Driving structure for regulating area of external culvert

A driving structure and area adjustment technology, which is applied in the direction of machines/engines, jet propulsion devices, etc., can solve problems such as low safety factor, easy sticking, and non-unique rotation degrees of freedom of the sub-slider.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

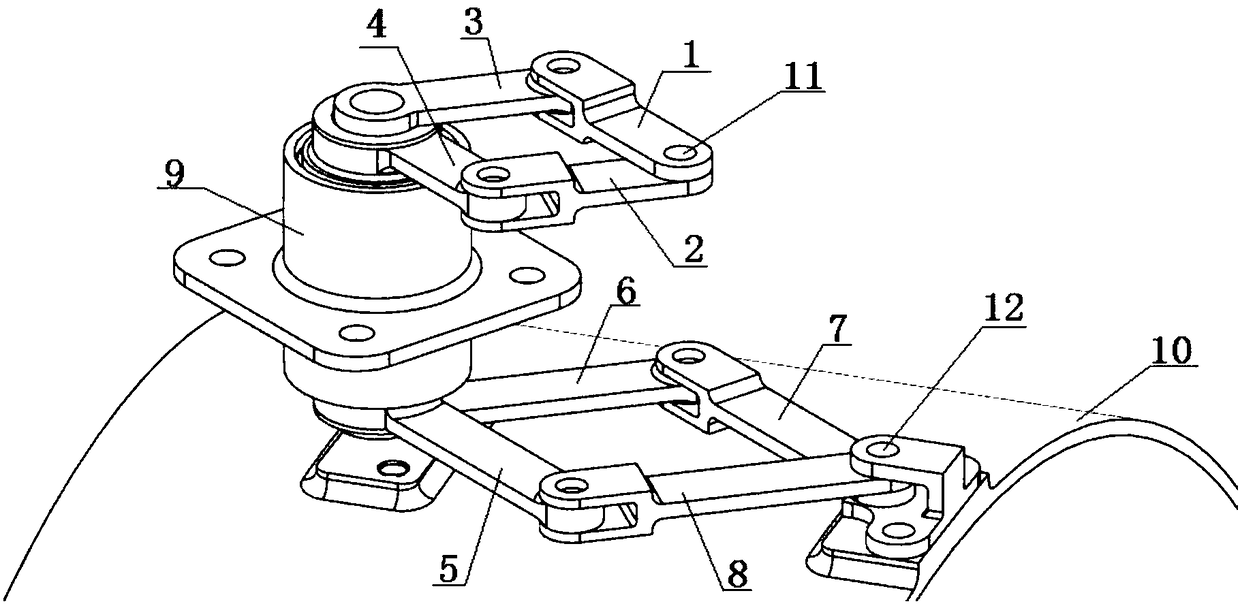

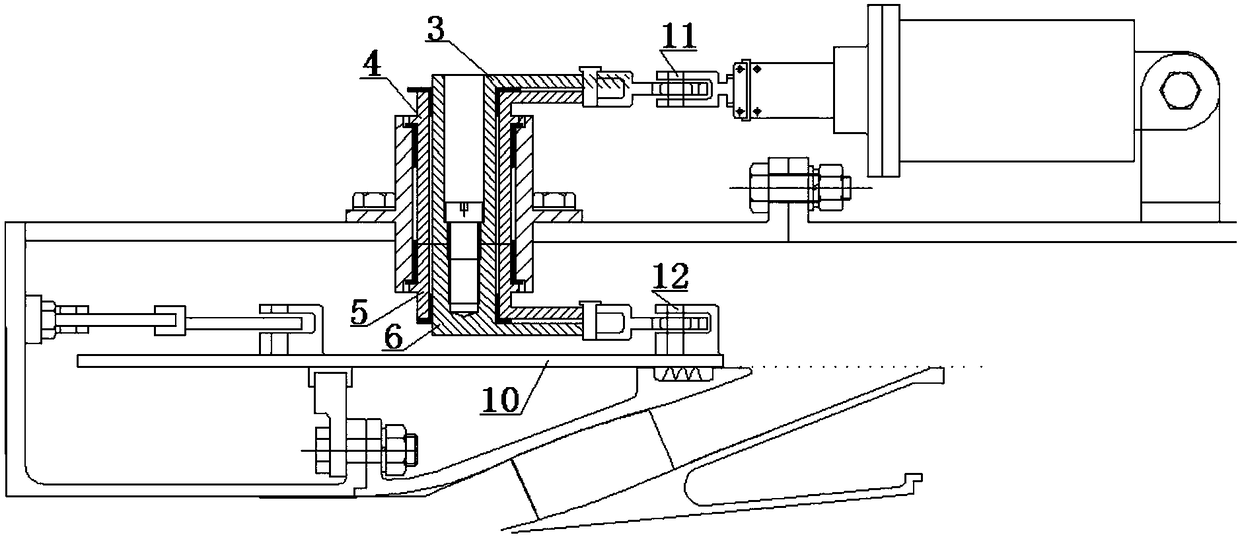

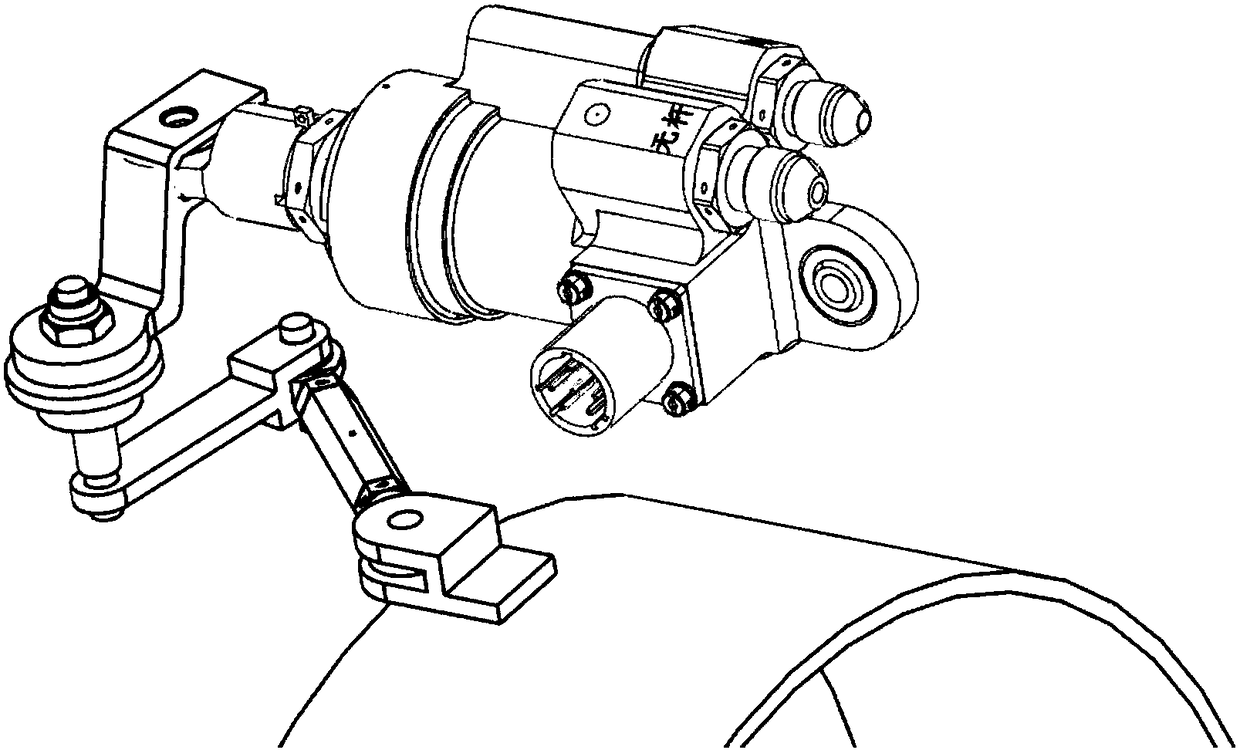

[0018] The first upper connecting rod 1, the second upper connecting rod 2, the third upper connecting rod 3, and the fourth upper connecting rod 4 constitute the first quadrilateral connecting rod, because the mounting base 9 is fixed. Therefore, when the actuator pushes the hinge point 11 of the first upper link 1 and the second upper link 2 to move axially, the third upper link 3 rotates counterclockwise, the fourth upper link 4 rotates clockwise, and the first The third upper link 3 is coaxial with the second lower link 6, and the fourth upper link 4 is coaxial with the first lower link 5, so the second lower link 6 rotates counterclockwise, and the crank 5 rotates clockwise. The first lower link 5, the second lower link 6, the third lower link 7, and the fourth lower link 8 form another quadrilateral structure. According to a similar ratio, the connecting seat 12 will also move axially, and the ratio of the displacement of the actuator to the displacement of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com