Safety valve

A safety valve and valve seat technology, applied in the field of safety valves, can solve problems such as inconvenient production and later maintenance, difficult adjustment of elastic force, and difficulty in disassembly and assembly, so as to facilitate production and later maintenance, improve production efficiency and product quality, and adjust easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

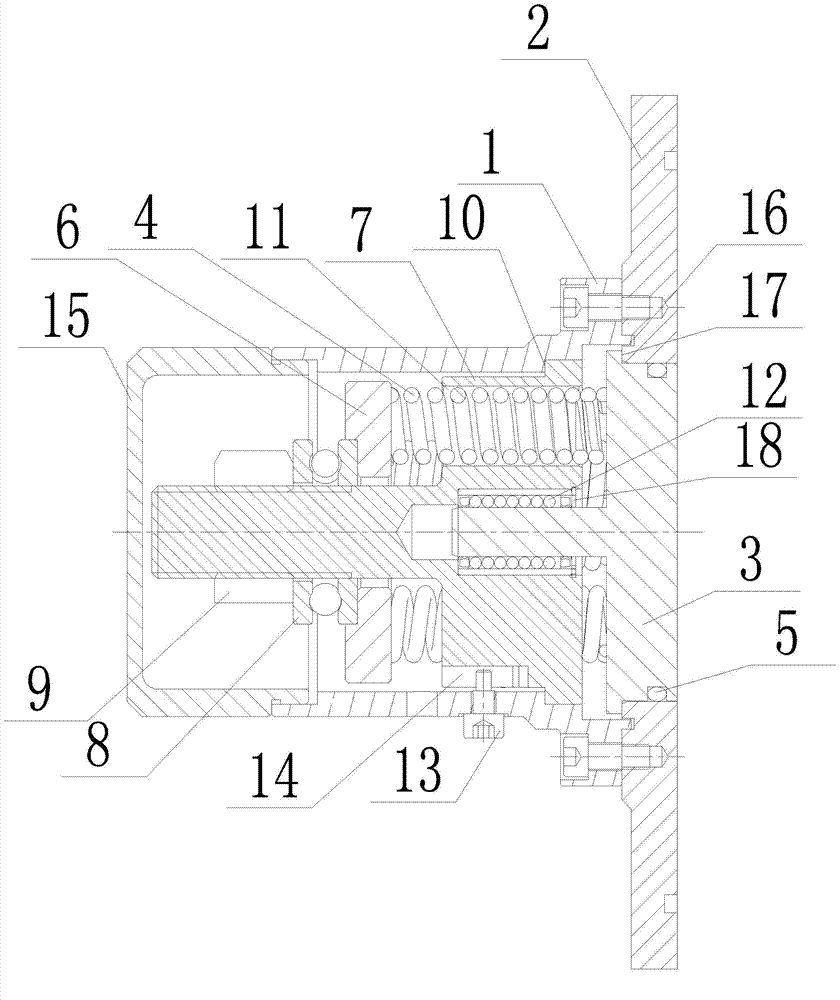

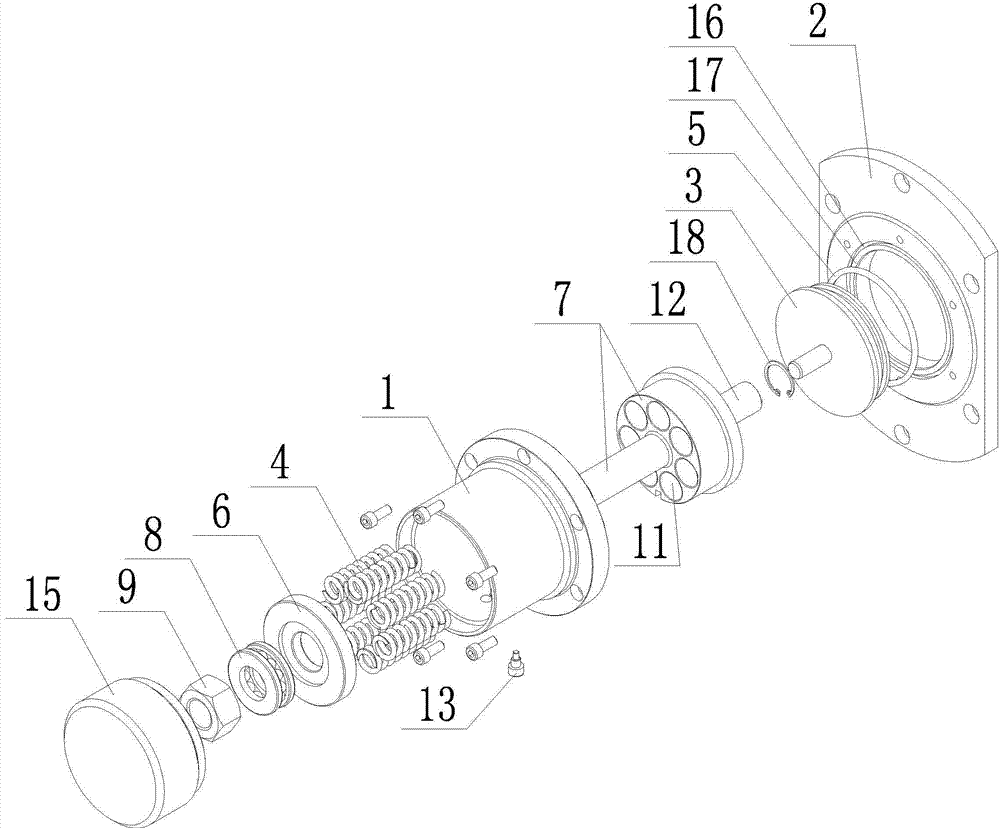

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] The safety valve of the present invention comprises a valve seat 1, a valve body 2, a valve core 3, and a spring 4, the valve core 3 is movably matched with the valve body 2, a sealing ring 5 is arranged between the valve core 3 and the valve body 2, and it also includes Spring seat 6, spring guide seat 7, plane bearing 8, adjusting nut 9, plane bearing 8, spring seat 6 are sequentially movably fitted on spring guide seat 7, and the spring guide part of spring guide seat 7 is located between spring seat 6 and spool 3, the valve core 3 is located on the right side of the spring guide part, the spring guide seat 7 is movably fitted with the valve seat 1, and the valve seat 1 is provided with a first limit structure 10 for the left limit of the spring guide seat 7, and the spring seat 6 and the spool 3 are provided with at least two springs 4, each spring 4 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com