Scissor-type simple lifting garage capable of preventing failing of mechanical safety hook interlock device

A safety hook and interlocking device technology, applied in the field of parking garages, can solve the problems of shaking, prone to failure to load the car board, lack of monitoring of working status, etc., and achieve the effect of avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

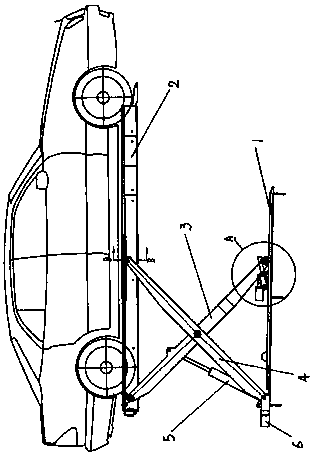

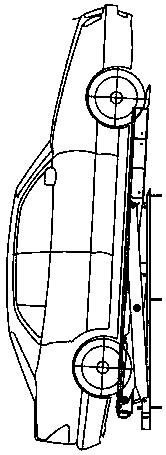

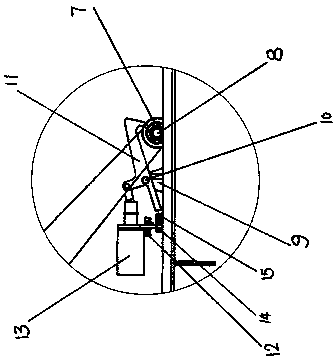

[0012] The present invention will be described in detail below in conjunction with the drawings:

[0013] A scissor-type simple lifting garage that can prevent mechanical safety hook interlocking device from malfunctioning. It includes left and right scissor arm bases 1 and loading car board 2. X-shaped scissor-type brackets are arranged between left and right scissor arm bases 1 and loading car board 2 , The top end of the leftward tilting pillar 3 in the X-shaped scissor bracket is fixed and hinged with the left end of the upper vehicle board 2. The bottom end of the leftward tilting pillar 3 is provided with a bottom movable end roller shaft 8, and the bottom movable end roller A bottom movable end roller 7 is provided on the shaft 8. The bottom movable end roller 7 is movably arranged on the left and right scissor arm bases 1, and the bottom end of the rightward tilting pillar 4 in the X-shaped scissor bracket is fixed with the left end of the left and right scissor arm base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com