Impregnation proofing press

A technology of proofing machine and dipping, which is applied in the directions of coating and coating liquid on the surface, etc., can solve the problems of uneven glue, small size of finished sample paper, and high running cost of production line, and achieves convenient operation and maintenance. Production cost, the effect of improving the quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

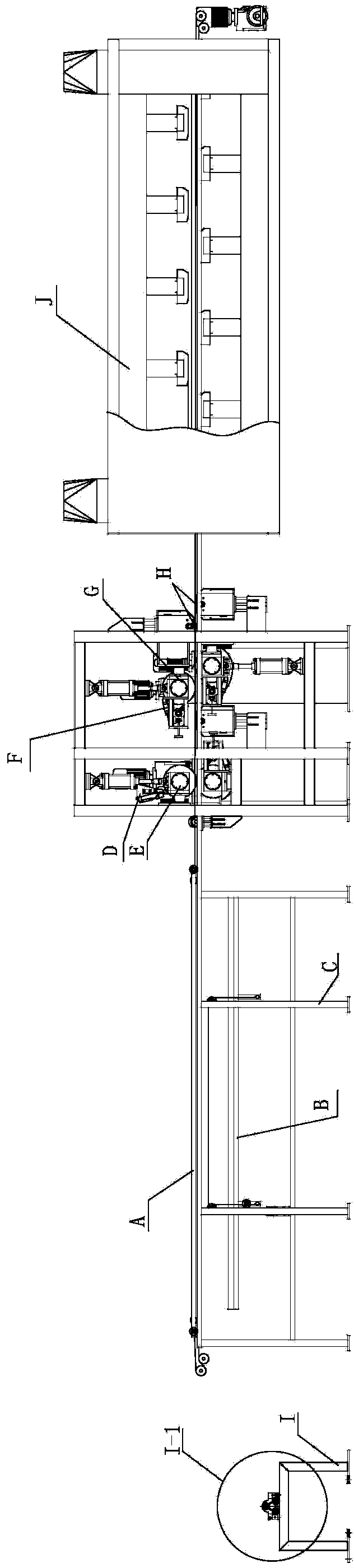

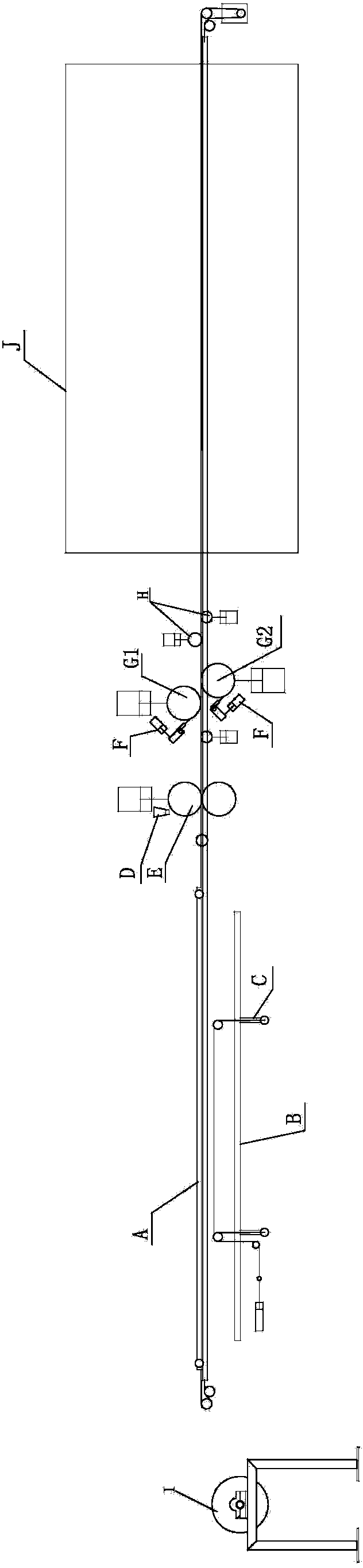

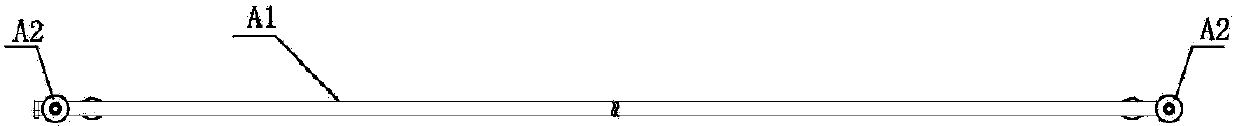

[0051] Such as figure 1 , figure 2 As shown, the dipping and proofing machine of the present invention includes a reciprocating drying mechanism J composed of a guide rail C-1, a printing paper tensioning mechanism A, a traction mechanism, and an oven J4. Finally, the lifting rubber tank B, the vertical action metering roller assembly, the upper rubber roller assembly and the smoothing roller H (one upper smoothing roller, one lower smoothing roller, and the finished sample paper between them) are installed on the frame in sequence channel), wherein the lifting glue tank is installed under the front of the guide rail, and the uncoiler I of the finished sample paper I-1 is installed in front of the frame. There are two guide rails, which are parallel to each other and fixed horizontally on the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com