Architecture art embossment stone wall surface dried hanging structure and construction method thereof

A relief and wall surface technology, applied in building structure, construction, covering/lining, etc., can solve the problems of high cost, complicated construction, and difficult exterior wall decoration, etc., and achieve the effect of simple construction technology and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with the accompanying drawings:

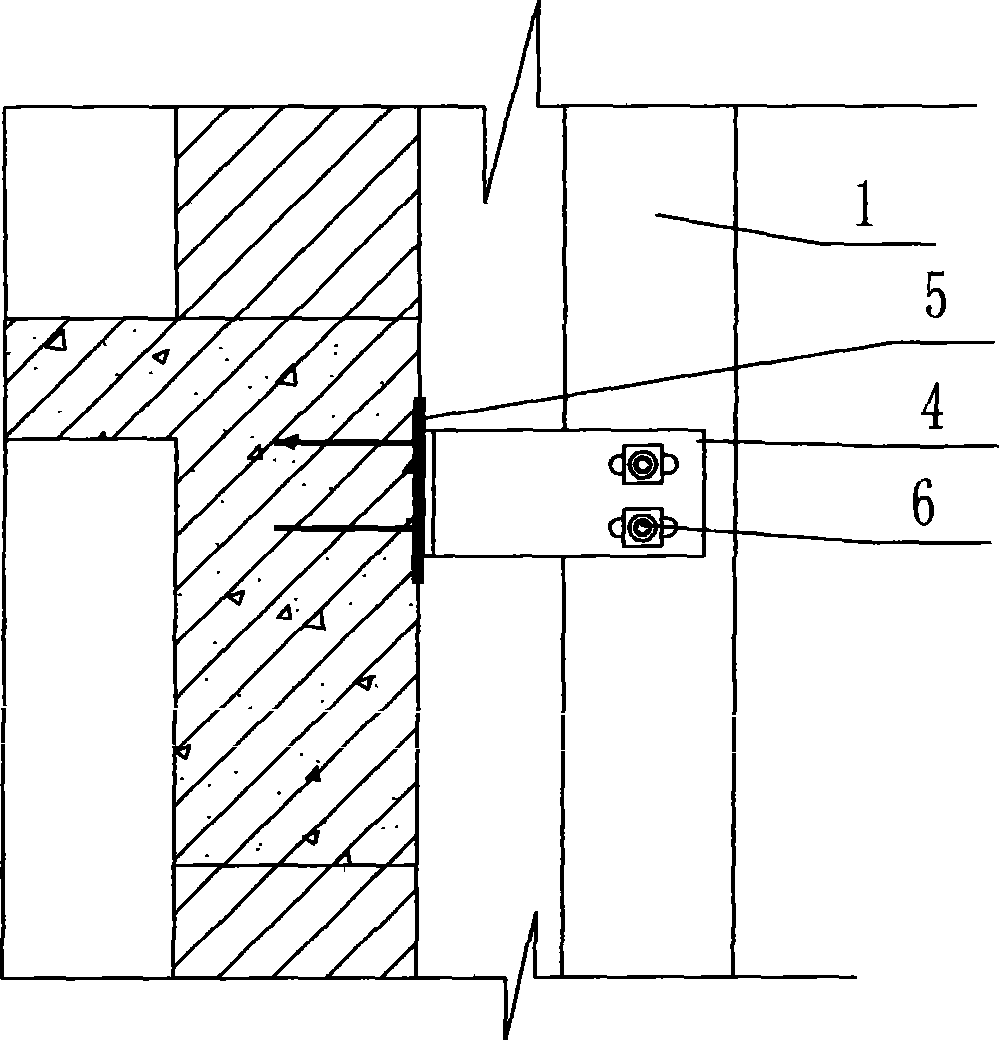

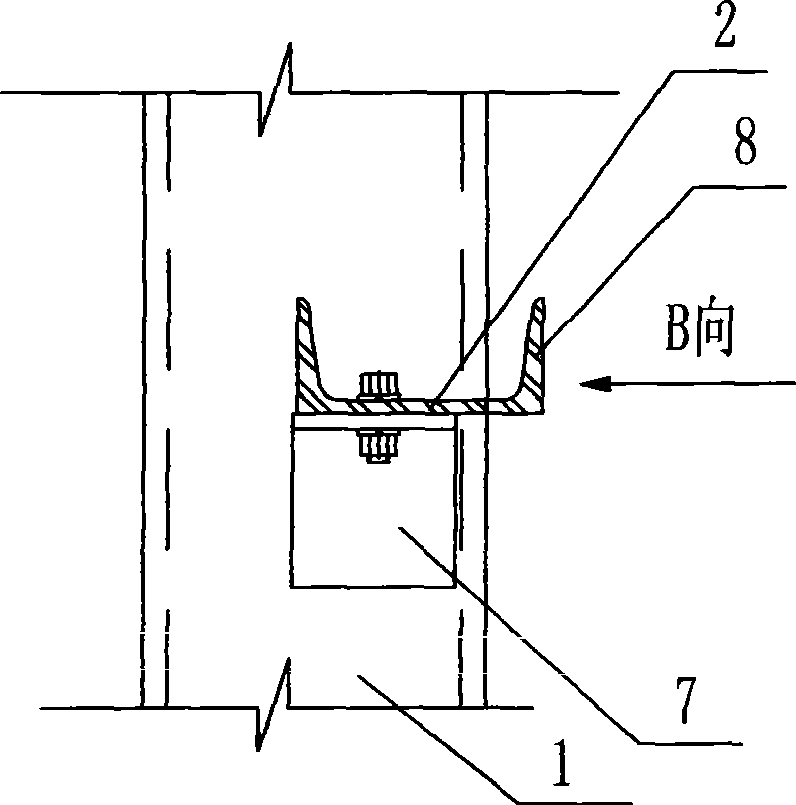

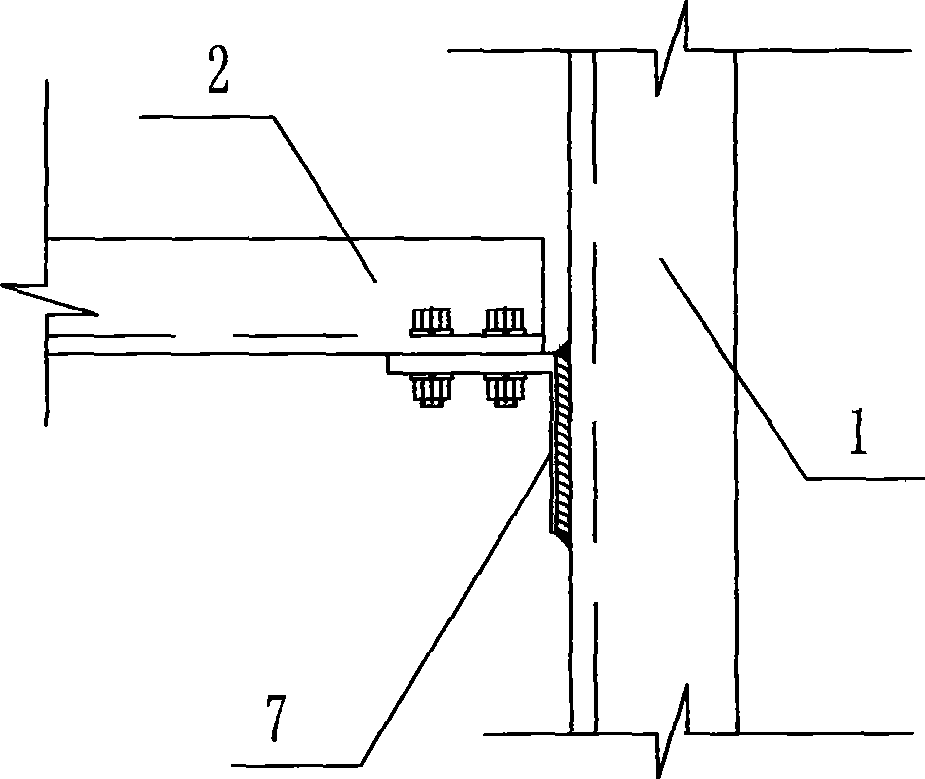

[0022] One, if figure 1 , figure 2 , Figure 2-1 , image 3 , Figure 3-1 , Figure 3-2 , Figure 3-3 , Figure 4 and Figure 4-1, the dry hanging structure of the architectural art embossed stone wall surface of the present invention, including vertical keel 1, horizontal keel 2 and relief stone slab 3, (1) vertical keel 1: use profiled steel as relief The vertical keel of the wall, the vertical keel 1 is fixedly connected with the embedded part 5 of the main structure of the outer wall by the bolt 6 (see details). figure 1 ). (2) Horizontal keel 2: Channel steel is used as the horizontal keel, and the horizontal keel 2 is connected to the vertical keel 1 through the corner yard 7, and the corner yard 7 is connected to the vertical keel 1 by surrounding welding (see details for details). figure 2 ). The horizontal keel 2 is fixed on the corner 7 by fixing bolts....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com