Patents

Literature

244 results about "Stone wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stone walls are a kind of masonry construction that has been used for thousands of years. The first stone walls were constructed by farmers and primitive people by piling loose field stones into a dry stone wall. Later, mortar and plaster were used, especially in the construction of city walls, castles, and other fortifications before and during the Middle Ages. These stone walls are spread throughout the world in different forms. One of the best example is the Cyclopean Wall in Rajgir, India.

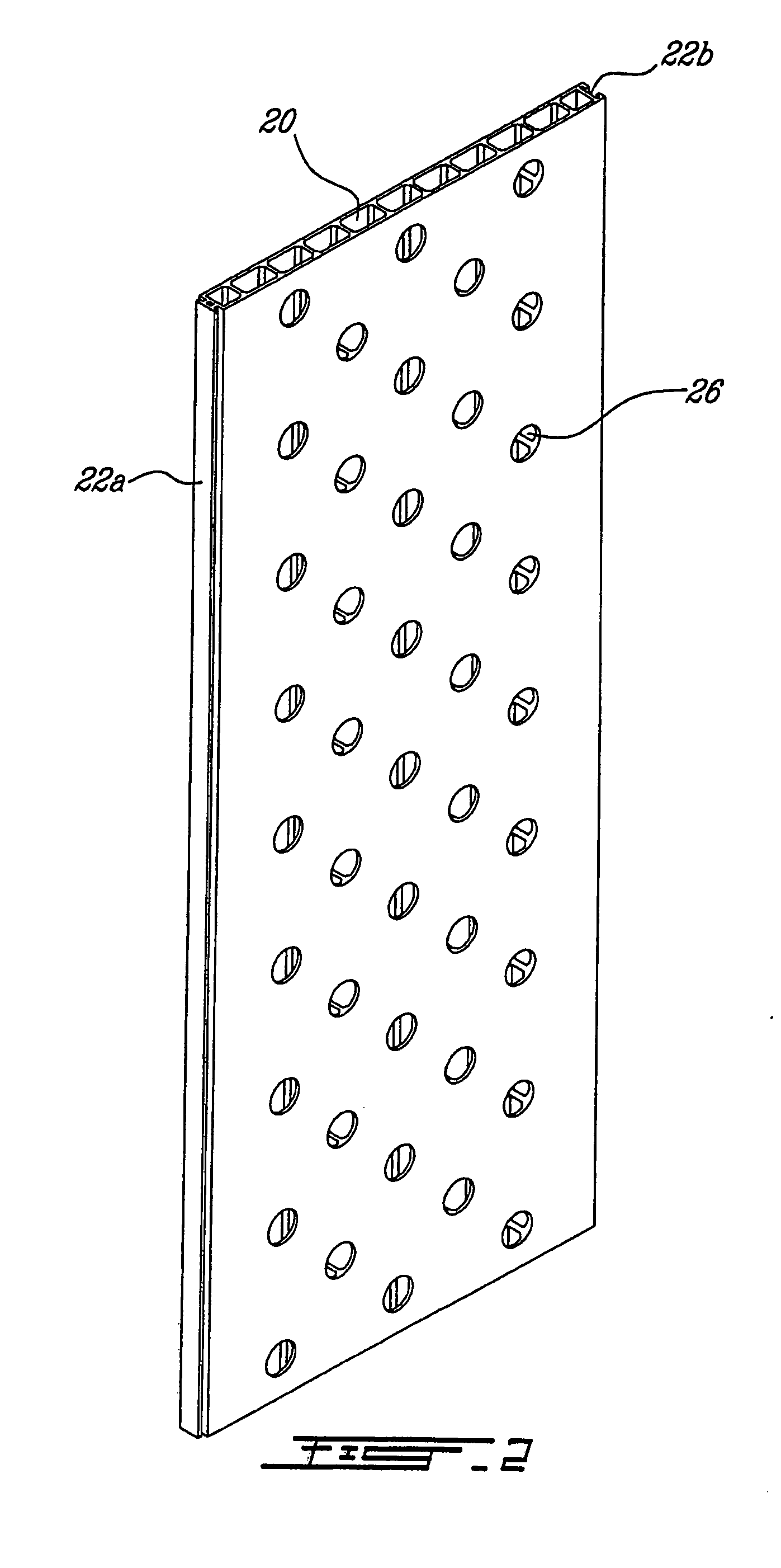

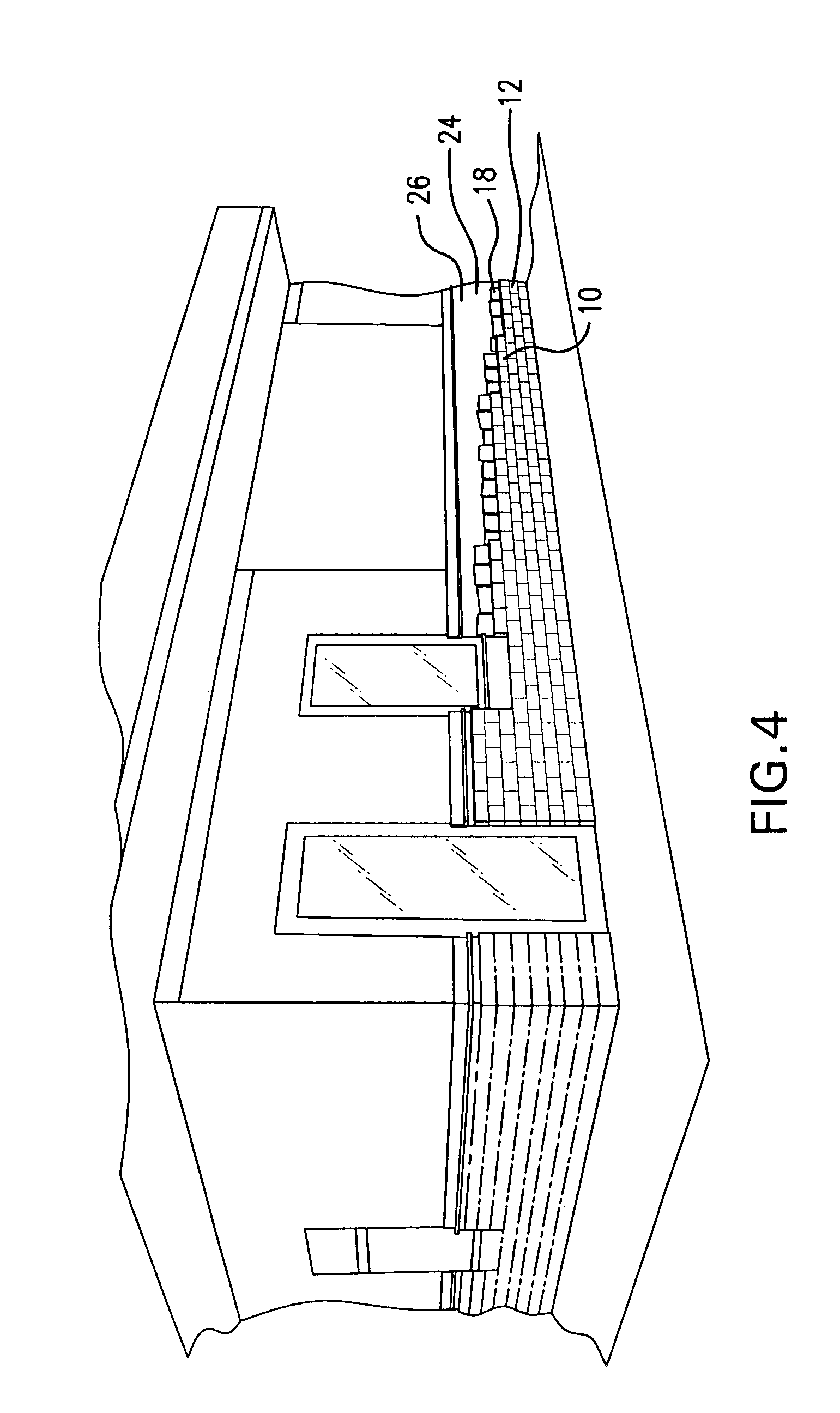

Panel, a kit and a method for forming a masonry wall

Owner:LES MATERIAUX DE CONSTR OLDCASTLE CANADA

Modular stone panel

A modular stone panel is disclosed. The panel is adapted to be mounted or fastened to a structural wall to provide a stone wall facade therefor. The panel is generally comprised of a shaped backboard and a plurality of stones solidly fastened on a front face thereof. The backboard is adapted to be fastened to the structural wall such that the front face thereof faces away from the wall to provide the stone wall facade. The stones may comprise natural or synthetic molded stones. The backboard may also be ventilated to provide ventilation to the stones fastened thereto. The panels may be fabricated to provide key-cut edges allowing an interlocking of adjacent panels. A method of fabricating such panels is also disclosed.

Owner:STONEADVISE PRODS NORTH AMERICA

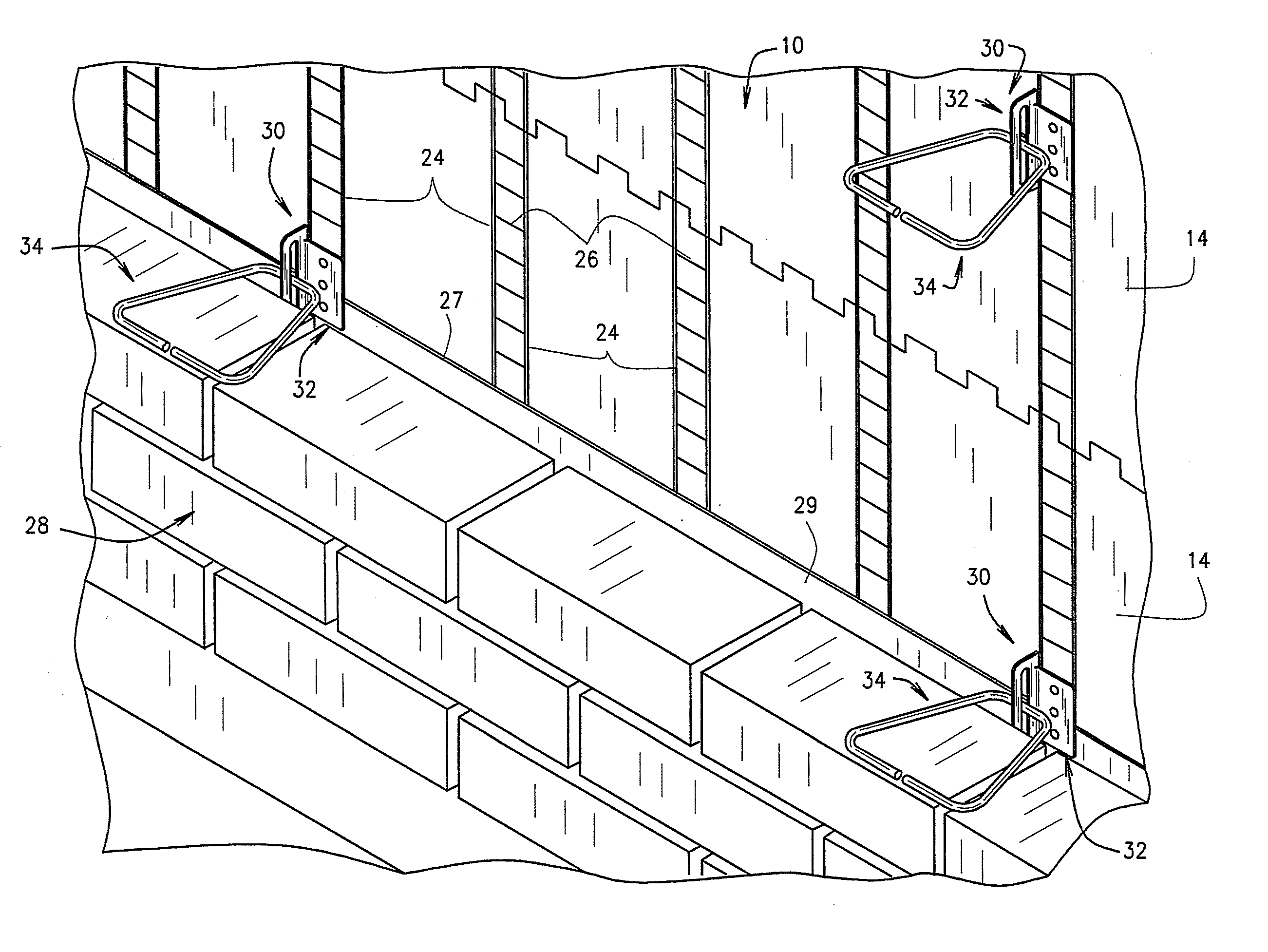

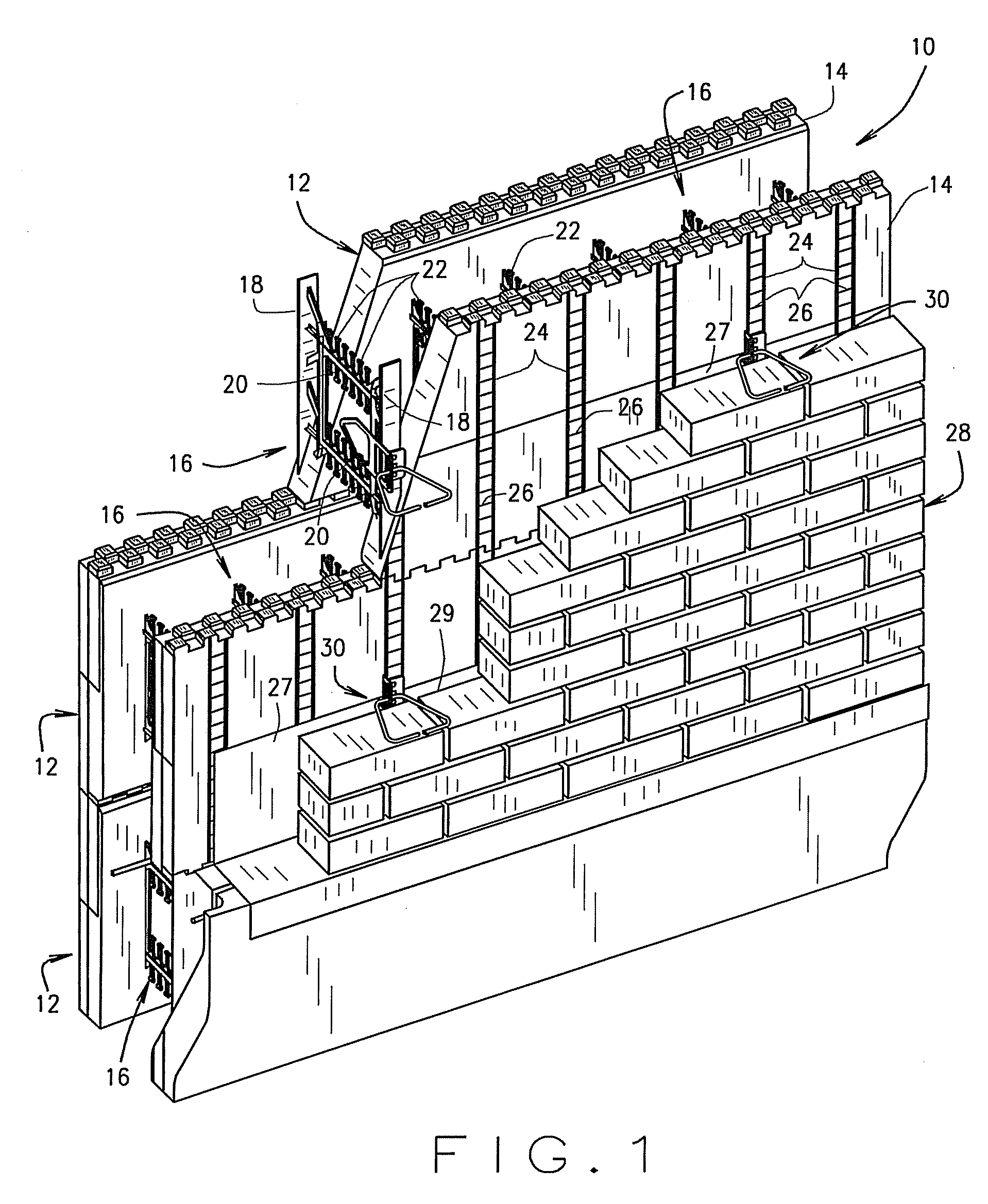

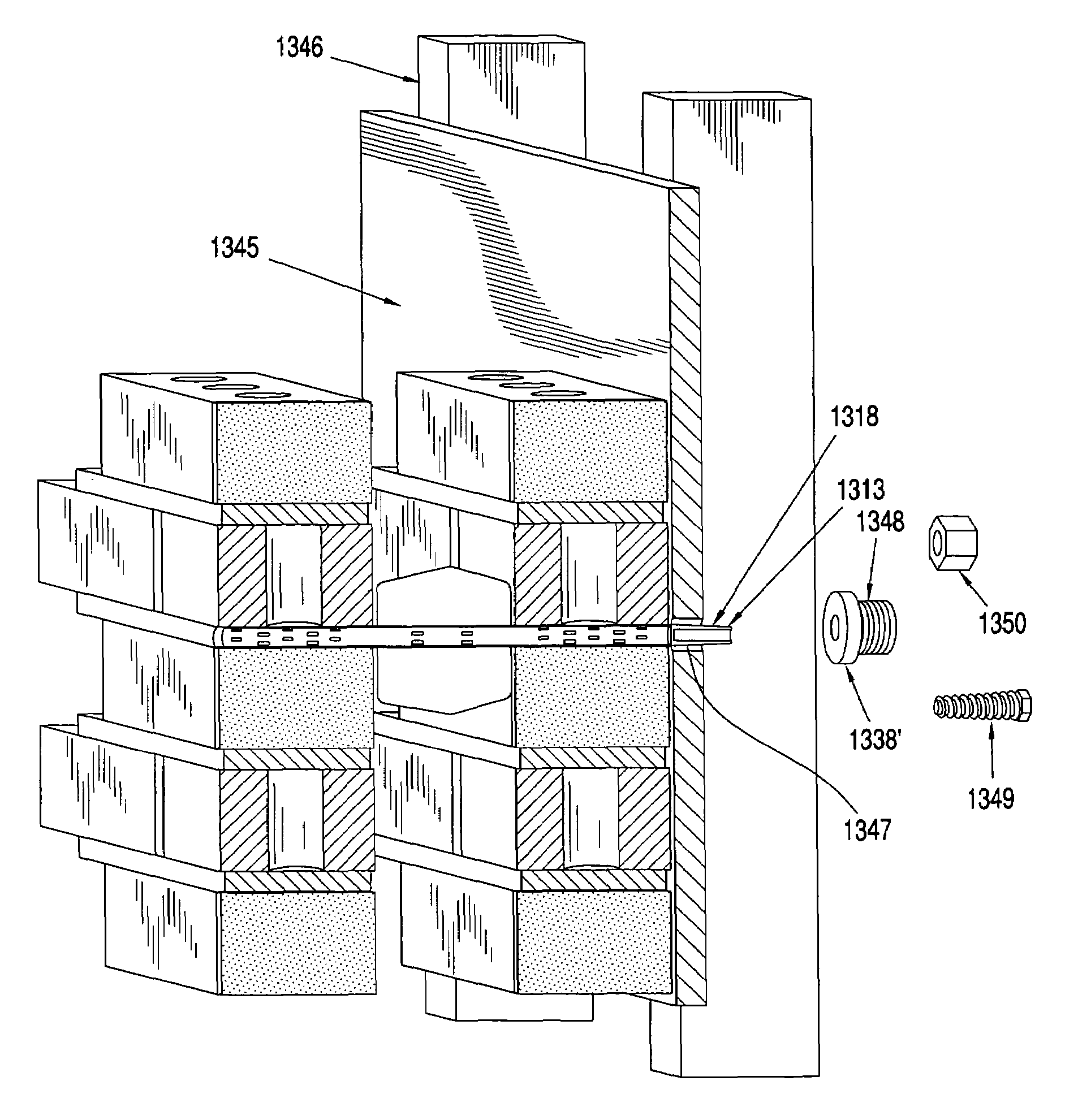

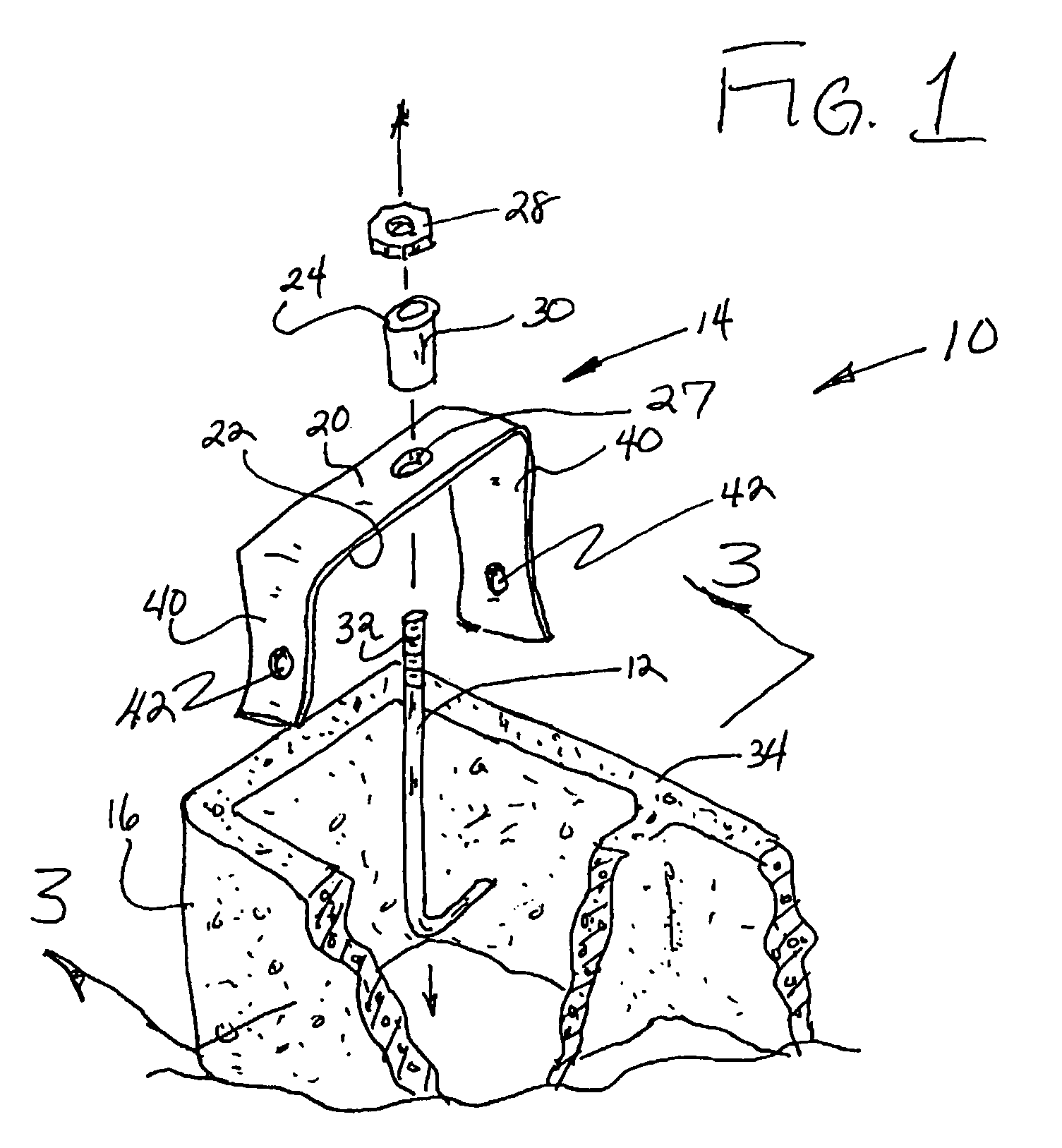

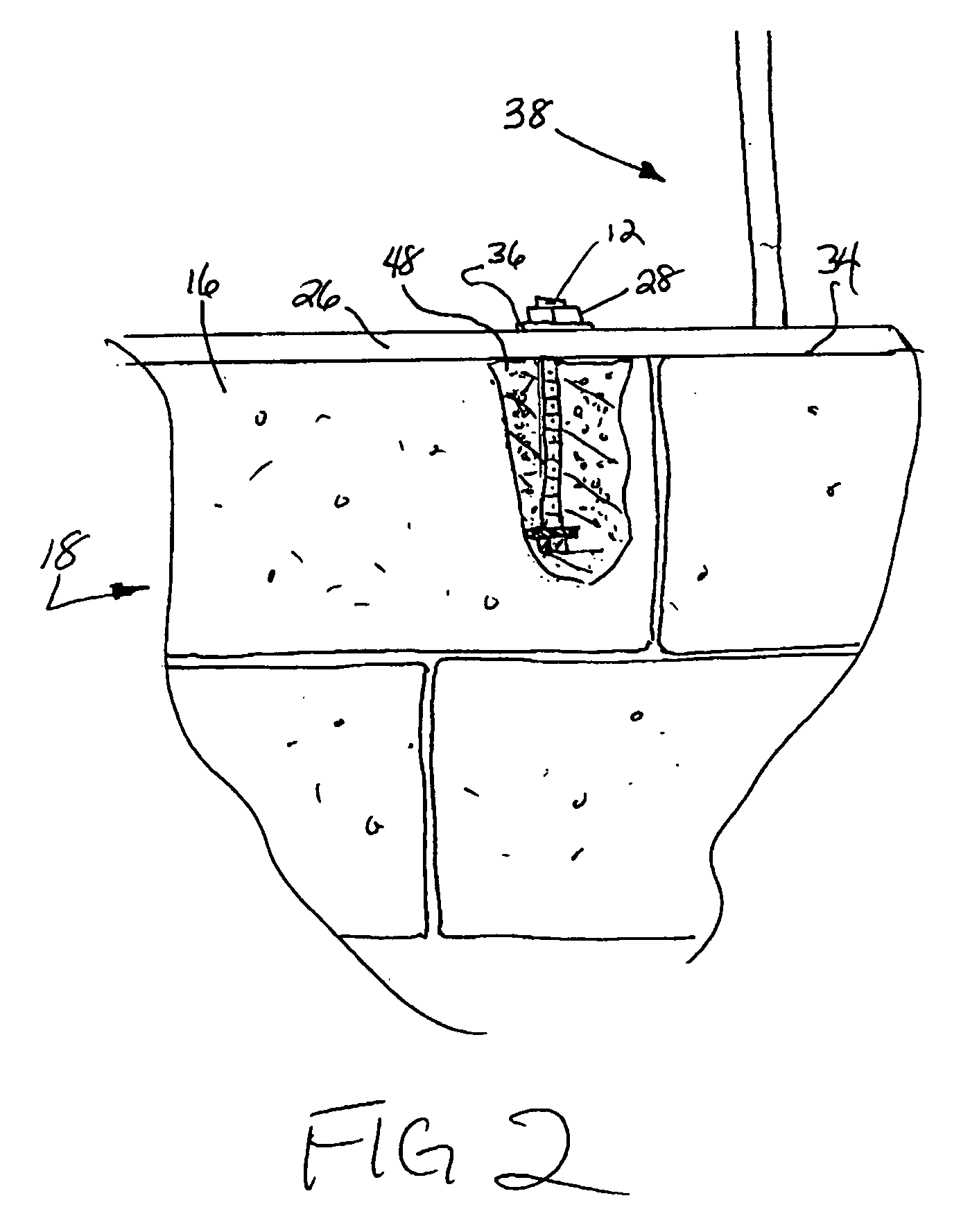

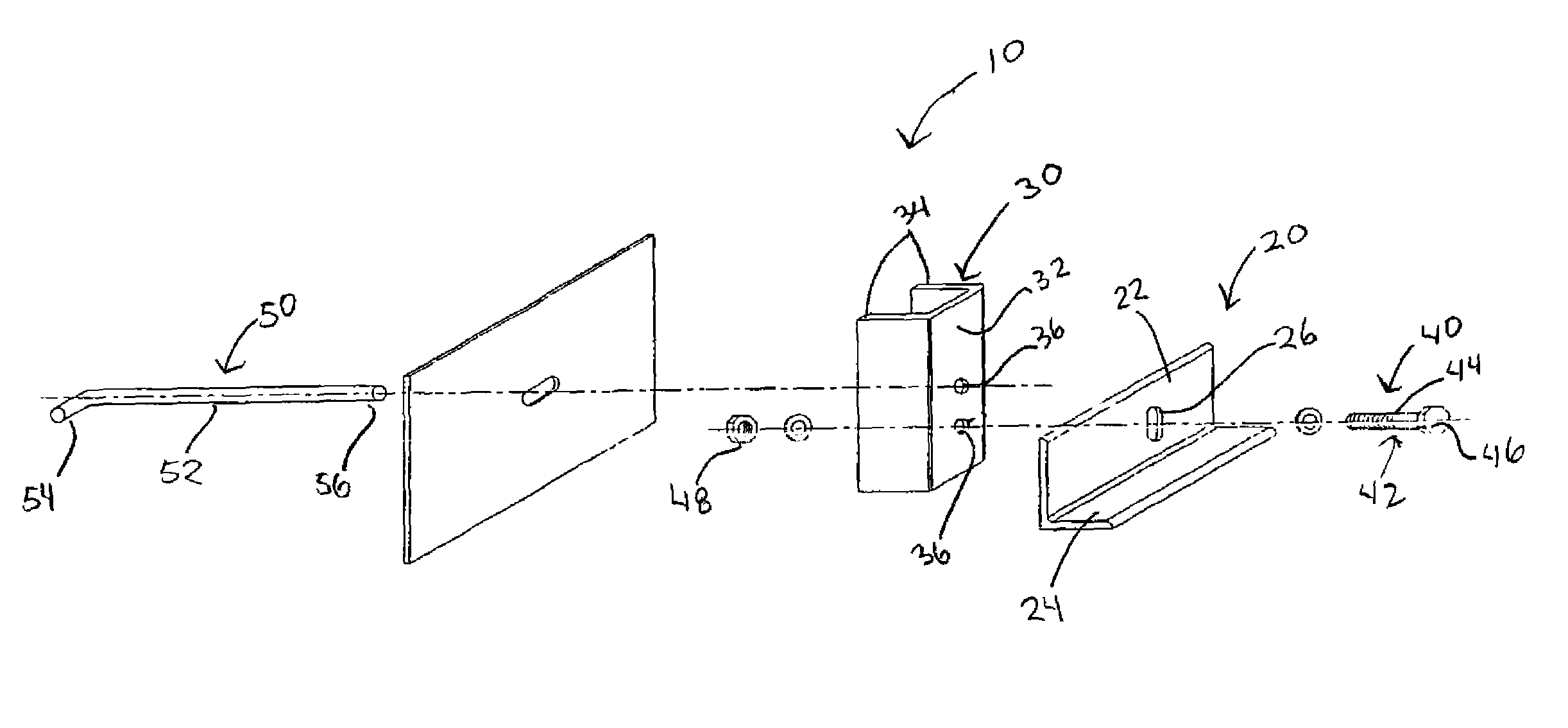

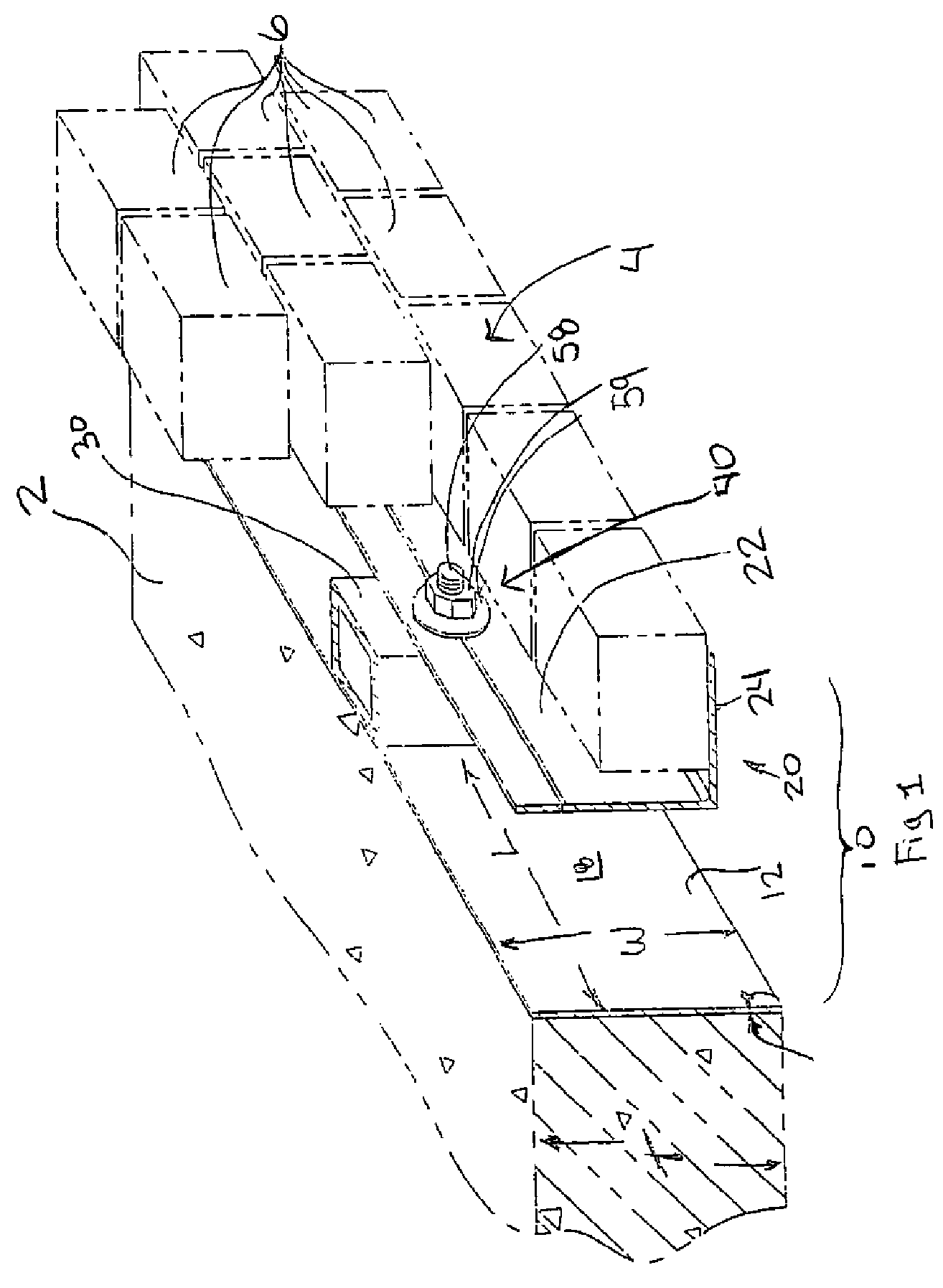

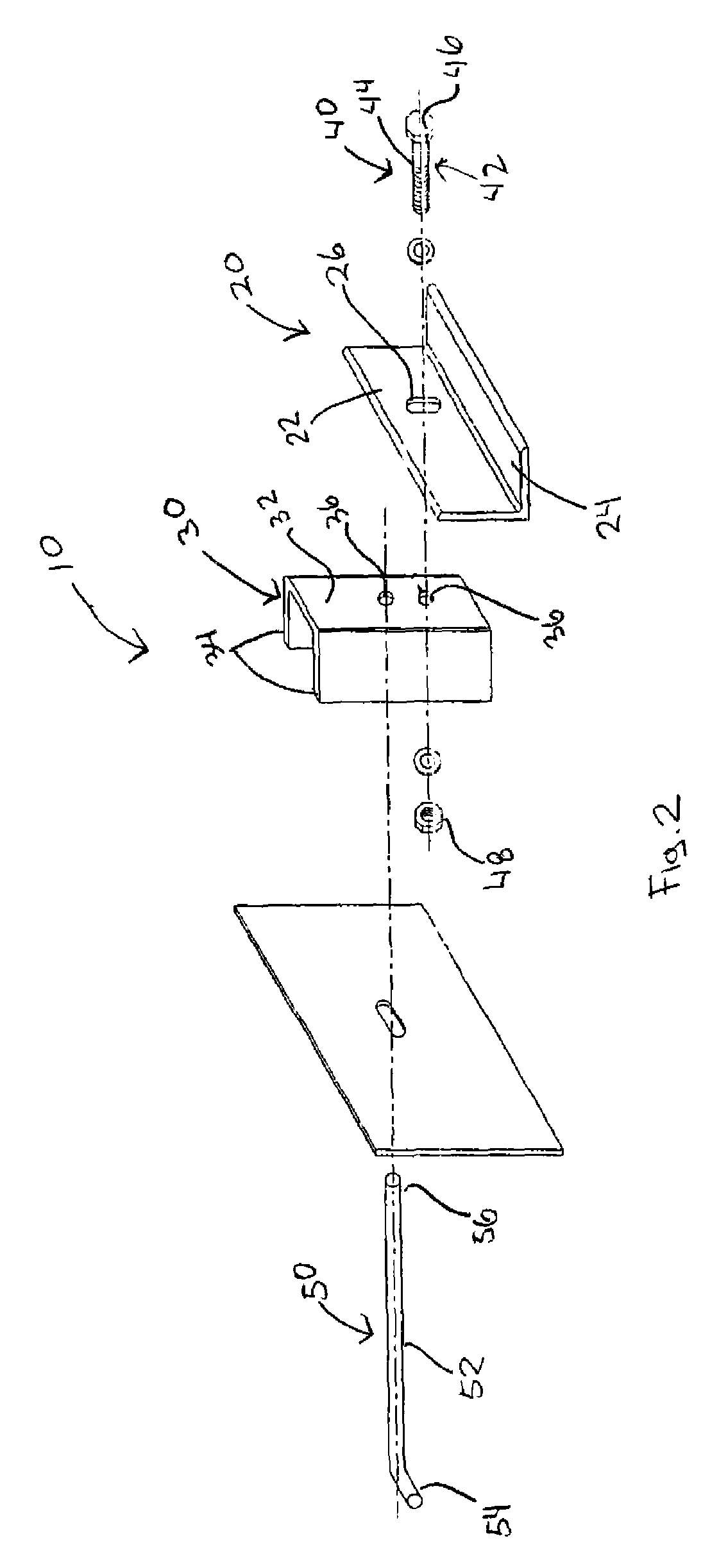

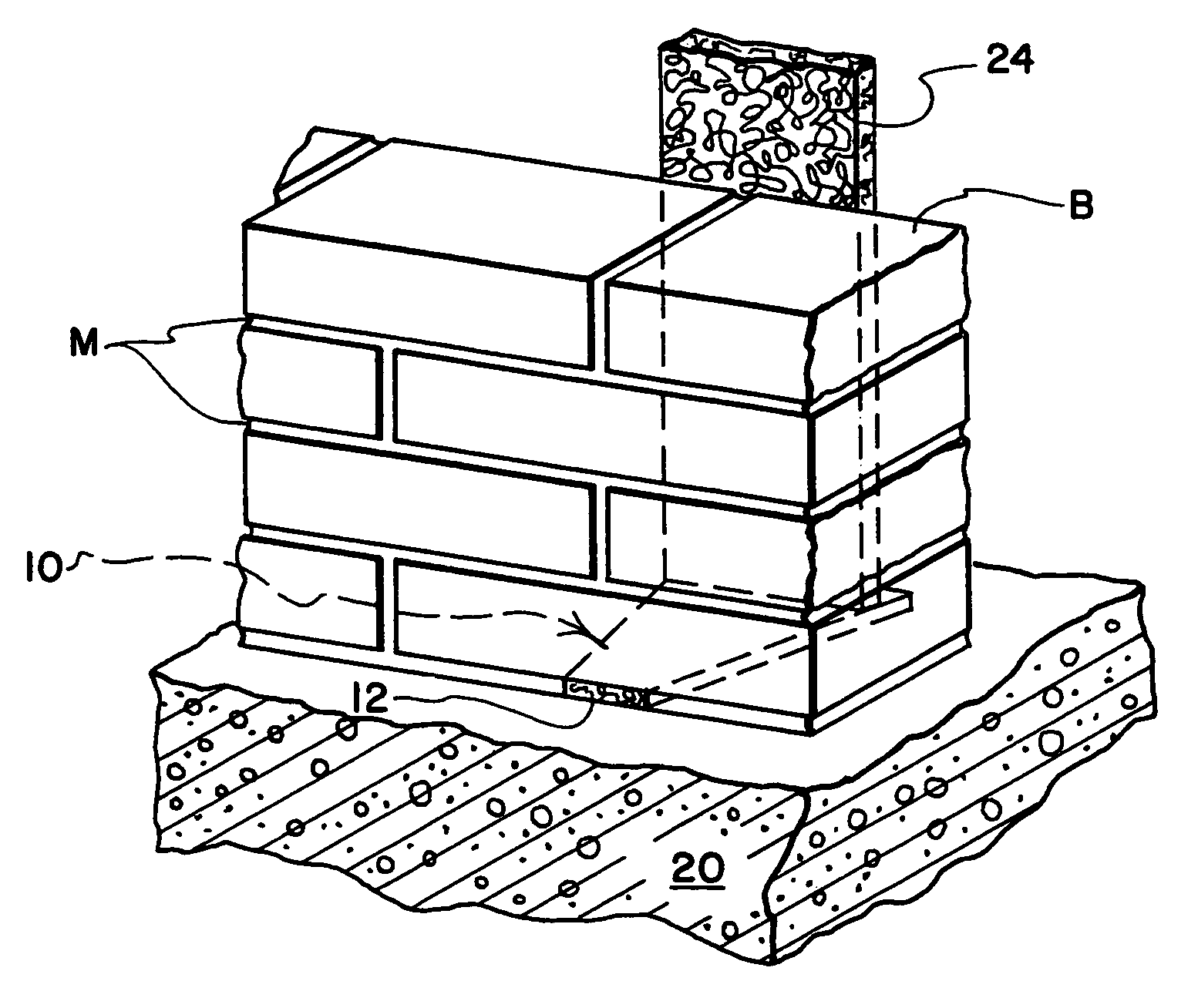

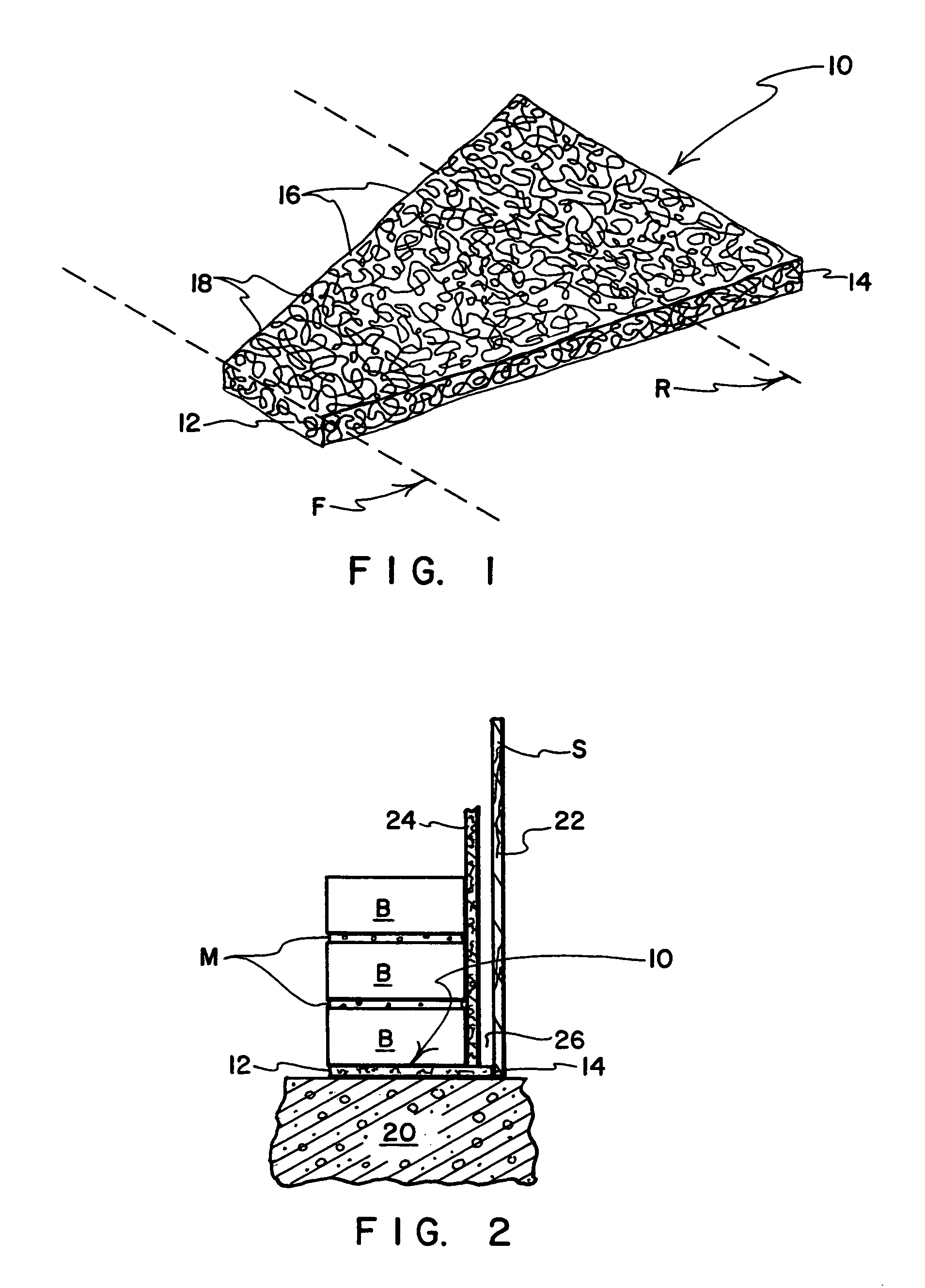

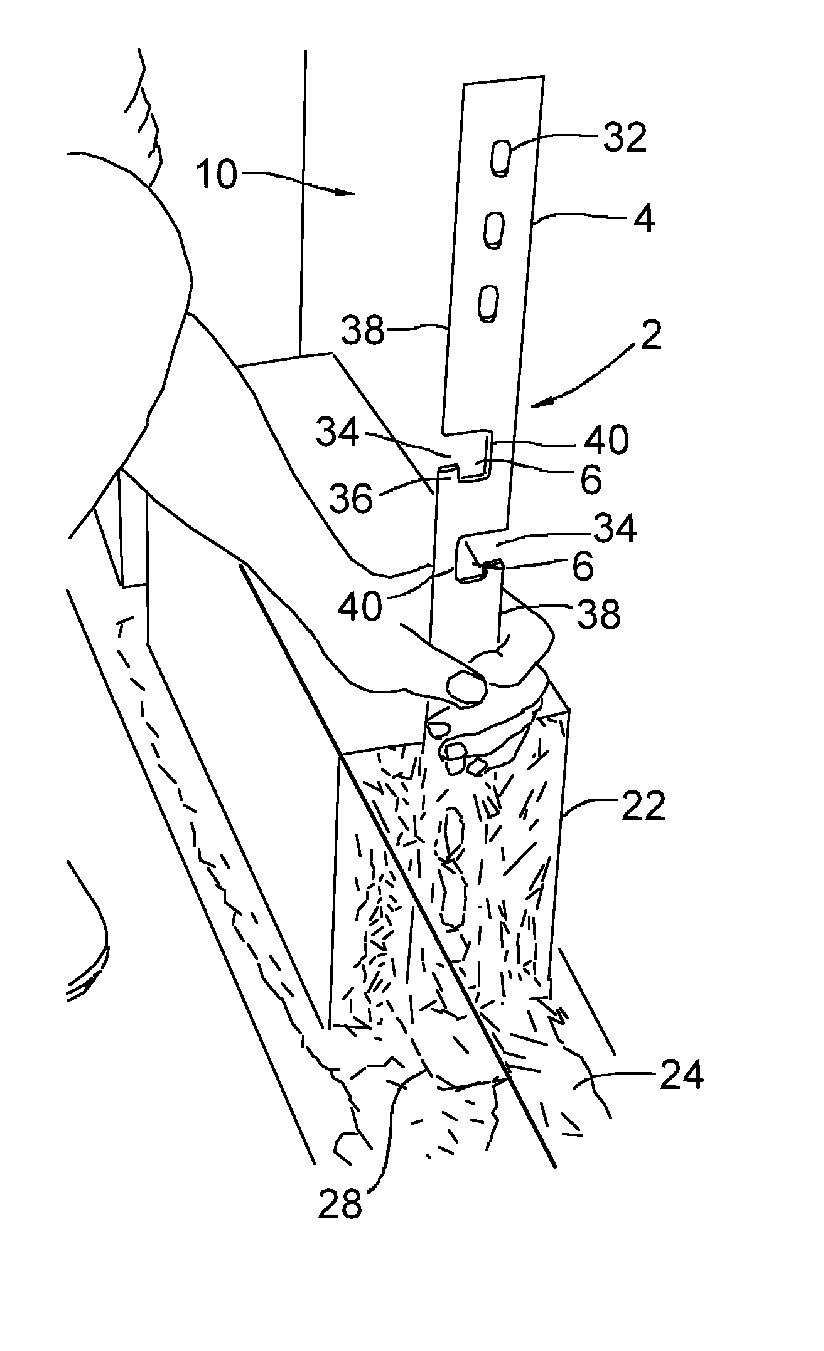

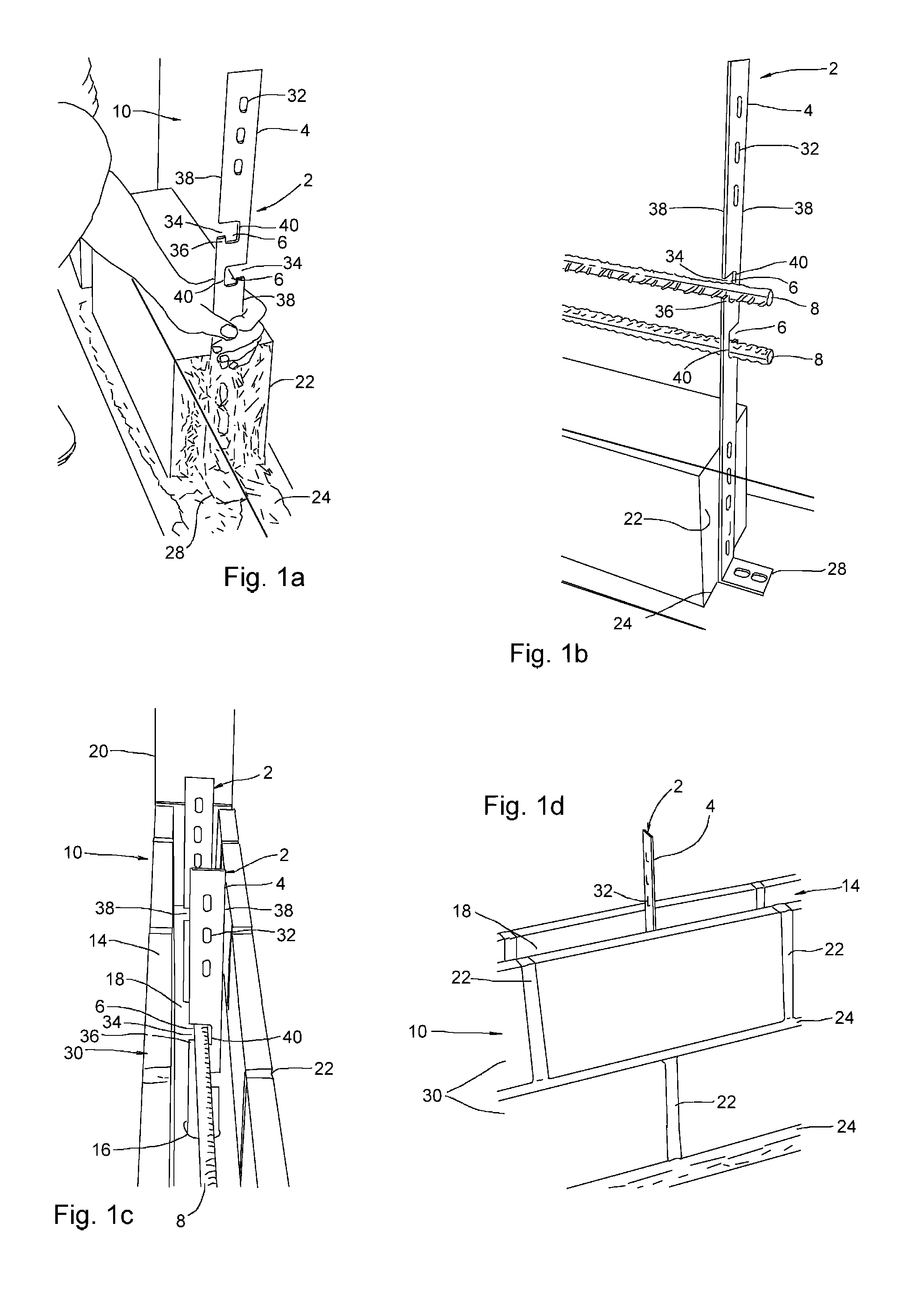

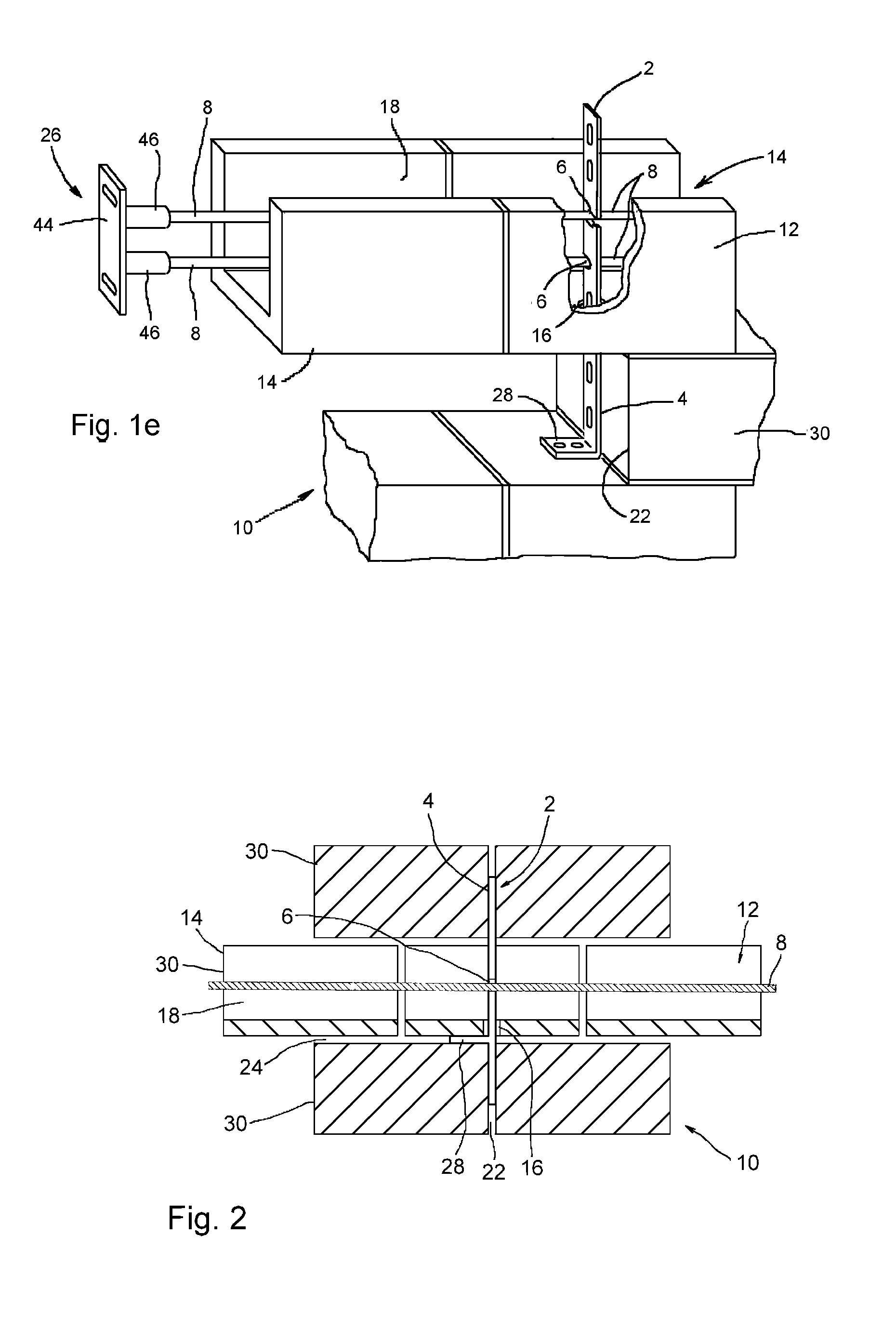

Adjustable masonry anchor assembly for use with insulating concrete form systems

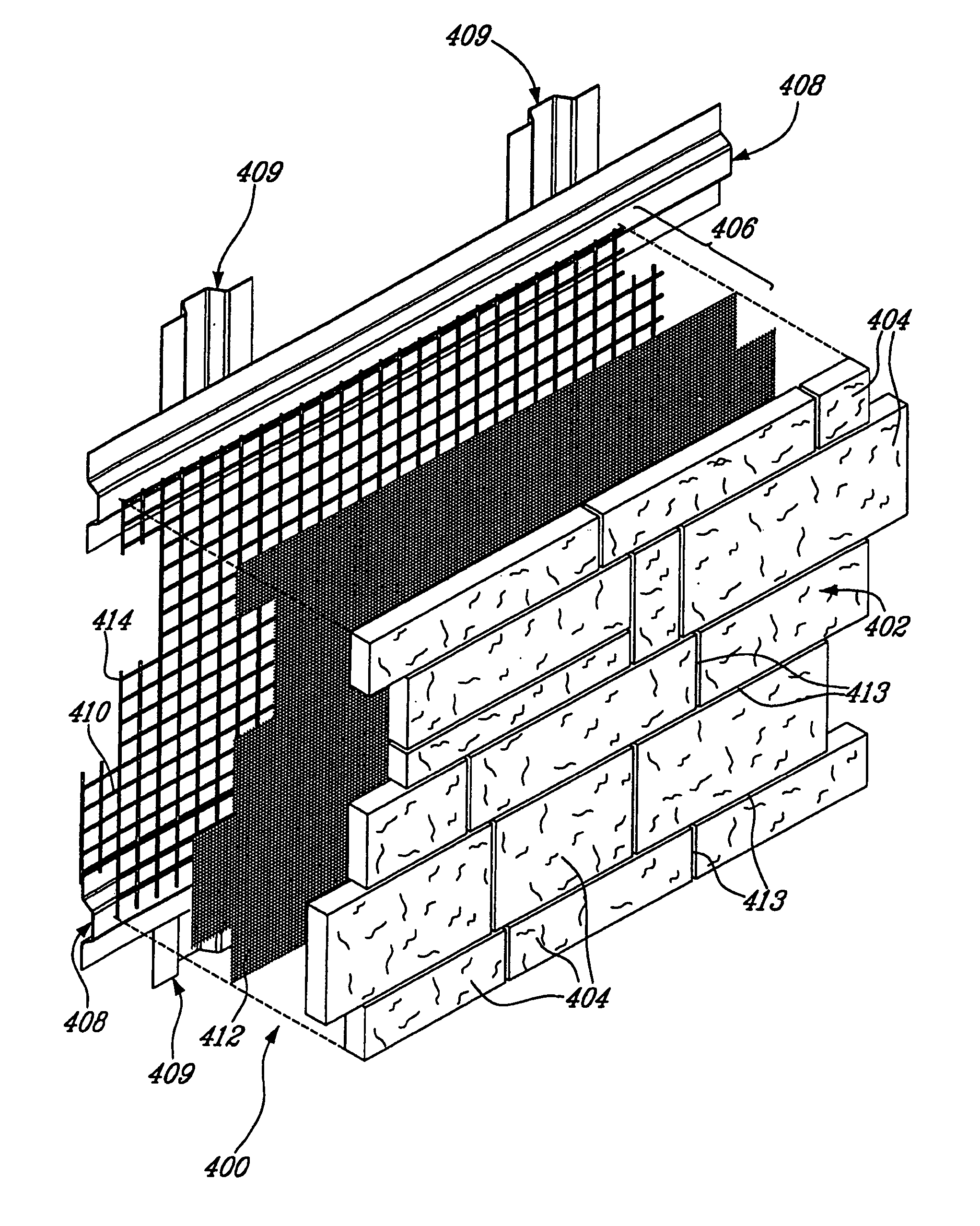

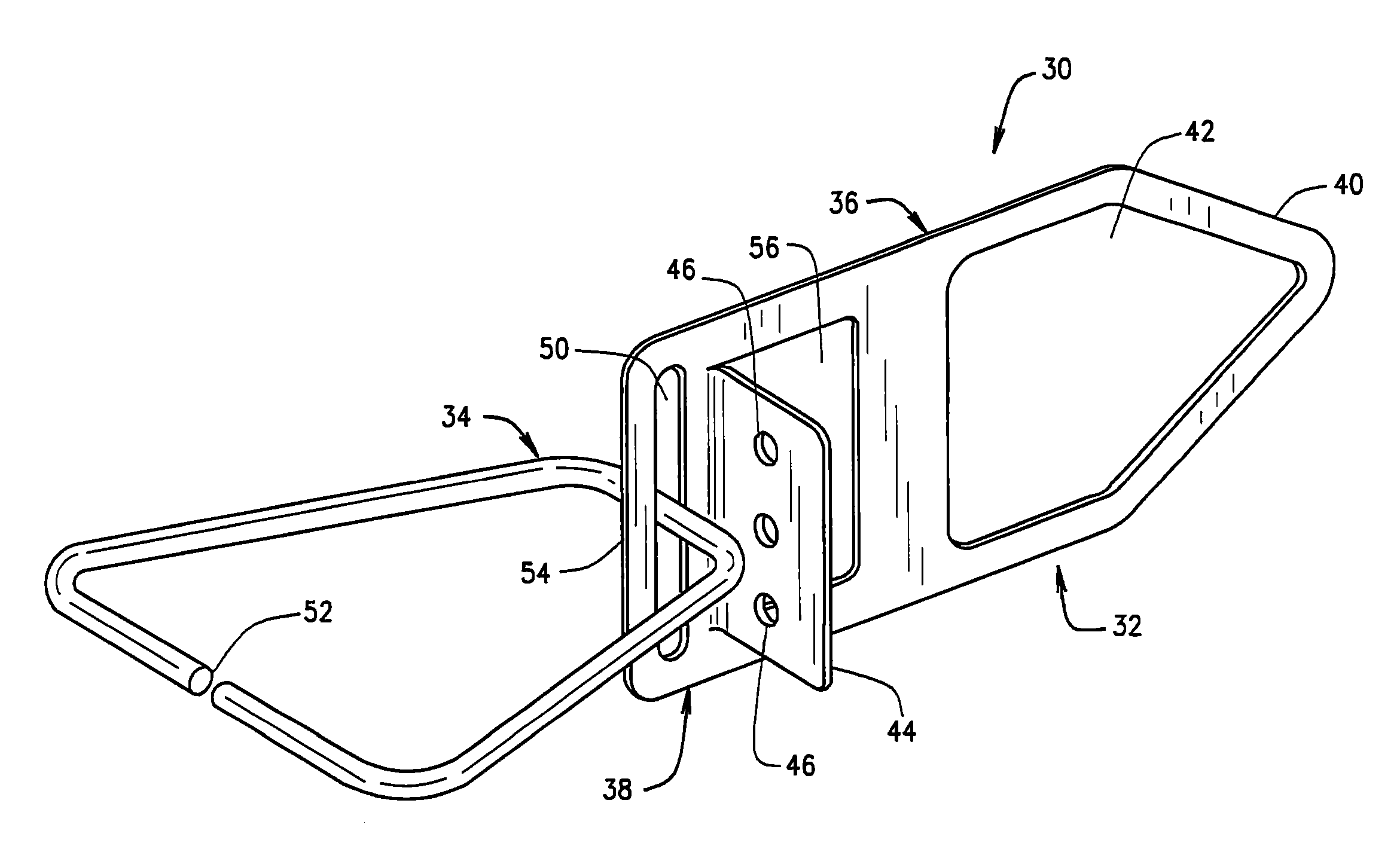

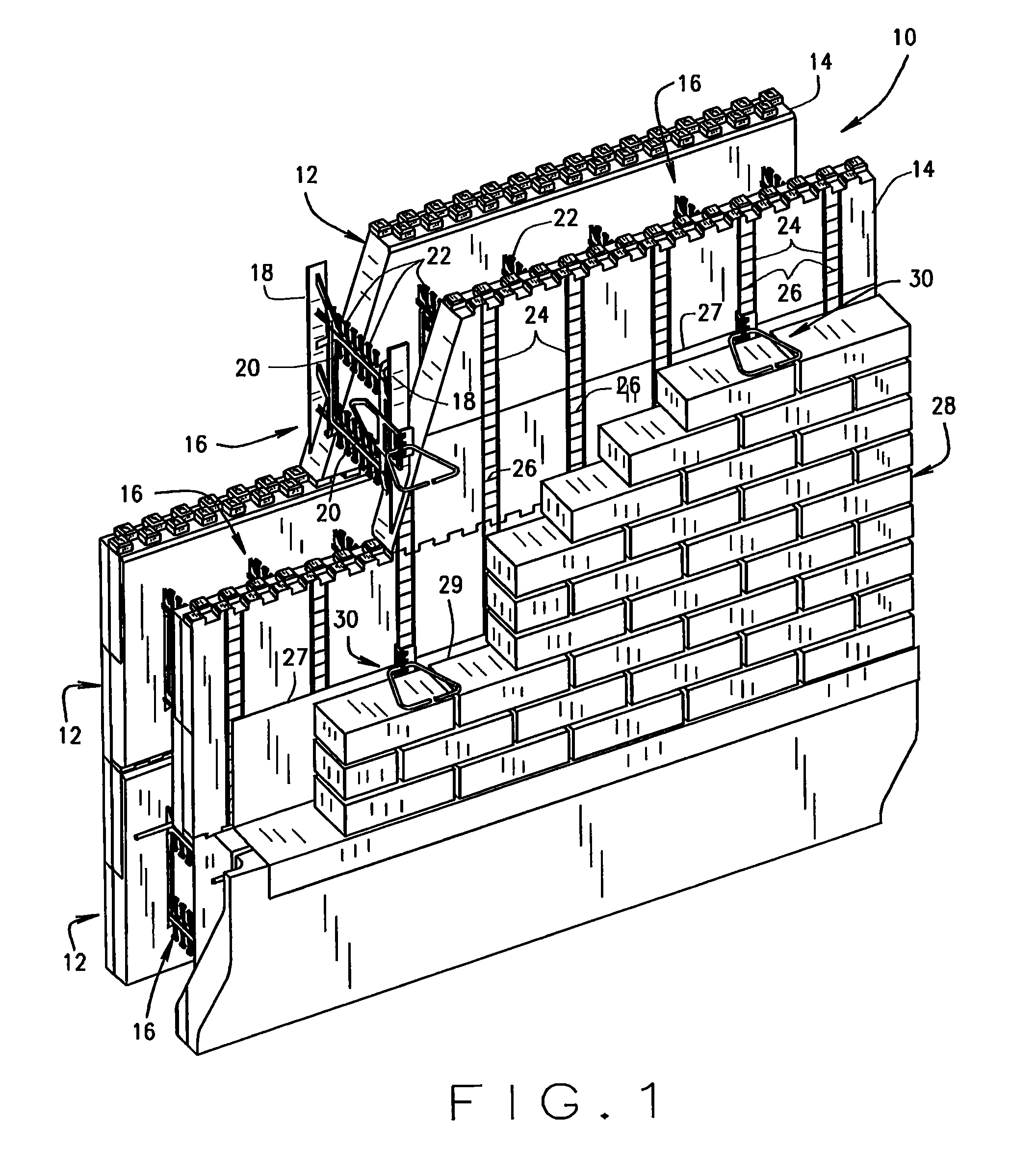

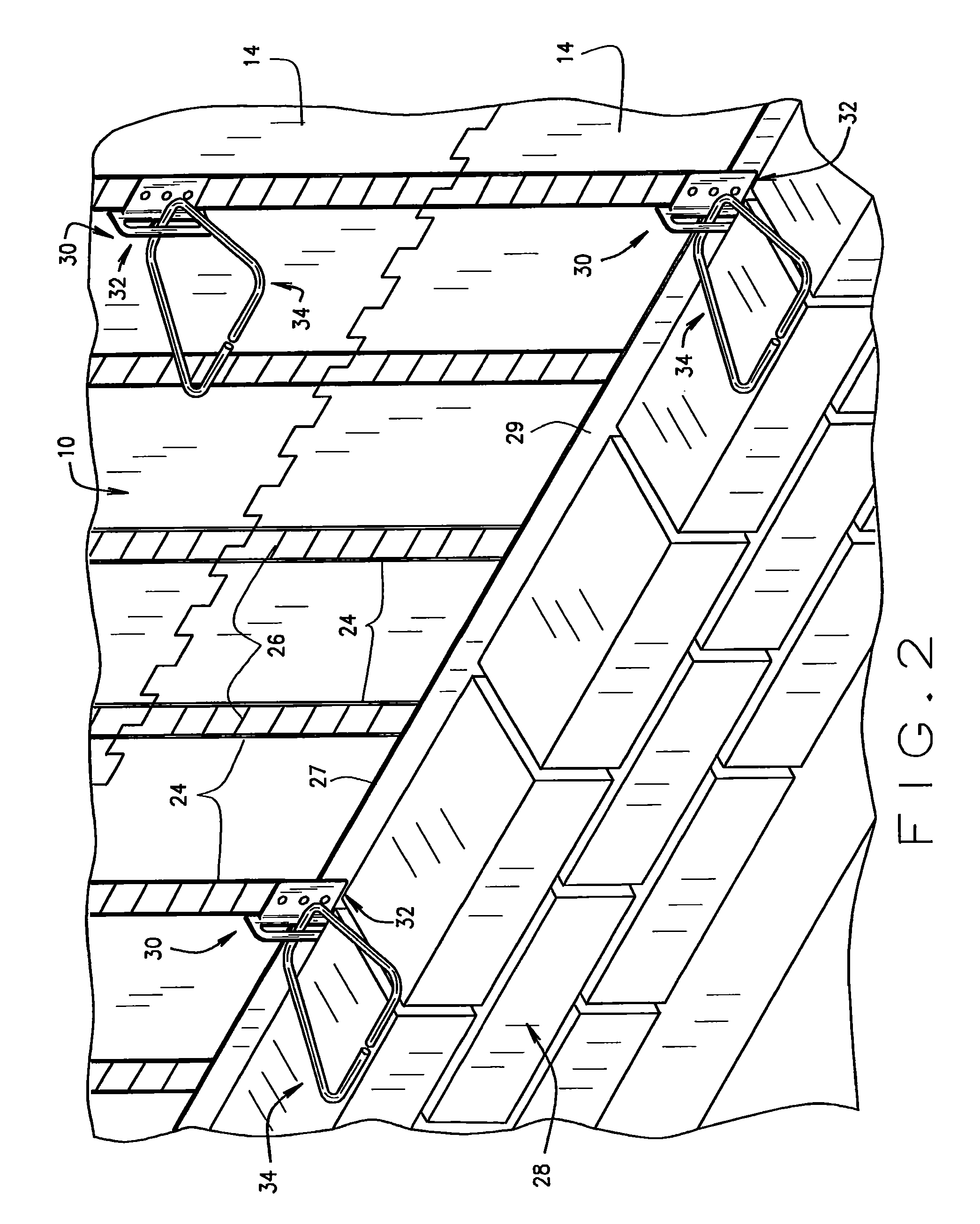

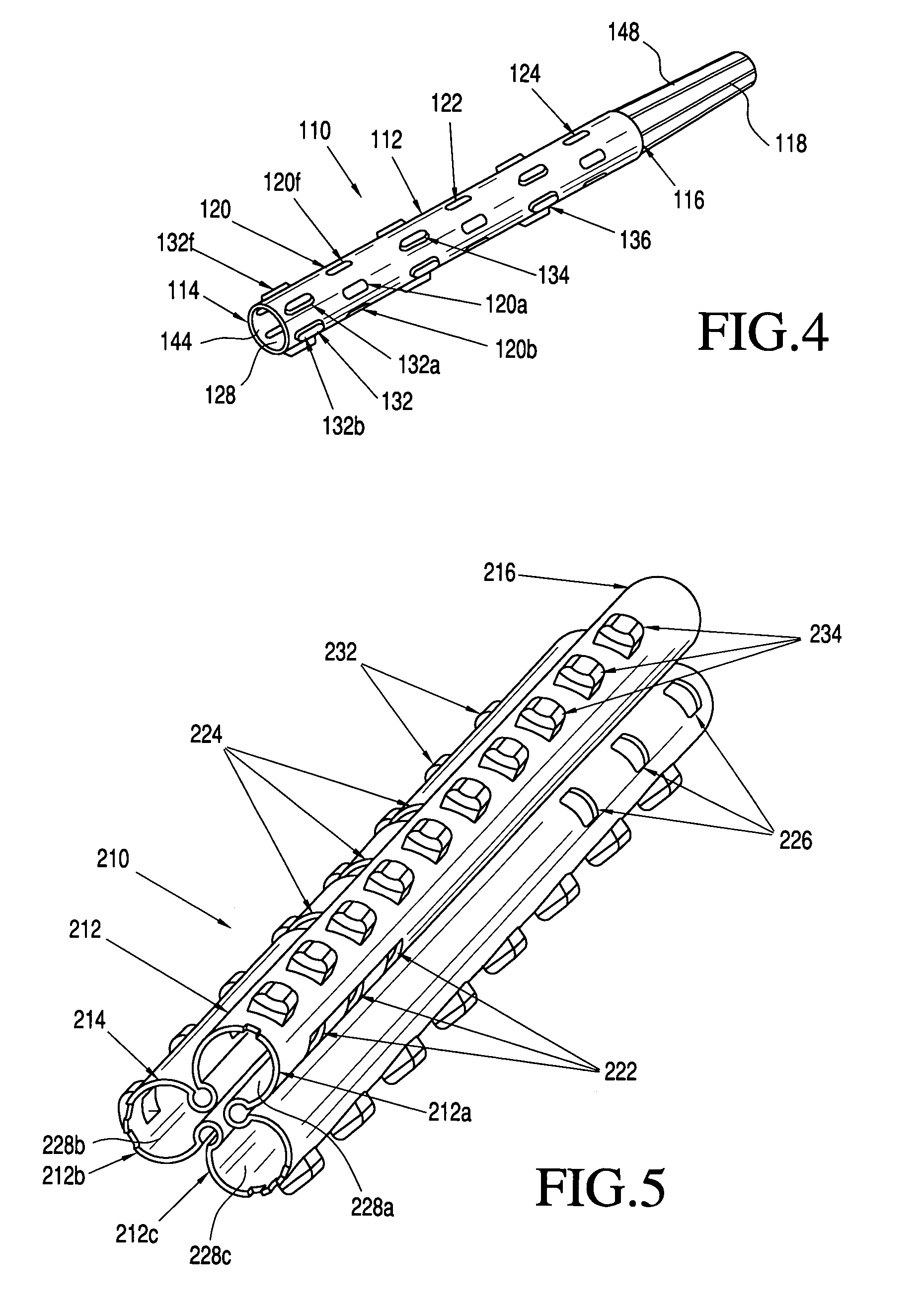

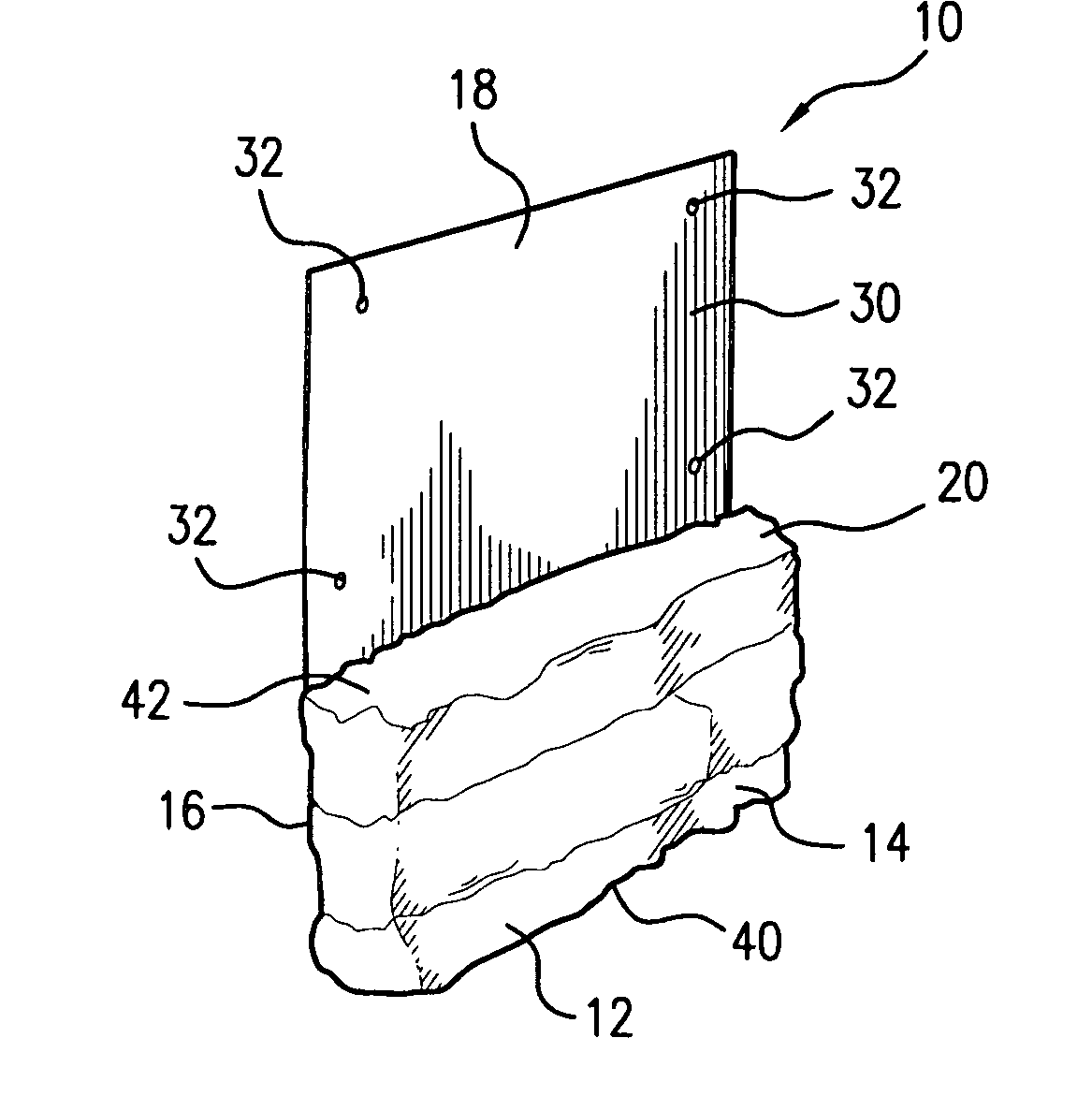

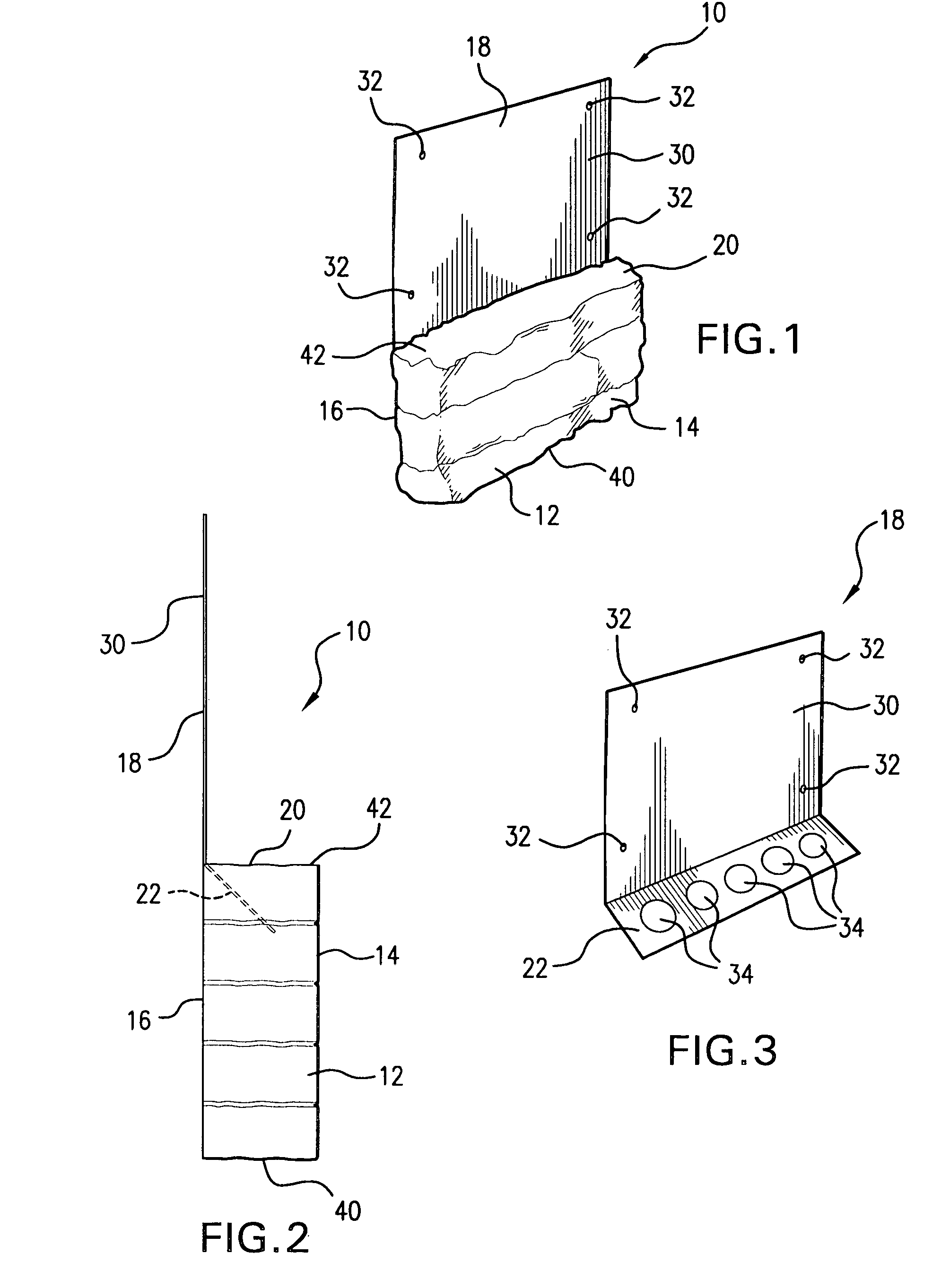

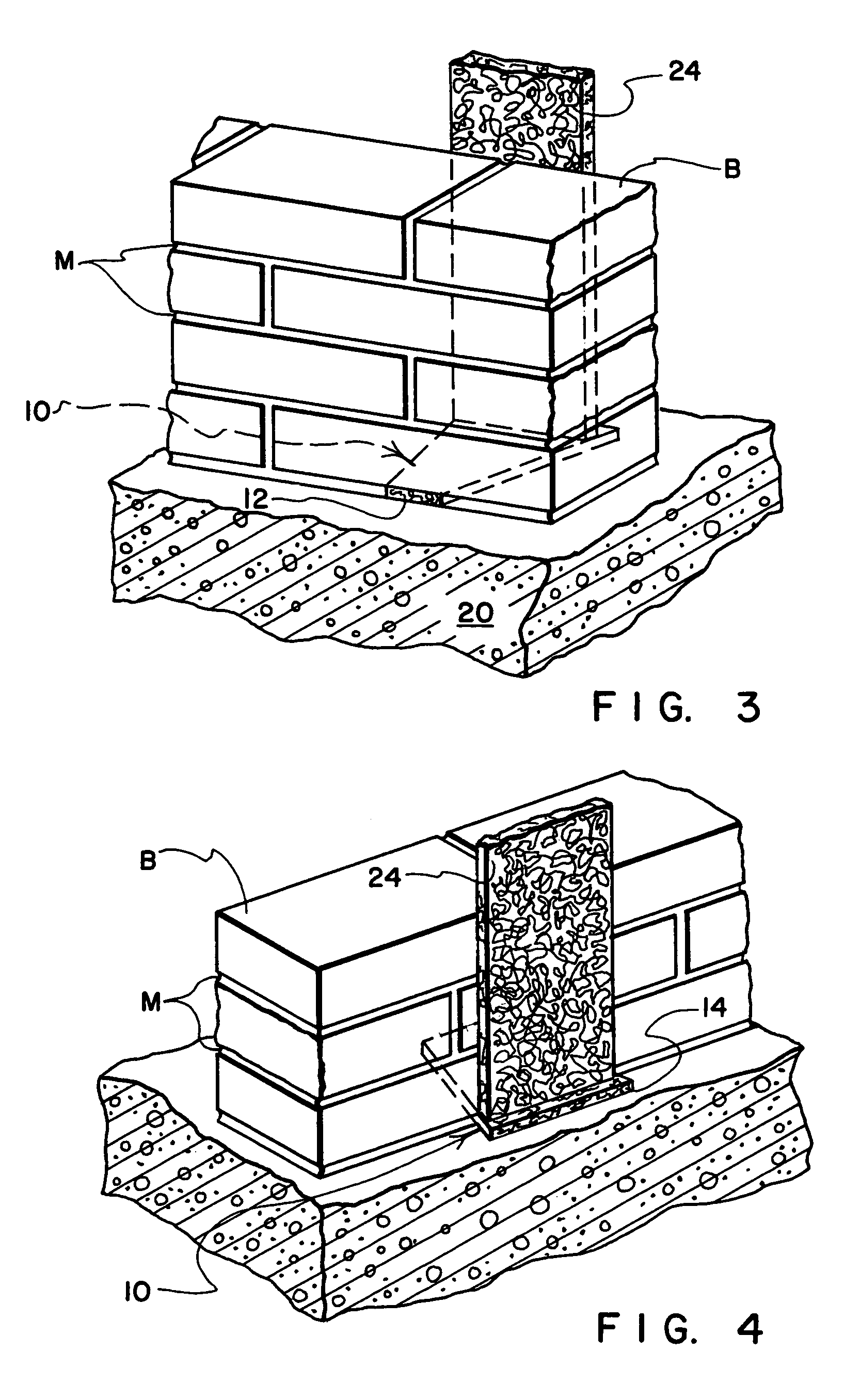

An anchor assembly for use in joining together a masonry wall structure and a supporting back wall structure wherein the back wall structure is preferably formed using insulated concrete form (ICF) blocks each having a pair of opposed ICF panels associated therewith, the anchor assembly including an anchor member and a tie member. The anchor member includes an anchor portion adapted to penetrate one of the ICF panels and having at least one opening associated therewith so as to lie between the opposed ICF panels when attached thereto for allowing poured concrete to flow therethrough, and an attachment portion having a tab member positioned and located to overlay an ICF panel flange member when the anchor member is inserted within the ICF panel, the tab member being attachable to the ICF panel flange member. The attachment portion further includes an elongated slot for receiving the tie member, the tie member being adjustably movable along the length of the slot so as to be positionable between the courses of brick or other masonry material associated with the masonry wall structure as the masonry wall structure is being erected.

Owner:AIRLITE PLASTICS

Adjustable masonry anchor assembly for use with insulating concrete form systems

An anchor assembly for use in joining together a masonry wall structure and a supporting back wall structure wherein the back wall structure is preferably formed using insulated concrete form (ICF) blocks each having a pair of opposed ICF panels associated therewith, the anchor assembly including an anchor member and a tie member. The anchor member includes an anchor portion adapted to penetrate one of the ICF panels and having at least one opening associated therewith so as to lie between the opposed ICF panels when attached thereto for allowing poured concrete to flow therethrough, and an attachment portion having a tab member positioned and located to overlay an ICF panel flange member when the anchor member is inserted within the ICF panel, the tab member being attachable to the ICF panel flange member. The attachment portion further includes an elongated slot for receiving the tie member, the tie member being adjustably movable along the length of the slot so as to be positionable between the courses of brick or other masonry material associated with the masonry wall structure as the masonry wall structure is being erected.

Owner:AIRLITE PLASTICS

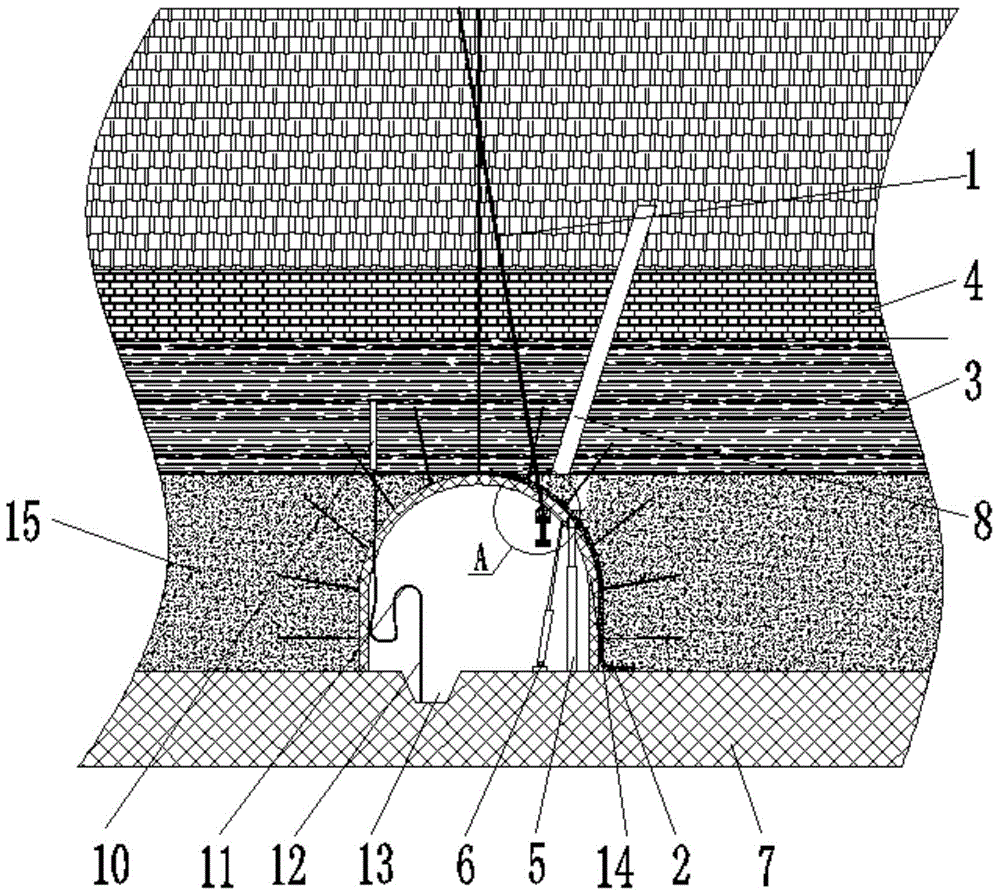

Top breaking gob-side entry retaining method for tender roofs

InactiveCN104929666ACollapse accident preventionAvoid damageUnderground chambersMine roof capsShotcreteStone wall

The invention discloses a top breaking gob-side entry retaining method for tender roofs. The top breaking gob-side entry retaining method includes steps of firstly, reinforcing and supporting the tender roofs of roadways jointly supported by original anchor meshes and cables or supported by sheds; secondly, laying wire meshes on gob sides; thirdly, preliminarily breaking the roofs of the roadways on the gob sides; fourthly, piling up preliminarily broken caved gangue until the caved gangue reaches rock of upper-end hard roofs to form gangue piled walls; fifthly, burying perforated grouting pipes in the formed gangue walls, spraying concrete on the surfaces of the wire meshes and the surfaces of the gangue walls to form concrete sprayed supporting layers; sixthly, injecting concrete grout in each preliminarily buried grouting steel pipe by the aid of a grouting pump after the concrete sprayed supporting layers are solidified; seventhly, sequentially detaching falling preventing devices and dense reinforcing columns along with advancing of working faces; eighthly, reinforcing and supporting the roofs under special conditions. The top breaking gob-side entry retaining method has the advantages that active bearing supporting effects can be realized for inherent characteristics of the tender roofs, supporting forms are simple, the cost is low, and entry retaining effects can be efficiently realized.

Owner:CHINA UNIV OF MINING & TECH

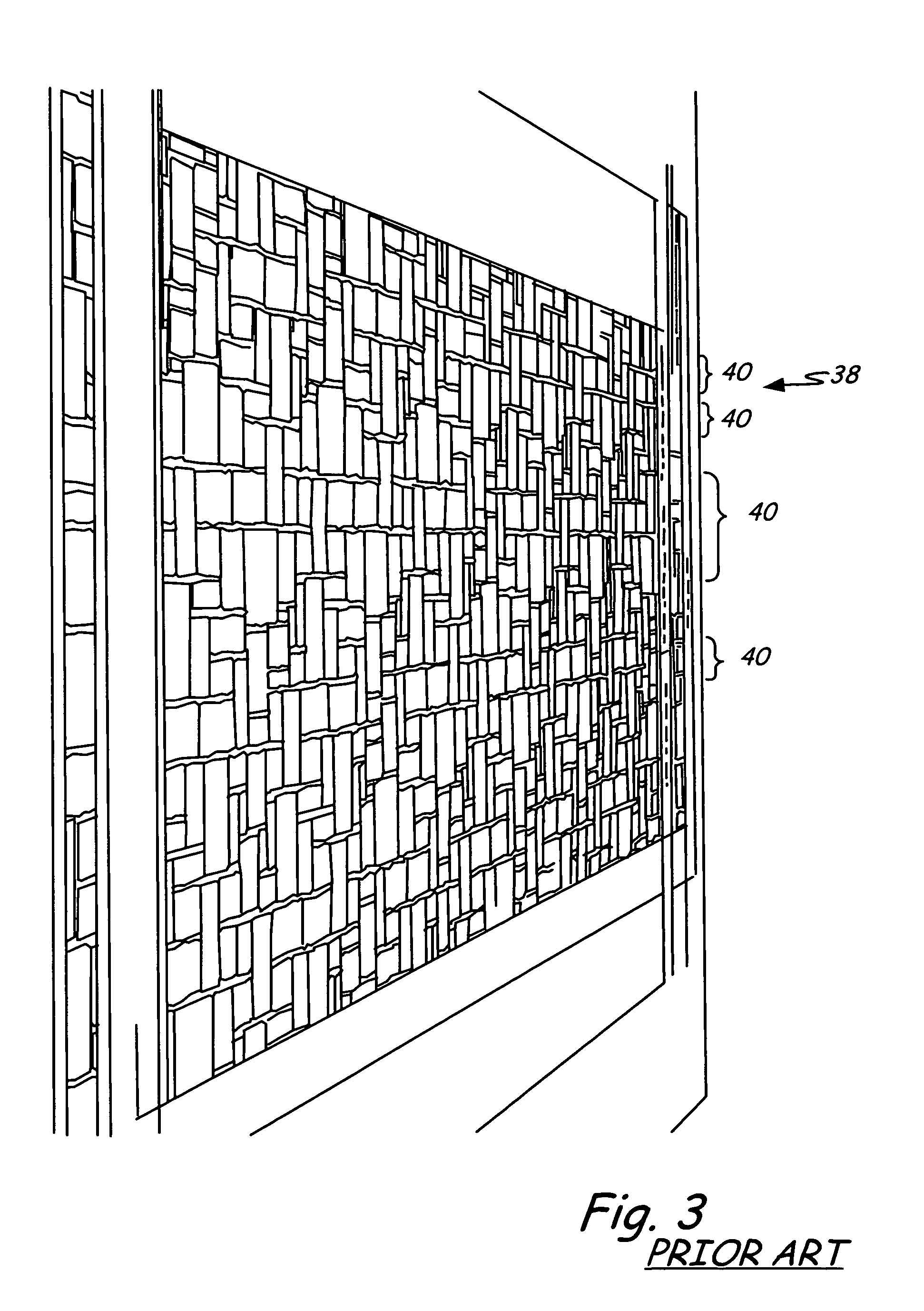

Form liner for creating a realistic stone wall pattern

The form liner of the present invention simulates a natural stone wall having a random pattern. The form liner comprises an outer edge and a surface that is contoured to resemble a plurality of stones held together by an adhesive substance. The outer edge of the form liner has six connection regions made up of multiple linear segments. No two adjacent connection regions are connected at a ninety degree angle and no linear segment of the fifth connection region lies along the same linear path as any linear segment of the sixth connection region.

Owner:NASVIK PAUL C

Masonry wall anchoring system

InactiveUS7404274B2Prolong lifeEarthquake proof and more resistant to damage and failureConstruction materialBuilding repairsBrickStone wall

Owner:HAYES JOHN T

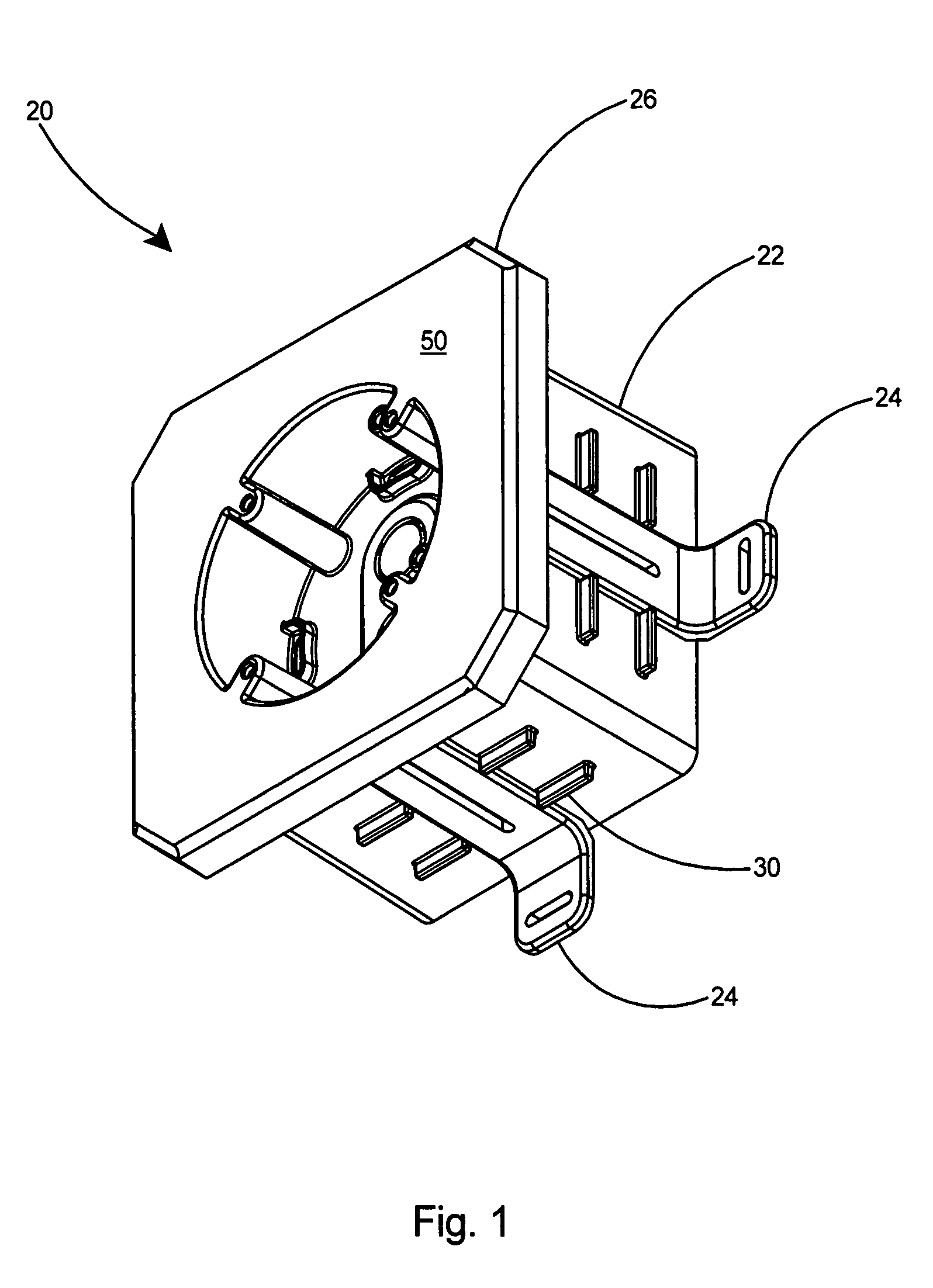

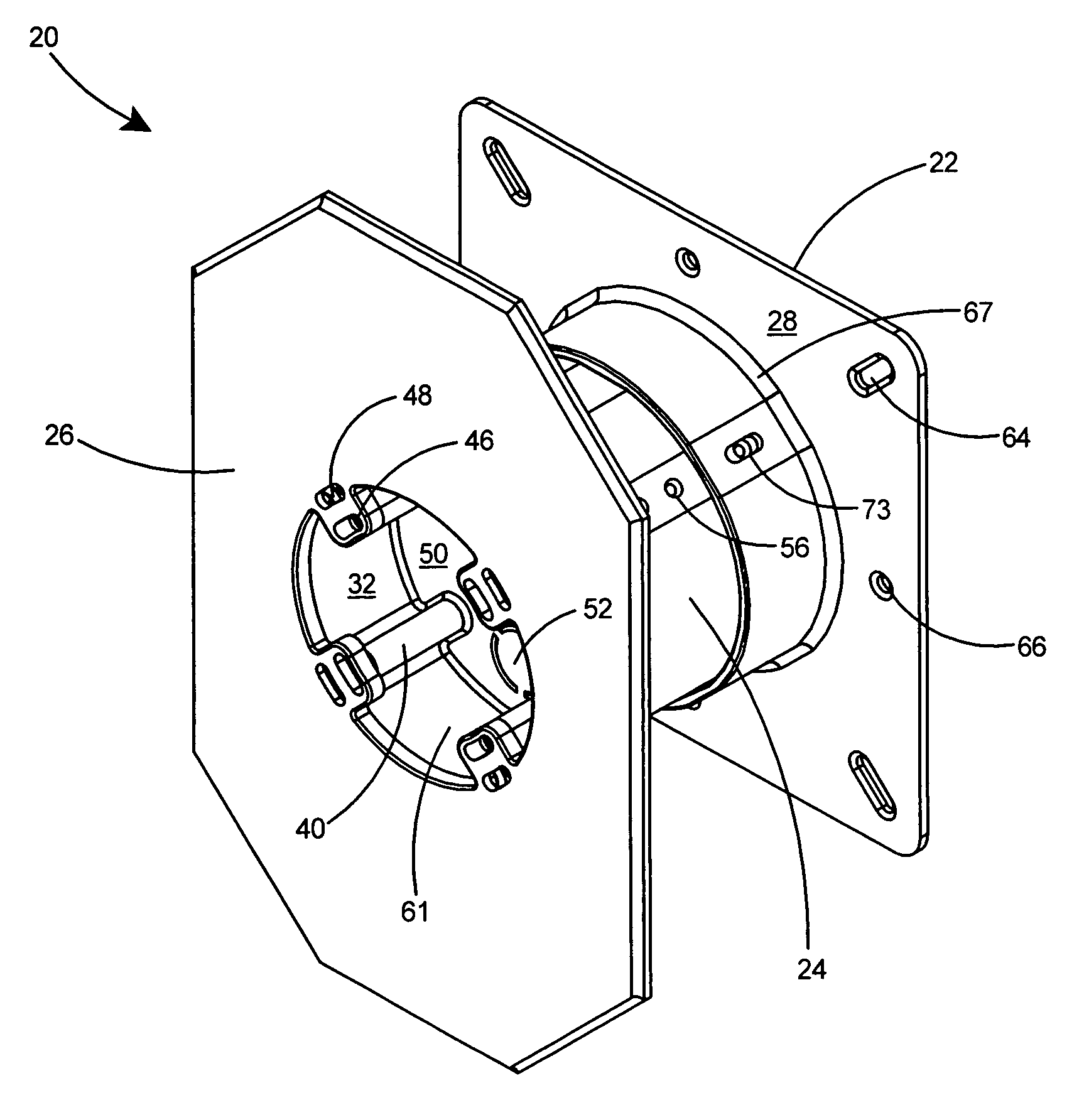

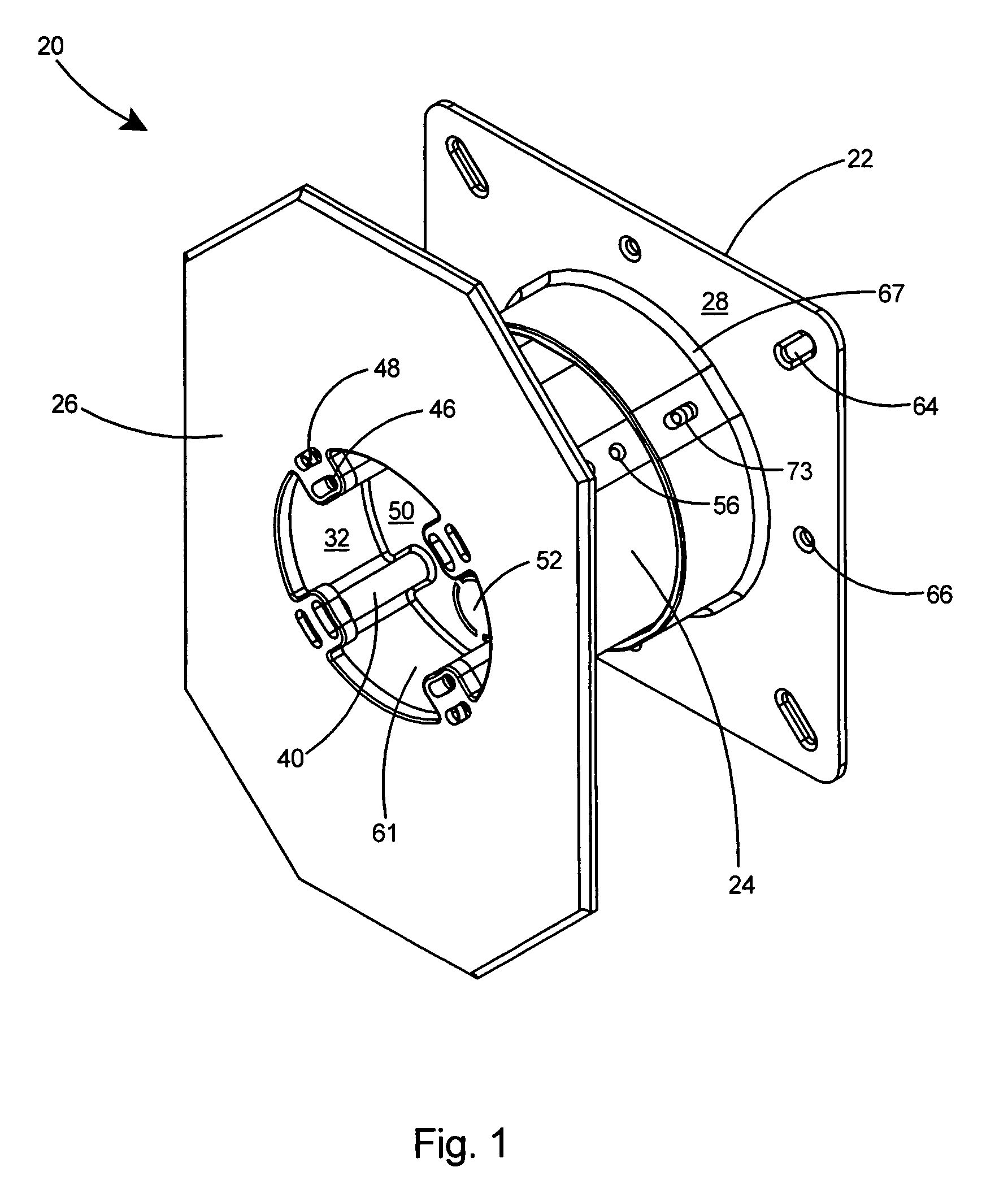

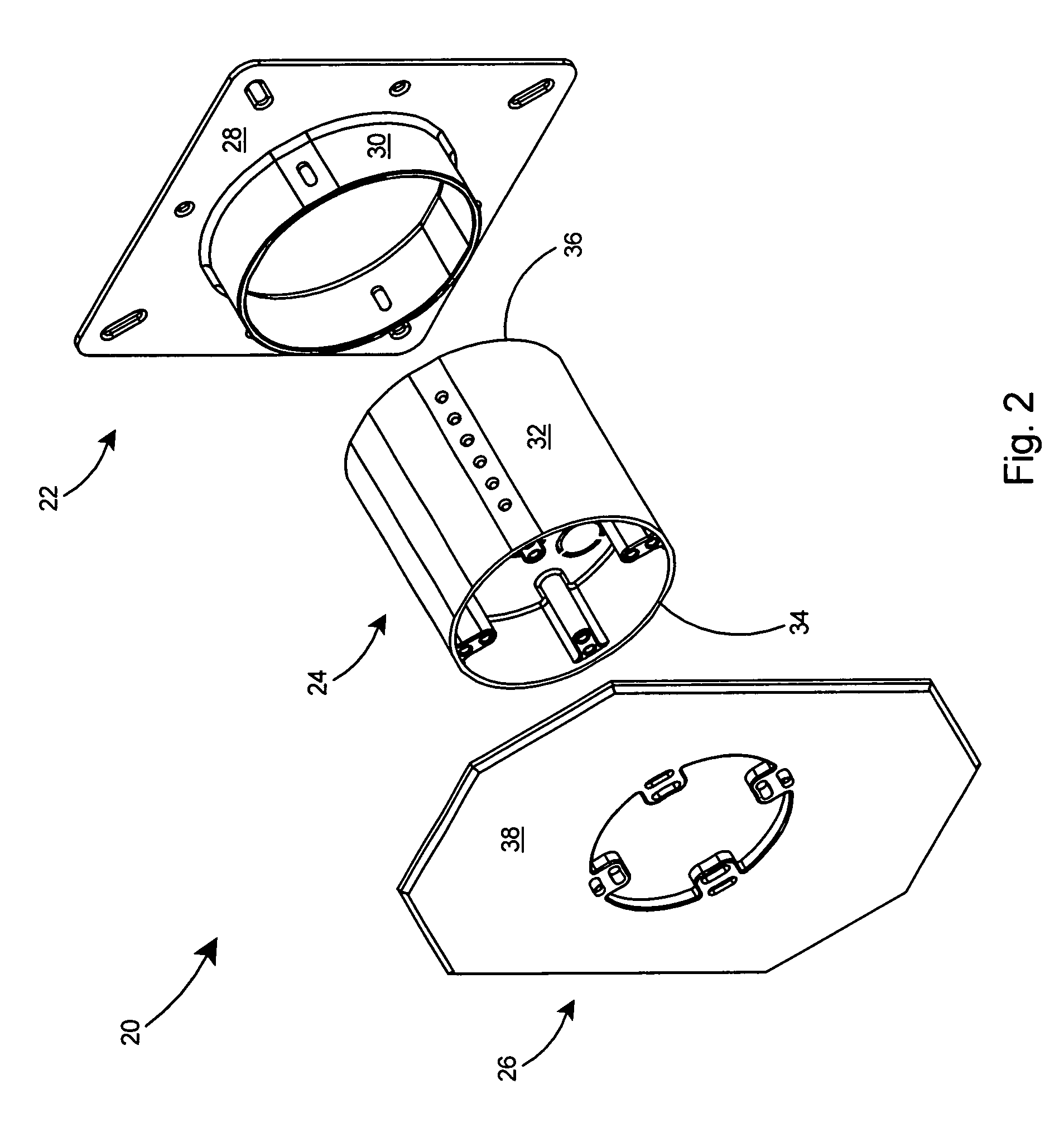

Adjustable electrical box for flush or offset mounting of electrical devices on brick or stone walls

An adjustable electrical box assembly for mounting an electrical device on a stone wall either flush with the wall or at a desired offset. The assembly includes a base member, anchoring members, an electrical box, and an optional base extender. For a wall constructed of narrow depth stones, the base member is mounted directly to the substrate using the anchoring members. For a wall constructed of thick stones, the base member and base extender are secured together with the anchoring members and the assembly is secured to the substrate. The offset of the electrical box from the wall surface is set by adjusting the position of attachment of the anchoring members with respect to the sidewalls of the base member and base extender. The electrical box is adapted to receive a light fixture or similar electrical device.

Owner:ARLINGTON INDS

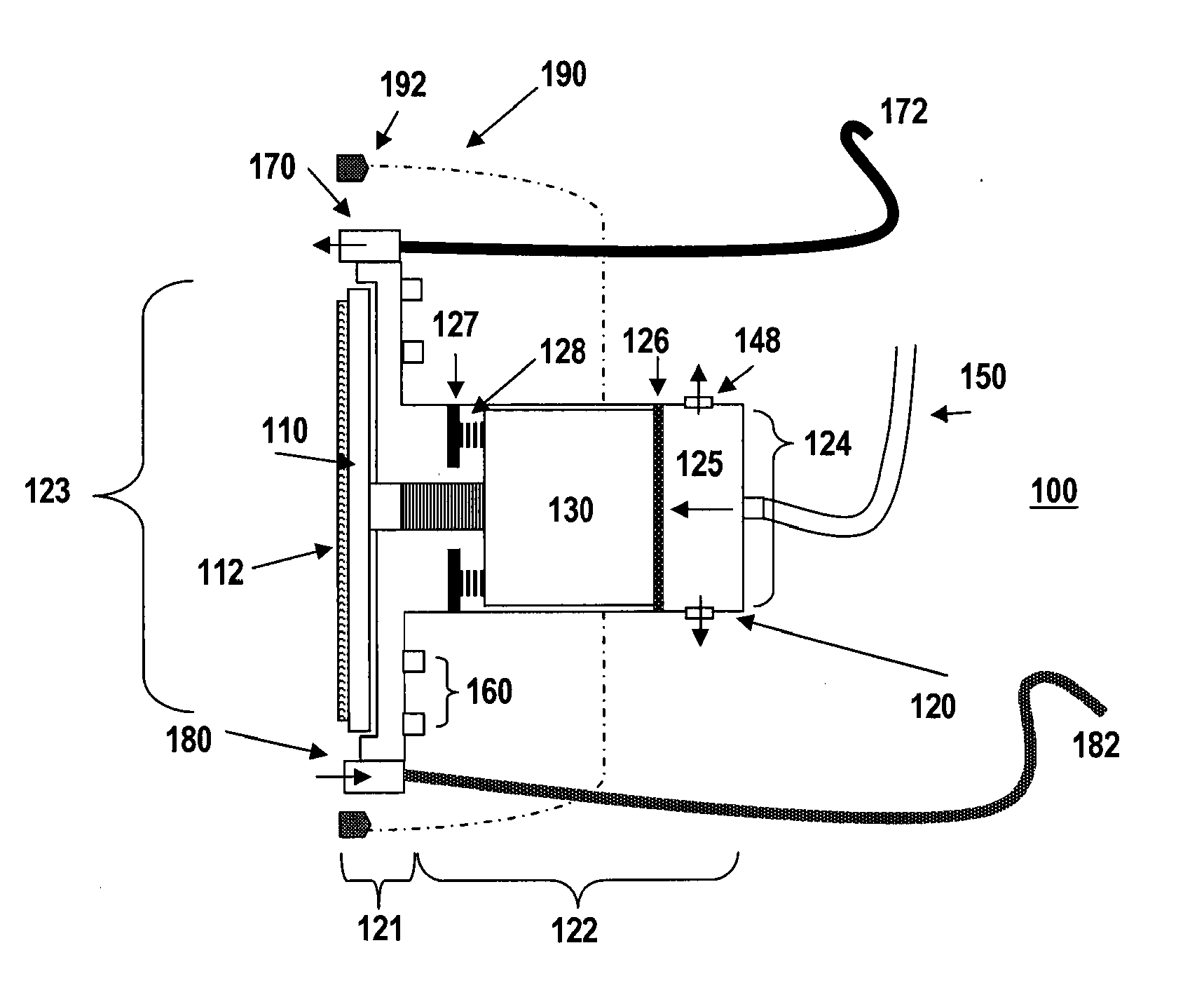

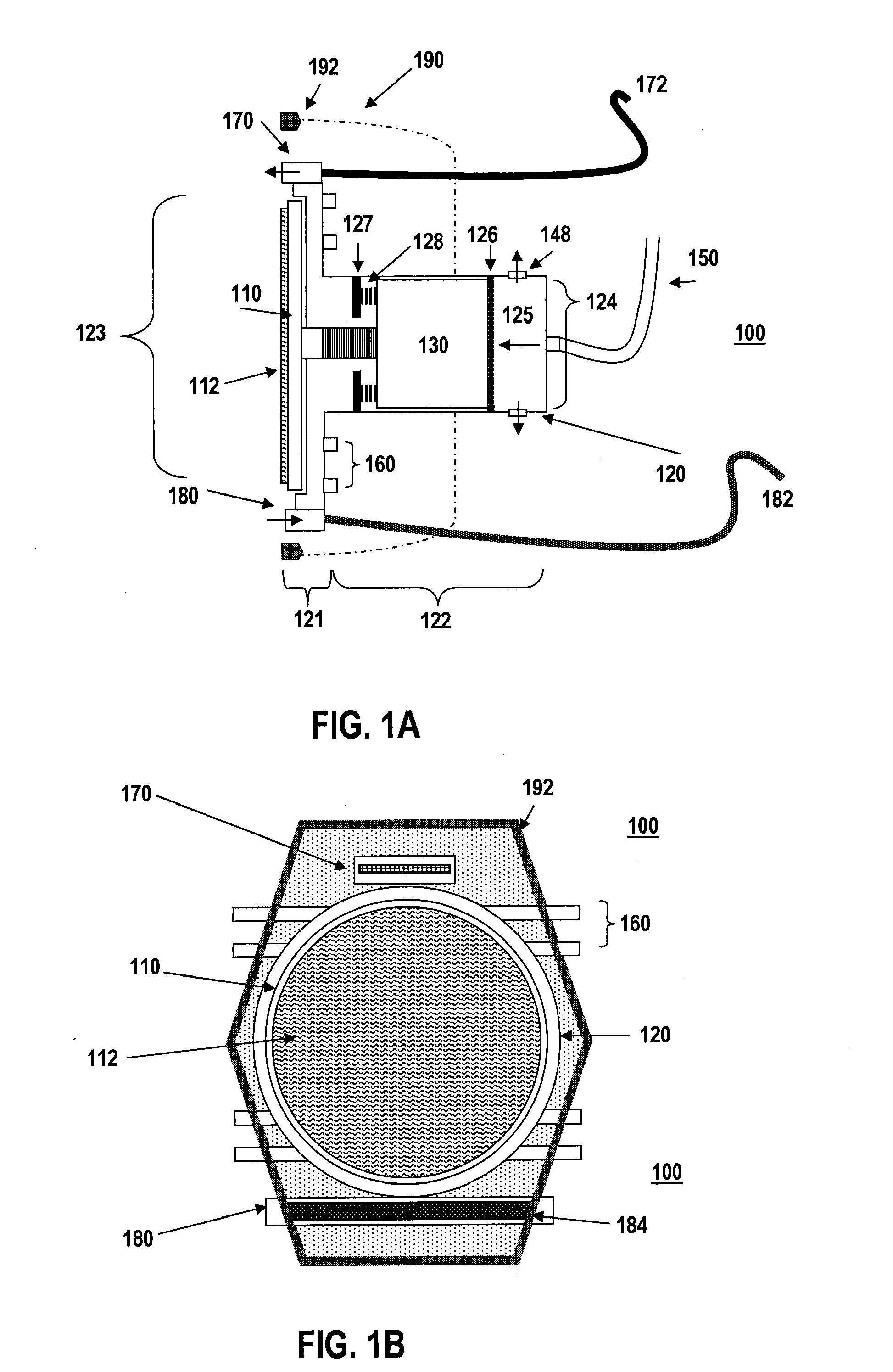

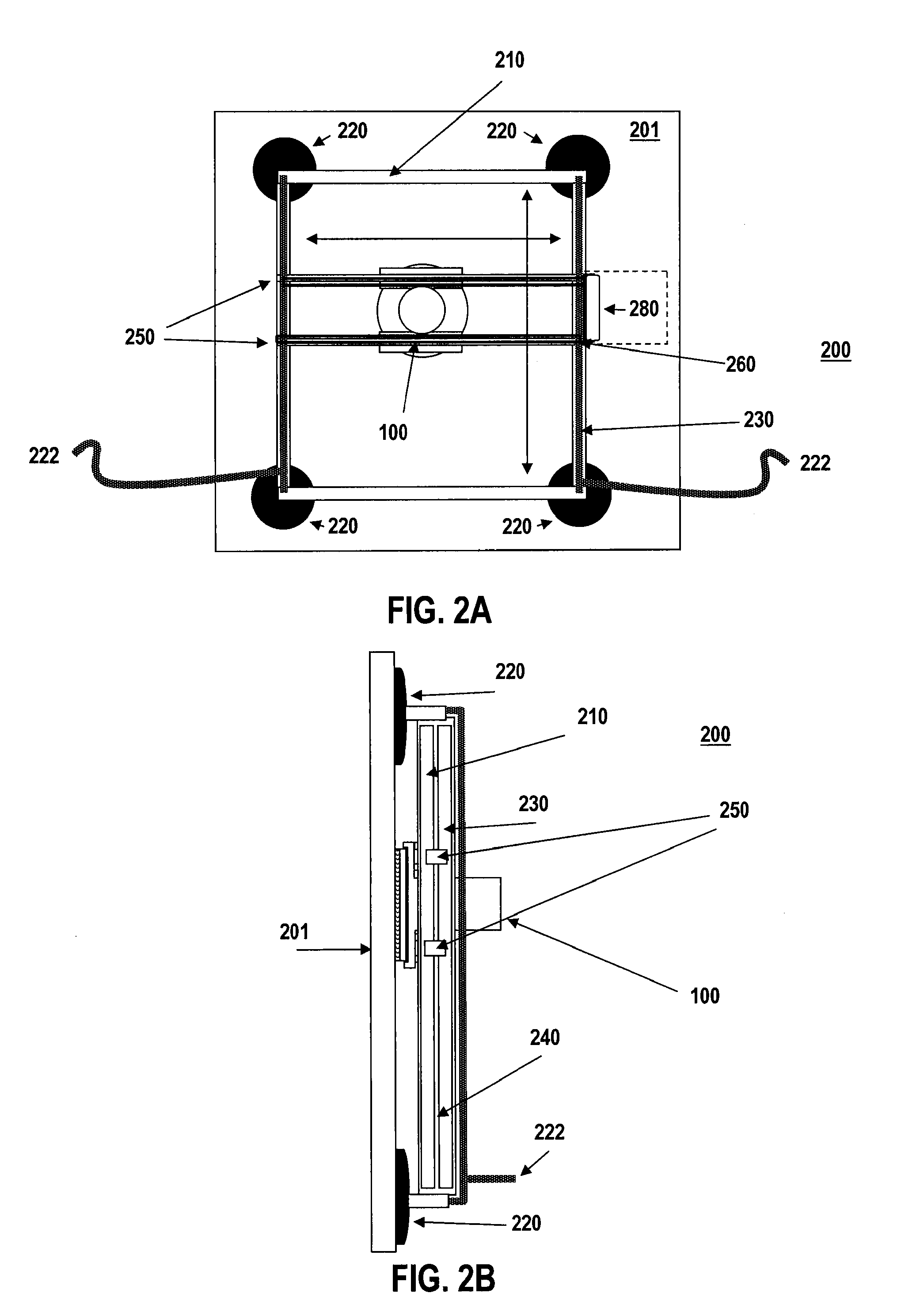

Stone wall grinding and polishing system

A system, apparatus and method capable of grinding and polishing fabricated vertical surfaces of varying shapes and sizes without the use of hand tools. The system comprises a frame which can be affixed to the surface and which supports a grinding and polishing apparatus. The grinding and polishing apparatus uses air pressure to force a rotating grinding or polishing disc against the surface being worked on. The frame is designed so that the grinding and polishing apparatus can be moved (via, e.g., tracking) both vertically and horizontally to any desired point within the frame. The grinding and polishing apparatus optionally includes a water nozzle and vacuum system to spray and recapture water used to cool the surface being operated on.

Owner:PERMASTEELISA NORTH AMERICA

Flexible tapestry brick of external wall outer insulation system and production method thereof

The invention discloses a flexible decorated brick for exterior wall insulation system, mainly comprising main-body bricks or a composite surface coating of main-body bricks. The main-body brick formula contains major components of soil and acrylic emulsion, and further contains dispersant, softening agent, coloring agent, flame retardant, antifreeze and water according to different product performance requirements. The surface coating formula contains the main components of metal powder or a compound powder of more than two kinds of non-metallic powder or metal powder and acrylic emulsion and further contains dispersant, softening agent, coloring agent, flame retardant, antifreeze and water according to the needs of different product performances. The product of the invention is light-weighted, freeze-thaw resistance, anti-aging, high in bond strength, flexible and good in water-repellent and permeability, the pollution resistance of which is equivalent to that of polished tiles and the color of which is as rich as the paint and the appearance of which can be made into a decorative texture of metal curtain walls, stone walls, ceramic, wood, leather or cloth. Particularly, the inventive product has an excellent compatibility with the exterior insulation system, suitable for the decorated layer of the exterior insulation system. In addition, the inventive product avoids using the clay resource which is in shortage as the main production raw material and is a low-cost, environment-friendly flexible decorated material with high performance for exterior wall insulation system.

Owner:石磊

Anchoring framework to a masonry wall

An upper framed portion of a building structure may be anchored to a lower masonry wall by using a conventional concrete anchor and an anchor retainer. The anchor retainer may have a body portion longer than the width of the wall and both upper and lower reference surfaces. An anchor retainer assembly is temporarily formed by inserting the anchor through a throughhole in the retainer body so that the threaded upper portion of the anchor extends above the upper reference surface of the retainer by a first selected height, so as to leave enough of the threaded end exposed above the retainer for at least one nut to be securely attached to the anchor. No unthreaded portion of the anchor extends above the lower reference surface by more than a second amount that is generally selected to be equal to the actual thickness of the framing member, so as to ensure that no substantial unthreaded portion of the anchor can extend above that member.

Owner:DEMING RICHARD ALLEN

Plant configuration and ecological engineering technology for embankment

InactiveCN1526886AIncreased shear strengthWon't wash awayExcavationsHorticultureStone wallEngineering

The present invention relates to the embankment protection in water conservancy and hydroelectric power system, especially inner slope in water reservoir. The plant configuration and ecological engineering technology of the present invention is superior to traditional concrete, laid stone wall, anchor pile and other traditional rigid means, which are lack of ecological effect of purifying water and lasting effect, and superior to available biological engineering means with non ideal effect. The present invention is one ecological engineering technology with vetiver as main body and other plant variety, and has superior ecological effect, lasting slope protection effect, low cost and simple construction process.

Owner:SOUTH CHINA PLANT INST CHINESE ACAD OF SCI +1

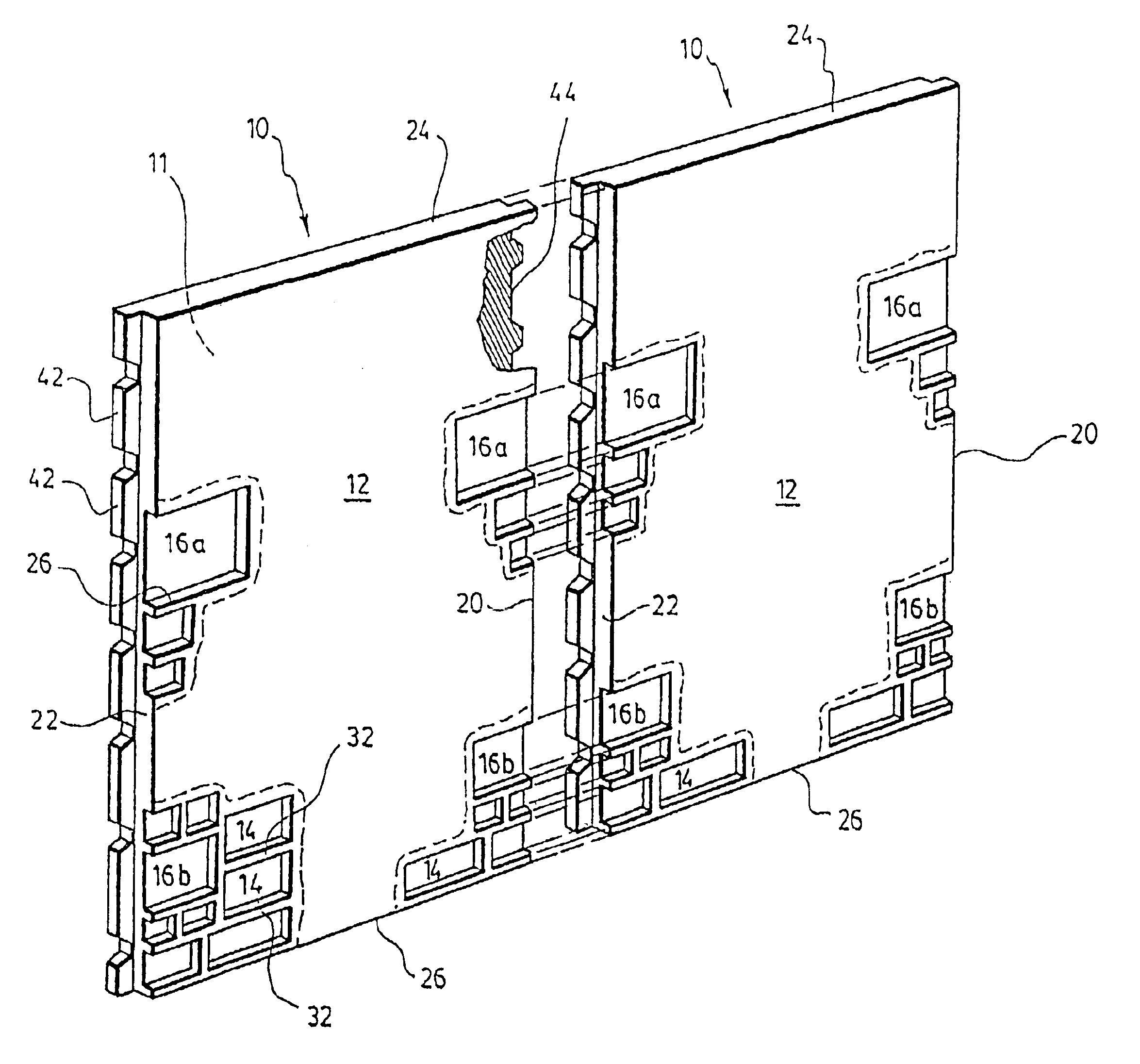

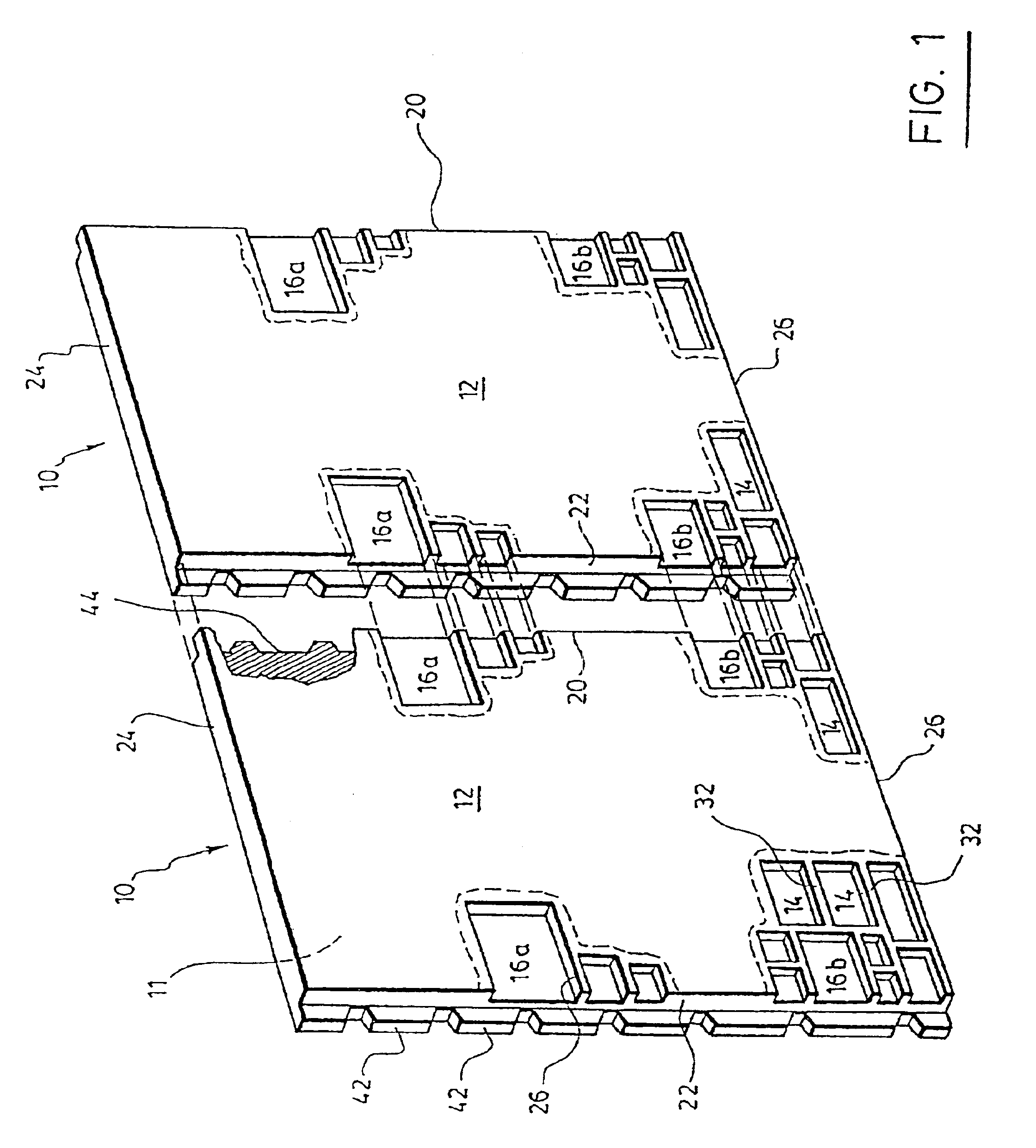

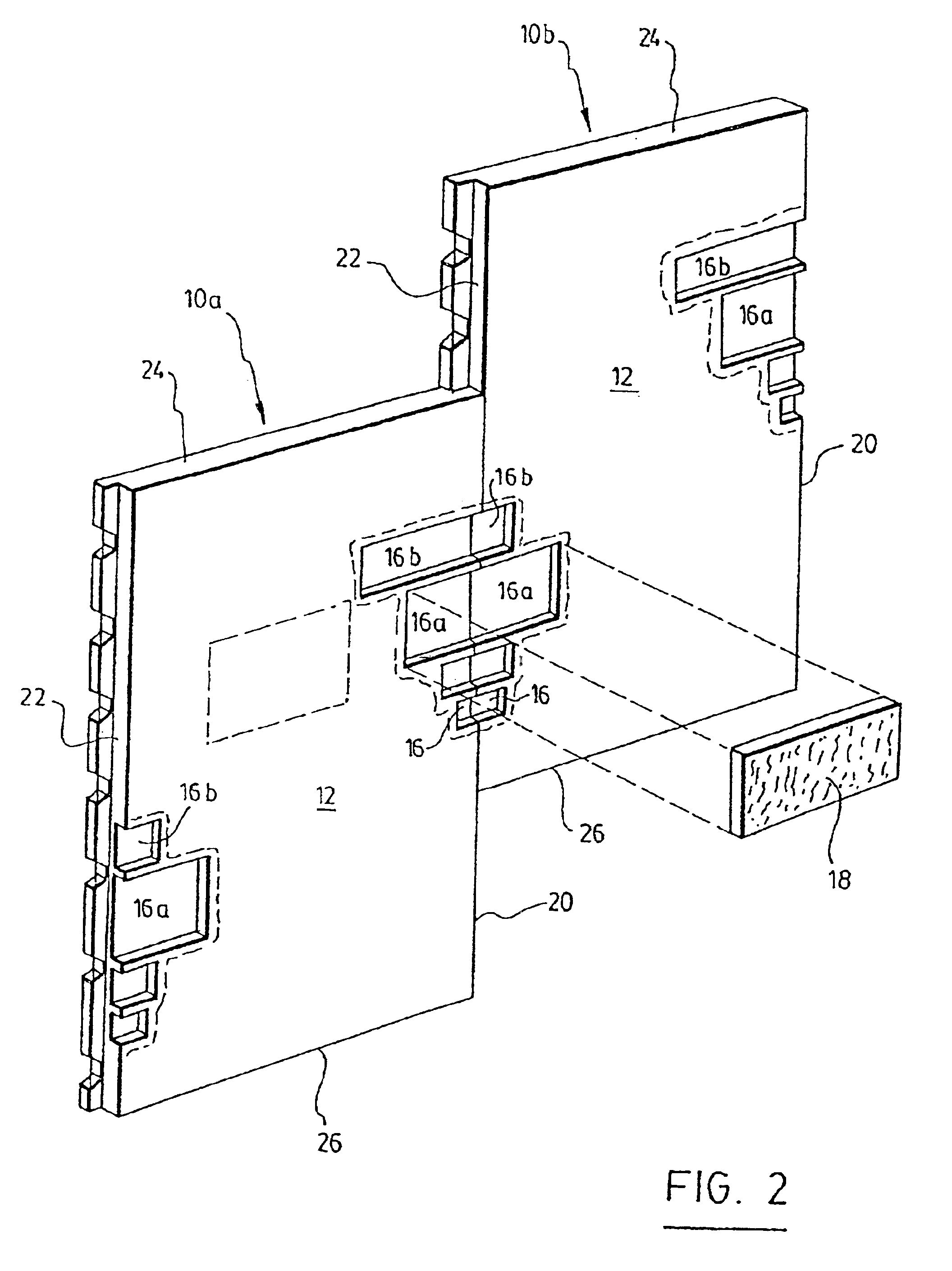

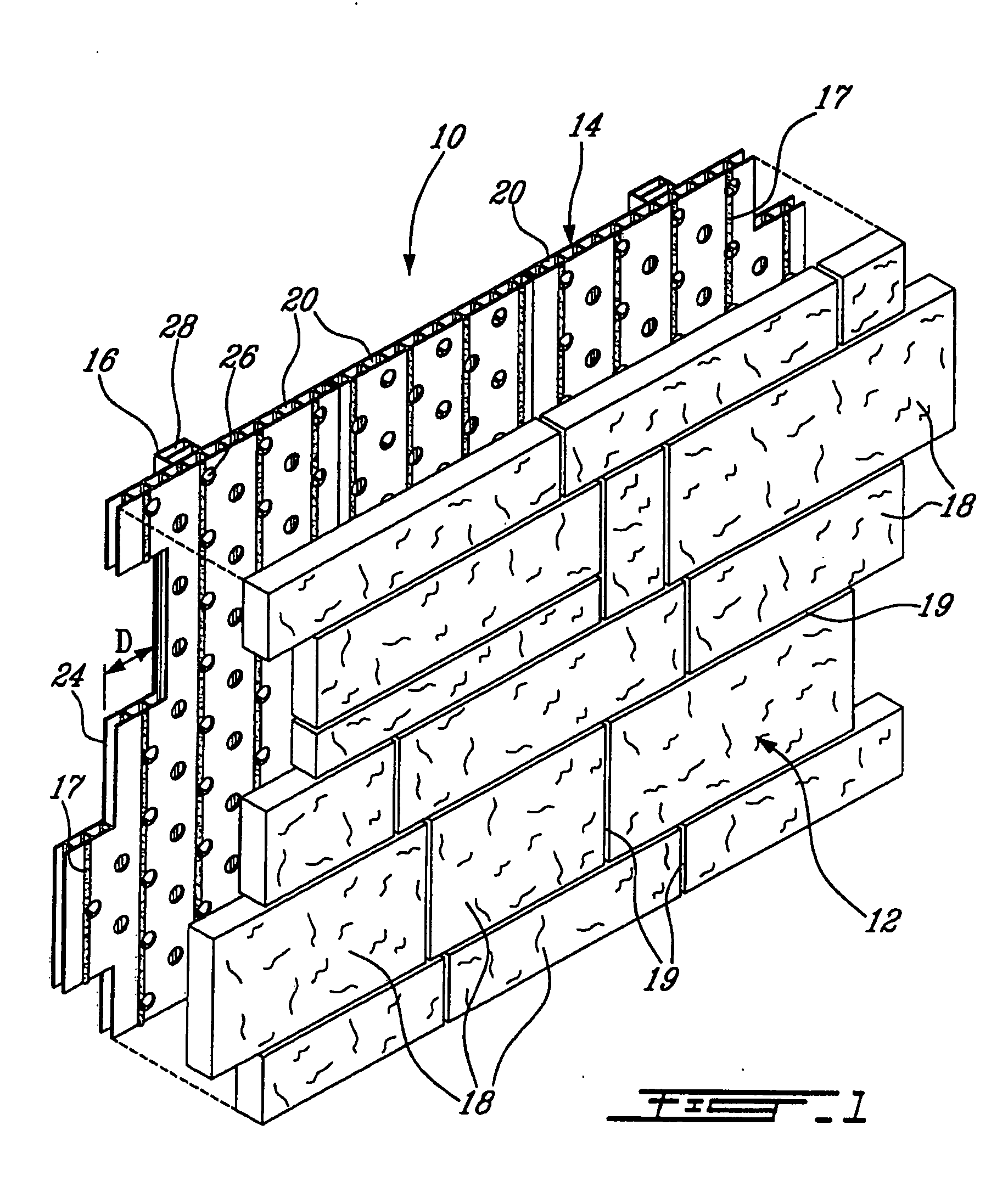

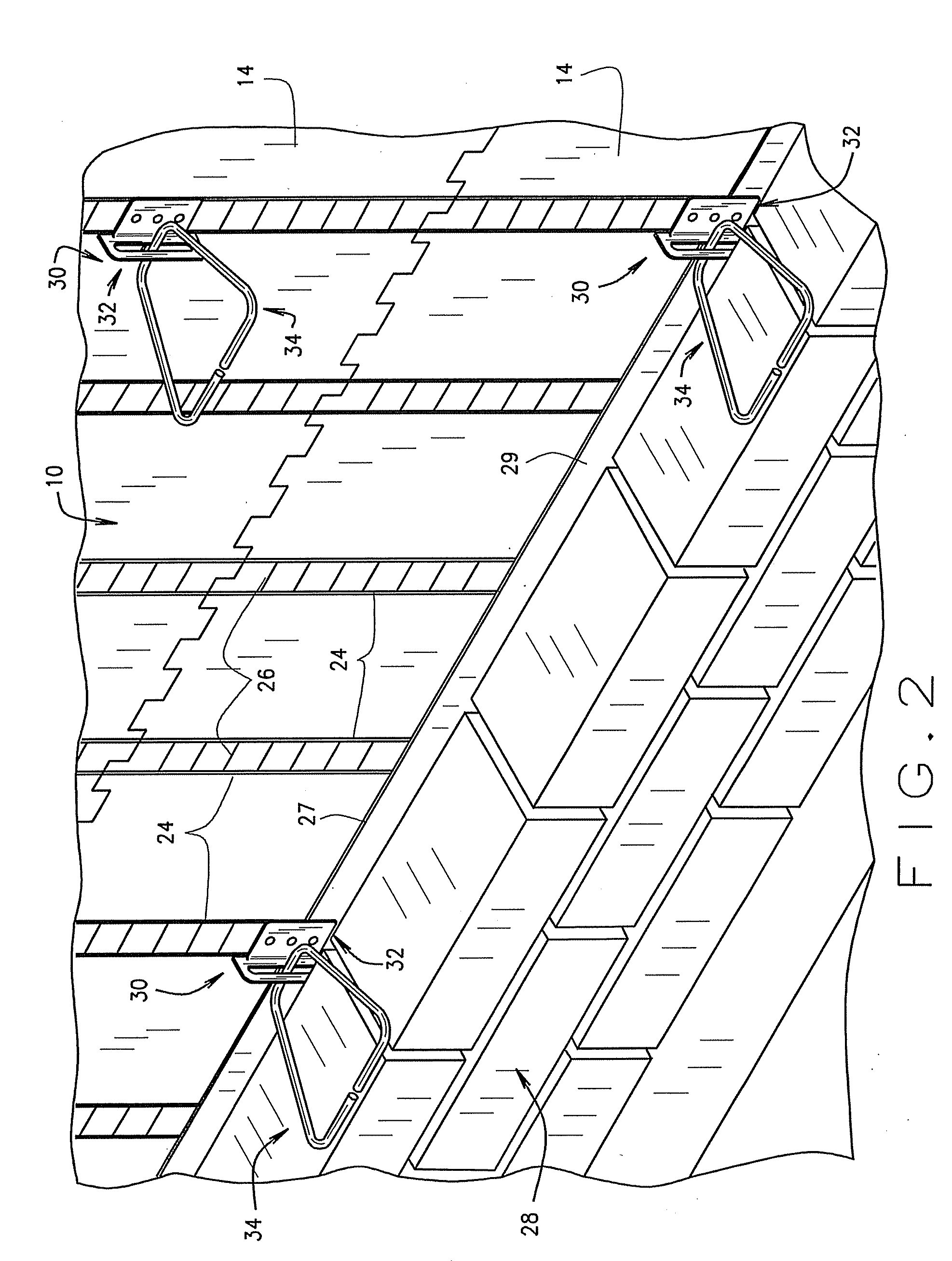

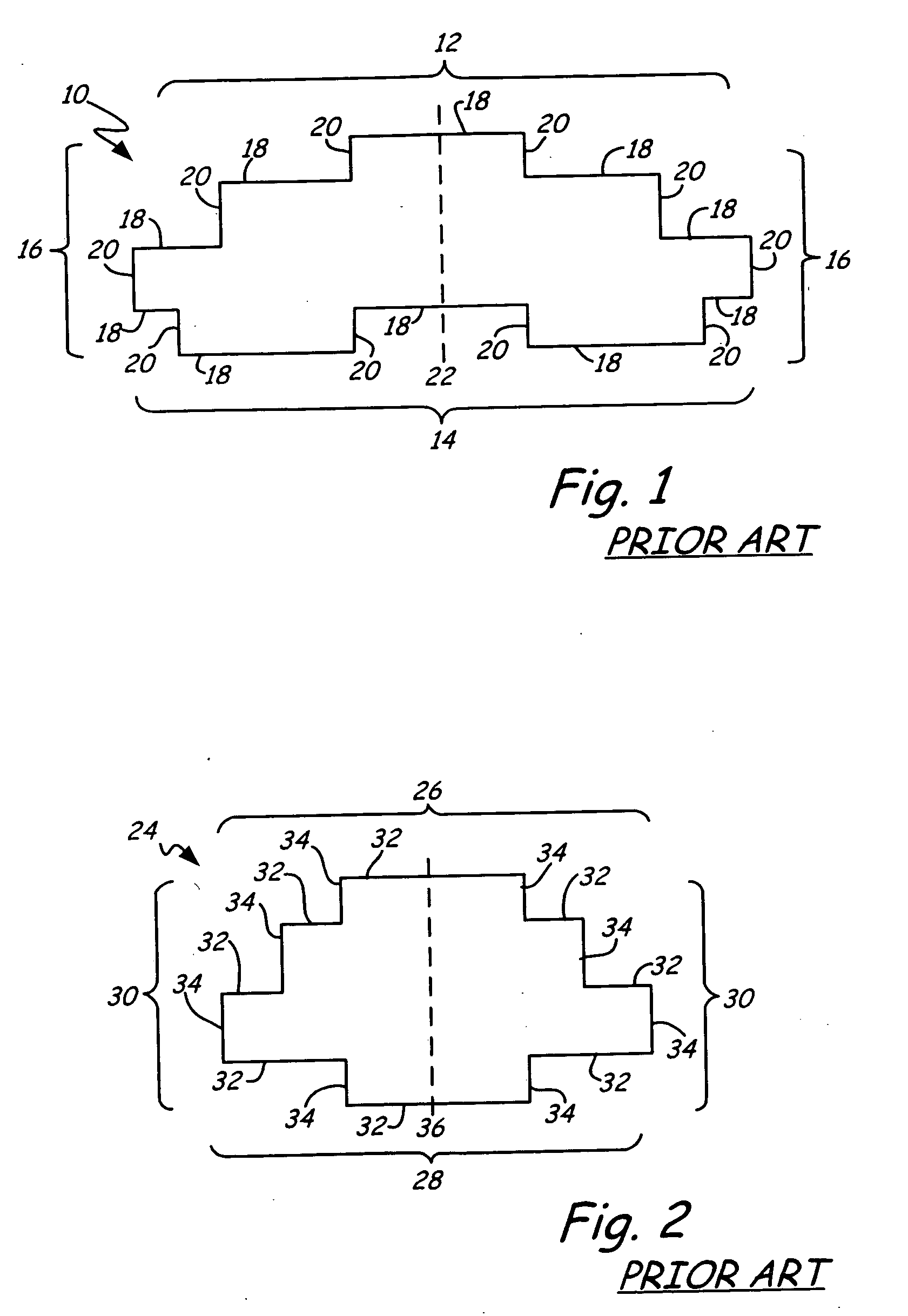

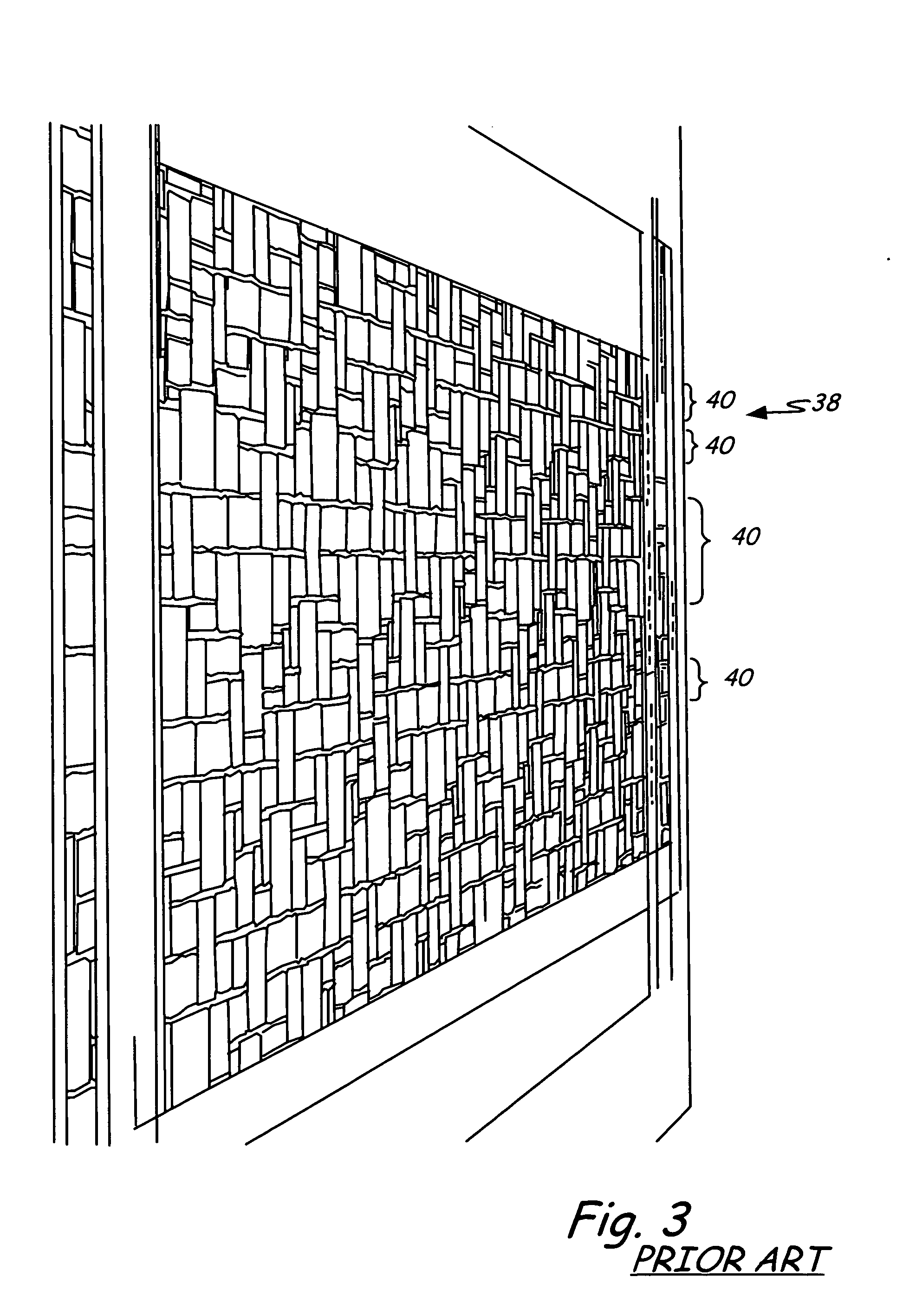

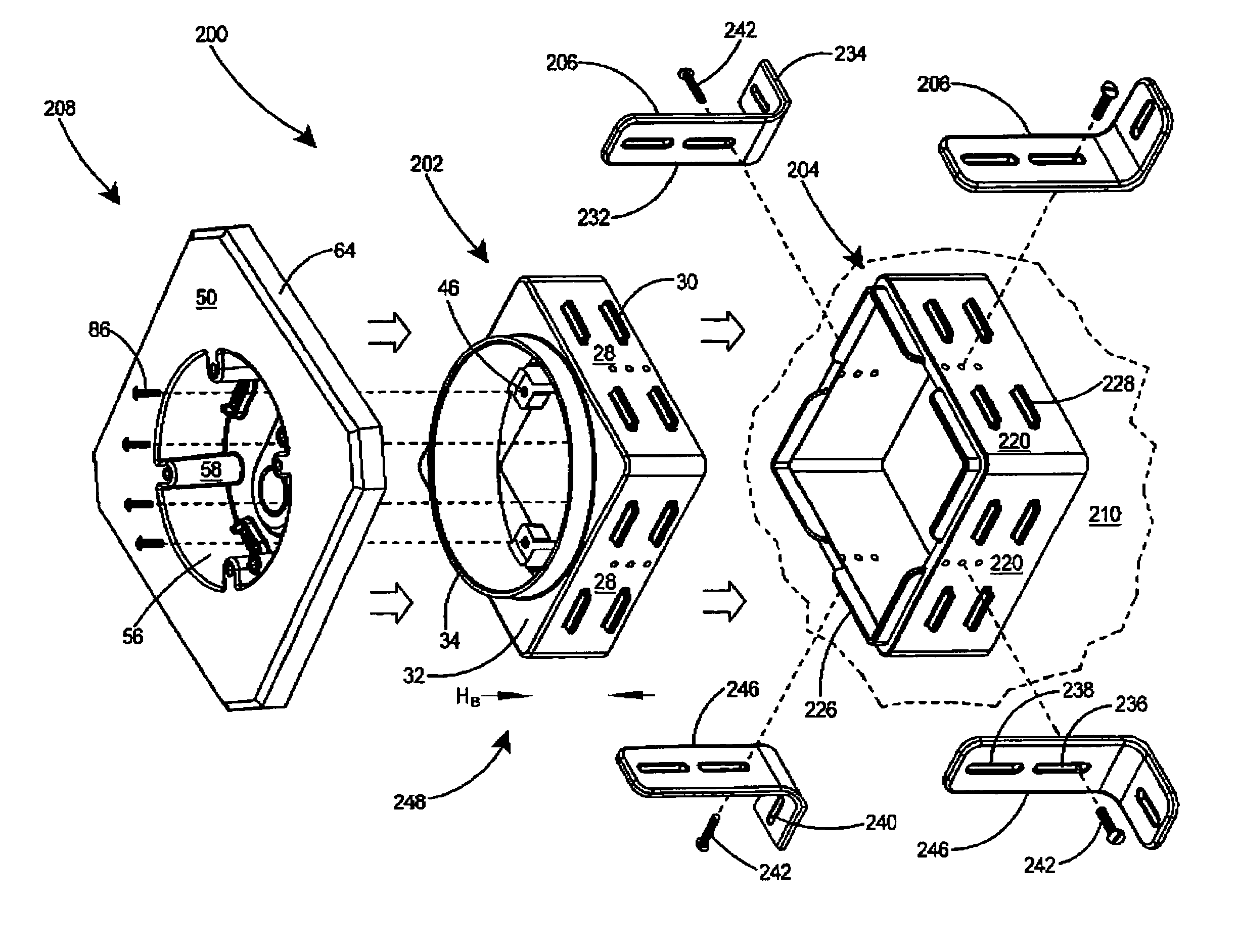

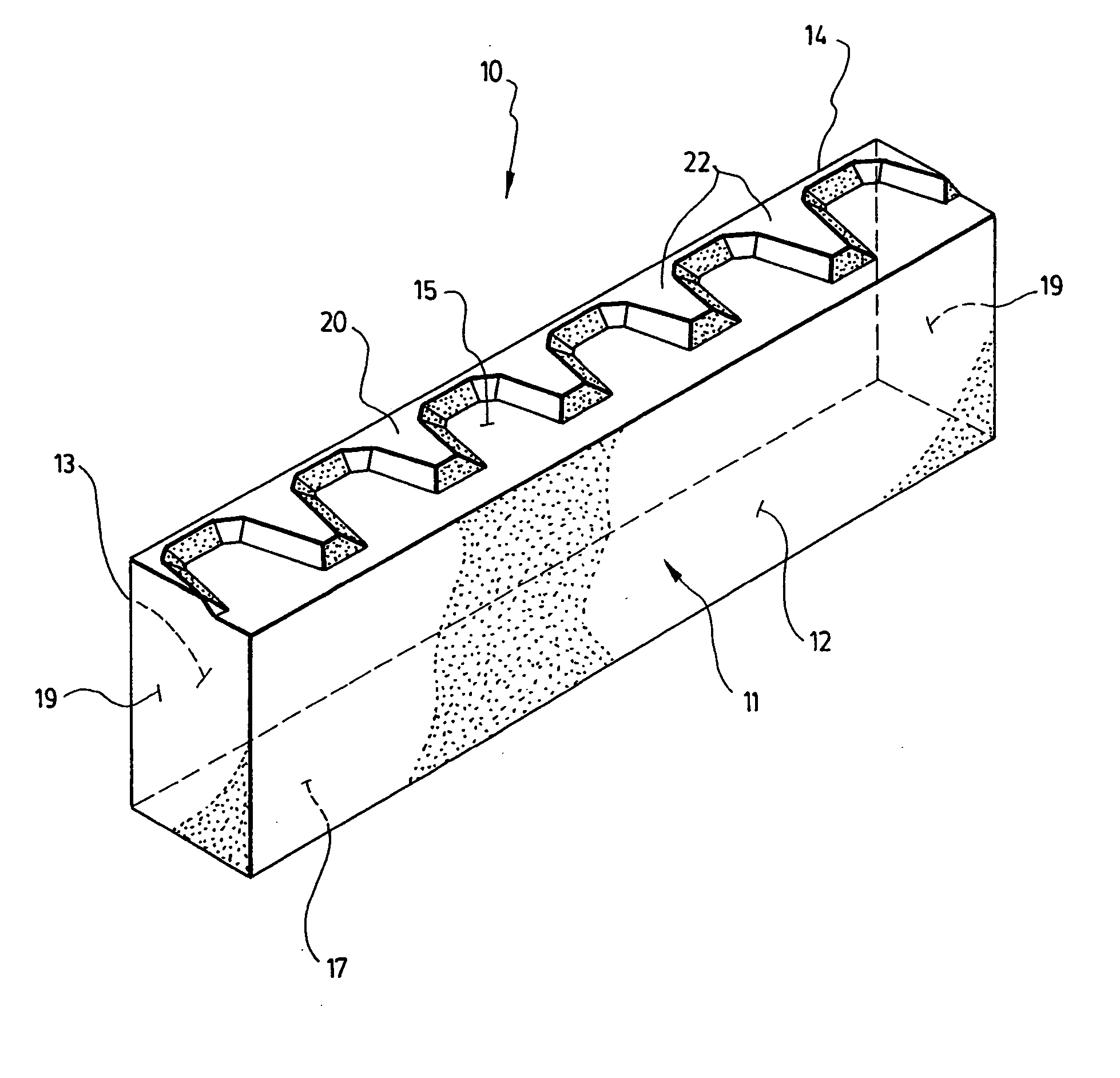

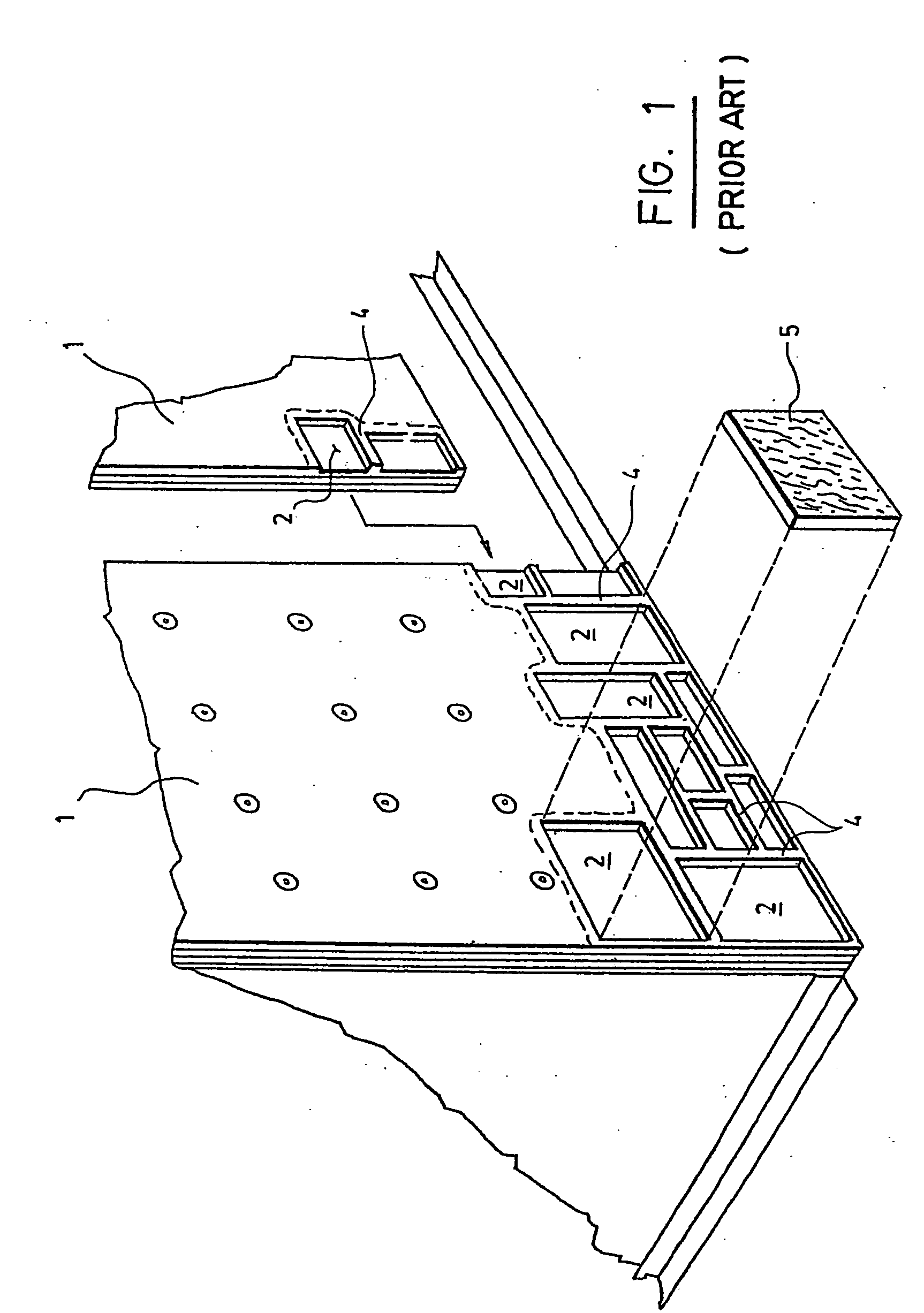

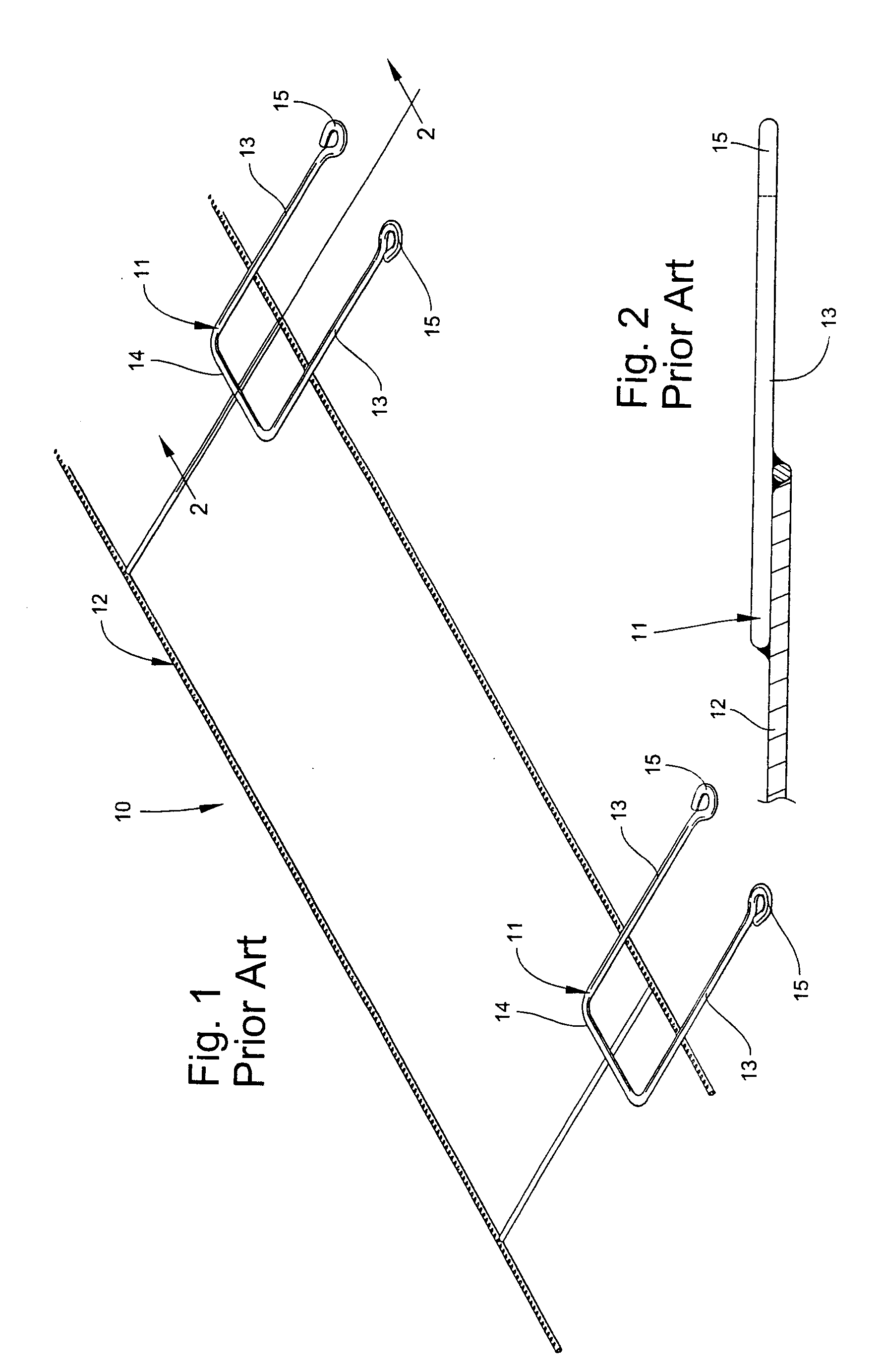

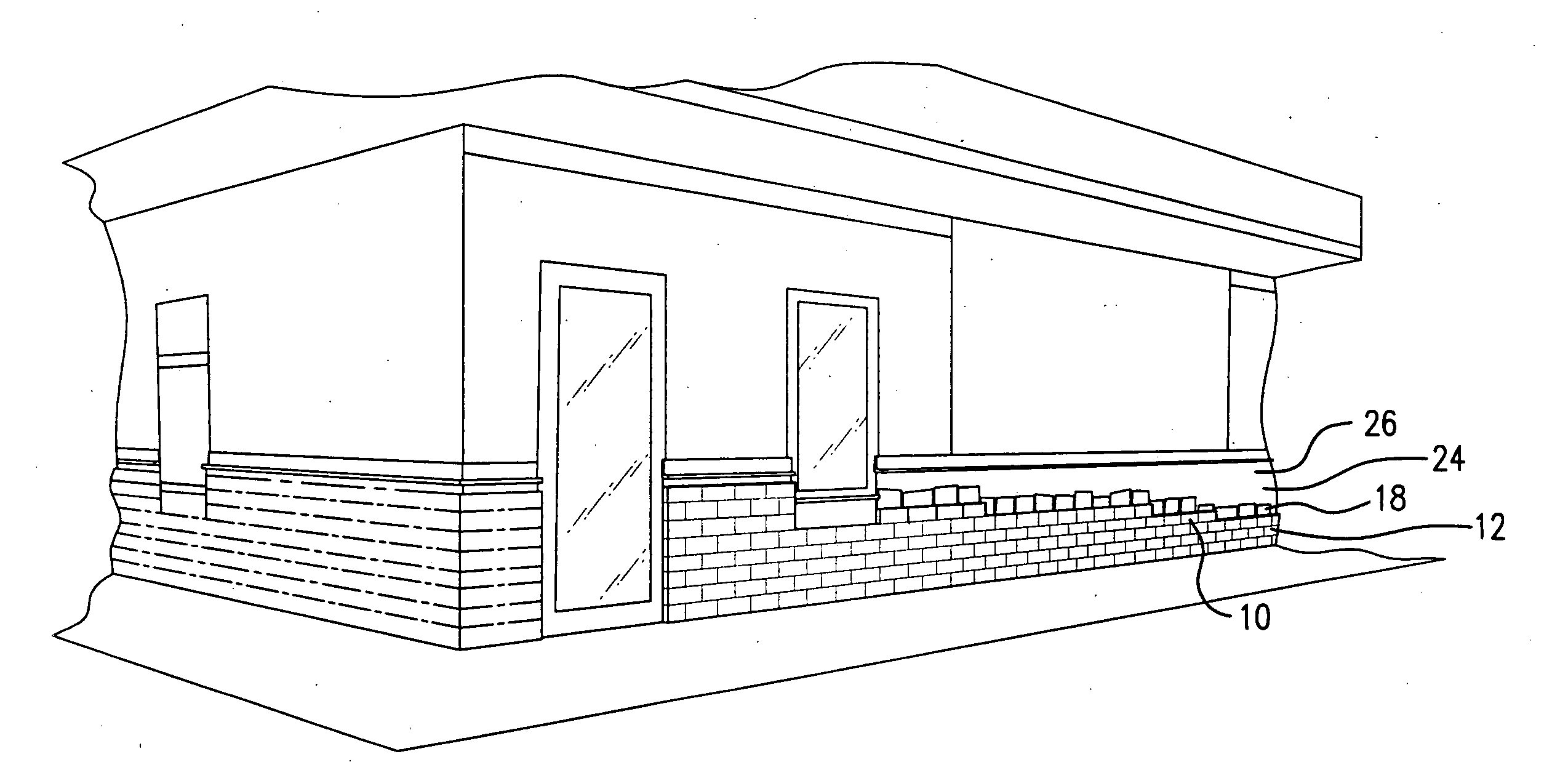

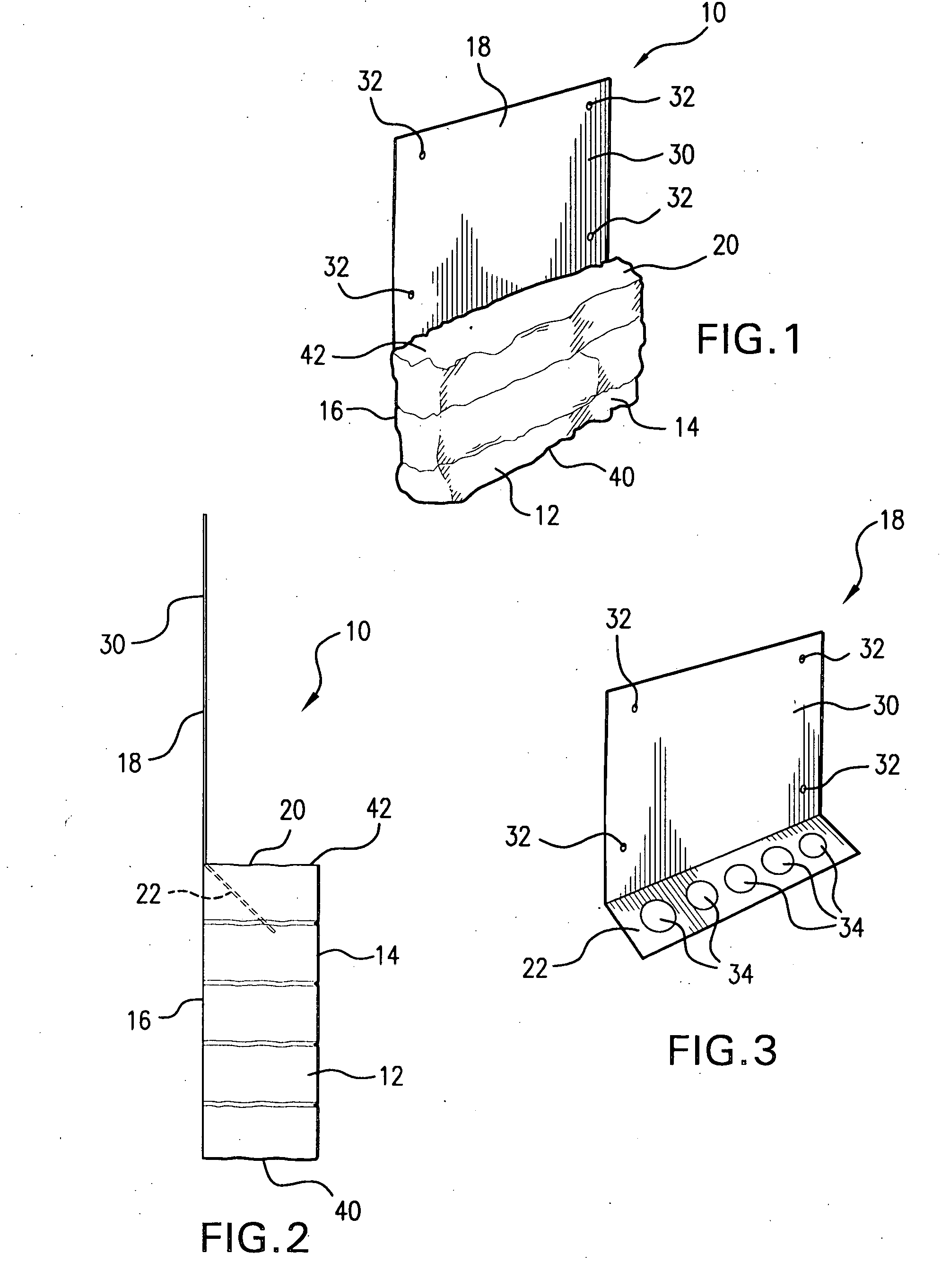

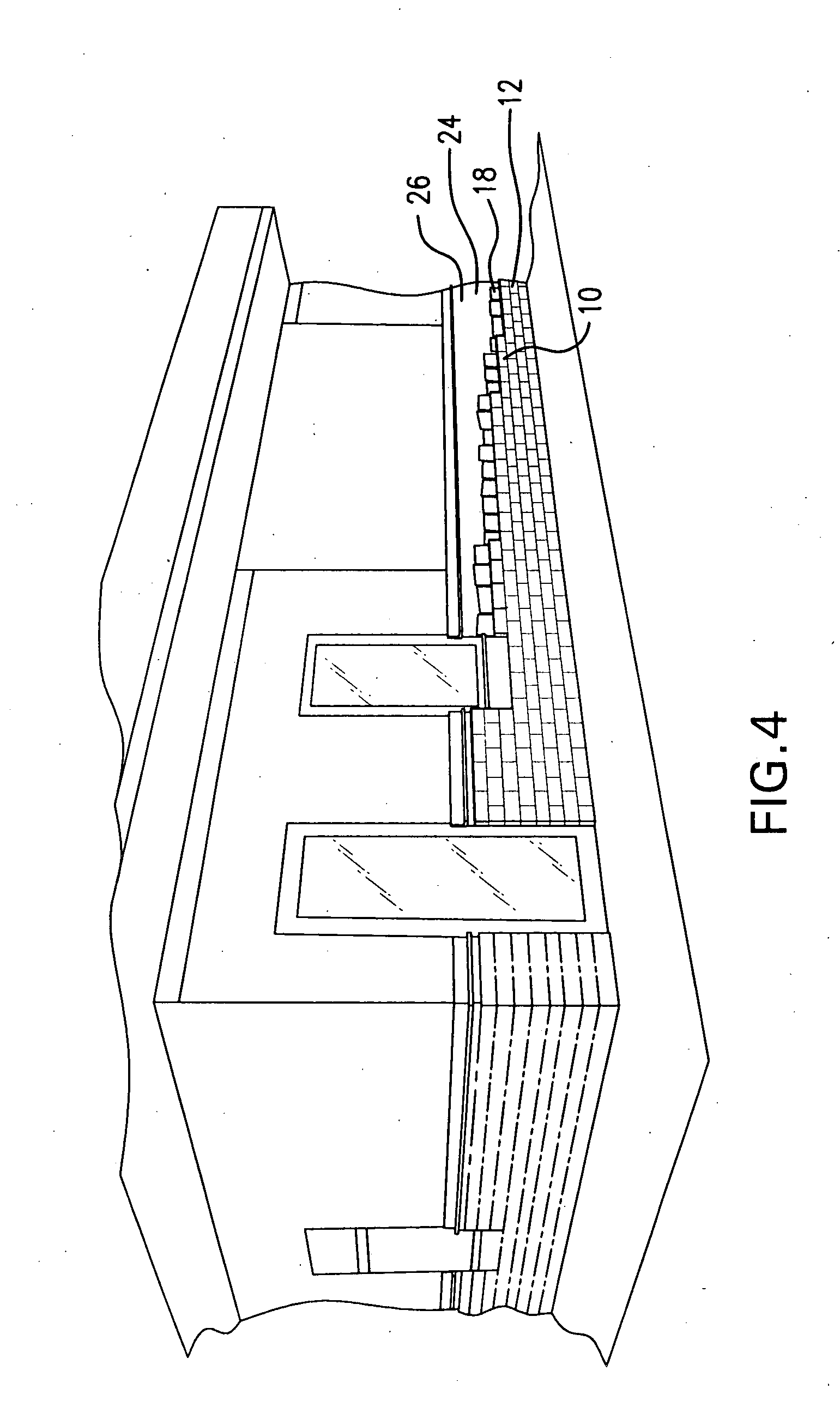

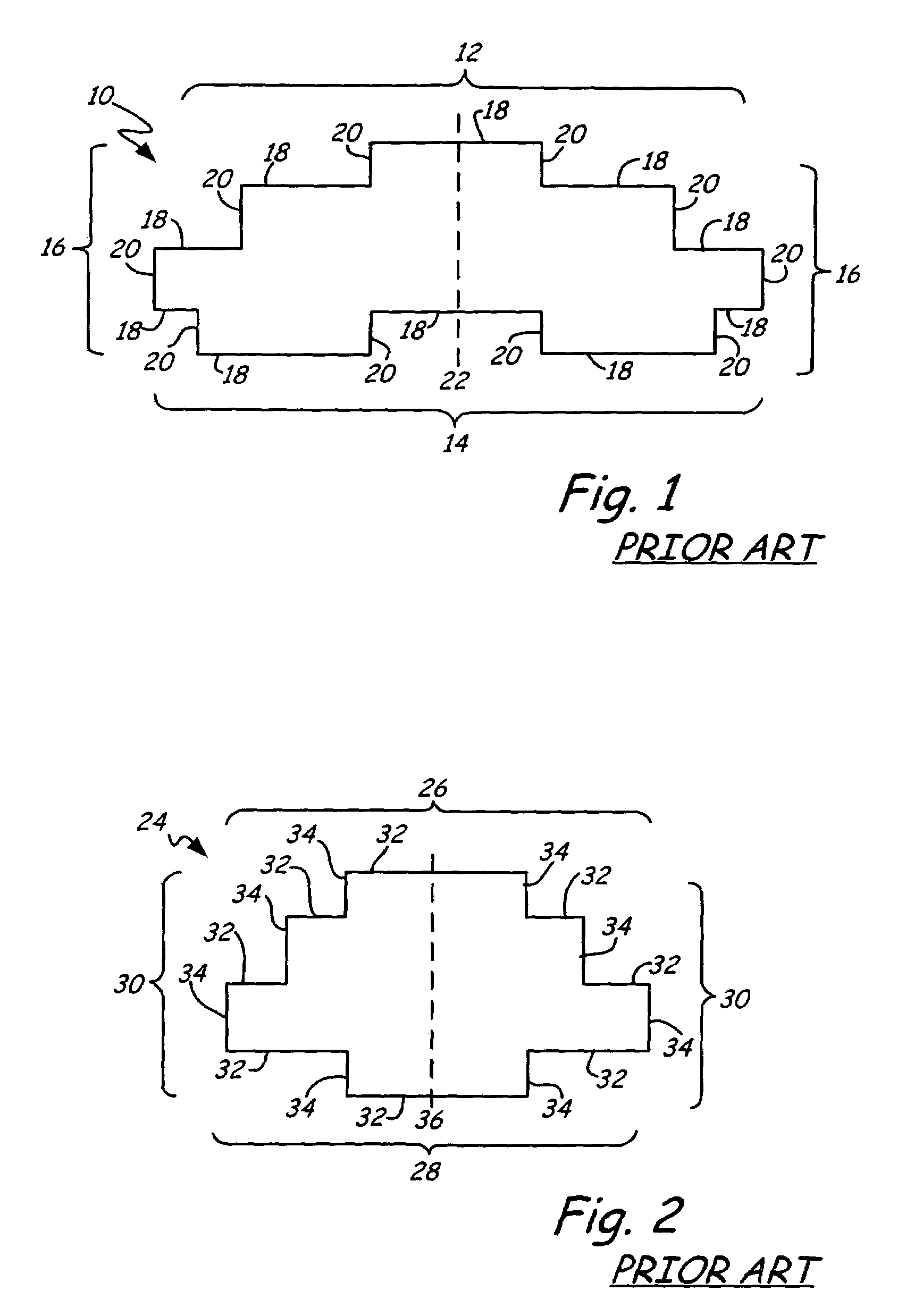

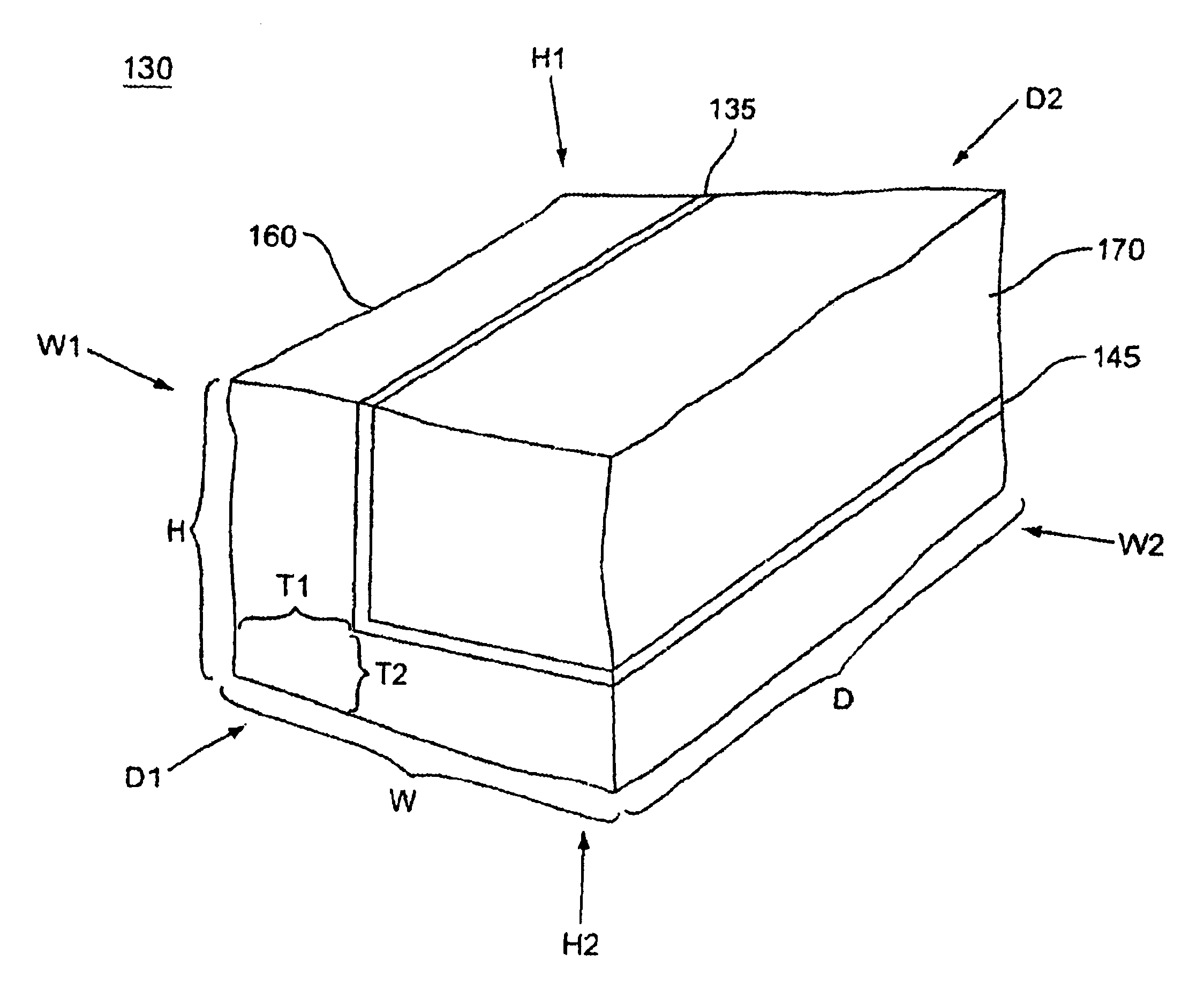

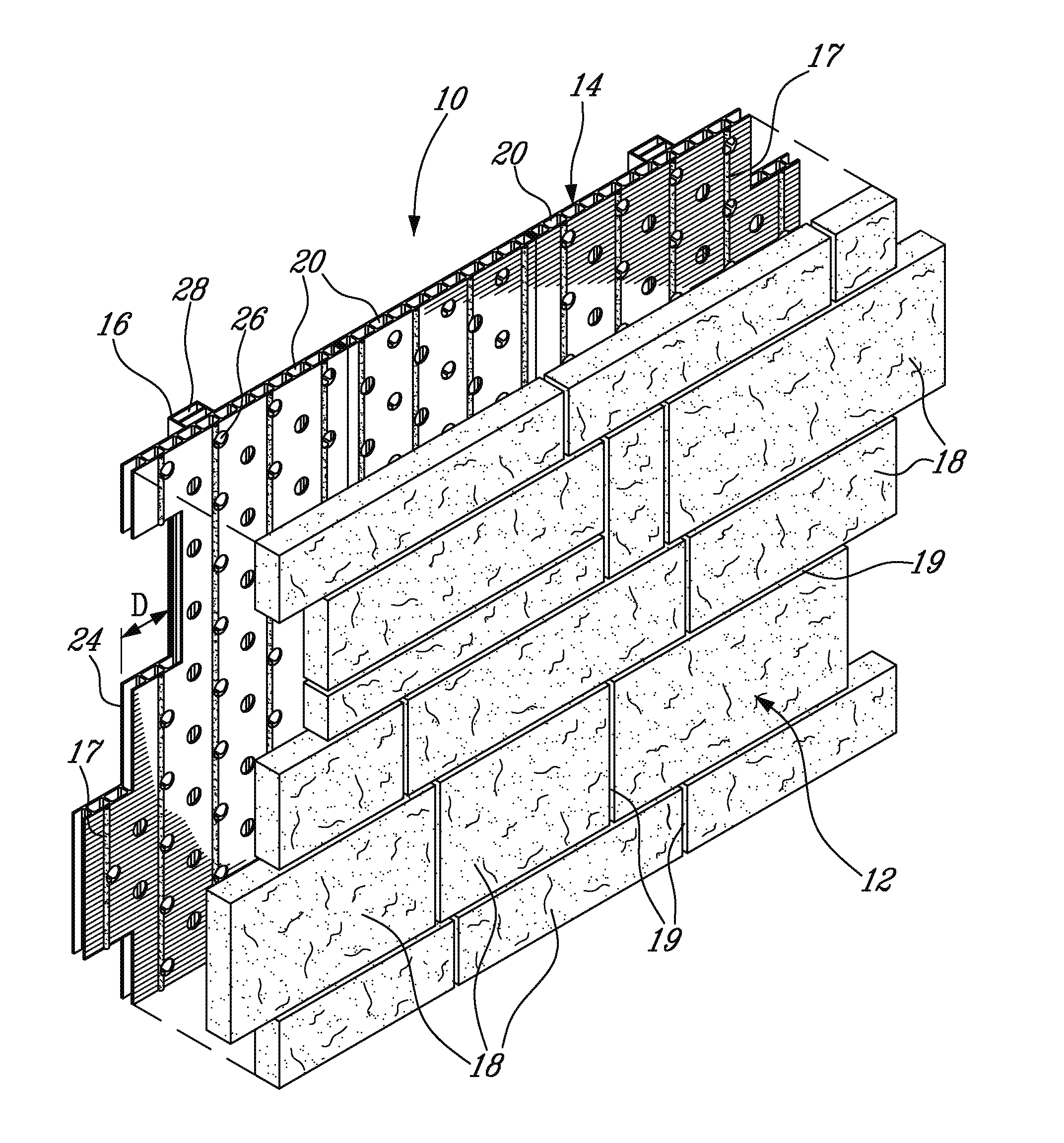

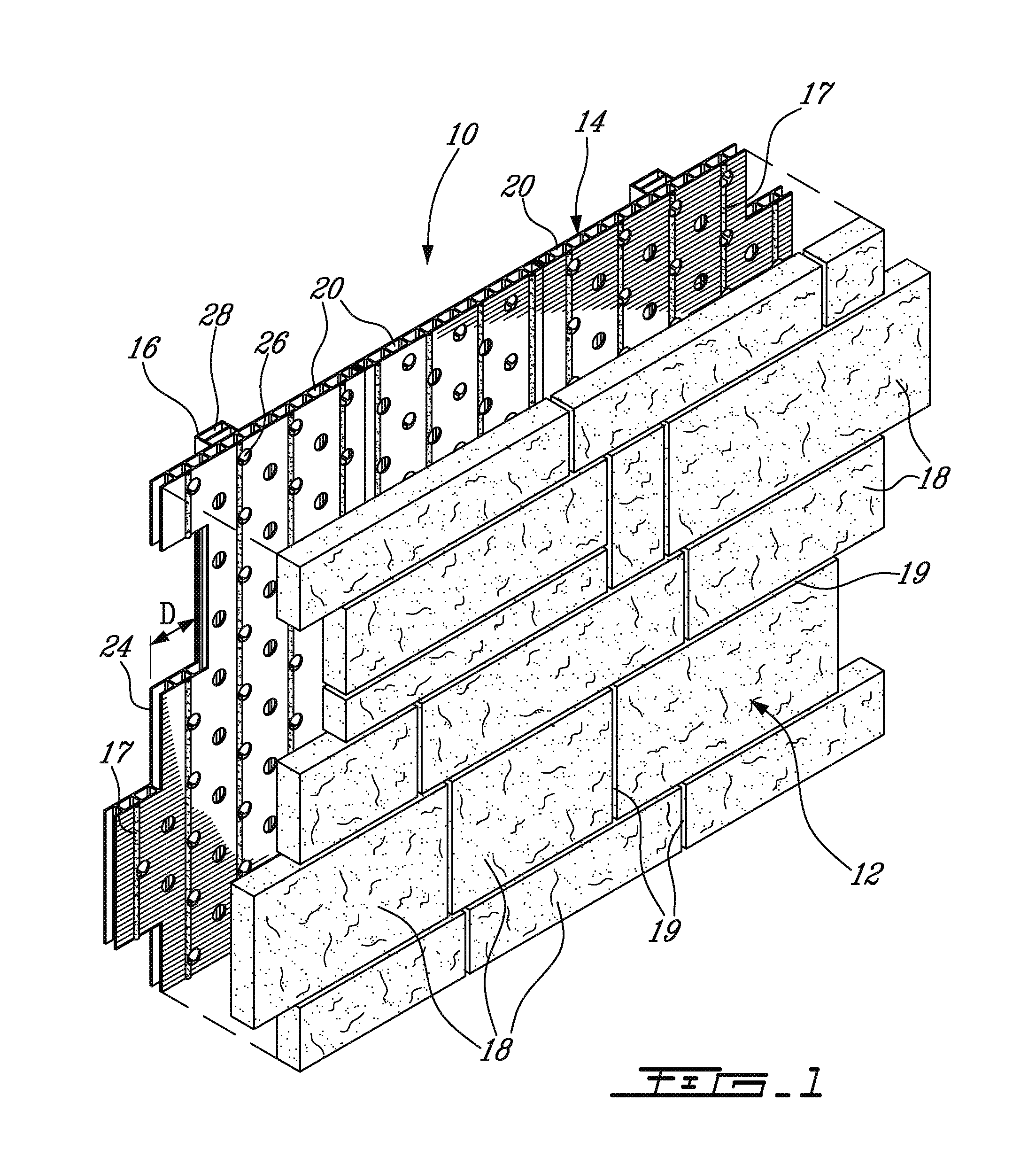

Artificial masonry unit, a masonry wall, a kit and a method for forming a masonry wall

InactiveUS20050028476A1Rapid and easy constructionConstruction materialCovering/liningsCompressible materialBrick

An artificial masonry unit suitable for use with a panel made of a compressible material having masonry unit receiving depressions in a front face thereof and protruding ribs defining and bordering the depressions. The depressions are sized to receive respective artificial masonry units in a close-fitting relationship. The artificial masonry unit comprises a body bounded by a front face, a back face, and a lateral face providing a thickness to the unit, and a back peripheral edge joining the back face and the lateral face. A tooth projection is projecting from the lateral face next to and parallel to the back peripheral edge for thrusting into the protruding rib when the masonry unit is inserted in a respective depression. Thanks to the tooth projection that is thrusting into the rib of a respective depression and that helps retaining the masonry unit within the depression prior to mortaring the wall, there is no need for using a mixture of cement to temporarily retain the masonry units within the depression. A method and a kit for making a masonry wall with the above described masonry unit is also disclosed.

Owner:LES MATERIAUX DE CONSTR OLDCASTLE CANADA

Artificial stone siding product

Owner:SILVERMINE STONE SIDING LLC

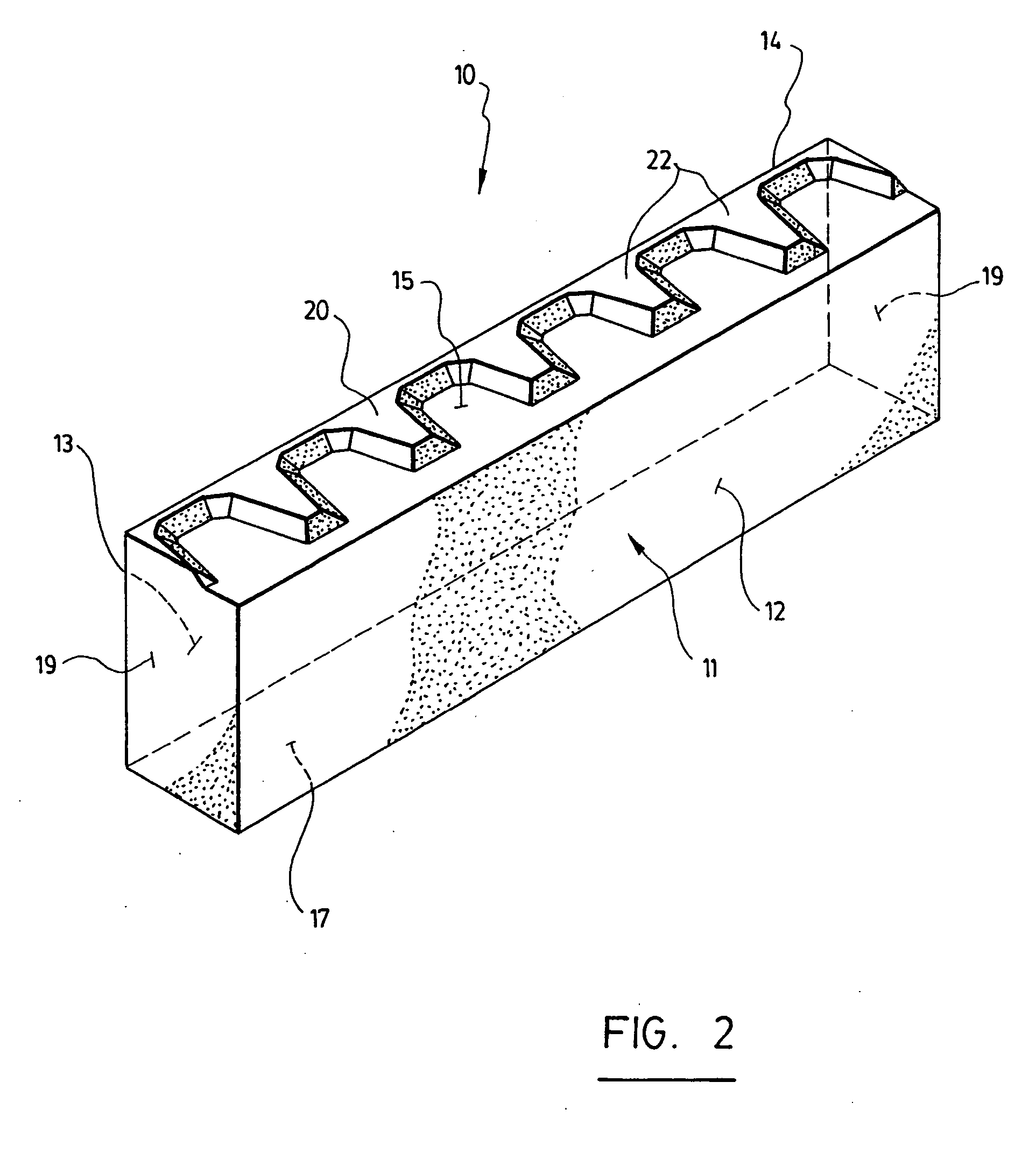

Structural lintel assembly and building construction method using the same

A prefabricated form assembly for making a concrete floor is disclosed. The form comprises an elongated form plate having a front for forming and retaining a flowable concrete material before it sets, anchor elements extending from the back face of the form plate, and being destined to be embedded into the concrete floor; and an L-shaped lintel having a back wall connected to the front face of the form plate and a bearing wall for supporting a masonry wall. Advantageously the construction of a concrete floor adapted to structurally retain a masonry wall using prefabricated form assemblies according to the invention no more requires the use of different groups of workers from different building trades as in the prior art, only one group of workers is required.

Owner:VIEIRA JOSE

Novel energy consumption damping stone blocking structure

InactiveCN101736707AReduce the amount of masonryIncreased resistance to overturning momentProtective constructionStone wallEngineering

The invention relates to a novel energy consumption damping stone blocking structure which belongs to structures for preventing and controlling stone rolling disasters. The structure comprises a stone blocking wall which is a flag concrete stone blocking wall; the top of the stone blocking wall is preembedded with a steel rail fence; a prestress anchor cable is arranged in the stone blocking wall, and the front slope surface of the stone blocking wall is sequentially provided with a foam plastic layer and a gravel filling layer which are arranged for playing the buffering function. The invention has the characteristics of light weight, economy, safety and simple construction.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

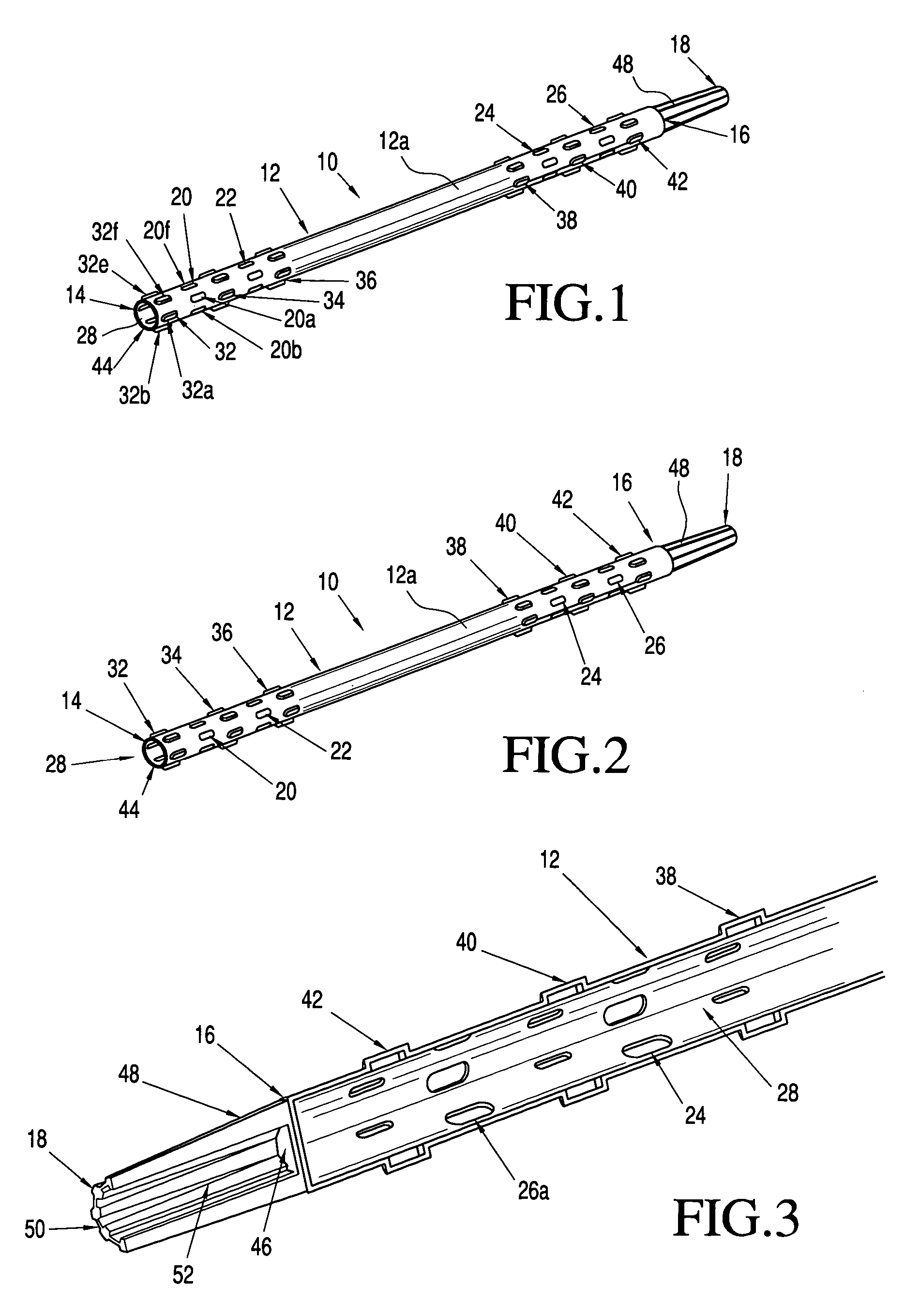

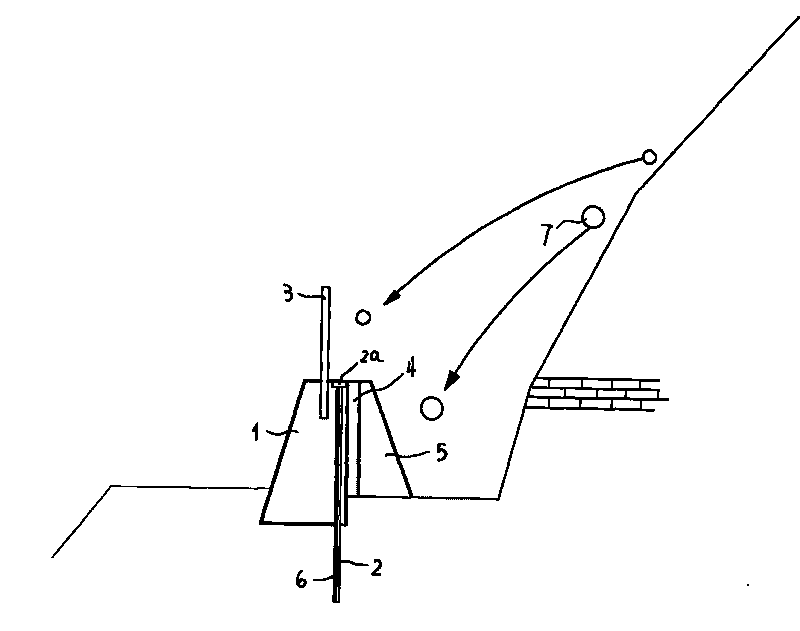

Masonry anchoring system

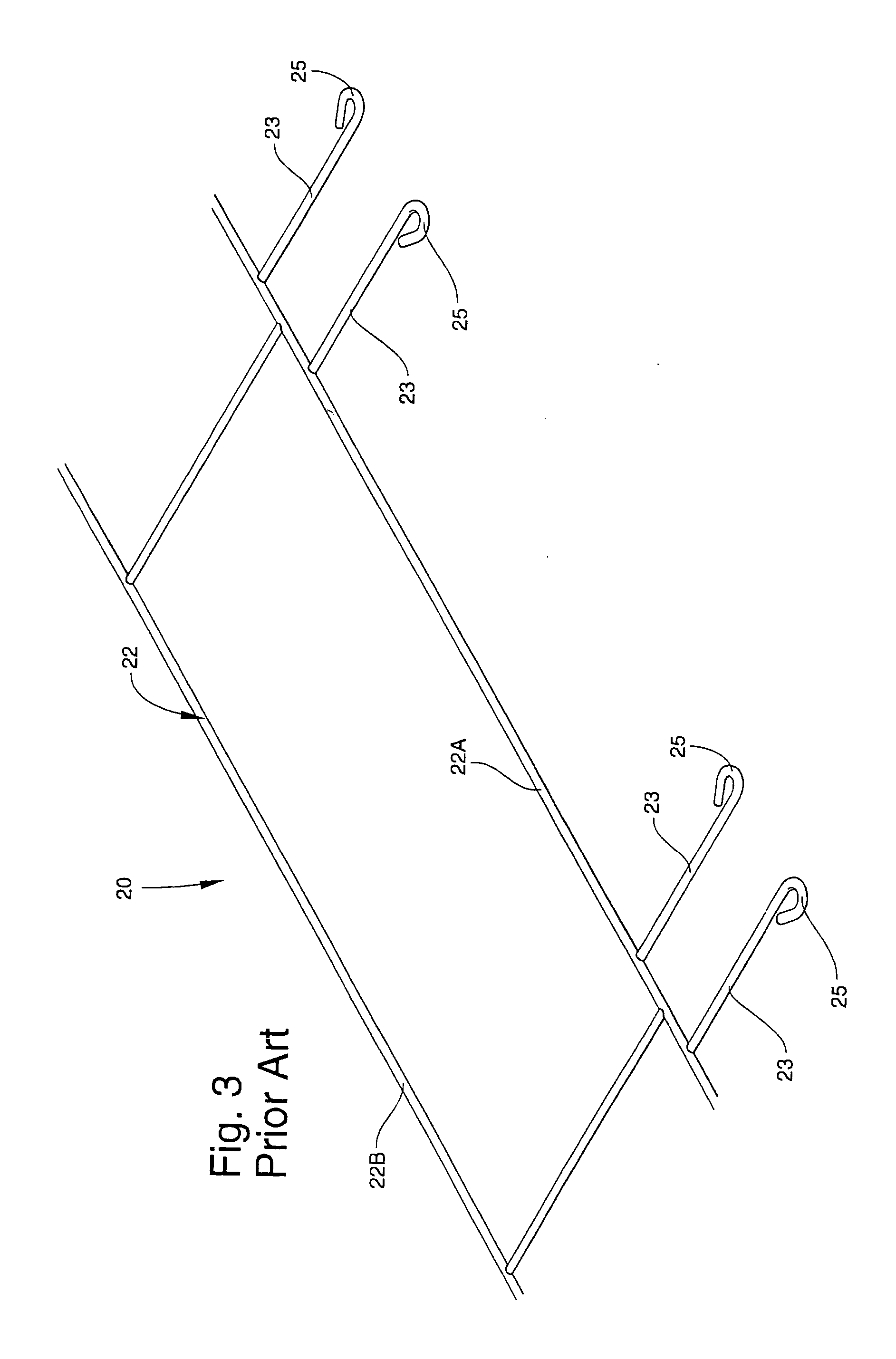

A masonry anchor system is disclosed for anchoring two spaced apart masonry walls together to form a single wall structure. The masonry anchor system includes a ladder or truss type support frame for positioning on top of a mortar joint in one wall, and a connecting bracket having a pair of elongate arms connected by a cross-member affixed to the support frame. The cross-member is curved to provide two spaced apart points on the cross-member for contacting the support frame and affixing the cross-member thereto. The elongate arms extend transversely from the support frame and are sized to extend into the space between the two walls. Each of the arms have an eye portion formed at the end opposite the cross-member to receive a connecting member connected to the second wall. The support frame and the bracket reside in the same horizontal plane.

Owner:MASONRY REINFORCING OF AMERICA

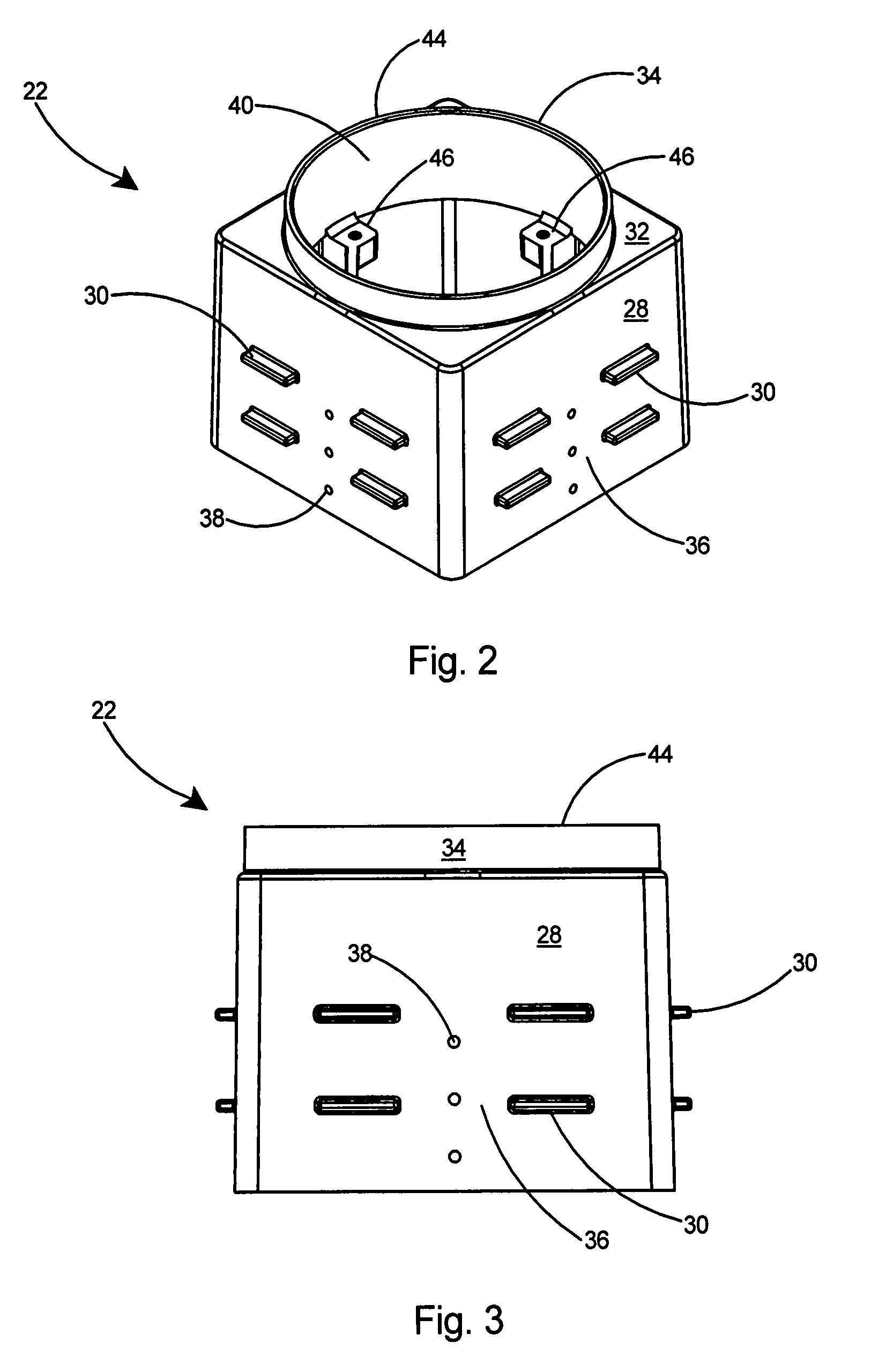

Adjustable electrical box and flange member for installation on a brick or stone wall

An adjustable electrical box assembly for providing electrical service on a brick or stone wall. The assembly includes a flange member, box member, and a faceplate. The flange member includes a flange and a forward extending collar. The electrical box includes sidewalls that are telescopically received in the collar of the flange member and a fastening arrangement for securing the electrical box to the flange member. After installing an electrical fixture within the electrical box, a faceplate is secured to the front of the box member.

Owner:ARLINGTON INDS

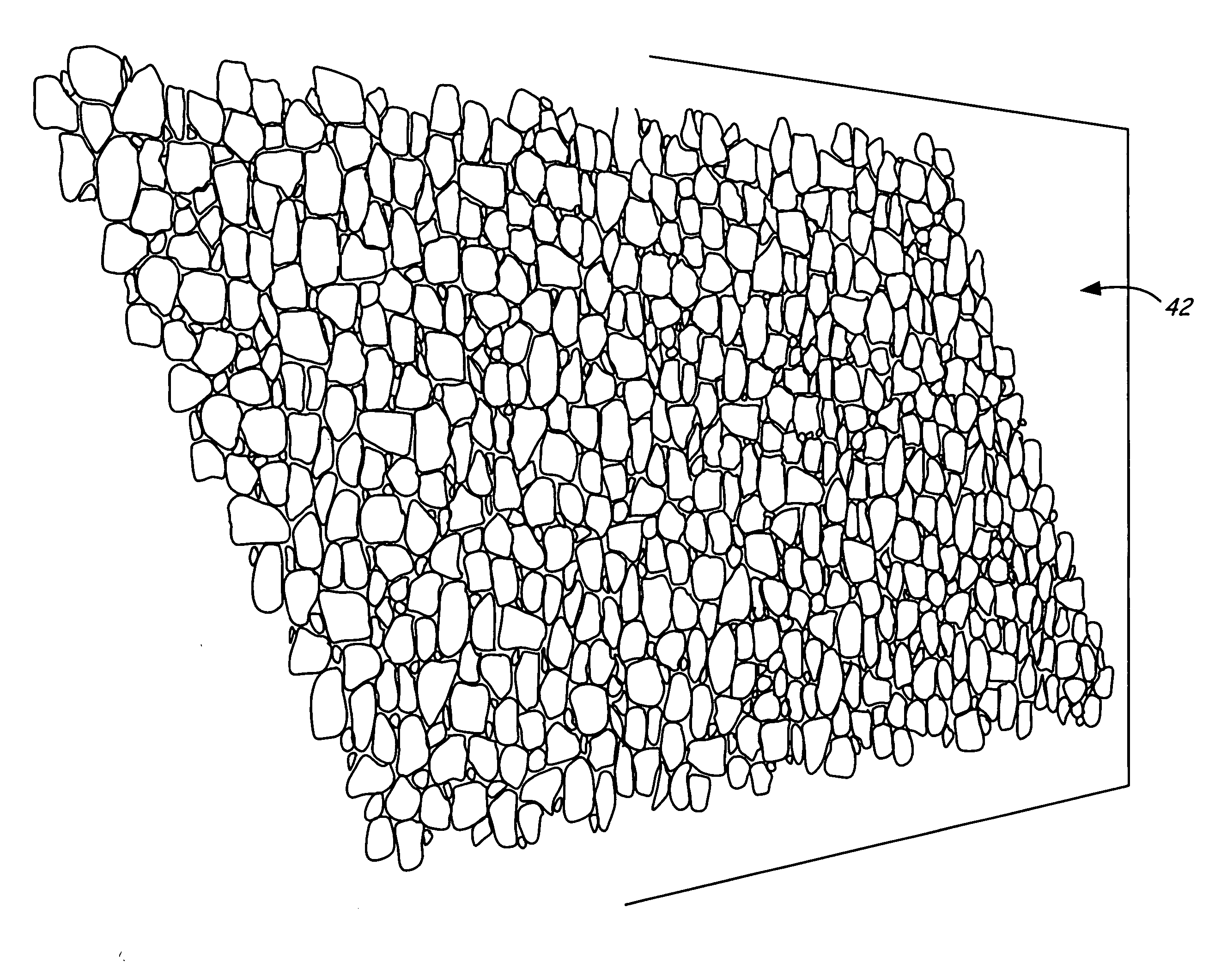

Artificial stone siding product

ActiveUS20090113837A1Roof covering using tiles/slatesConstruction materialStone wallArtificial stone

An artificial stone siding product for use as siding for homes, commercial buildings, and other structures, as well as for hearths, mantles, and other similar indoor structures, is provided. The artificial stone siding product includes a stone body cast of a cement aggregate and having an outer visible surface area shaped and colored to resemble real stone. An integral mounting support extends from at least one edge of the stone body. The mounting support allows the attachment of the artificial stone siding product to a surface of a wall using fasteners inserted through apertures defined by the support. The artificial stone siding product may be used to quickly and easily construct a stone wall by mounting a plurality of the artificial stone siding products to the exterior of a wall in much the same way as standard siding.

Owner:SILVERMINE STONE SIDING LLC

Form liner with connection regions having a plurality of linear segments for creating a realistic stone wall pattern

Owner:NASVIK PAUL C

Weep venting system for masonry walls

A system for venting moisture from wall and building structures, especially masonry walls constructed from masonry elements such as of brick, block, stone, faux stone or the like, without weakening the wall or building structure, utilizes open matrix weep vent members that are fabricated, for example from a mass of intertwined and intertangled polymeric filaments that are bonded at a plurality of intersections thereby to form one-piece or unit-handled weep vent members that preferably are inserted in place of mortar at spaced locations along horizontally extending mortar joints between rows of bricks, blocks or other masonry wall elements. Weep vent members that embody the present invention have wider portions at their rearward or intake end regions, and narrower portions at their forward or discharge end regions, with a preferred form characterized by a generally trapezoidal shape that helps to retain the weep vent members in their associated mortar joints, and that provide a funnel-like ducting of moisture from their relatively wider rear end regions toward their relatively narrower forward end regions.

Owner:KEENE BUILDING PRODS

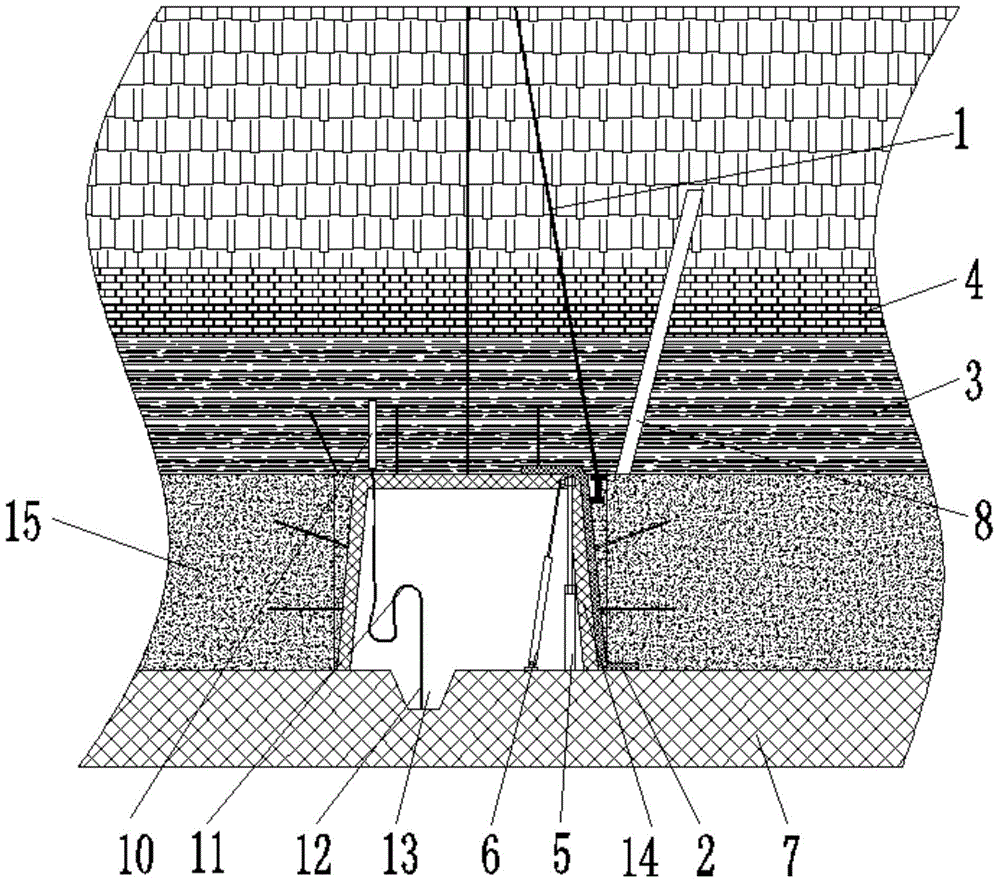

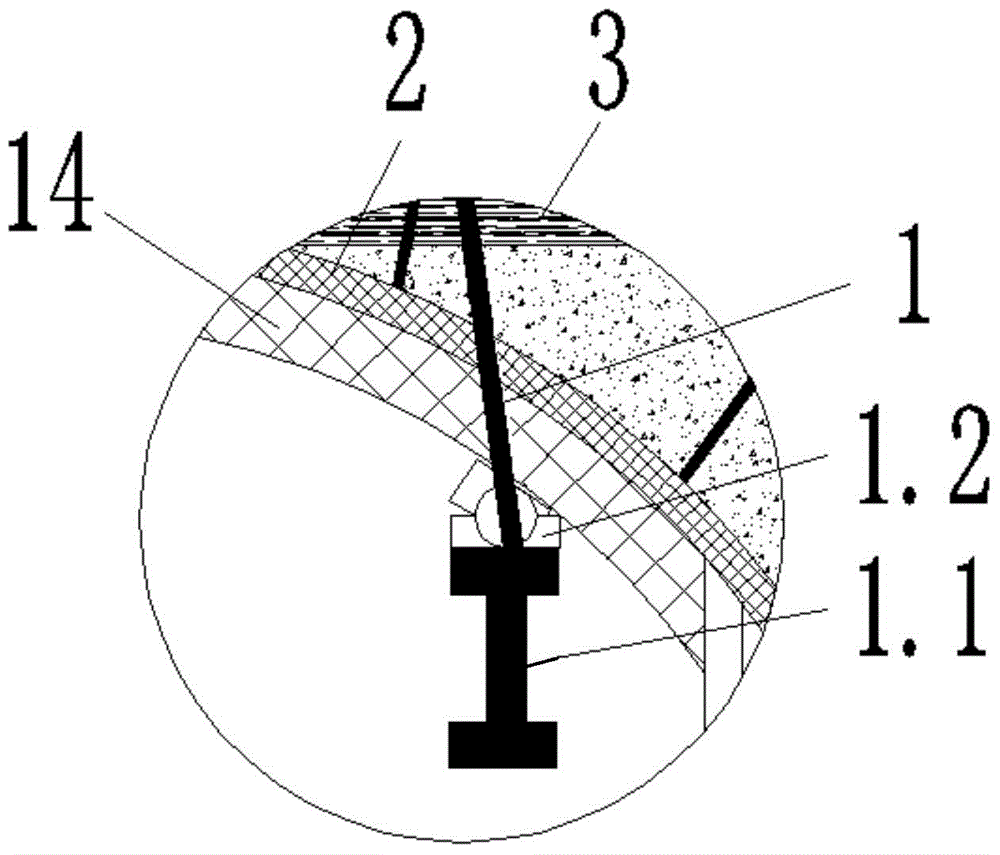

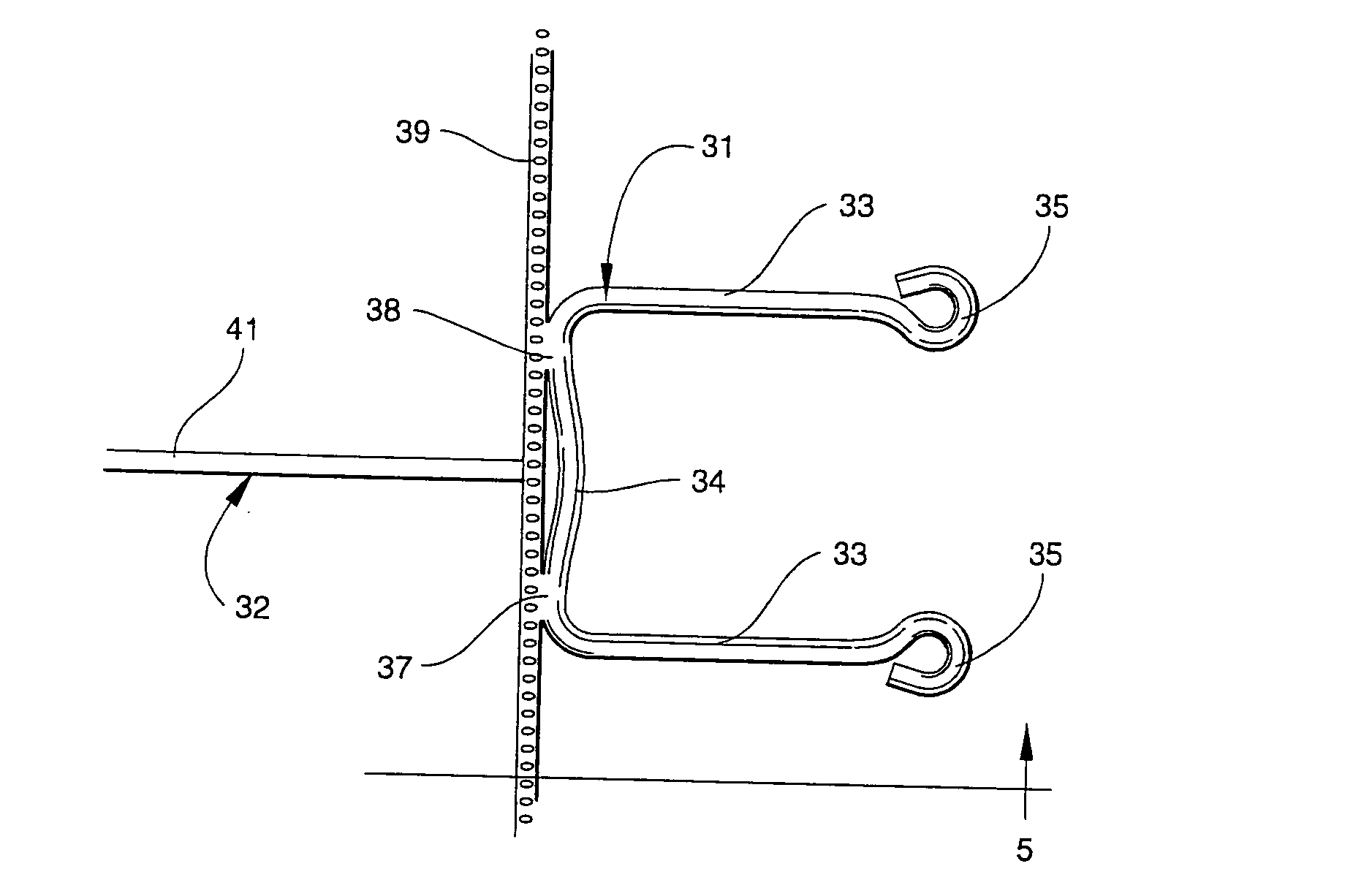

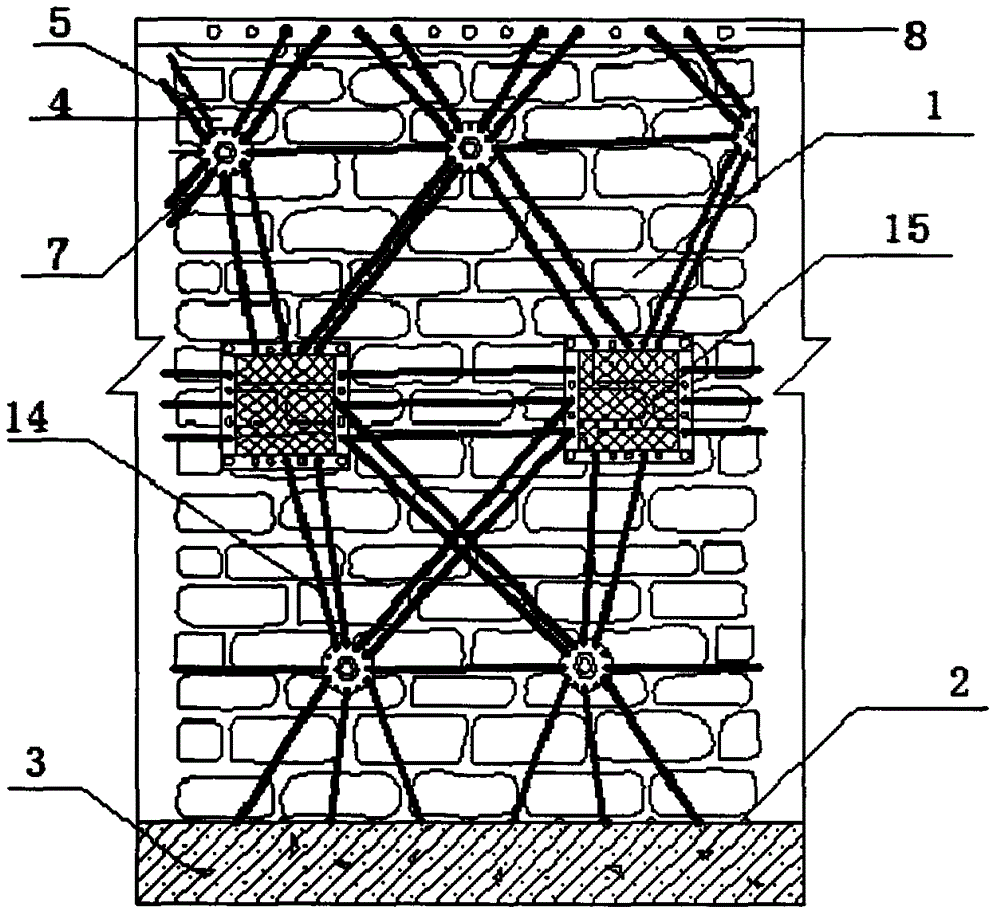

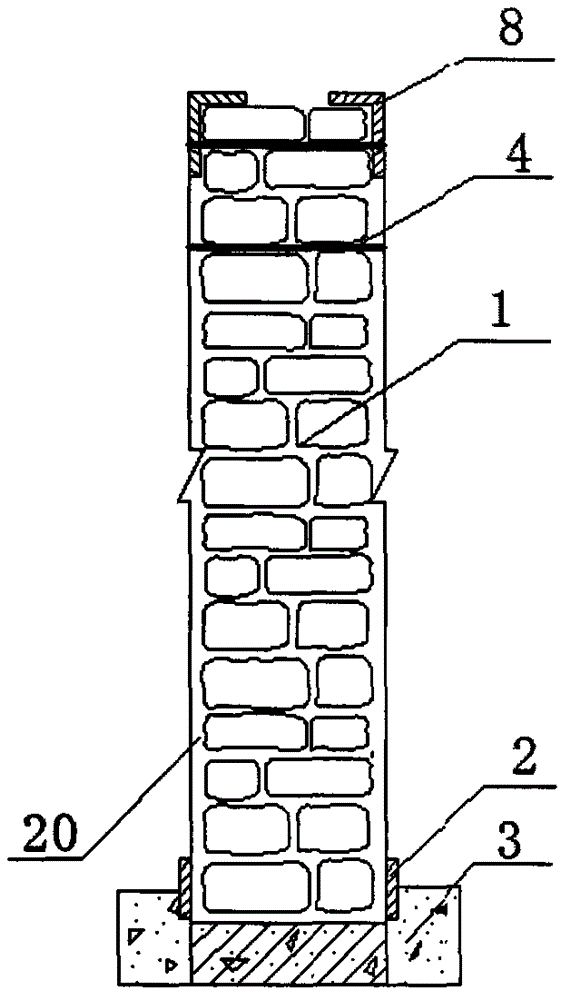

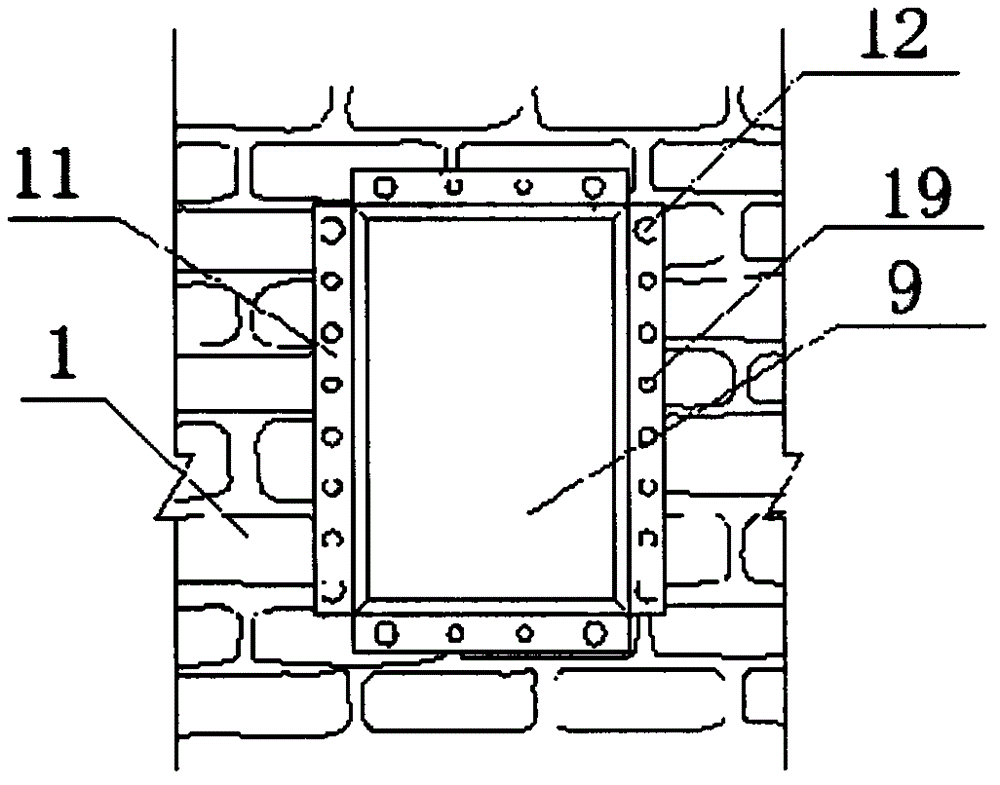

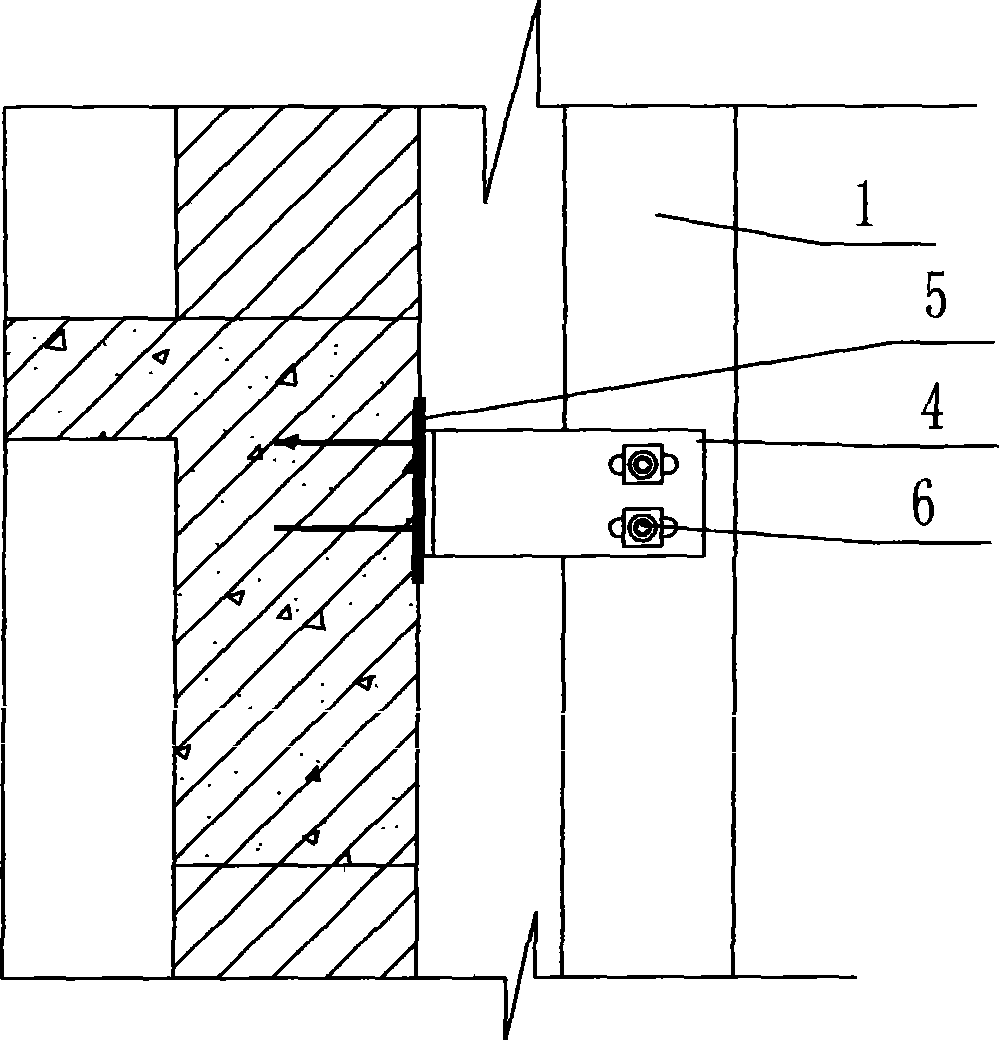

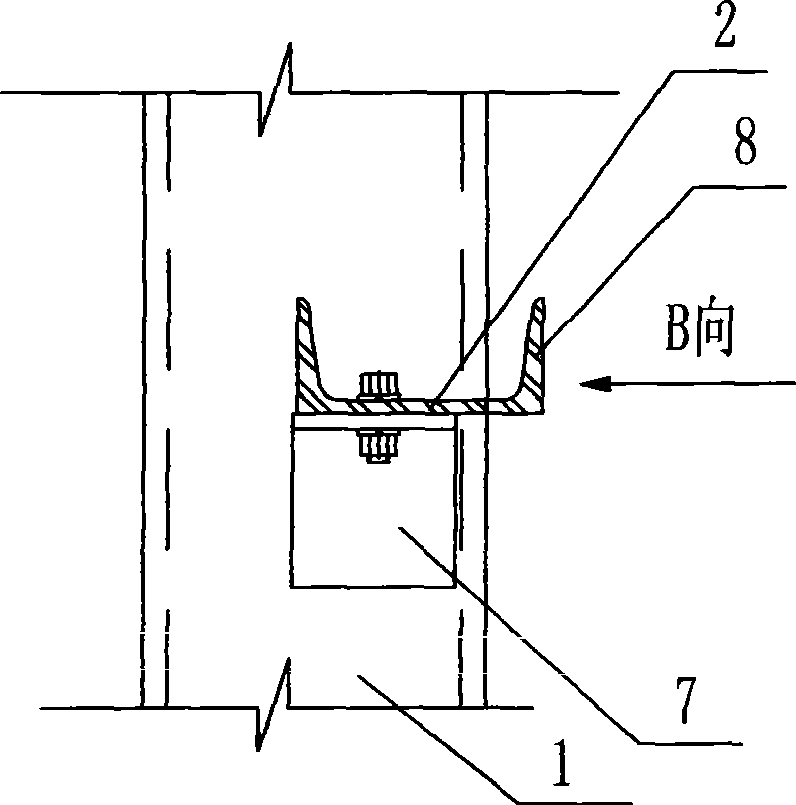

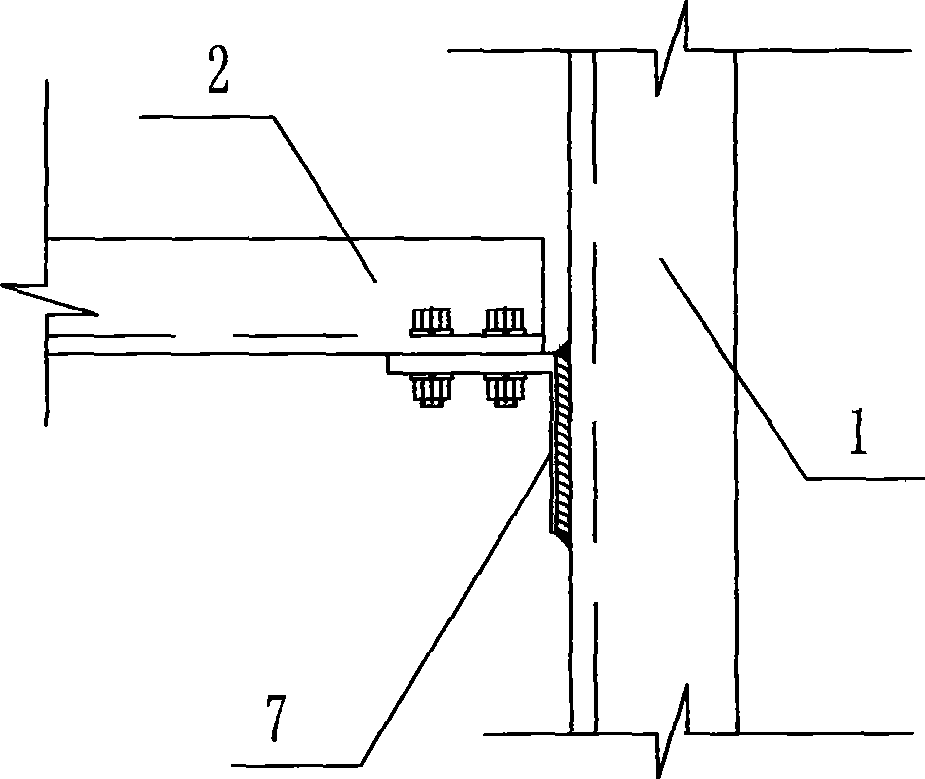

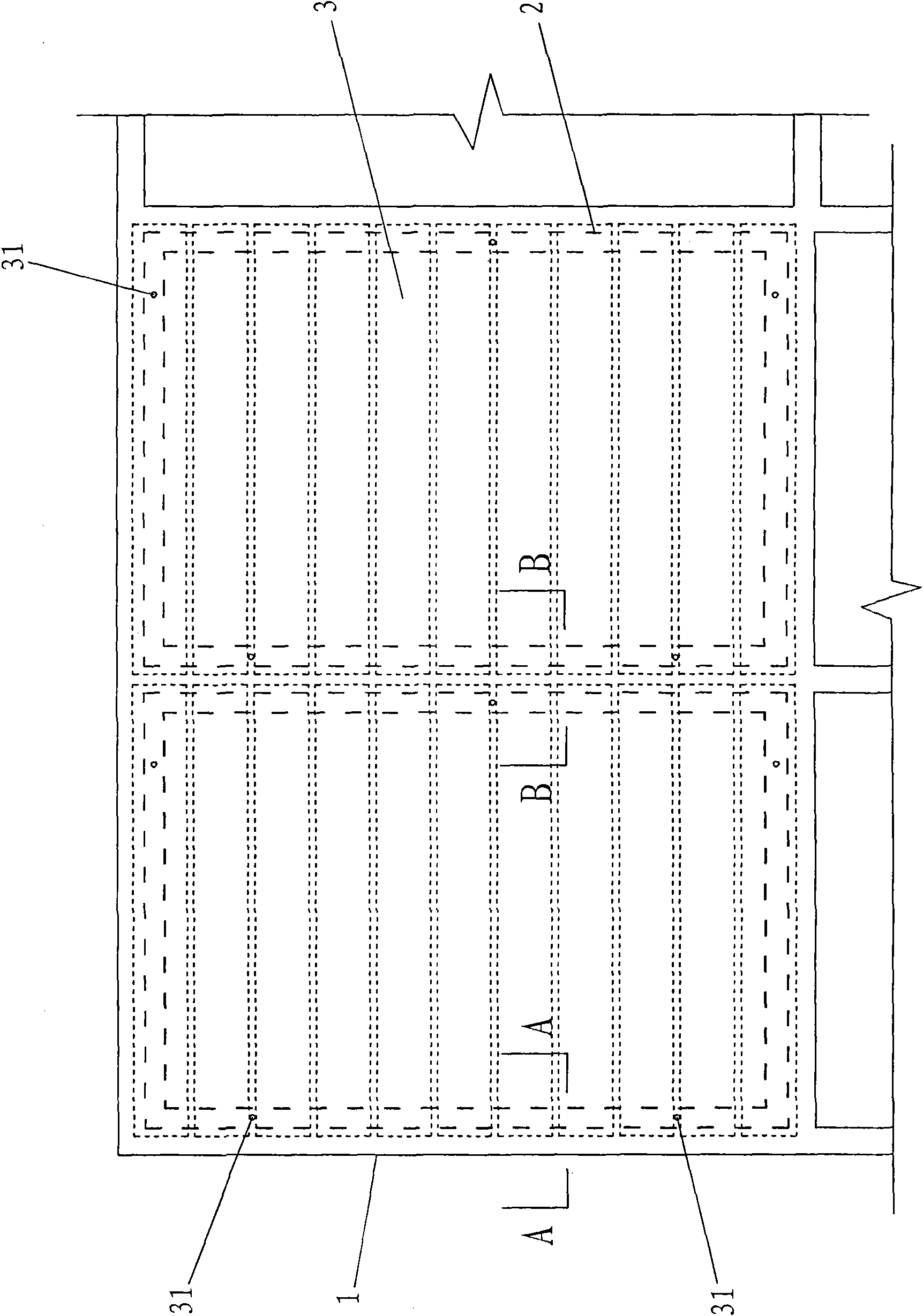

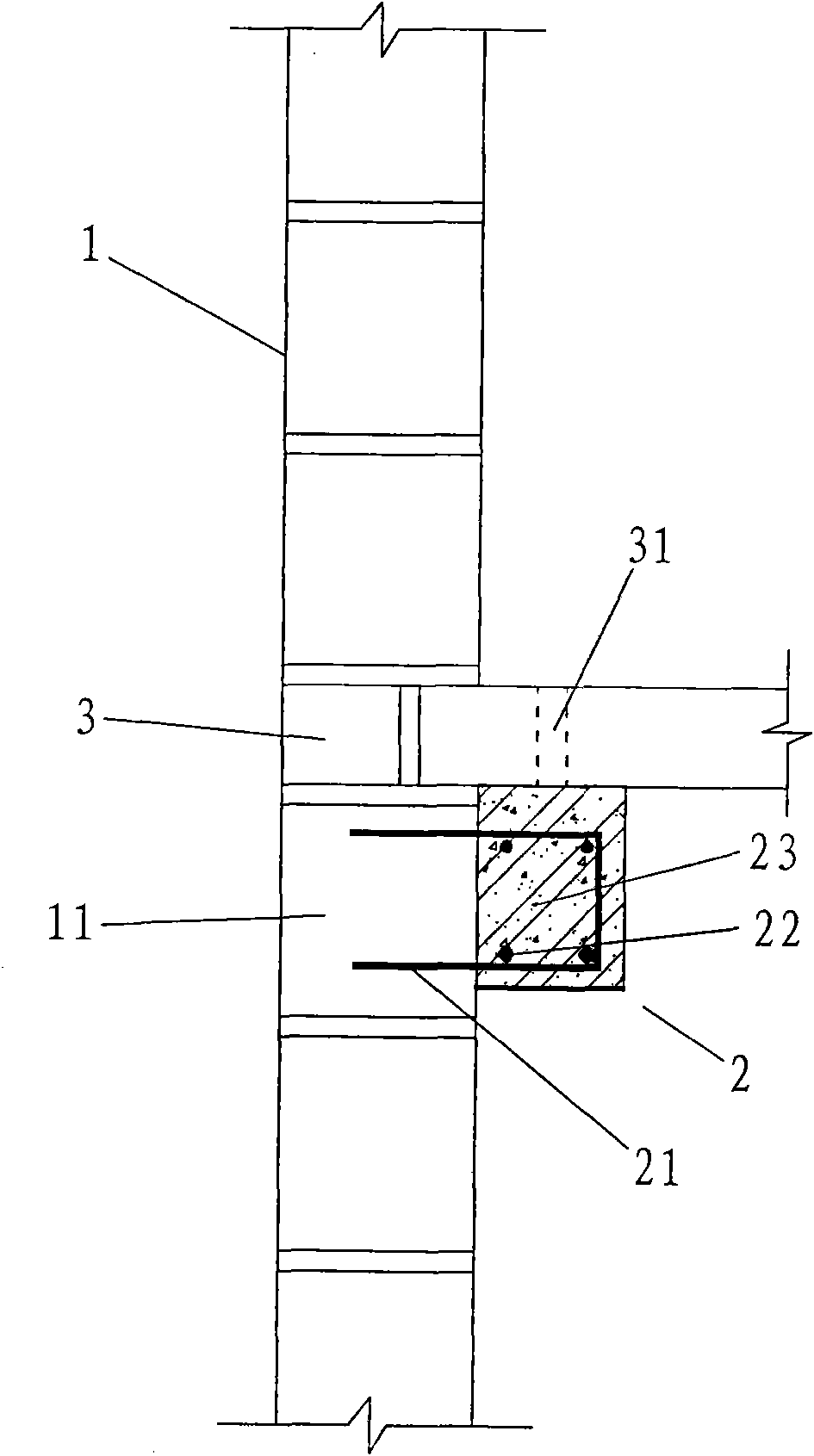

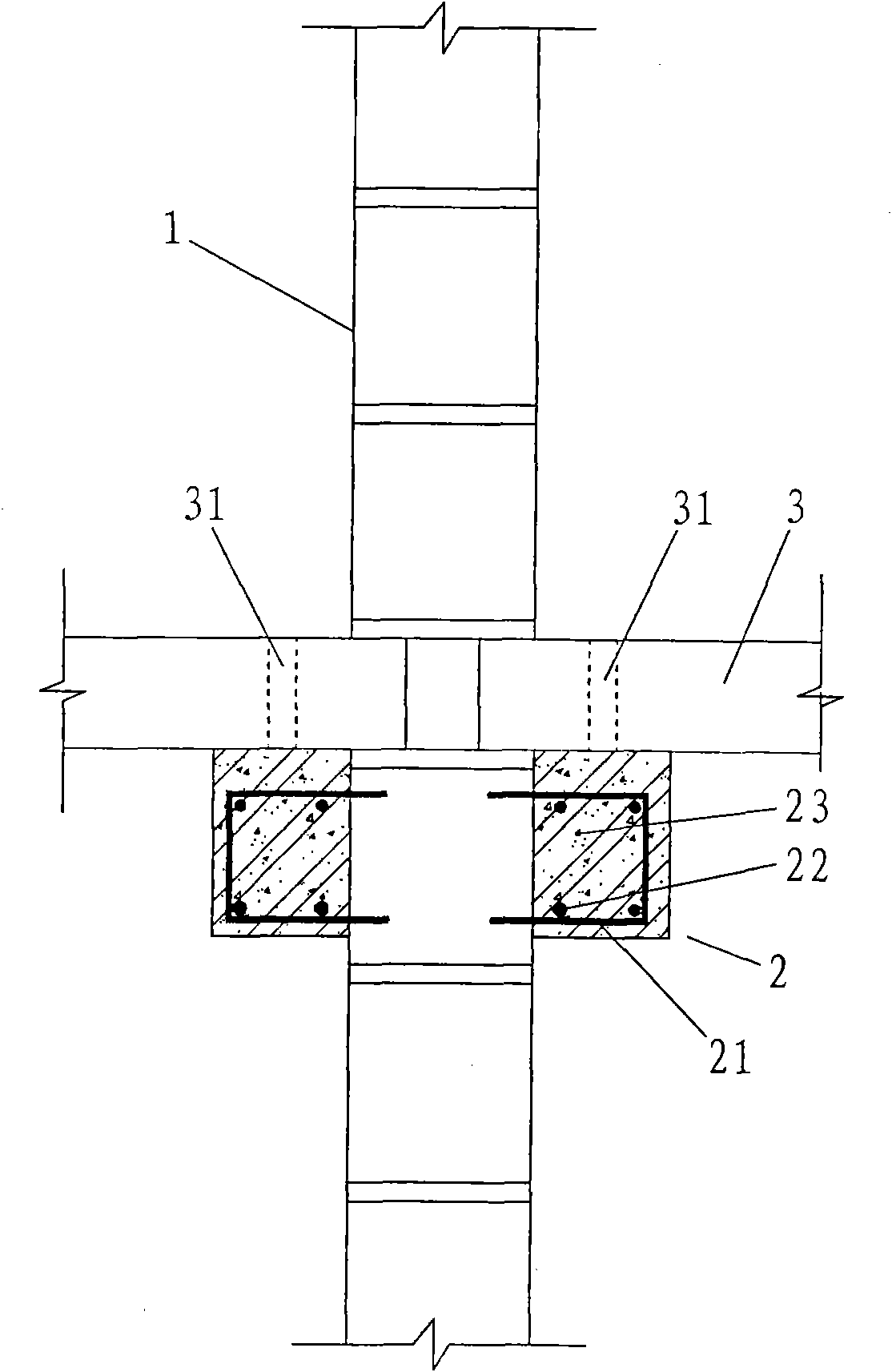

Strengthening method for stone wall body

The invention discloses a strengthening method for a stone wall body. The strengthening method including preparing pre-buried hook members (2), screws (4), flange plates (5), nuts (7), steel angles (8, 11), expansion bolts (12), zinc-coated wires (14), assembling units of steel plates and meshes (15), structural adhesive and concrete material; then excavating foundation pits on two sides of the stone wall body, pouring a concrete foundation (3) and inserting the pre-buried hook members (2); punching through holes in the stone wall body (1), blowing off dust, allowing the screws (4) to penetrate through the through holes, fixing two ends of each screw (4) by the nuts (7); arranging the assembling units of steel plates and meshes (15) on the stone wall body (1) and fixing by the expansion bolts (12); connecting flange plate holes (16), the hook members (2), binding holes (19) and eyelets (18) by binding through the zinc-coated wires (14), to form a criss-cross zinc-coated wires (14) net; the strengthening of the stone wall body (1) is achieved by jetting fine aggregate concrete (20).

Owner:SOUTHWEAT UNIV OF SCI & TECH

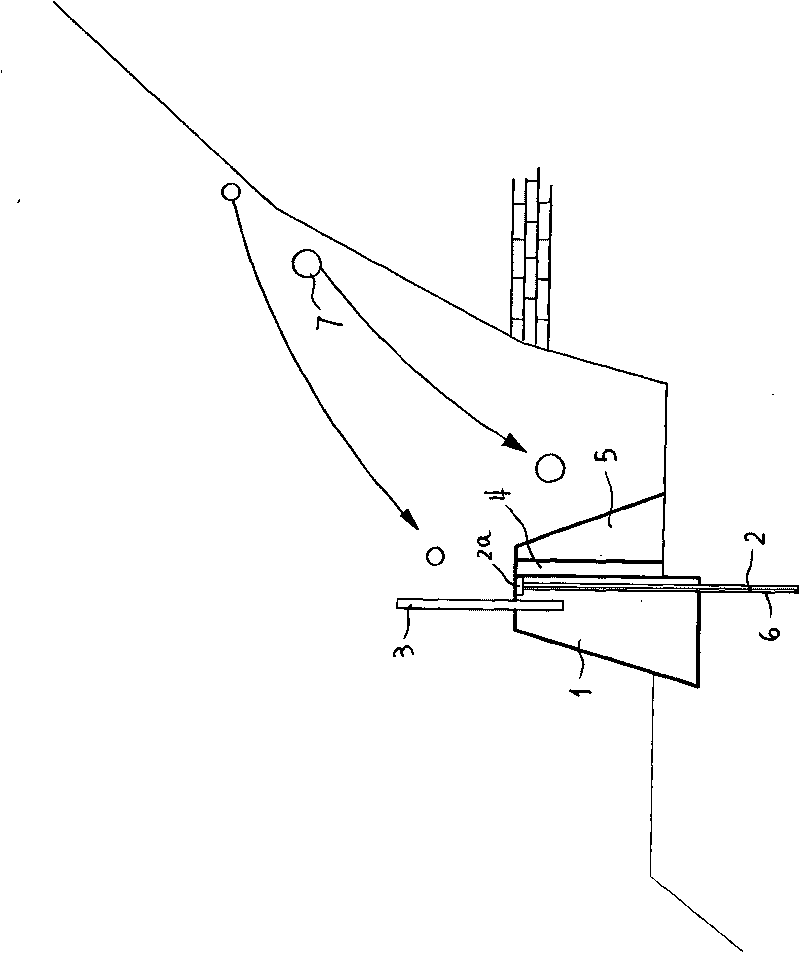

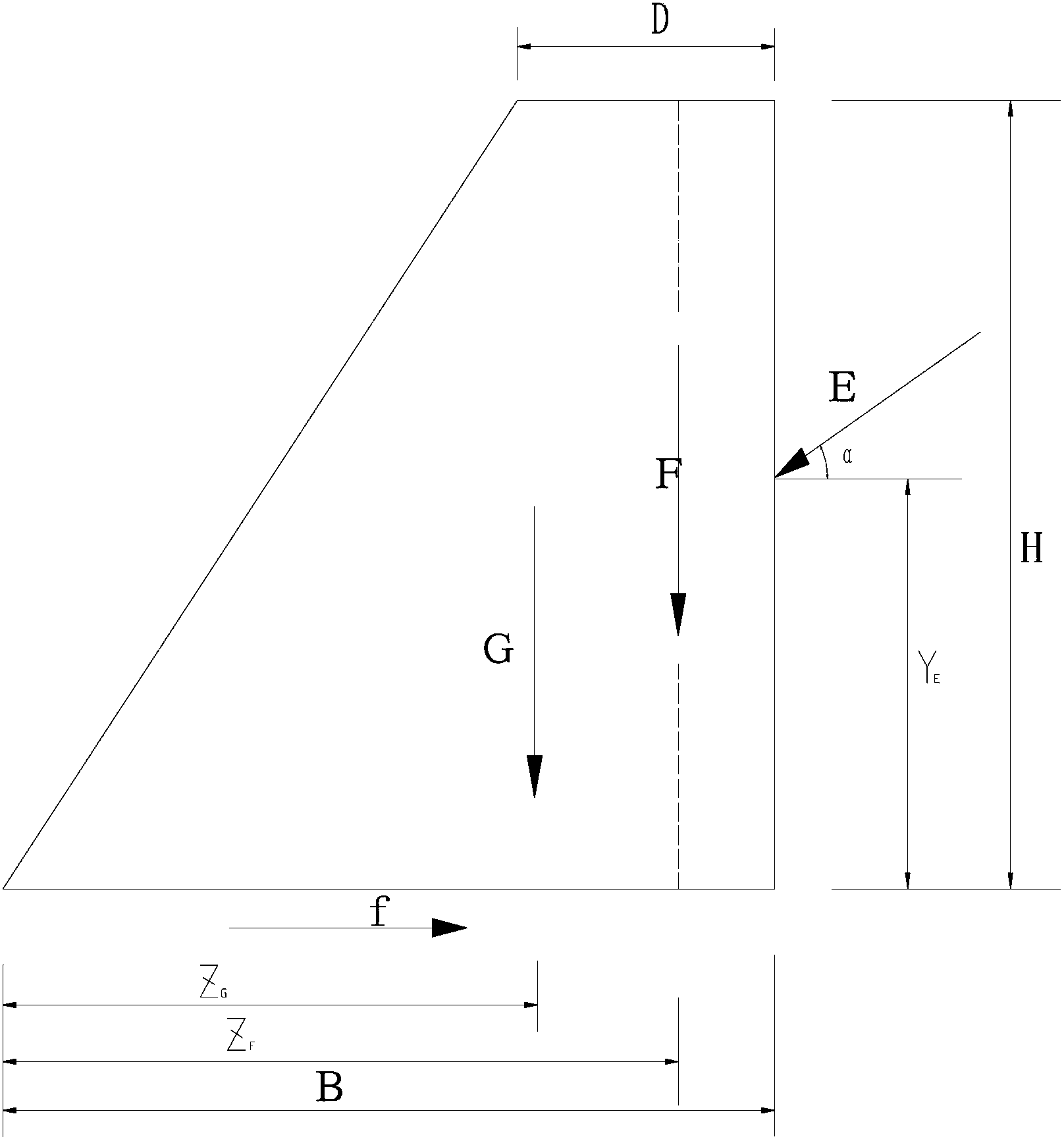

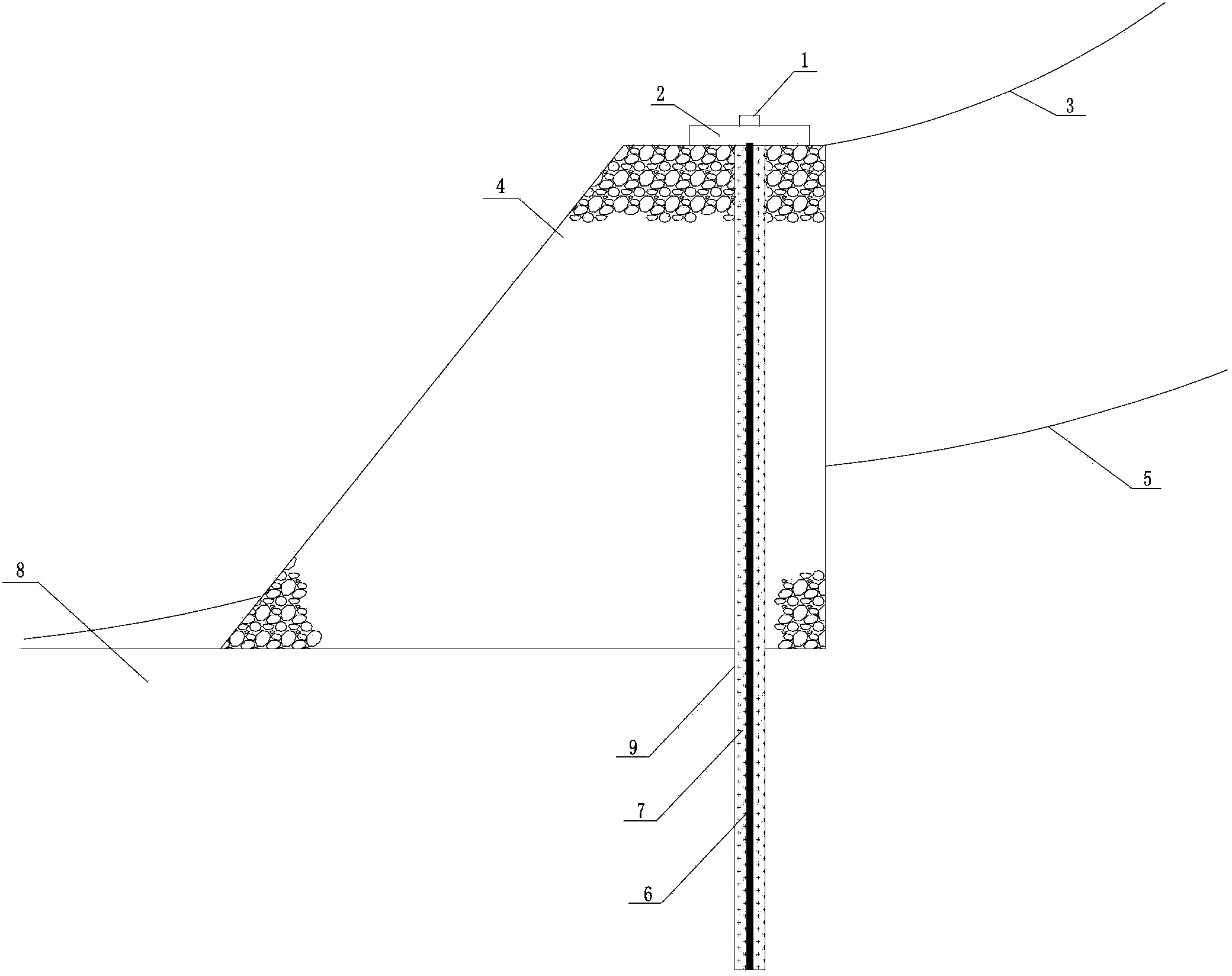

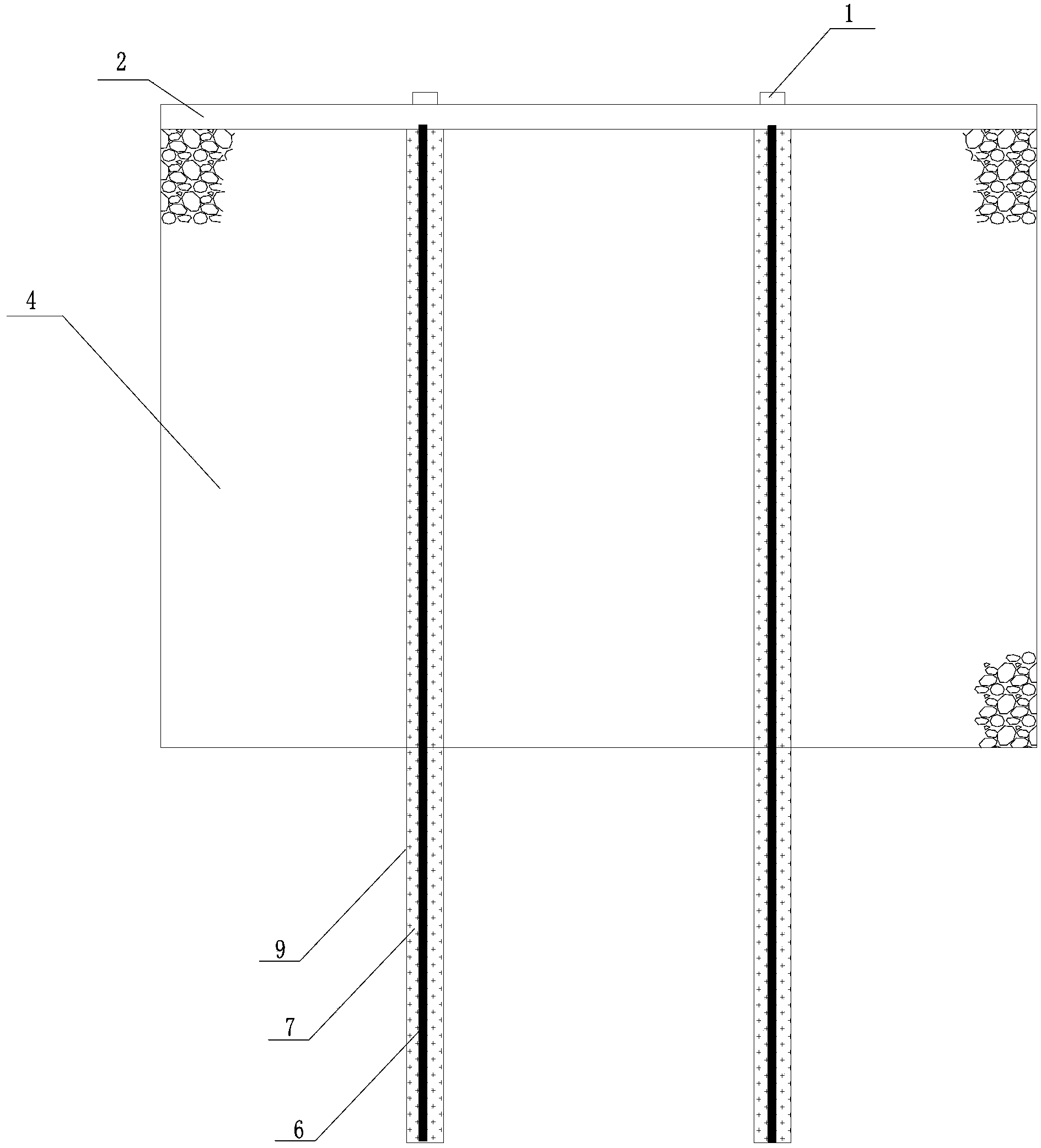

Vertical pres-stressed anchor rod gravity-type composite retaining wall and method for designing and constructing retaining wall

InactiveCN103352477AReduce gravityReduced footprintArtificial islandsUnderwater structuresStone wallPre stress

The invention relates to the technical field of geotechnical engineering disaster prevention and control, in particular to a vertical pre-stress anchor rod gravity-type composite retaining wall which comprises a mortar building block stone wall arranged on a bed rock layer. Anchor holes are formed in the mortar building block stone wall and the bed rock layer in the vertical direction. An anchor rod is arranged inside each anchor hole. Cement mortar is filled between the anchor rod and the anchor holes. A concrete anchor beam is arranged at the top end of each anchor hole. The concrete anchor beams are arranged at the upper end of the mortar building block stone wall. A concrete anchor head is arranged on each concrete anchor beam. Compared with a traditional gravity-type retaining wall, the vertical pre-stress anchor rod gravity-type composite retaining wall has the advantages that elastic retraction of the anchor rods is utilized for applying pre-stressing force on the wall body, the weight of retaining wall masonry can be replaced, the sectional size of the retaining wall is reduced, and the integrality and the shearing strength of the wall body of the retaining wall are strengthened.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Masonry bracket, system and construction method

The present invention provides a masonry wall reinforcing bracket (2) comprising an elongate inter-course shear transfer member (4), the shear transfer member (4) comprising a rebar cradling feature (6). The shear transfer member (4) may further comprise a plate (5) operative to be located within at least a perpend (22) of a masonry wall (10). The bracket may further comprise a supporting member (28) that protrudes perpendicularly from the length of the shear transfer member (4). The supporting member (28) may comprises a plate operative to be located within a bed joint (24) of the masonry wall (10). The supporting member (28) may be a stabilising foot. The rebars and brackets are used in a bond beam (10) system incorporated within the wall (10).

Owner:WEMBLEY INNOVATION

Method for manufacturing non-seamed stone corners for veneer stone surfaces

A method is disclosed for constructing non-seamed stone corners for use on outside edges formed by joining thin stone walls at right angles. Thin stone is used to lay the field of the walls. Then first and second cuts are made in a building stone, removing a residual piece and leaving a corner stone with sides ½ inch to 3 inch thick to match the thickness of the thin stone on the field of the walls. These corner stones are laid on the corner formed by the right angle joint between the walls, giving the illusion of a thick building stone wall with nearly the low cost and easy laying of thin stone. Where the residual piece is large enough, it is used to cut a second corner stone in the same manner.

Owner:HOLMES MARK J

Architecture art embossment stone wall surface dried hanging structure and construction method thereof

ActiveCN101413334AThe dry hanging method is firm, safe and reliableSimple construction processCovering/liningsStone wallKeel

The invention discloses a dry hanging structure for a building art relief sculpture stone wall surface and a construction method. The dry hanging structure comprises a vertical keel, a horizontal keel and relief sculpture stone plates, and is characterized in that the vertical keel is fixed with a preembedded piece; the horizontal keel is fixed with the vertical keel through a corner connector, and is provided with an upper hook; the periphery of the rear side of each relief sculpture stone plate is provided with auxiliary frames, the upper auxiliary frame is provided with a hook which is exposed outside the rear side of the relief sculpture stone plate, and is welded with a positioning pin, the lower auxiliary frame is welded with a positioning hole, the hook of the upper auxiliary frame of the relief sculpture stone plate is hooked on the upper hook of the horizontal keel, wherein the positioning hole of the lower auxiliary frame of the relief sculpture stone plate at the upper part is sleeved on the positioning pin on the upper auxiliary frame on the relief sculpture stone plate at the adjacent lower part for coordination positioning. The construction method comprises the following steps: firstly, the whole relief sculpture wall surface is decomposed into a plurality of relief sculpture stone plates which are favorable for the construction, and then the relief sculpture stone plates are numbered. The periphery of each stone plate is provided with the auxiliary frames, and the stone plates form the relief sculpture wall surface with the horizontal keel by adopting a mode of the upper hook, the lower pin, and hole inserting positioning. The dry hanging structure has the advantages of firmness, safety, reliability, and simple construction technology.

Owner:FUJIAN LIUJIAN GRP

Reinforcing method for improving earthquake resistance of stone structure buildings

The invention discloses a reinforcing method for improving earthquake resistance of stone structure buildings. The method is realized by the following scheme: closed cast-in-place reinforced concrete inner ring beams are poured around the bottom surface of the floor system of a stone structure building, and the stirrups of the closed cast-in-place reinforced concrete inner ring beams are anchored on the bar stone on the top of the stone wall of the stone structure building so that the inner ring beams, the stone wall and the floor system form an integer. Due to the scheme, the invention has the following advantages that: (1) with high strength, the granite bar stone can provide enough anchoring strength for the inner ring beams; and because of the large size and rough interface of the bar stone, close connection and tying action of the latterly added inner ring beams and the bar stone are facilitated so as to form a combined ring beam which plays a good role in enhancing the building integrity and the tying action between the longitudinal and transverse walls; (2) the stirrups of the inner ring beams also have functions of tying shear connectors and erecting longitudinal steel bars; and (3) the inner ring beams increase the support length of prefabricated floor plates or stone floor plates, reduce the calculation length and therefore enhance the integrity of the floor system as well as the bearing capability and collapse resistance of the floor system.

Owner:HUAQIAO UNIVERSITY

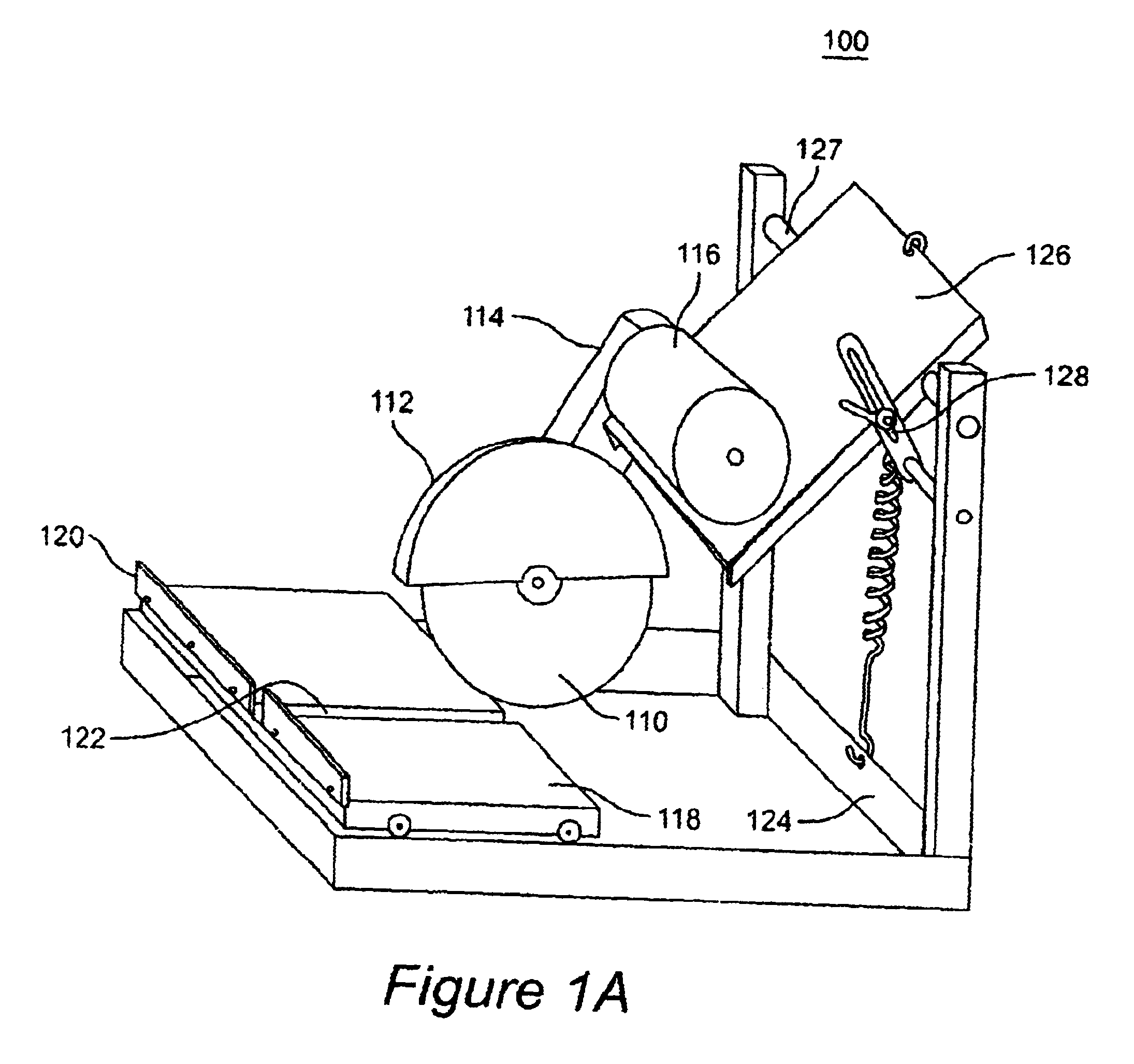

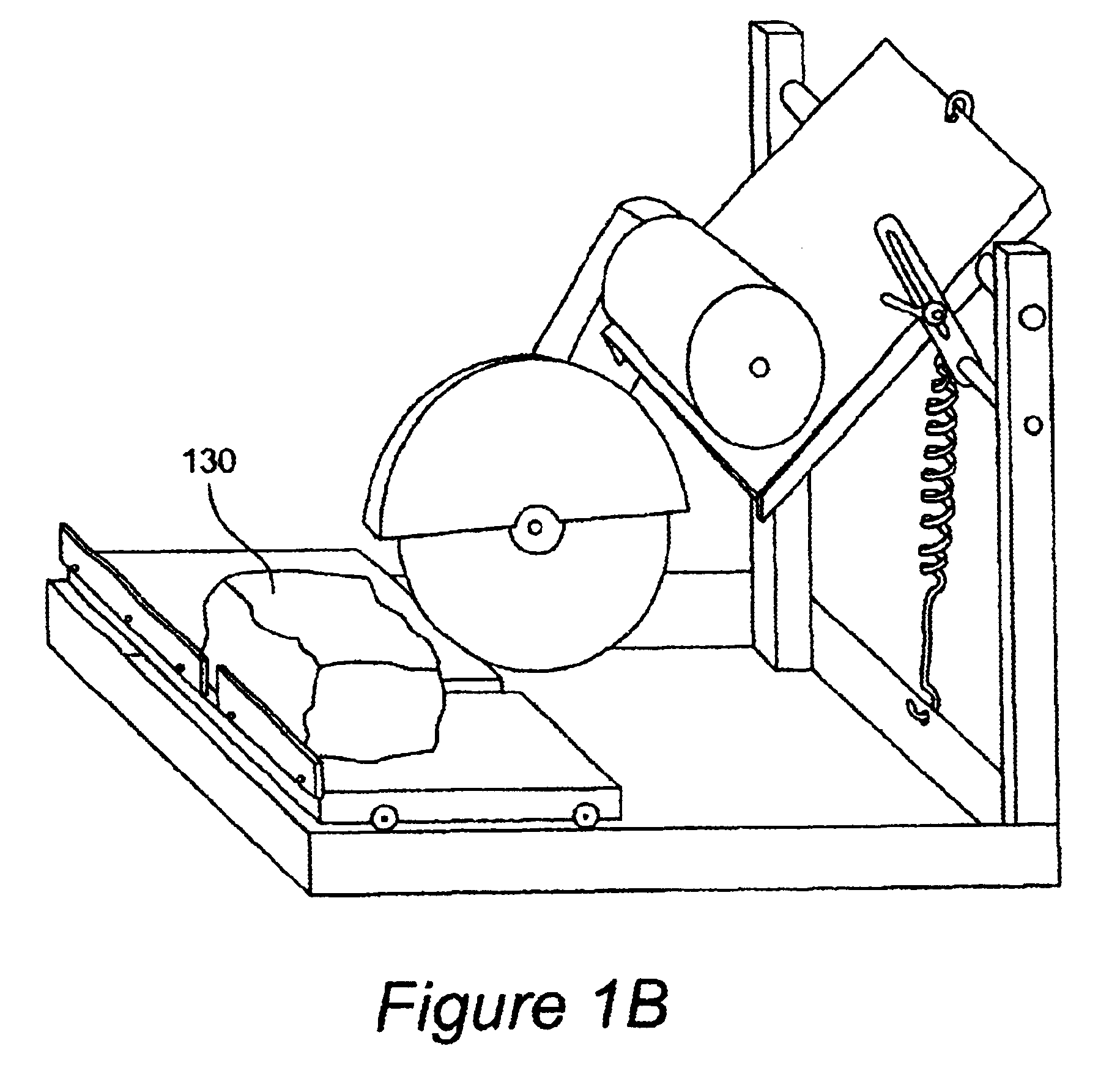

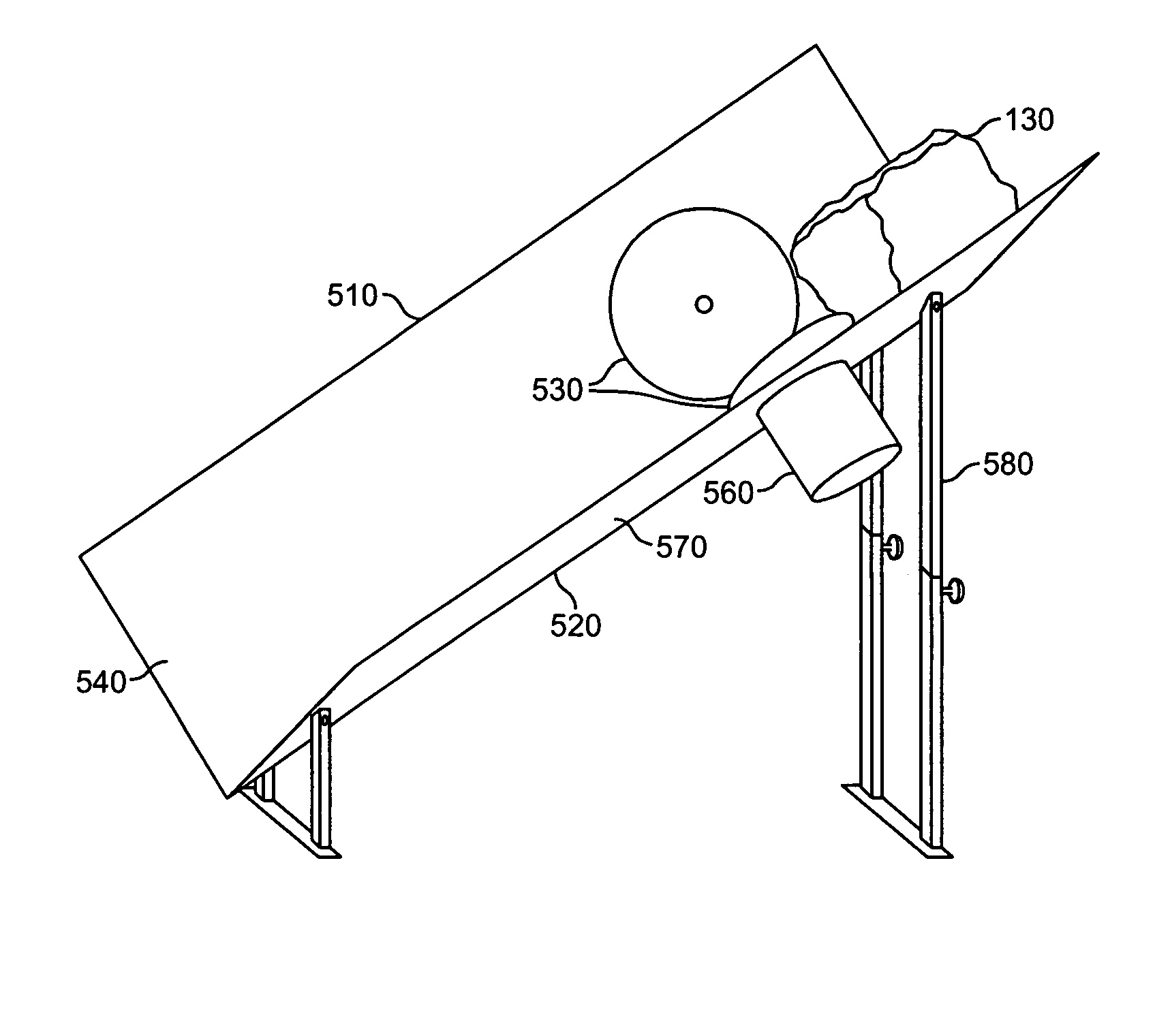

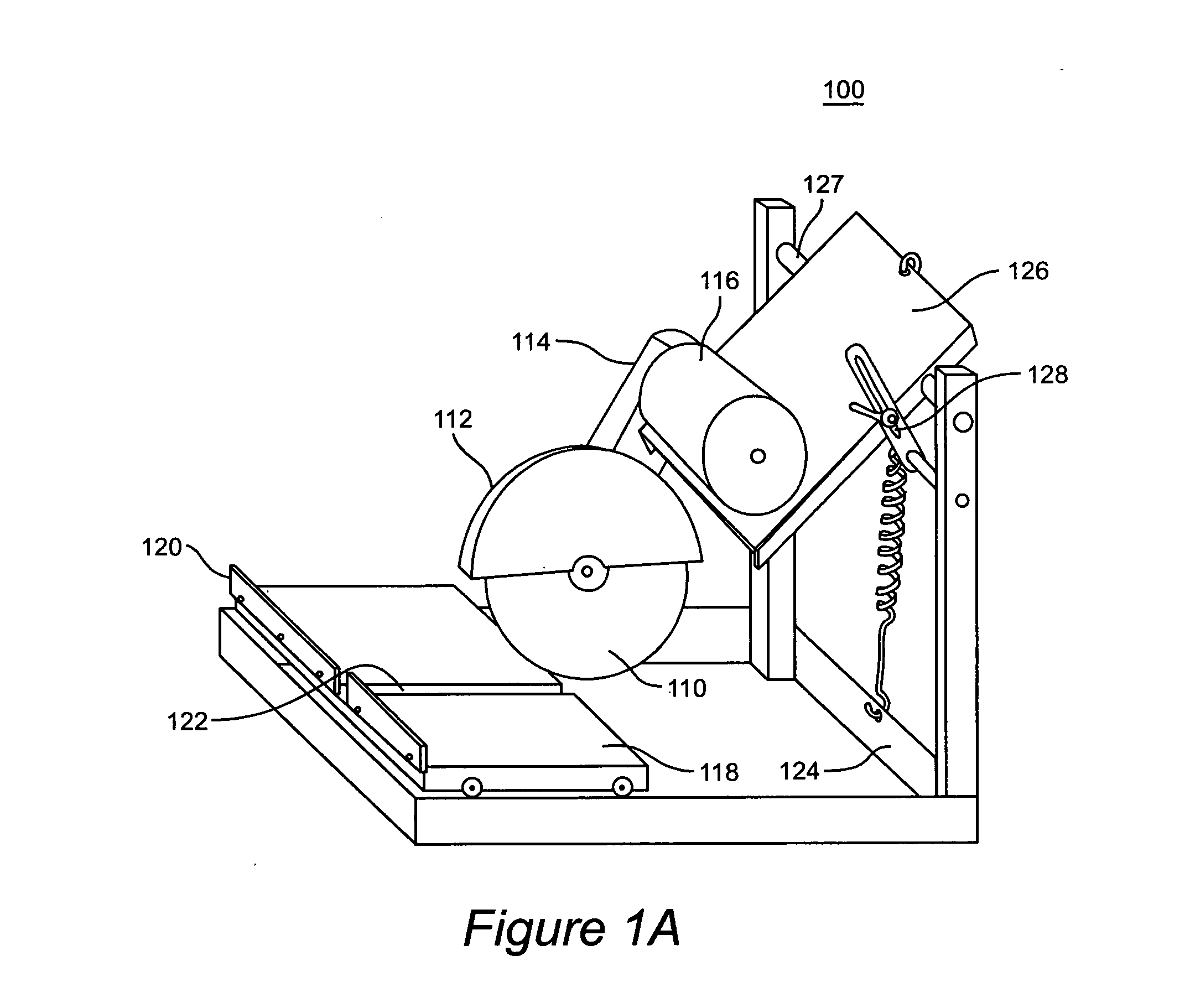

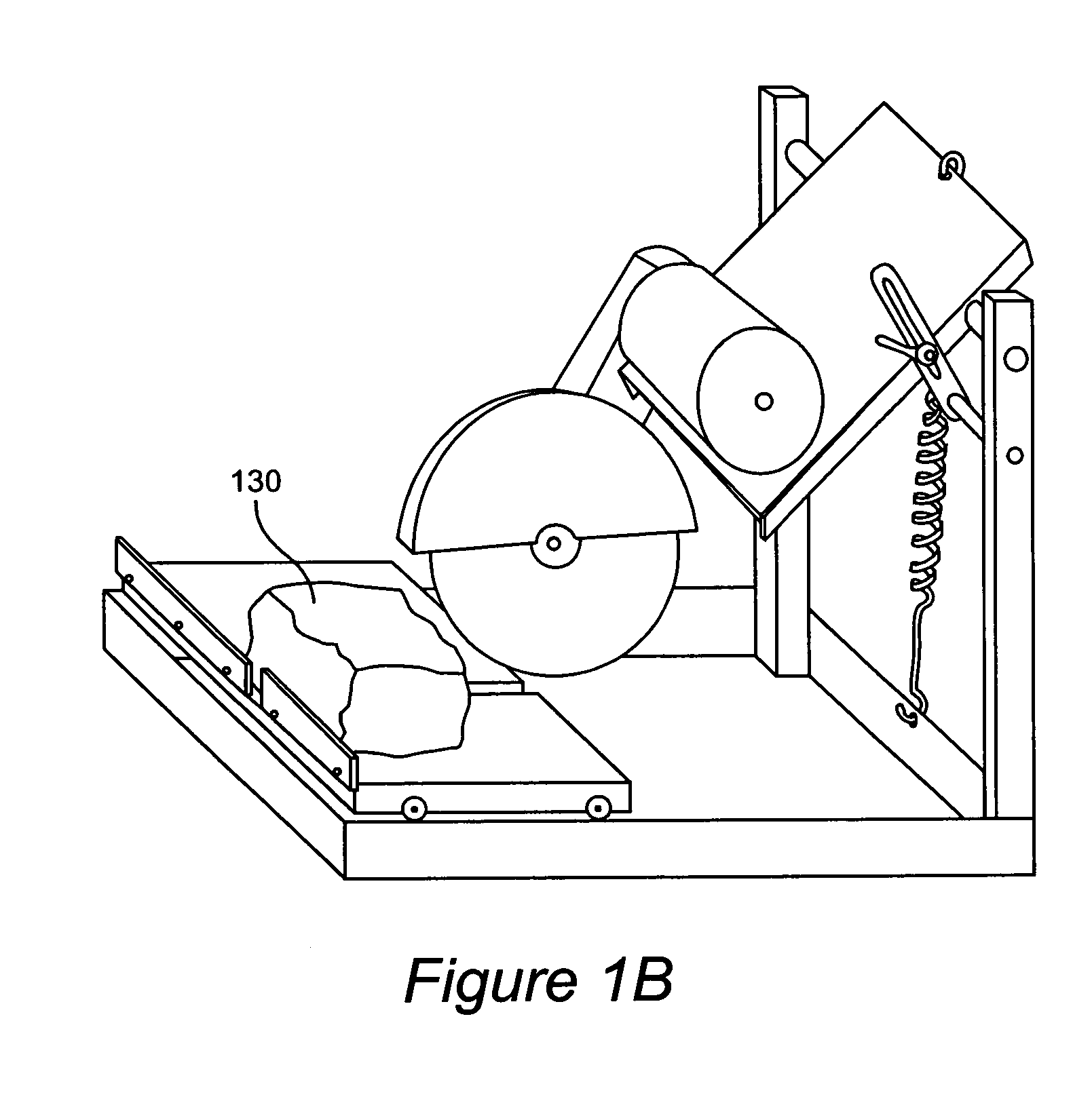

Method for manufacturing non-seamed stone corners for veneer stone surfaces

InactiveUS6945858B1Low costEasy to layMetal sawing devicesConstruction materialStone wallCivil engineering

A method is disclosed for constructing non-seamed stone corners for use on outside edges formed by joining thin stone walls at right angles. Thin stone is used to lay the field of the walls. Then a building stone is oriented and fed down a chute, having perpendicular sides, through two stone cutting saws at right angles to one another, where the distance between the saw blades and the sides of the chute correspond to the thickness of the respective thin stone walls, and where the cutting edges of the saw blades have a clearance between them of about one-eighth of an inch. A residual piece is removed from the cut building stone, leaving a corner stone. These corner stones are laid on the corner formed by the right angle joint between the walls, giving the illusion of a thick building stone wall with nearly the low cost and easy laying of thin stone. Where the residual piece is large enough, it is used to cut a second corner stone in the same manner.

Owner:HOLMES MARK J

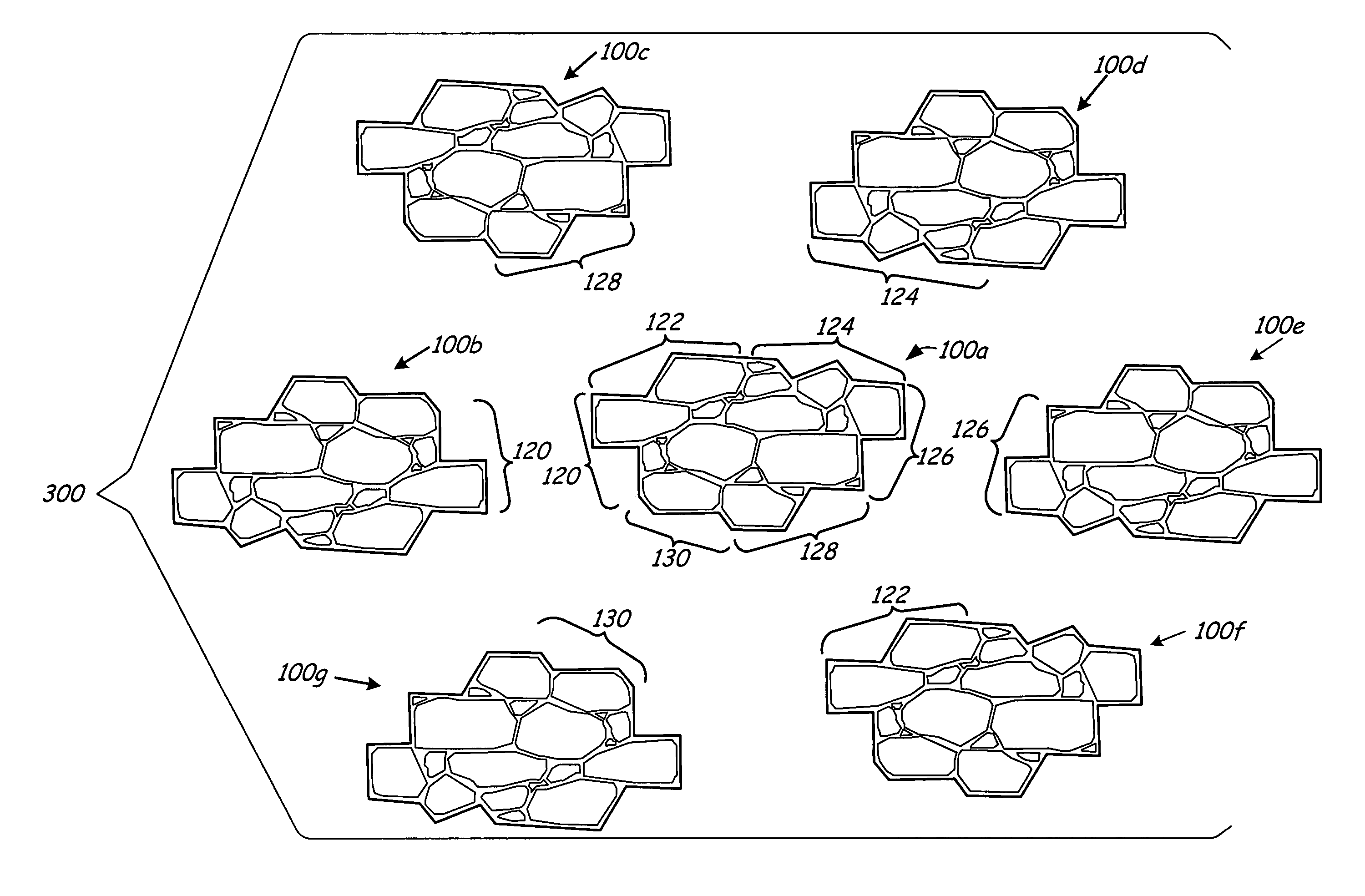

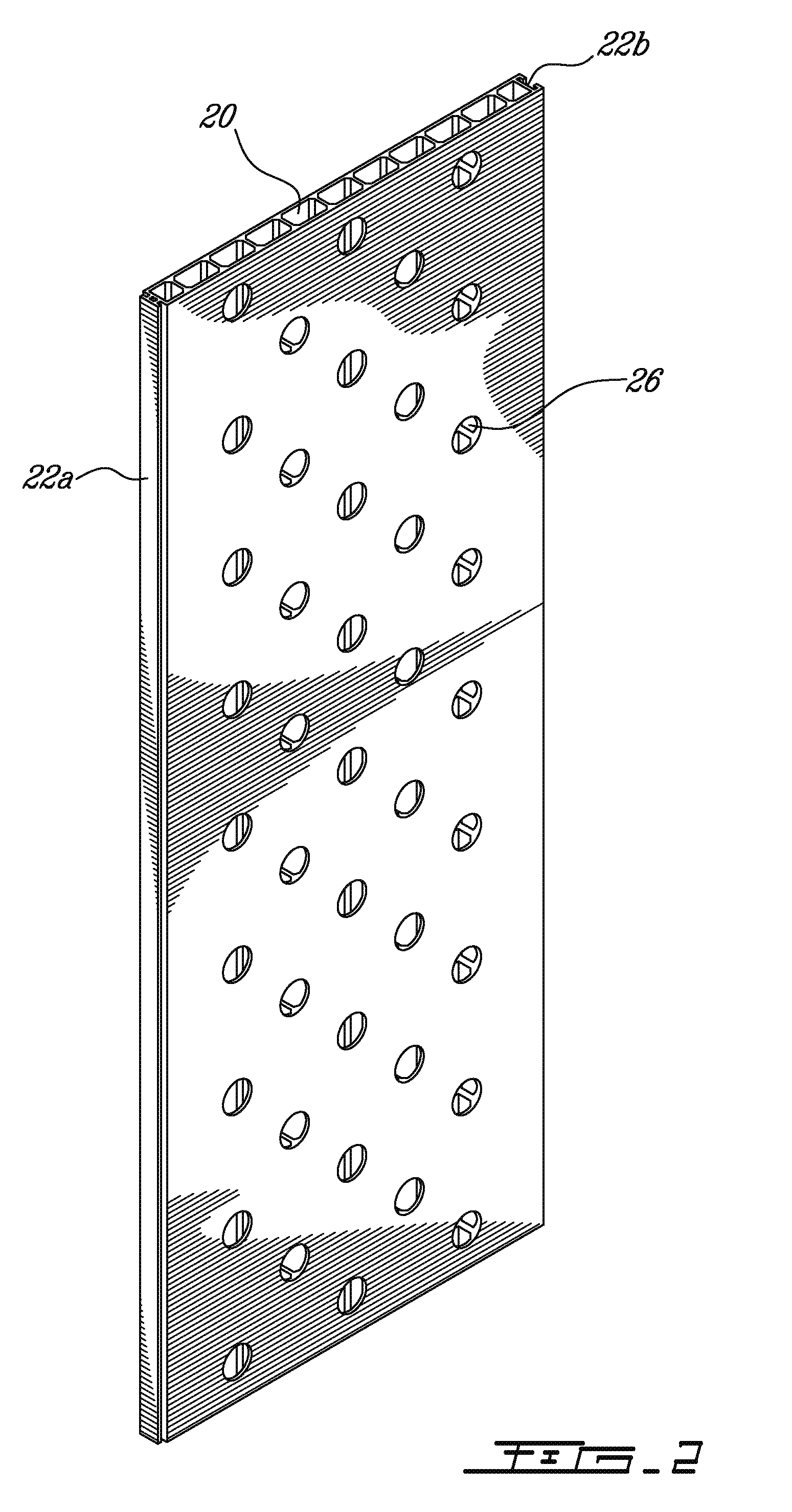

Modular stone panel

A modular stone panel is disclosed. The panel is adapted to be mounted or fastened to a structural wall to provide a stone wall façade therefor. The panel is generally comprised of a shaped backboard and a plurality of stones solidly fastened on a front face thereof. The backboard is adapted to be fastened to the structural wall such that the front face thereof faces away from the wall to provide the stone wall façade. The stones may comprise natural or synthetic molded stones. The backboard may also be ventilated to provide ventilation to the stones fastened thereto. The panels may be fabricated to provide key-cut edges allowing an interlocking of adjacent panels. A method of fabricating such panels is also disclosed.

Owner:VIAU NICOLAS +3

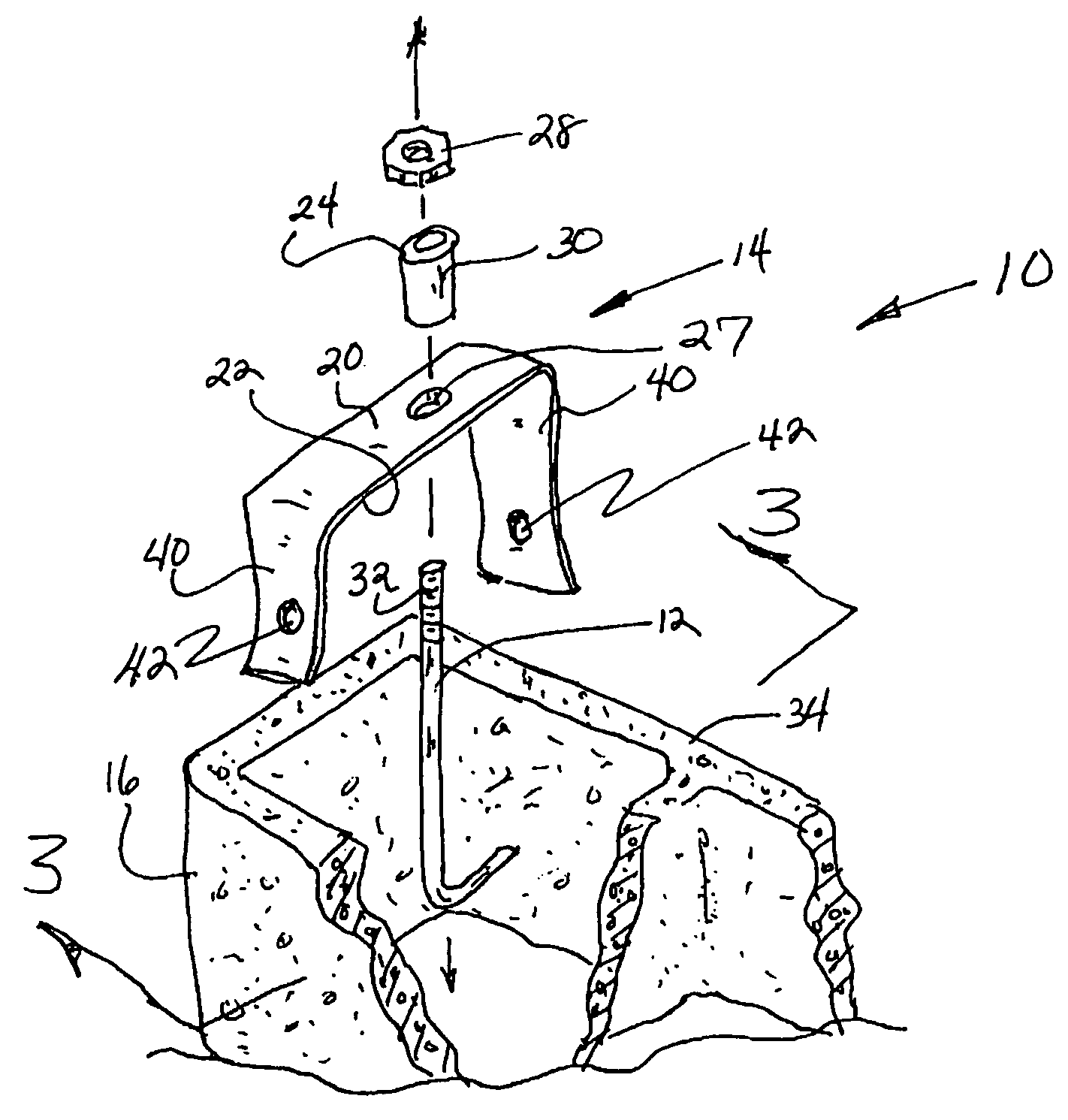

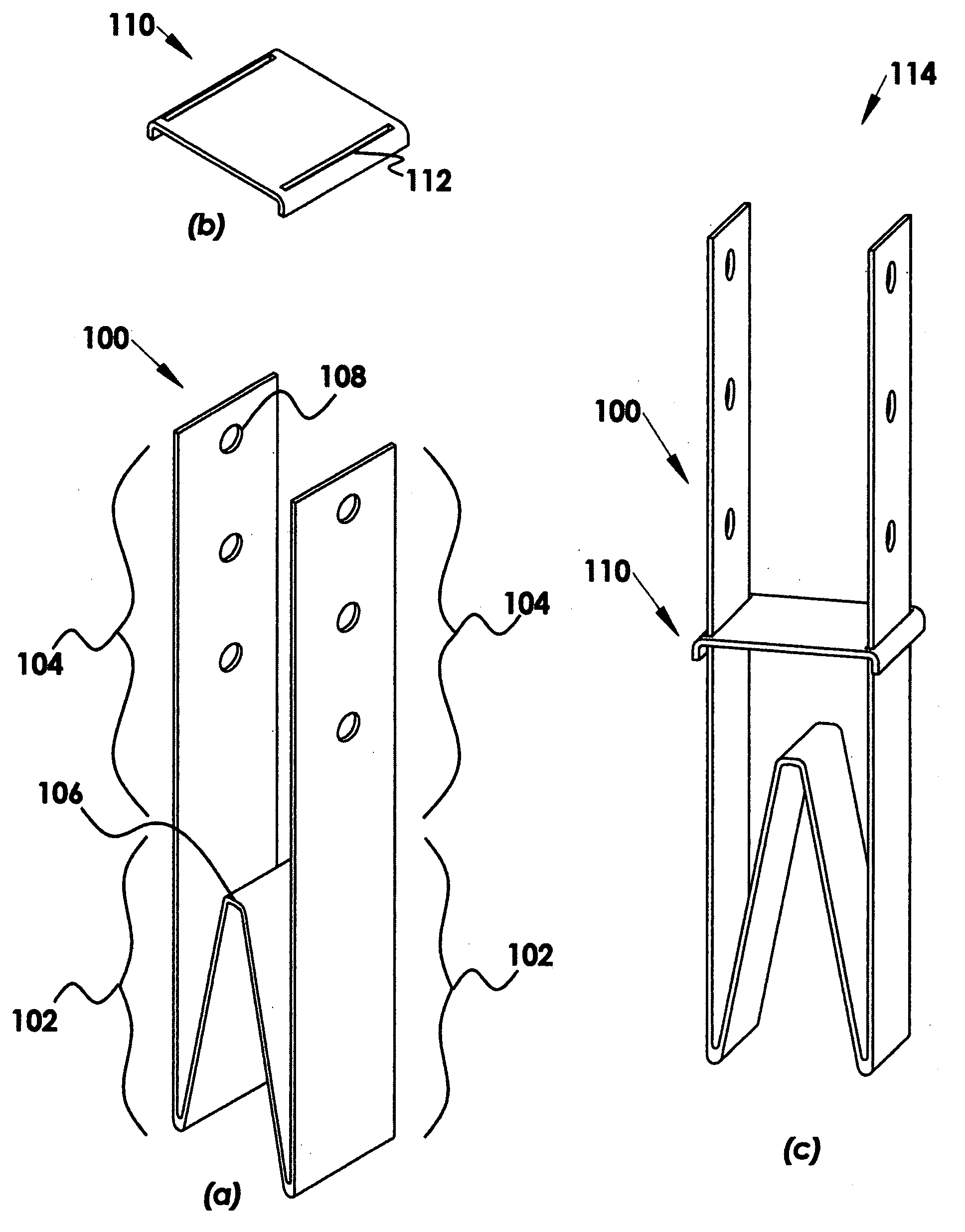

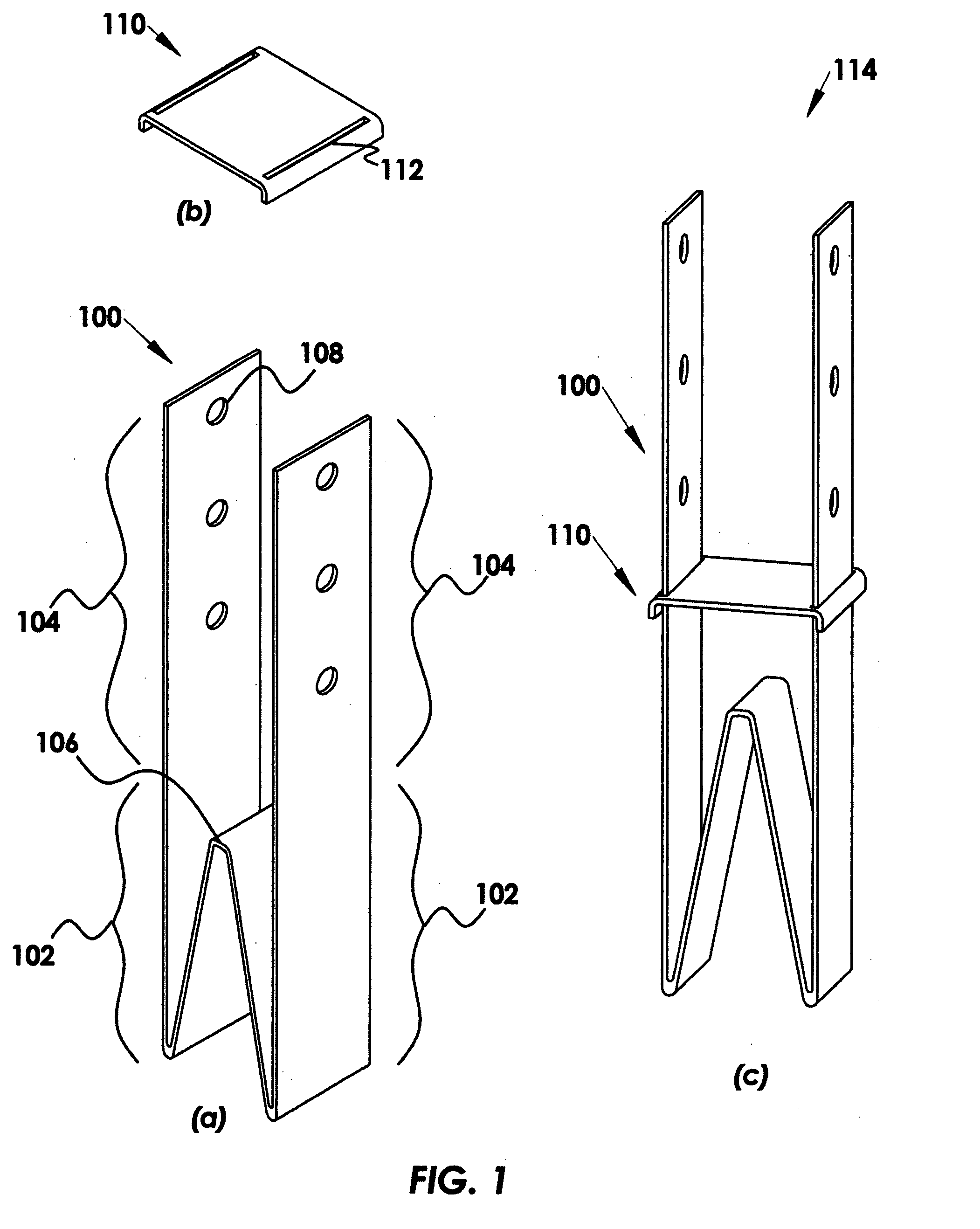

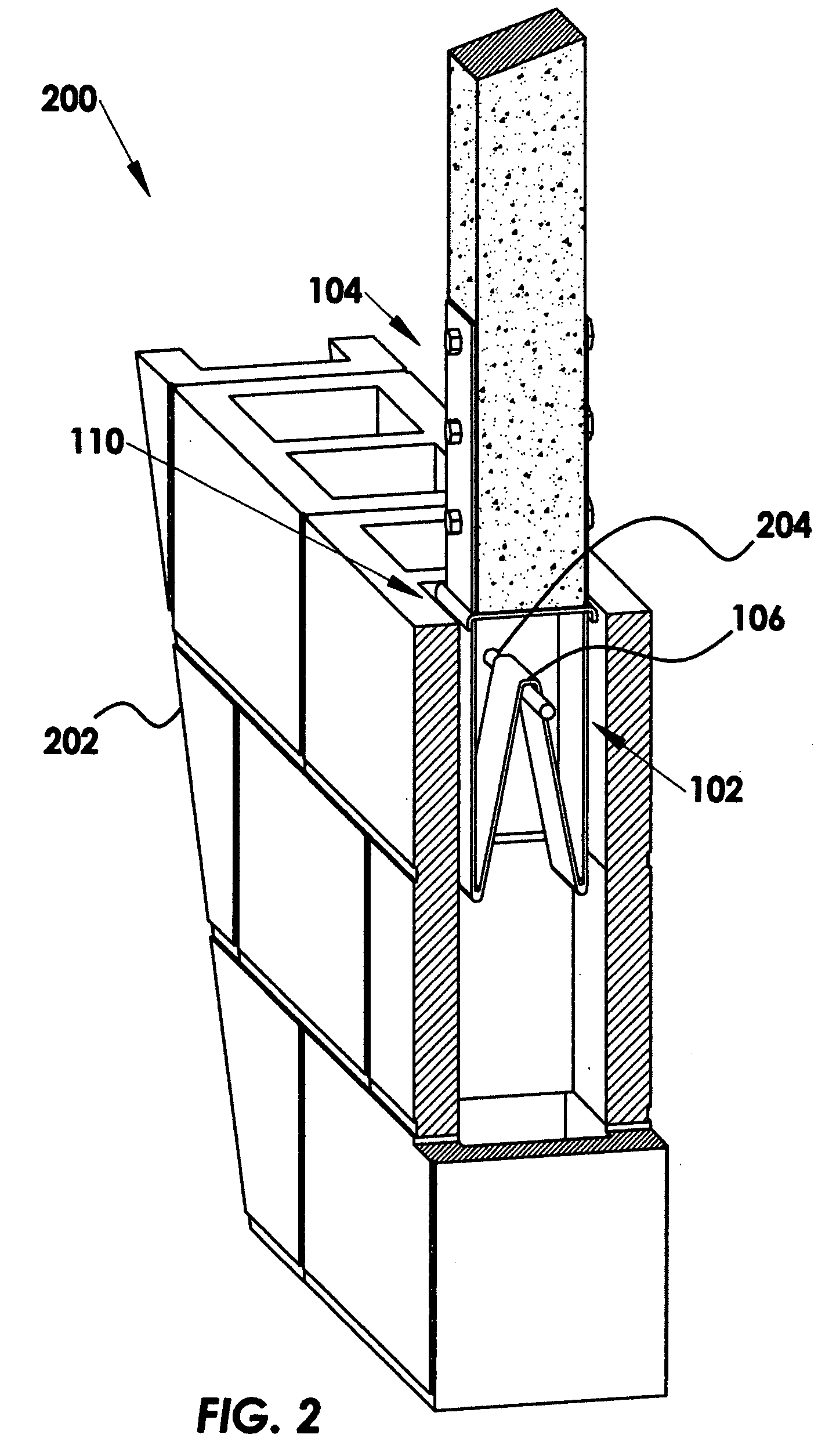

Non-top supported fence installation bracket

A non-top-supported column attachment bracket assembly is provided, that includes a generally W-shaped bracket to provide a strong connection between non-top supported wood fences and masonry walls such as concrete masonry unit (CMU) walls or cast in place (CIP) walls. The W-shape provides a matrix inside the hardening structure of the wall, while simultaneously engaging the horizontal reinforcing bar of the wall. The W-anchor further includes a cover plate disposed onto the bracket. The W-shaped bracket can be installed to the upper portion of the wall just prior to grouting or during grouting, where the bracket can be pressed onto the horizontal bar before the grout has hardened. After the hardening structure is cured, fencing posts are attached to a column connection portion of the W-anchor that extends from the top of the wall.

Owner:SANDERS STEVEN H +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com