Device for clamping and locking inching switch

A jog switch and locking technology, which is applied to the testing of measuring devices, measuring device casings, and mechanical components, can solve problems such as fixed automatic clamping devices for low-voltage switches, and achieve precise positioning and clamping. The degree of automation and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

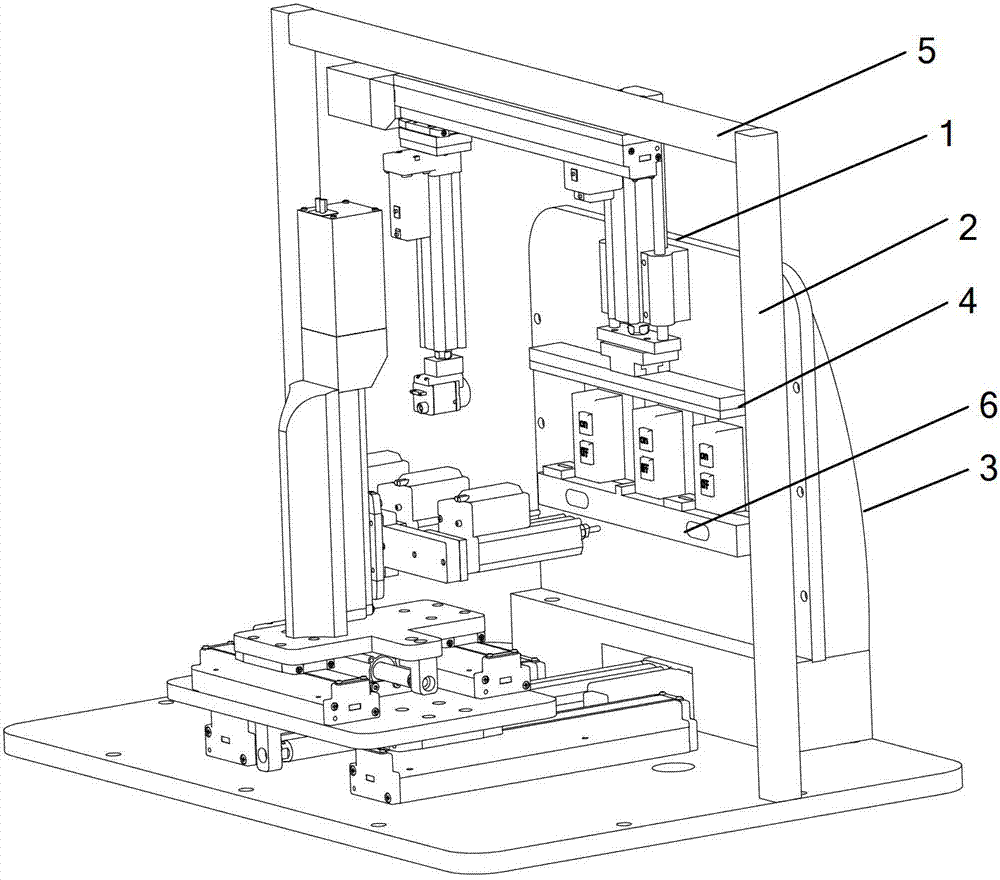

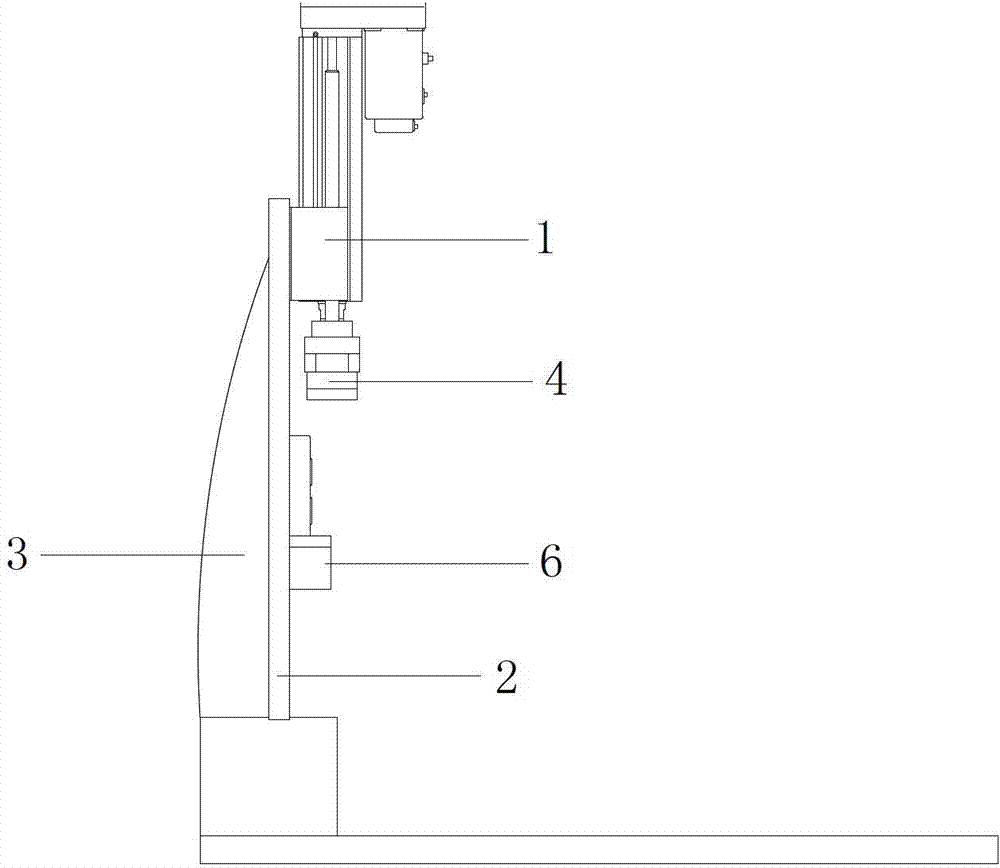

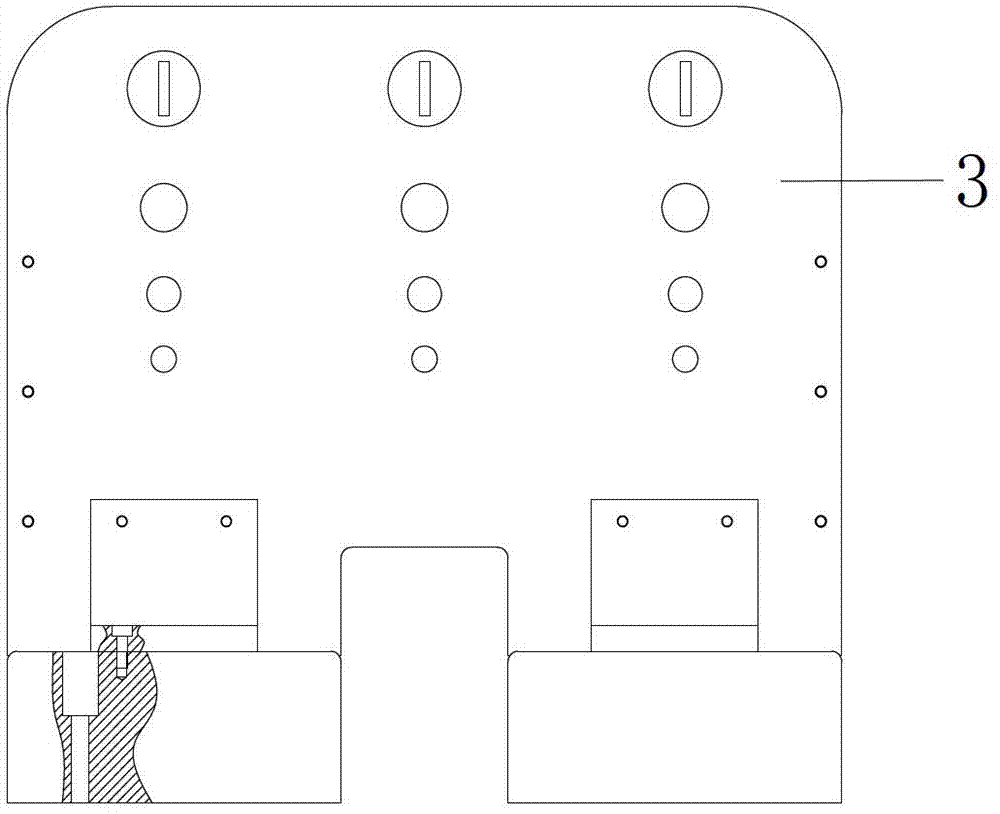

[0024] A device for clamping and locking a point switch, its structure is as follows Figure 1-2 As shown, it includes workbench, bracket 5, electric cylinder 1 and assembly plate 2. The workbench can move up and down in the Z direction. There are guide rails on the workbench, and the bracket 5 is connected to the guide rail of the workbench. The electric cylinder 1 and The vertical posture is connected with the assembly plate 2, in order to provide power for automatic pressing, the lower part of the electric cylinder is equipped with a platen spring buffer mechanism 4, and the assembly plate 2 is provided with a supporting plate 6 for placing the tested sample.

[0025] The lower part of the electric cylinder is provided with a protruding shaft rod, which is threadedly connected with the pressure plate spring buffer mechanism 4. The pressure plate spring buffer mechanism 4 is connected with the shaft of the electric cylinder 1, and the pressure plate spring buffer mechanism 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com