Method for founding aluminium alloy slab ingot

A process method and aluminum alloy technology, applied in the field of aluminum alloy flat ingot melting and casting process, can solve the problems such as the difficulty in guaranteeing the manufacturing quality of aluminum ingots, and the easy cracking of aluminum ingots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

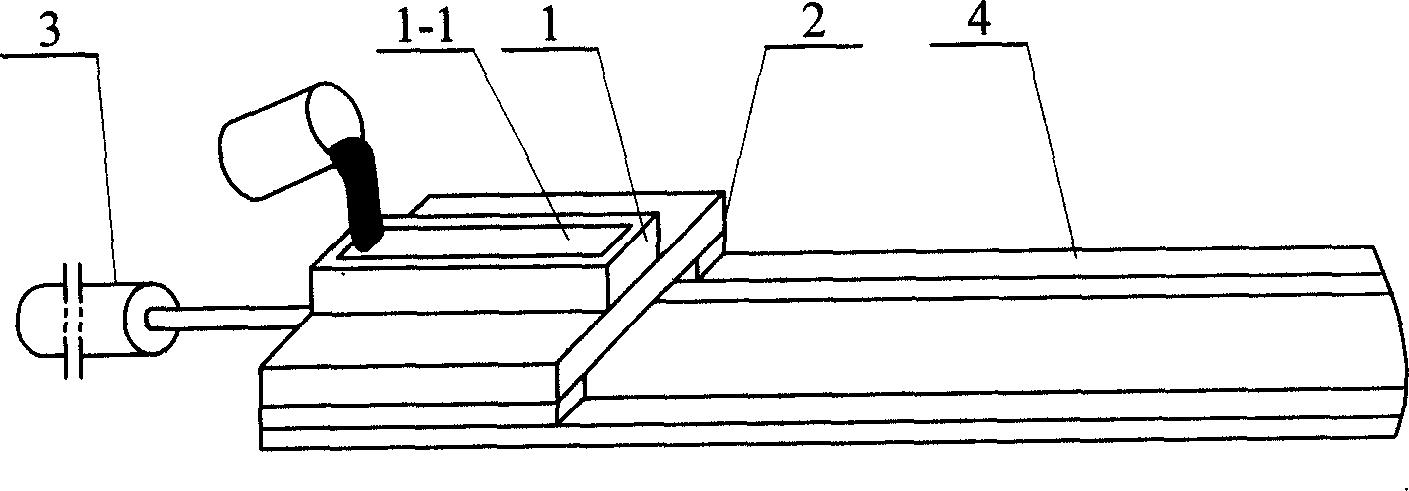

[0005] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment is realized by the following steps: 1. Heat the alloy raw material to 740-760°C, stir and remove slag while heating, and control the mass percentage of each element in the alloy to be Si: 0.60-0.8%, Fe: 0.4- 0.7%, Cu: 0.15~0.40%, Mn: 0~0.15%, Mg: 0.8~1.2%, Cr: 0.04~0.35%, Zn: 0~0.25%, Ti: 0~0.15%, other individual impurities≤0.05% %, the total of other impurities ≤ 0.10%, and the rest is Al; 2. Introduce chlorine gas to the bottom of the alloy melt while keeping the temperature of the alloy melt at 700-740°C for 25-35 minutes, then let it stand for 15-25 Minutes; 3. Pouring the alloy melt into one end of the elongated cavity 1-1 of the ingot mold 1, the ingot mold 1 is placed on the sliding platform 2 driven by the hydraulic system 3, and the sliding platform 2 is on the guide rail 4, the ingot mold 1 moves with the sliding platform 2, a...

specific Embodiment approach 2

[0006] Specific embodiment two: the difference between this embodiment and embodiment one is: in step 3, when sliding platform 2 moves distance from 0 to 90 millimeters, the moving speed of sliding platform 2 is 50 millimeters / minute, the moving of sliding platform After the distance is greater than 90 mm, the moving speed becomes 55 mm / min. Such setting makes the initial contact speed of the alloy melt with the ingot mold 1 relatively slow, avoiding the stress of uneven shrinkage in the ingot caused by too fast cooling rate at the beginning, and reducing the occurrence of cracks.

specific Embodiment approach 3

[0007] Specific embodiment three: the difference between this embodiment and embodiment one is: in step one, the alloy raw material is heated to 740°C, stirring and slag removal are carried out while heating, and the mass percentage of each element in the alloy is controlled as Si: 0.60%, Fe: 0.4%, Cu: 0.15%, Mg: 0.8%, Cr: 0.04%, and the rest are Al; in step 2, feed chlorine gas to the bottom of the alloy melt while keeping the temperature of the alloy melt at 700 ℃ for 25 minutes, and then stand for 15 minutes; other steps are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com