Patents

Literature

51results about How to "Guaranteed horizontal accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

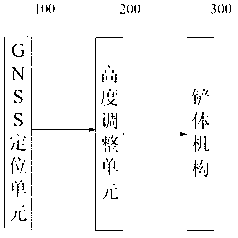

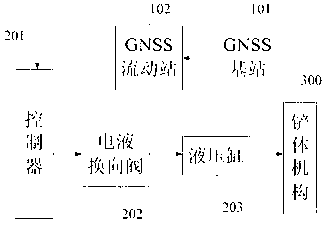

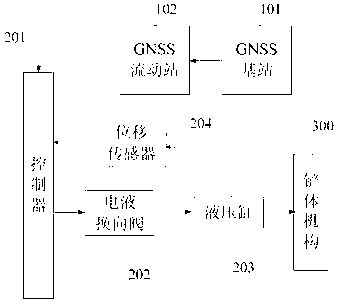

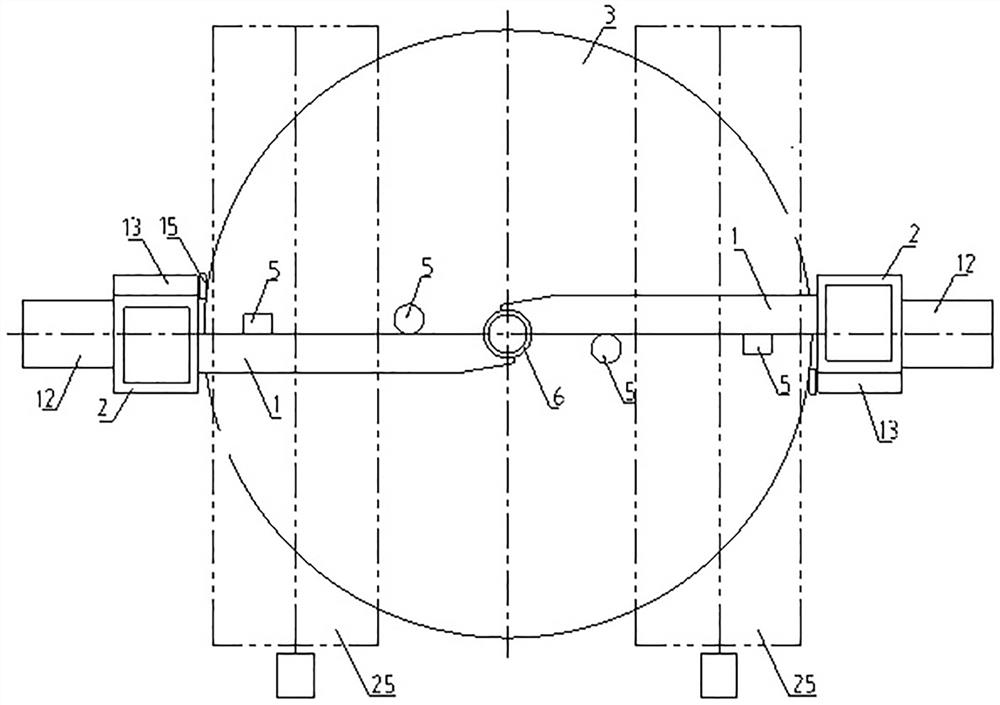

GNSS (global navigation satellite system) based intelligent flat shovel control system and method and flat shovel device

ActiveCN103293974ARealize attitude adjustmentGuaranteed horizontal accuracySoil-working equipmentsSatellite radio beaconingHydraulic cylinderDifferential signaling

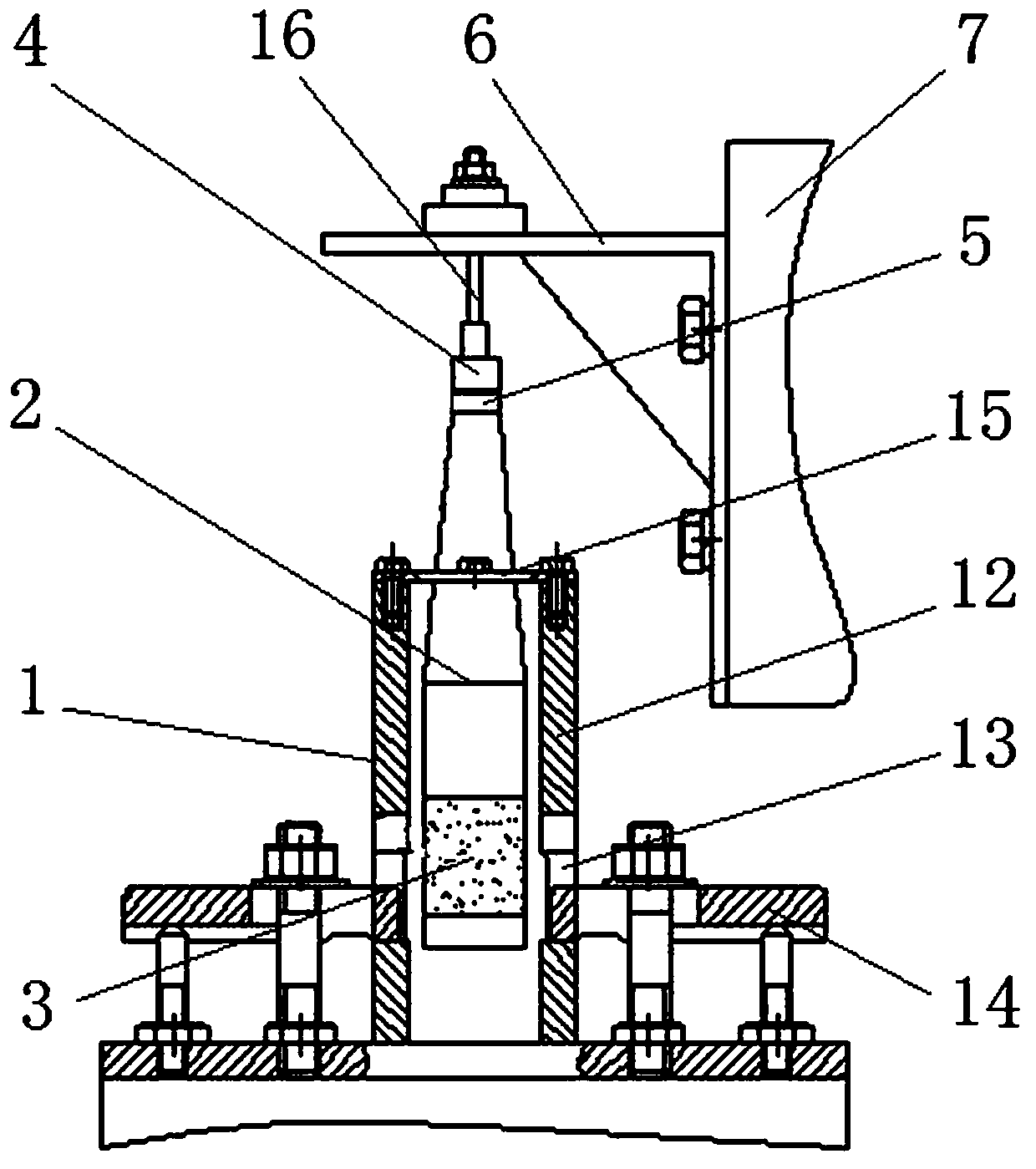

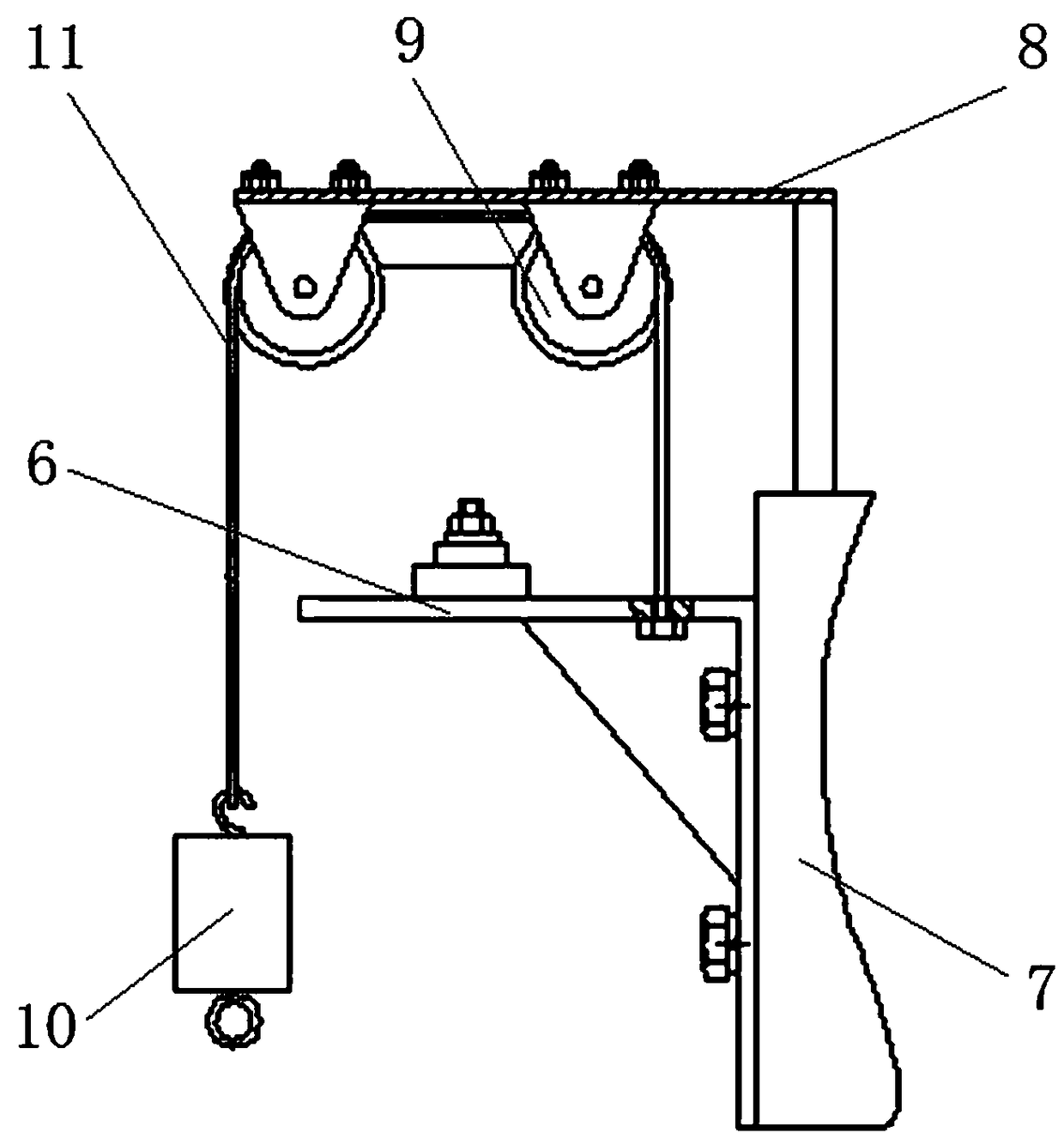

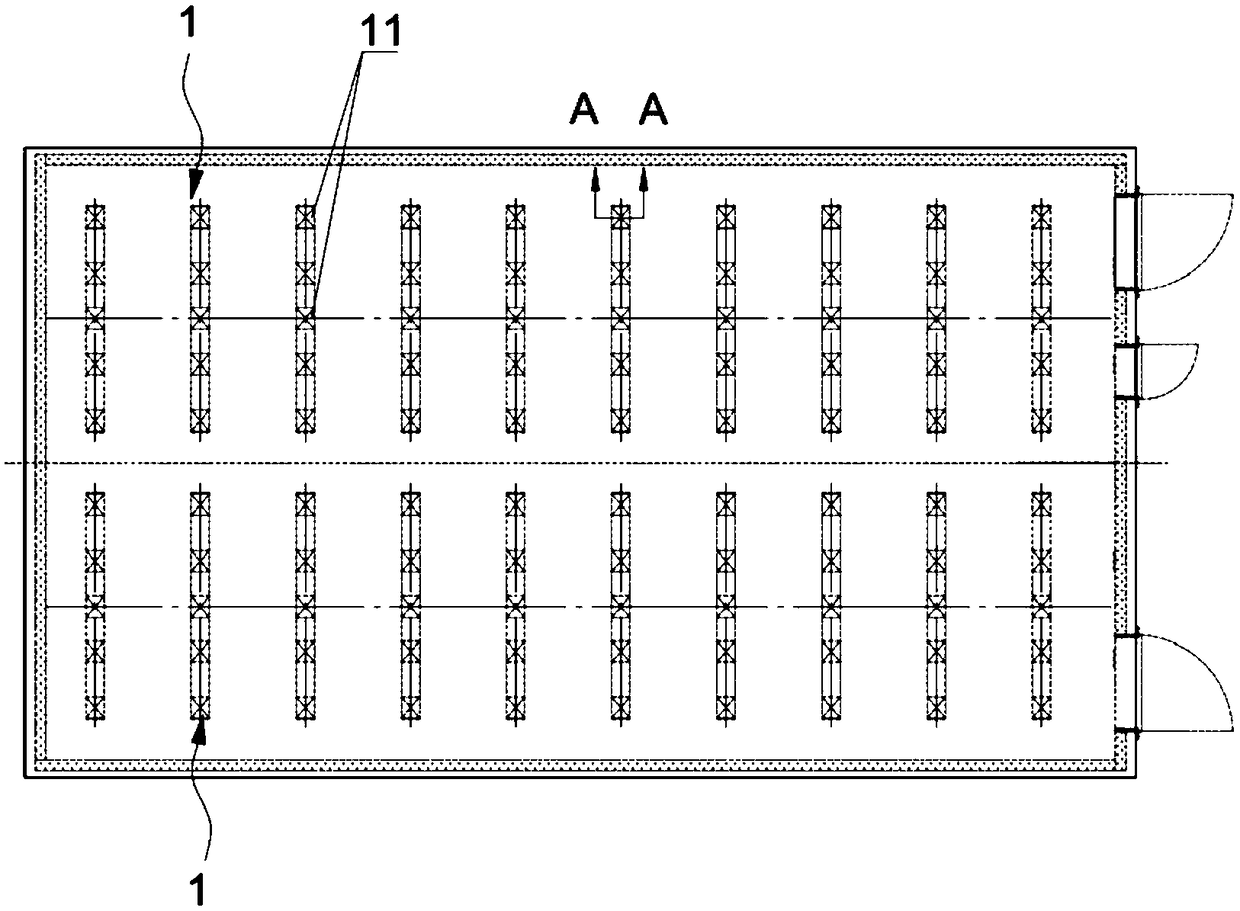

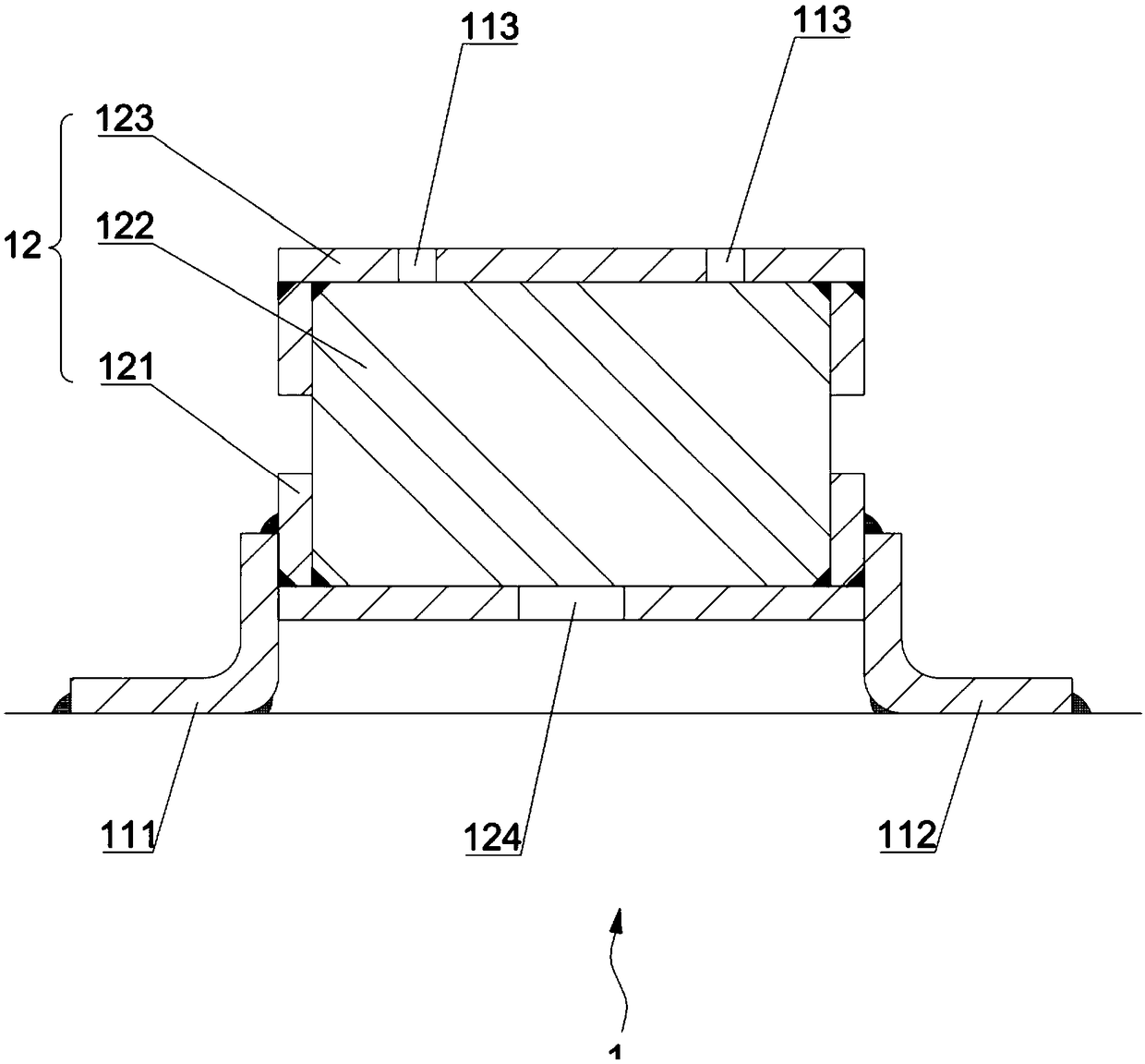

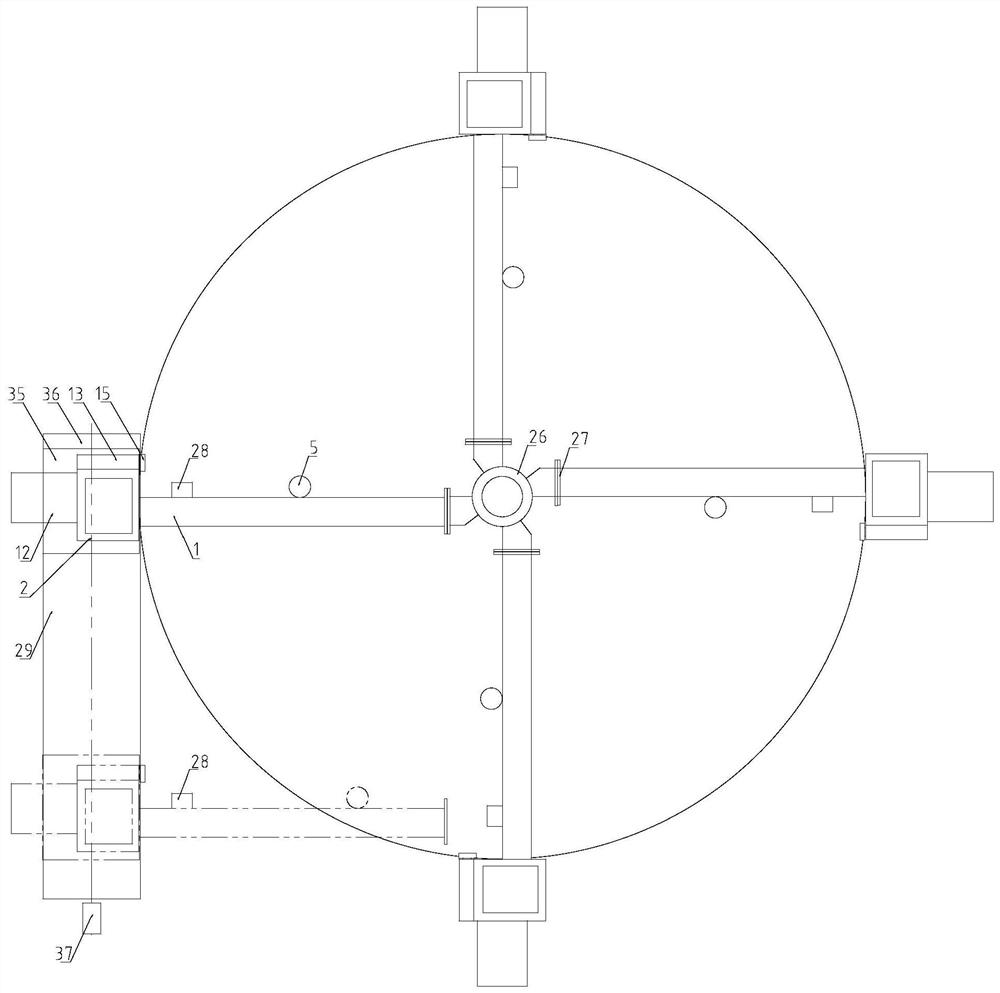

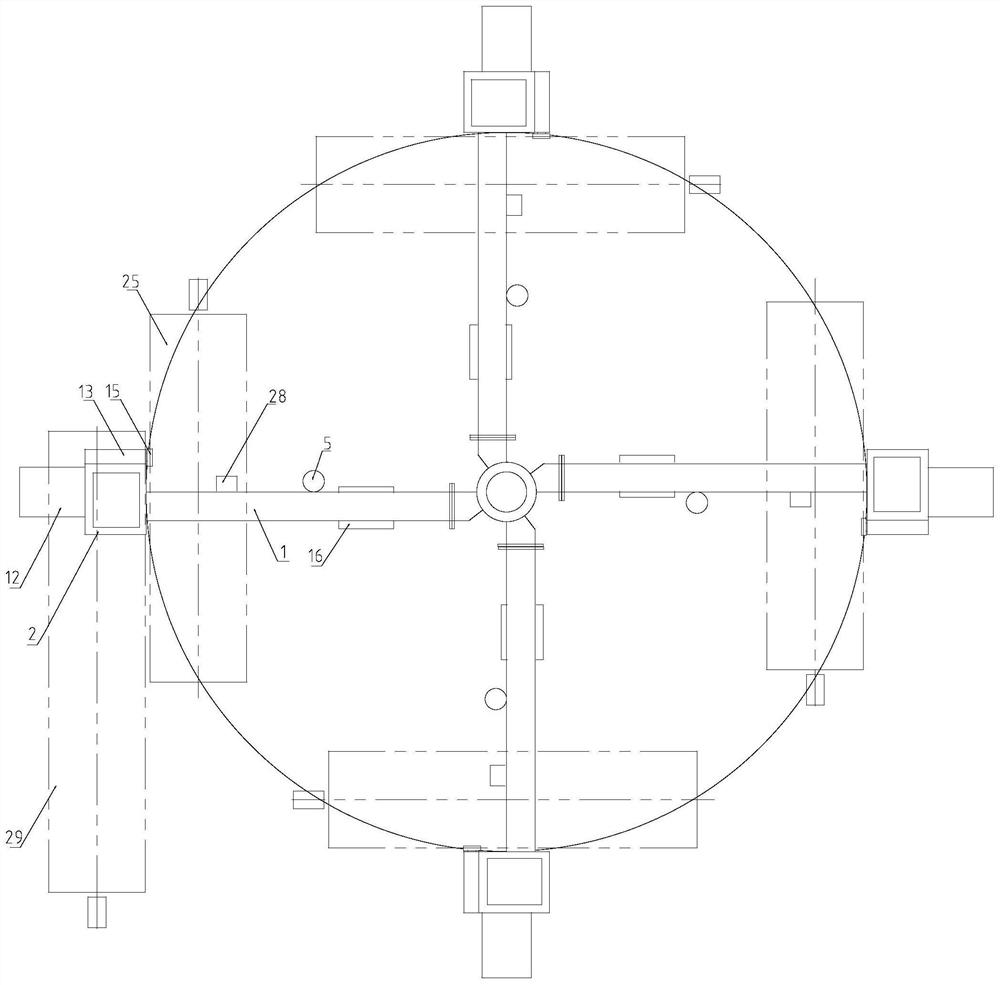

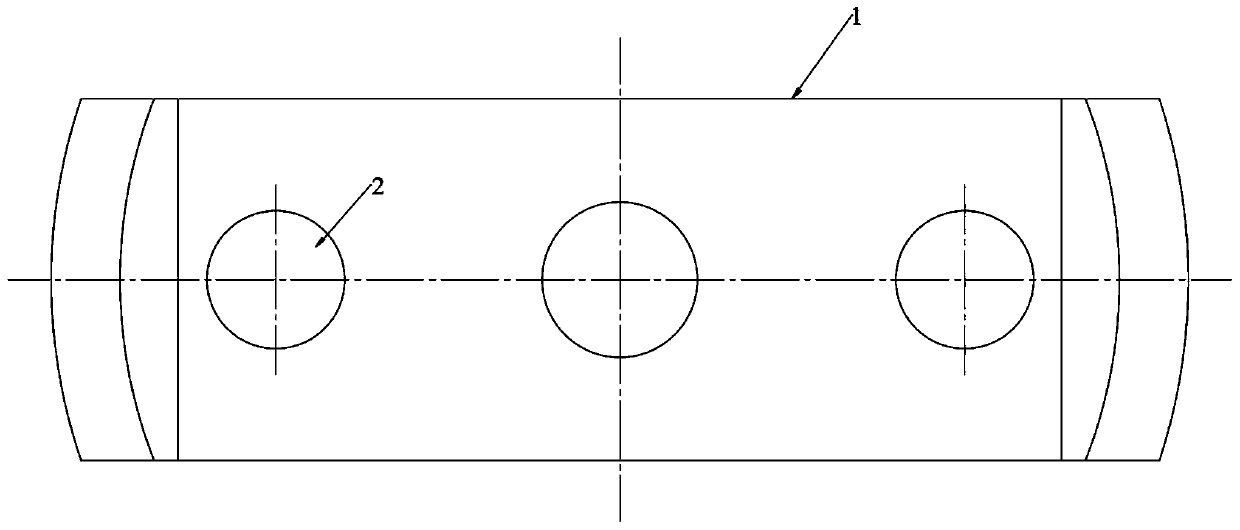

The invention relates to the field of fine flattening of lands, in particular to a GNSS (global navigation satellite system) based intelligent flat shovel control system and method and a flat shovel device applying the control system. The system comprises a GNSS positioning unit and a height adjusting unit, wherein the GNSS positioning unit comprises a GNSS base station and a GNSS moving station. The GNSS base station is used for receiving GNSS signals and calculating and transmitting differential signals. The GNSS moving station is used for receiving the differential signals from the GNSS base station and calculating and transmitting spatial information. The height adjusting unit comprises a controller, an electro-hydraulic directional control valve and a hydraulic cylinder. The controller is used for receiving the spatial information output by the GNSS moving station and transmitting action commands to the electro-hydraulic directional control valve connected with the hydraulic cylinder. By the GNSS based intelligent flat shovel control system and method, the problems about limited operation range, low operation efficiency, failure in accurate operation on slopes, large error in large-range operation, poor environmental adaptability and the like of laser control on the flat shovel device are solved.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

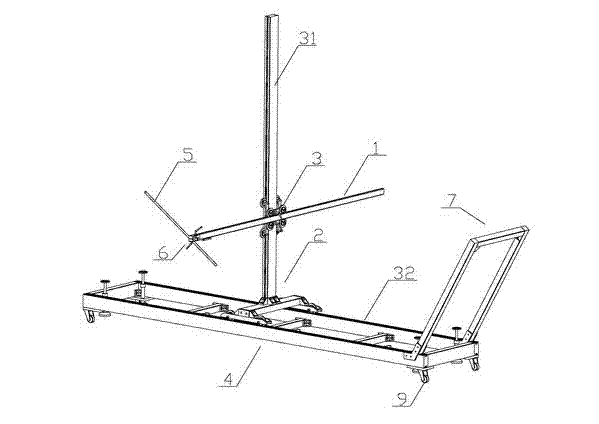

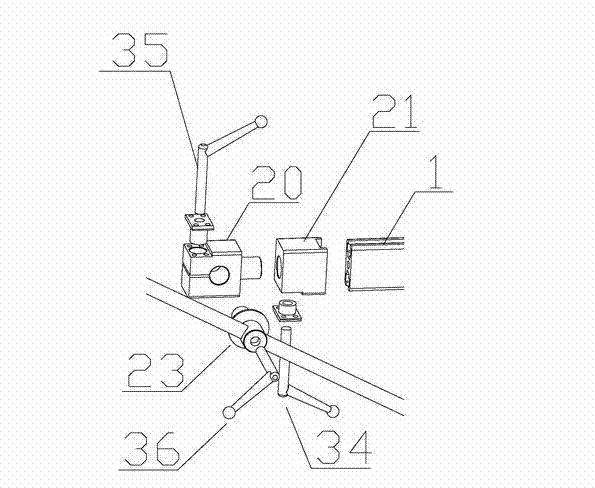

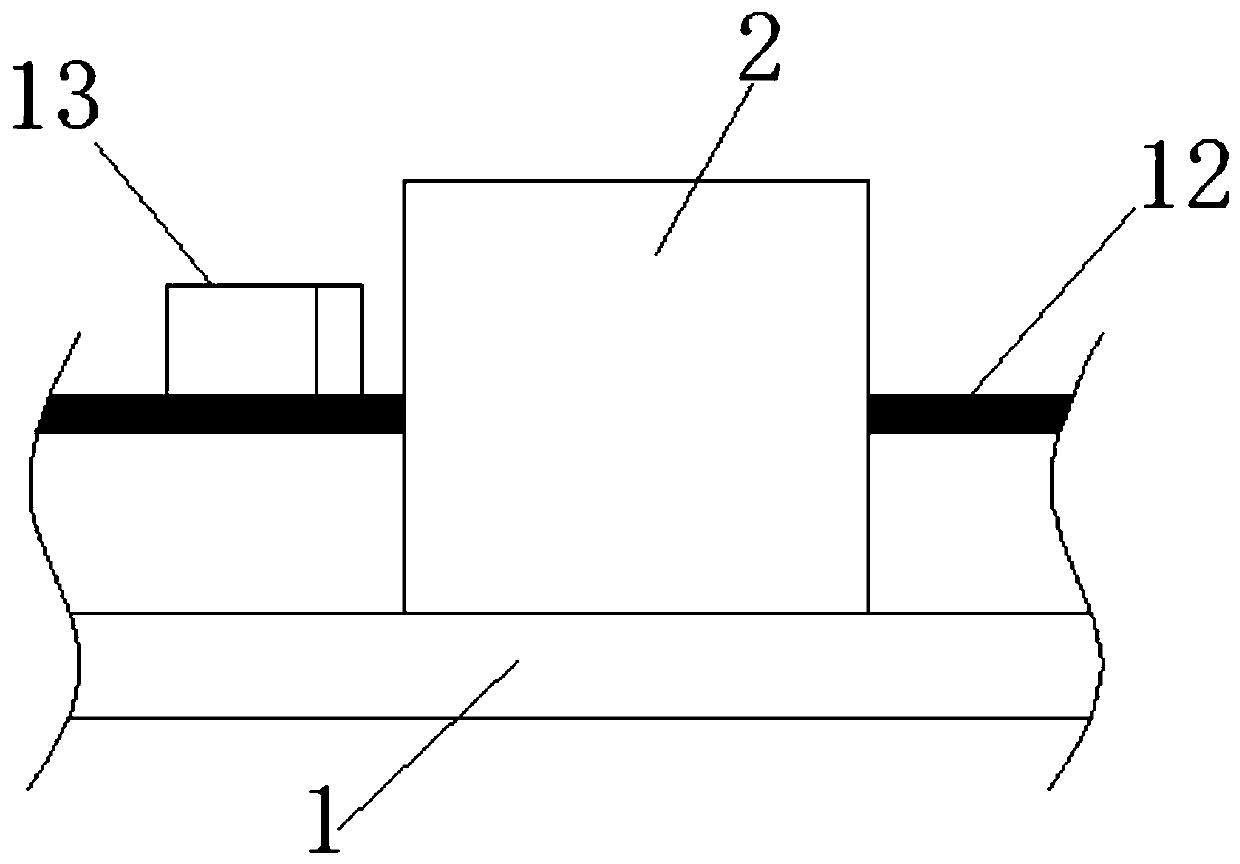

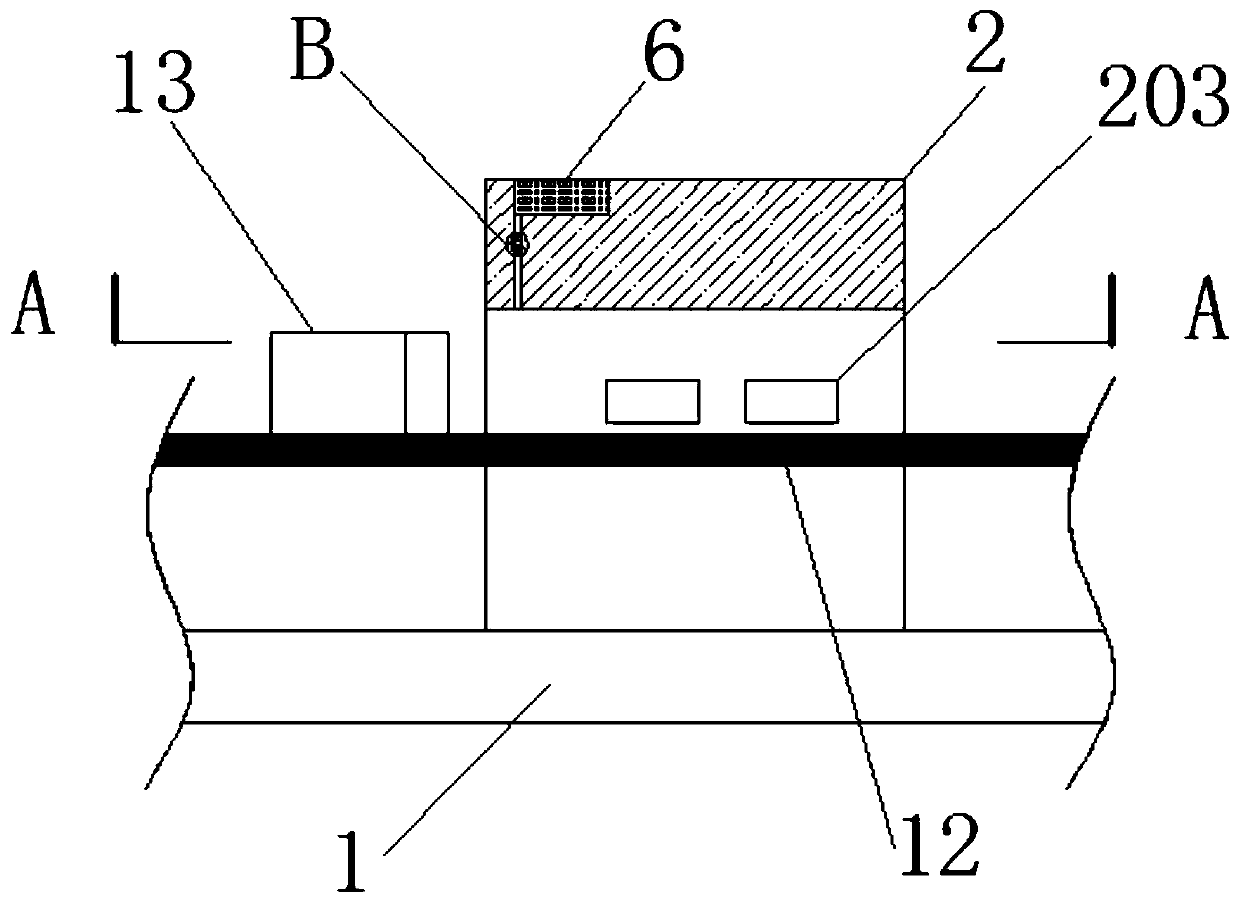

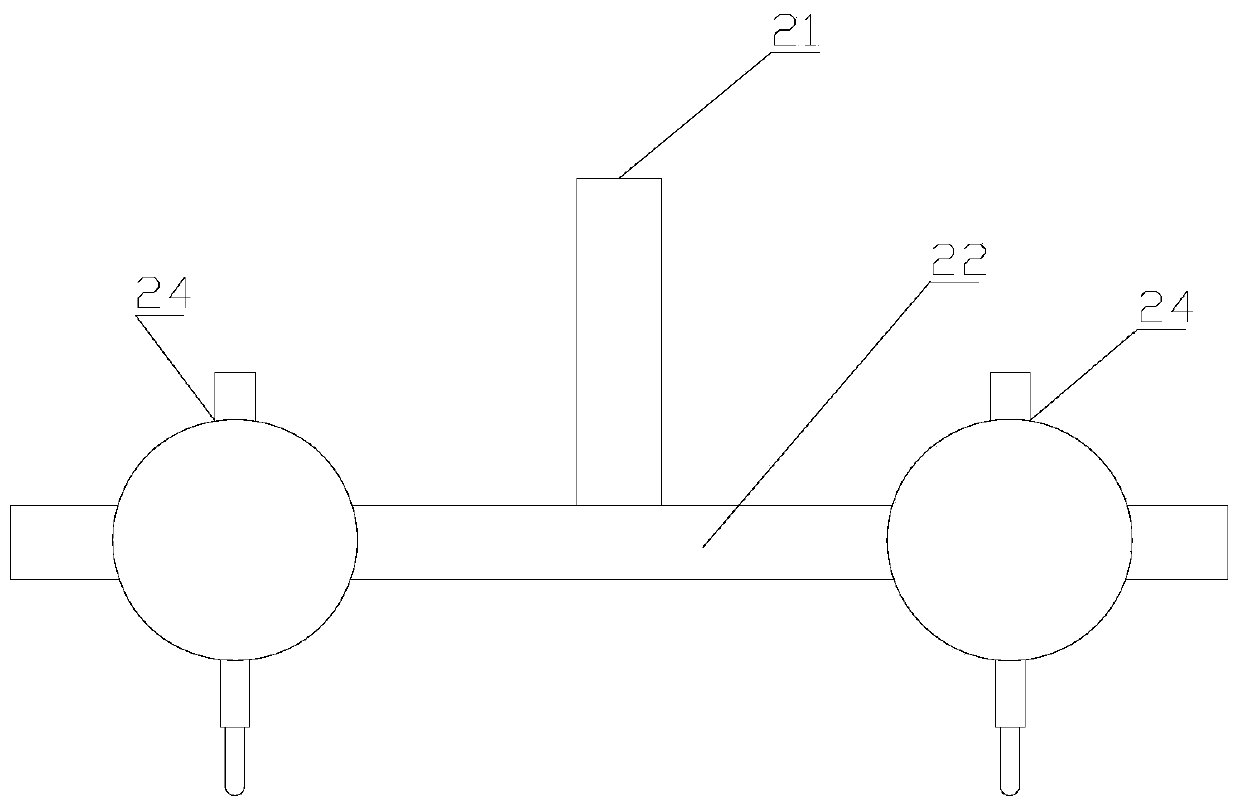

Pedestrian protecting vehicle scriber used for collision test

ActiveCN102501237AEasy to operateImprove marking efficiencyOther workshop equipmentUniversal jointScriber

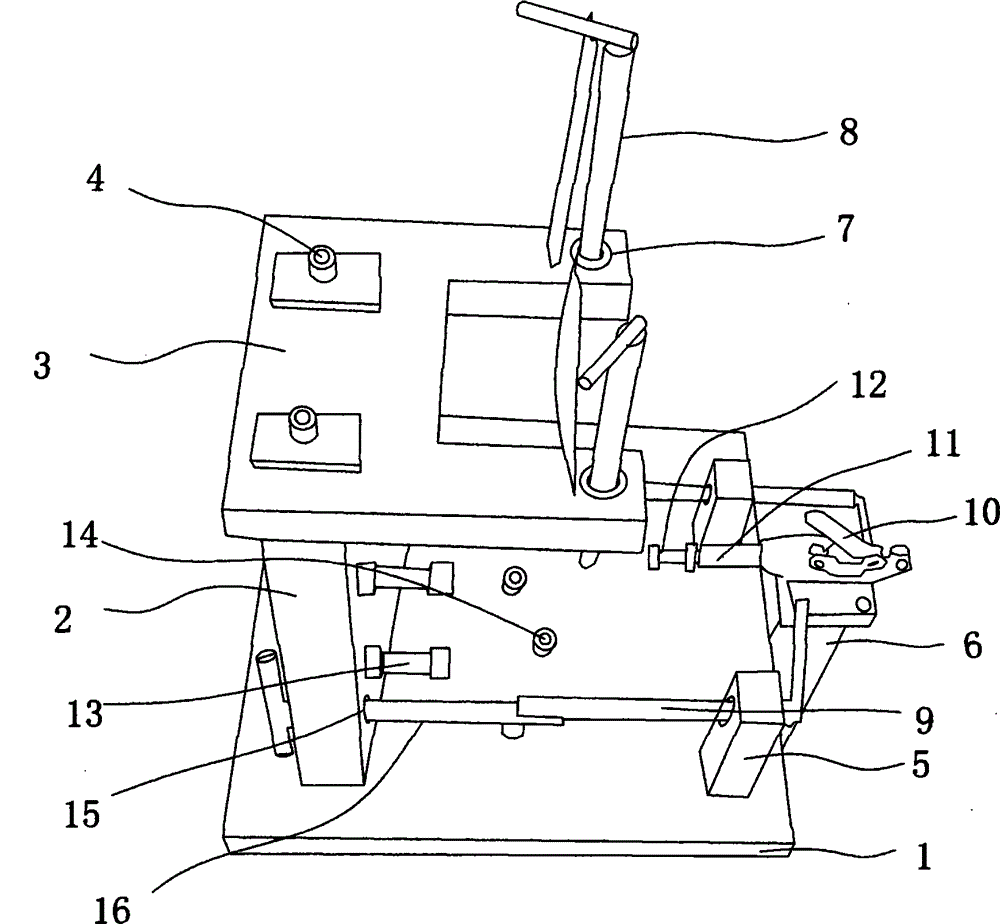

The invention discloses a pedestrian protecting vehicle scriber used for a collision test, which comprises a movable base arranged in the Y direction, a horizontal moving rack, a longitudinal moving rod and a scribing rod, wherein the movable base is provided with a self-arranged leveling and fixing device; the horizontal moving rack and the movable base are in Y-direction sliding fit; a Z-direction extending vertical strut is fixed on the horizontal moving rack; the longitudinal moving rod is horizontally arranged on the vertical strut along the X direction; the longitudinal moving rod can horizontally slide along the X direction and the Z direction on the vertical strut and is locked and positioned; the scribing rod is arranged on one end of the longitudinal moving rod by a universal joint; and a space angle between the scribing rod and the longitudinal moving rod can be regulated at will. The pedestrian protecting vehicle scriber has the characteristics of low working intensity, high scribing efficiency and high scribing precision, is convenient and simple to operate, is convenient to move and saves space, can be made of belt trough aluminium profile, aluminium alloy plates and few steel materials to guarantee integral strength and have portability. The pedestrian protecting vehicle scriber is suitable for various vehicle collision test processes to serve as an auxiliary tool to carry out pedestrian protecting scribing operation.

Owner:长城汽车股份有限公司平湖分公司

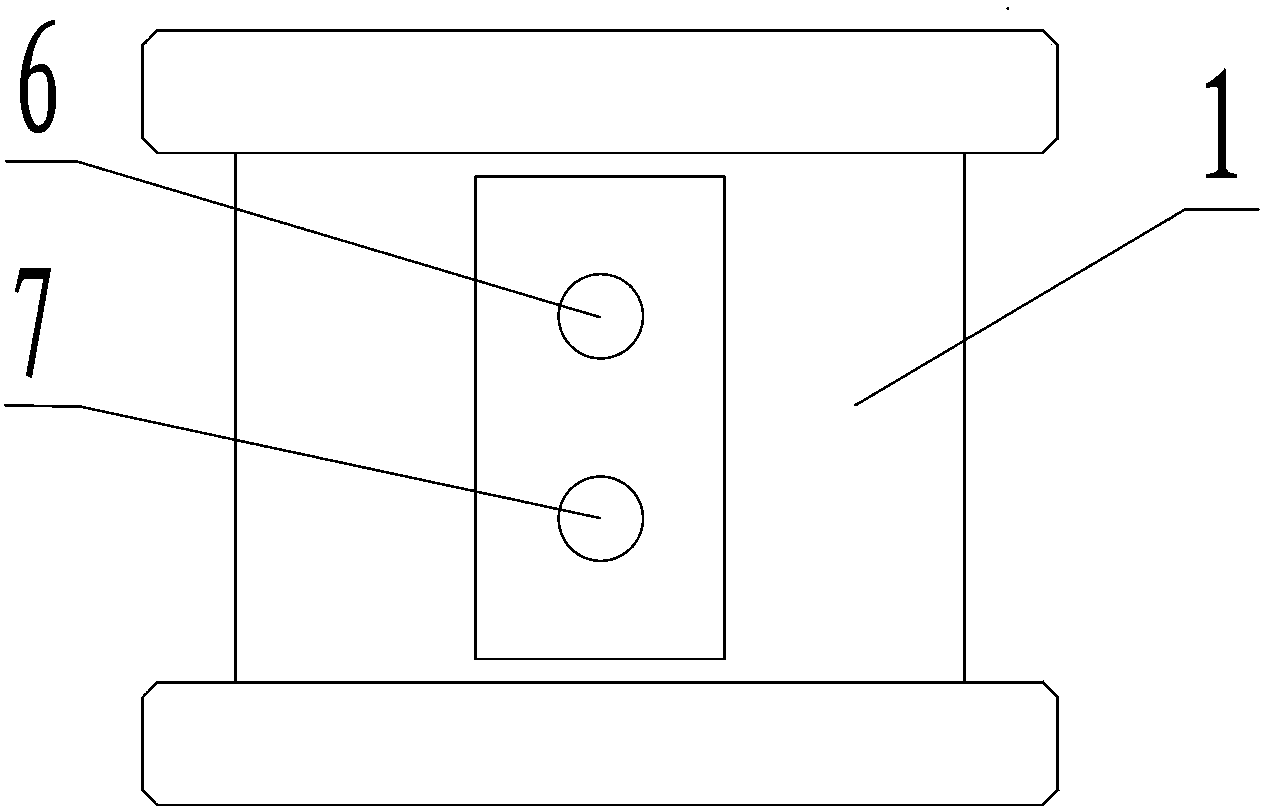

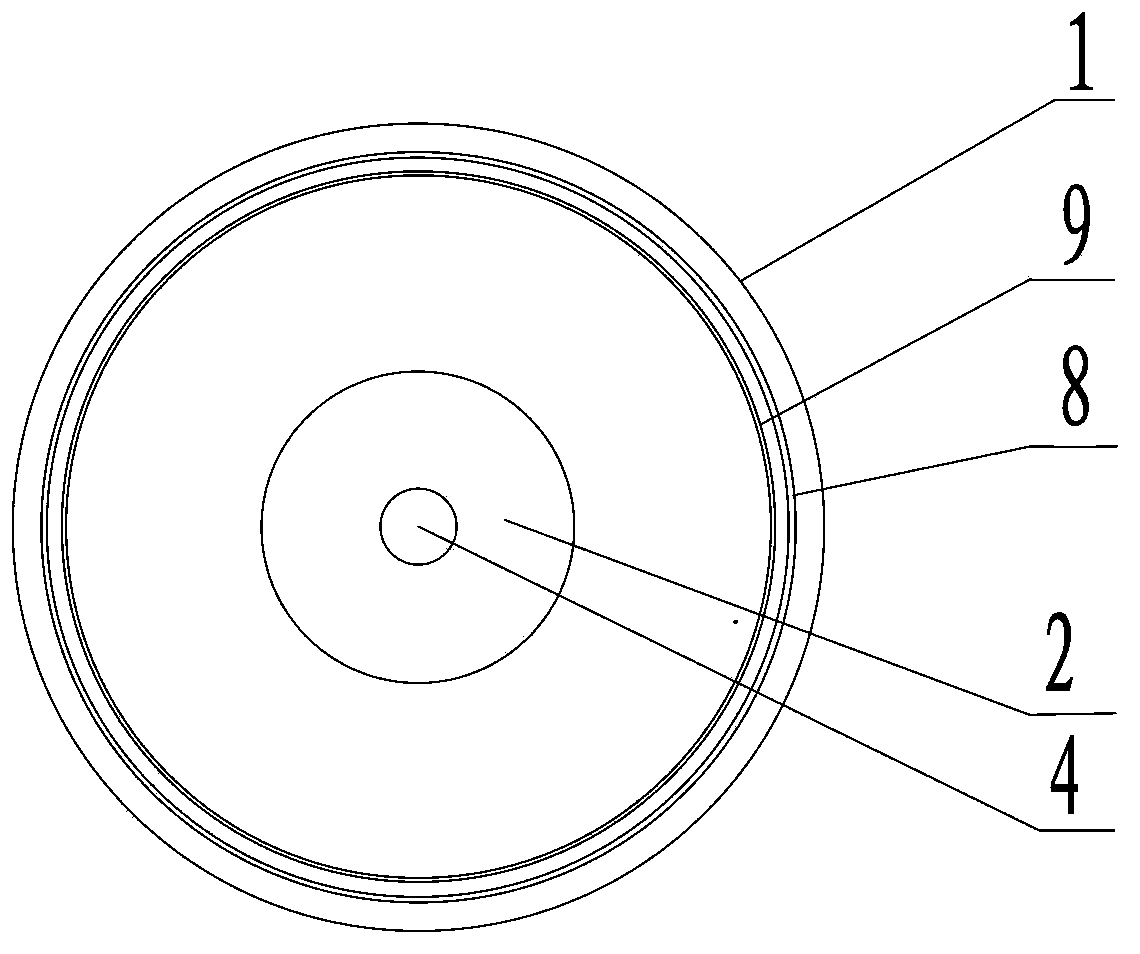

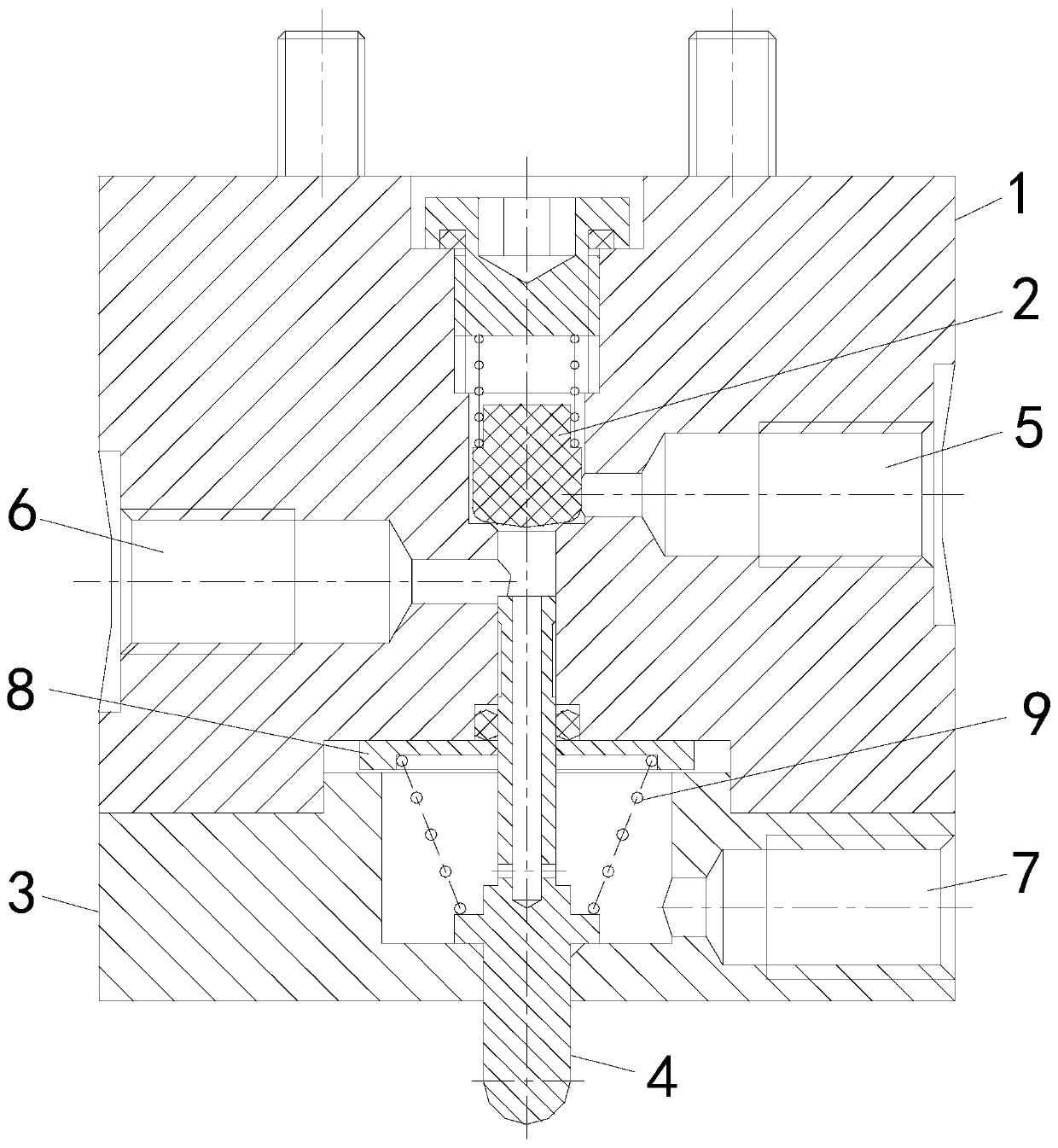

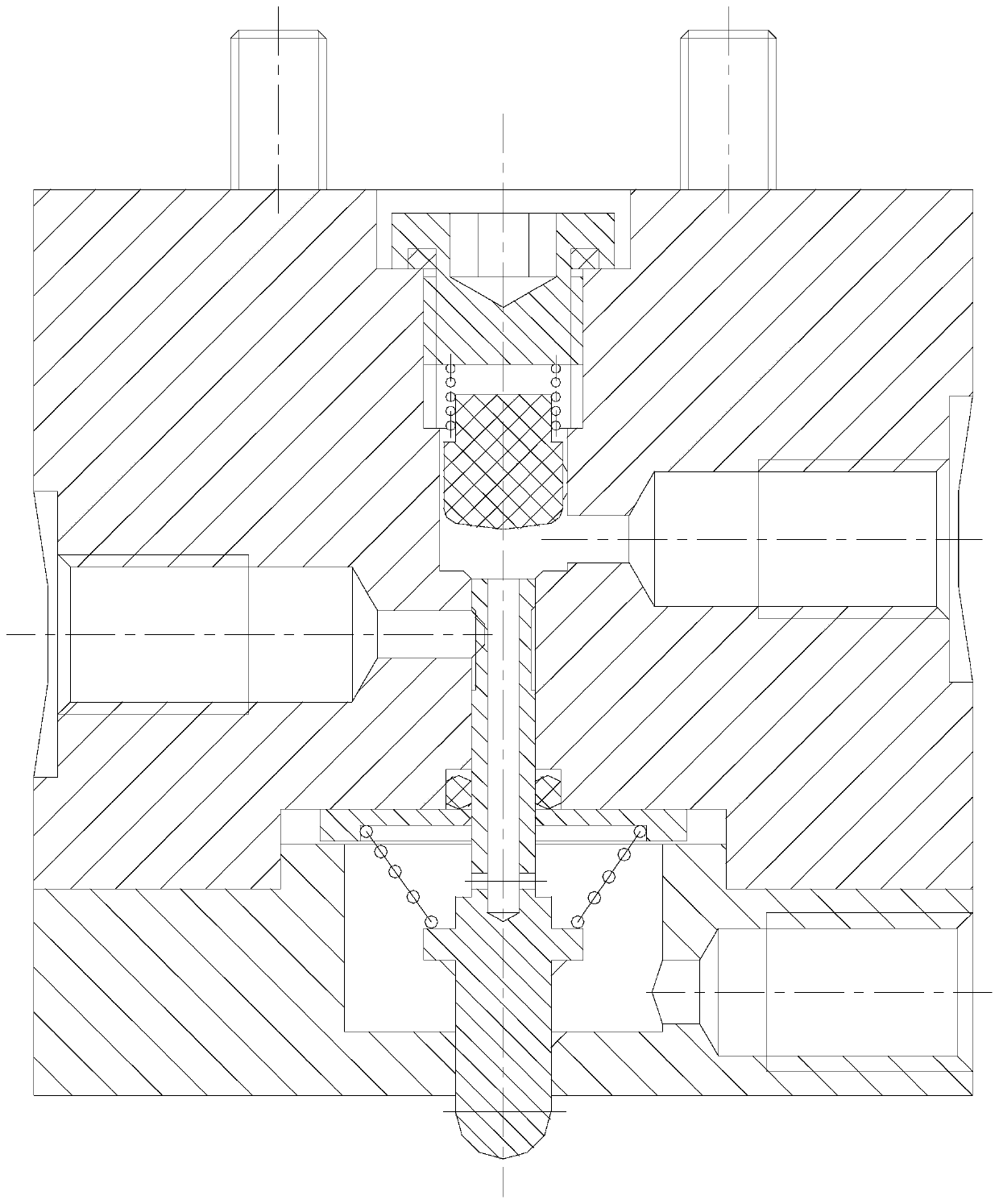

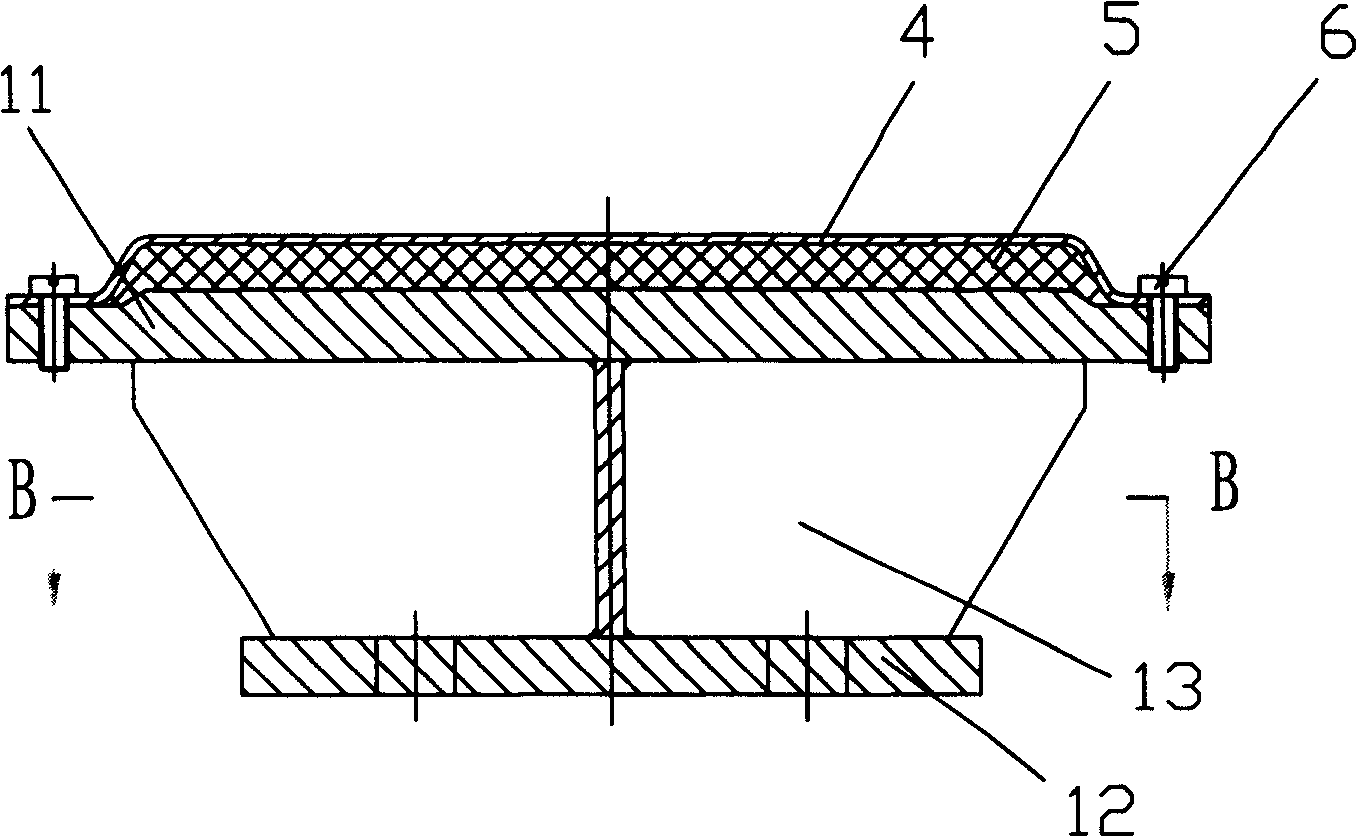

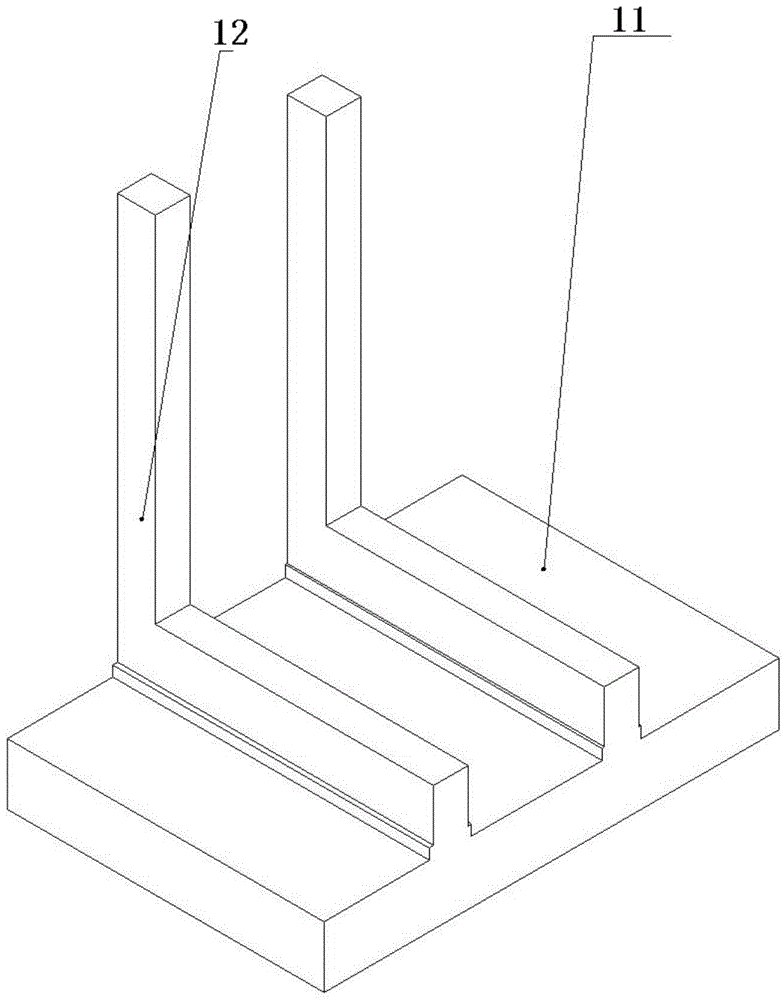

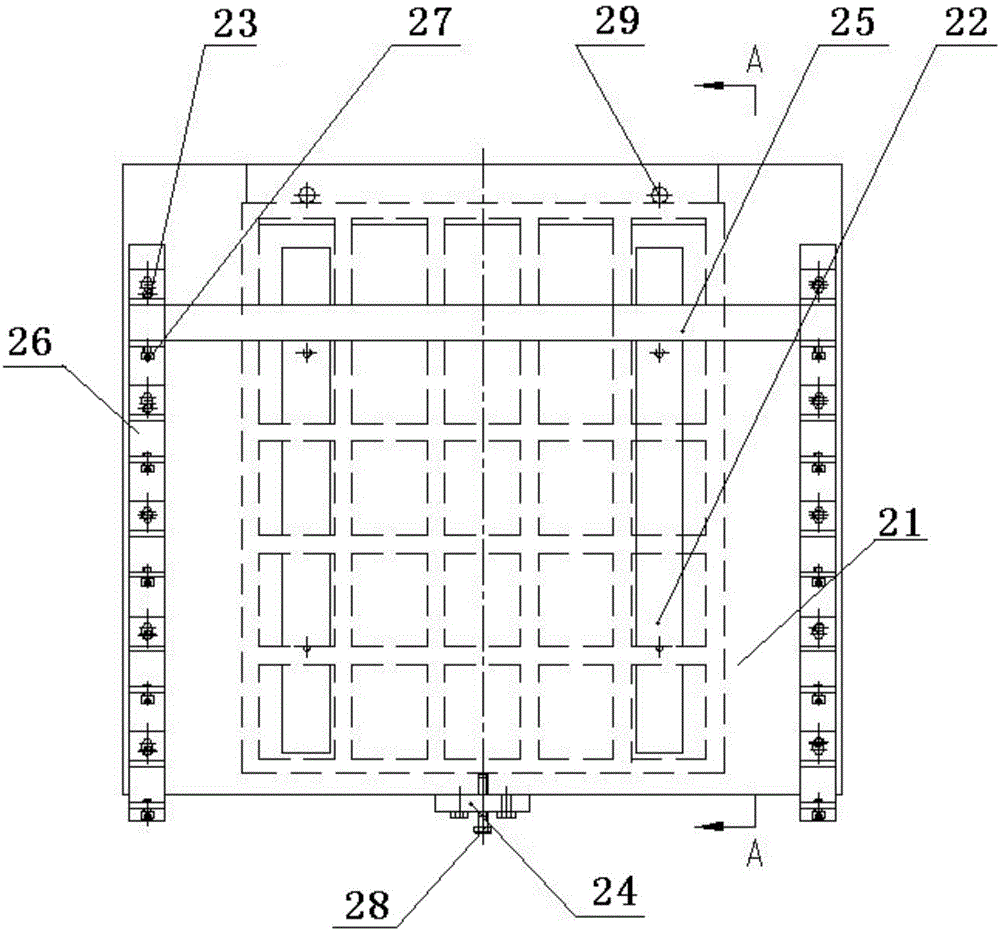

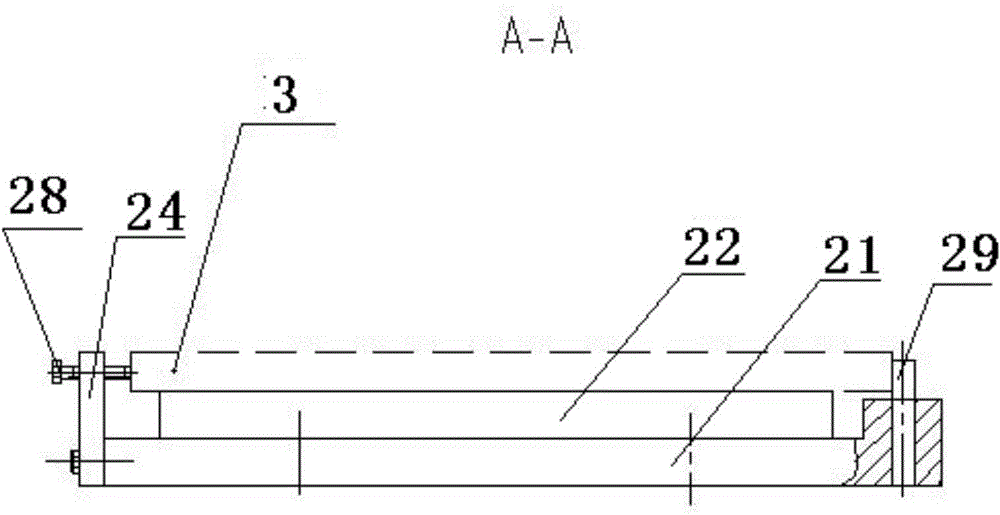

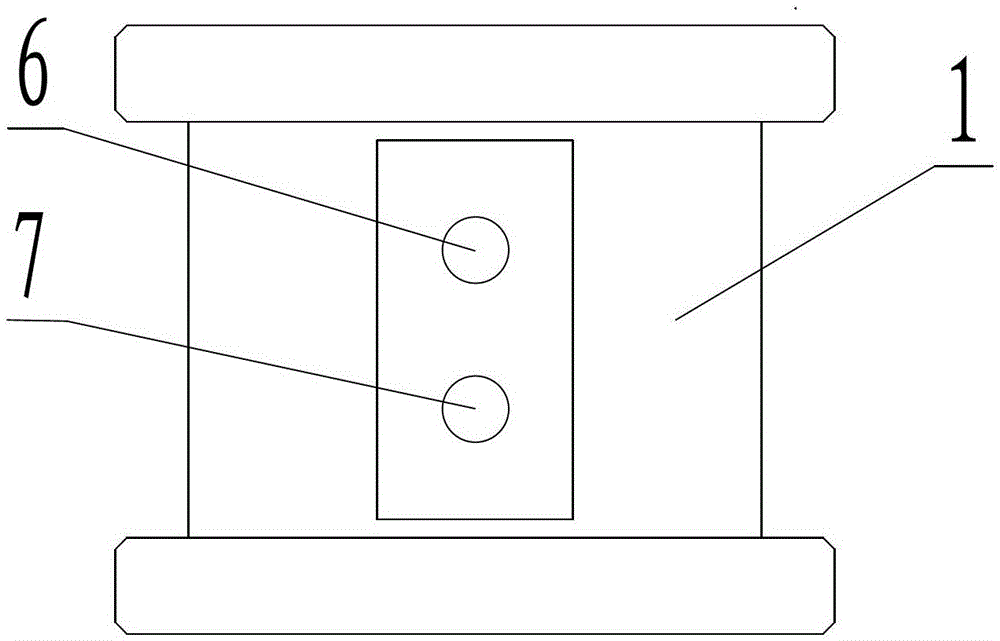

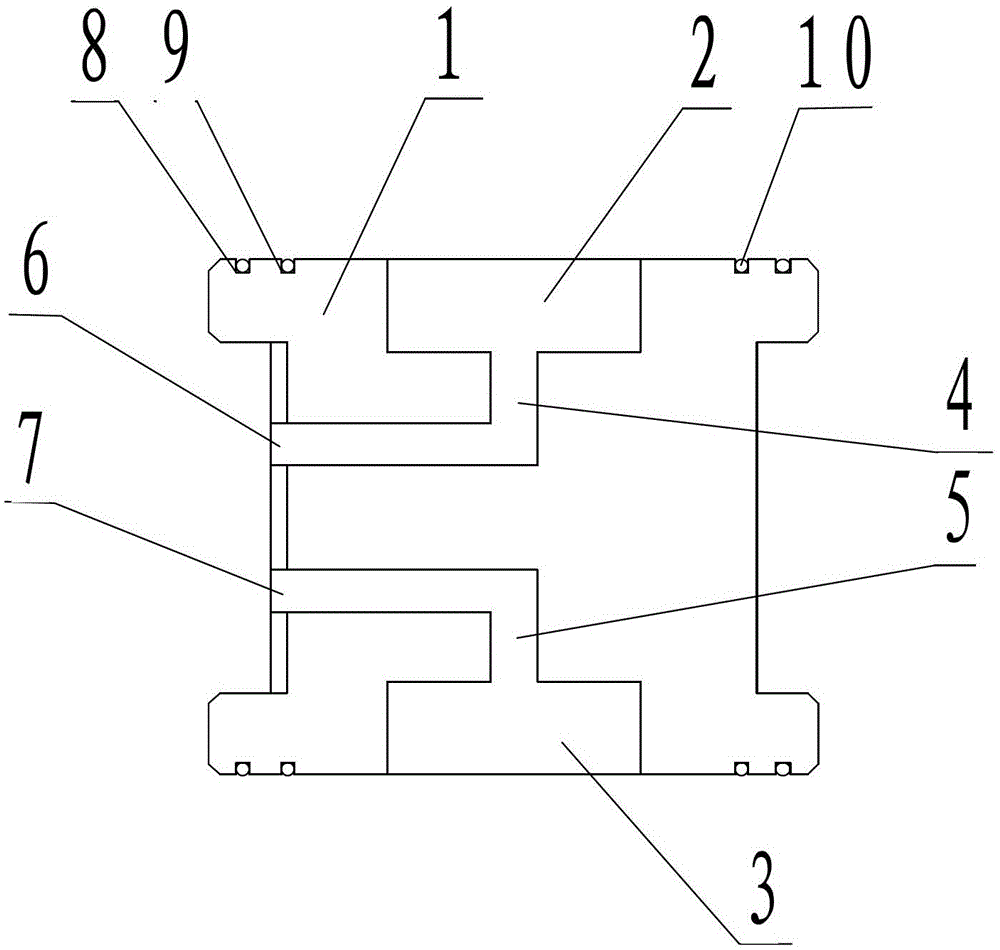

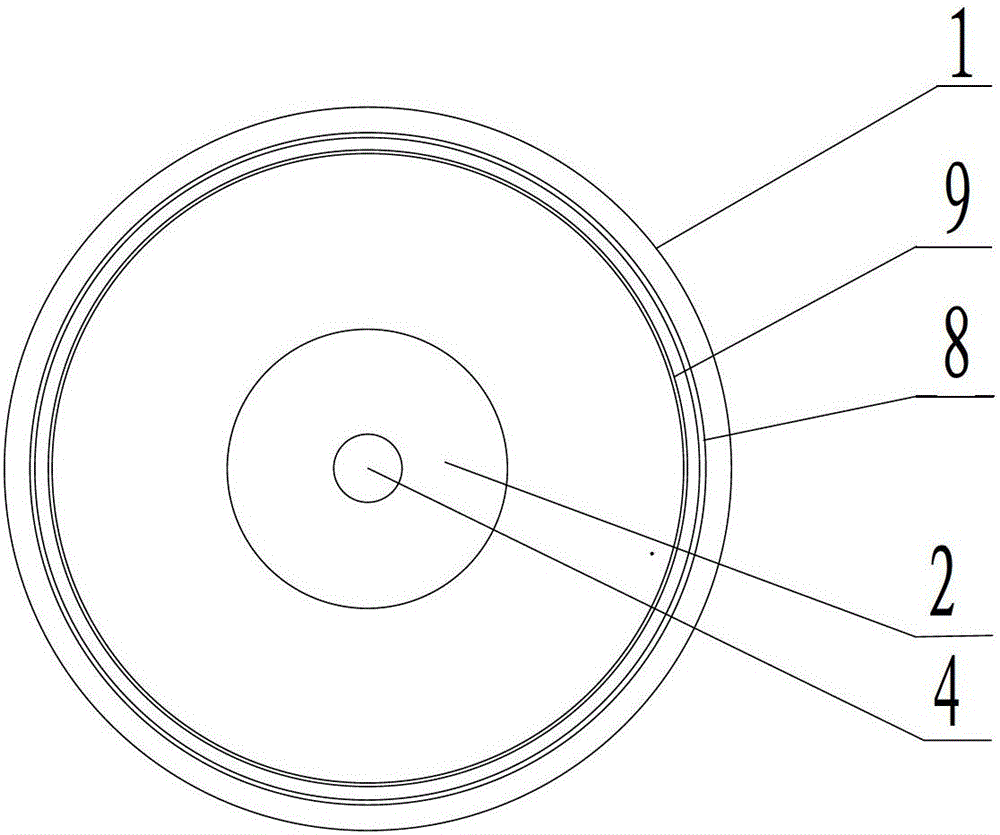

Glass location vacuum pad assembly and use method

ActiveCN103406853ASimple and efficient structural designIdeal positioning and adsorption effectWork holdersEngineeringMechanical engineering

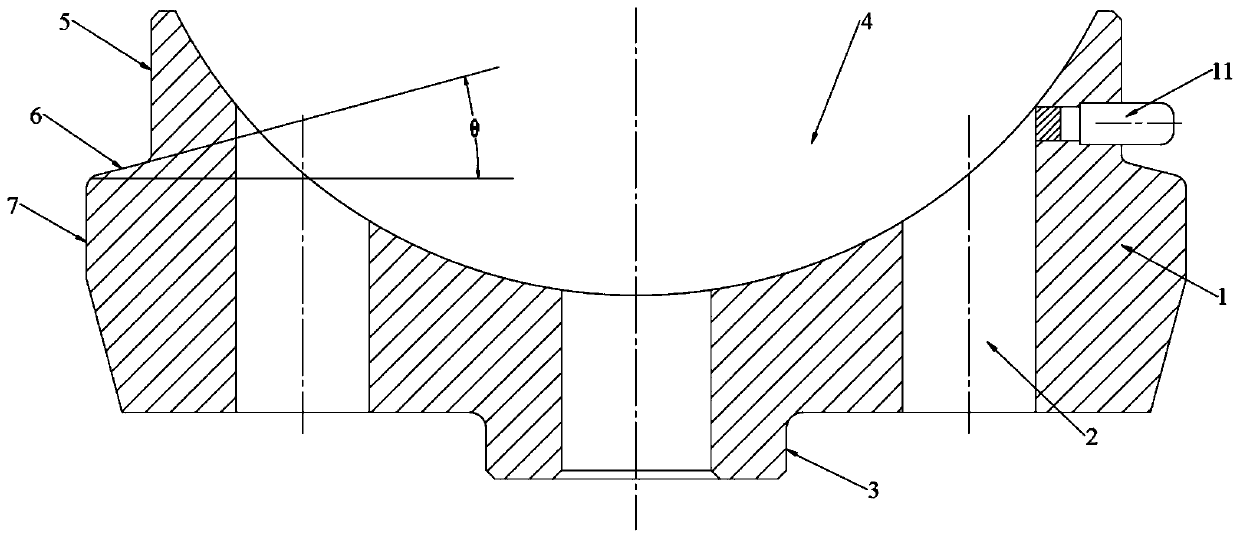

Provided is a glass location vacuum pad assembly and use method. A glass location vacuum pad is formed by a pad body, an upper vacuum cavity, a lower vacuum cavity, an upper vacuum channel, a lower vacuum channel, an upper connector, a lower connector, a first annular sealing groove, a second annular sealing groove and O-shaped sealing ring pads. The pad body is cast to be of an I-shaped structure, the cylindrical upper vacuum cavity is processed in the middle of the upper portion of the pad body, the cylindrical lower vacuum cavity is processed in the middle of the lower portion, at least two annular sealing grooves are formed in the upper plane and the lower plane of the pad body, and the O-shaped sealing ring pads are installed in the annular sealing grooves correspondingly. The glass location vacuum pad is simple and efficient in structure design, ideal in location and attraction effect, convenient to manufacture, simple in operation, capable of reducing labor intensity of operators, low in manufacture cost, capable of saving rubber raw materials, easy to operate, convenient to maintain, flexible in operation and suitable for popularization and use.

Owner:ZAOZHUANG HAIDI ENERGY TECH

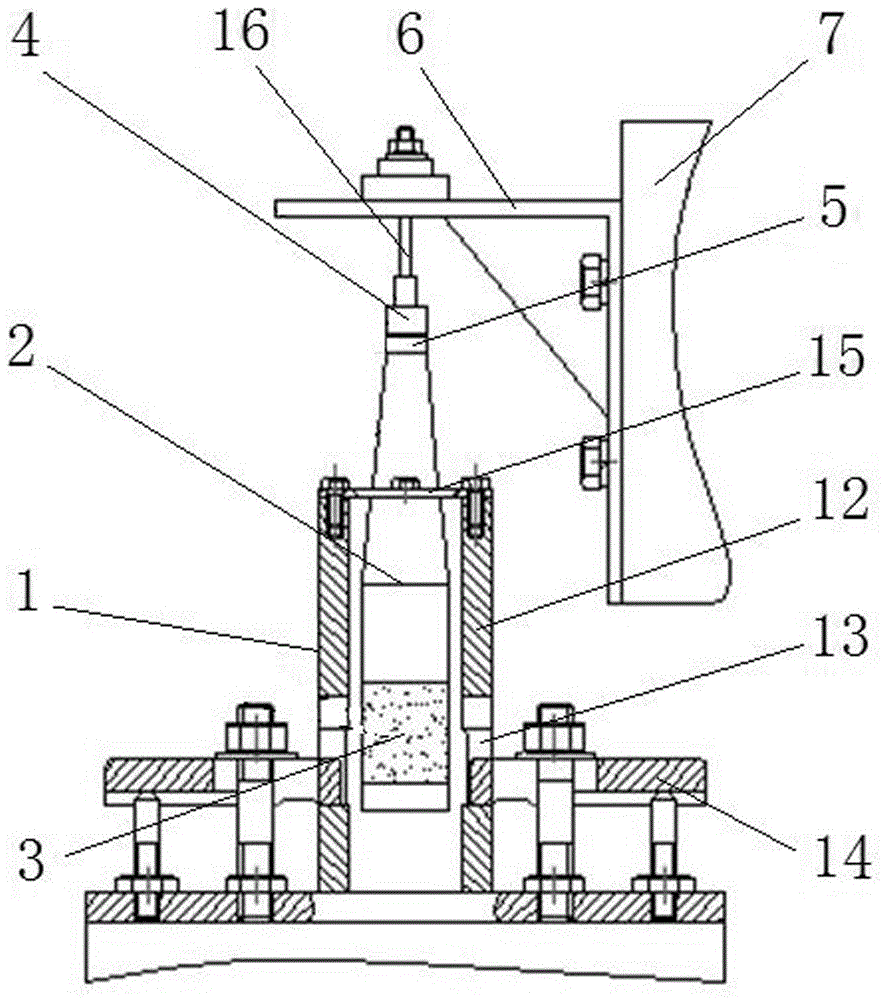

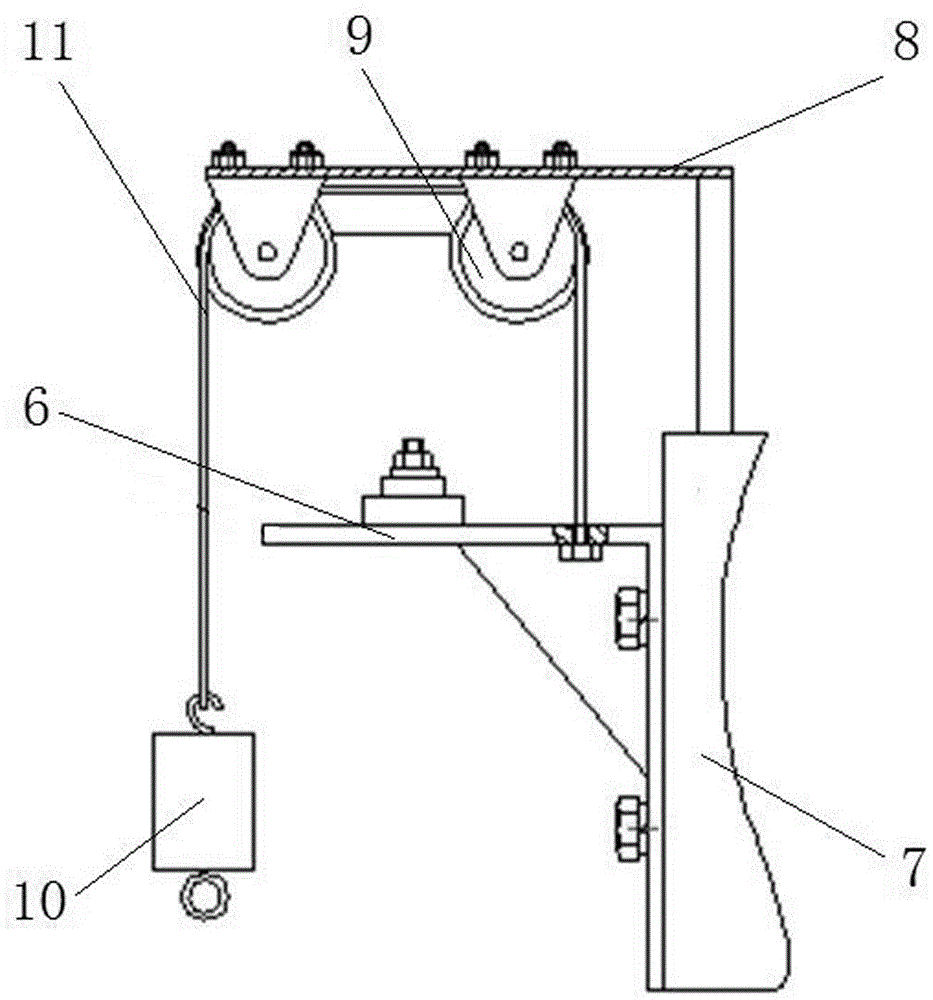

Engineering-ceramic complex-frequency ultrasonic processing device

InactiveCN106313340AOvercoming processing qualityOvercome processing efficiencyWorking accessoriesStone-like material working toolsTransducerEngineering

The invention relates to a ceramic hole processing device, in particular to an engineering-ceramic complex-frequency ultrasonic processing device and solves problems that an existing processing device is poor in processing quality and efficiency, high in cost and limited in processing shape. The engineering-ceramic complex-frequency ultrasonic processing device comprises a frame, an amplitude-change pole is arranged on the frame, a transducer connected with the amplitude-change pole is arranged at the lower end of the same, a stepped connecting block with the upper diameter larger than the lower diameter and connected with the amplitude-change pole is arranged at the upper end of the same, the stepped connecting block is sleeved with a free-quality casing located between the stepped surface of the stepped connecting block and the upper end face of the amplitude-change pole, a drill is connected to the upper end of the stepped connecting block, a workpiece worktable is arranged above the drill, and a guide rail sliding vertically is arranged on one side of the workpiece worktable. The engineering-ceramic complex-frequency ultrasonic processing device is reasonable and reliable in structural design, low in energy consumption, simple in structure and light in weight, processing precision and processing efficiency are greatly improved, few movement parts are involved, rotational motion is omitted, keeping of rotation torque is not needed, and the device can be used for environments under high temperature, low temperature or vacuum and the like.

Owner:TAIYUAN UNIV OF TECH

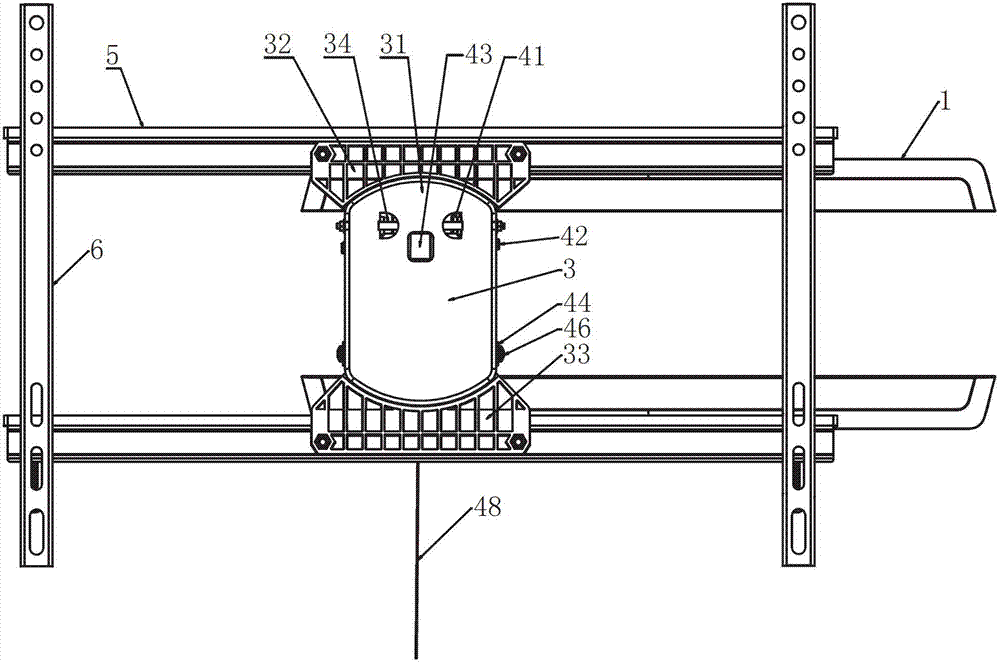

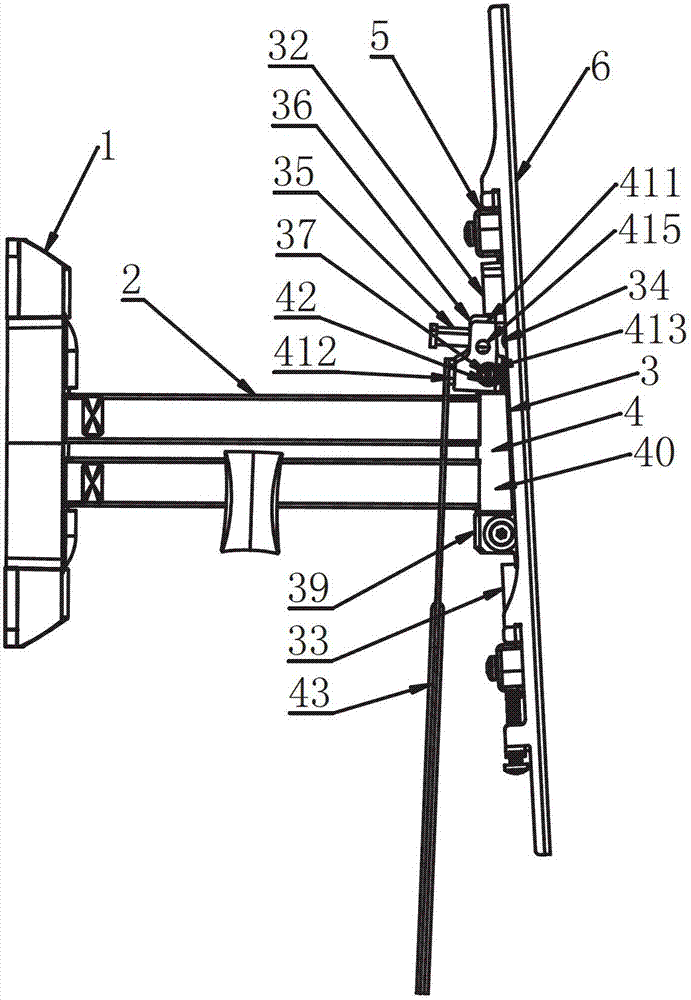

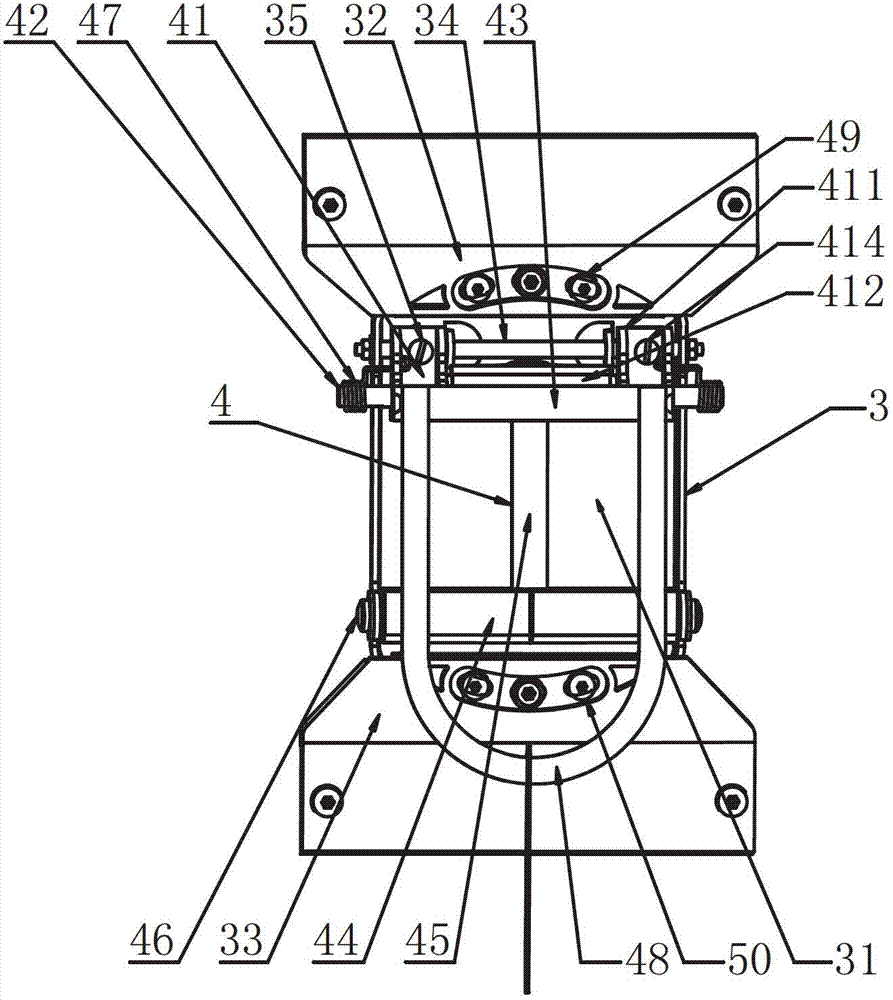

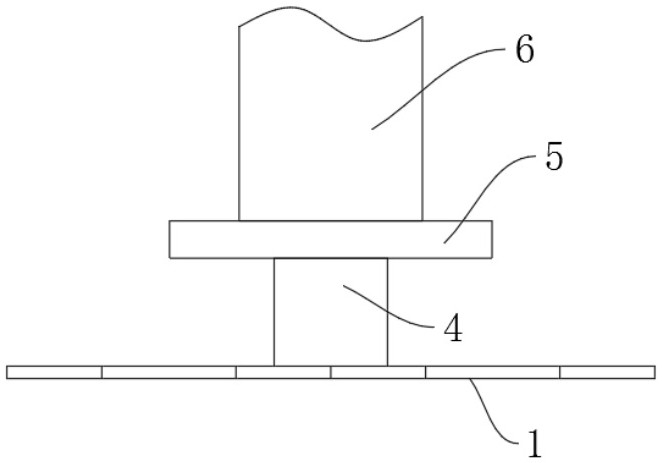

Adjustable LCD TV bracket

ActiveCN102889461AGuaranteed horizontal accuracyPerfect support function expansionStands/trestlesLiquid-crystal displayLocking mechanism

The invention relates to the LCD (liquid crystal display) TV bracket technical field, specifically relates to an adjustable LCD TV bracket, comprising a baseboard, a connecting arm, a panel, and a substrate, wherein said connecting arm is hinged with the baseboard in one end and hinged with the substrate in the other end. It is characterized in that the upper part of the panel is provided with a connecting mechanism and the lower part of the panel is hinged with the lower part of the substrate. The upper part of the substrate is equipped with a locking mechanism, and the connecting mechanism is connected with the locking mechanism. The invention is compact in the structure, rational in the design, simple in installation and nice in the use effect. An upper adjusting block and a lower adjusting block perform rotational adjustment by taking a connecting plate as the center so as to correct the baseboard and bracket on the wall by means of connecting deformation to guarantee the horizontal accuracy of an LCD TV. Upper adjustment and lower adjustment by taking the bottom edges of an LCD TV as the axis are increased on the basis of the connecting arm achieving LCD TV left rotation and right rotation to further perfect the bracket function expansion for multi-view use of an LCD TV.

Owner:NINGBO CINEMOUNT DESIGN & MFG

Plate straightening device capable of reducing abrasion and avoiding blockage

The invention relates to the technical field of industrial automation equipment, and discloses a plate straightening device capable of reducing abrasion and avoiding blockage. The device comprises a base, a rubber ball is connected into a supporting plate, a metal ball is arranged at a right end of a right side slide arm, a metal sheet corresponding to the metal ball is arranged in the supportingplate, each rear baffle plate is connected to a lower side of an outer end of each telescopic rod, and a second spring is connected between a rear end of an arc-shaped guide rod and each telescopic rod. One end of an inclined plate is firstly aligned with a through hole, a space range for air exhaust of the through hole is reduced, an air flow rate at a lower side of the through hole is accelerated, the accelerated air flow pushes the rubber ball to slide in a sliding chute, the rubber ball drives the metal ball on the slide arm to contact with the metal sheet, the telescopic rods at a right upper side and a left lower side begin to stretch out to straighten the plate, and the problems that the plate straightening device of the existing industrial automation equipment cannot adjust the level of the plate and the working efficiency is low are solved by the structure.

Owner:绍兴柯桥新兴门业有限公司

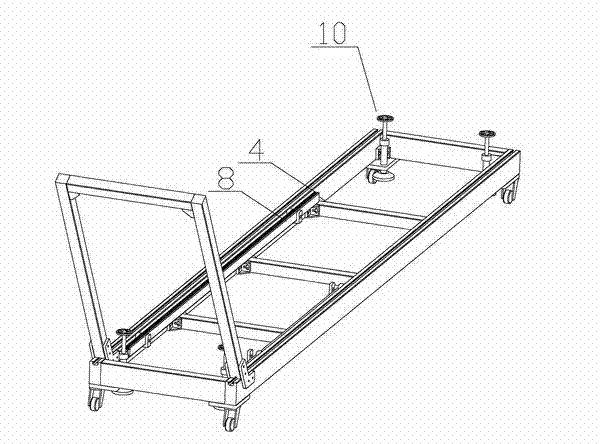

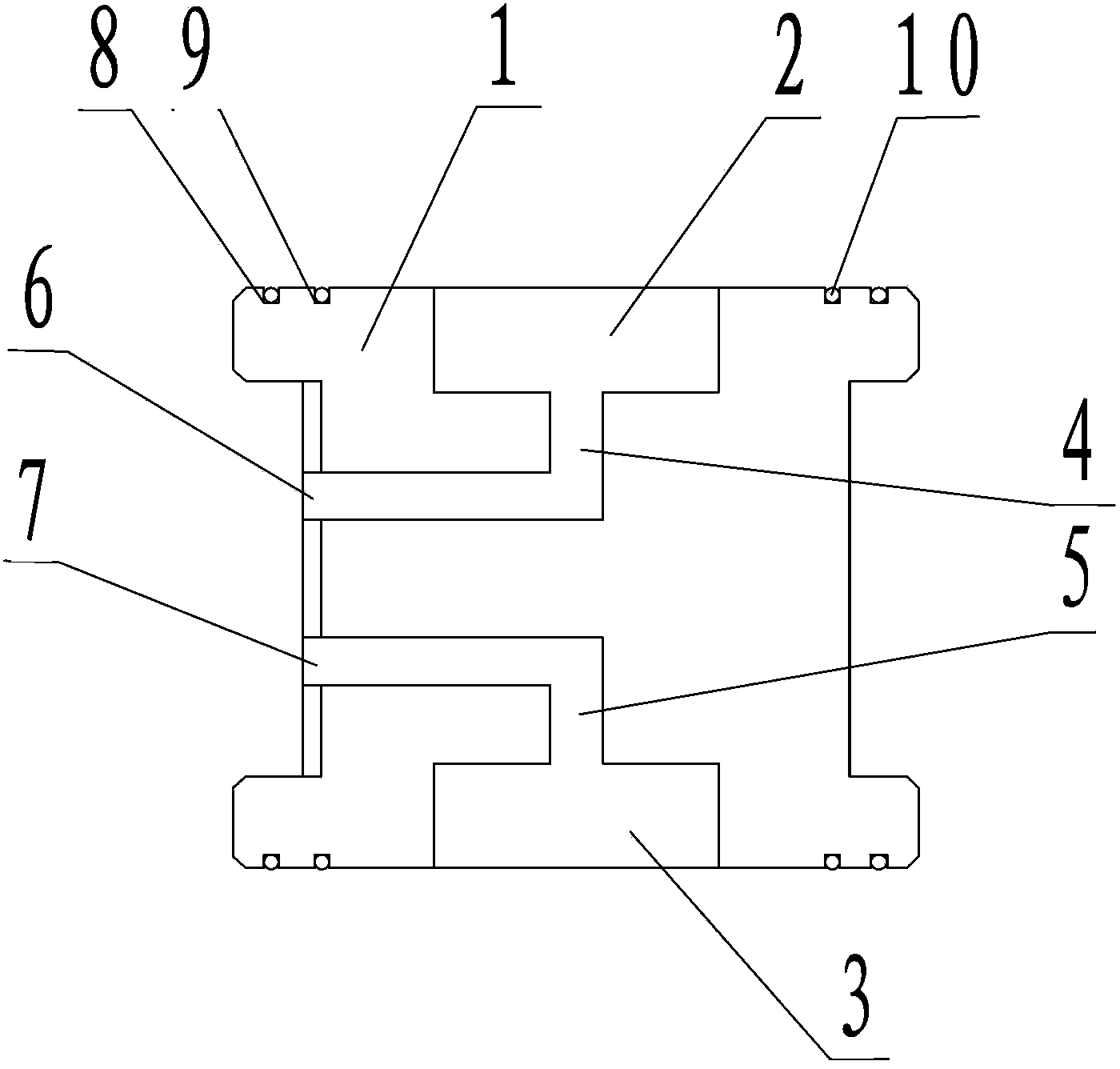

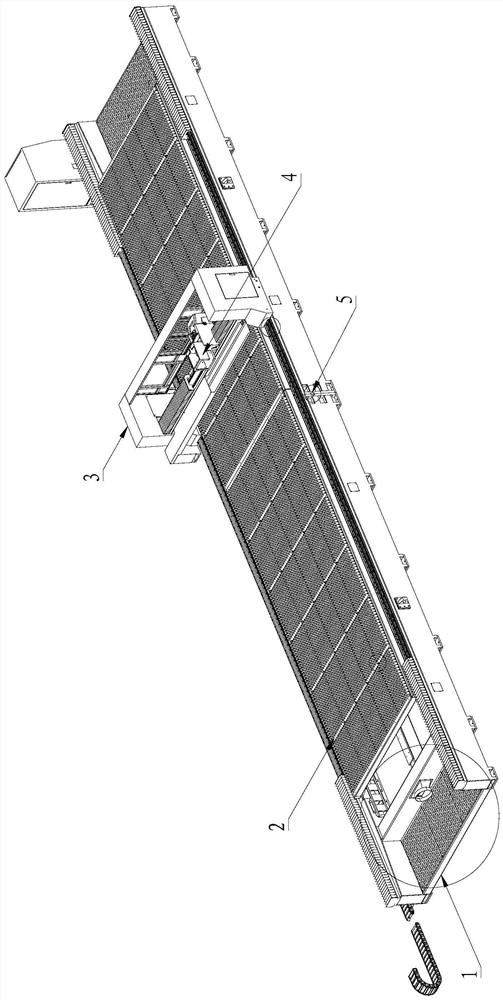

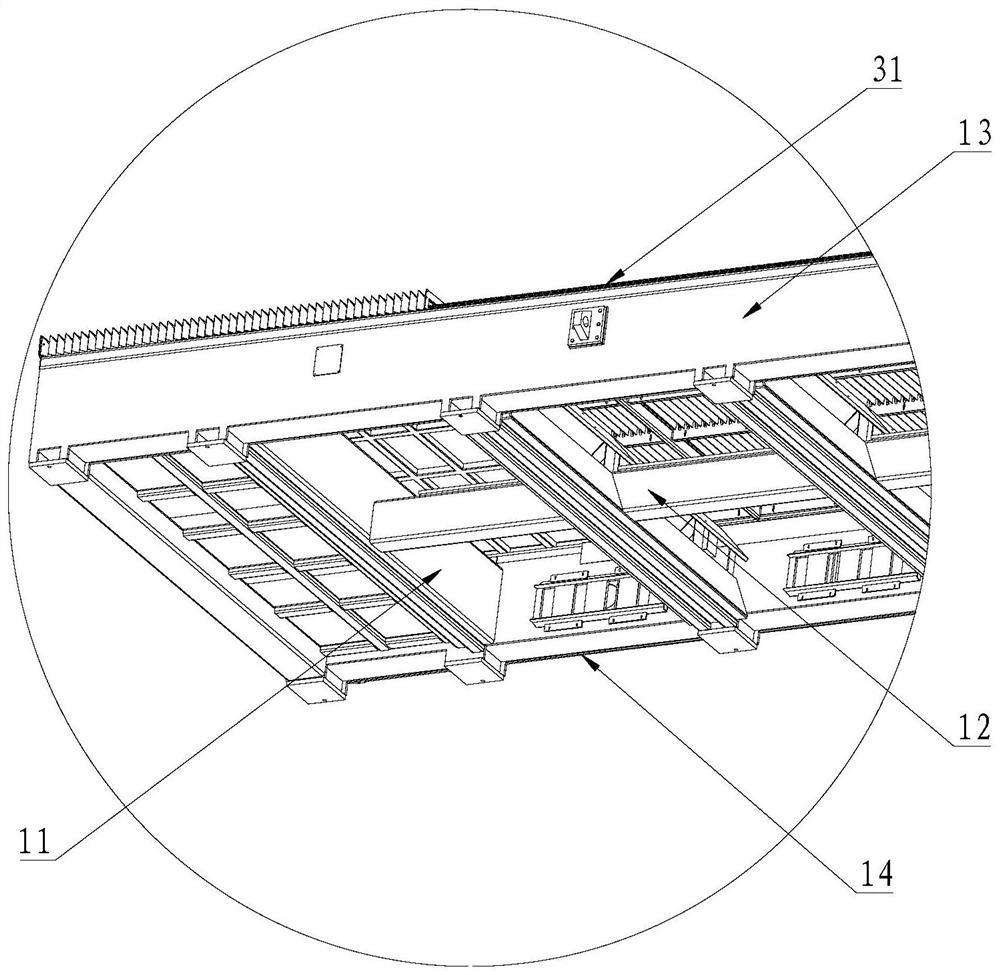

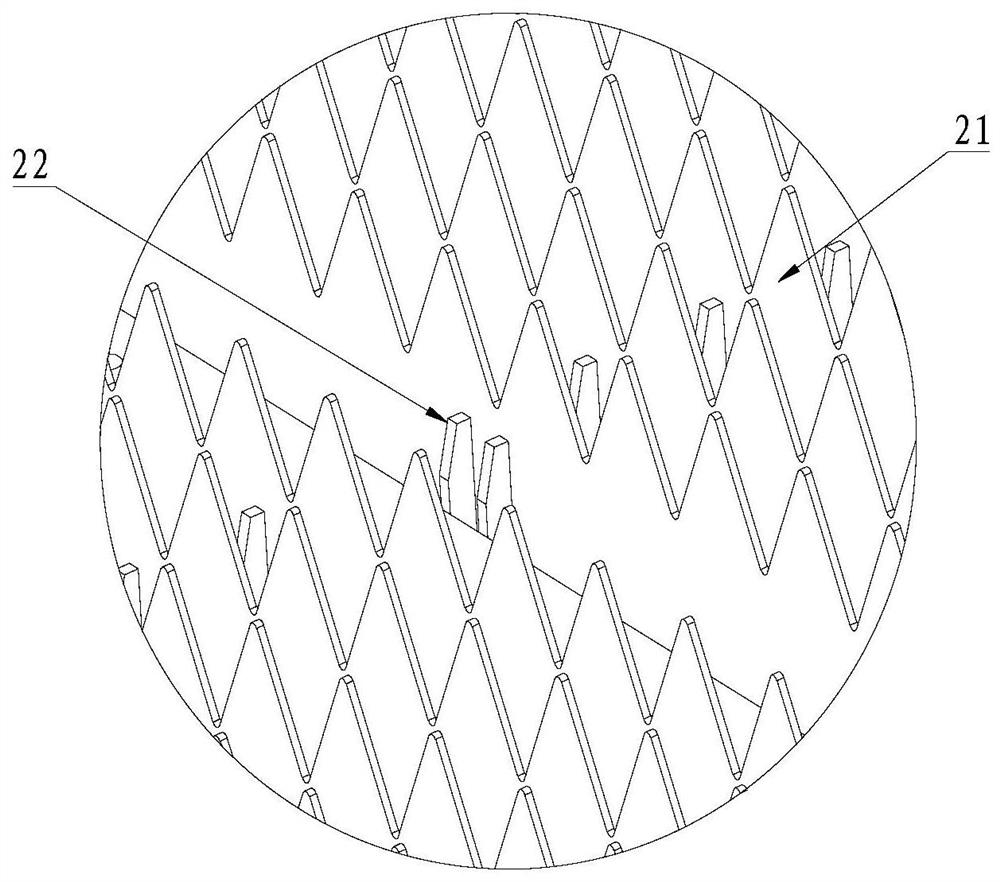

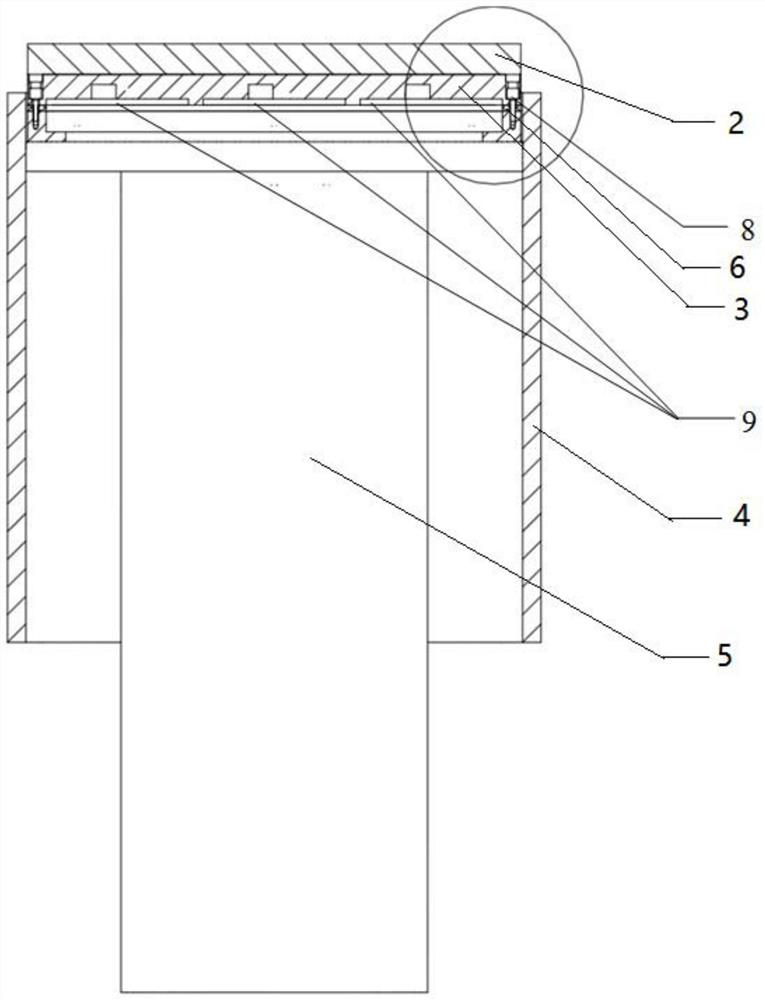

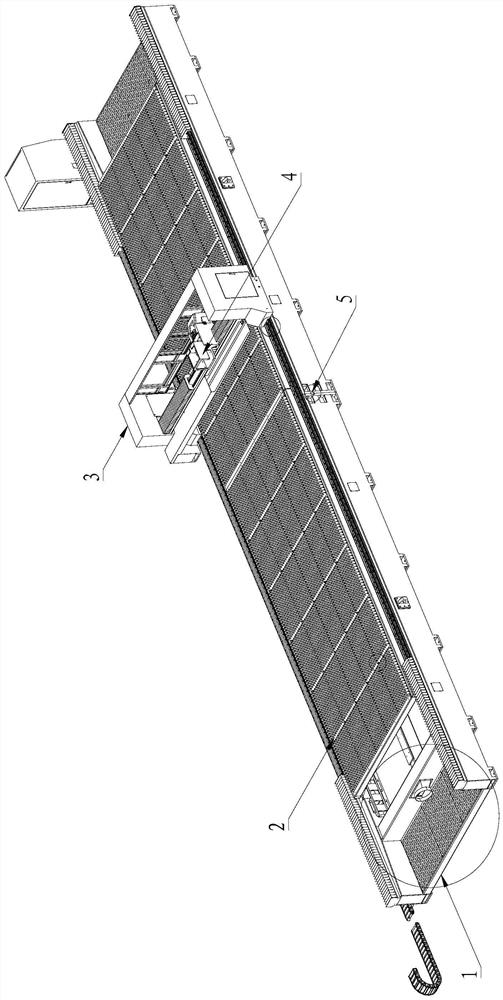

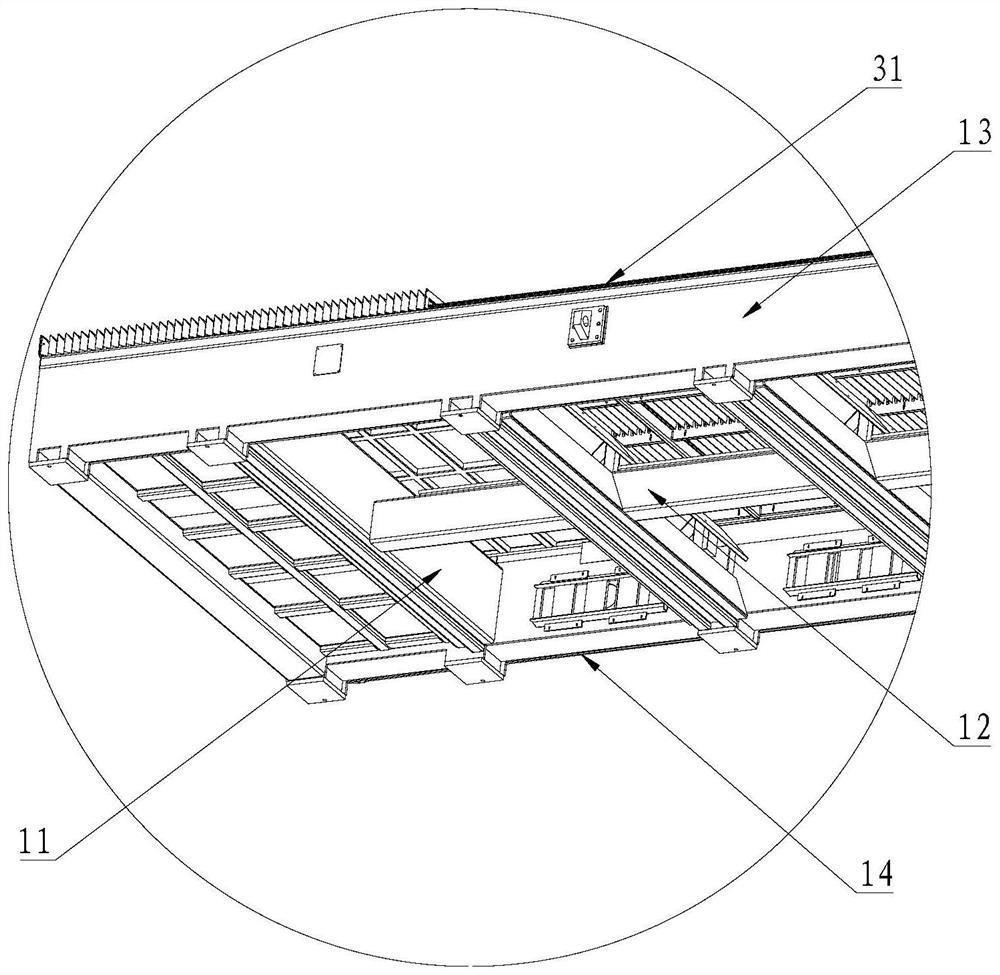

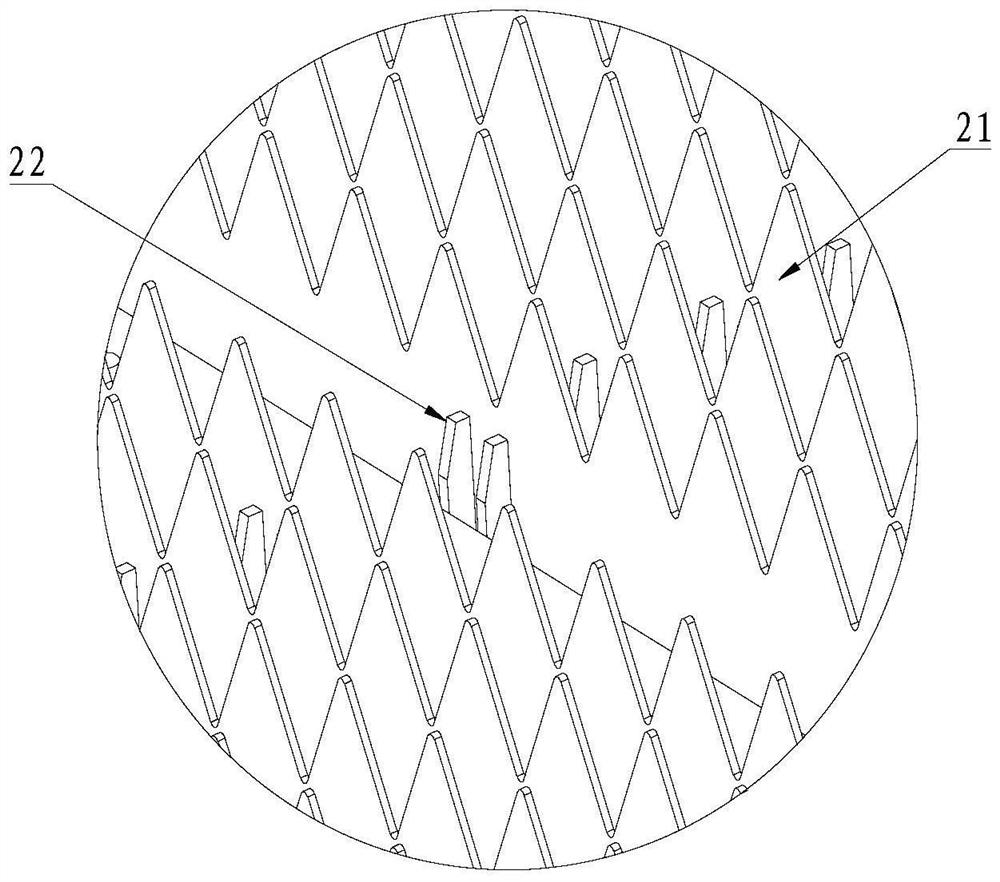

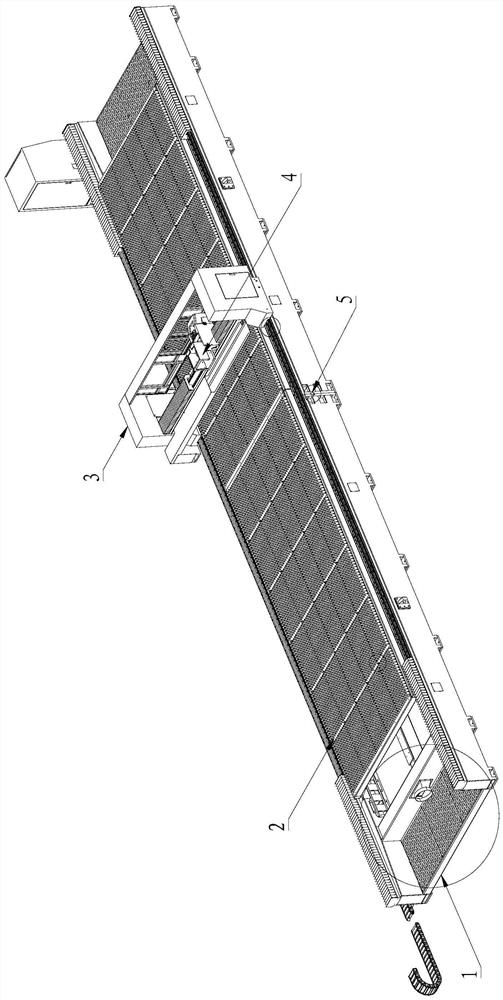

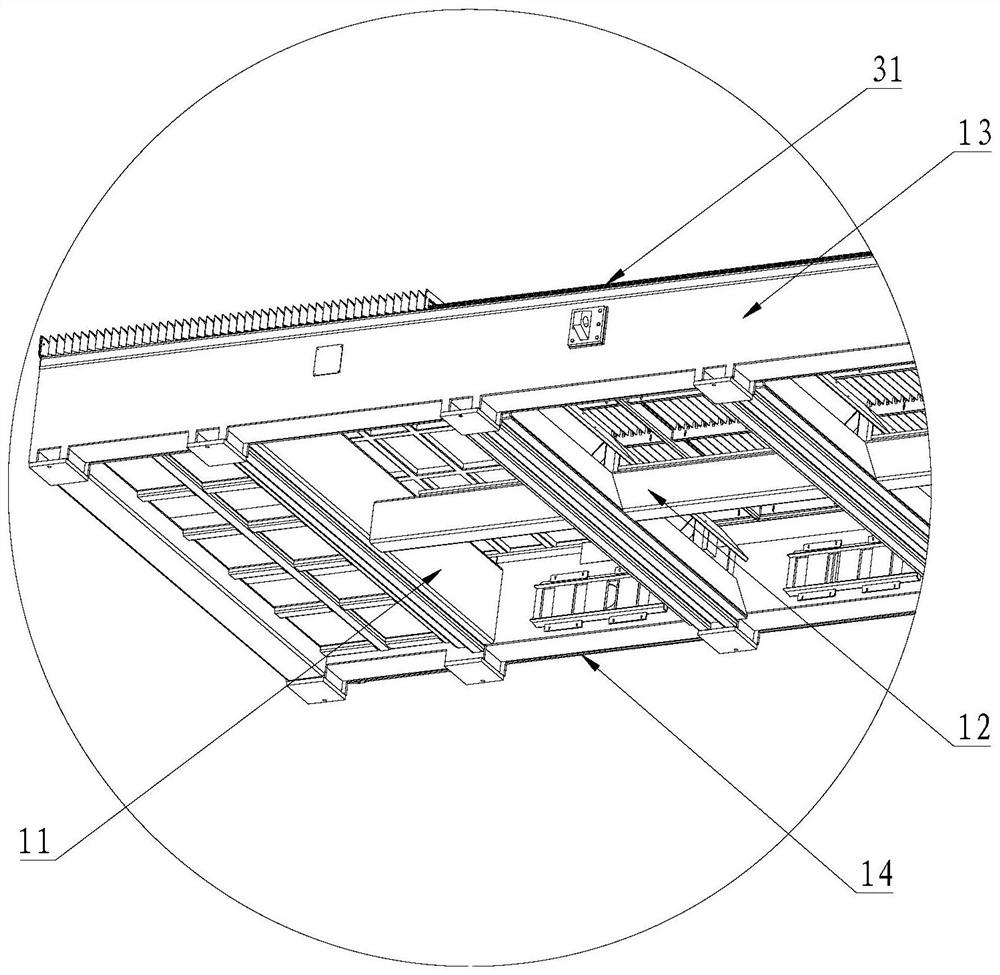

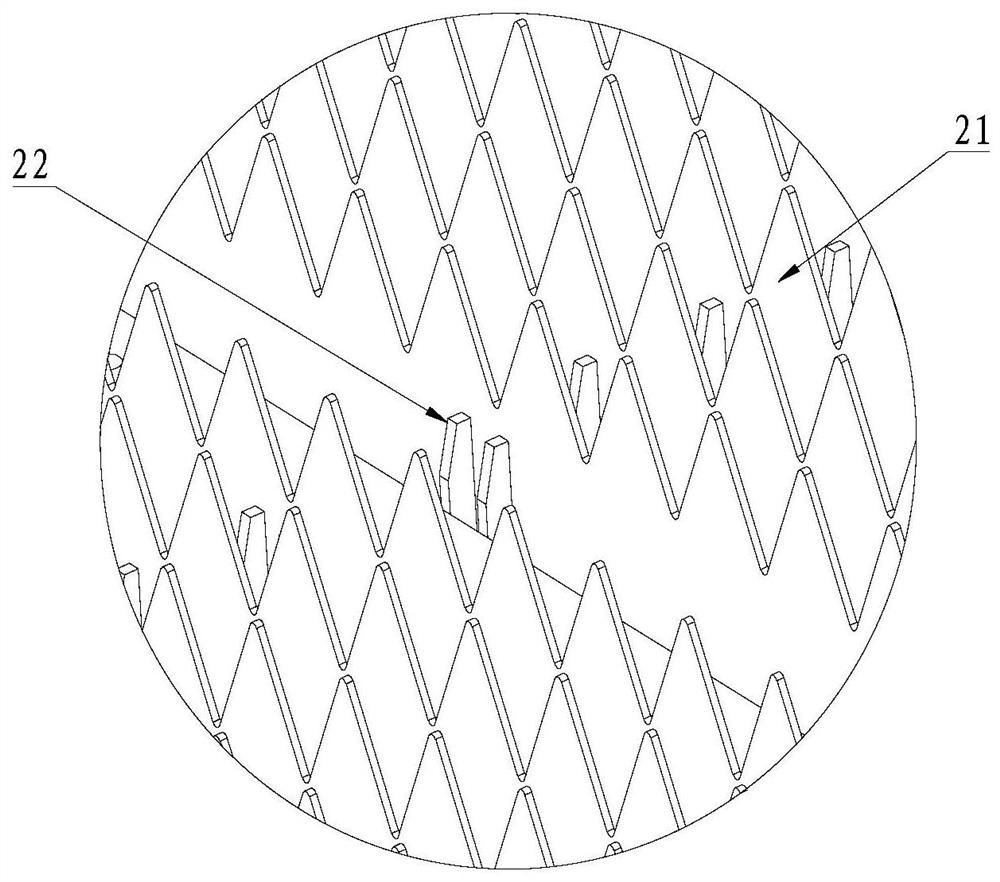

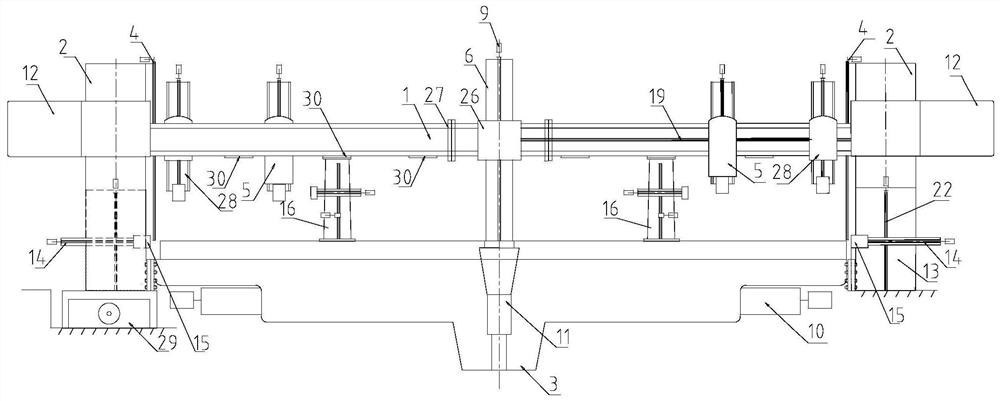

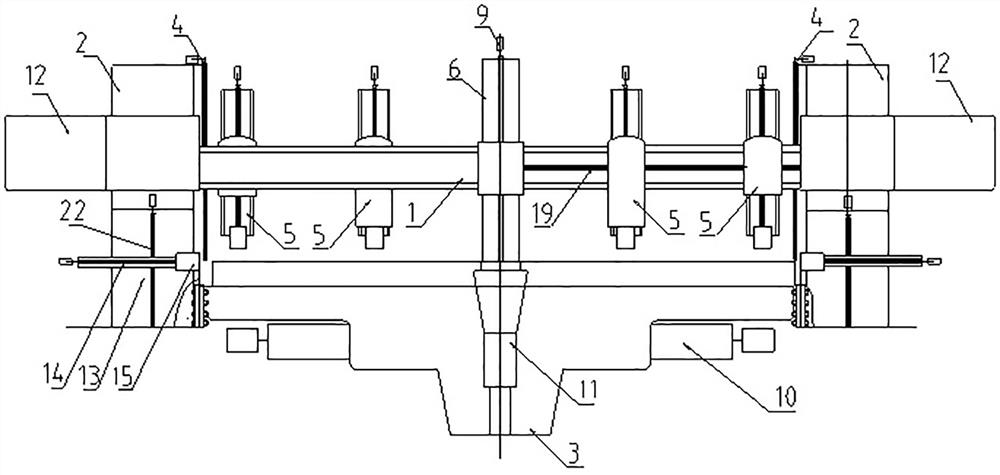

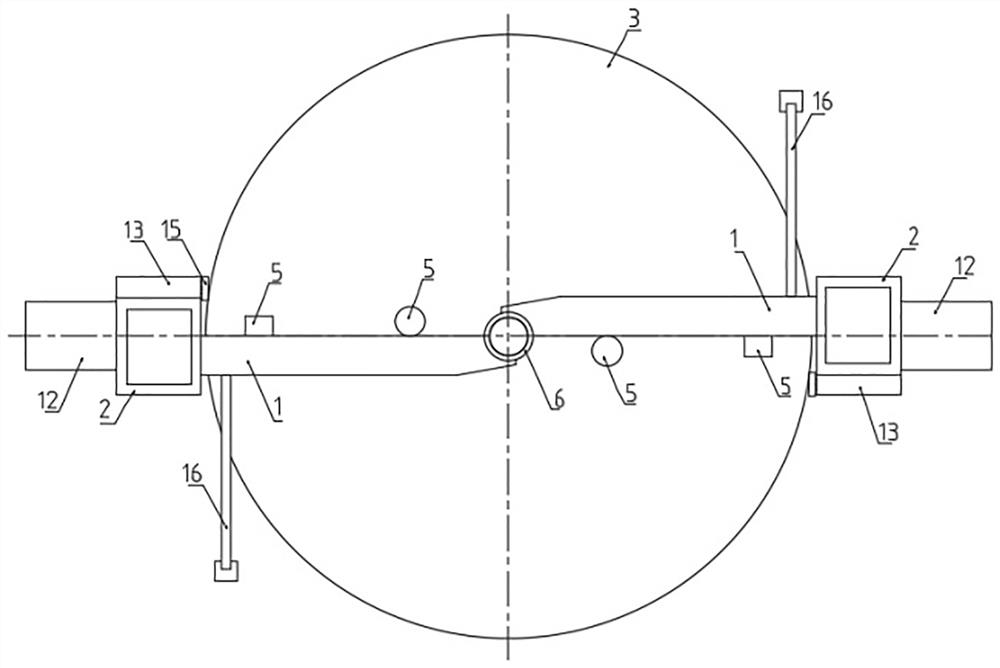

Large-breadth laser cutting machine

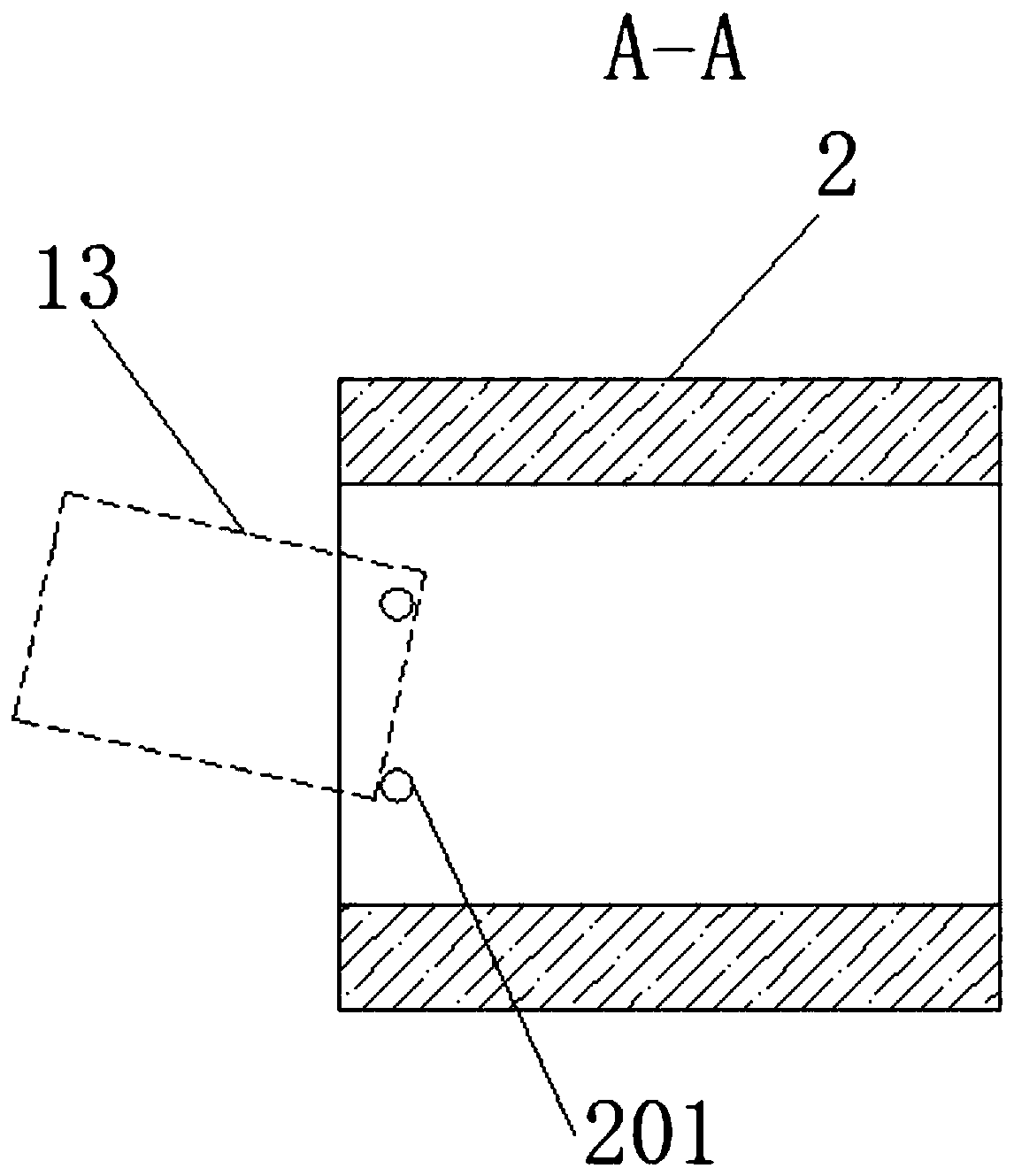

ActiveCN112059433AEasy to install, remove and replaceGuaranteed horizontal accuracyLaser beam welding apparatusPhysicsElectric machinery

The invention relates to the technical field of laser cutting equipment, in particular to a large-breadth laser cutting machine which comprises a machine tool, and a material supporting mechanism, a gantry mechanism, a cutting mechanism, position adjusting mechanisms, a heat insulation mechanism and a dust removal mechanism respectively arranged on the machine tool. The rack comprises a main crossbeam, a main longitudinal beam, a first boundary beam and a second boundary beam; the material supporting mechanism comprises a first material frame and a second material frame; the gantry mechanismcomprises a first rack, a gantry, a first motor, a second rack and a guide rail; the cutting mechanism comprises a moving frame, a second motor and a laser cutting machine, the moving frame is slidably connected with the guide rail, the second motor is arranged on the moving frame, the second motor is connected with the second rack through a gear, and the laser cutting machine is installed on themoving frame; and the two sets of position adjusting mechanisms are symmetrically arranged on the first boundary beam and the second boundary beam. The large-breadth laser cutting machine provided bythe invention can adapt to the cutting machining of large-breadth plates, and is high in precision and good in effect.

Owner:CHINA MACHINERY CNC TECH FUJIAN CO LTD

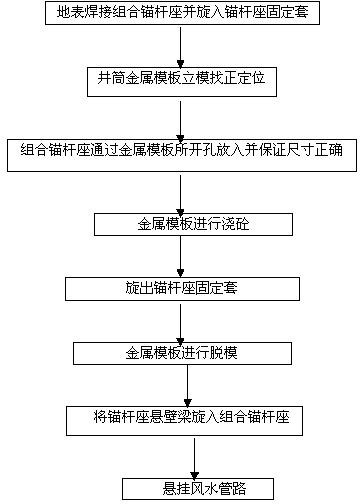

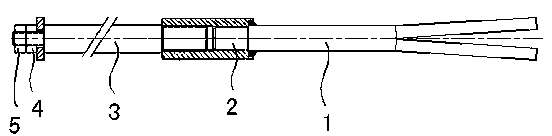

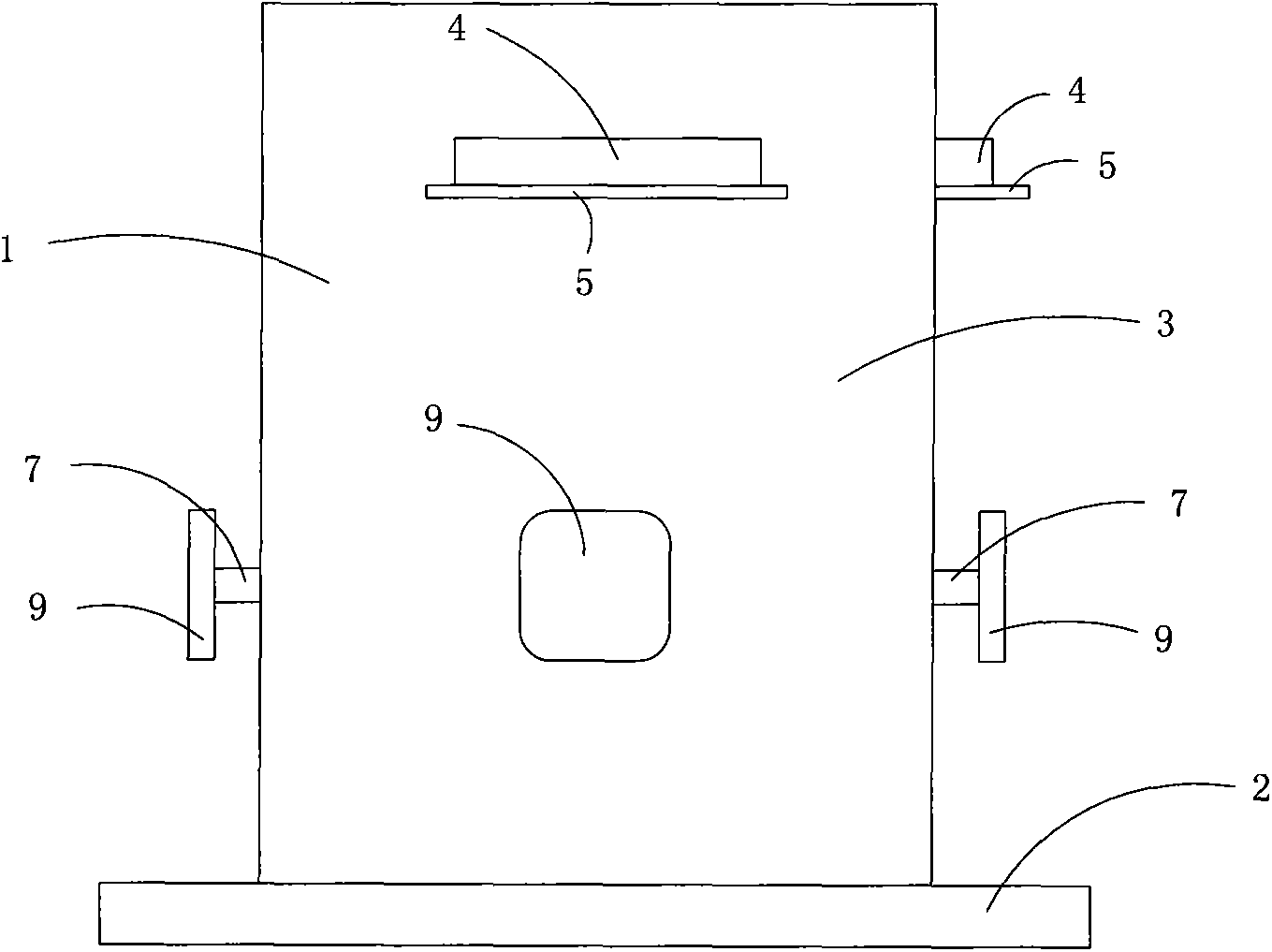

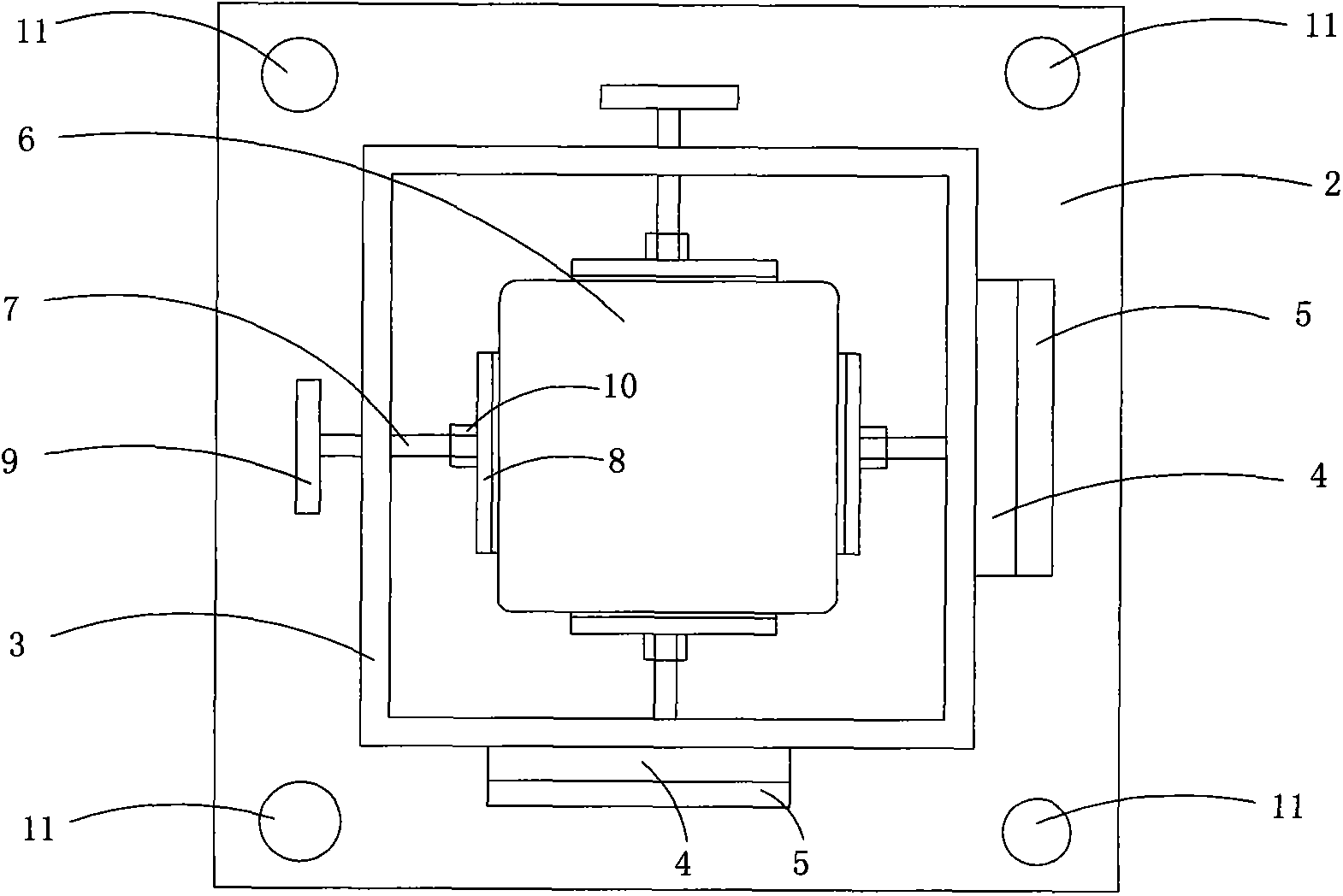

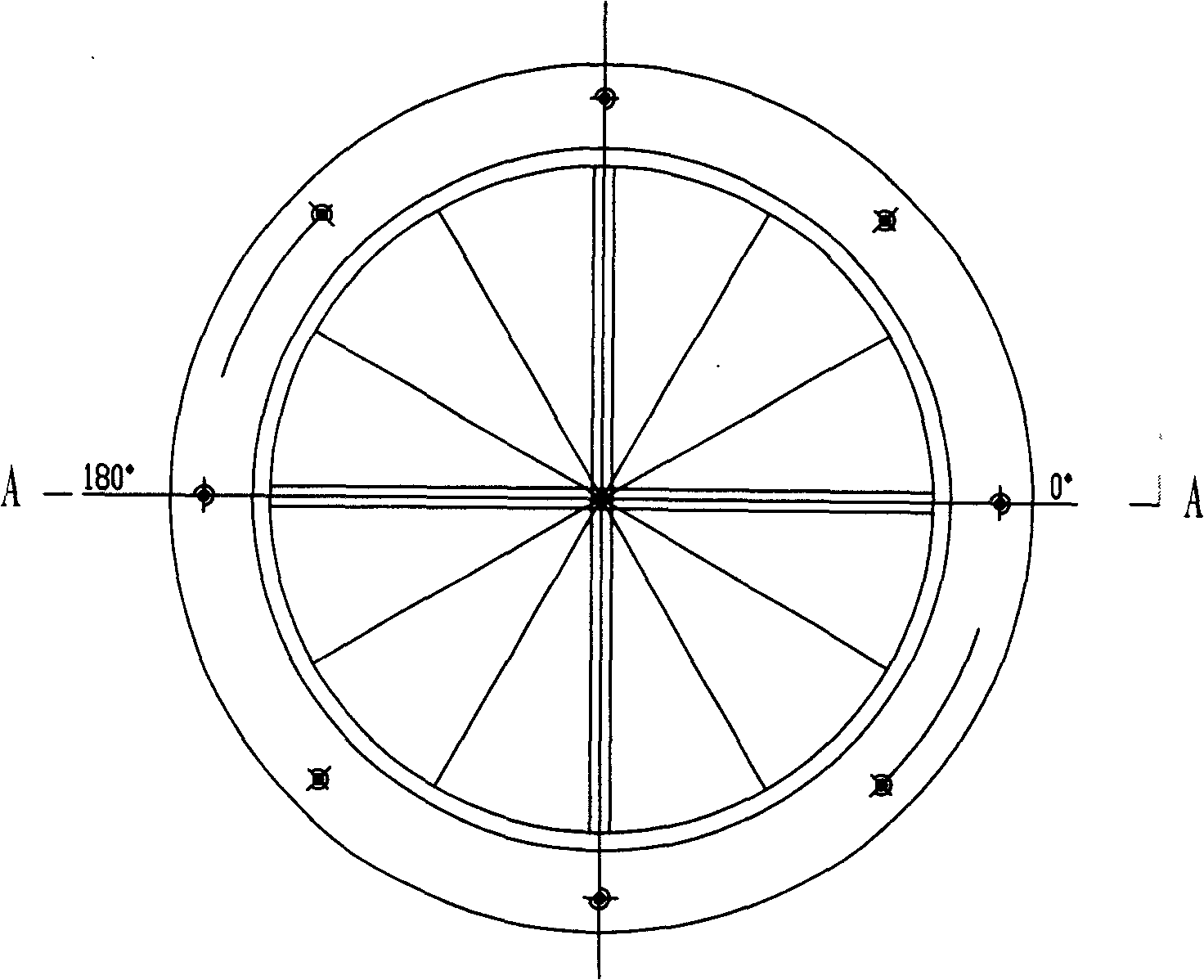

Installation method of special anchor rod for pre-installing temporary wall-hanging air and water pipeline during shaft construction

ActiveCN103953374ASaving Horizontal AccuracySave vertical accuracyAnchoring boltsEarth surfaceRock bolt

The invention discloses an installation method of a special anchor rod for pre-installing a temporary wall-hanging air and water pipeline during shaft construction. The installation method comprises the following steps: (1) welding a combined anchor rod seat on the ground and screwing an anchor rod seat fixing sleeve in the combined anchor rod seat; (2) aligning and positioning a shaft metal template vertical mould; (3) trepanning a metal template; (4) putting the combined anchor rod seat through the holes formed in the metal template; (5) casting concrete on the metal template; (6) screwing out the anchor rod seat fixing sleeve from the combined anchor rod seat after cast shaft concrete is solidified; (7) demolding the metal template; (8) screwing an anchor rod seat suspension beam in the combined anchor rod seat.

Owner:TONGLING ZHONGDU MINING CONSTR

Novel firework support

InactiveCN103712526AEasy to install and removePrevent dumpingFirecrackersMagnetStructural engineering

The invention discloses a novel firework support. The novel firework support comprises a support body made of metal. The support body comprises a base and a firework barrel fixed to the base. The cross section of the firework barrel is square. Strip type level gauges which are parallel to the bottom face of the base are arranged on the two adjacent faces of the firework barrel. Each strip type level gauge is connected with the firework barrel through a magnet arranged on the strip type level gauge. Supporting plates used for supporting the strip type level gauges are welded to the outer walls of the firework barrel and are parallel to the bottom face of the base. According to the novel firework support, the horizontal accuracy of the novel firework support is more guaranteed through the arrangement of the strip type level gauges, so the novel firework support can be horizontally placed, surrounding buildings will not be damaged in the process of setting off a firework which is placed in the firework barrel.

Owner:卢新民

A multi-frequency ultrasonic processing device for engineering ceramics

InactiveCN106313340BGuaranteed horizontal accuracyImprove machining accuracyWorking accessoriesStone-like material working toolsSonificationTransducer

Owner:TAIYUAN UNIV OF TECH

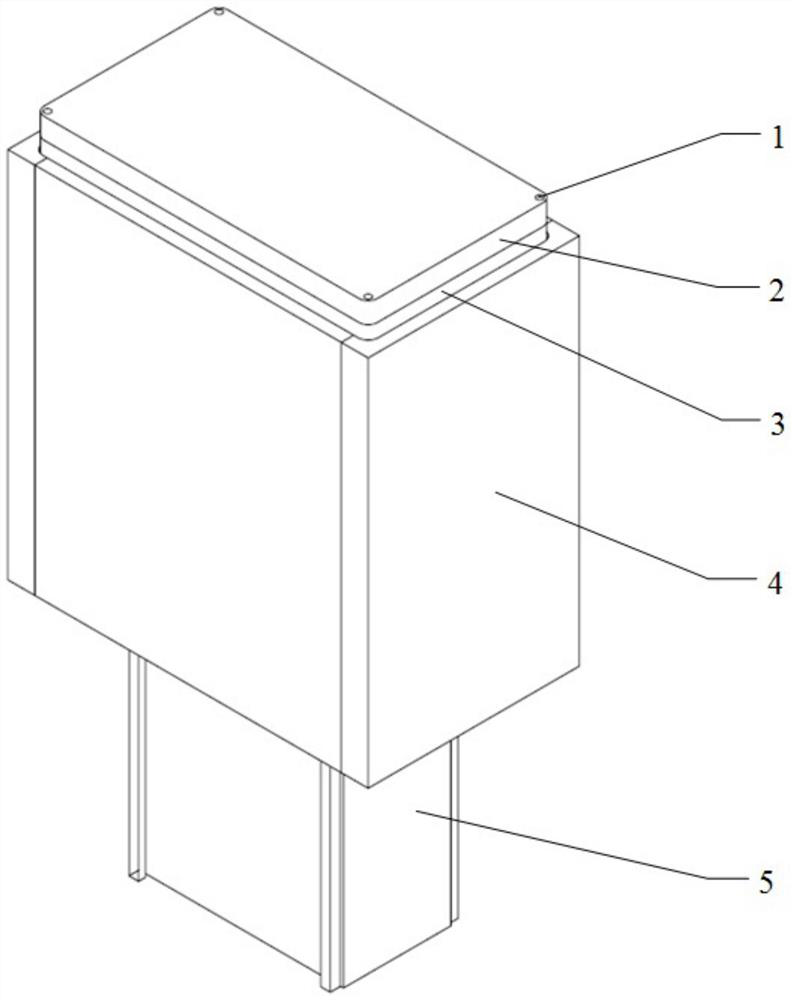

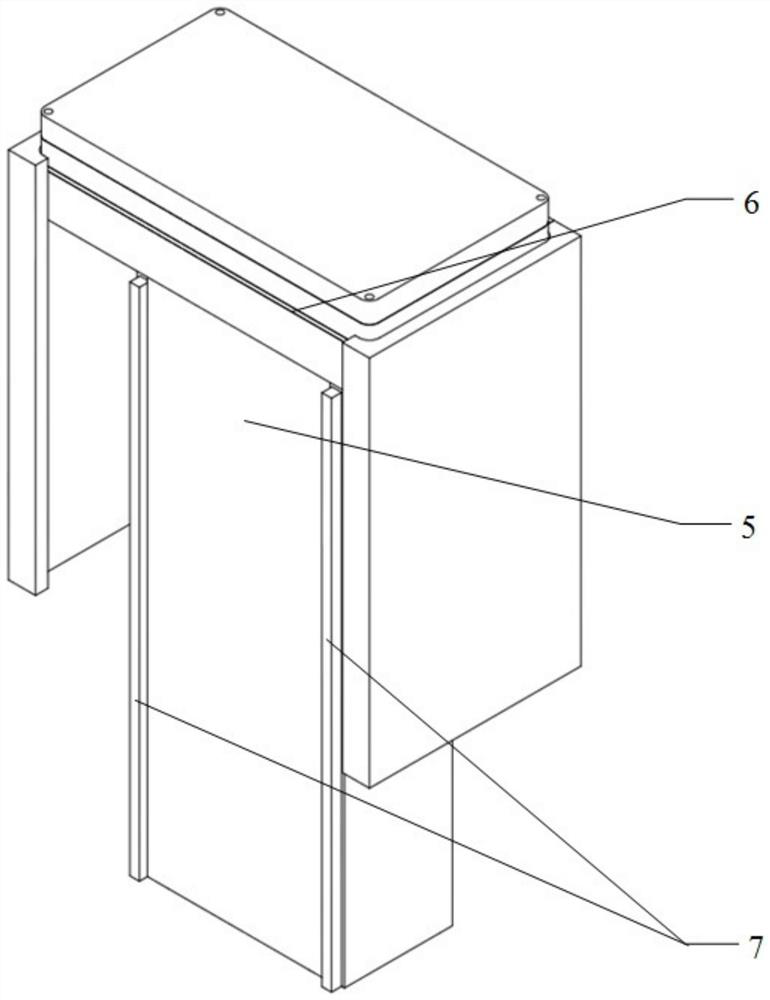

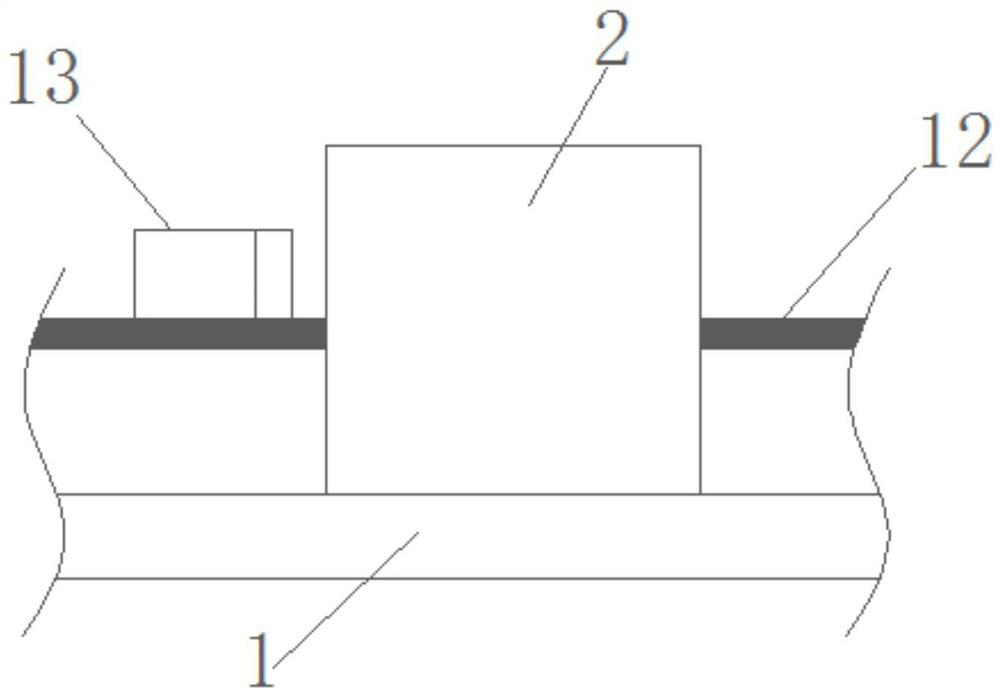

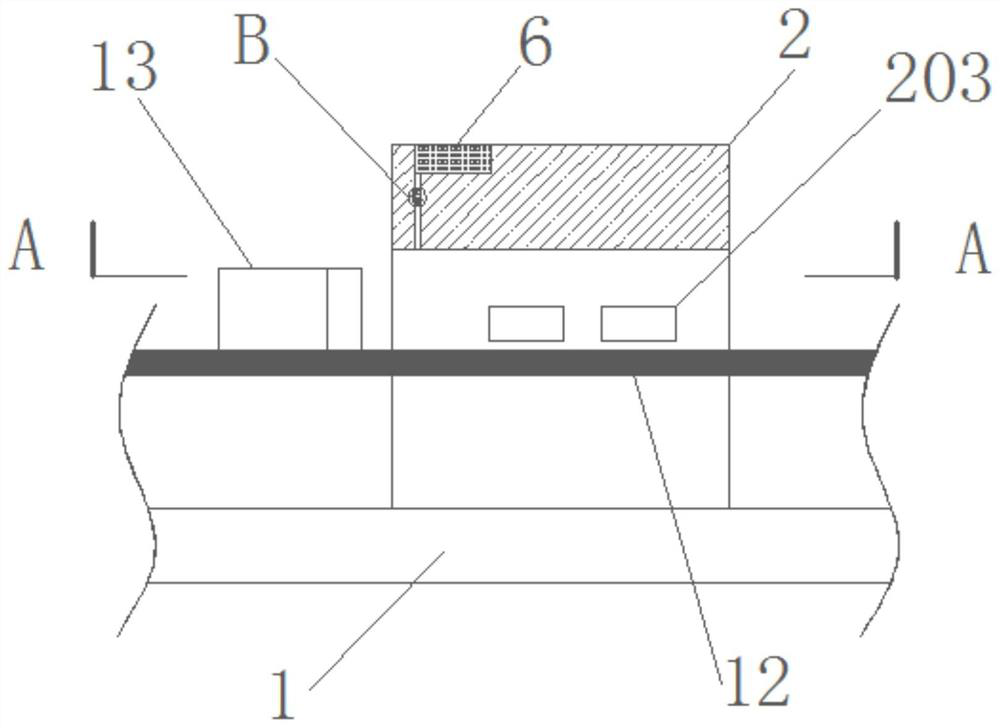

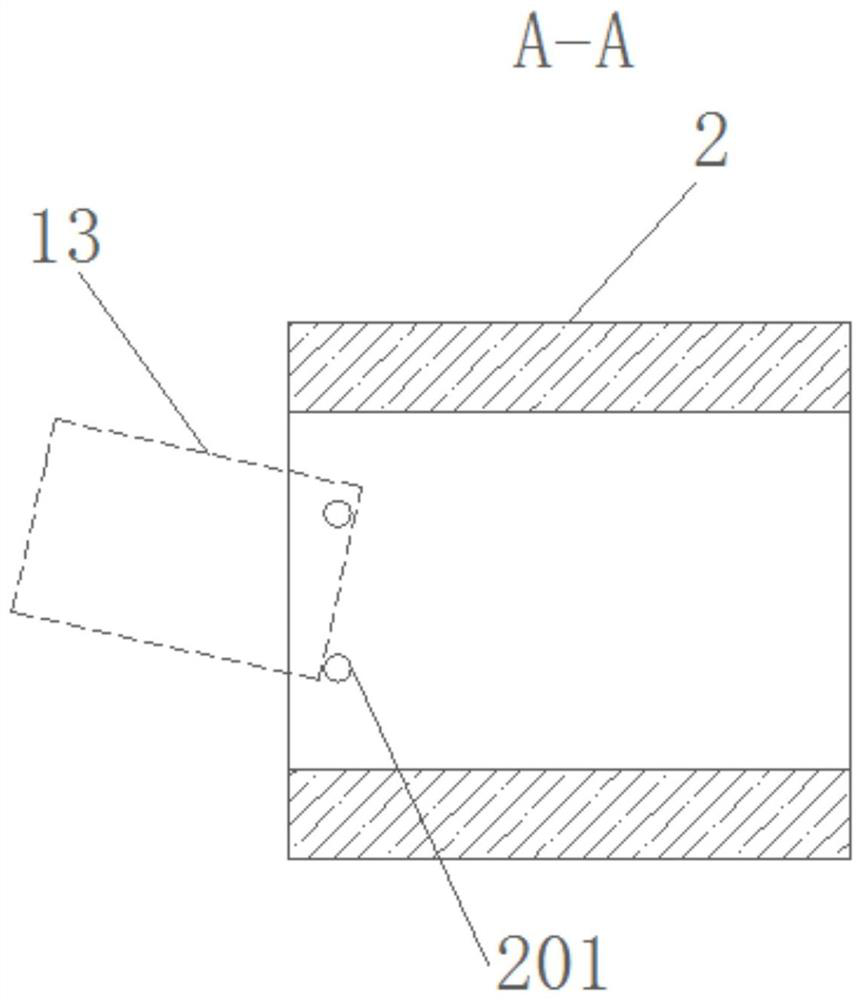

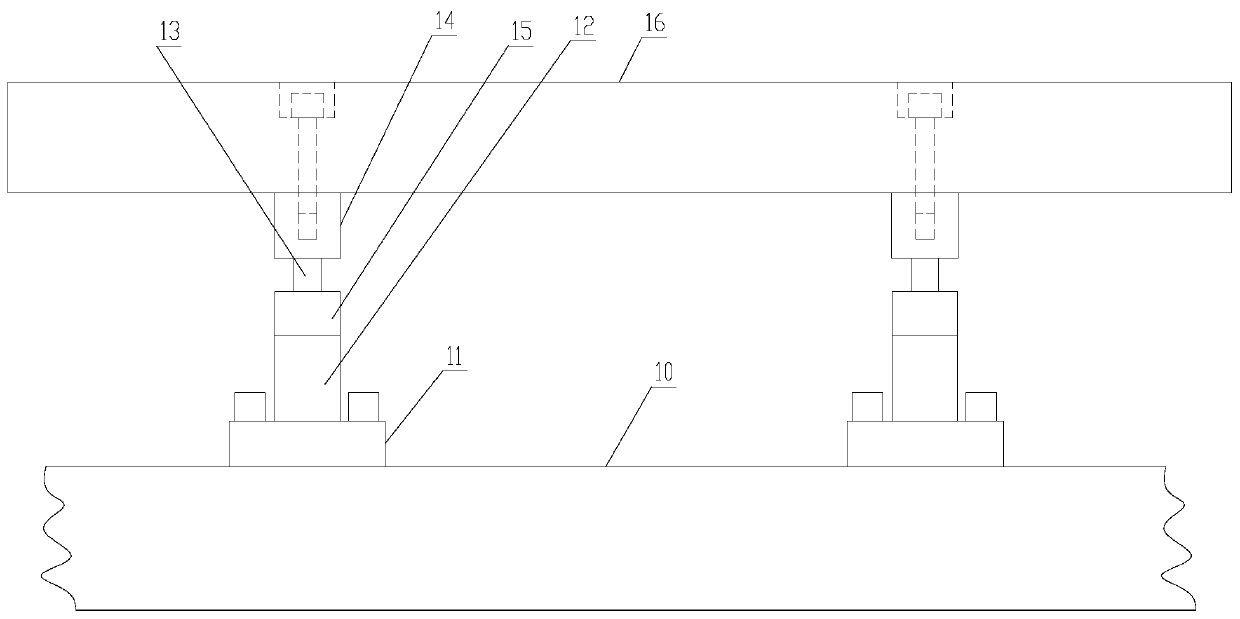

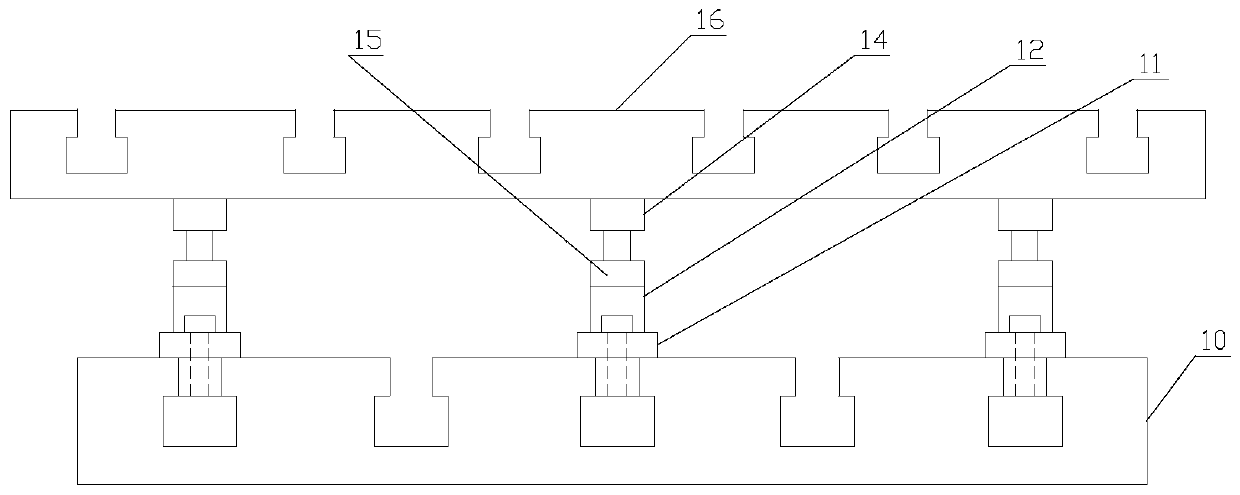

Refrigeration house goods shelf foundation and installing method thereof

The invention relates to the technical field of ship manufacturing, in particular to a refrigeration house goods shelf foundation and an installing method thereof. The refrigeration house goods shelffoundation comprises multiple goods shelf bases arranged at intervals, the upper surfaces of the goods shelf bases are located in the same horizontal plane, and each goods shelf base comprises overlapping racks and supporting assemblies, wherein the overlapping racks are provided with containing channels; the supporting assemblies are arranged in the containing channels and connected with the sidewalls of the containing channels, and the upper surfaces of the supporting assemblies are located in the same horizontal plane. The installing method of the refrigeration house goods shelf foundationincludes the steps that an installing line is marked out; multiple mark poles are erected, a horizontal height line is marked on each mark pole, and multiple horizontal height lines are located in the horizontal plane; according to the position of the installing line, the overlapping racks are arranged at preset positions and fixed; according to the horizontal height lines on the mark poles, thepositions of the supporting assemblies are determined, and the supporting assemblies are fixed to the overlapping racks.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

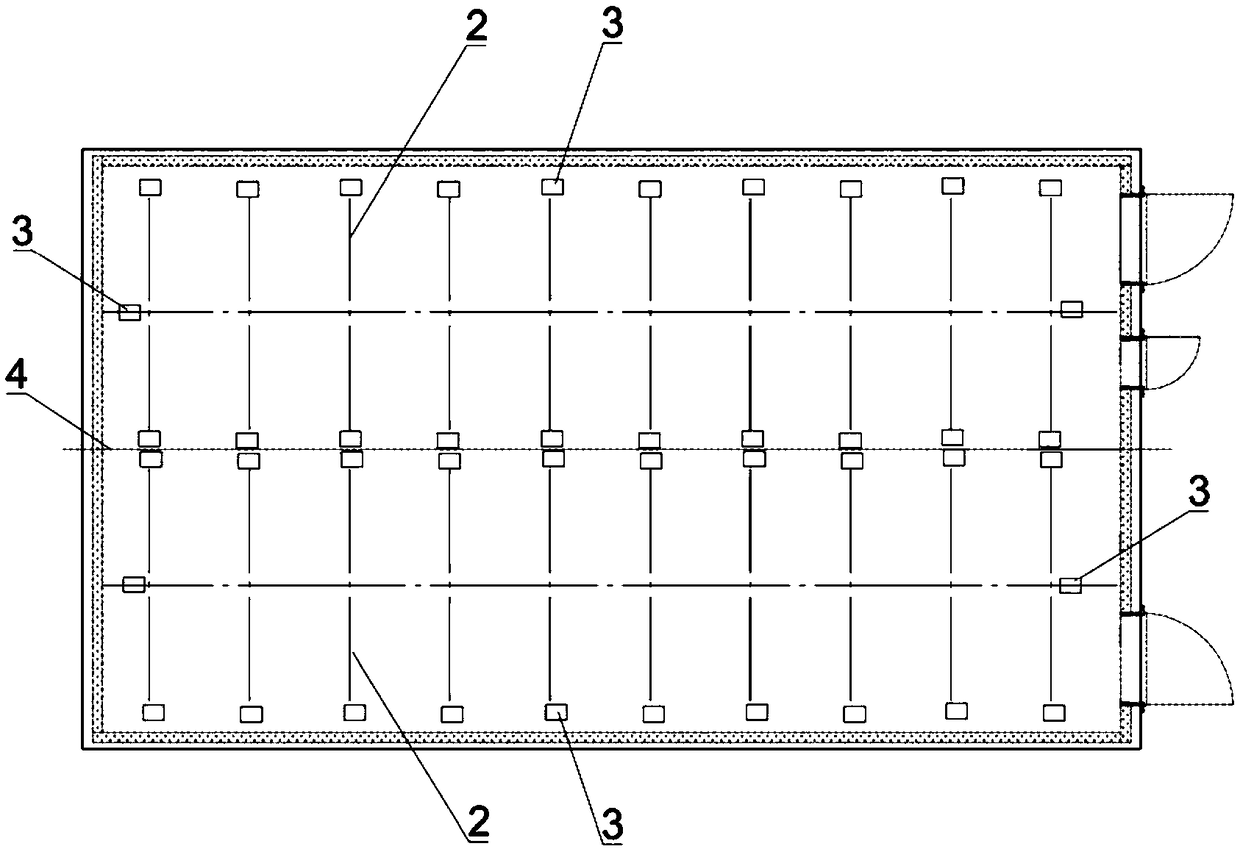

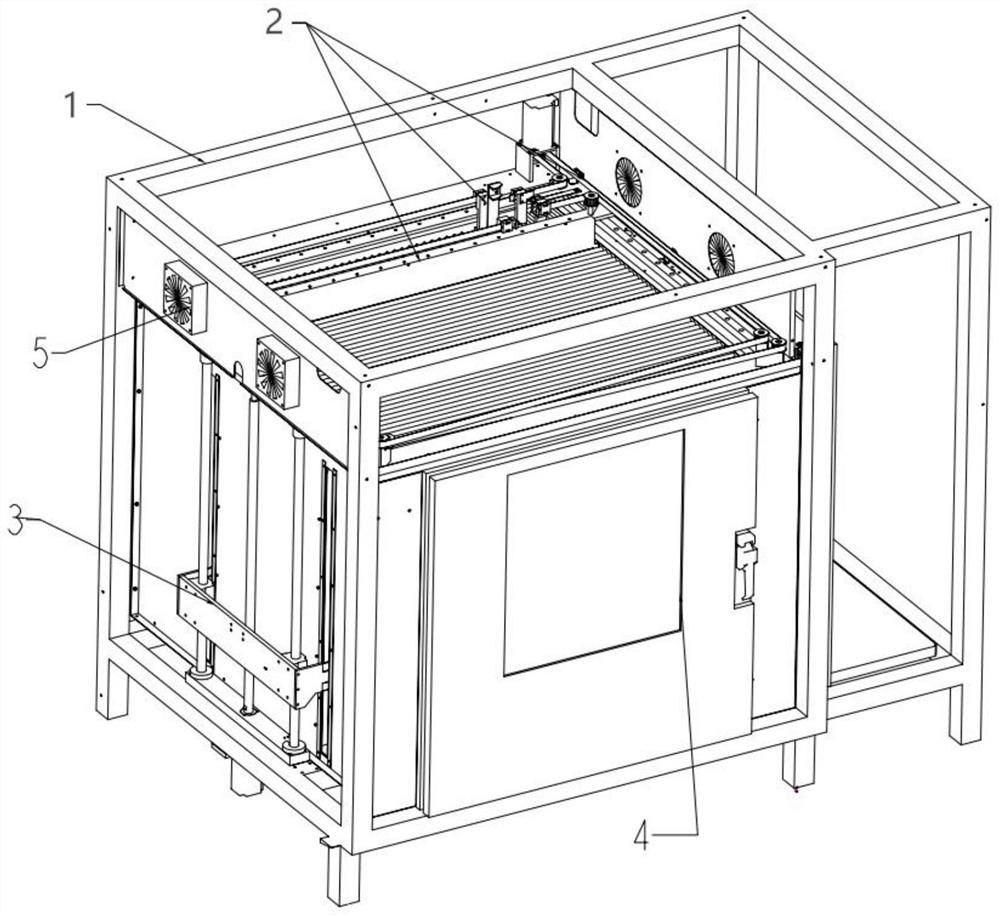

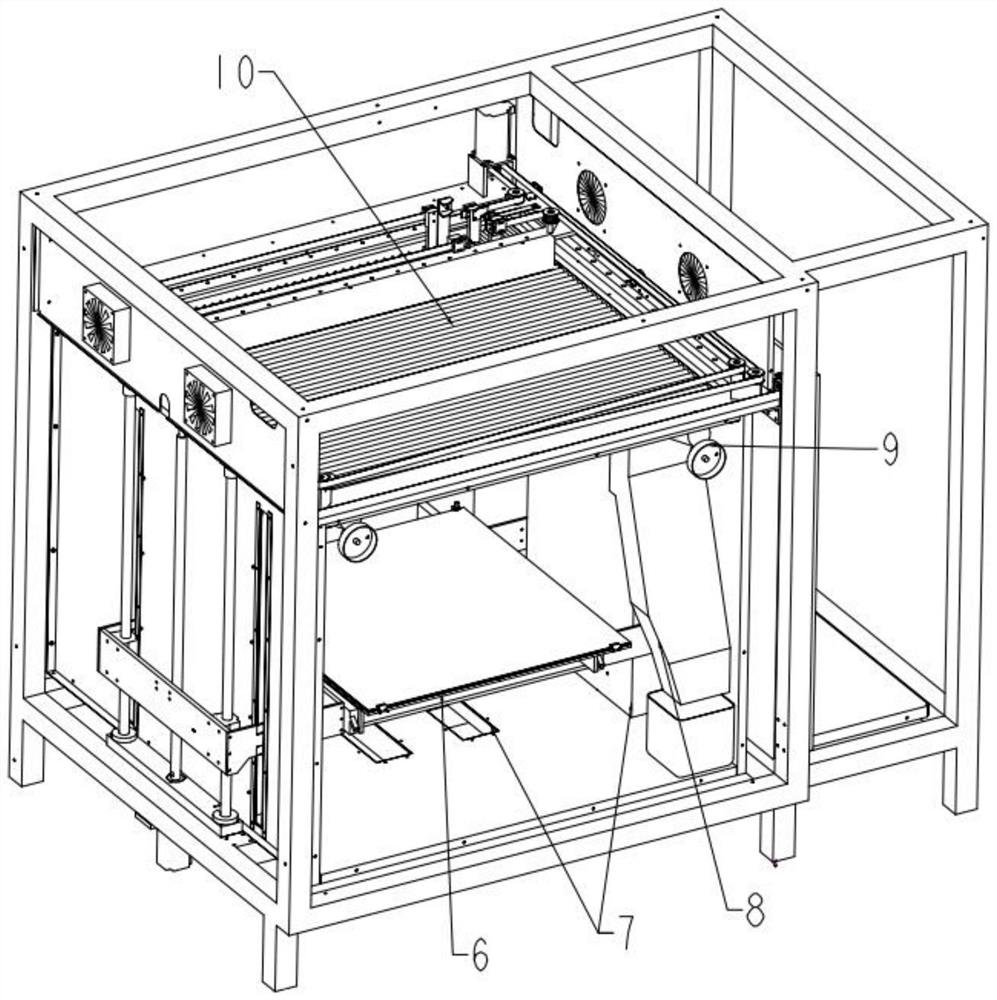

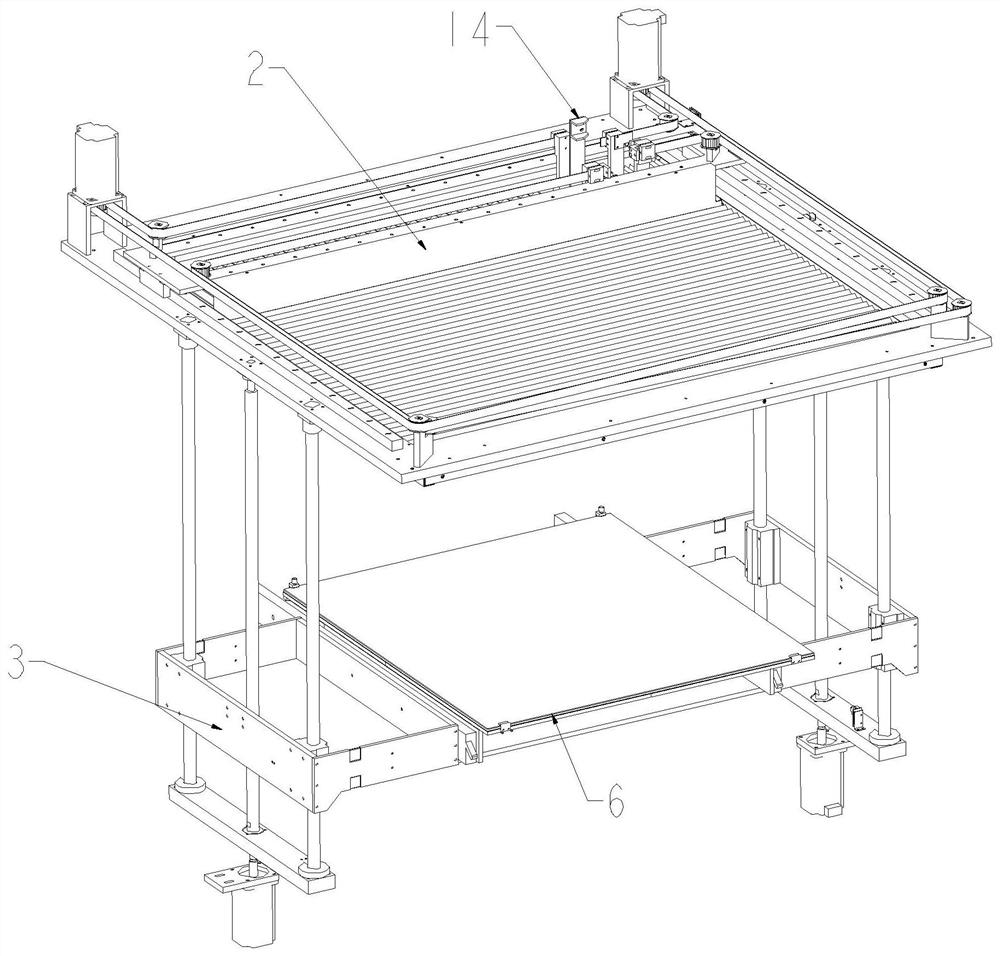

Space constant-temperature large-size printing platform 3D printing device

PendingCN112223741AGuaranteed horizontal accuracyEasy to operateManufacturing platforms/substratesLighting elementsPhysicsEngineering

The invention discloses a space constant-temperature large-size printing platform 3D printing device. The space constant-temperature large-size printing platform 3D printing device comprises a devicerack, a heat preservation layer is arranged on the inner side of the rack, a front door is arranged on the front face of the rack, a forming space is formed by the heat preservation layer and a cavitydefined by the interior of the front door, a printing platform assembly, a spray head assembly and a hot air double-circulation space heating assembly are arranged in the forming space, the printingplatform assembly is arranged at the bottom in the forming space, an air inlet of the hot air double-circulation space heating assembly is formed in the top of the forming space, and an air outlet ofthe hot air double-circulation space heating assembly is formed under the printing platform assembly; and a hot bed of the printing platform assembly is formed by splicing a plurality of hot bed units, and each hot bed unit is provided with a horizontal adjusting assembly and a locking assembly. According to the space constant-temperature large-size printing platform 3D printing device, stress deformation of a large-size hot bed during heating can be effectively avoided, hot air blown out of the forming space is diffused all around, the whole forming space is evenly filled with the hot air, and the forming precision and the surface quality of products are effectively improved.

Owner:GUANGZHOU ELECTRONICS TECH

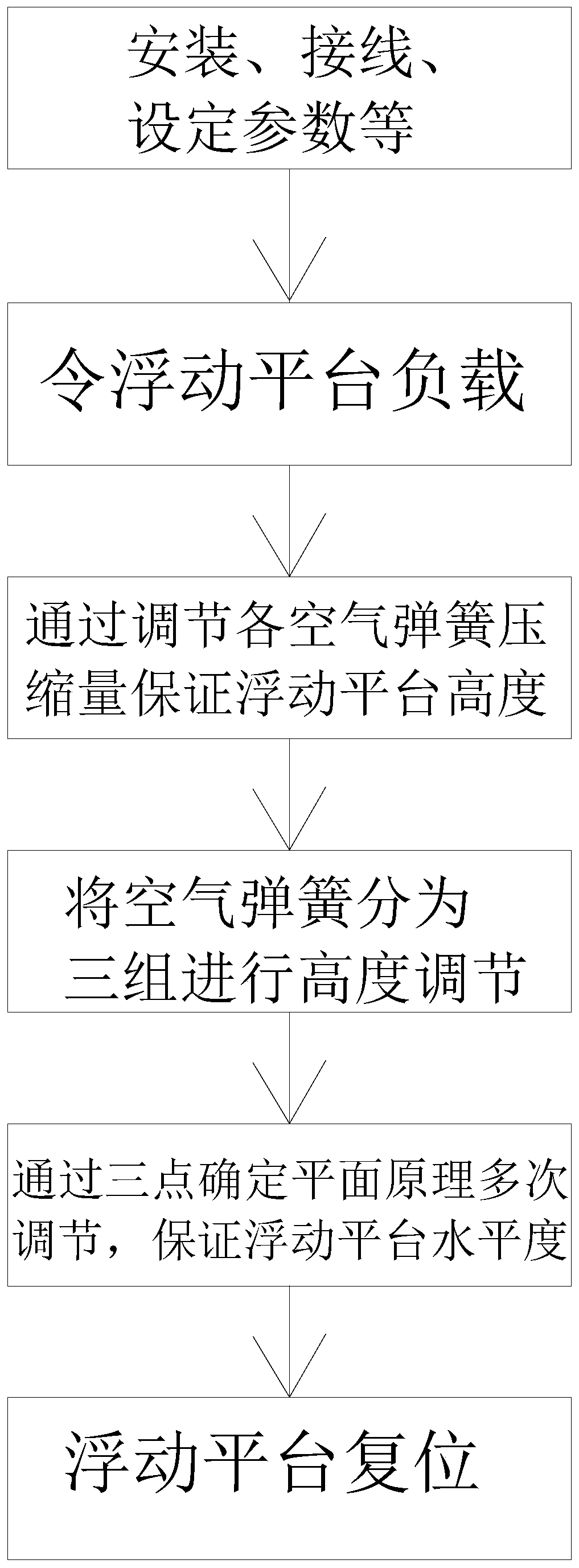

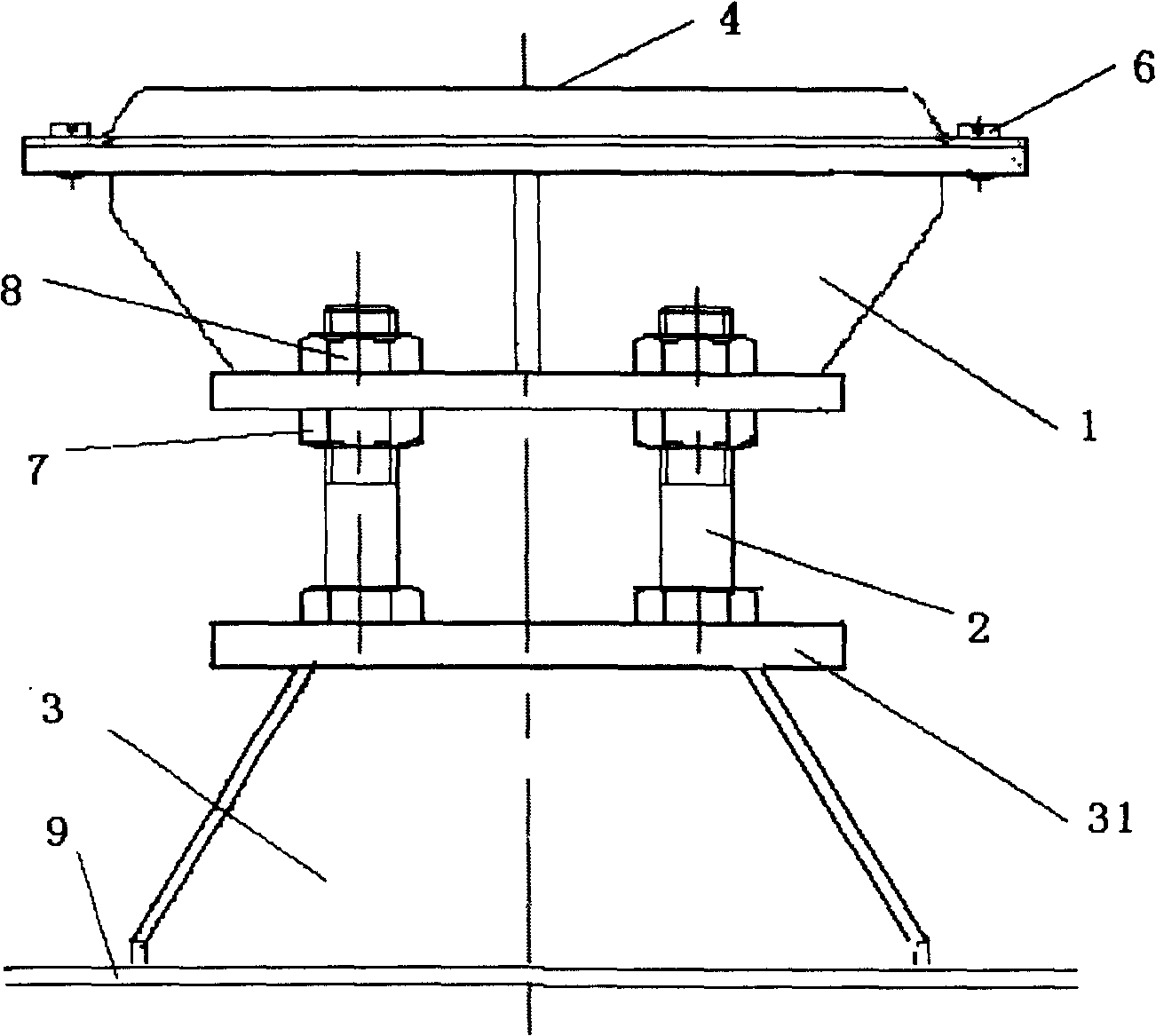

Height and levelness adjusting method for floating platform

ActiveCN110594350AGuaranteed heightGuaranteed horizontal accuracyMeasurement devicesVibration suppression adjustmentsControl systemAir spring

A height and levelness adjusting method for a floating platform comprises the steps of arranging corresponding displacement sensors, connecting the displacement sensors with a control system, settingthe height of the floating platform in the control system, controlling the compression amount of an air spring through a horizontal adjusting valve, and controlling the height of the air spring through a height control valve. By adopting the air spring as the support of the floating platform, the vibration isolation effect is effectively improved; by controlling the air inlet and outlet of the airspring, the air spring is guaranteed to be at the same horizontal position, so that the height of the floating platform is guaranteed; and according to the principle that the plane is determined by three points, the height of the air spring is adjusted, so that the horizontal precision of the floating platform is guaranteed, and the test work on the floating platform is guaranteed to be carried out smoothly.

Owner:热测测试技术(苏州)有限公司

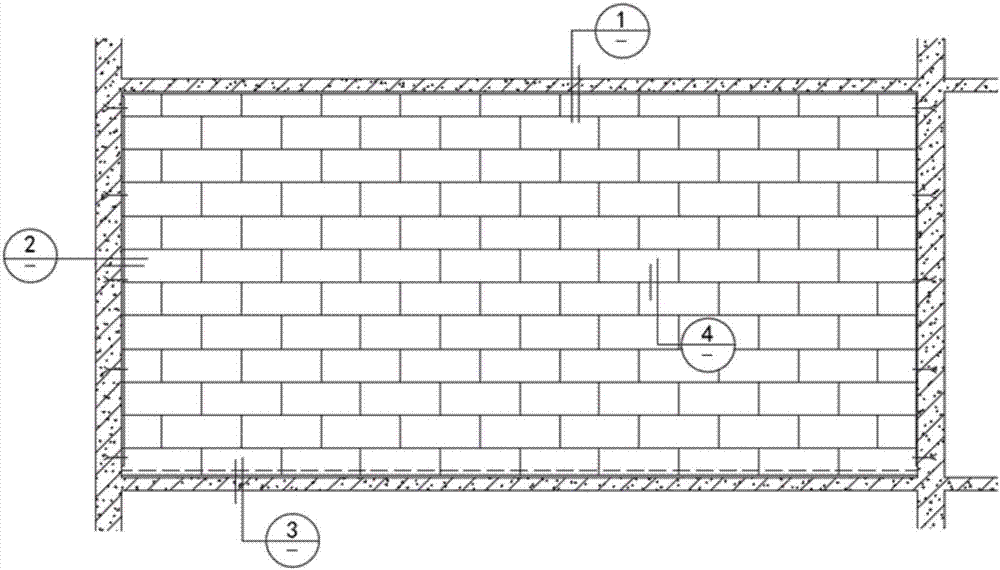

Assembly type bentonite stone wallboard and combined mounting method thereof

ActiveCN107268837APrecise positioning functionAccurate leveling and straightening functionWallsClimate change adaptationFloor slabArchitectural engineering

The invention discloses an assembly type bentonite stone wallboard and a combined mounting method thereof, and relates to the field of fixed buildings. The assembly type bentonite stone wallboard comprises a layer of panel and a plurality of layers of standard boards; the panel is arranged on the upper surface of a lower floor of a building; an upper floor of the building is in rigid connection with the standard board at the top end of a wall body; and the standard boards and the panel are in tenon-and-mortise connection, and every two adjacent layers of standard boards are also in tenon-and-mortise connection. The method comprises the steps that S1, a leveling-out layer and a leveling layer are laid and the panel is mounted; S2, the standard boards are assembled; and S3, a top rigid structure is connected, and combined mounting of the assembly type bentonite stone wallboard is finished. The precision of the appearance shape and size of the wallboard is strictly controlled, a pin lock and a pin hole have the precise positioning function, and tenons and mortises have the accurate leveling and straightening functions; and at the same time, the connection and construction methods with the building have multiple function features, the connection function is ensured, the precision is also ensured, and the optimal effect is generated through mutual restriction.

Owner:BEIJING TIANJI NEW MATERIALS

Navigation system level reference apparatus

ActiveCN1932443BEasy to makeEasy to installInstrumental componentsNavigation instrumentsGuidance systemBasement

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

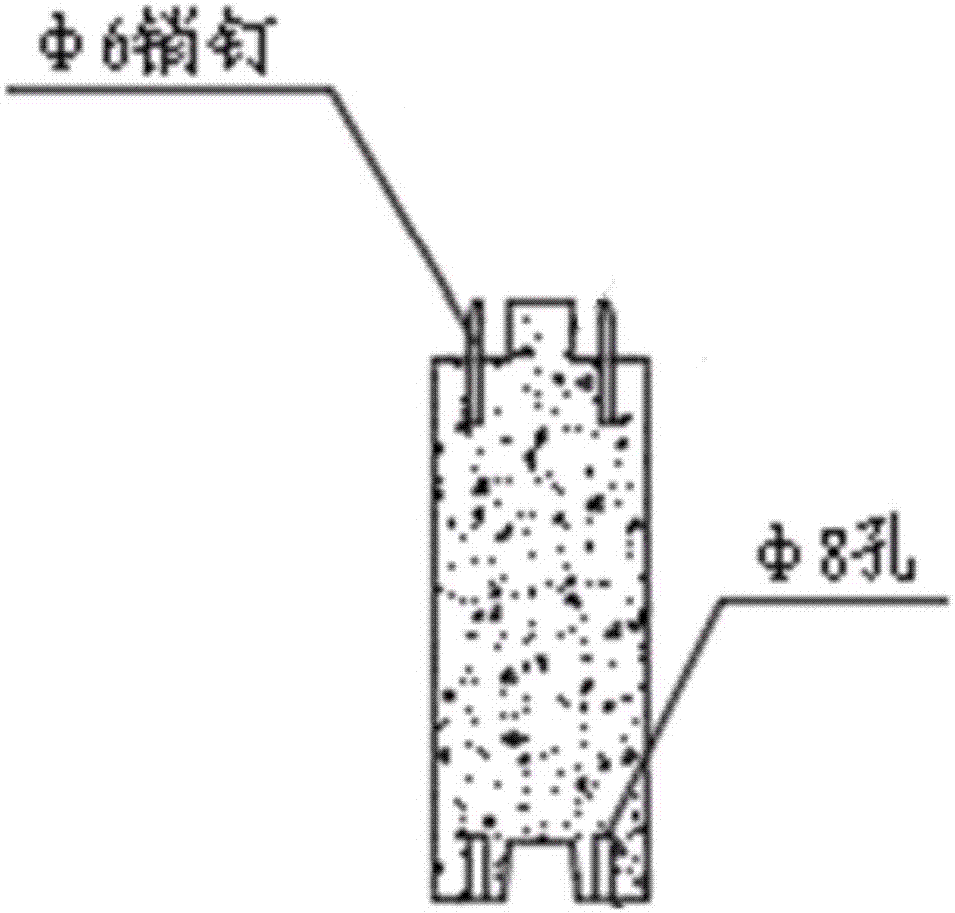

Material adhering tool assembly for machining bulk NdFeB (neodymium iron boron)

ActiveCN104100618AImprove machining accuracyGuaranteed vertical accuracyFastening meansKnurlingEngineering

The invention discloses a material adhering tool assembly for machining bulk NdFeB (neodymium iron boron). The material adhering tool assembly comprises a material adhering tool and a positioning tool, wherein the material adhering tool comprises a support plate and knife edge angle rulers distributed at the top surface of the support plate; the positioning tool comprises a support bottom plate, regulating seats, a compressing plate and a positioning strip; two slender regulating seats are arranged and are distributed at the left and right sides of the top surface of the support bottom plate in parallel; positioning strip mounting slots are correspondingly formed at the two top ends of the two regulating seats at intervals; a locking bolt is arranged at the side surface of each positioning strip mounting slot in a penetrating mode; a material plate support strip is distributed at the top surface of the support bottom plate between the two regulating seats; the lower part of the compressing plate is fixed at the lower side of the support bottom plate; knurling bolts are arranged at the upper part of the compressing plate in a penetrating mode. Positioning pins are transversely distributed at the upper side, corresponding to the knurling bolts, of the support bottom plate. According to the material adhering tool assembly for machining the bulk NdFeB, the machining precision and machining efficiency of a multi-wire sawing machine are improved.

Owner:SINO MAGNETICS TECH

A kind of construction method of ship deck general section

The invention discloses a ship deck block building method. A cargo hold block and deck panels are supplied, a plurality of supporting columns are arranged on an inner base plate of a cabin of the cargo hold block, the deck panels are lifted to the cargo hold block, the multiple supporting columns are supported to the positions, likely to deform, of the deck panels, and the multiple deck panels arewelded so that the deck panels can be connected to form a deck block on the cargo hold block. The multiple supporting columns are arranged on the inner base plate of the cabin of the cargo hold blockin advance, the supporting columns are supported to the positions, likely to deform, of the deck panels, after the deck panels are lifted and welded and a lengthened row is disassembled, an extra effective supporting structure is arranged for supporting the deck blocks, the phenomenon that the assembled and formed deck block sinks and deforms is effectively avoided, the horizontal precision of the deck surface of the deck block is ensured, the building precision of a later hatch coaming is improved, repairing and correcting workloads are reduced, and the machining speed is increased.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

A combined structure that controls heat conduction deformation in a closed state

ActiveCN110605850BAvoid heat conductionSmall thermal deformationManufacturing heating elementsManufacturing environment conditioningThermal breakRAM drive

The invention relates to a combined structure for controlling thermal conduction deformation in a closed state. The structure includes a printing substrate, a supporting platform, a forming box, a ram and a guide rail. The printing substrate and the ram are respectively arranged on the upper and lower parts of the supporting platform by fasteners, and are connected as an integral structure, so A vertical guide rail is arranged between the ram and the forming box, and the ram drives the support plane and the printing substrate to move up and down in the closed space of the forming box through the guide rail, and inside the supporting platform An embedded preheating element is installed, a thermal insulation layer and an automatic thermal deformation adjustment structure are arranged between the ram and the support platform, and the thermal insulation layer is used to isolate the heat conduction to the ram and the guide rail. , During preheating, the thermal deformation automatic adjustment structure is used to adjust the vertical installation gap between the support platform and the ram, so as to eliminate the thermal deformation of the printing substrate caused by heat conduction.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

High-precision large-breadth laser cutting machine

ActiveCN114654110AGuaranteed horizontal accuracyEasy to install and disassembleLaser beam welding apparatusElectric machineDust control

The invention relates to the technical field of laser cutting equipment, in particular to a large-breadth laser cutting machine which comprises a machine tool as well as a material supporting mechanism, a gantry mechanism, a cutting mechanism, a position adjusting mechanism, a heat insulation mechanism and a dust removal mechanism which are respectively arranged on the machine tool, the machine tool comprises a main cross beam, a main longitudinal beam, a first edge beam and a second edge beam. The material supporting mechanism comprises a first material frame and a second material frame; the gantry mechanism comprises a first rack, a gantry frame, a first motor, a second rack and a guide rail; the cutting mechanism comprises a moving frame, a second motor and a laser cutting machine, the moving frame is slidably connected with the guide rail, the second motor is arranged on the moving frame and connected with the second rack through a gear, and the laser cutting machine is installed on the moving frame; and the two groups of position adjusting mechanisms are symmetrically arranged on the first edge beam and the second edge beam. The large-breadth laser cutting machine can adapt to cutting machining of large-breadth plates, and is high in precision and good in effect.

Owner:CHINA MACHINERY CNC TECH FUJIAN CO LTD

A sheet straightening device that reduces wear and avoids clogging

The invention relates to the technical field of industrial automation equipment, and discloses a plate straightening device capable of reducing wear and avoiding clogging, which includes a base, a rubber ball connected to the inside of the support plate, and a metal ball arranged at the right end of the right slide arm to support the A metal sheet corresponding to the metal ball is arranged inside the plate, a tailgate is connected to the lower side of the outer end of the lifting and retracting rod, and a second spring is connected between the rear end of the arc-shaped guide rod and the lifting and retracting rod. By passing through one end of the inclined plate and facing the through hole first, the space range of the through hole pumping air is reduced, the air flow velocity at the lower side of the through hole is accelerated, and the accelerated airflow pushes the rubber ball to slide in the chute, and the rubber ball drives the slide. The metal ball on the arm is in contact with the metal sheet, and the lifting and retracting rods on the upper right and lower left begin to stretch out to straighten the board. This structure solves the problem that the board straightening device of the existing industrial automation equipment cannot adjust the board. The problem of low level and work efficiency.

Owner:绍兴柯桥新兴门业有限公司

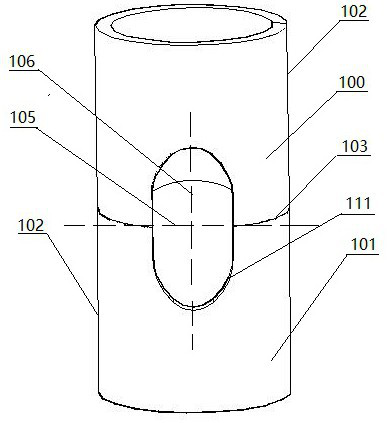

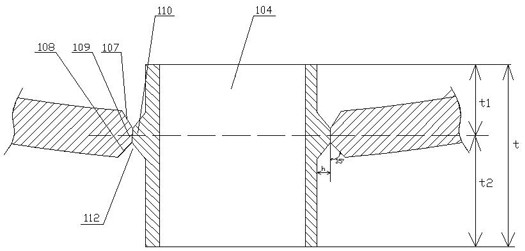

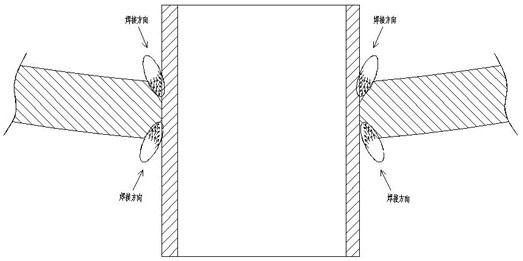

Welding process for tower door frame

ActiveCN111730179AGuaranteed dimensional accuracyAvoid size deviationWelding accessoriesStress levelSpot welding

The invention relates to a welding process for a tower door frame. The welding process comprises the following specific steps of S1, coiling a tower drum; S2, forming a hole in the tower drum; S3, beveling a door frame hole; S4, positioning a door frame; S5, performing spot welding positioning; S6, preheating a joint; S7, selecting a welding wire; and S8, welding an inner bevel and an outer bevel.The welding process has the advantages that a second cone part is arranged on the outer edge of the door frame, so that the horizontal accuracy and positioning-embedding size of the door frame embedded in the tower drum are ensured; transverse concentration of the welding stress is avoided; and the reduction of the stress level and stress balance are ensured.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

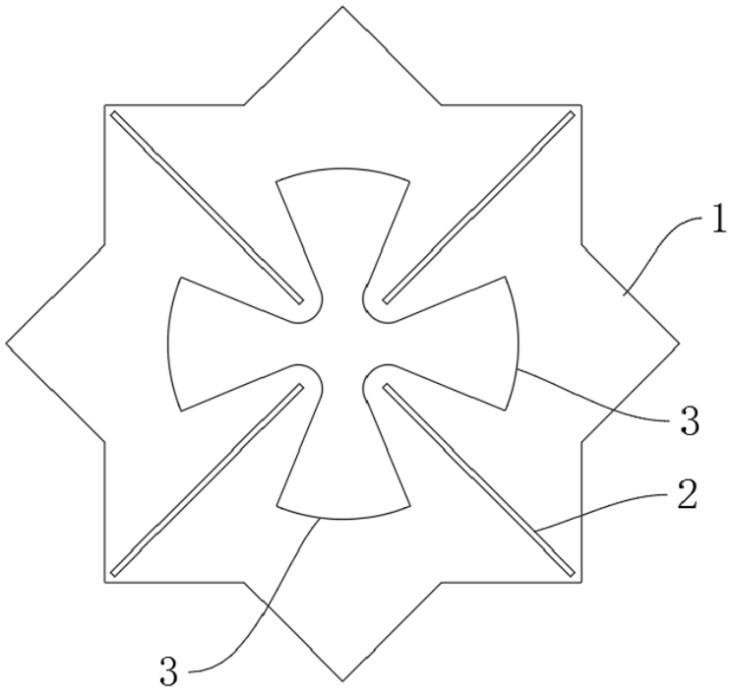

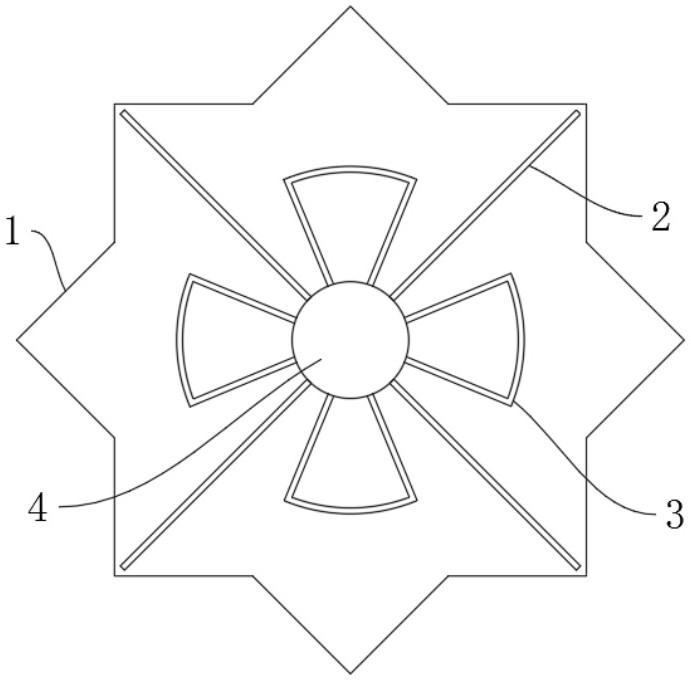

Large-span equipment frame foundation leveling and assembling construction device and method

PendingCN113737844AGuaranteed horizontal accuracyReduce mistakesFoundation engineeringMaterial consumptionLong span

The invention discloses a large-span equipment frame foundation leveling and assembling construction device and method, and belongs to the technical field of frame assembling. The large-span equipment frame foundation leveling and assembling construction device comprises base anchor positioners, digging holes and square pipe connecting frames, wherein the base anchor positioners are arranged in a bent octagon manner; and the digging holes are formed in the base anchor positioners, and the square pipe connecting frames are detachably connected to the digging holes and used for connecting and allowing an equipment frame to be arranged. According to the large-span equipment frame foundation leveling and assembling construction device and method, the plurality of base anchor positioners are pre-buried on the ground, and the square pipe connecting frames used for adjusting the levelness are welded to the base anchor positioners, so that leveling on the ground, leveling and assembling from points to faces are achieved, the horizontal precision of the large-span equipment frame can be effectively guaranteed, errors are reduced, then the construction period is shortened, and material consumption is reduced.

Owner:QINGDAO INSTALLATION & CONSTR +1

A processing technology for eliminating the time difference of milling plane when the equipment has positioning error

ActiveCN109352043BGuaranteed horizontal accuracyGuaranteed smooth and brightMilling equipment detailsMachining processKnife blades

The invention discloses a machining technology capable of eliminating a segment gap during plane milling under the condition of the presence of an equipment positioning error. The technology comprisesthe following steps that a) a high-precision four-axis linkage full-closed-loop horizontal machining center is selected for use, and a cutterhead with the diameter phi being 200 and blades are adopted; b) a workpiece mounting table is mounted and leveled; c) rough milling is performed; d) semi-finish milling is performed; e) finish milling is performed; and f) sleeking is performed. Compared withthe prior art, the machining technology can be used for guaranteeing that a large plane is smooth and bright, free of segment gap hand feel and capable of meeting requirements for the appearance.

Owner:浙江坤博精工科技股份有限公司

A large format laser cutting machine

ActiveCN112059433BGuaranteed horizontal accuracyEasy to install and disassembleLaser beam welding apparatusGear wheelElectric machinery

The present invention relates to the technical field of laser cutting equipment, in particular to a large-format laser cutting machine, including a machine tool and a racking mechanism, a gantry mechanism, a cutting mechanism, a positioning mechanism, a heat insulation mechanism and a dust removal mechanism respectively arranged on the machine tool ; The frame includes a main beam, a main longitudinal beam, a first side beam and a second side beam; the racking mechanism includes a first rack and a second rack; the gantry mechanism includes a first rack, a gantry frame, a first motor, a second rack and a guide rail; the cutting mechanism includes a moving frame, a second motor and a laser cutting machine, the moving frame is slidably connected with the guide rail, and the second motor is arranged on the moving frame , the second motor is connected to the second rack through a gear, and the laser cutting machine is installed on a moving frame; two sets of positioning mechanisms are symmetrically arranged on the first side beam and the second side beam. The large-format laser cutting machine provided by the invention can be adapted to the cutting processing of large-scale plate materials, and has high precision and good effect.

Owner:CHINA MACHINERY CNC TECH FUJIAN CO LTD

Multi-column and multi-tool high-efficiency composite machining center

ActiveCN112589448BGuaranteed rigidityEasy to processOther manufacturing equipments/toolsEngineeringMachine

The invention relates to the field of vertical lathes, in particular to a multi-column multi-tool high-efficiency composite machining center, comprising a beam, a column and a worktable, and a column lifting assembly is arranged between the beam and the column, and is characterized in that the column is 4-8 They are evenly arranged on the periphery of the worktable in the form of extremely symmetrical distribution; the worktable is provided with a central column in the center, and a central beam sleeve is arranged on the central column, and the central beam sleeve is connected with the lifting assembly of the central column. The flange is connected to the center beam sleeve, the lifting and lowering of the beam, the lifting and lowering of the boring and milling head on the beam, the horizontal movement of the boring and milling head and the turning tool holder, the column retraction operation of the column, and the rotation of the worktable are controlled by the numerical control system respectively. . Compared with the prior art, the beneficial effects of the present invention are as follows: equipped with different tools and accessories, it can realize five functions of gantry boring and milling, gear milling machine, radial drill, vertical turning and floor boring and milling, and becomes an efficient and multifunctional machine. The compound vertical lathe doubles the processing efficiency.

Owner:徐绍波

Square silencer shield and connecting bracket welding tool

InactiveCN105880896AAvoid displacementGuaranteed horizontal accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a square silencer shield and connecting bracket welding tool comprising a pedestal, a side support and a n-shaped top press seat; a guide rail support and a control support are arranged on the pedestal; the guide rail support and the side support are symmetrically arranged on the pedestal; ends of two vertical edges of the n-shaped top press seat are respectively provided with a vertical positioning hole; a vertical positioning insert bar is arranged in the vertical positioning hole; a transverse guide rail insert bar is arranged on the guide rail support; a transverse control pusher is arranged on the control support; the front end of a transverse push rod of the transverse control pusher is provided with a thread fixed screw rod; the side face of the side support is provided with a press positioning crossbar. The square silencer shield and connecting bracket welding tool is simple in structure, strong in positioning reliability, can effectively control silencer shield offset, thus improving welding precision and efficiency, ensuring the connecting bracket horizontal precision and symmetrical precision, and improving welding efficiency and quality; the square silencer shield and connecting bracket welding tool is good in applicability and strong in practicality.

Owner:CHONGQING YUKANG MACHINERY

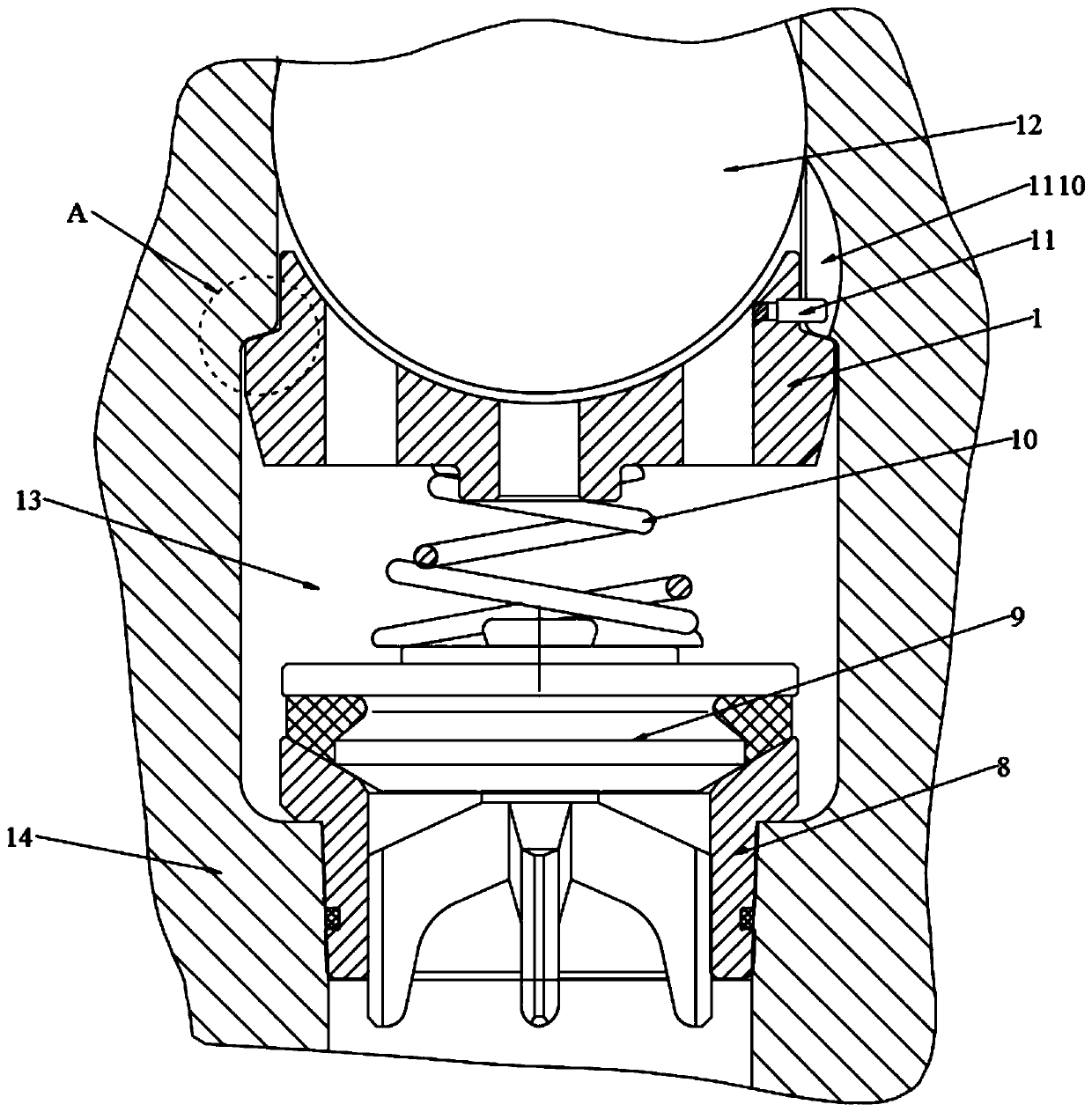

Y-shaped spring locator for hydraulic end of fracturing pump

PendingCN109915357AIncreased intensityEliminate the problemPositive displacement pump componentsLiquid fuel engine componentsStress concentrationEngineering

The invention discloses a Y-shaped spring locator for a hydraulic end of a fracturing pump, and belongs to the technical field of fracturing pump devices. The Y-shaped spring locator for the hydraulicend of the fracturing pump is used for solving the problems of fatigue crack damage and the like caused by stress concentration caused by adopting a groove structure in the matching of an existing spring locator and a valve box body. The Y-shaped spring locator for the hydraulic end of the fracturing pump comprises the valve box body, wherein a suction cavity is formed in the valve box body, a suction valve body is arranged at the lower end of the suction cavity, an adsorption valve seat sleeves the suction valve body, a suction spring is arranged at the upper end of the suction valve body, and a locator body is arranged at the upper end of the suction spring; and a circular boss sleeves with the suction spring is arranged at the lower end of the locator body, the upper end of the locatorbody is sunken downwards to form a positioning groove, the outer walls of the left side and the right side of the locator body both comprise upper sections and lower sections, the outer diameter of each upper section is smaller than the outer diameter of each lower section, the upper sections and the lower sections are connected with one another through conical surfaces, limiting structures are symmetrically arranged on the inner wall of the upper end of the suction cavity, and inclined surfaces matched with the conical surfaces are arranged at the lower ends of the limiting structures.

Owner:宝石机械成都装备制造分公司

Two-column multi-cutter vertical machining center

InactiveCN112658807AGuaranteed rigidityEasy to processLarge fixed membersMetal working apparatusSynchronous controlClassical mechanics

The invention relates to the field of vertical lathes, in particular to a two-column multi-cutter vertical machining center. The two-column multi-cutter vertical machining center comprises a cross beam, two stand columns and a workbench, and the two stand columns are arranged on the two sides of the workbench respectively. The cross beam is of a horizontally-arranged integrated structure, a middle column lifting assembly is arranged between the cross beam and a middle column, a stand column lifting assembly is arranged between the cross beam and the stand columns, the middle column lifting assembly and the stand column lifting assembly are synchronously controlled to achieve lifting movement of the cross beam, four boring and milling heads are arranged on the cross beam, and every two boring and milling heads are symmetrically distributed relative to the middle column. The lifting movement of the cross beam, the horizontal movement of each boring and milling head on the cross beam, the lifting movement of a square ram of a side tool rest and the rotation of the workbench are respectively controlled by a numerical control system. Compared with the prior art, the two-column multi-cutter vertical machining center has the following advantages that different tools and accessories are arranged, five functions of gantry boring and milling, a gear milling machine, a radial drill, a vertical lathe and floor type boring and milling can be achieved, the combined vertical lathe is efficient and multifunctional, and the machining efficiency is improved by multiple times.

Owner:徐绍波

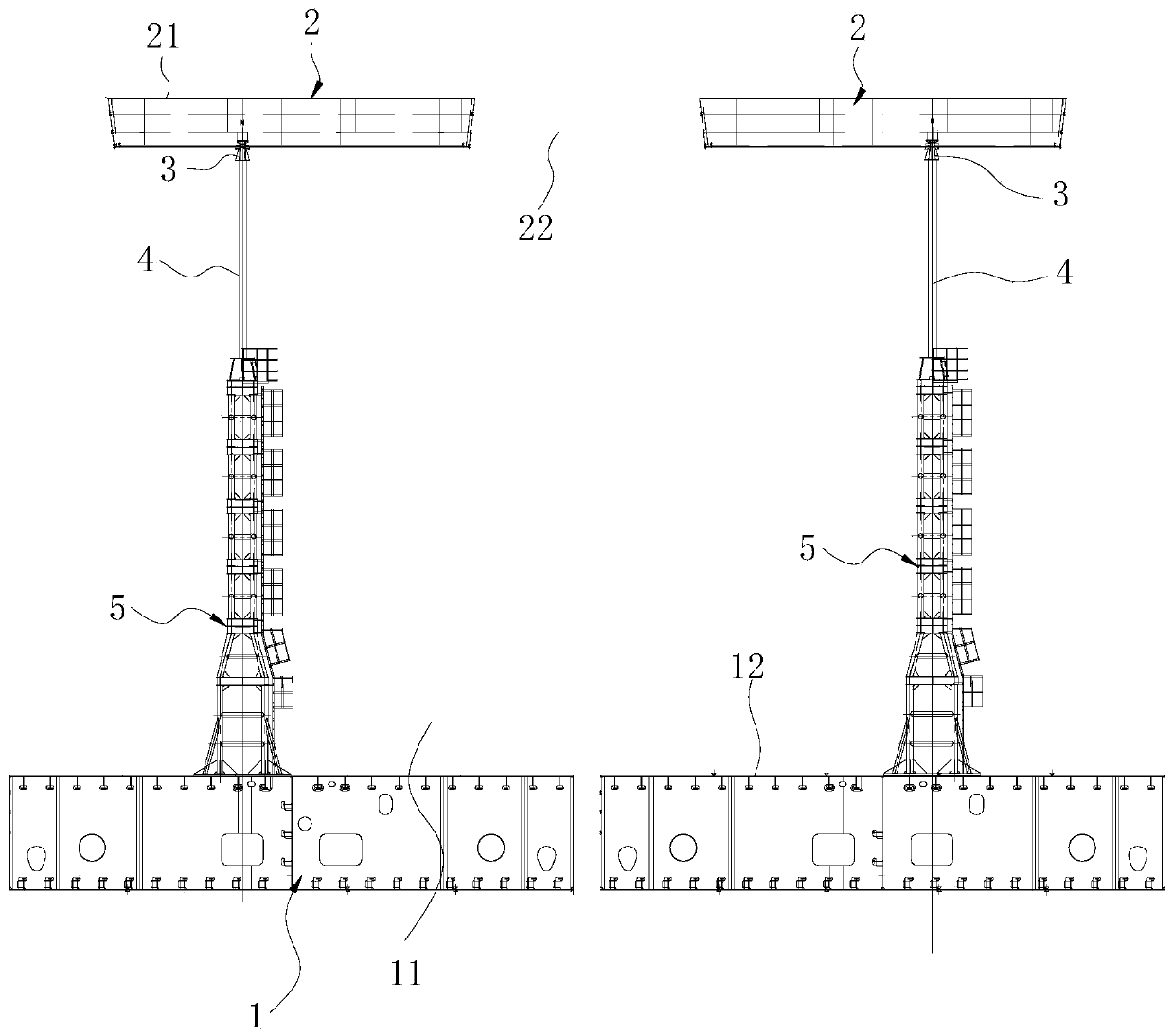

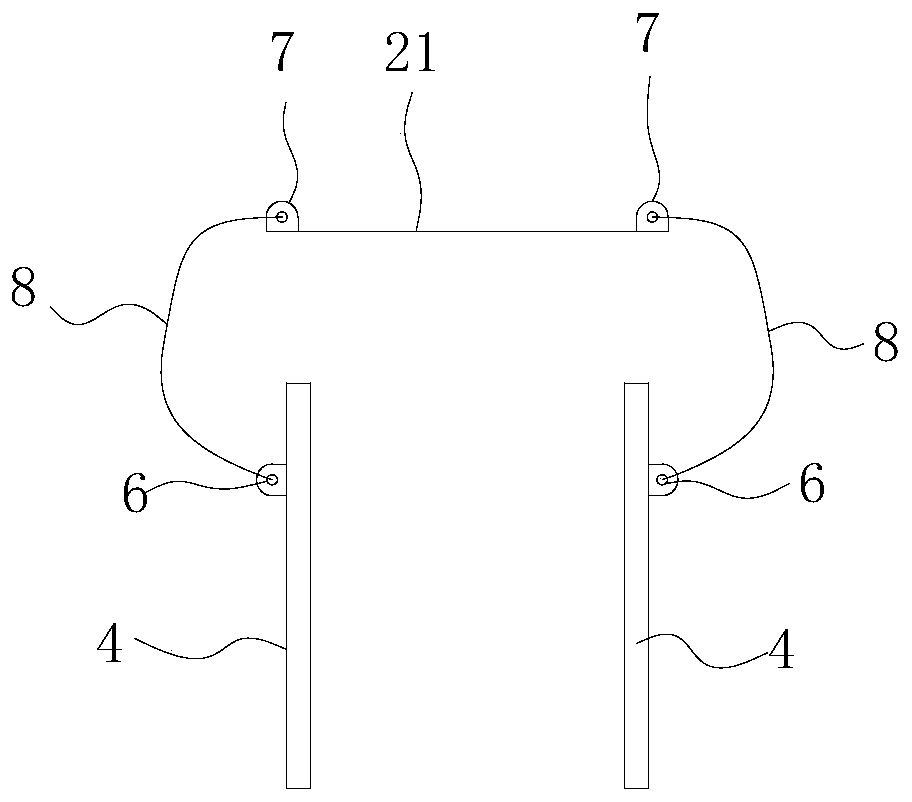

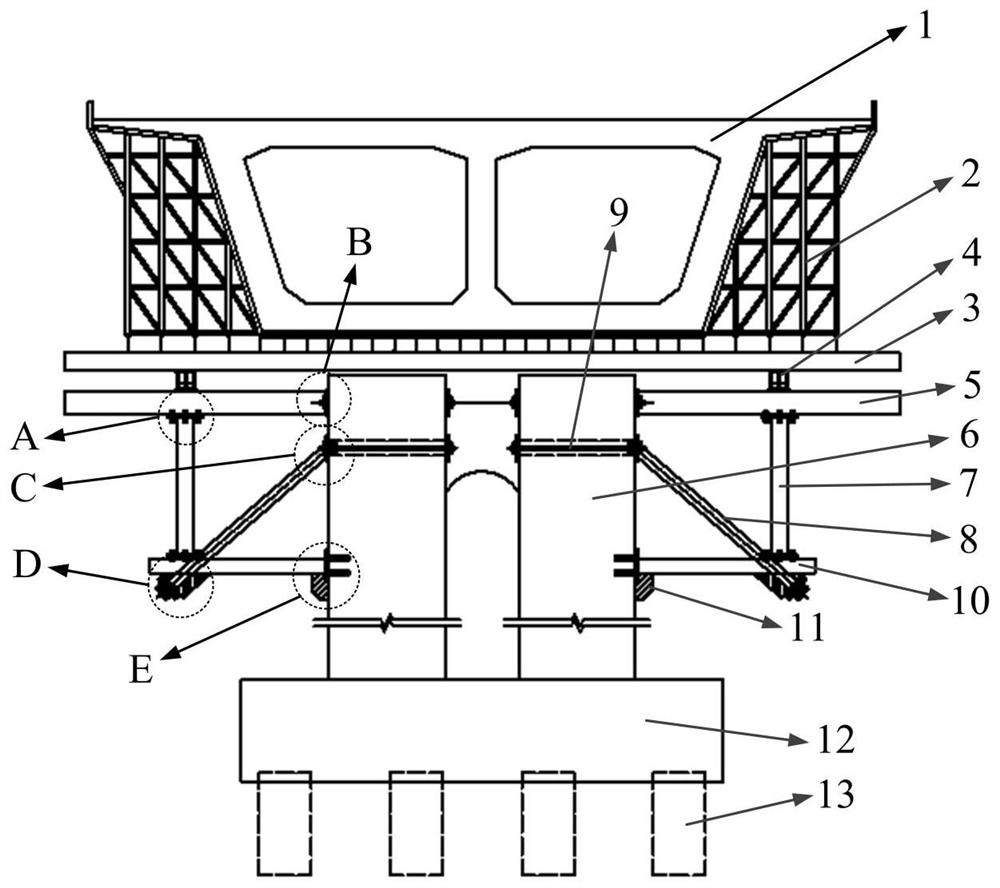

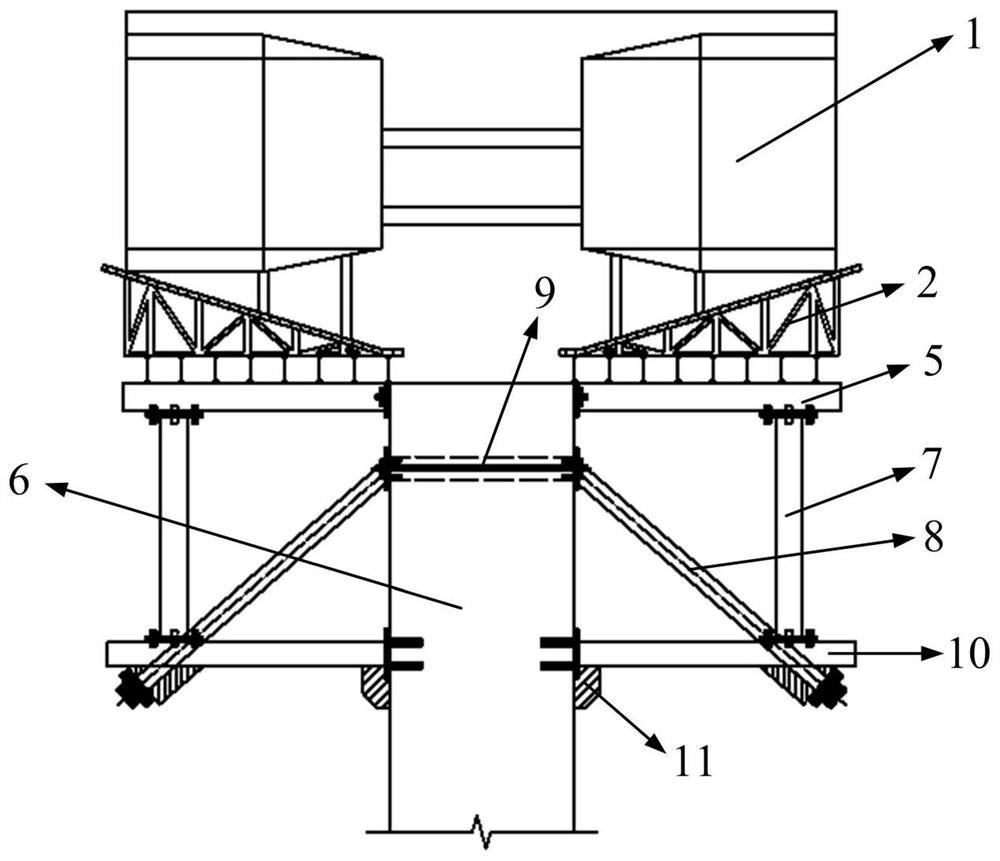

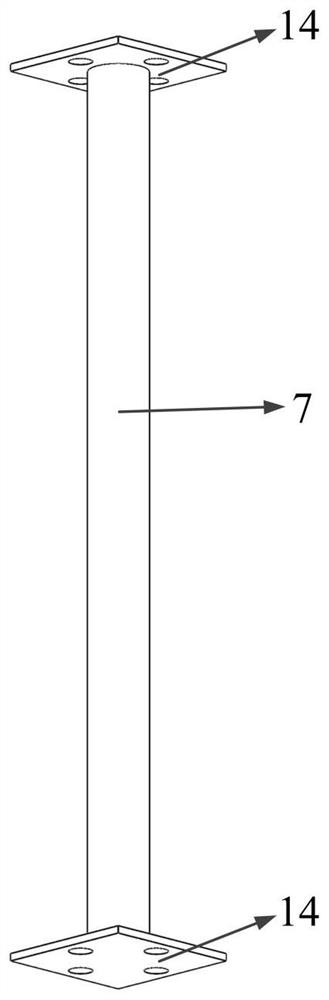

Super-huge 0 # block cast-in-place box girder bracket structure and mounting method thereof

PendingCN114657882AImprove tensile propertiesGuaranteed levelBridge erection/assemblyBridge materialsArchitectural engineeringBox girder

The invention relates to the technical field of road and bridge construction, in particular to a super-huge 0 # block cast-in-place box girder bracket structure and a mounting method thereof. 2, pier body embedded parts are installed; 3, the brackets are assembled according to the assembling sequence; 4, the steel cable is tensioned; 5, a formwork is installed; step 6, carrying out bracket prepressing detection; step 7, 0 # box girder construction; compared with a traditional triangular bracket, the bridge bracket structure does not affect the navigation and passing requirements of the lower portion of a bridge span; the structure is more stable, the wind load can be resisted, the construction safety risk is reduced while the structure safety is guaranteed, and the device can well adapt to the construction of various large 0 # block cast-in-place box girders and is safe, reliable and convenient to construct. When the bracket is installed, a large number of tailor-welding procedures are not needed, the assembly efficiency is high, rapid installation and disassembly can be achieved, the overall construction period can be effectively shortened, the turnover utilization rate of materials is increased, and the bracket has wide application and popularization value.

Owner:NANTONG UNIVERSITY

Assembling and using method of a glass positioning vacuum suction cup

ActiveCN103406853BImprove adsorption capacityReduce labor intensityWork holdersEngineeringLow vacuum

Provided is a glass location vacuum pad assembly and use method. A glass location vacuum pad is formed by a pad body, an upper vacuum cavity, a lower vacuum cavity, an upper vacuum channel, a lower vacuum channel, an upper connector, a lower connector, a first annular sealing groove, a second annular sealing groove and O-shaped sealing ring pads. The pad body is cast to be of an I-shaped structure, the cylindrical upper vacuum cavity is processed in the middle of the upper portion of the pad body, the cylindrical lower vacuum cavity is processed in the middle of the lower portion, at least two annular sealing grooves are formed in the upper plane and the lower plane of the pad body, and the O-shaped sealing ring pads are installed in the annular sealing grooves correspondingly. The glass location vacuum pad is simple and efficient in structure design, ideal in location and attraction effect, convenient to manufacture, simple in operation, capable of reducing labor intensity of operators, low in manufacture cost, capable of saving rubber raw materials, easy to operate, convenient to maintain, flexible in operation and suitable for popularization and use.

Owner:ZAOZHUANG HAIDI ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com