Assembly type bentonite stone wallboard and combined mounting method thereof

A prefabricated and puffed stone technology, applied to walls, building components, buildings, etc., can solve the problems of poor accuracy of prefabricated composite walls, damage of prefabricated composite walls, and failure of prefabricated composite walls to cope with earthquake force, etc., to achieve safety The effect of high strength and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

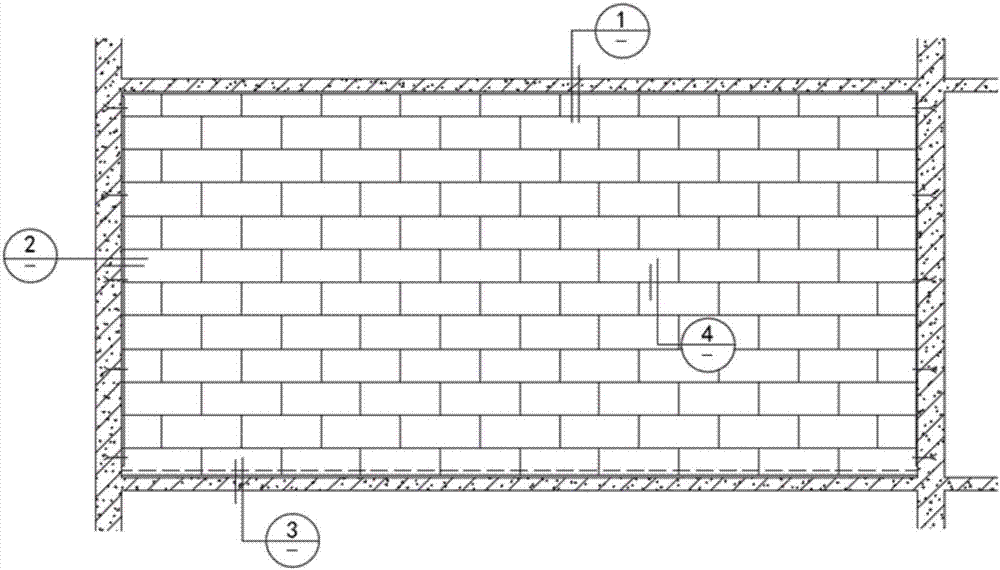

[0045] refer to figure 1 , the prefabricated puffed stone wall in this embodiment, the wall includes a layer of panels and multi-layer standard panels, the panels are arranged on the upper surface of the lower floor of the building, and the lower surface of the upper floor of the building The surface is rigidly connected to a standard plate at the top of said wall, such as Figure 8 As shown, the connection between the standard board and the panel and between two adjacent standard boards are mortise and tenon connections;

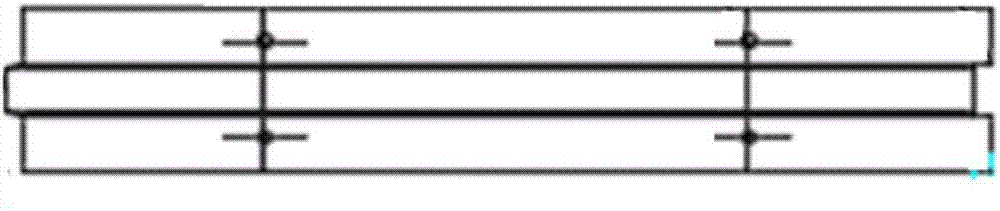

[0046] refer to Figure 2 to Figure 4 , the main structure of the standard board is a first cuboid, the top of the first cuboid is provided with a first tenon, the bottom of the first cuboid is provided with a first tenon, and the right side of the first cuboid is provided with a second tenon groove, the left side of the first cuboid is provided with a second tenon;

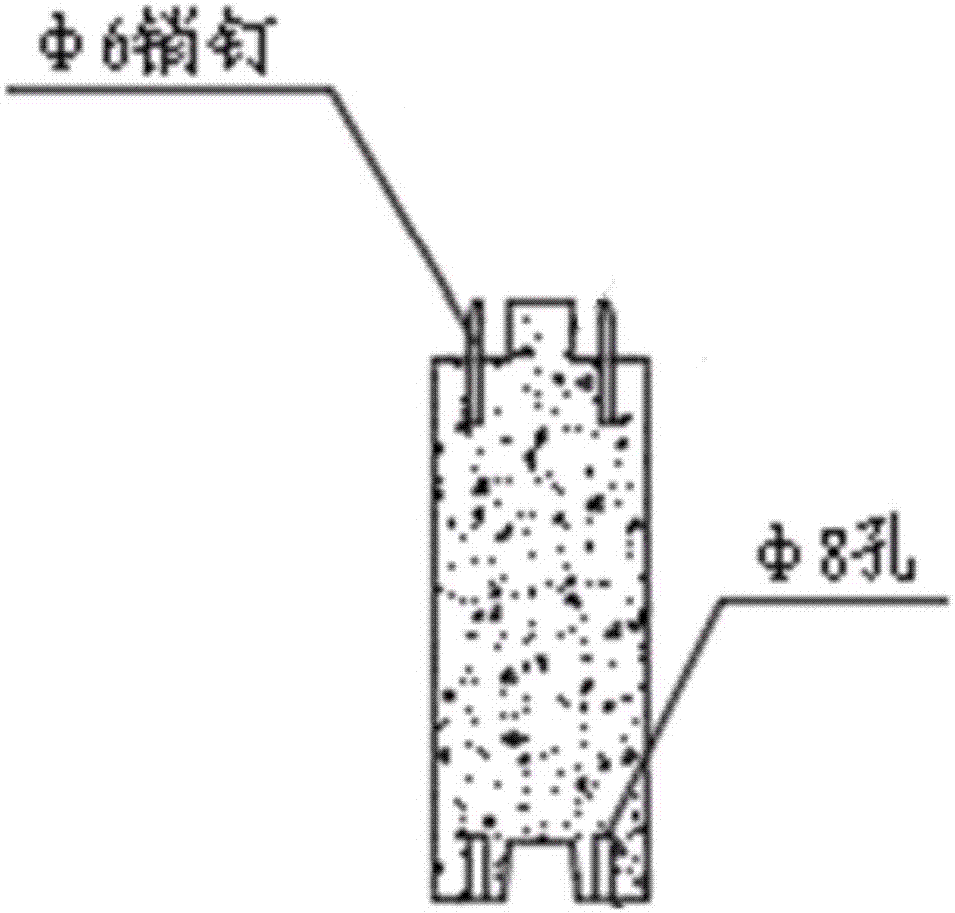

[0047] refer to Figure 5 to Figure 7 , the main structure of the panel is a second cu...

Embodiment 2

[0080] The combined installation method of the prefabricated puffy stone wallboard described in this embodiment, the method includes:

[0081] S1, laying screeds, leveling layers, installing panels

[0082] First, surface cleaning is carried out on the upper surface of the lower floor of the building where the prefabricated puffed stone wallboard is to be installed;

[0083] Then, lay the cement mortar leveling layer;

[0084] Then, on the basis of the leveling layer, the polymer mortar is laid to level the bonding layer, and the square steel pipe is fixed, and at the same time, U-shaped draw-in grooves are set on the opposite and adjacent vertical sides of the building;

[0085] Finally, the panel is clamped on the square steel pipe, and at the same time, the panel is connected with the polymer mortar leveling bonding layer;

[0086] S2, Assembly of standard board

[0087] According to the rule that the boards in the upper and lower adjacent rows of the prefabricated puffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com