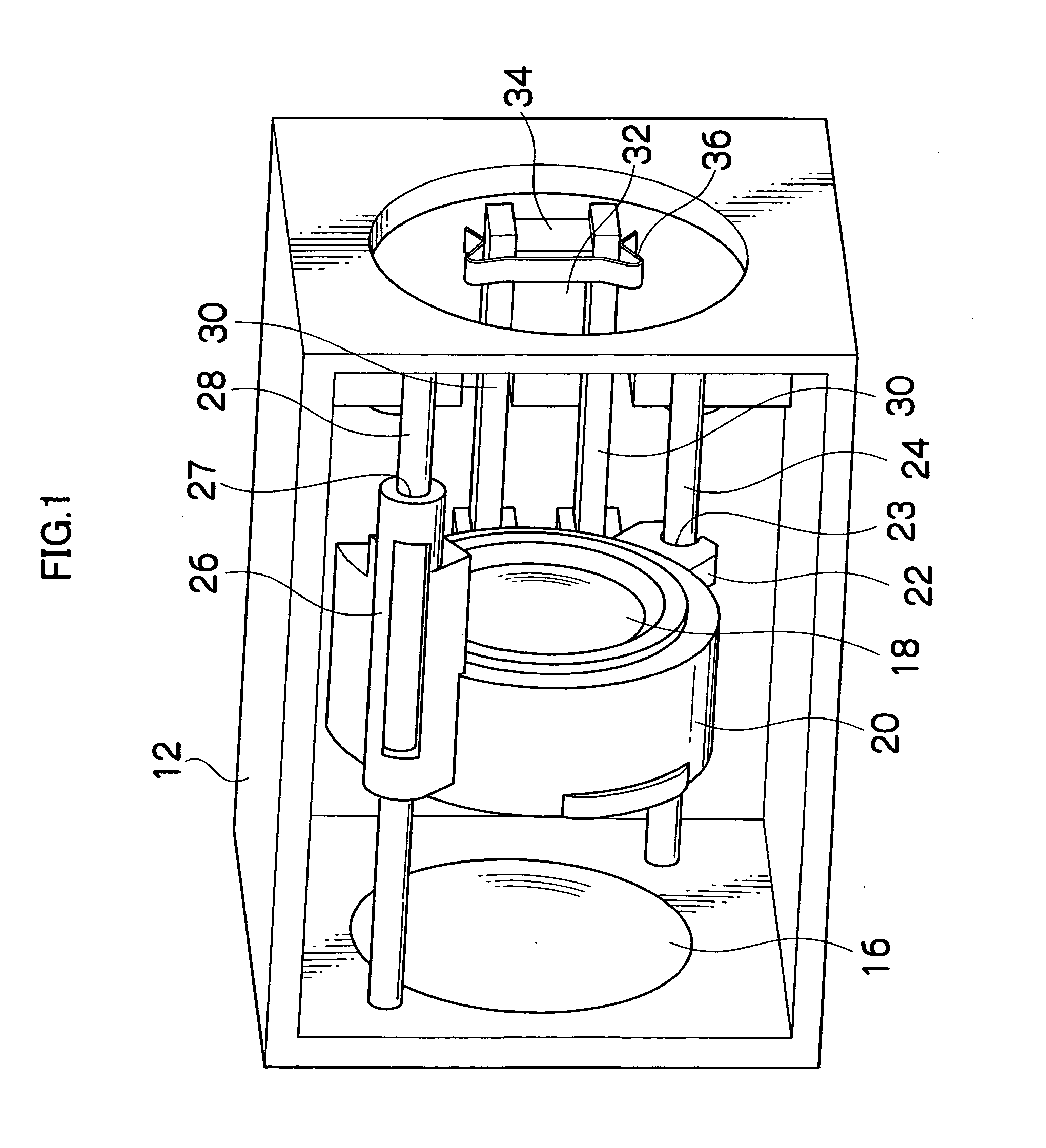

Piezoelectric actuator for driving lens

InactiveUS7199506B2Stably and accurately movingMove preciselyPiezoelectric/electrostriction/magnetostriction machinesMountingsPiezoelectric actuatorsEngineering

An actuator of the present invention comprises a piezoelectric element, one end face of the piezoelectric element in a displacement direction being supported by a fixing member, a block shaped driving member attached to the other end face of the piezoelectric element in the displacement direction, and a driven member frictionally engaged with at least one end face of the driving member in a direction orthogonal to the displacement direction, the driven member being extended along the displacement direction.

Owner:FUJI PHOTO OPTICAL CO LTD

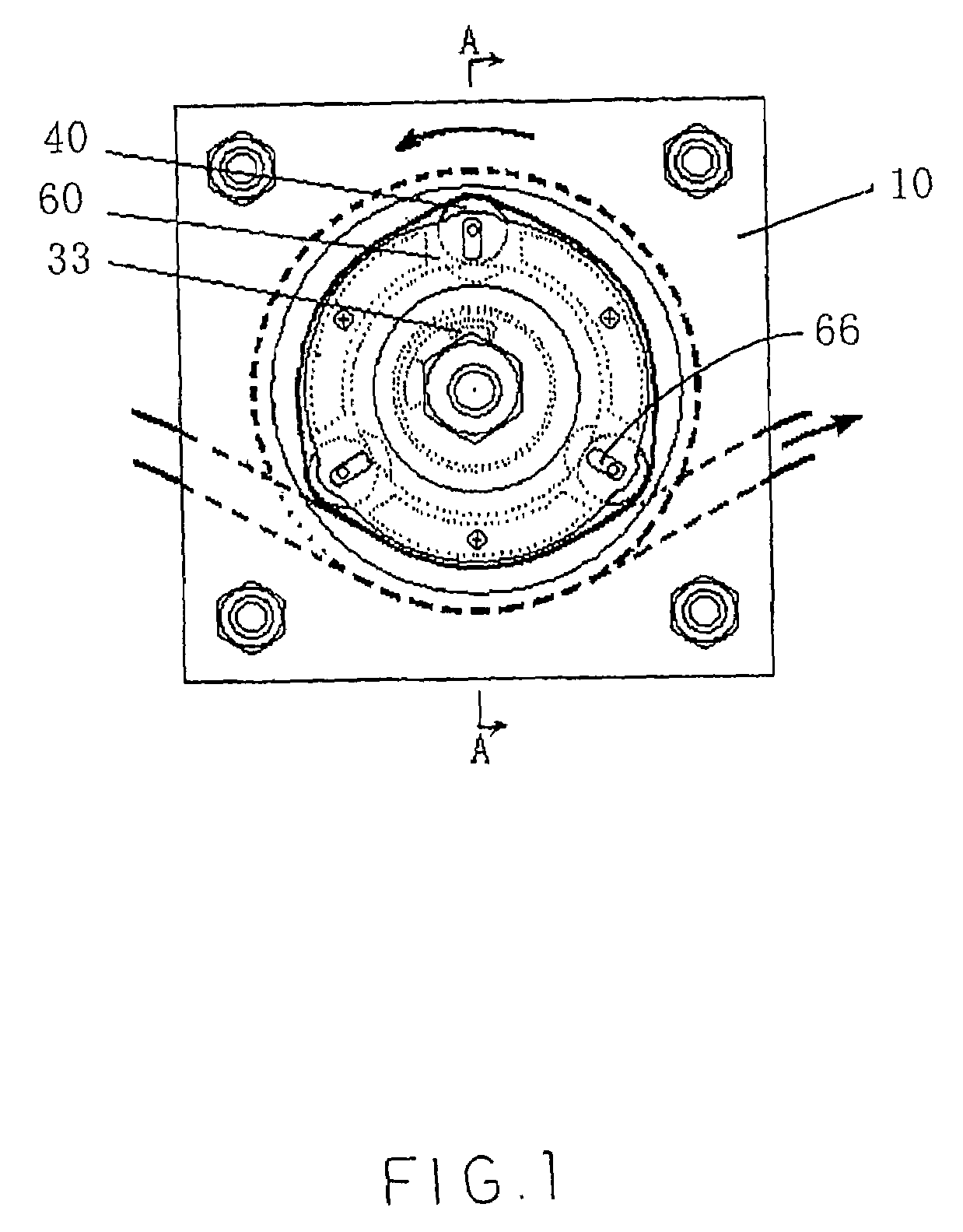

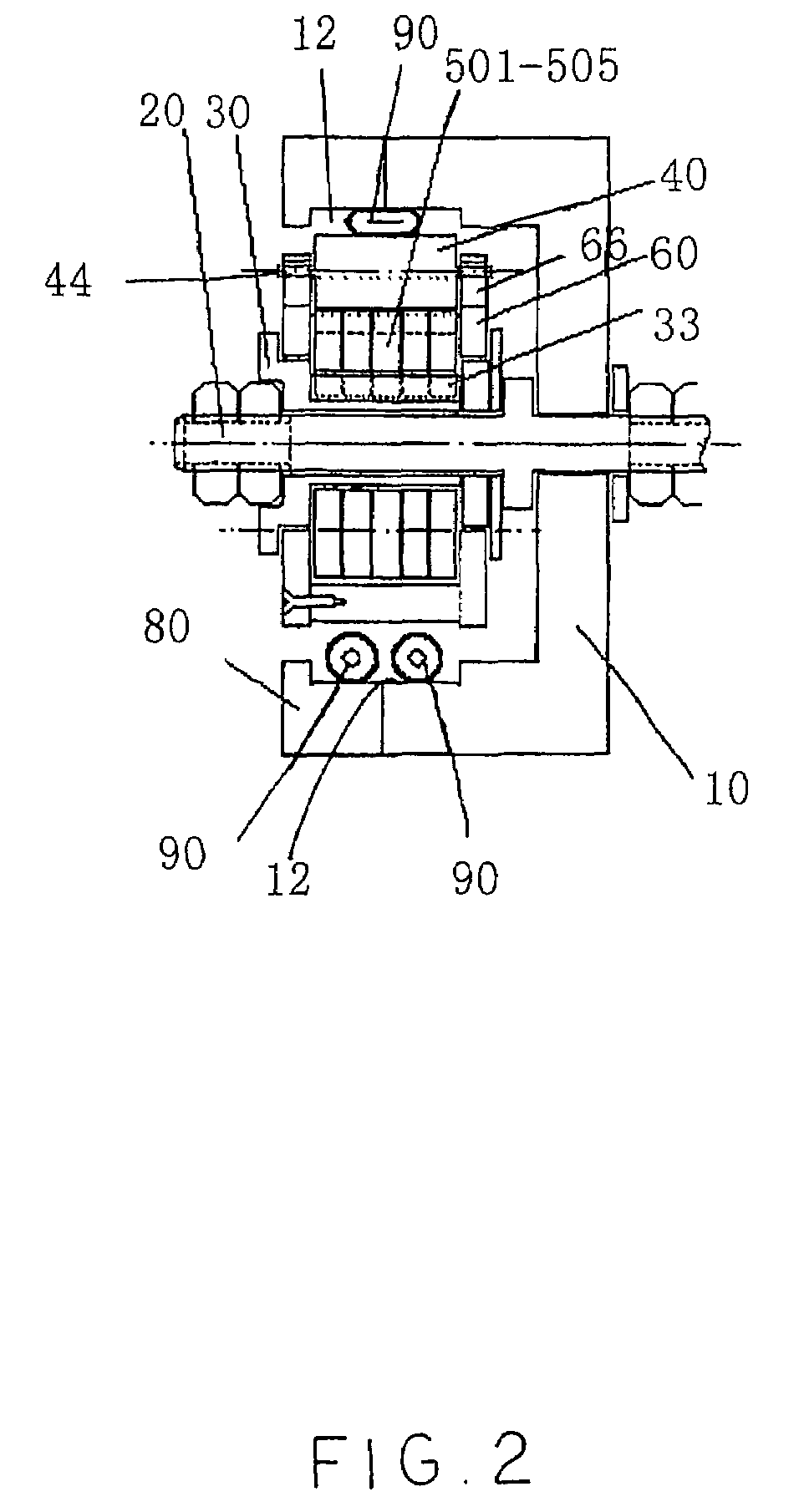

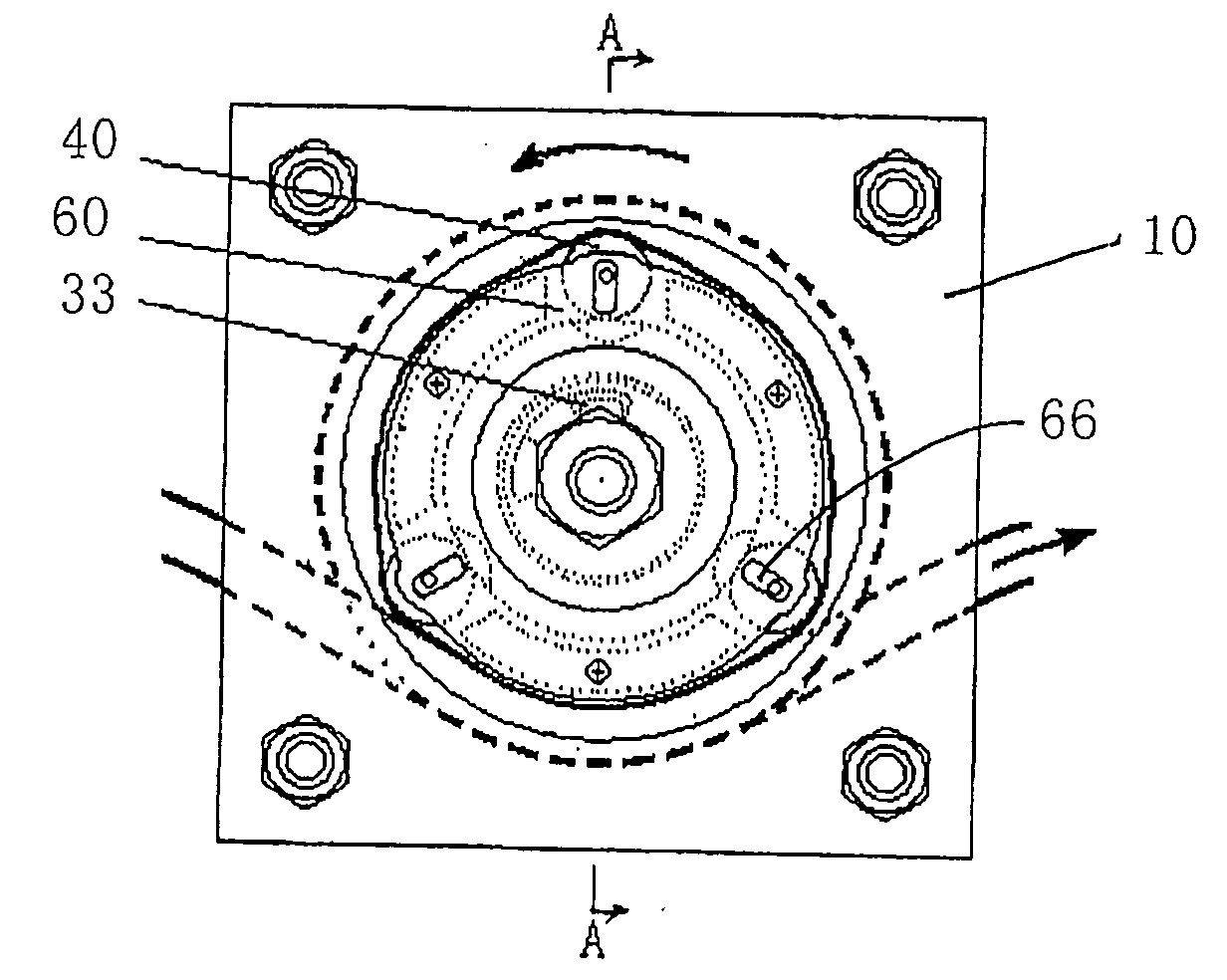

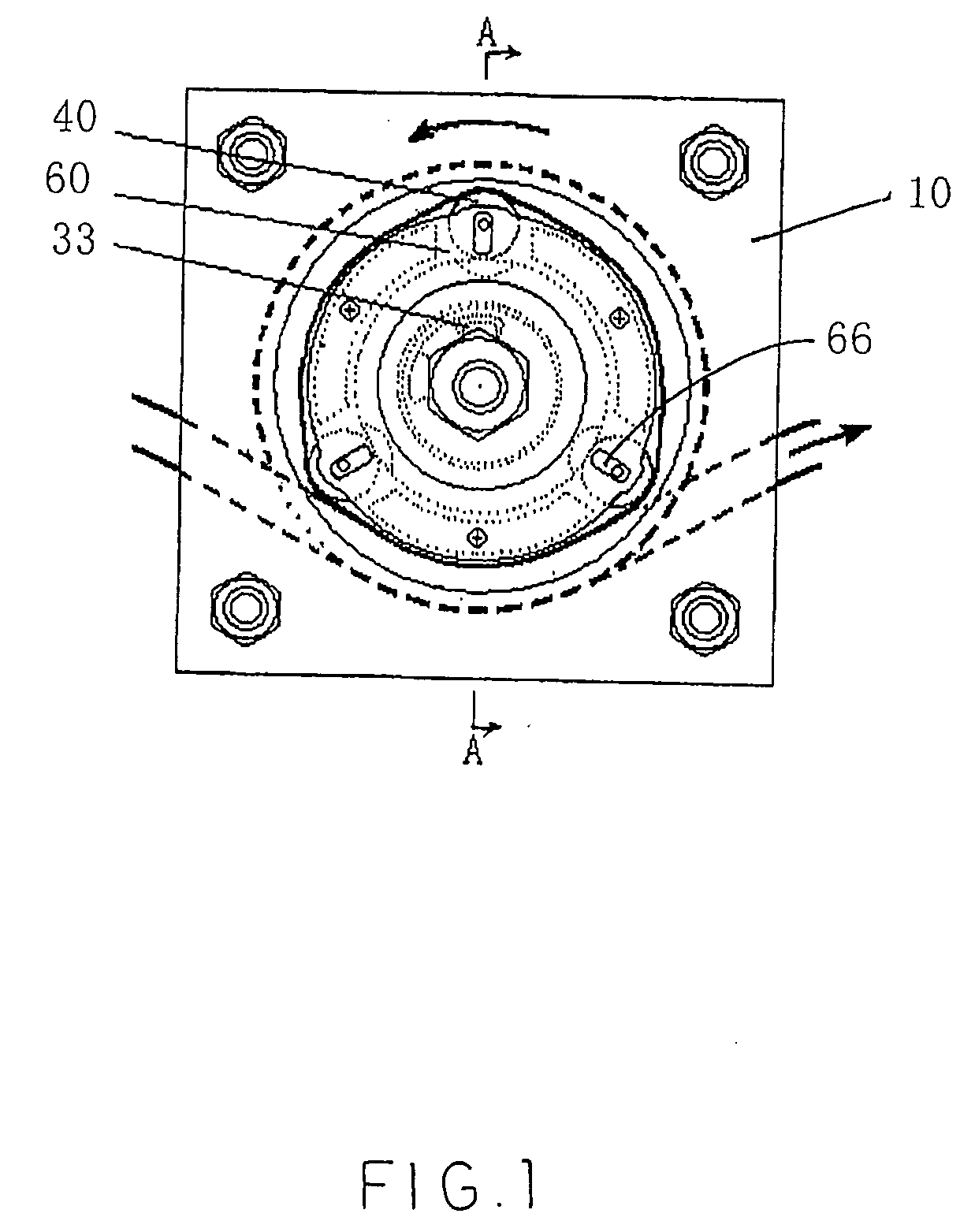

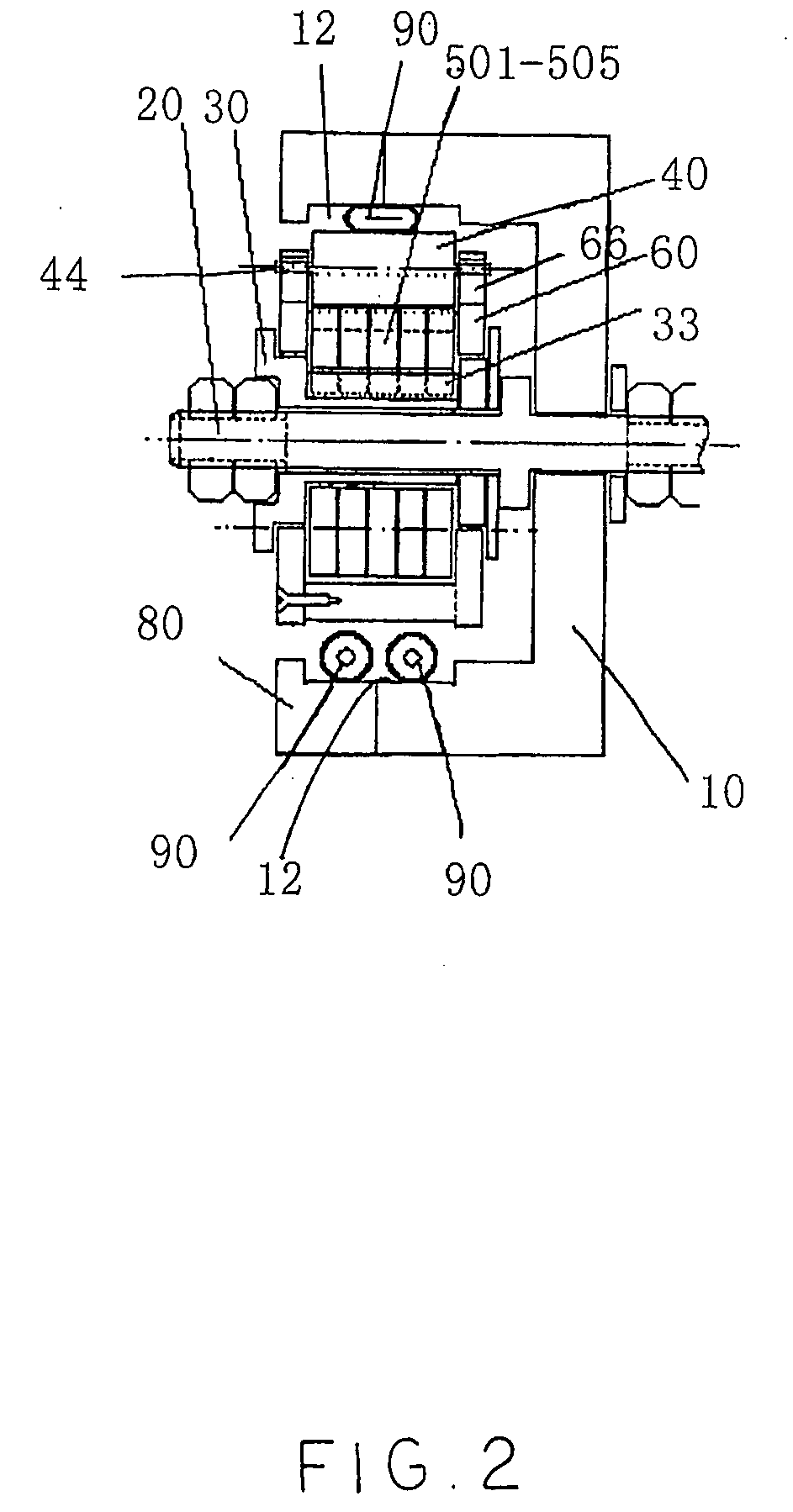

Peristaltic pump

InactiveUS7625189B2Minimizes problemLow costFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

A peristaltic pump, for propelling liquid through a flexible pump tube, includes an outer casing having a guiding channel wherein an operating portion of the pump tube extends along the guiding channel. The peristaltic pump further includes at least two pressuring rollers supported at the outer casing in a radially movable manner which can move outwardly to press against the operating portion of the pump tube. A center driving mechanism is supported at a center portion of the outer casing to radially push the pressure rollers and to drive the pressuring rollers to concurrently rotate such that the pressuring rollers roll against the operating portion of the pump tube for continuously propelling the fluid in the pump tube in the direction of rotation.

Owner:CHENG ZAIJUN

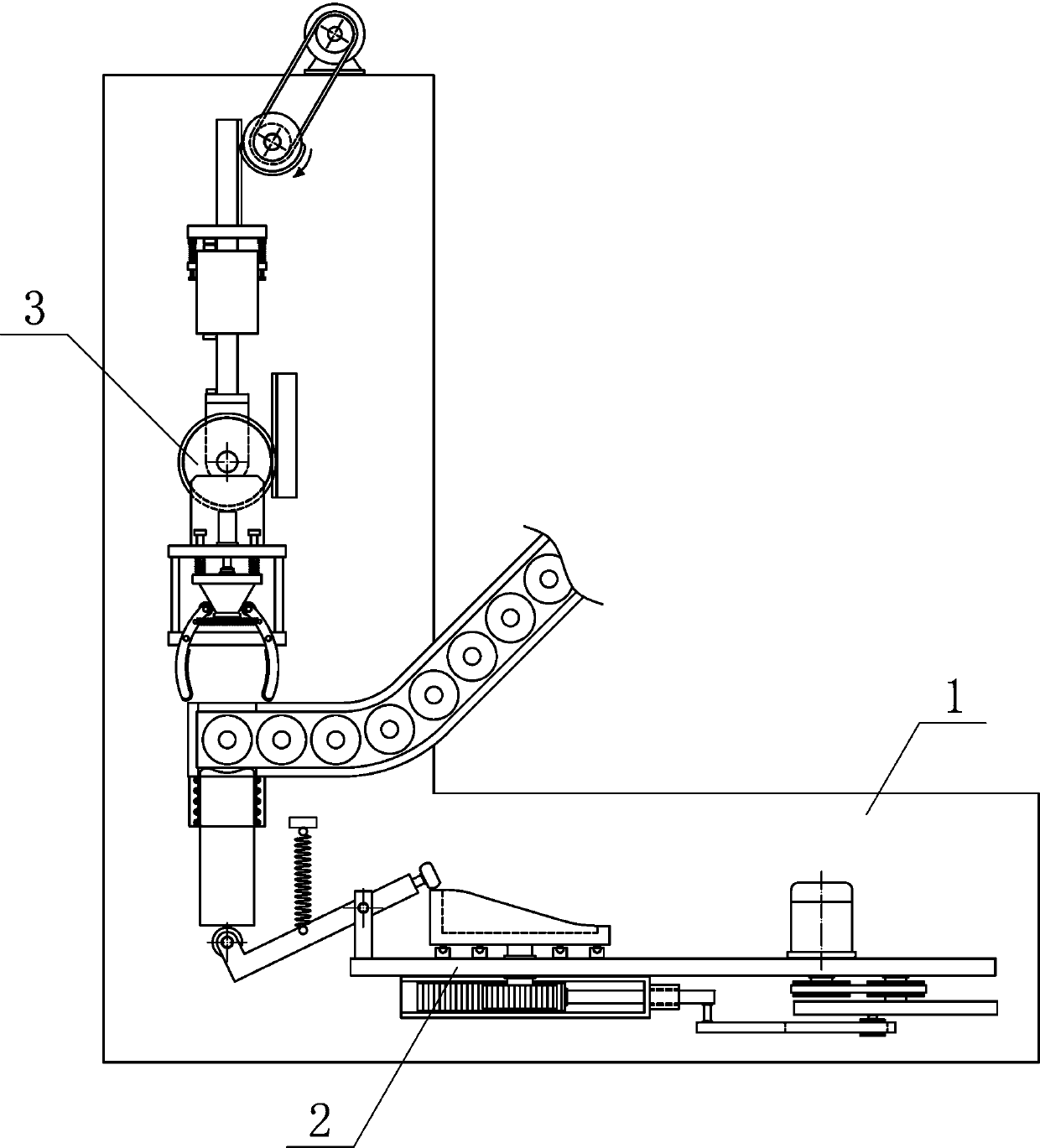

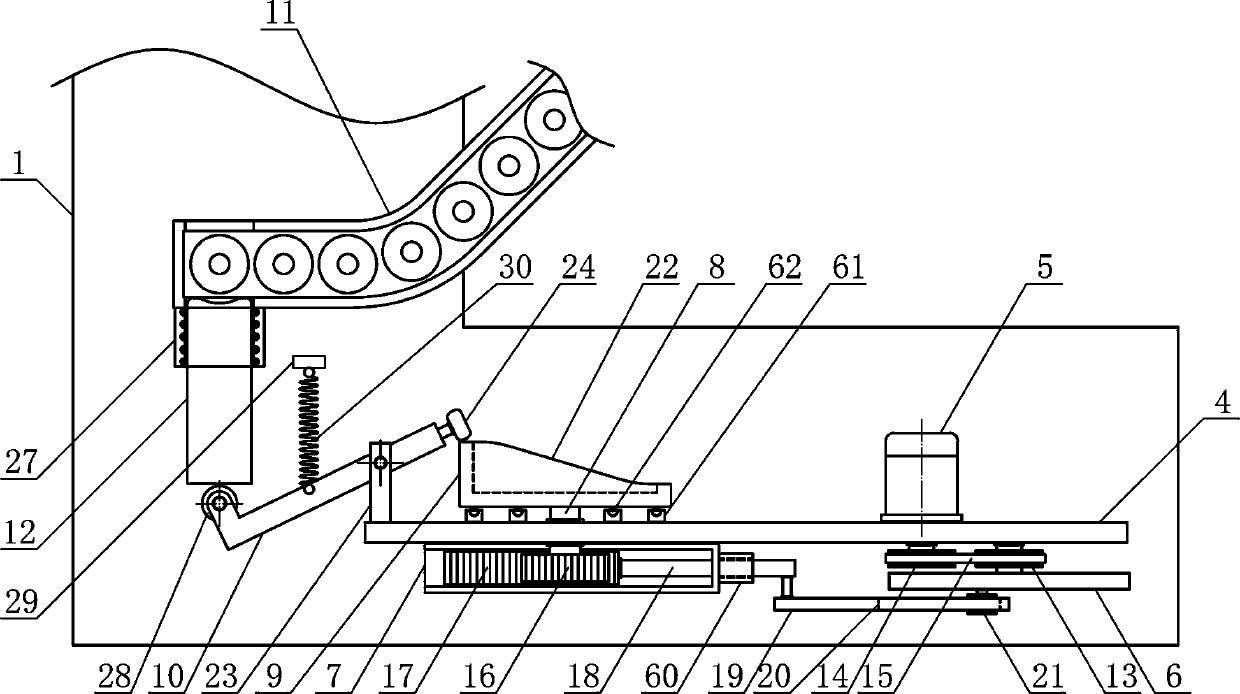

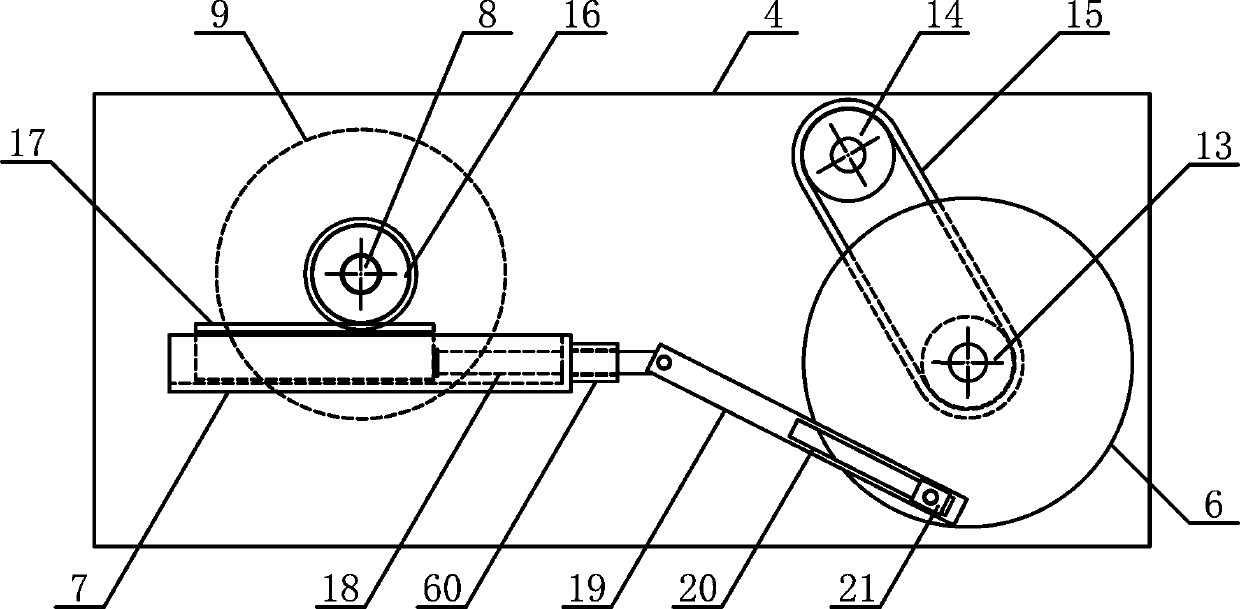

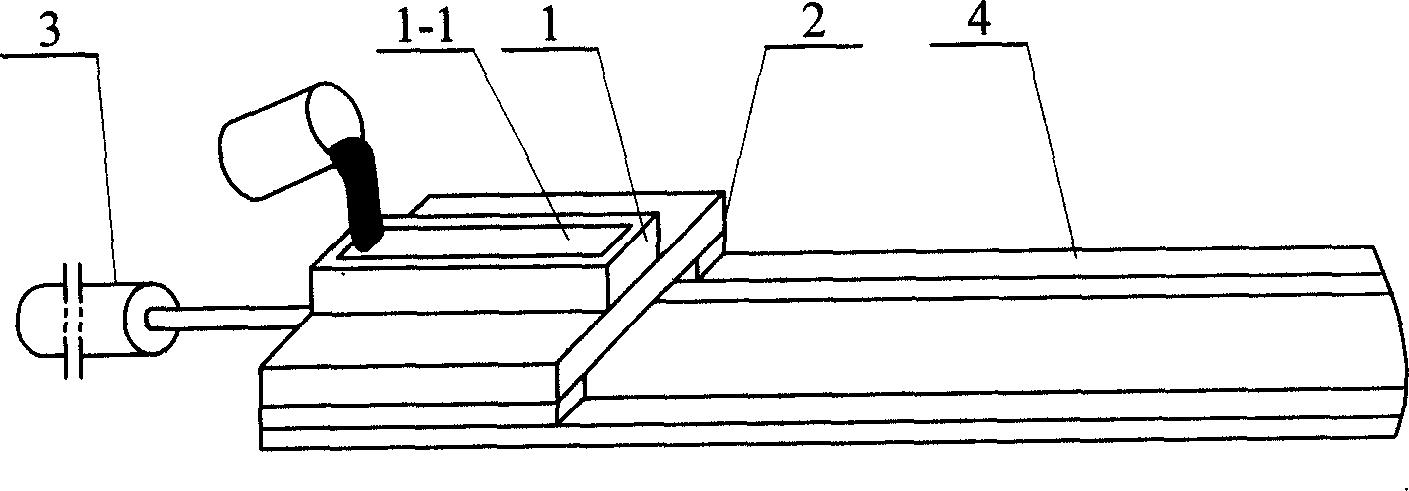

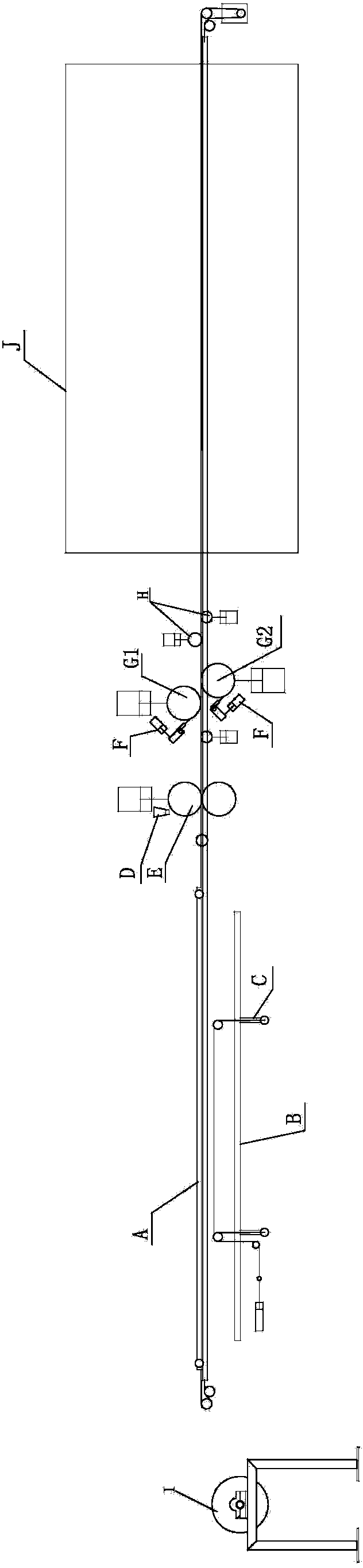

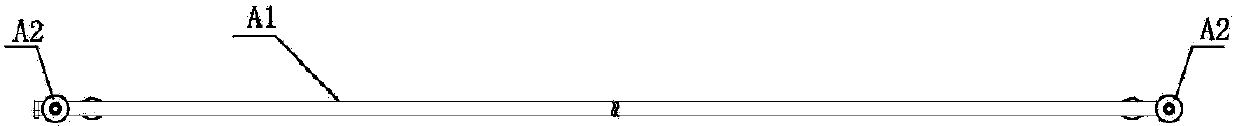

Chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing

ActiveCN111039094AHigh degree of automationSmooth and accurate reciprocating translational movementFilament handlingFiberGear wheel

The invention discloses a chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing and belongs to the field of textile processing mechanical equipment. Accordingto the chemical fiber bobbin continuous transferring and feeding device for chemical fiber processing of the invention, a bobbin feeding mechanism is horizontally and fixedly arranged at the lower side of a bobbin guiding support; a bobbin transferring mechanism above one side of the bobbin feeding mechanism is vertically arranged on the bobbin guiding support; a push rod rotating slope is arranged on the upper side of a reciprocating rotating cam; the middle of a reciprocating rotating rod is hinged to the upper side of a rotating rod supporting seat; a bobbin guiding and feeding pipe locatedabove the reciprocating rotating rod is fixedly arranged on the bobbin guiding support; a lifting transferring guide plate is slidably arranged on a lifting fixing sleeve in a vertical direction; a gear rotating support at the lower end of the lifting transferring guide plate is vertically and rotationally connected with a lifting rotating gear; and a bobbin clamping mechanism is fixedly arrangedon one side of the lifting rotating gear in the radial direction of the lifting rotating gear. The chemical fiber bobbin continuous transferring and feeding device is reasonable in structural design,can efficiently, stably and sequentially feed and machine chemical fiber bobbins one by one, is high in automation degree, and meets processing and using requirements.

Owner:桐乡市富昌化纤股份有限公司

Peristaltic pump

InactiveUS20070148022A1Minimizes problemAccurate and stable propelling motionFlexible member pumpsPositive-displacement liquid enginesPeristaltic pump

A peristaltic pump, for propelling liquid through a flexible pump tube, includes an outer casing having a guiding channel wherein an operating portion of the pump tube extends along the guiding channel. The peristaltic pump further includes at least two pressuring rollers supported at the outer casing in a radially movable manner which can move outwardly to press against the operating portion of the pump tube. A center driving mechanism is supported at a center portion of the outer casing to radially push the pressure rollers and to drive the pressuring rollers to concurrently rotate such that the pressuring rollers roll against the operating portion of the pump tube for continuously propelling the fluid in the pump tube in the direction of rotation.

Owner:CHENG ZAIJUN

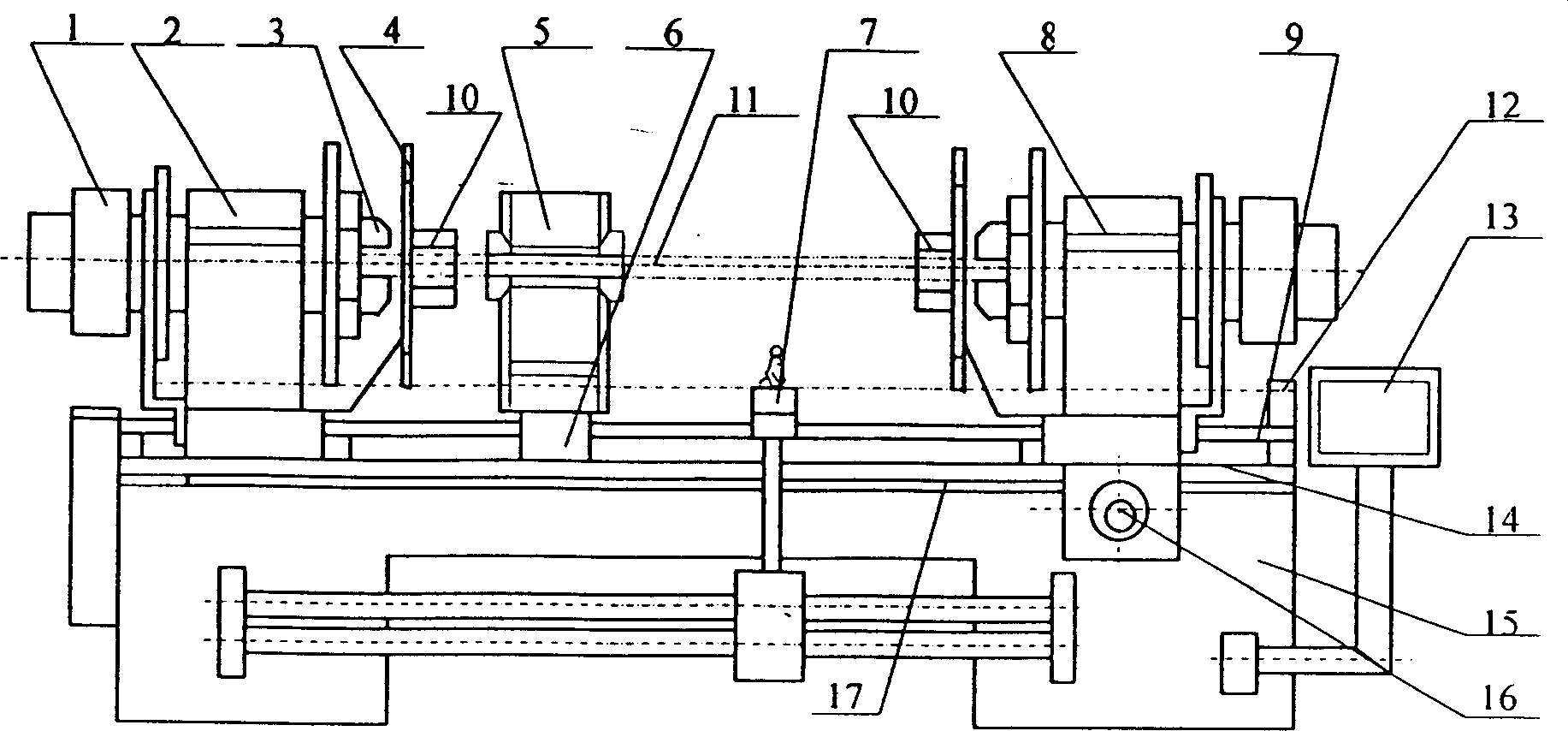

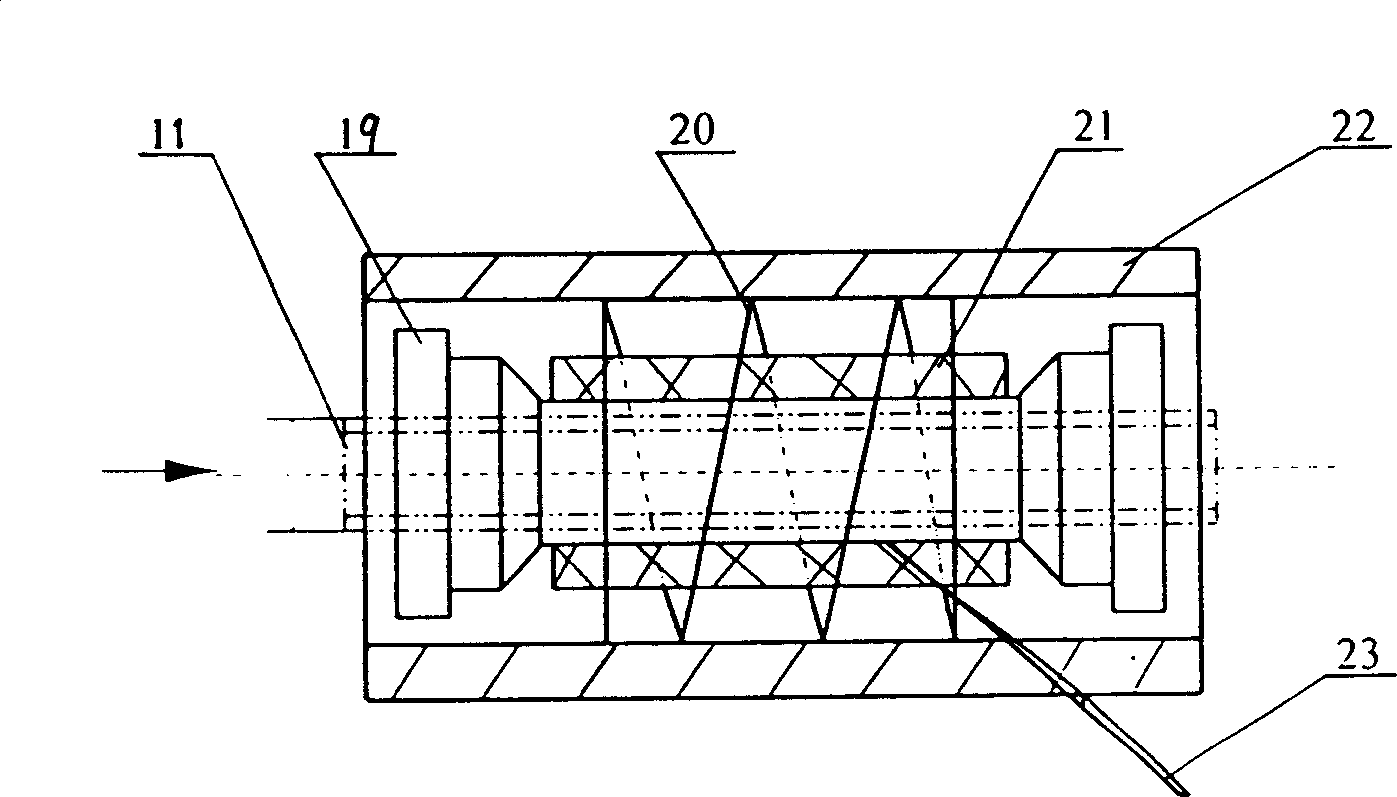

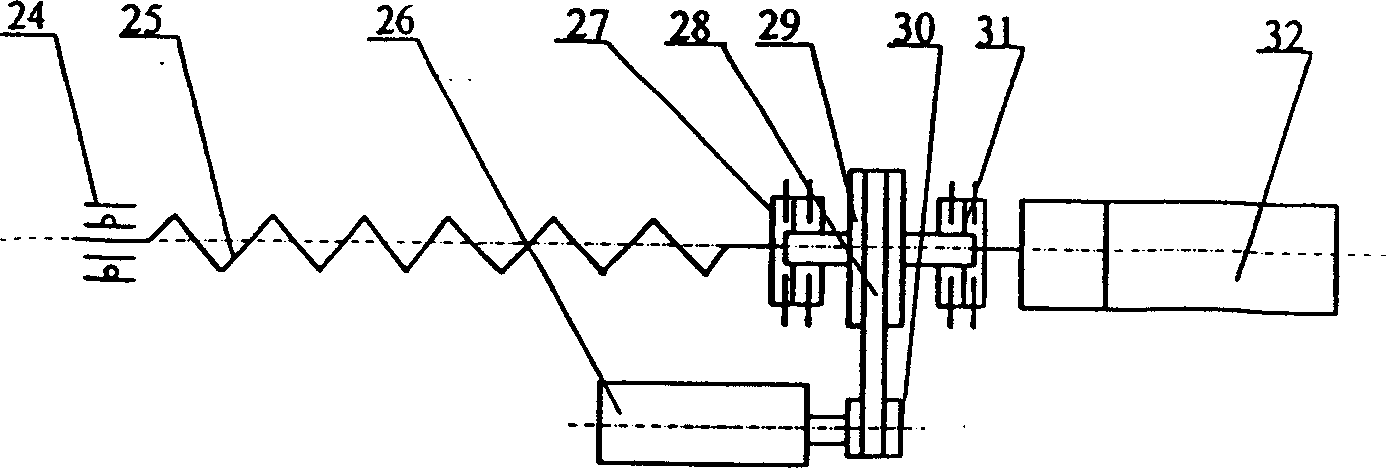

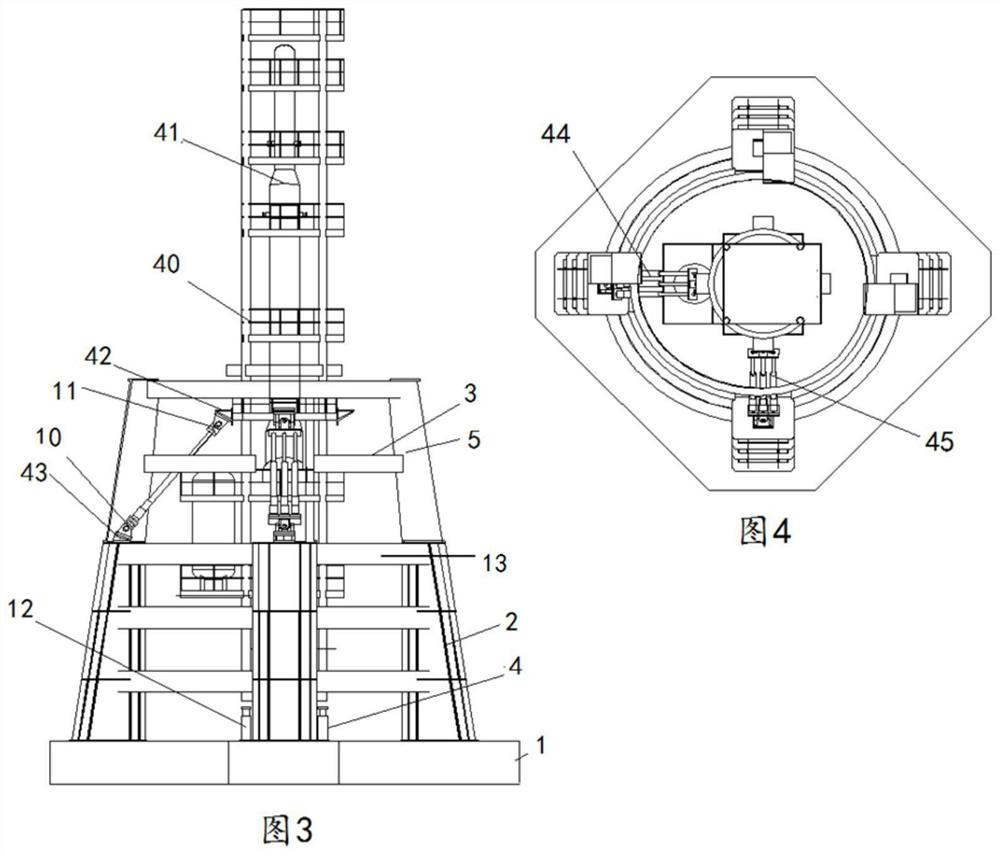

Machine for forming rod of prefabricated optical fibre rod by induction heating

InactiveCN1433981APrecise and stable movementReduce lossesGlass making apparatusEngineeringHeating furnace

The present invention relates to an induction heating preform-forming machine used in the PCVD and MCVD optical fiber preform production process, including machine body, one side of upper portion of said machine body is equipped with fixed main shaft box, and its another side is equipped with moved main shaft box, on the guideway between the fixed main shaft box moved main shaft box a mobile carrier table is mounted, and the lower portion of said mobile carrier table is connected with a reciprocating driving device, and a jacket-shaped induction heating furnace is set on the mobile carrier table. Said invention adopts the inductino heating furnace as main working heat source of the machine, and can raise the quality of optical fiber preform.

Owner:FENGHUO COMM SCI & TECH CO LTD

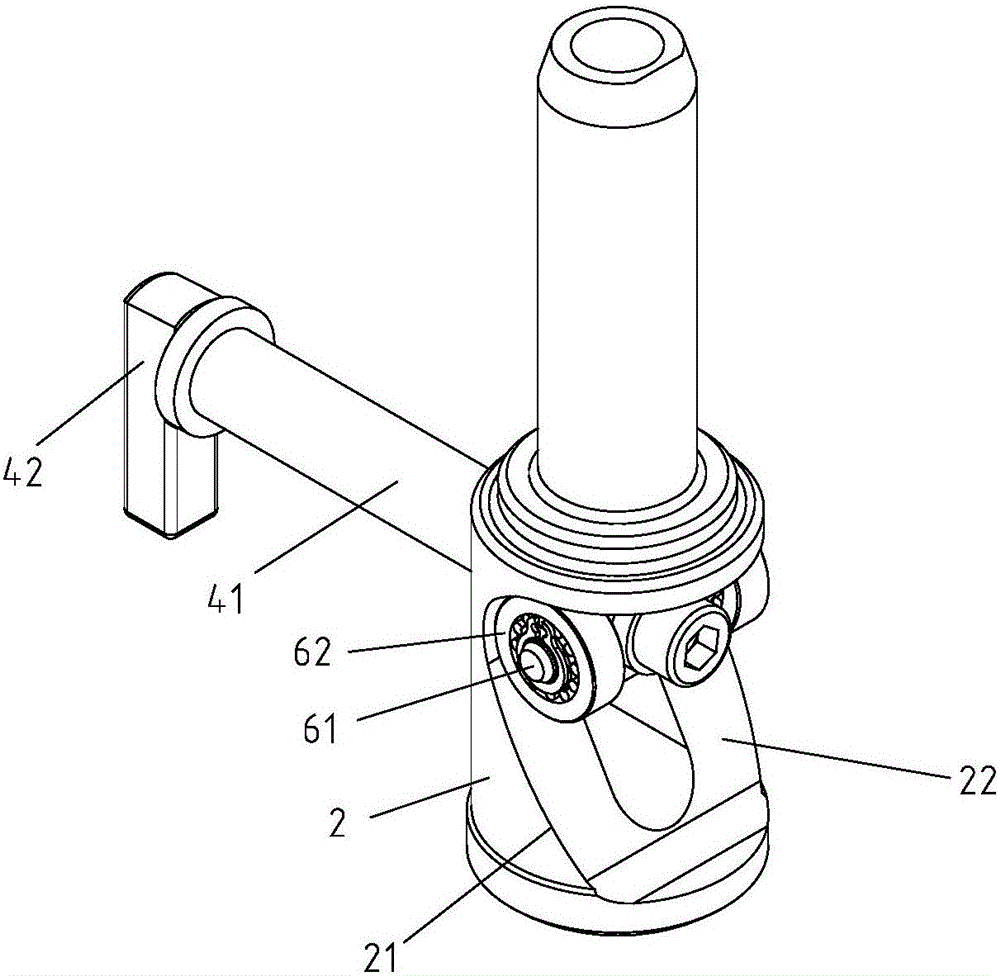

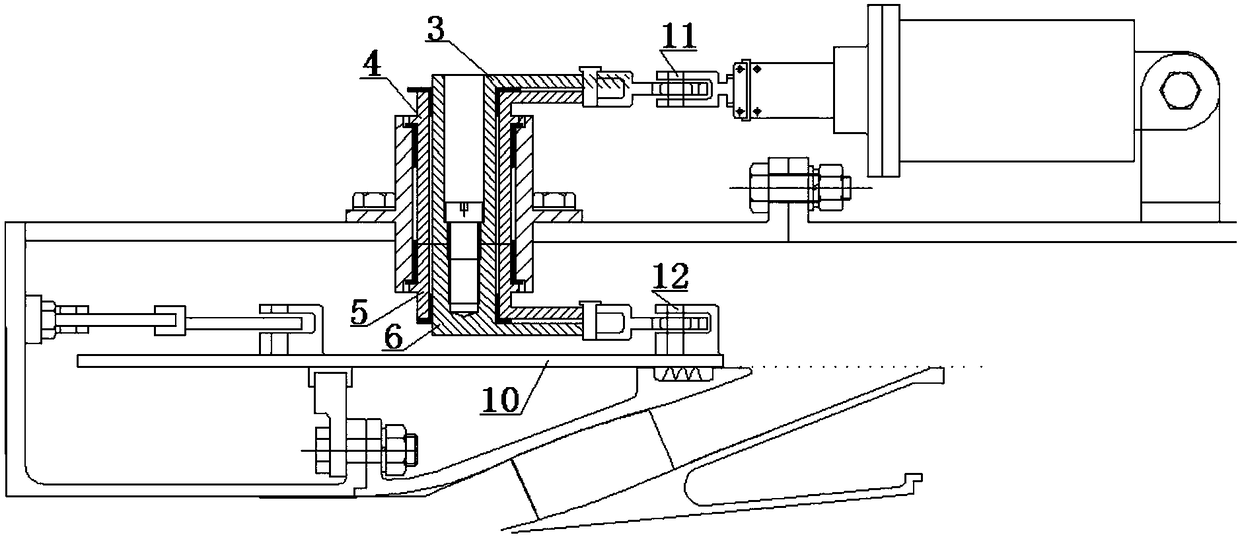

Manual relief device for track vehicle parking brake cylinders

InactiveCN106740971AChange direction of motionQuick resetRail brake actuationEngineeringAtmospheric pressure

Disclosed is a manual relief device for track vehicle parking brake cylinders. The manual relief device comprises a relief support seat, a pull rod slidably mounted in the cavity arranged in the relief support seat, relief stay ropes driving the pull rod to slide and a relief pin slidably mounted in a mounting hole arranged in the side wall of the relief support seat; motion direction of the relief pin is changed through a slanting wedge structure formed by a guiding surface tilting in a driving groove, tensile force needed in manual pull relief is reduced, difficulty in operation of manual relief is lowered, and operation efficiency is improved; the pull rod and a relief rod are perpendicular to each other, so that change in motion direction of the relief pin is maximized; a reset spring is mounted on the relief rod, so that the relief rod can be reset after completion of manual relief, a ratchet wheel of a parking cylinder is clamped, and the parking cylinder can be reset when a vehicle restores brake pressure. The reset spring is mounted on the pull rod, so that the pull rod and the relief pin can be reset more rapidly.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

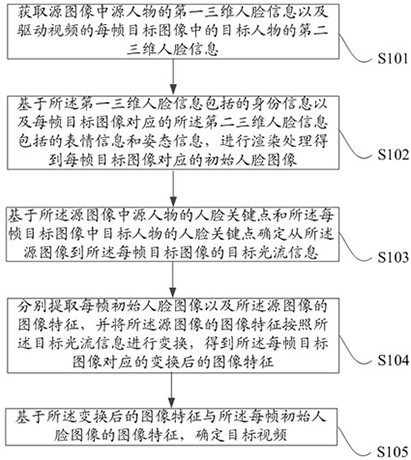

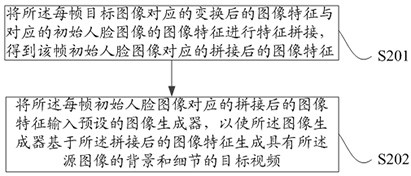

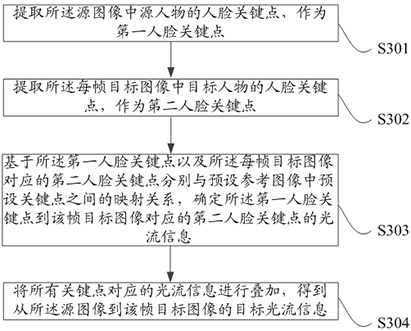

Image processing method and device, electronic equipment and storage medium

ActiveCN113313085AImprove driving effectAccurate and stable driving resultsAcquiring/recognising facial featuresThree-dimensional object recognitionImaging processingComputer graphics (images)

The embodiment of the invention provides an image processing method and device, electronic equipment and a storage medium, and the method comprises the steps: obtaining first three-dimensional face information of a source person in a source image and second three-dimensional face information of a target person in each frame of target image of a drive video, based on identity information included in the first three-dimensional face information and expression information and posture information included in second three-dimensional face information corresponding to each frame of target image, performing rendering processing to obtain an initial face image, and determining target optical flow information based on face key points of the source person and face key points of the target person, and extracting image features of each frame of initial face image and the source image, transforming the image features of the source image according to the target optical flow information to obtain transformed image features, and jointly determining a target video based on the transformed image features and the image features of each frame of initial face image. The transformed image features and the image features of each frame of initial face image complement each other, and the face driving effect is improved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

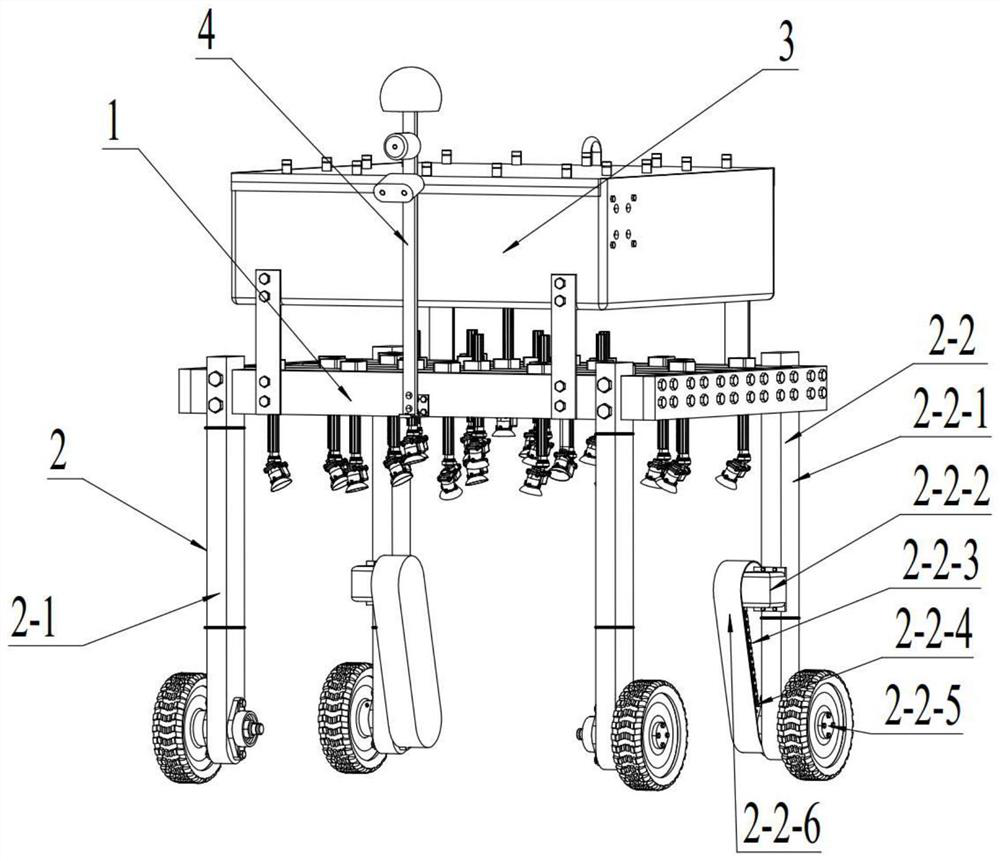

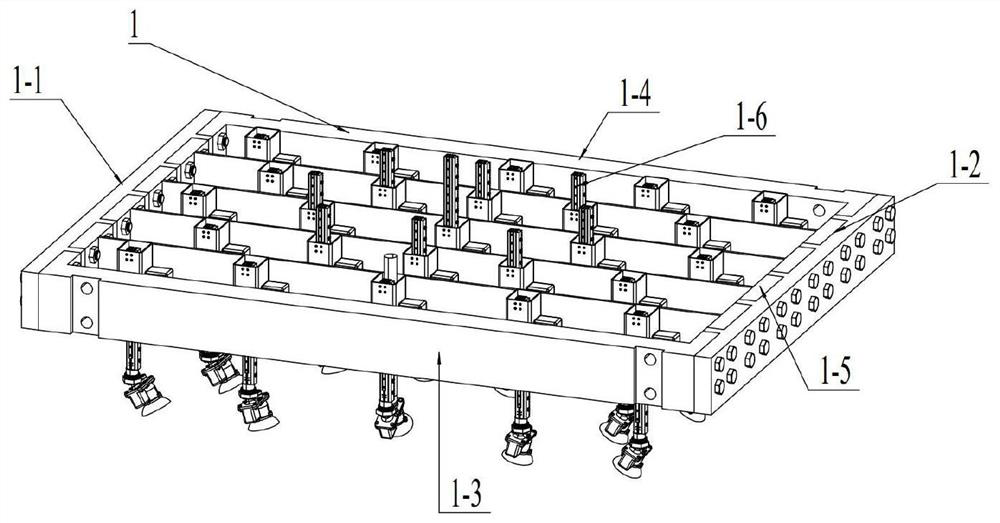

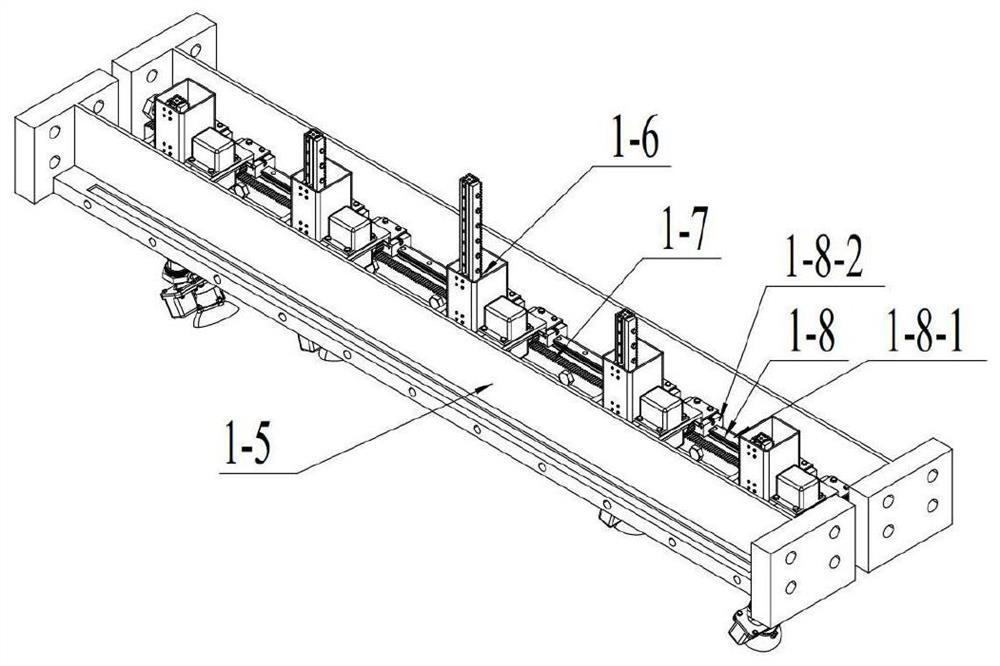

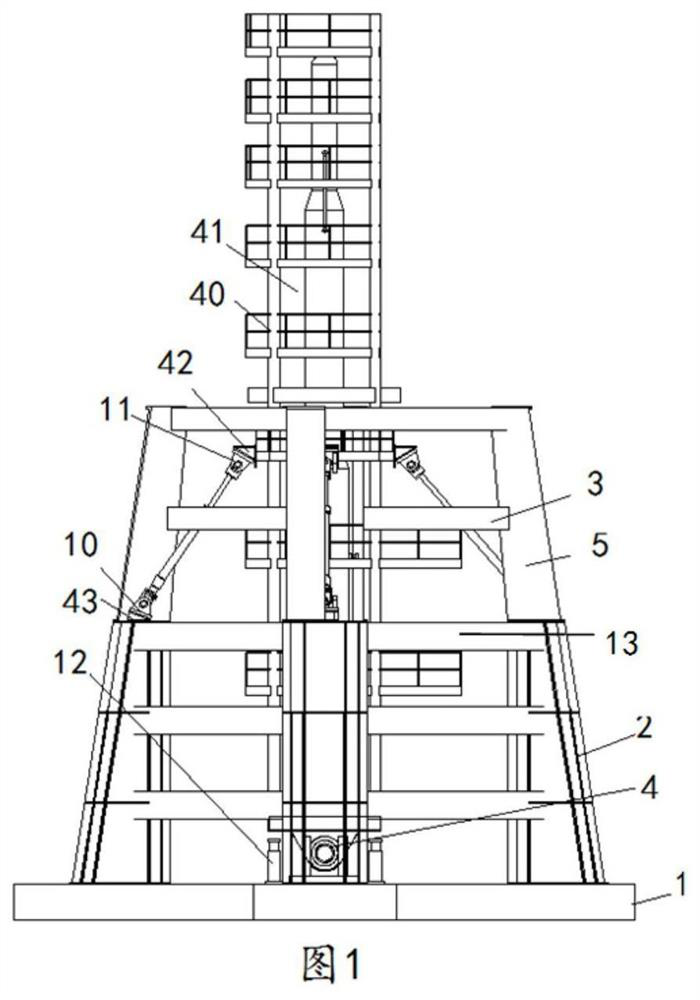

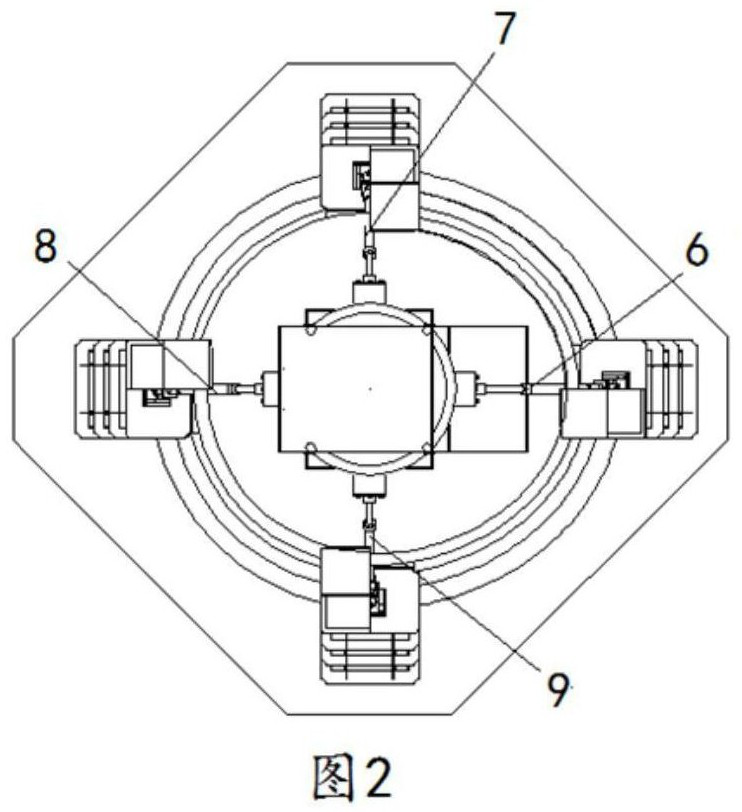

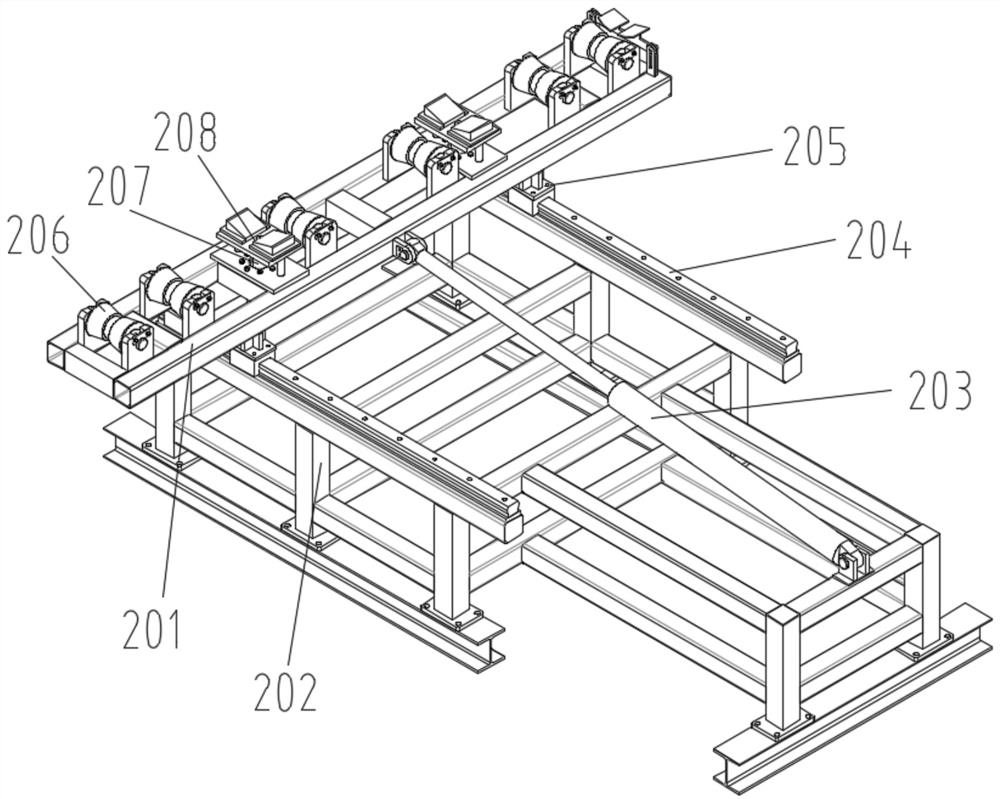

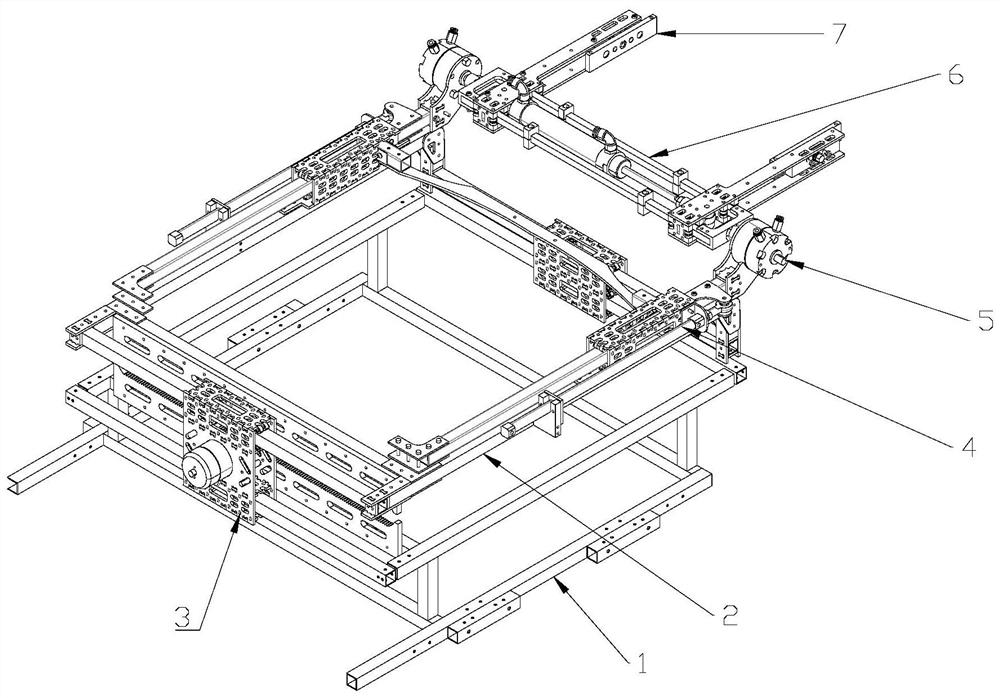

Self-propelled full-coverage multi-target safflower filament picking robot

The invention relates to a self-propelled full-coverage multi-target safflower filament picking robot. The robot comprises a picking manipulator guide frame, walking devices, a filament collecting system and a multi-information fusion filament positioning, navigation and recognition system; the four walking devices with adjustable height are fixedly connected to the four corners of the horizontally-arranged rectangular picking manipulator guide frame respectively; the filament collecting system is fixedly connected above the picking manipulator guide frame; the multi-information fusion filament positioning, navigation and recognition system is fixedly connected to the front end of the picking manipulator guide frame to realize accurate recognition and positioning of safflower plants; and the picking manipulator guide frame comprises a left supporting frame, a right supporting frame, a front supporting frame, a rear supporting frame, a guide rail supporting frame, a picking manipulatorsingle body, a horizontal moving rack and horizontal moving guide rails. According to the robot, safflower fruit balls are divided into regions in a gridding mode, the whole safflower is picked in a covering mode, missing picking of filaments is avoided, and therefore the missing picking rate of the safflower picking robot is reduced, and the purpose of improving the picking efficiency of the robot is achieved.

Owner:XINJIANG AGRI UNIV

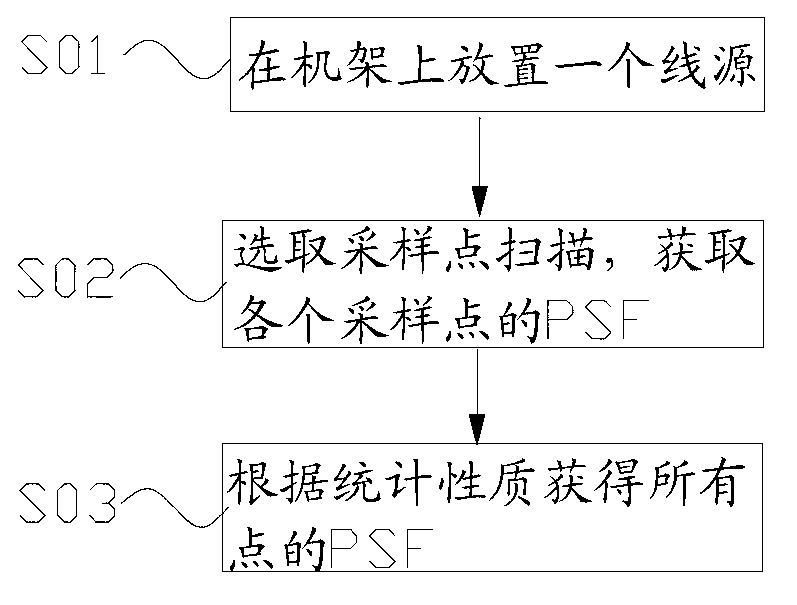

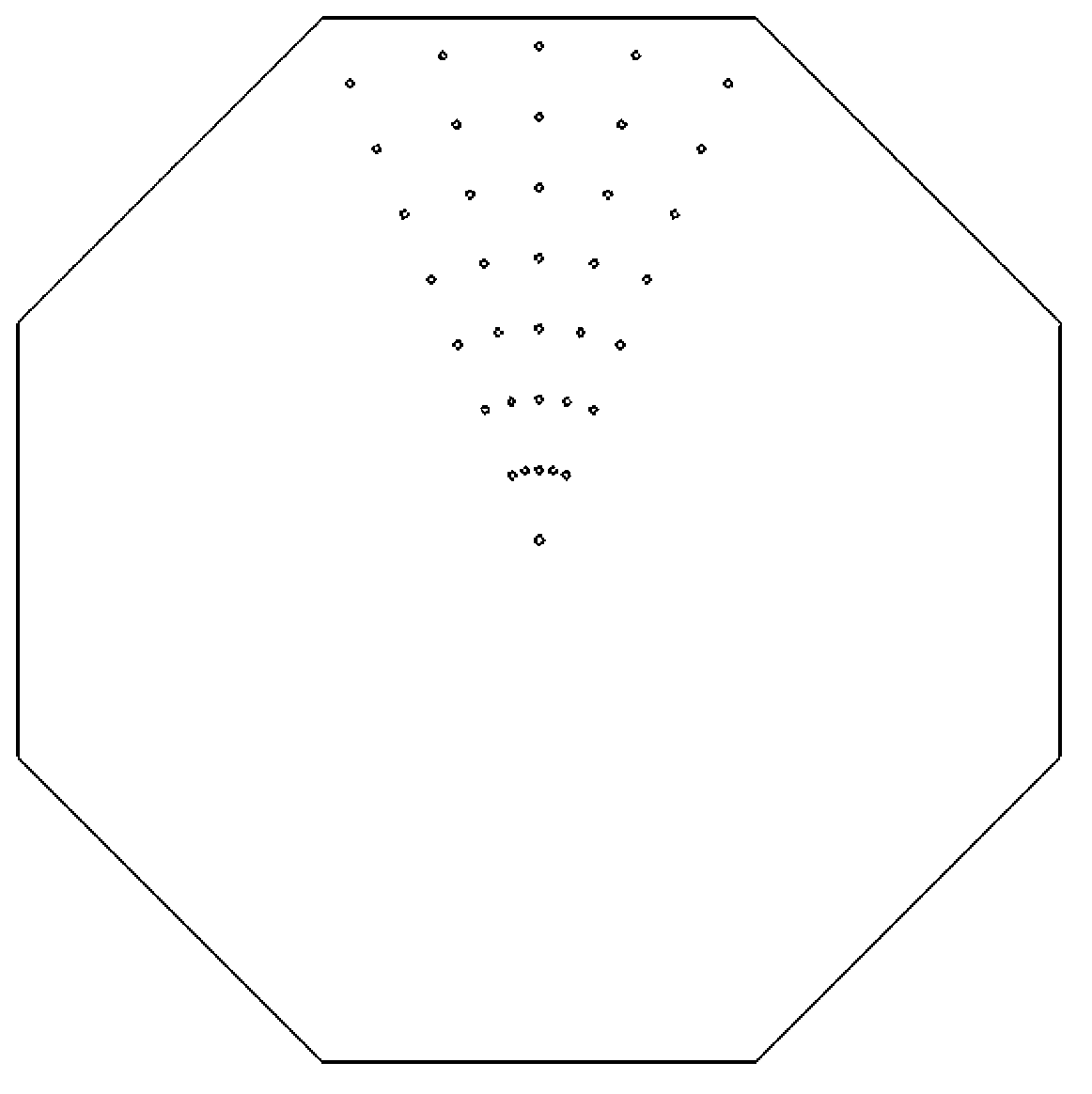

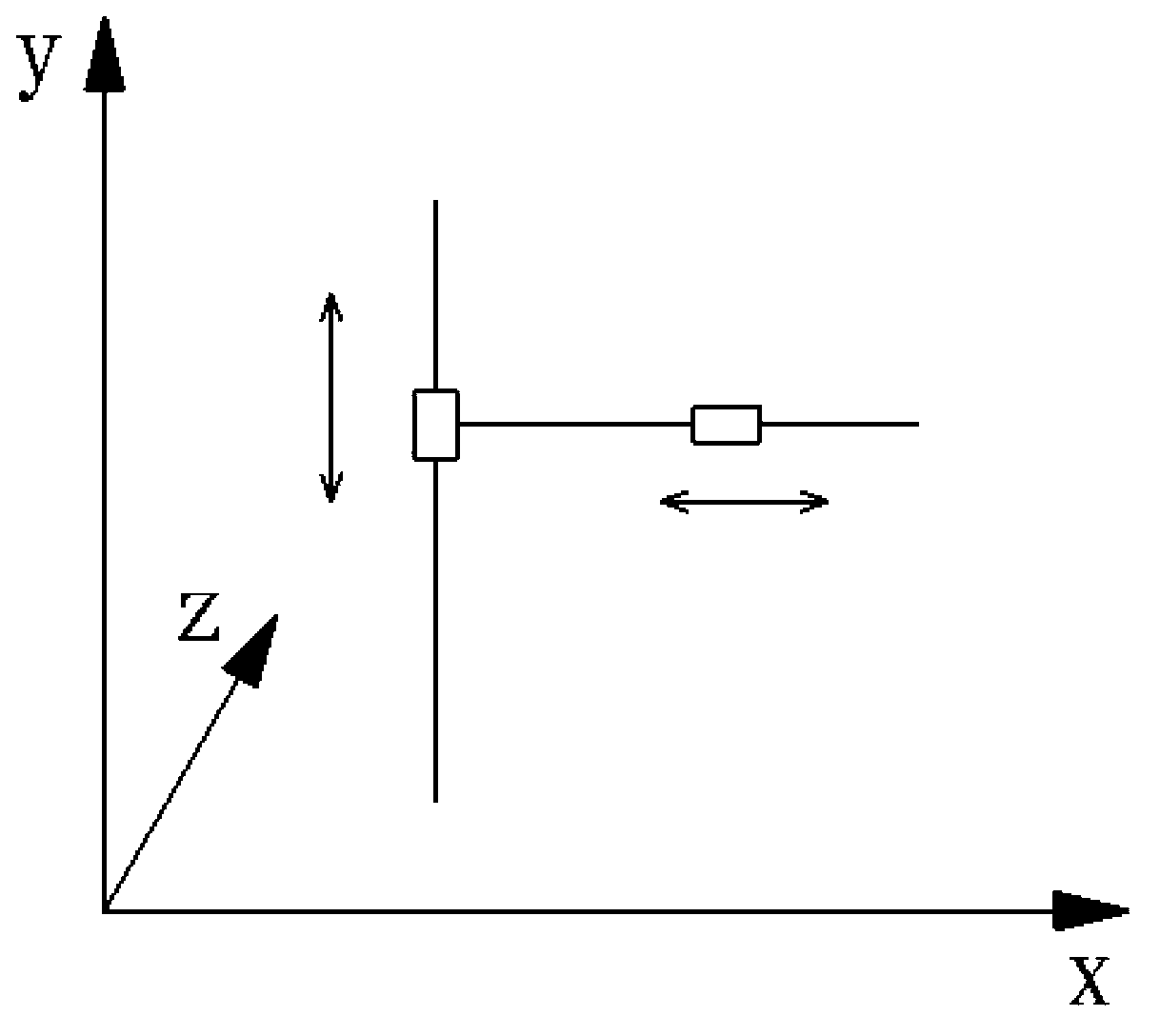

Measuring method and measuring device for point spread function of PET (positron emission tomography) system

ActiveCN103006252ASimplified measurementSimplify computational problemsComputerised tomographsTomographyDiffusion functionPoint spread function

The invention provides a measuring method and a measuring device for a point spread function of a PET (positron emission tomography) system, and the measuring efficiency and precision can be improved. The measuring method comprises the following step: 11) dividing a scanning range of a detector into a plurality of measuring areas, and selecting a plurality of sampling points in one measuring area; 12) carrying out emission scanning on the sampling points one by one by a line source, and recording a polar coordinate of each sampling point; and 13) obtaining the polar coordinate of each sampling point in other measuring areas according to the polar coordinate of each sampling point in one measuring area, and calculating the point spread function. The measuring device comprises the line source, an angle ruler and a graduated scale, wherein the angle ruler and the graduated scale are respectively used for measuring polar angles and polar diameters of the sampling points; the graduated scale is provided with a datum line labeled with polar diameter scribed lines along a longitudinal direction; the line source is arranged in a vertical surface of the graduated scale, and is vertical to the datum line and can move along the datum line; and the graduated scale can rotate around a measuring center point of the angle ruler in a flat surface parallel to the angle ruler, and can be positioned at a preset angle.

Owner:SHENYANG INTELLIGENT NEUCLEAR MEDICAL TECH CO LTD

Plastic panel die of jack of power socket

InactiveCN103895187APrecise and stable movementLow costBlind holeElectrical and Electronics engineering

Owner:东莞市大正精密模具有限公司

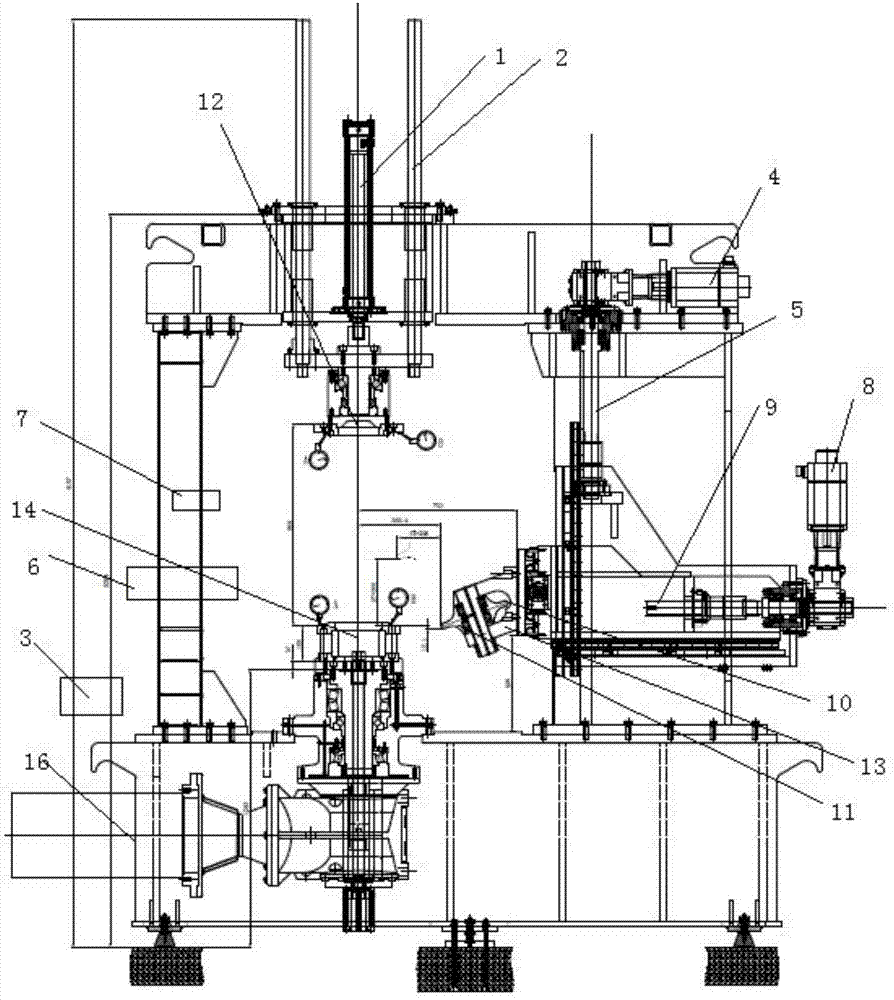

Light single-wheel spinning device for aluminum alloy wheel

A light-duty single-wheel spinning equipment for aluminum alloy wheels, which is characterized in that it includes two spinning tables, a spindle bed, a demoulding system, a tail jacking system, a hydraulic system, a lubrication system, a cooling system, a compressed air system, a spraying system, The gas system, operation panel and electrical control cabinet, the demoulding system is separated from the mold after the blank is formed, the tail jacking system completes the compaction of the blank during the blank spinning process, and the hydraulic system provides power and lubrication for the demoulding system and the tail jacking system The system delivers a certain amount of clean lubricating oil to the surface of the parts in relative motion. Spraying system: The spraying system mainly sprays the release agent and lubricant on the surface of the spinning mold and the blank through the nozzle under the action of compressed air; the gas system Used for baking molds, it has simple structure, diversified functions and high processing precision.

Owner:BAODING CITY LIZHONG WHEEL MFG

Servo device and method matched with swing table

PendingCN112857738ASolve bulkyOvercome the problems of large size, high center of gravity, and large moment of inertiaHydrodynamic testingVibration testingControl systemElectric machine

The invention discloses a servo device and method matched with a swing table, and belongs to the technical field of motion simulation test and test equipment. When the power source is hydraulic oil, the driving assembly is a servo oil cylinder, the driving principle of the servo oil cylinder is that the hydraulic oil is conveyed into the servo oil cylinder from an oil source through an oil source electrical control system and a hydraulic device, and the hydraulic oil serves as the power source of the servo oil cylinder. The motion control system is matched with the oil source electrical control system to realize motion control, safety protection and real-time monitoring of the swing table; when the power source is electricity, the driving assembly is a servo electric cylinder, according to the driving principle of the servo electric cylinder, a kinematic pair of the ball screw is used for converting rotary motion of the motor into linear motion of the servo electric cylinder to achieve telescopic motion of the servo electric cylinder, and the control system achieves control over the telescopic motion of the servo electric cylinder. Therefore, the swing table generates single-degree-of-freedom or two-degree-of-freedom compound motion with different frequencies and different amplitudes.

Owner:北京星光凯明智能装备有限公司

Method for founding aluminium alloy slab ingot

A technology for casing flat Al-alloy ingot includes such steps as proportionally mixing Al, Si, Fe, Cu, Mn, Mg, Cr, Zn and Ti, heating to 740-760 deg.C while stirring and skimming, smelting by introducing chlorine gas from the bottom of molten alloy, putting a mould on a platform driven by hydraulic system, and pouring the molten alloy in the moving mould while inserting Al-Ti-B wire in it.

Owner:NORTHEAST LIGHT ALLOY CO LTD

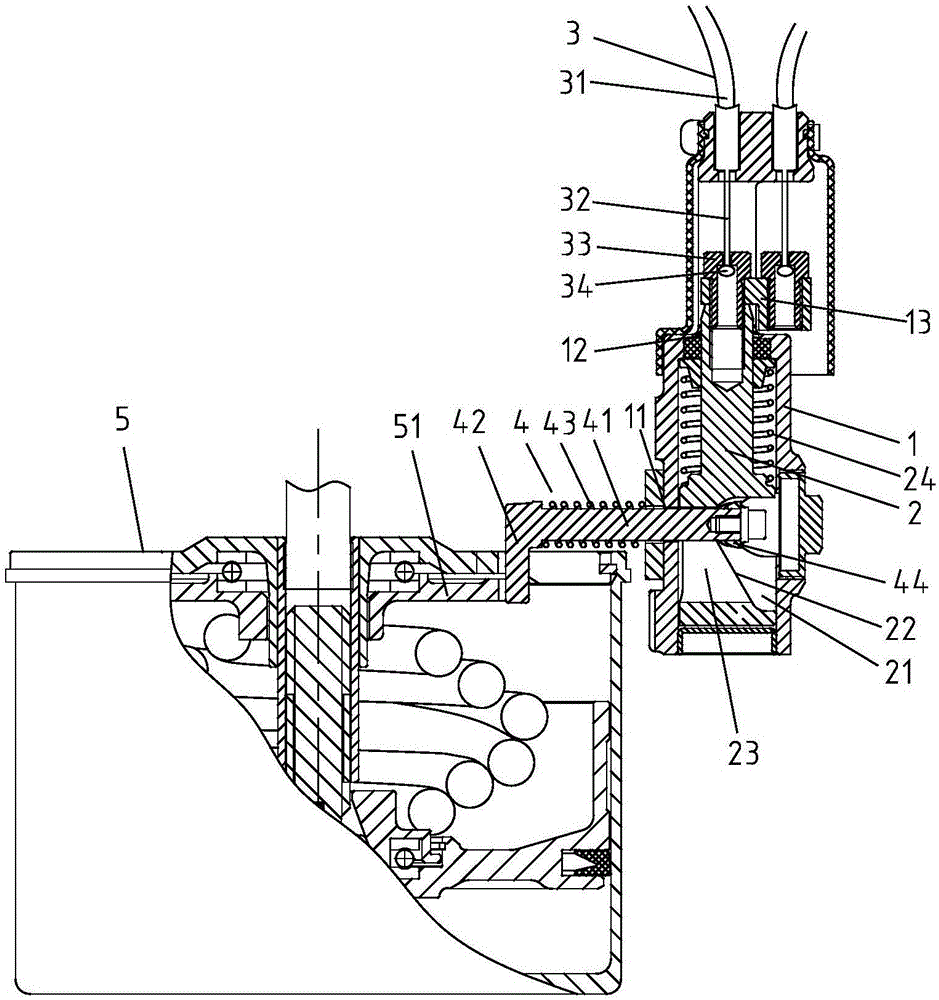

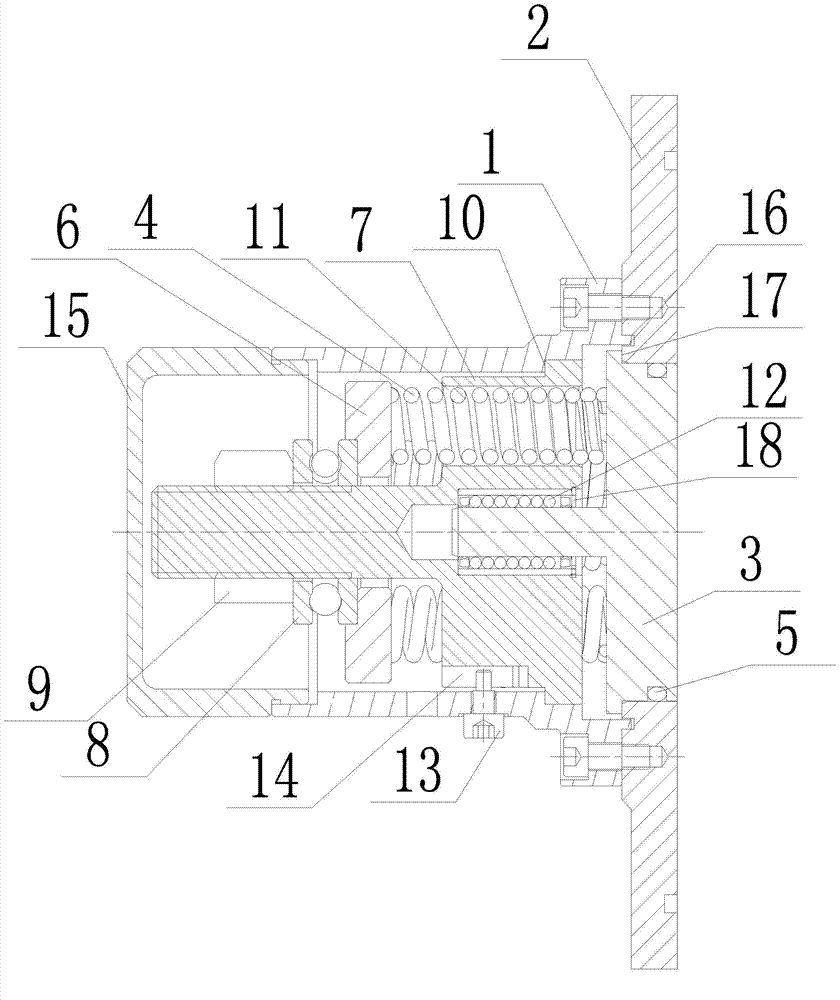

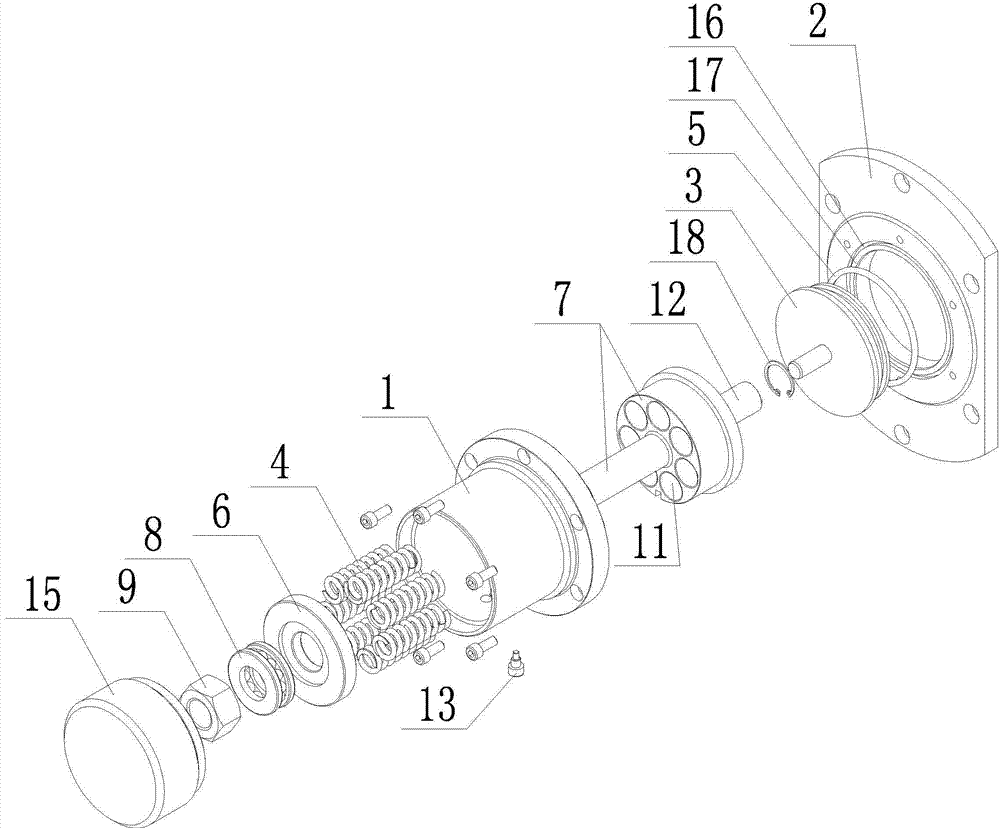

Safety valve

The invention discloses a safety valve which is easy to dismount, easy for adjusting elastic force and convenient to produce and maintain. The safety valve comprises a valve seat (1), a valve body (2), a valve core (3) and springs (4), wherein the valve core (3) is movably matched with the valve body (2), a sealing ring (5) is arranged between the valve core (3) and the valve body (2), and the safety valve also comprises a spring seat (6), a spring guide seat (7), a plane bearing (8) and an adjusting nut (9), the plane bearing (8) and the spring seat (6) sequentially and movably sleeve the spring guide seat (7), the spring guide seat (7) is movably connected with the valve seat (1), a first limiting structure (10) for limiting the spring guide seat (7) on the left is arranged on the valve seat (1), one end of each spring (4) respectively pushes against the spring seat (6), the other end of each spring (4) respectively pushes against the valve core (3), the adjusting nut (9) is arranged on the left side of the plane bearing (8), and the adjusting nut (9) is connected with the spring guide seat (7) in a screwing manner.

Owner:NINGBO DELISHI PUMP IND CO LTD

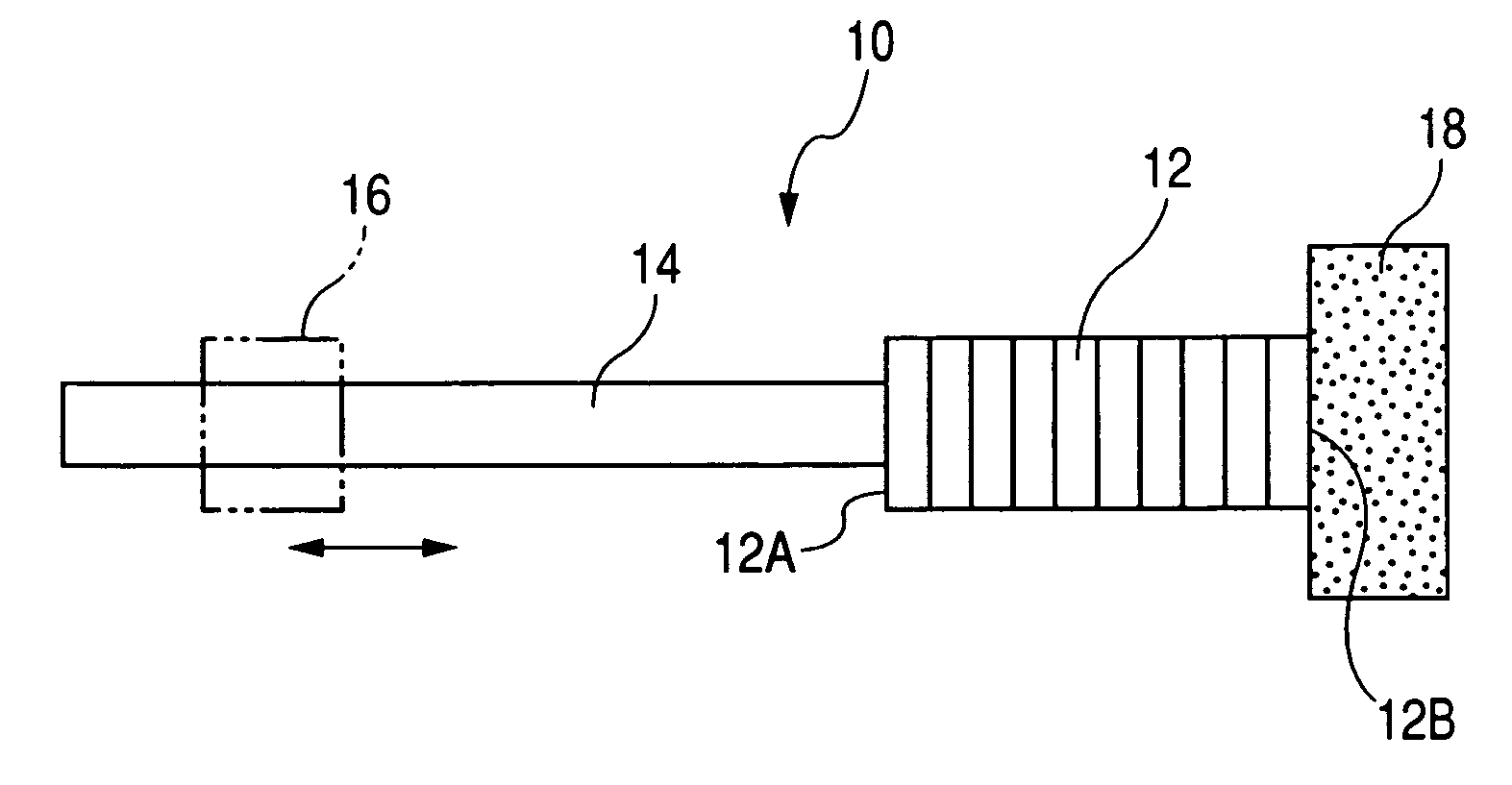

Actuator

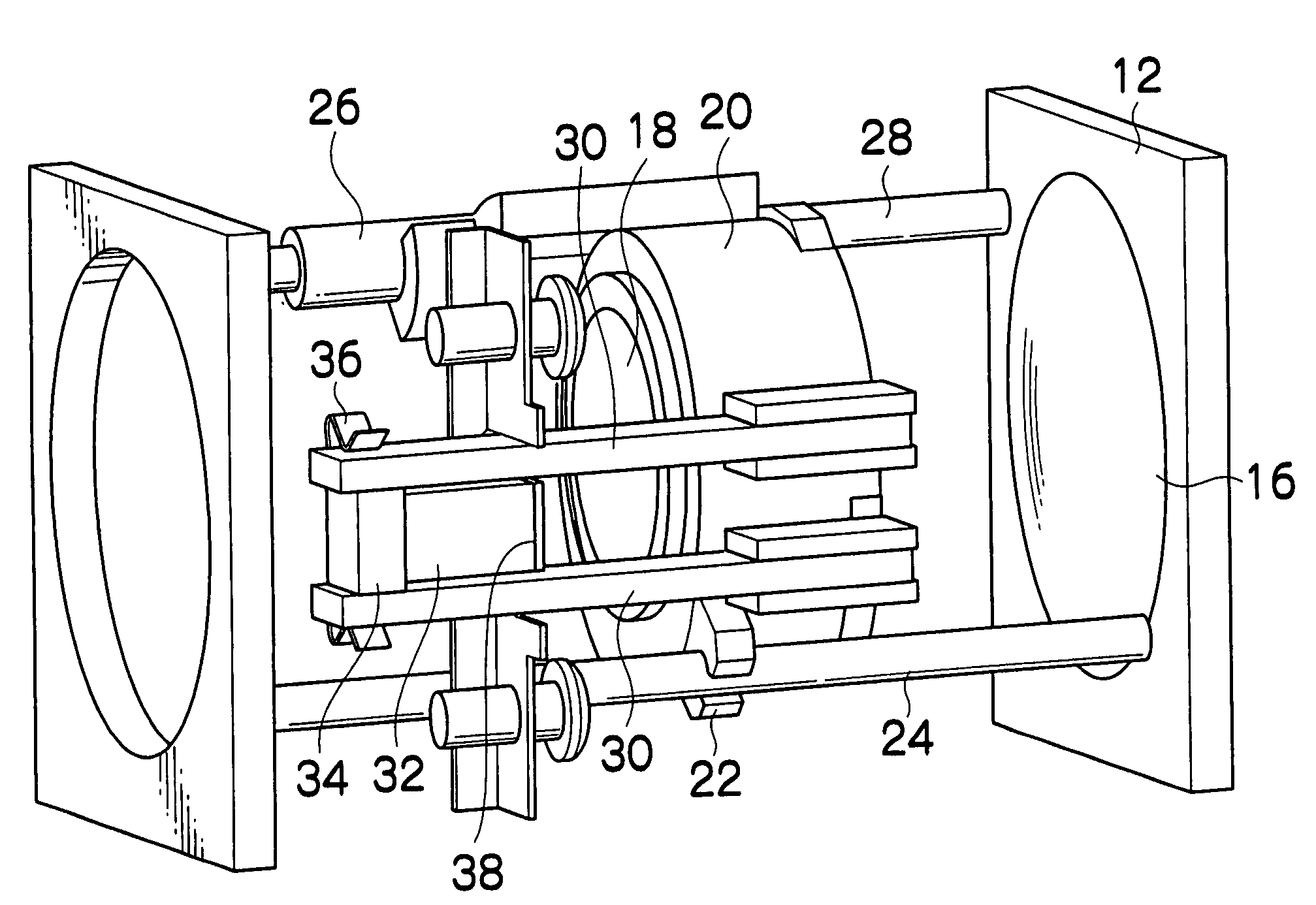

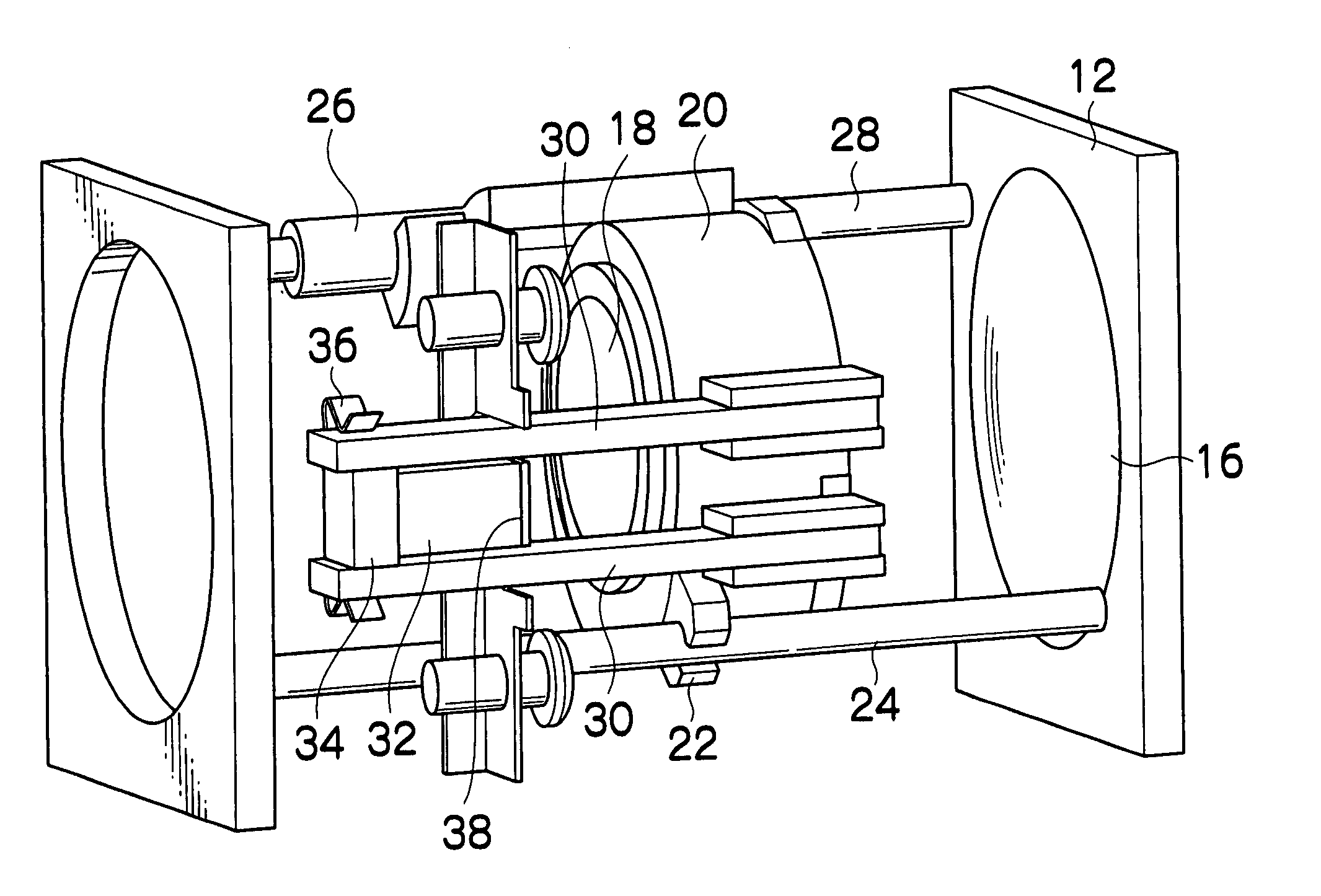

InactiveUS20050275314A1Move preciselyStably and accurately movingPiezoelectric/electrostriction/magnetostriction machinesMountingsEngineeringActuator

An actuator of the present invention comprises a piezoelectric element, one end face of the piezoelectric element in a displacement direction being supported by a fixing member, a block shaped driving member attached to the other end face of the piezoelectric element in the displacement direction, and a driven member frictionally engaged with at least one end face of the driving member in a direction orthogonal to the displacement direction, the driven member being extended along the displacement direction.

Owner:FUJI PHOTO OPTICAL CO LTD

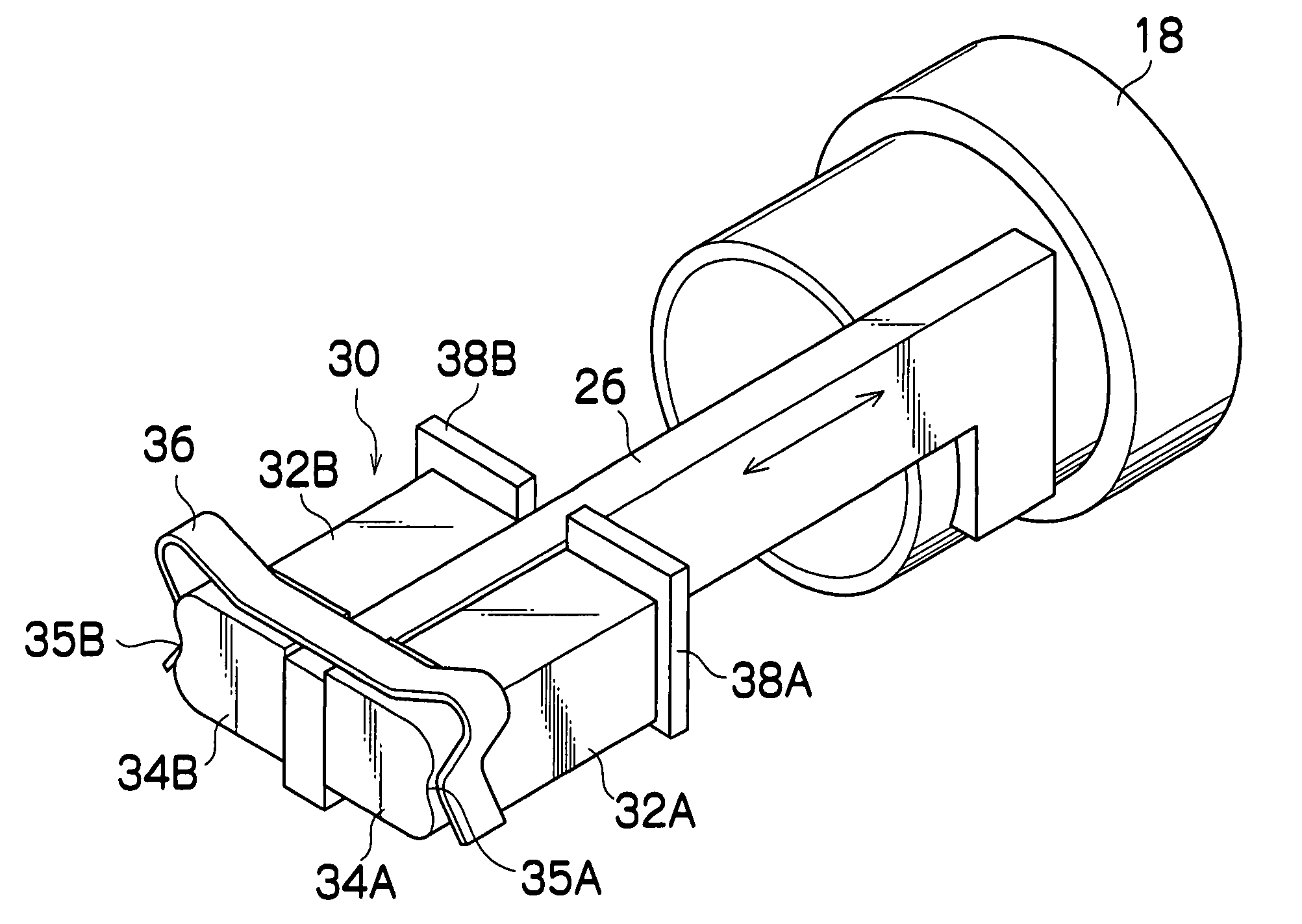

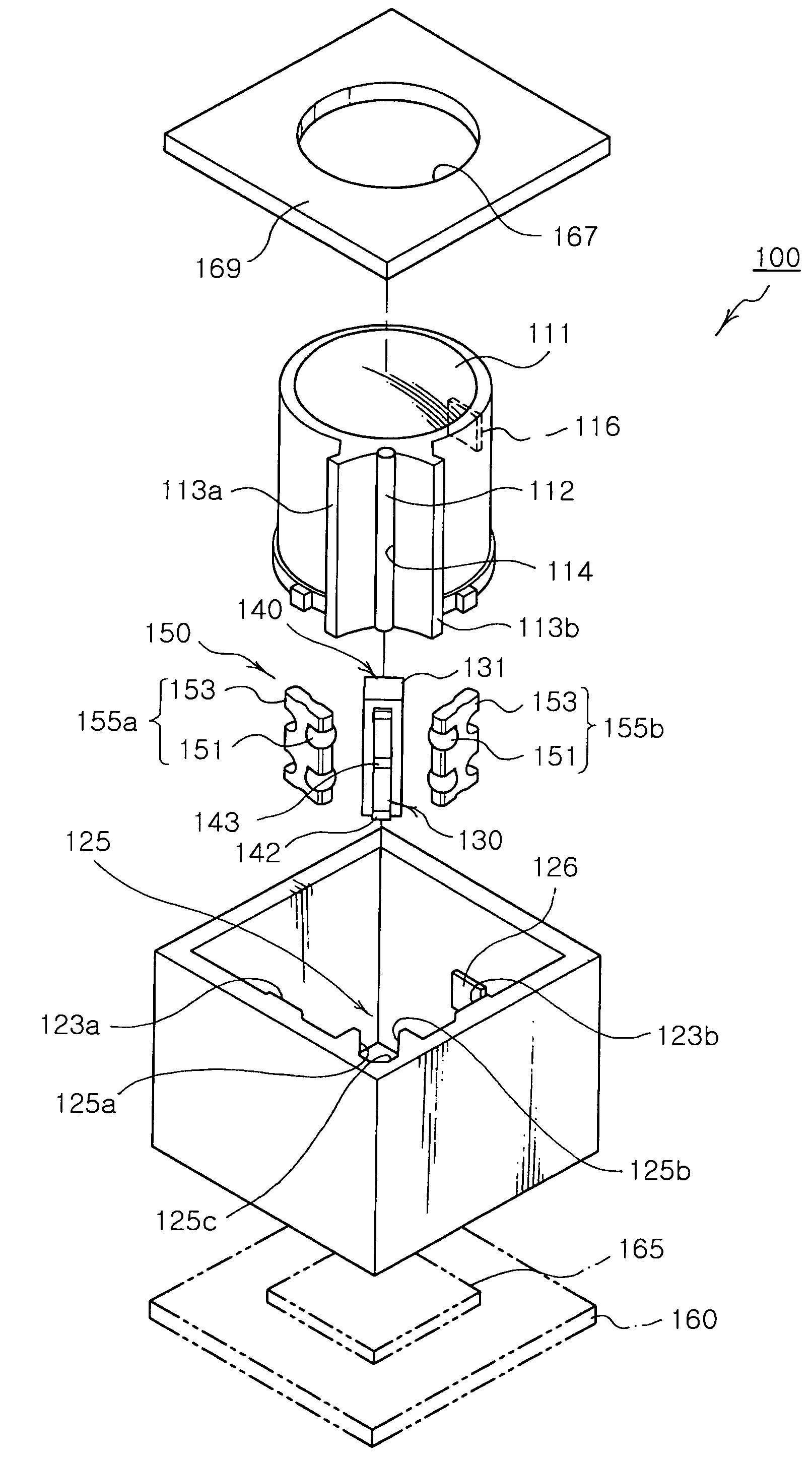

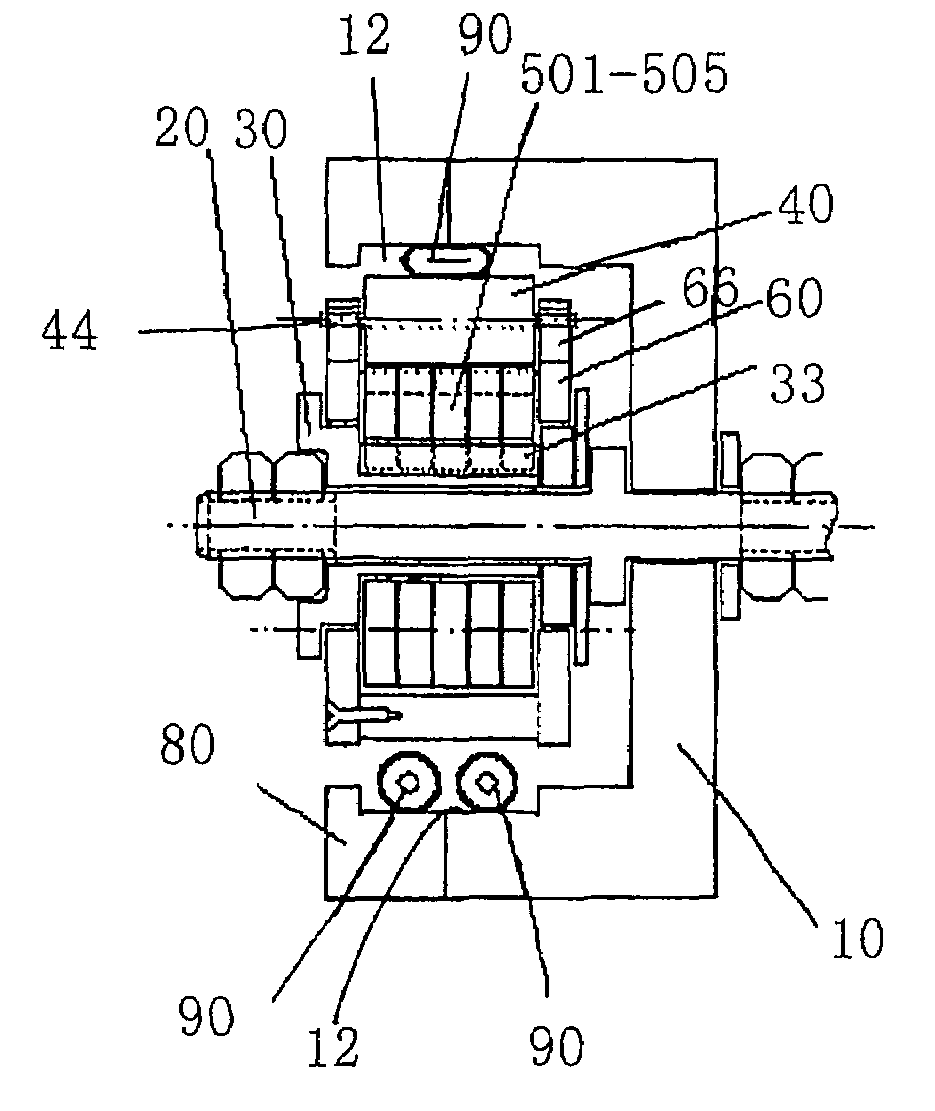

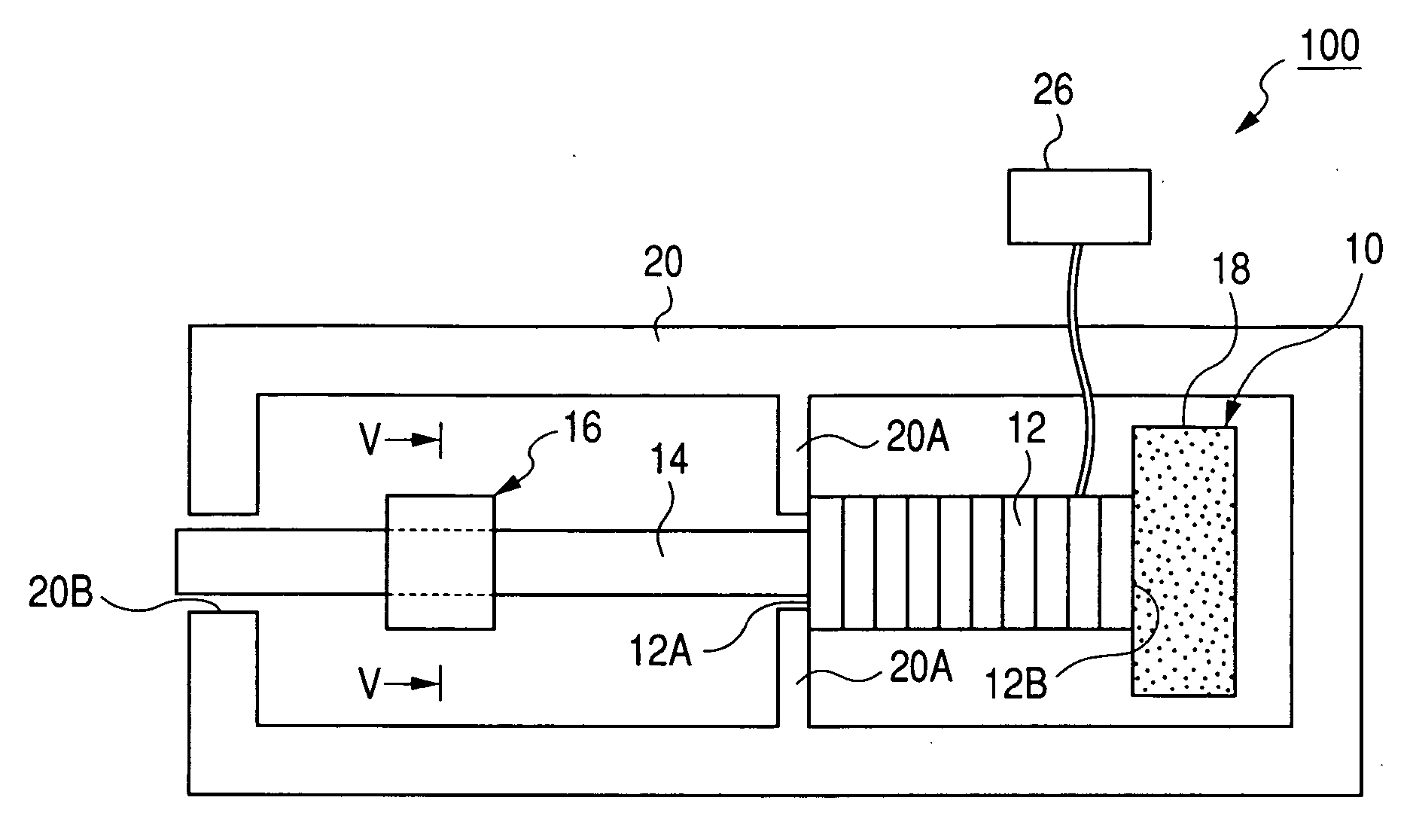

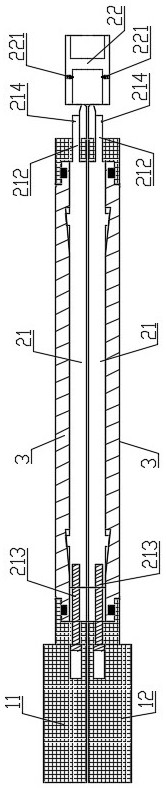

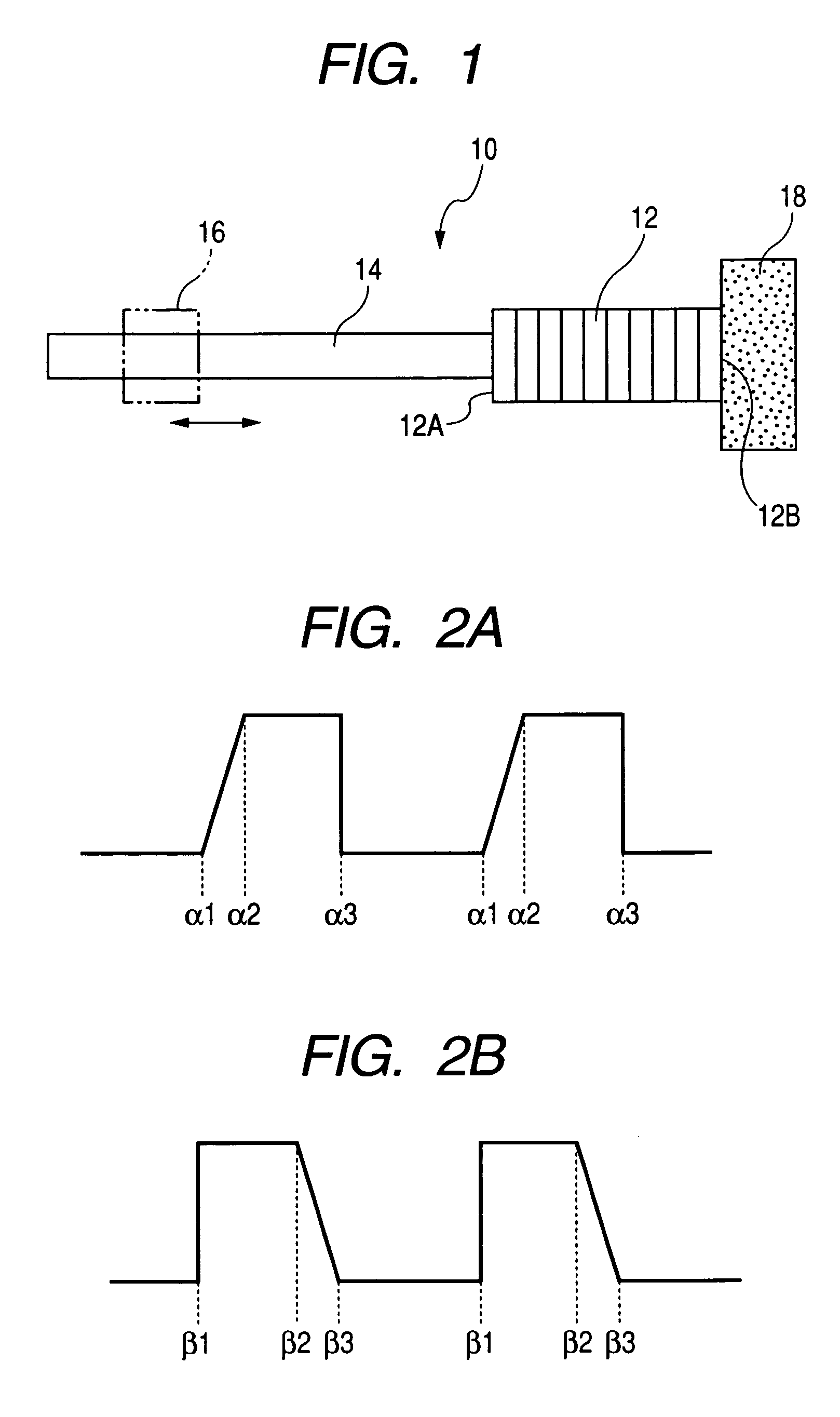

Driving mechanism, photographic mechanism and cellular phone

ActiveUS20060232169A1Driving and controlling driven accurately and stablyDriving force is stablePiezoelectric/electrostriction/magnetostriction machinesProjector focusing arrangementResonanceEngineering

A driving mechanism comprises: (i) an actuator comprising: an electro-mechanical conversion element; a driving member which is connected to one end of the electro-mechanical conversion element and moves in accordance with elongation or contraction of the electro-mechanical conversion element; and a weight member provided on the other end of the electro-mechanical conversion element; and (ii) a driven member frictionally engaged with the driving member, wherein the actuator allows the driven member to move along the driving member, and the weight member comprises a member which reduces a resonance frequency of the actuator.

Owner:FUJI PHOTO OPTICAL CO LTD

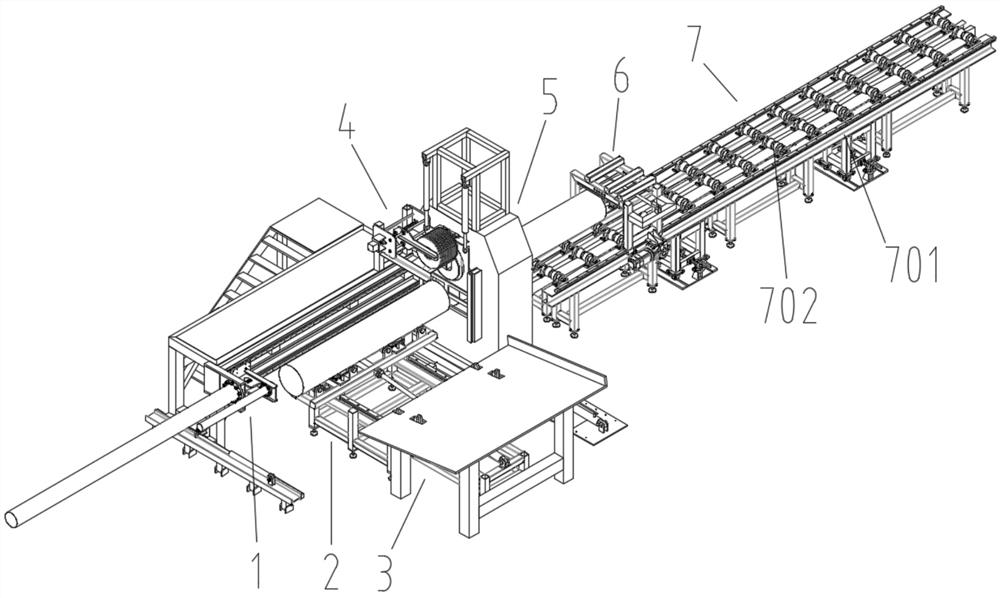

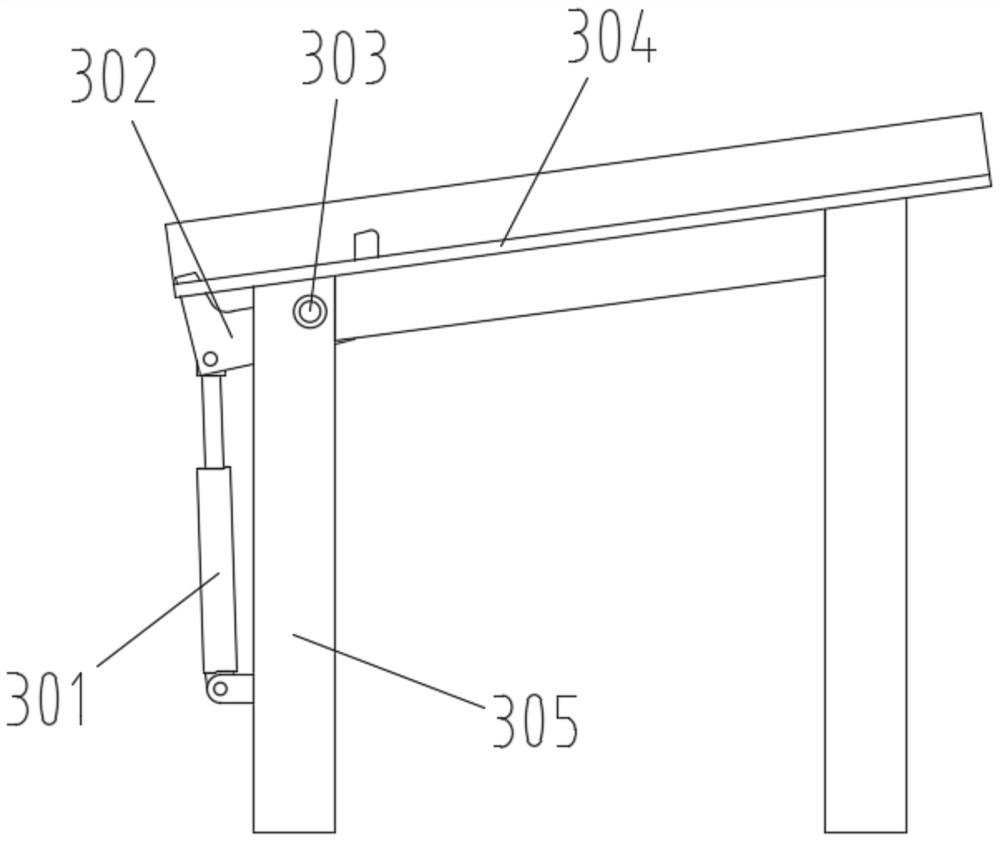

Graphite electrode grouping system

ActiveCN112224565AAccurate and stable movementReduce labor intensityPackagingGraphite electrodeEngineering

The invention relates to a graphite electrode grouping system, and relates to the technical field of graphite electrode graphitization production. The graphite electrode grouping system comprises a propelling device, a material piece transferring device, an electrode winding device and an electrode conveying device which are sequentially and correspondingly arranged, wherein the electrode conveying device comprises a conveying frame; conveying rollers are installed on the upper surface of the conveying frame; a discharging device is arranged outside the material piece transferring device; thematerial piece transferring device is used for transferring graphite electrodes unloaded by the discharging device to a position between the propelling device and the electrode winding device; the propelling device is used for pushing the graphite electrodes to the electrode winding device; a gasket feeding device is arranged above a position between the material piece transferring device and theelectrode winding device; a tail jacking device is mounted on the conveying frame; and the electrode winding device is used for clamping a fed graphite gasket between the corresponding ends of each two adjacent graphite electrodes, and laminating, packaging and fixing the graphite gasket and the two corresponding graphite electrodes. The graphite electrode grouping system can be suitable for various graphite electrode specifications, the grouping efficiency is greatly improved, and workers are thoroughly liberated.

Owner:HENAN WEIHUA HEAVY MACHINE

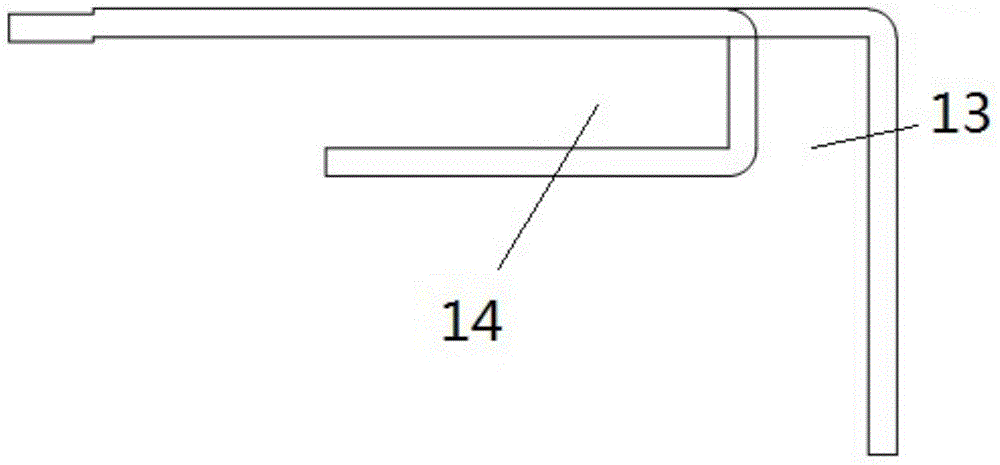

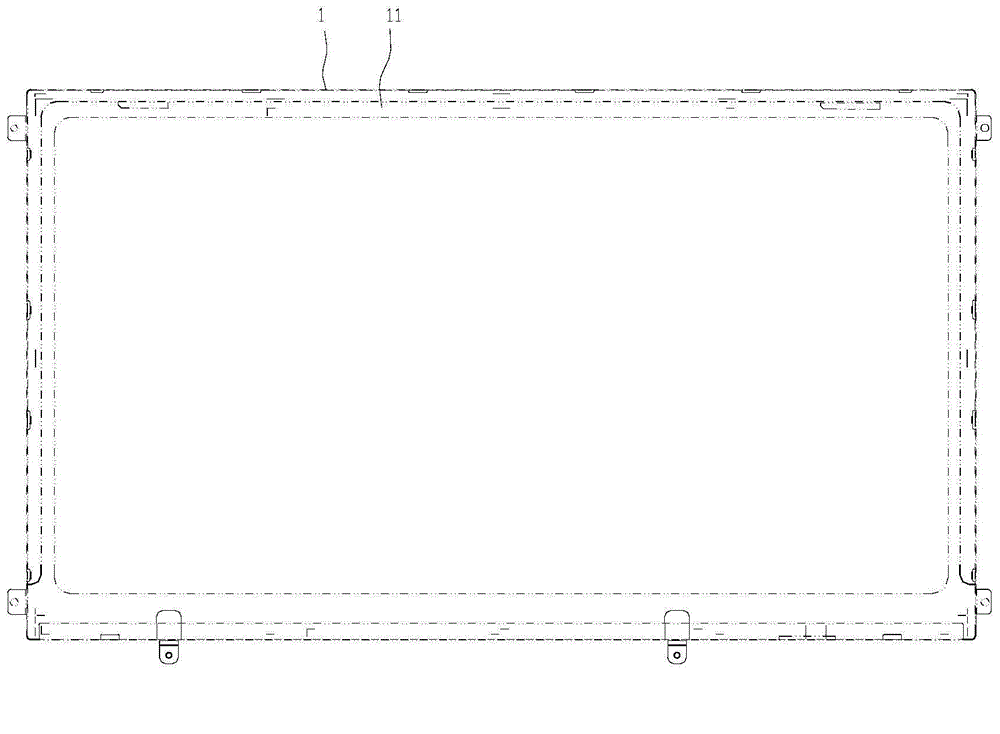

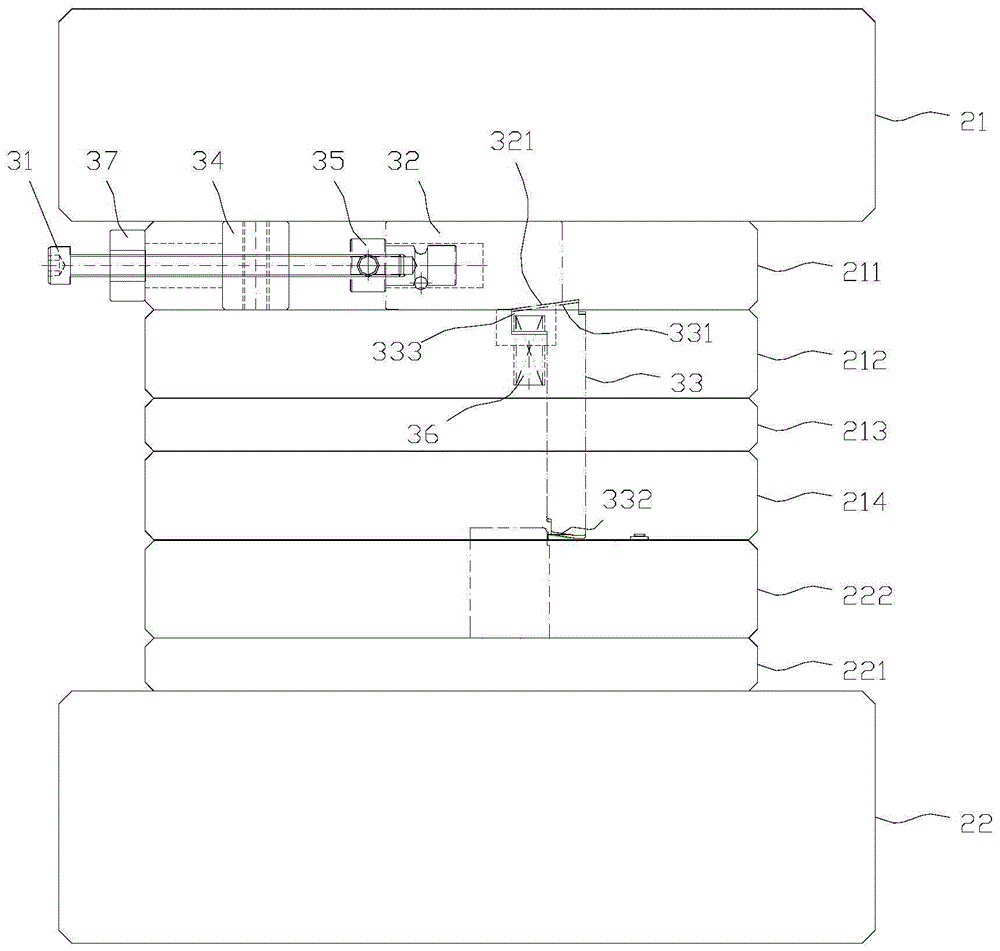

LED display backplane groove dressing die

The invention discloses an LED display backplane groove dressing die. The LED display backplane groove dressing die comprises an upper die base (21) and a dressing adjusting part (3) arranged under the upper die base (21); the dressing adjusting part (3) comprises an adjusting lead screw (31), an oblique die (32) and an adjusting punch (33); the adjusting lead screw (31) is transversely arranged on the lower end face of the upper die base (21) by use of a lead screw fixed block (34); the adjusting punch (33) is perpendicular to the adjusting lead screw (31); the oblique die (32) is arranged at the end portion of the adjusting lead screw (31) by use of a ball roller (35); the left end of the ball roller (35) is fixedly connected with the end portion of the adjusting lead screw (31); the right end of the ball roller (35) is arranged in the oblique die (32) and capable of rotating relatively to the oblique die (32). The adjusting lead screw directly provides acting force to the oblique die in a linear manner and then the oblique die controls the adjusting punch to move; the LED display backplane groove dressing die has the advantages of stable force transfer and accurate oblique die motion.

Owner:JIANGSU FANRUN ELECTRONICS

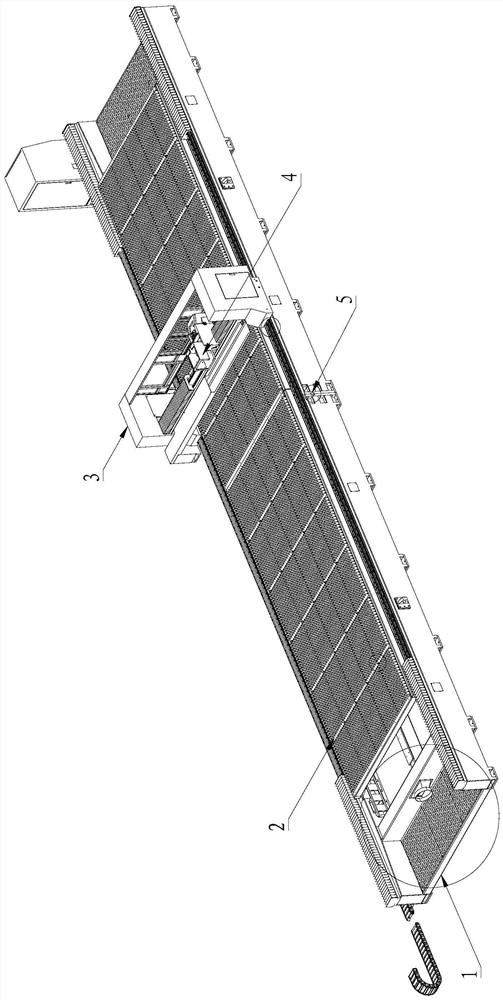

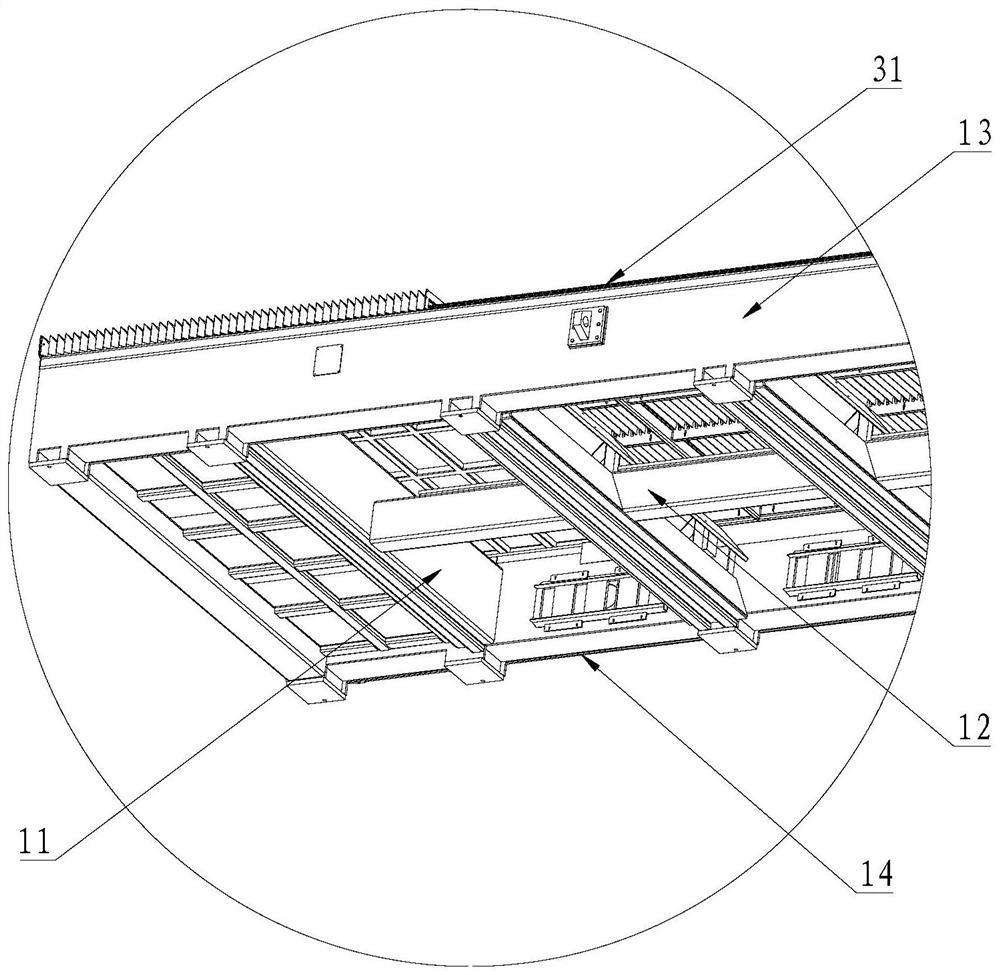

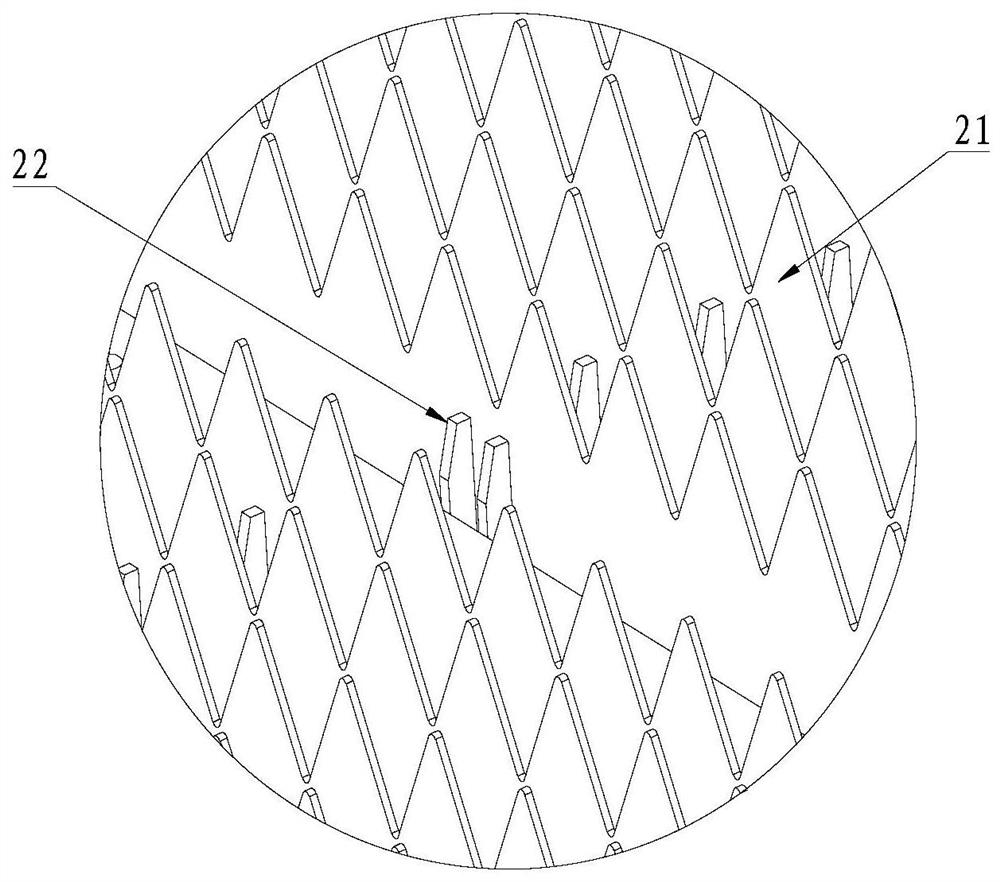

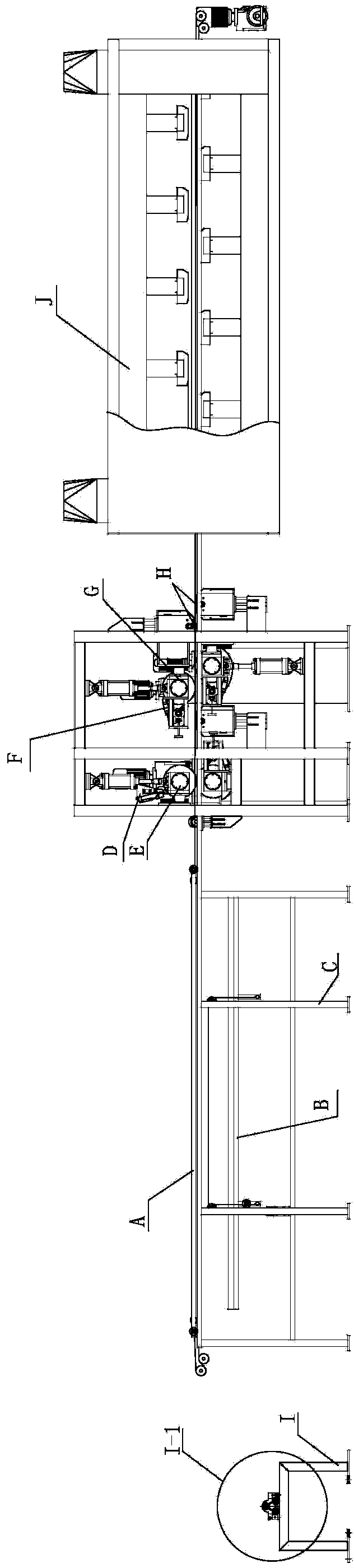

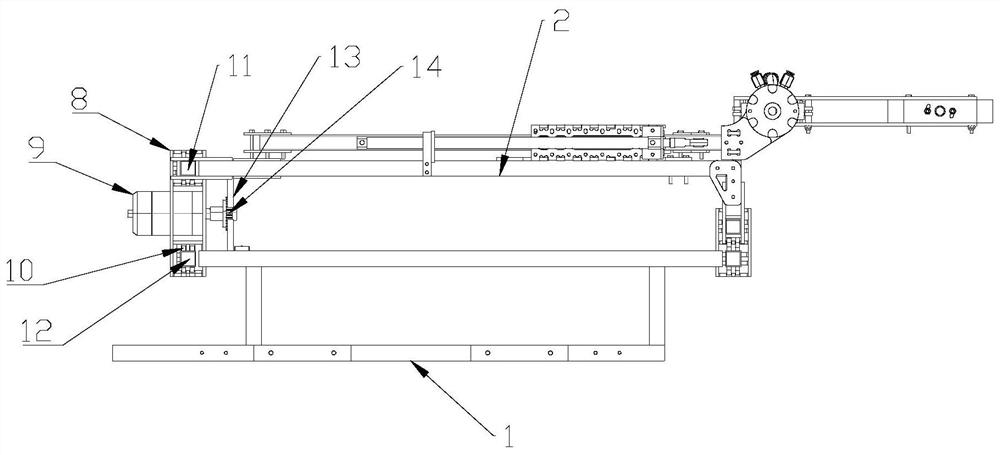

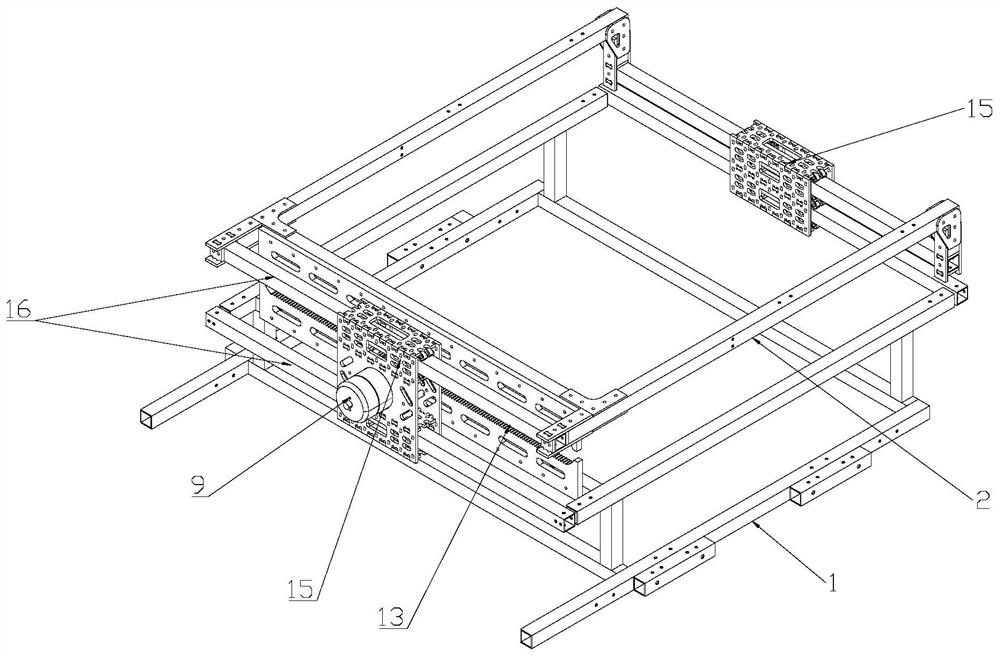

Large-breadth laser cutting machine

ActiveCN112059433AEasy to install, remove and replaceGuaranteed horizontal accuracyLaser beam welding apparatusPhysicsElectric machinery

The invention relates to the technical field of laser cutting equipment, in particular to a large-breadth laser cutting machine which comprises a machine tool, and a material supporting mechanism, a gantry mechanism, a cutting mechanism, position adjusting mechanisms, a heat insulation mechanism and a dust removal mechanism respectively arranged on the machine tool. The rack comprises a main crossbeam, a main longitudinal beam, a first boundary beam and a second boundary beam; the material supporting mechanism comprises a first material frame and a second material frame; the gantry mechanismcomprises a first rack, a gantry, a first motor, a second rack and a guide rail; the cutting mechanism comprises a moving frame, a second motor and a laser cutting machine, the moving frame is slidably connected with the guide rail, the second motor is arranged on the moving frame, the second motor is connected with the second rack through a gear, and the laser cutting machine is installed on themoving frame; and the two sets of position adjusting mechanisms are symmetrically arranged on the first boundary beam and the second boundary beam. The large-breadth laser cutting machine provided bythe invention can adapt to the cutting machining of large-breadth plates, and is high in precision and good in effect.

Owner:CHINA MACHINERY CNC TECH FUJIAN CO LTD

Impregnation proofing press

ActiveCN104190590AQuality improvementAchieve normal functionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to an impregnation proofing press, aiming to provide an impregnation proofing press which can be used for proofing by using finished pattern paper of small size so as to save printing paper and has the characteristics of high production efficiency, convenience in use, accurate result and simple structure. According to the technical scheme, the impregnation proofing press is characterized by comprising a reciprocating drying mechanism consisting of a guide rail, a printing paper tightening mechanism, a traction mechanism and a drying oven, and also comprises a lifting rubber tank, a vertical action metering roller component, a gluing roller component and a flattening roller, which are sequentially arranged on a rack from front to back along the guide rail, wherein the lifting rubber tank is arranged below the front part of the guide rail; the guide rail is horizontally fixed on the top of the rack along the front and back directions; the drying oven is fixed on the rack and at the rear part of the guide rail; the printing paper tightening mechanism is arranged on the guide rail through multiple rollers; and the traction mechanism drives the printing paper tightening mechanism to move back and forth in the guide rail in a reciprocating mode.

Owner:LINAN NANYANG DECORATIVE PAPER

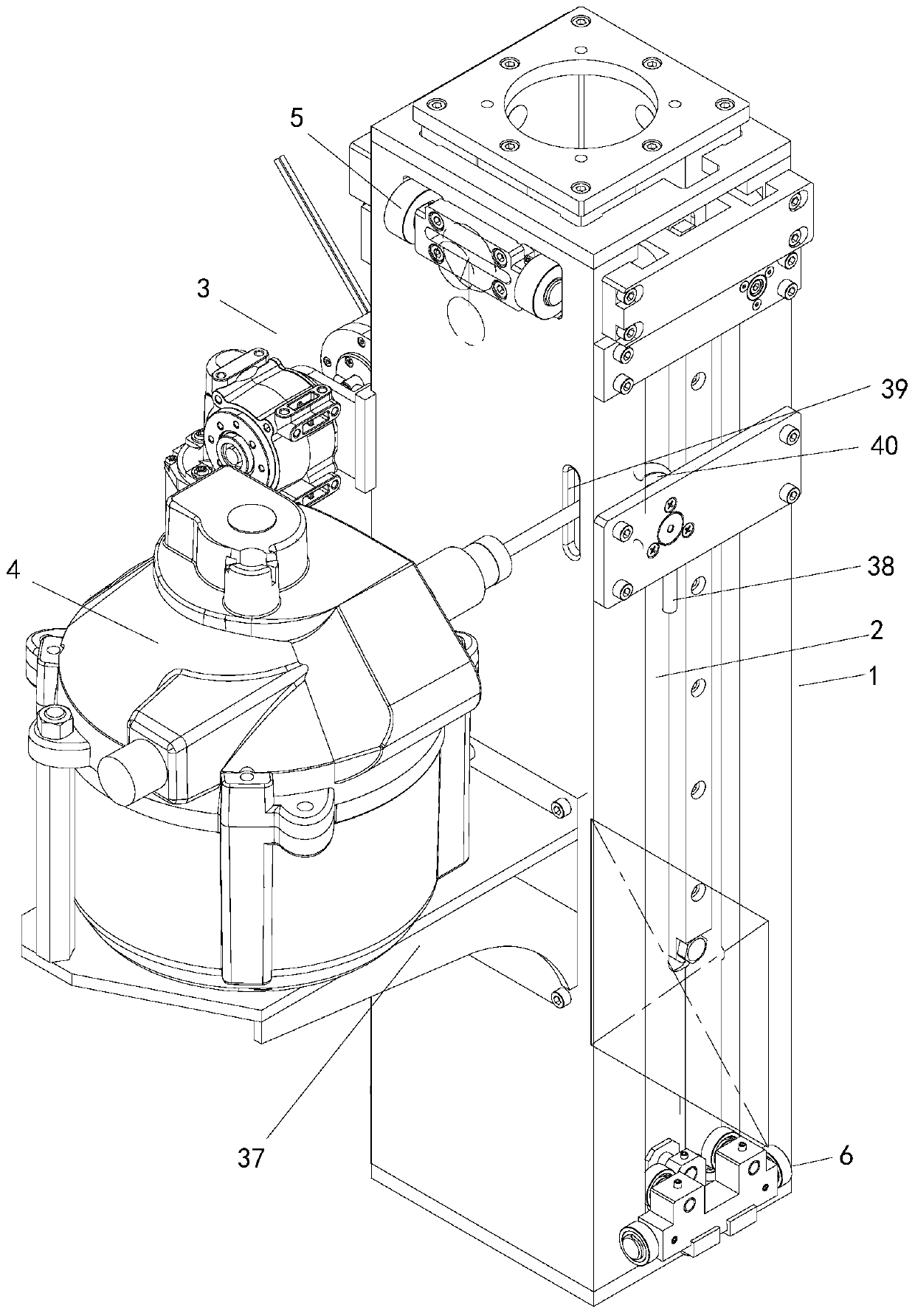

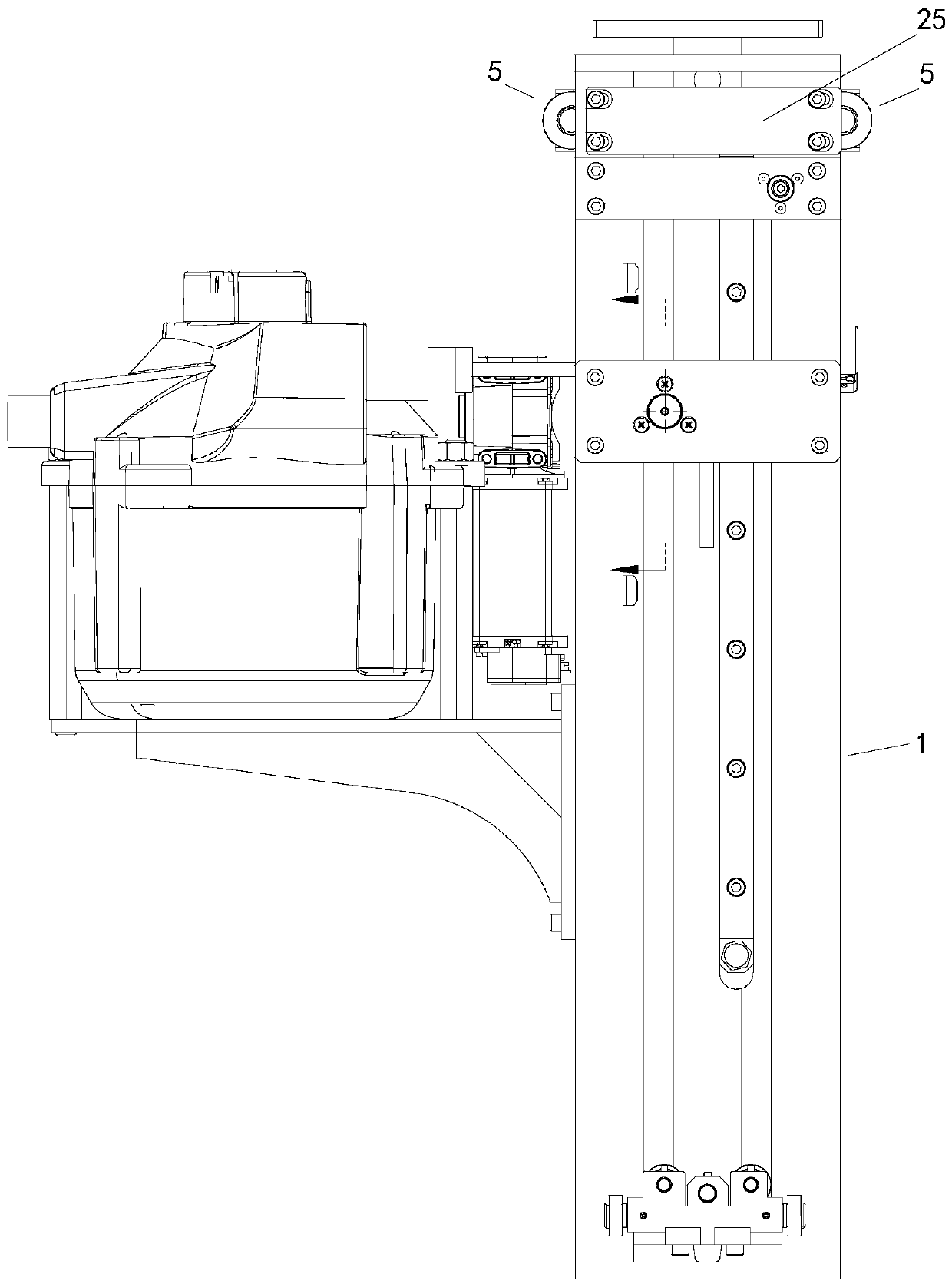

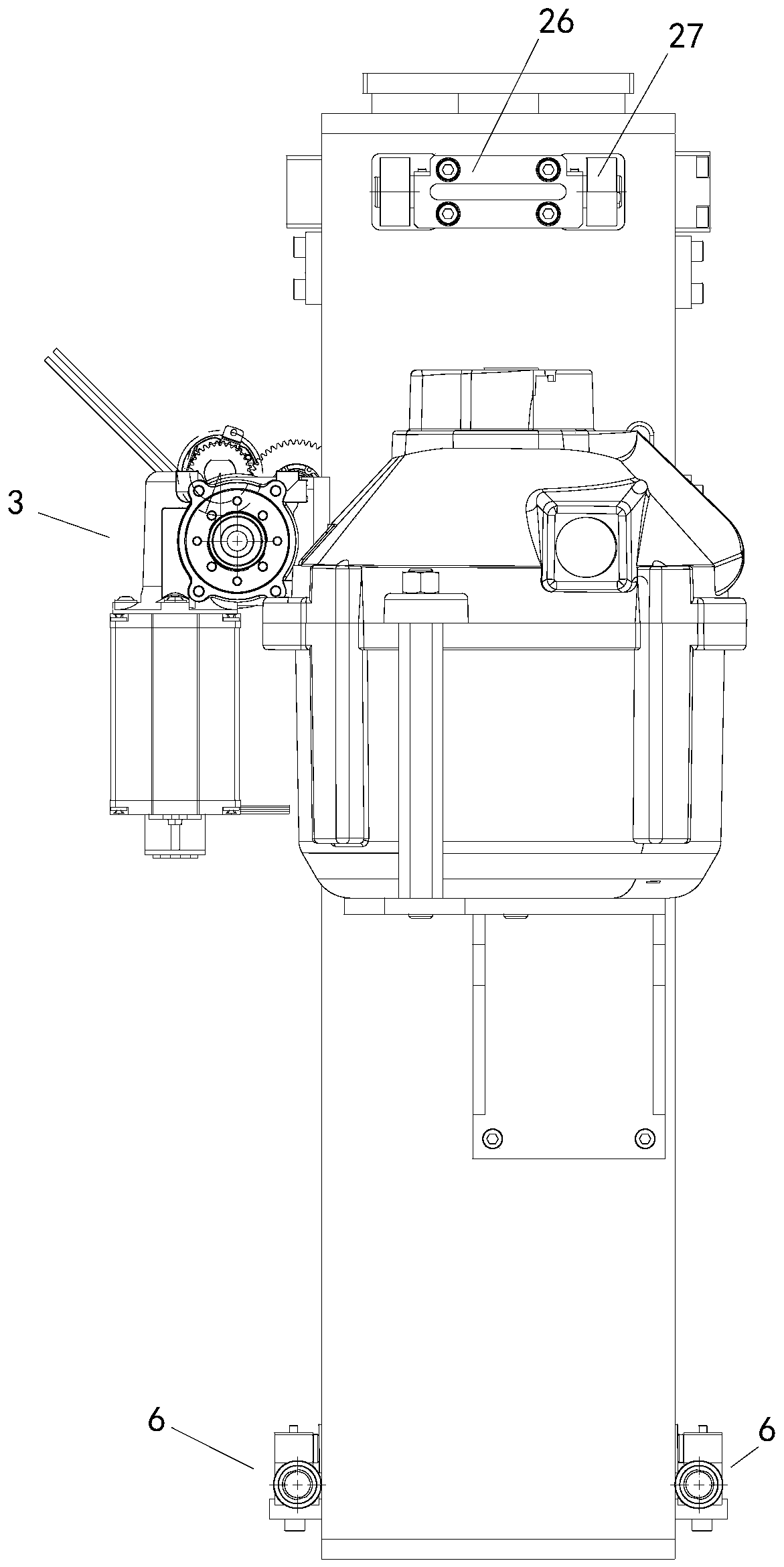

Vertical lifting stand column integrating manual operation and automation

PendingCN110974264AMove preciselyPrecise and stable movementRadiation diagnosticsPull forceControl engineering

The invention relates to a vertical lifting stand column integrating manual operation and automation. The lifting stand column comprises a lifting stand column outer cylinder and a lifting stand column inner cylinder. A guide mechanism is arranged between the lifting stand column outer cylinder and the lifting stand column inner cylinder. A driving mechanism and a balancer are arranged on the lifting stand column outer cylinder. The balancer enables the lifting stand column inner cylinder and borne unbalance loading force bearing to be in a balanced state with balancer tension in the lifting action process of the lifting stand column inner cylinder. The stand column adopts an inner-outer cylinder telescopic structure. The driving mechanism drives the inner cylinder to ascend and descend and passes through the guide mechanism. Accurate movement of the inner cylinder relative to the outer cylinder is realized. The energy storage function of the volute spring of the balancer is applied toovercome the F unbalance loading force bearing with the unbalance distance about 0.8 m. The unbalance loading force bearing and the balancer tension are in a balanced state, so that the functions ofpausing and staying at any position can be realized manually. The energy storage inertia of the balancer volute spring is only about 5% of the rated bearing capacity of the balancer volute spring during electric operation, so that the balancer volute spring is driven by a friction clutch with smaller torque force to stably and accurately move up and down without shaking.

Owner:赵正龙

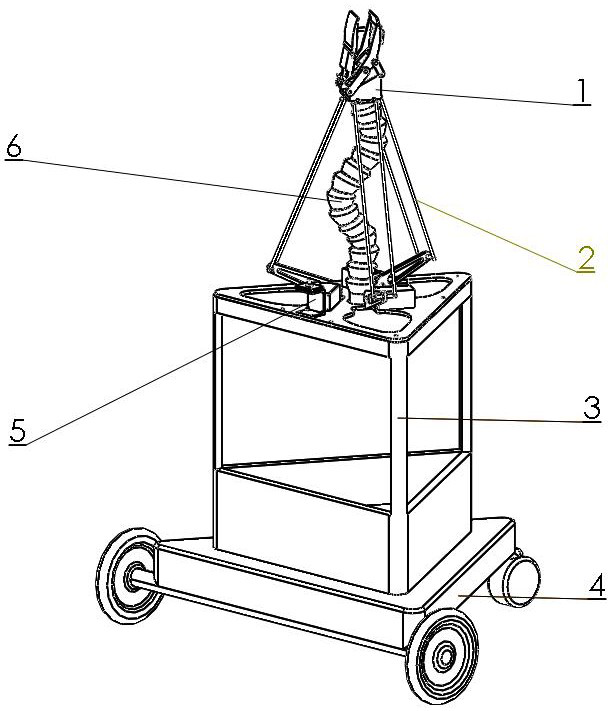

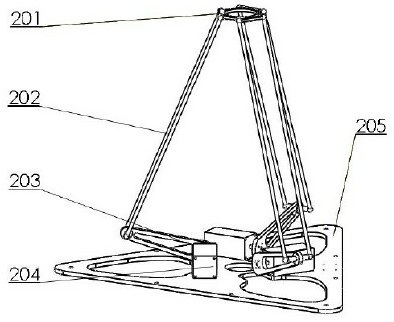

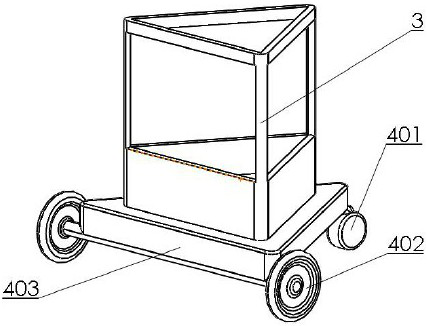

Kiwi fruit picking device based on Delta mechanical arm

PendingCN112917481AEfficient collectionAvoid damageProgramme-controlled manipulatorPicking devicesVehicle frameAgricultural engineering

The invention discloses a kiwi fruit picking device based on a Delta mechanical arm, and belongs to the field of fruit product picking mechanical equipment. The kiwi fruit picking device comprises six parts including a picking hand, Delta arms, a moving chassis, a vehicle frame, an identifying camera, a flexible collecting pipe and the like. The kiwi fruit picking device is characterized in that a base of the picking hand is fixedly connected with a moving platform of the Delta mechanical arm; a static platform of the Delta mechanical arm is fixedly connected with the upper end plane of the vehicle frame; the lower end plane of the vehicle frame is fixedly connected with a profile rack of the moving chassis; the camera support is fixedly connected with the static platform of the Delta mechanical arm; the upper end of the flexible collecting pipe is fixedly connected with the base of the picking hand; and the lower end of the flexible collecting pipe is inserted into a circular through hole of the static platform of the Delta mechanical arm. The kiwi fruit picking device is reliable in structure, efficient in operation, high in automation degree, is high in intelligence, is reduced in a large quantity of manpower costs, and has strong research and practical values.

Owner:NORTHWEST A & F UNIV

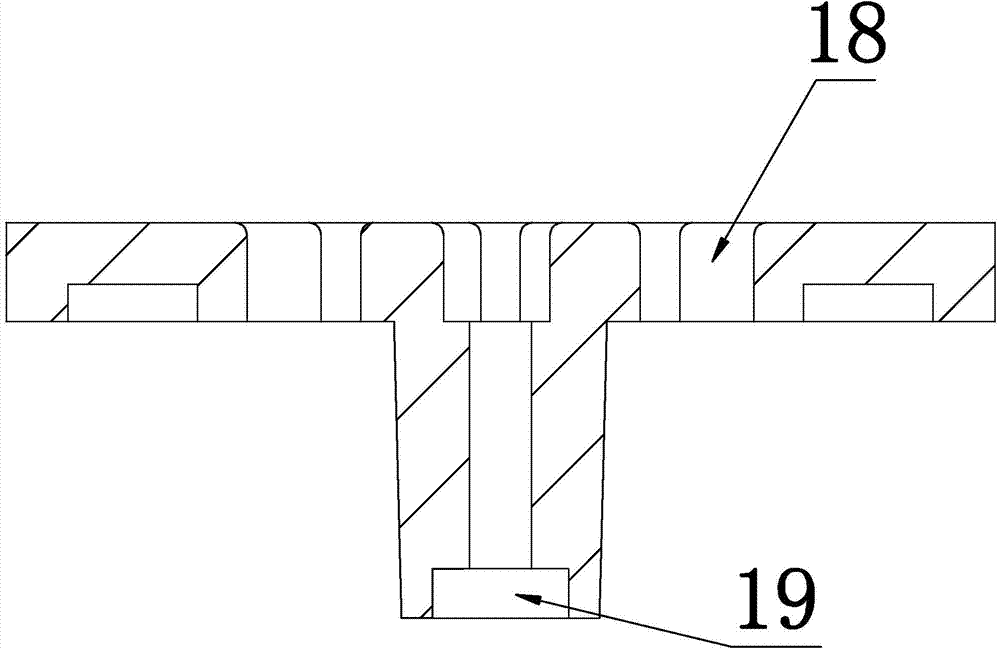

Winding needle outer perimeter adjusting device, winding machine and winding needle outer perimeter adjusting method

PendingCN113224367AReduce labor maintenance costsImprove precision and flexibilityPrimary cell manufactureAssembling battery machinesWinding machineElectrical and Electronics engineering

The invention relates to a winding needle outer perimeter adjusting device, a winding machine and a winding needle outer perimeter adjusting method. The adjusting device comprises a winding needle main body, a driving assembly and at least one variable-diameter sliding block; the variable-diameter sliding block is arranged on the periphery of the winding needle main body, can slide along the radial direction of the winding needle main body, and is provided with a driving slope which forms an included angle in the axial direction of the winding needle main body; the driving assembly comprises a push block and a push block driving piece, and the push block is provided with an adjusting part abutting against the driving slope; and the push block driving piece is arranged at one end of the winding needle main body, can slide along the axial direction of the winding needle main body and pushes the push block to slide along the axial direction of the winding needle main body, so that the adjusting part slides along the driving slope and further drives the variable-diameter sliding block to slide along the radial direction of the winding needle main body. The adjusting device is simple in structure and convenient to use, and can automatically and continuously adjust the outer perimeter of the winding needle.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

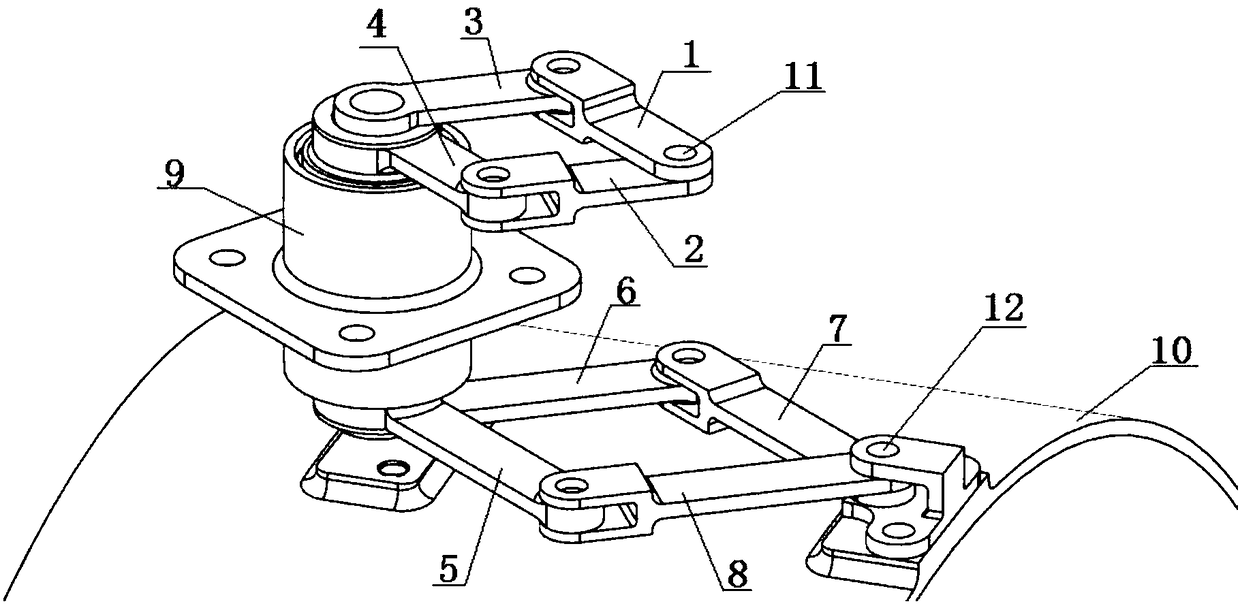

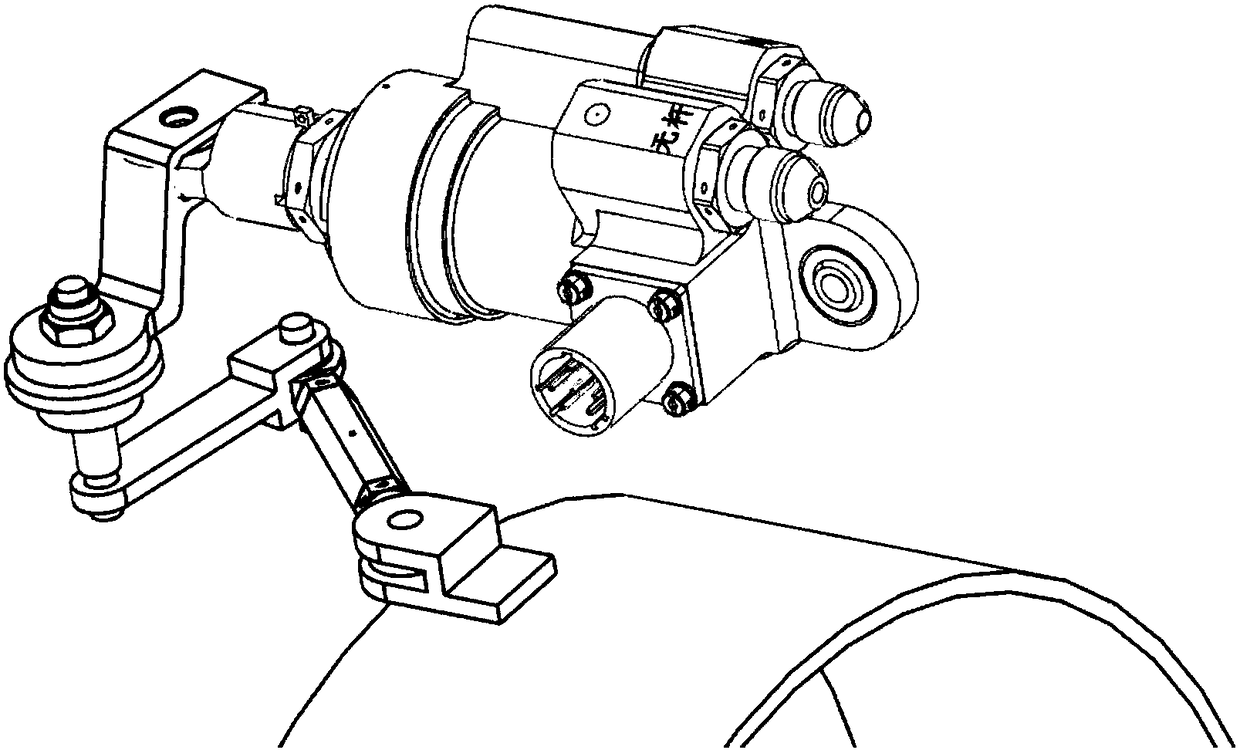

Driving structure for regulating area of external culvert

ActiveCN108561243AEasy to movePrecise and stable movementJet propulsion plantsFour-bar linkageStable system

The invention provides a driving structure for adjusting the area of an outer culvert. The driving structure comprises a sliding cylinder (10), an upper four-bar mechanism and a lower four-bar mechanism, wherein the sliding cylinder (10) is located at an outlet of the outer culvert, the sliding cylinder (10) axially moves to change the area of the outlet of the outer culvert, the upper four-bar mechanism is connected with an actuating cylinder, the lower four-bar mechanism is connected with the sliding cylinder (10), and the upper four-bar mechanism and the lower four-bar mechanism are connected through a coaxial connection. The driving structure controls the smooth and accurate axial movement of the outer culvert way sliding cylinder, limits the freedom of the sliding cylinder through theapplication of a symmetrical crank-connecting rod mechanism, and has the advantages of unique movement direction, good displacement precision, stable system, rapid reaction and no clamping stagnation.

Owner:AECC SICHUAN GAS TURBINE RES INST

Driving mechanism, photographic mechanism and cellular phone

ActiveUS7650066B2Driving force is stableLower resonance frequencyPiezoelectric/electrostriction/magnetostriction machinesProjector focusing arrangementResonanceEngineering

A driving mechanism comprises: (i) an actuator comprising: an electro-mechanical conversion element; a driving member which is connected to one end of the electro-mechanical conversion element and moves in accordance with elongation or contraction of the electro-mechanical conversion element; and a weight member provided on the other end of the electro-mechanical conversion element; and (ii) a driven member frictionally engaged with the driving member, wherein the actuator allows the driven member to move along the driving member, and the weight member comprises a member which reduces a resonance frequency of the actuator.

Owner:FUJI PHOTO OPTICAL CO LTD

Multi-point clamping device and robot for picking up articles

PendingCN113084779APrecise and stable movementShort timeProgramme-controlled manipulatorGripping headsStructural engineeringControl theory

The invention relates to a multi-point clamping device which comprises an upper-layer frame, a lower-layer frame, a left-right sliding mechanism, a front-back telescopic mechanism, a front-back turnover mechanism, a left-right opening and closing mechanism and a clamping mechanism. The left-right sliding mechanism comprises double-layer tackles and a left-right sliding component driving the upper-layer frame to slide in the left-right direction relative to the lower-layer frame. The upper-layer frame is arranged on the lower-layer frame through the double-layer tackles, and the two double-layer tackles are located at the front end and the rear end of the upper-layer frame respectively. The upper-layer frame is connected with the left-right sliding component, and the lower-layer frame is connected with the left-right sliding component. The front-back telescopic mechanism is installed on the upper-layer frame, the front-back turnover mechanism is installed on the front-back telescopic mechanism, the left-right opening and closing mechanism is installed on the front-back turnover mechanism, and the clamping mechanism for clamping articles is installed on the left-right opening and closing mechanism. The invention further relates to the robot for picking up articles. The structure is simple and reliable, and a plurality of articles at the determined positions can be automatically clamped in sequence. The invention belongs to the field of article carrying instruments.

Owner:SOUTH CHINA UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com