Light single-wheel spinning device for aluminum alloy wheel

A spinning equipment, aluminum alloy technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of unsuitable development needs of small aluminum alloy wheels, high maintenance costs, high prices, etc., to solve the problem of manual demoulding Dangerous or imprecise, improved precision, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

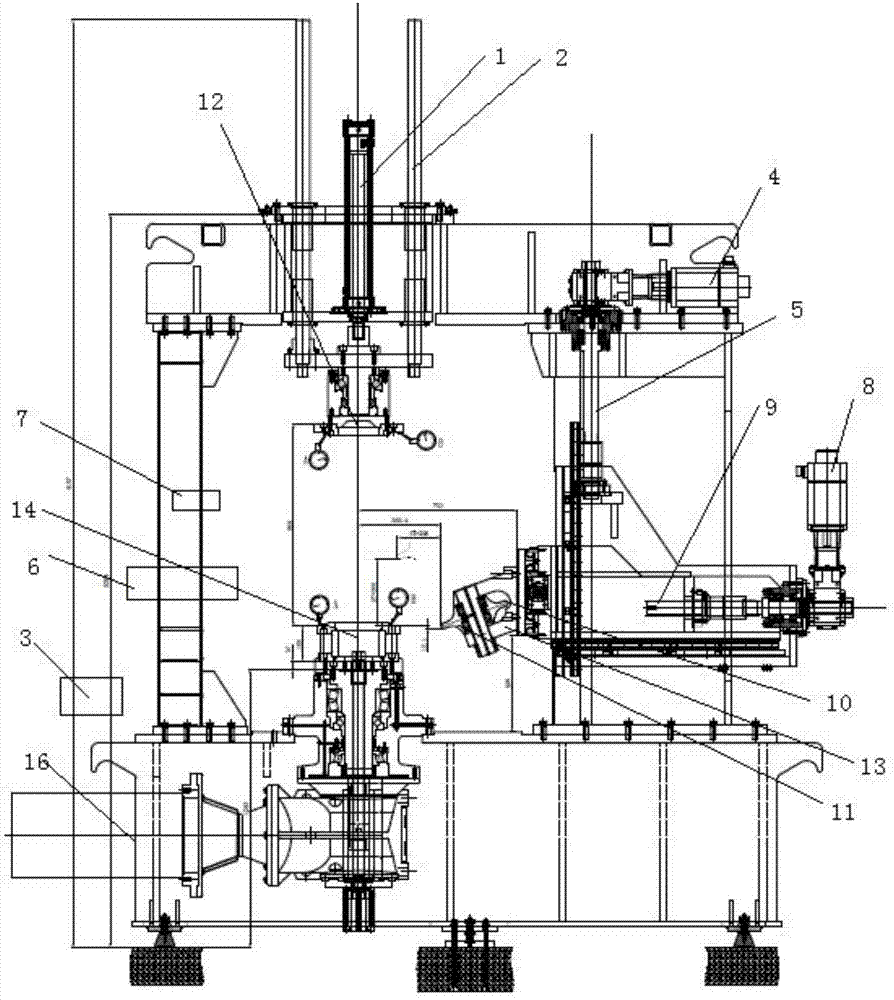

[0016] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0017] The invention provides a light-duty single-wheel spinning equipment for aluminum alloy wheels, which includes two spinning tables, a spindle bed, a demoulding system, a tail jacking system, a hydraulic system, a lubrication system, a cooling system, a compressed air system, a spraying system, a gas System, operation panel, electrical control cabinet, etc.

[0018] The spinning table consists of spinning rollers, roller bearings, roller brackets, high-load drive ball screws (one for X-axis and one for Z-axis), screw support bearings, and linear guides. The power is a servo motor. The spinning roller is installed on the roller bracket through the roller bearing, and the bracket with the roller can move in the horizontal direction (X d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com