Patents

Literature

88results about How to "Improve horizontal accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

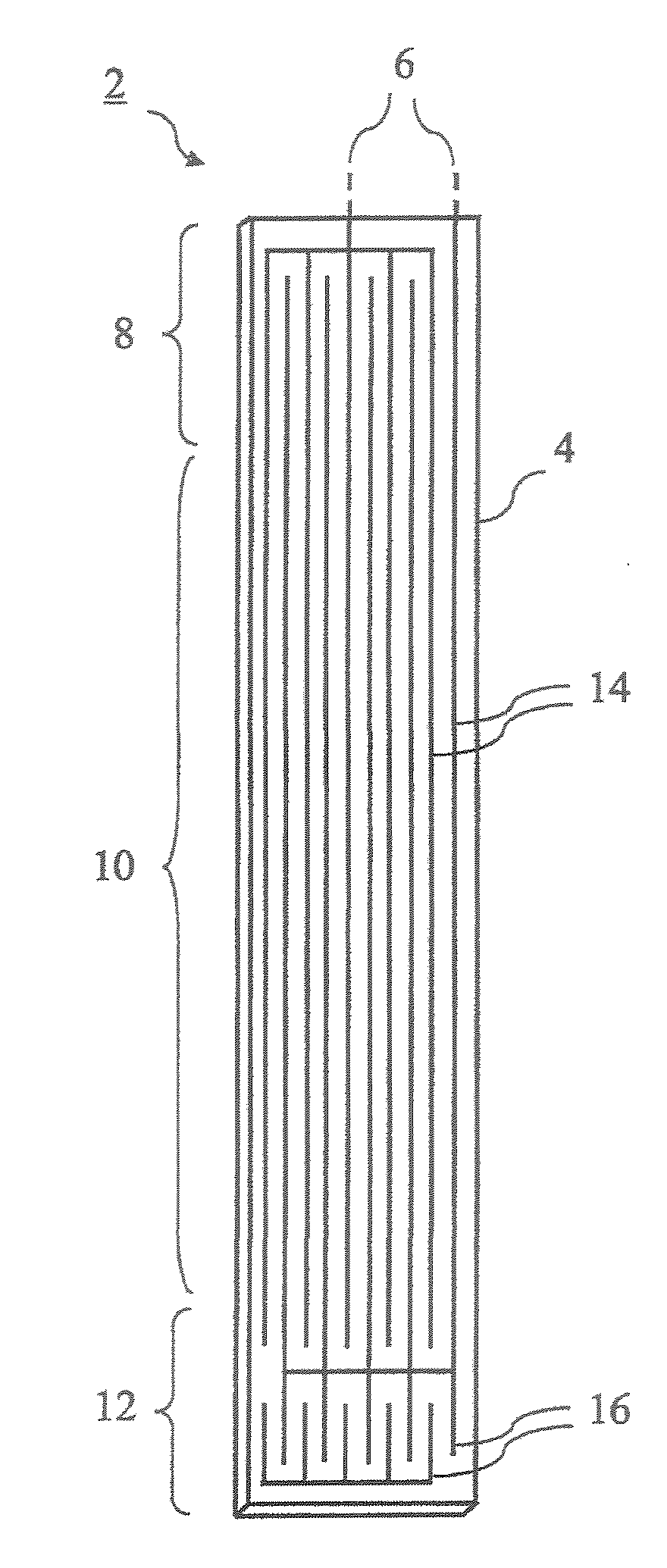

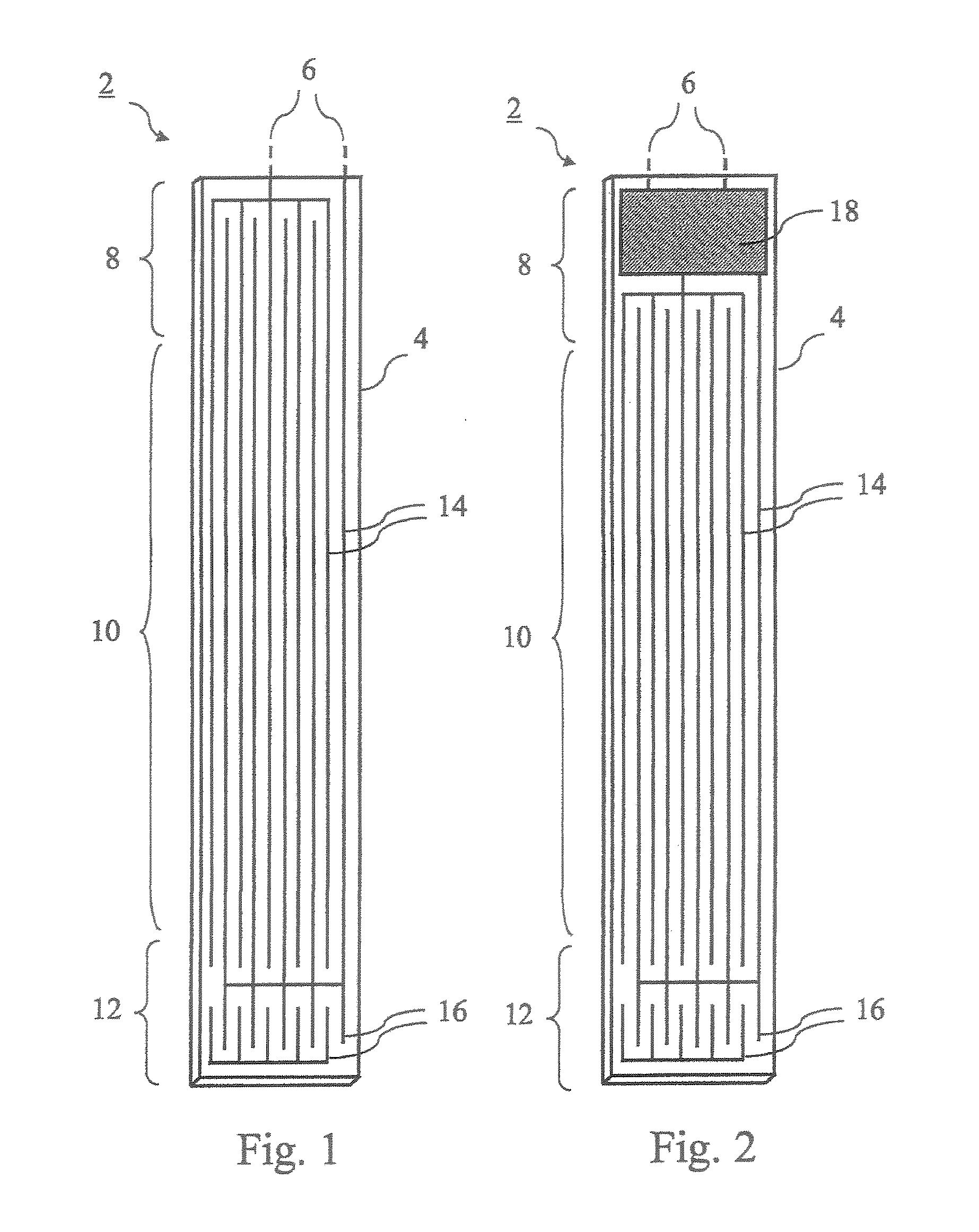

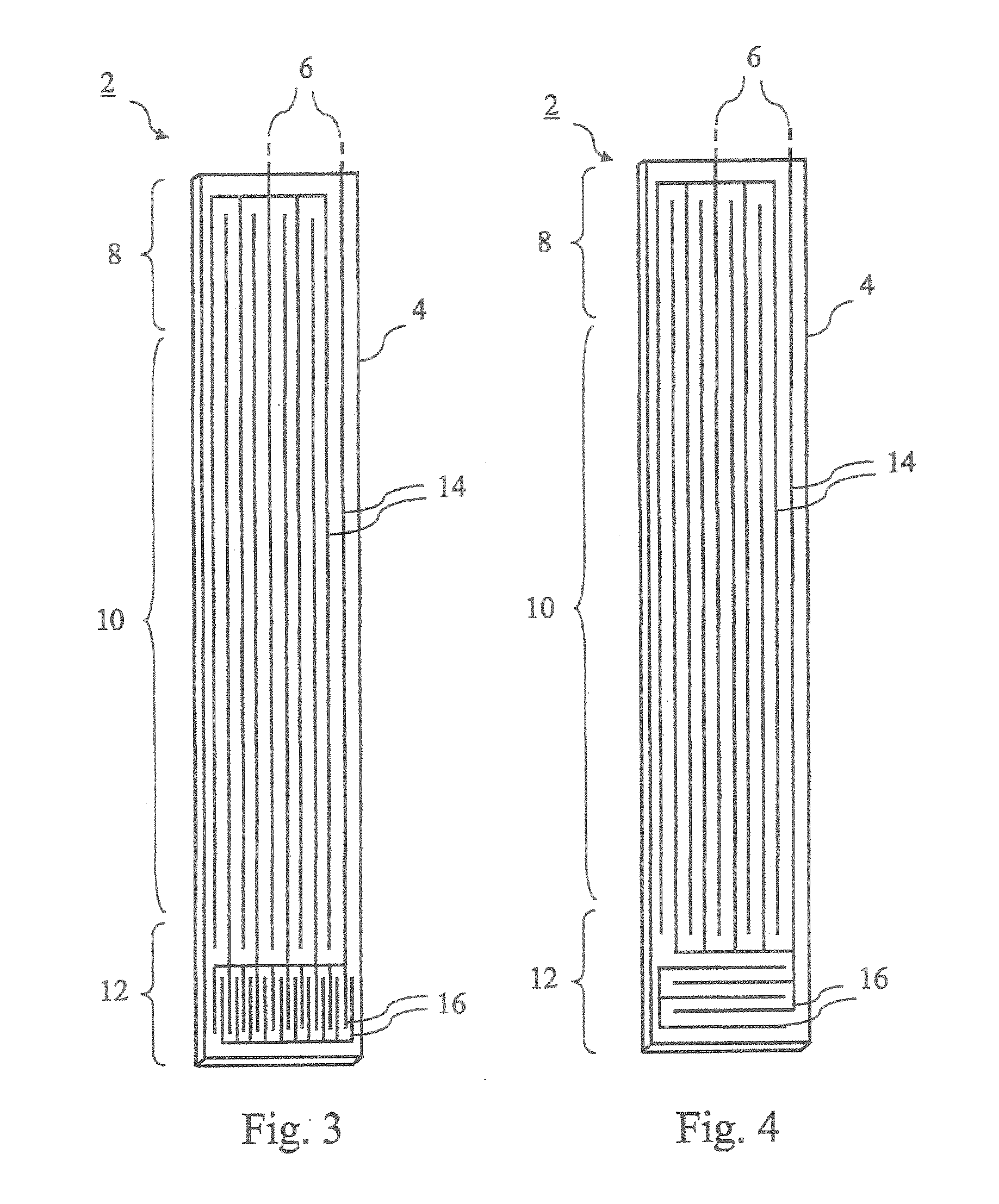

Capacitive liquid level sensor

InactiveUS20110120219A1Measurement accuracyEqual manufacturing costMachines/enginesLubrication indication devicesEngineeringCapacitance transducer

The invention relates to a capacitive sensor (2) for detecting the level (52) of a liquid (54) in a tank (48). The inventive sensor consists of: a flat longitudinal support (4) comprising proximal (8), central (10) and distal (12) parts and connection means (6) which are located in the proximal part (8) and which are used to connect the support (4) and the exterior of the support (4) electrically; a measuring pair (14) comprising interdigital arms which are disposed on the support (4) at least in the central part (10) thereof; and a reference pair (16) comprising interdigital arms which are disposed on the support (4) in the distal part (12) thereof. The aforementioned support (4) comprises at least three layers, and the reference pair (16) is linked to at least one connection track (26) which is located in an inner layer (24) of the support (4) and which is linked to the above-mentioned connection means (6). The invention also relates to a tank (48) comprising one such sensor (2).

Owner:INERGY AUTOMOTIVE SYST RES (SA)

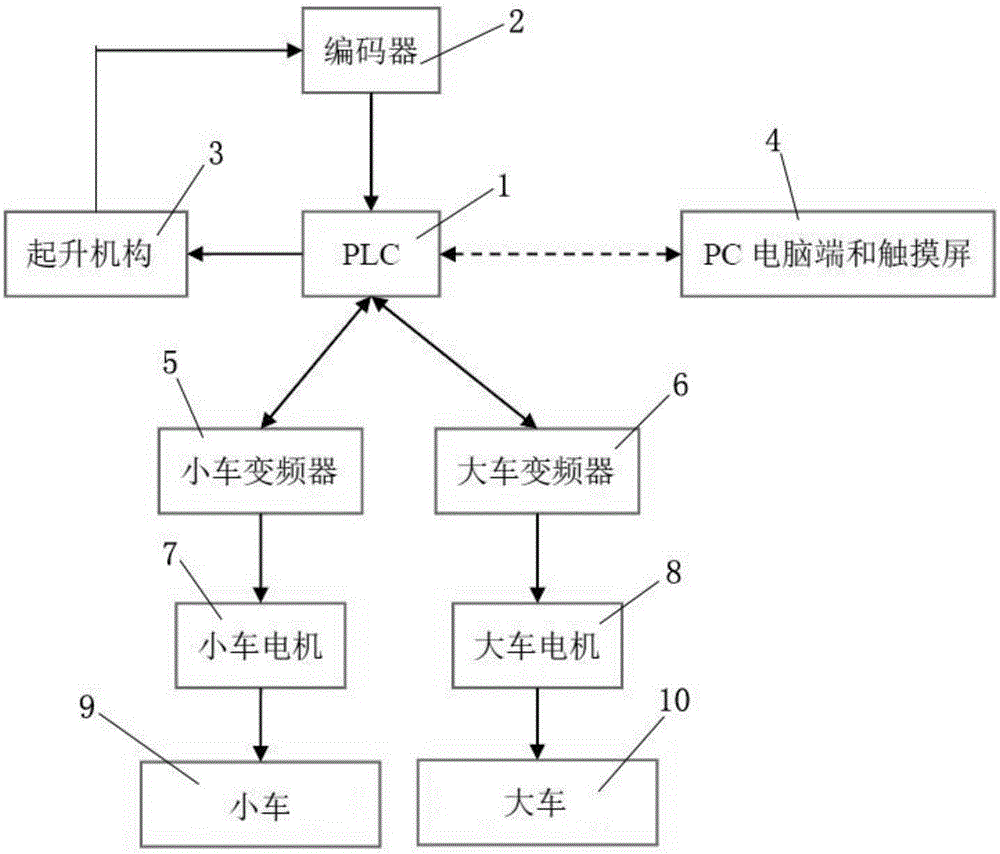

Intelligent anti-swing control method for multi-section uniformly-variable-speed crane

ActiveCN105883615AFully consider the use of securityImprove horizontal accuracyLoad-engaging elementsEngineeringLoad deflection

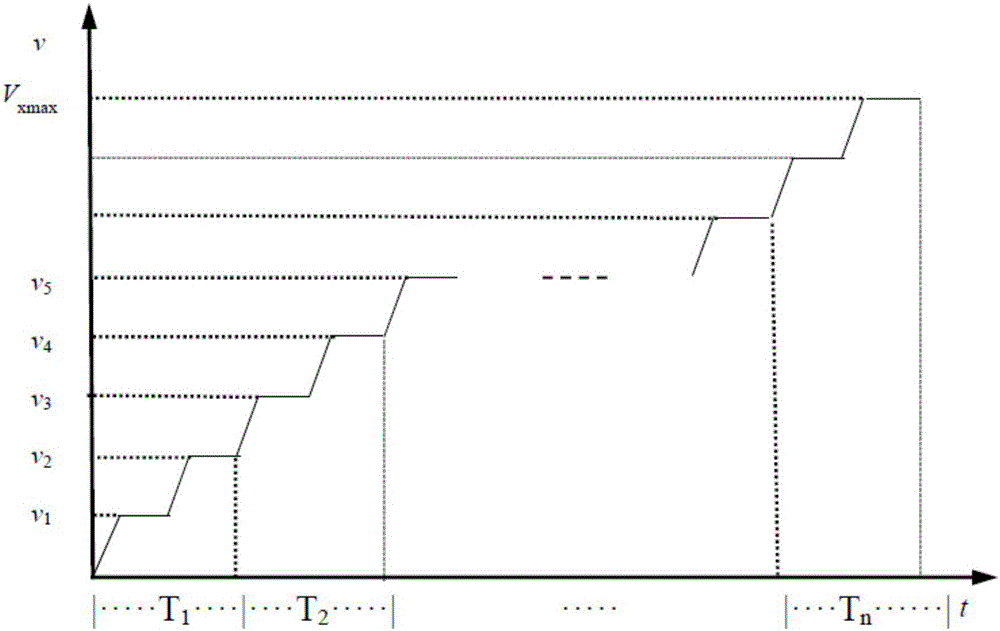

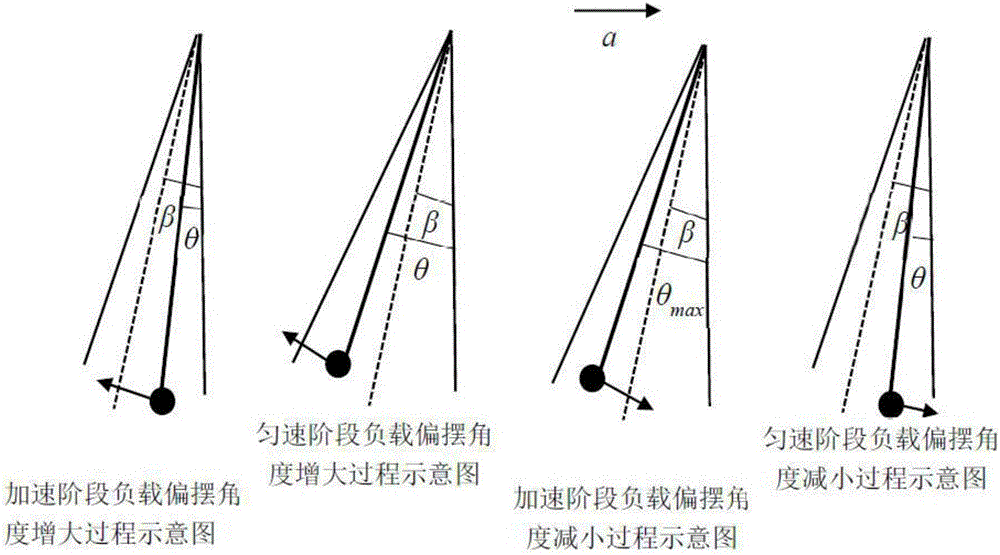

The invention discloses an intelligent anti-swing control method for a multi-section uniformly-variable-speed crane. The acceleration process of a running mechanism is divided into multiple sections of the uniform acceleration processes or the deceleration process of the running mechanism is divided into multiple sections of the uniform deceleration processes by taking the preset maximum allowable load swing amplitude and the lifting rope length as input variables on the basis of the system dynamics analysis rule of the crane through the input shaping principle of a two-order oscillation system according to the load deflection cycle, and load deflection is finally inhibited by controlling running of the running mechanism; meanwhile, multiple sections of the uniformly variable speed processes are optimized through an interpolation method. According to the method, by taking the maximum allowable load swing amplitude as the input variable, the safety of the crane in the running process is fully taken into account, the precision is controlled, and the safety and the working efficiency of the crane are significantly improved.

Owner:SHANDONG ZHONGYANG MACHINERY CO LTD +1

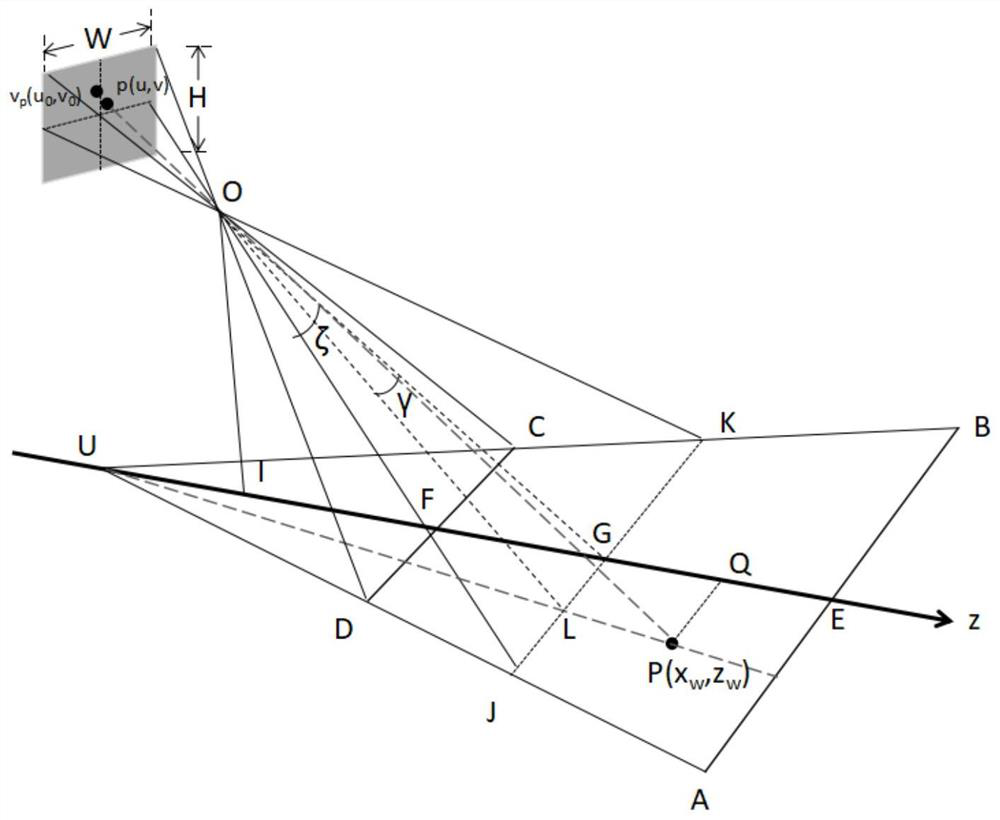

Vehicle-mounted camera automatic calibration method and device, and readable storage medium

ActiveCN111696160AAvoid errorsImprove stabilityImage analysisInternal combustion piston enginesReference sampleComputer graphics (images)

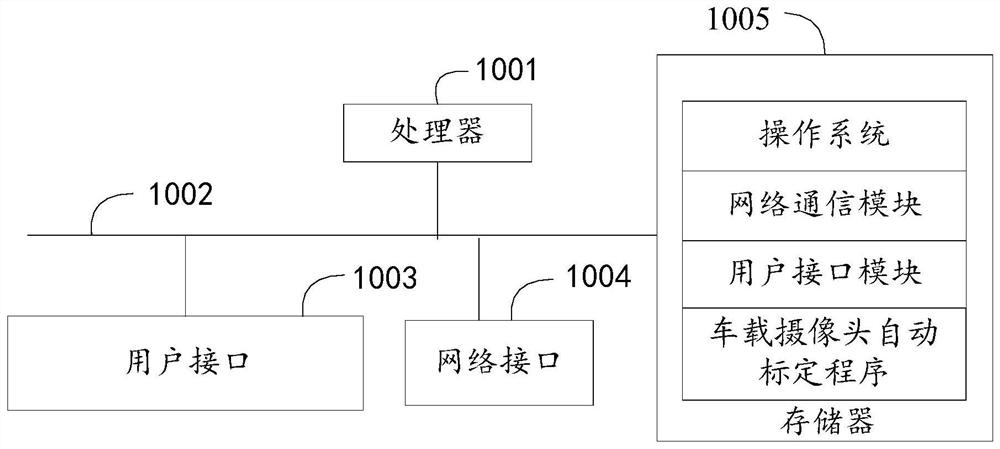

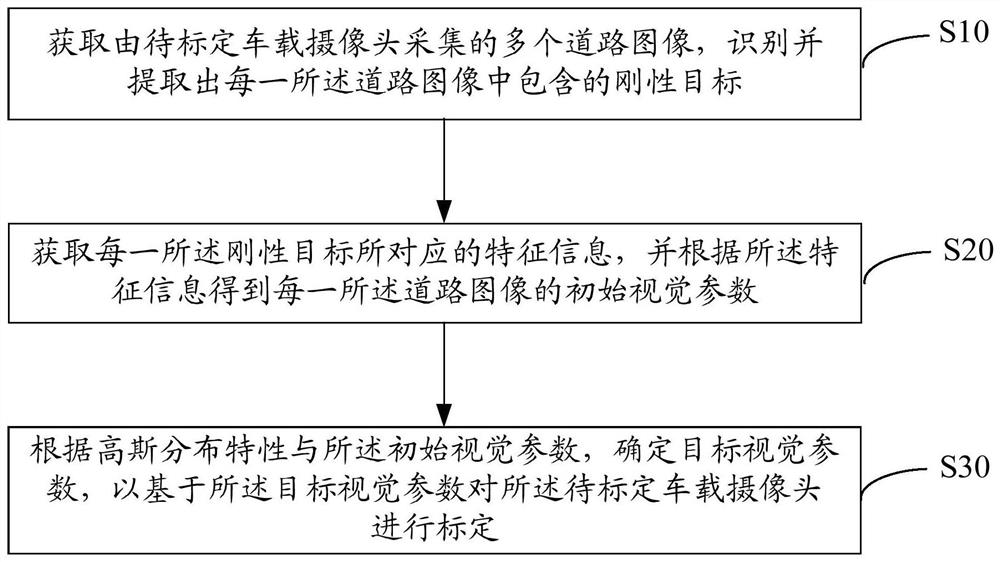

The invention discloses a vehicle-mounted camera automatic calibration method and device, and a readable storage medium. According to the vehicle-mounted camera automatic calibration method, rigid targets in a plurality of road images acquired by the vehicle-mounted camera to be calibrated are identified, so that relatively large errors caused by taking changeable flexible targets such as a humanbody in the images as a calibration basis to a calibration result are avoided, and the stability and the precision level of a calibration process are improved; the method comprises the following steps: acquiring initial visual parameters of a plurality of road images so as to obtain a plurality of reference sample data; and determining the target visual parameter with the maximum possibility through the Gaussian distribution characteristics and the plurality of initial visual parameters to calibrate the vehicle-mounted camera, so that the calibration precision is improved. Besides, compared with the prior art, the method has the advantages that full-automatic calibration can be carried out without any external manual assistance, professional technical support is not needed, the calibrationdifficulty is greatly reduced, and the method has wide adaptability and advancement.

Owner:SHENZHEN ZHONGTIAN ANCHI CO LTD

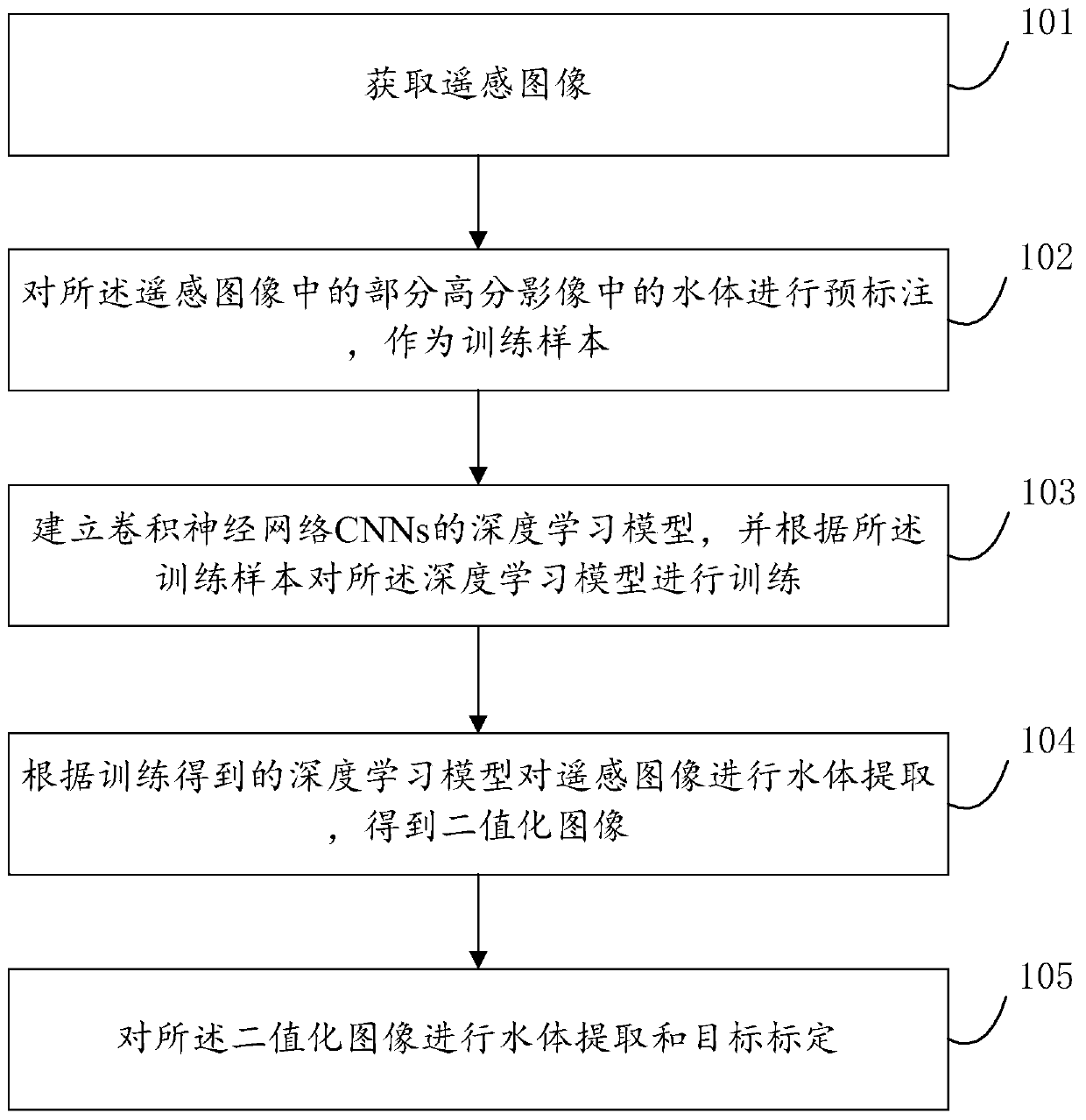

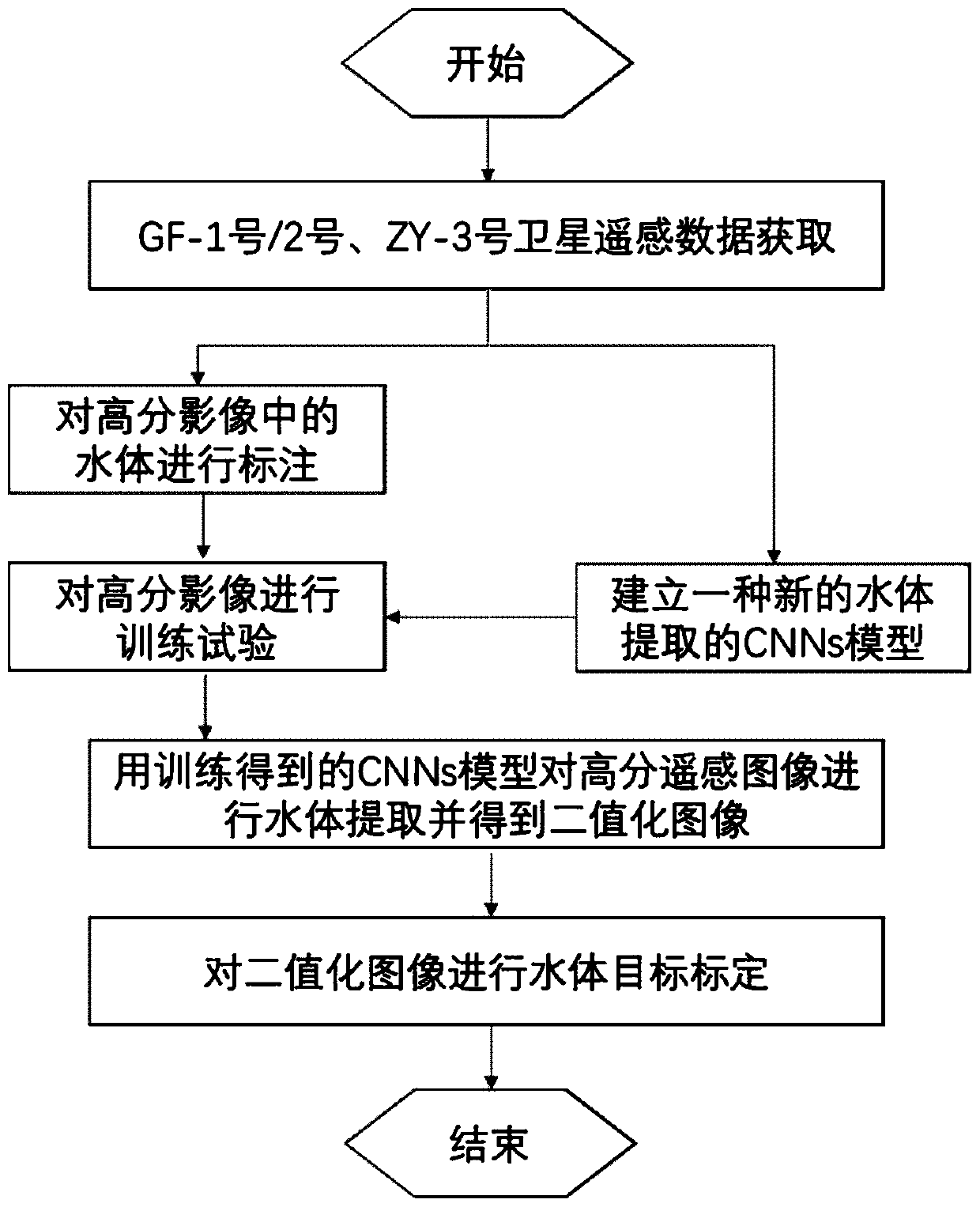

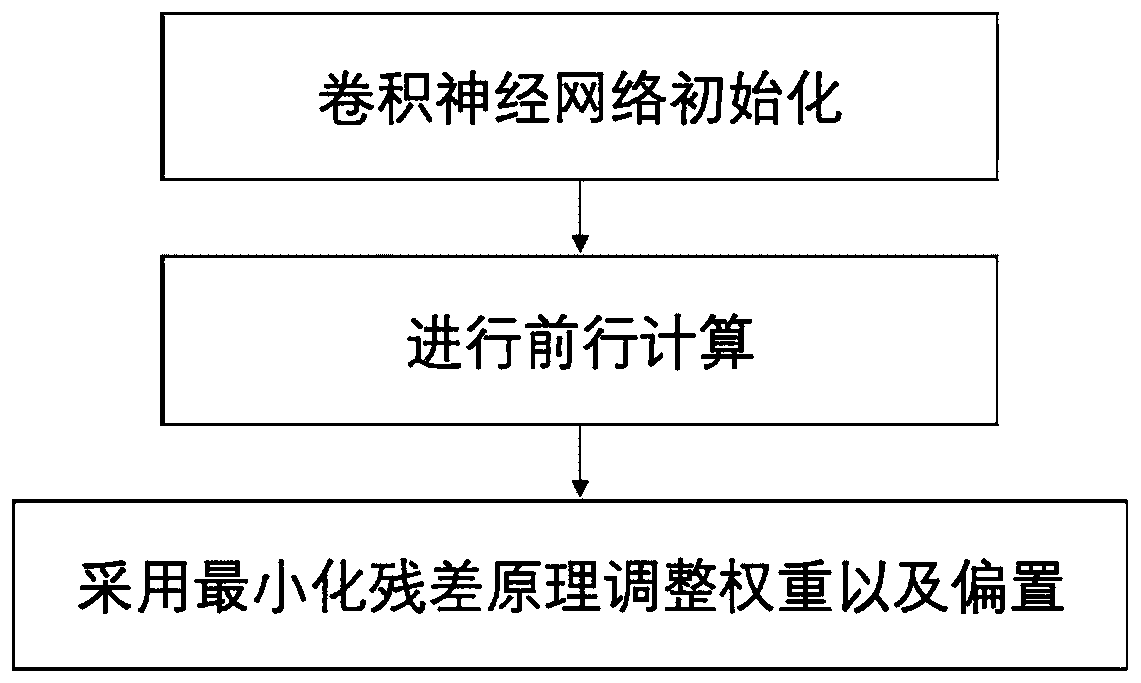

A remote sensing image water body extraction method and system based on deep learning

InactiveCN109934095AImprove intelligenceImprove horizontal accuracyCharacter and pattern recognitionNeural architecturesSatellite imageryComputer science

The invention discloses a remote sensing image water body extraction method and system based on deep learning. By utilizing China's high score-No.1 / No.2 (GF-1 / GF-2) and resource-No.3 (ZY-3) satelliteimages and two kinds of deep learning convolution neural networks (CNNs) of U-net and Densenet, a novel CNNs model for extracting water bodies is provided. By labeling water bodies in a large number of high-resolution remote sensing images, obtaining water body labeling results in the images to serve as a training set; Carrying out a training test on the high-resolution remote sensing image by using the established CNNs model to obtain a binary image of the water body; And identifying the pixel value identified in the binary image to obtain the water body target. According to the method, the water body information in the high-resolution remote sensing image can be quickly extracted in a high-precision and automatic manner, the intelligence, automation level and extraction precision of water body extraction are improved, and the method can be widely applied to various fields related to water body extraction.

Owner:中交信息技术国家工程实验室有限公司

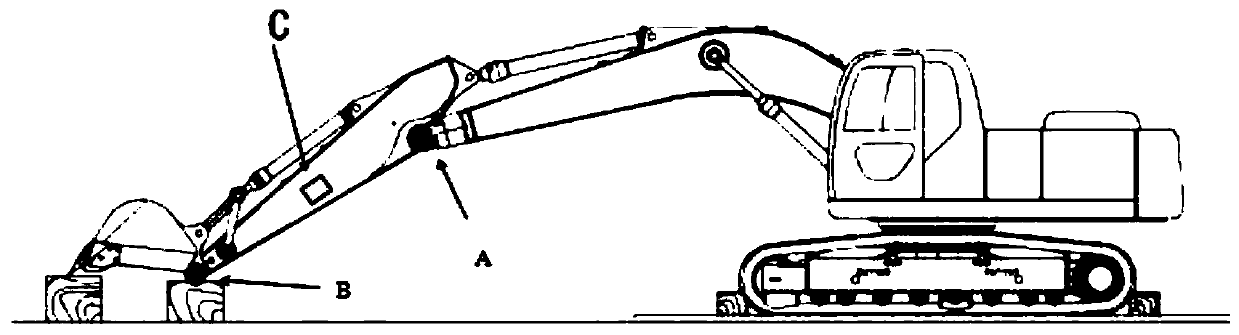

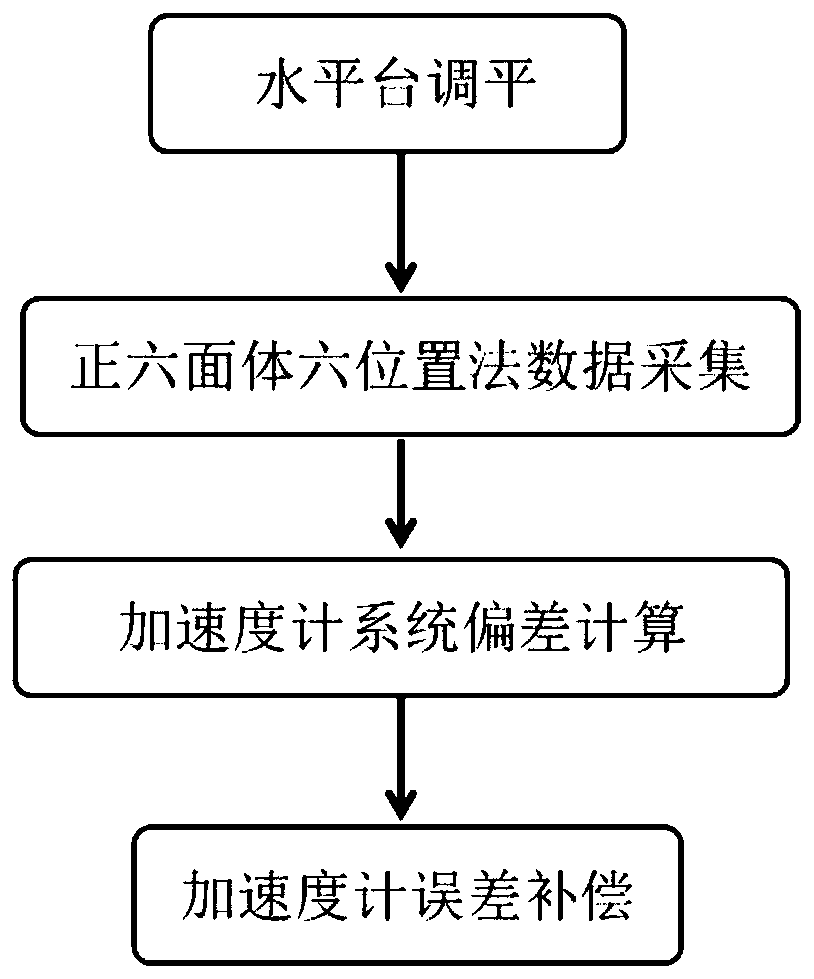

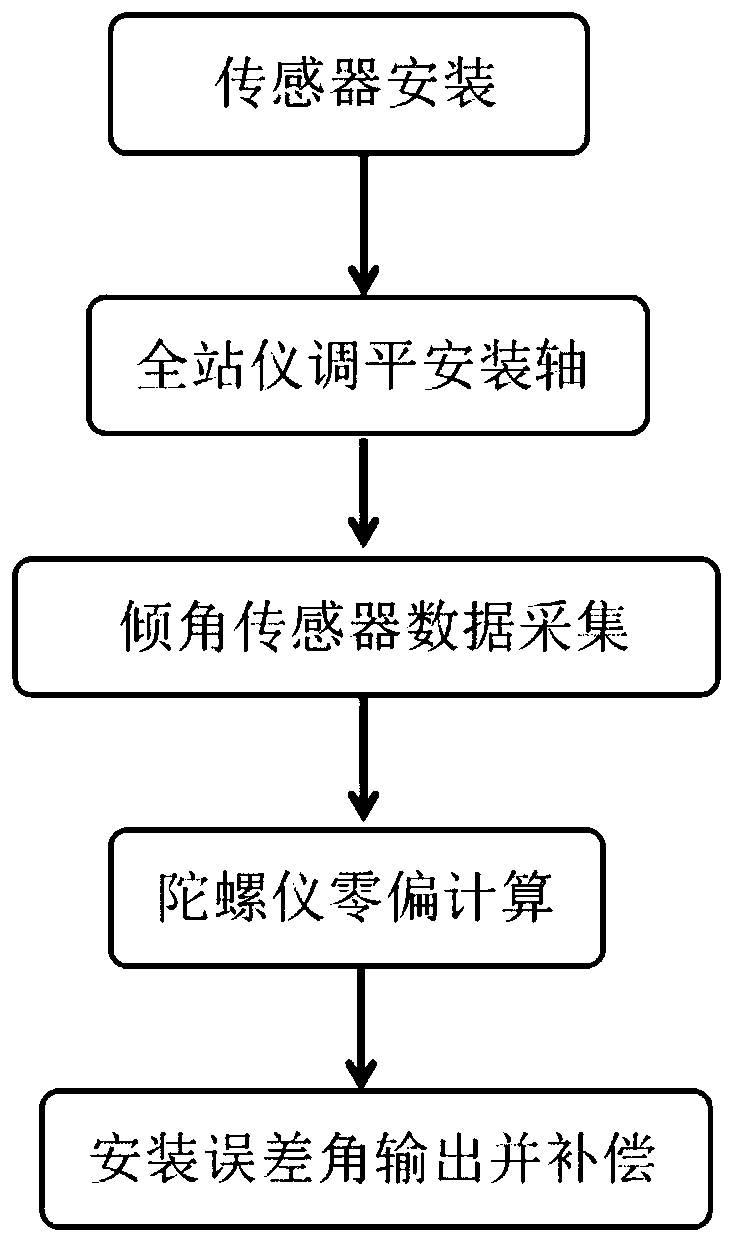

Method of calibrating error of engineering machinery attitude sensor system

The invention relates to a method of calibrating an error of an engineering machinery attitude sensor system, including factory calibration of sensors and calibration of field installation errors. Take a small arm of an excavator as an example. A connection rotary axis of the small arm and a large arm is controlled by combining a total station, and the connection rotary axis and a connection rotary axis of the small arm and bucket are kept in the same horizontal plane, and then an angle output by a small arm sensor is an installation error angle of a small arm angle of inclination sensor. In the method, the high-precision total station provides the horizontal plane; the installed shaft is leveled; the total station can automatically detect an error of a dial system and then correct the error, so as to guarantee the precision of the horizontal plane and improves installation error calibration precision. Compared with the existing commonly used installation error calibration solution, the method has advantages of making installation fasts, using the total station with high level accuracy, and improving field calibration accuracy and efficiency of the sensor installation error.

Owner:SHANGHAI HUACE NAVIGATION TECH

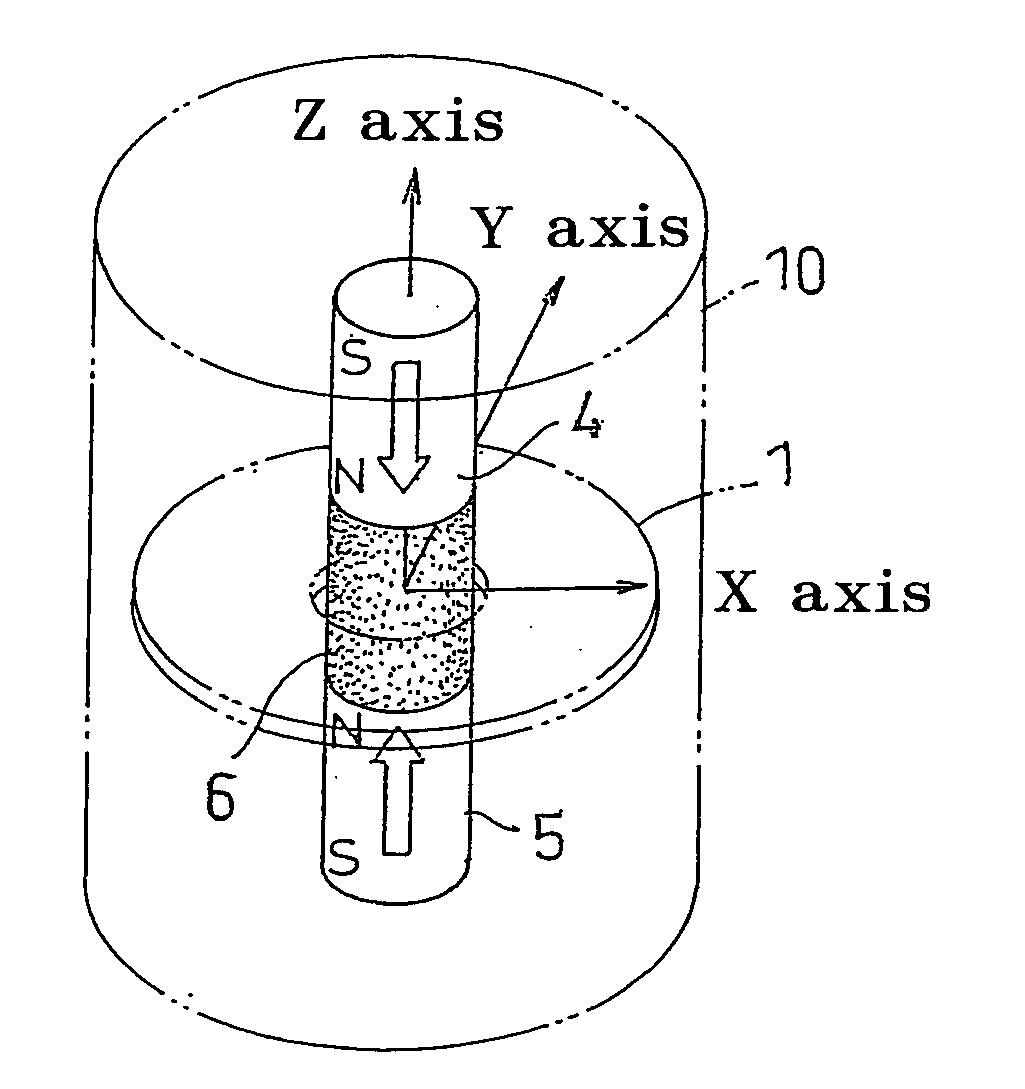

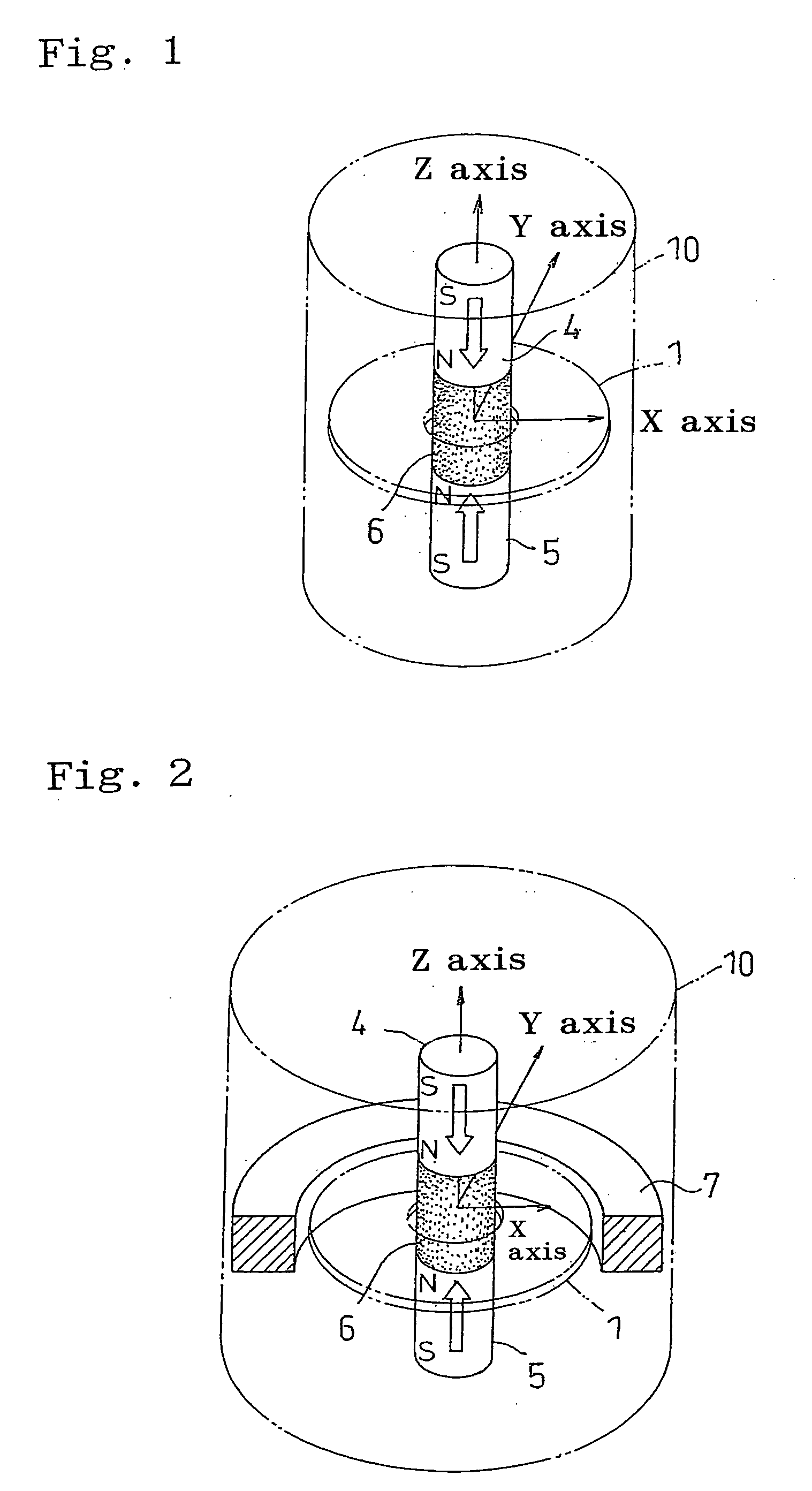

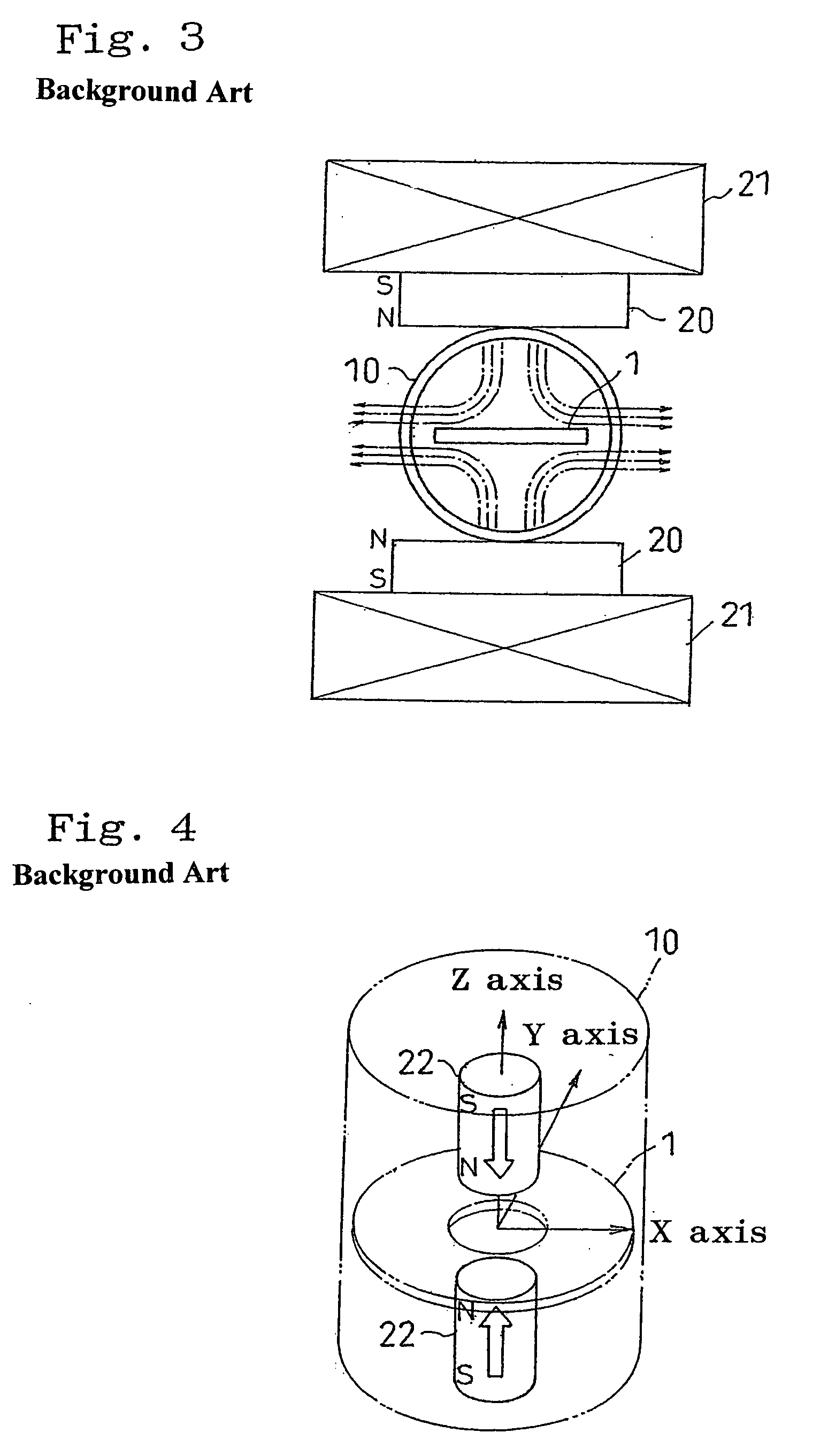

In-magnetic-field heat-treating device

InactiveUS20060082035A1Improve propertiesImprove horizontal accuracyMagnetic field orientationFurnace typesHeat treatedRecording media

A magnetic annealing device for inserting a recording medium 1 provided with an axial hole formed at a center thereof and having a disk shape into a chamber 10 and applying a heat treatment to the recording medium 1 in a magnetic field is provided with a magnetic circuit for forming a magnetic field in the chamber 10, the magnetic circuit comprises a pair of magnets 4 and 5 disposed with a distance therebetween along an axial direction of the axial hole and having magnetic fields directionally opposed to each other and a first ferromagnetic substance 6 disposed between the pair of magnets 4 and 5, wherein the recording medium 1 to be heat-treated is disposed at an intermediate position between the pair of magnets 4 and 5 facing each other in the state in which the first ferromagnetic substance 6 is inserted into the axial hole. A second ferromagnetic substance 7 having a ring shape is preferably disposed in a periphery of the recording medium 1.

Owner:HITACHI METALS LTD +1

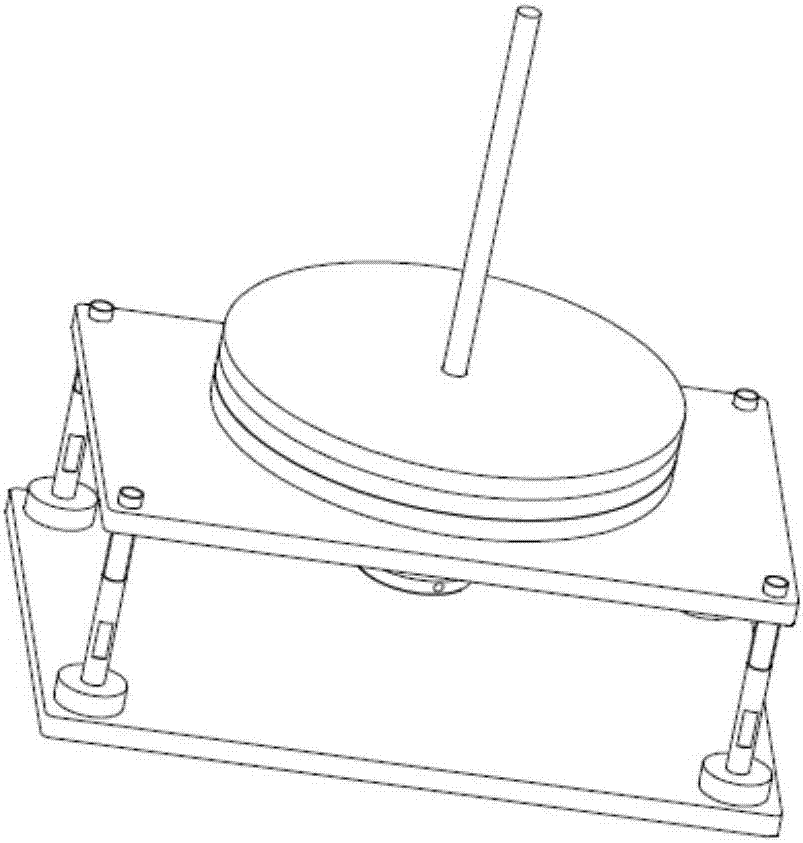

Knob type horizontal workbench

The invention provides a knob type horizontal workbench which is used in industrial production or experimental process to provide an excellent horizontal working plane. The knob type horizontal workbench consists of a workbench surface, horizontal tubes, screw rods, knobs and bottom pins, wherein the workbench surface is a flat rectangular solid with excellent flatness, and is grinded by stainless steel; four sides of the workbench surface are provided with a horizontal tube respectively; the horizontal tubes are horizontally embedded into the sides of the workbench surface, and the length of the horizontal tube is half long side of the rectangular shape of the side; the horizontal tubes are made or organic glass, are filled with water, and a bubble is reserved in each horizontal tube respectively; the four bubbles are in positions of center scale of the horizontal tubes when the plane is completely horizontal, and four completely same precise screw rods are fixed under the workbench surface, fine screws are formed on the precise screw rods, and the lower side of each screw rod extends into a sleeve type bottom pin through a screw knob; a corner of the workbench surface can be effectively lifted by rotating the knob, the size of each part of the horizontal workbench is determined according to particular use condition; and when working, the horizontal workbench is placed on the plane, and the bubbles in the four horizontal tubes are in the positions of the center scale by rotating the knobs above the four bottom pins, so that the workbench surface is in an accurate horizontal state. The knob type horizontal workbench can provide an excellent horizontal working surface, is convenient to adjust, and has high horizontal accuracy.

Owner:费金华

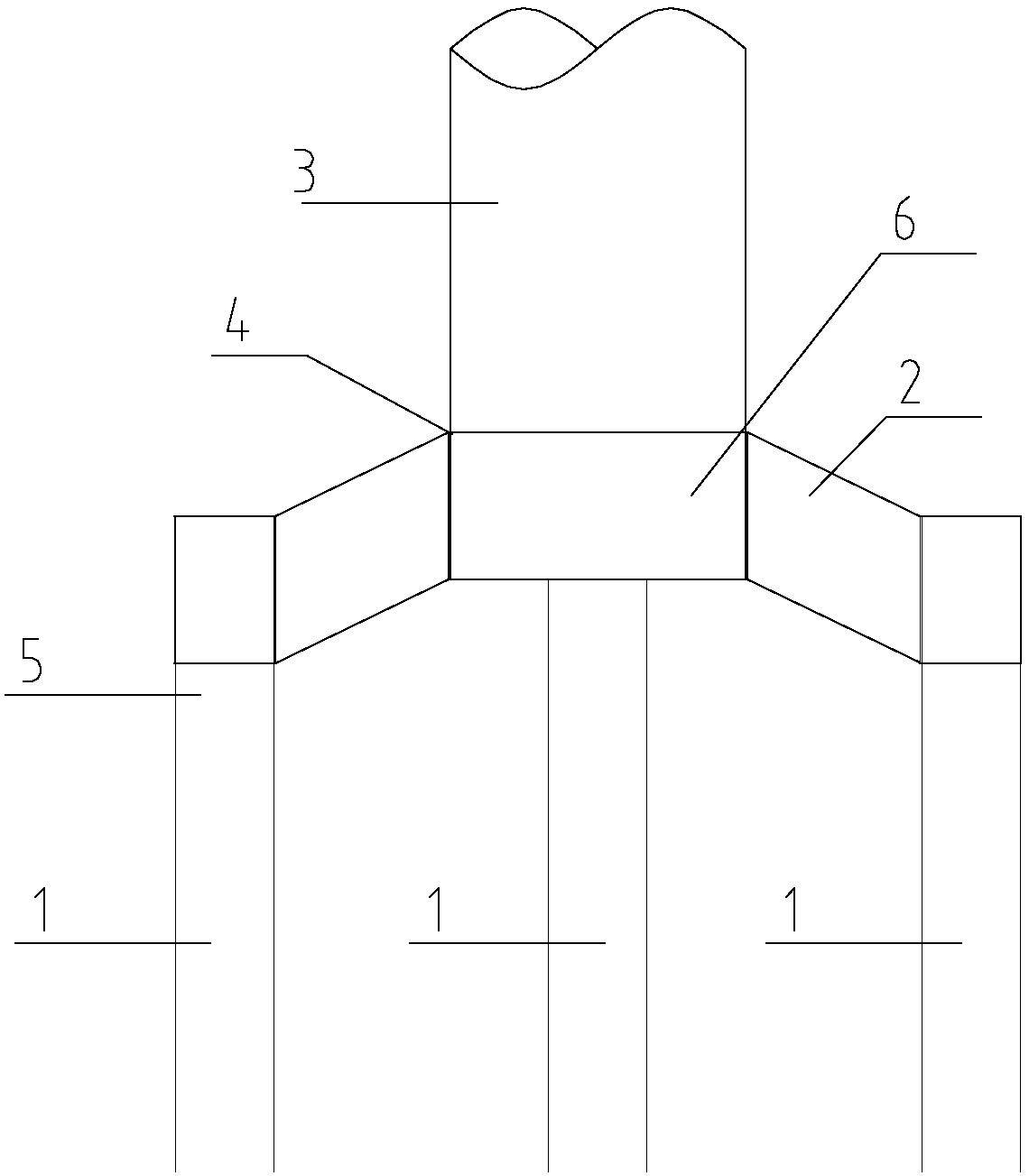

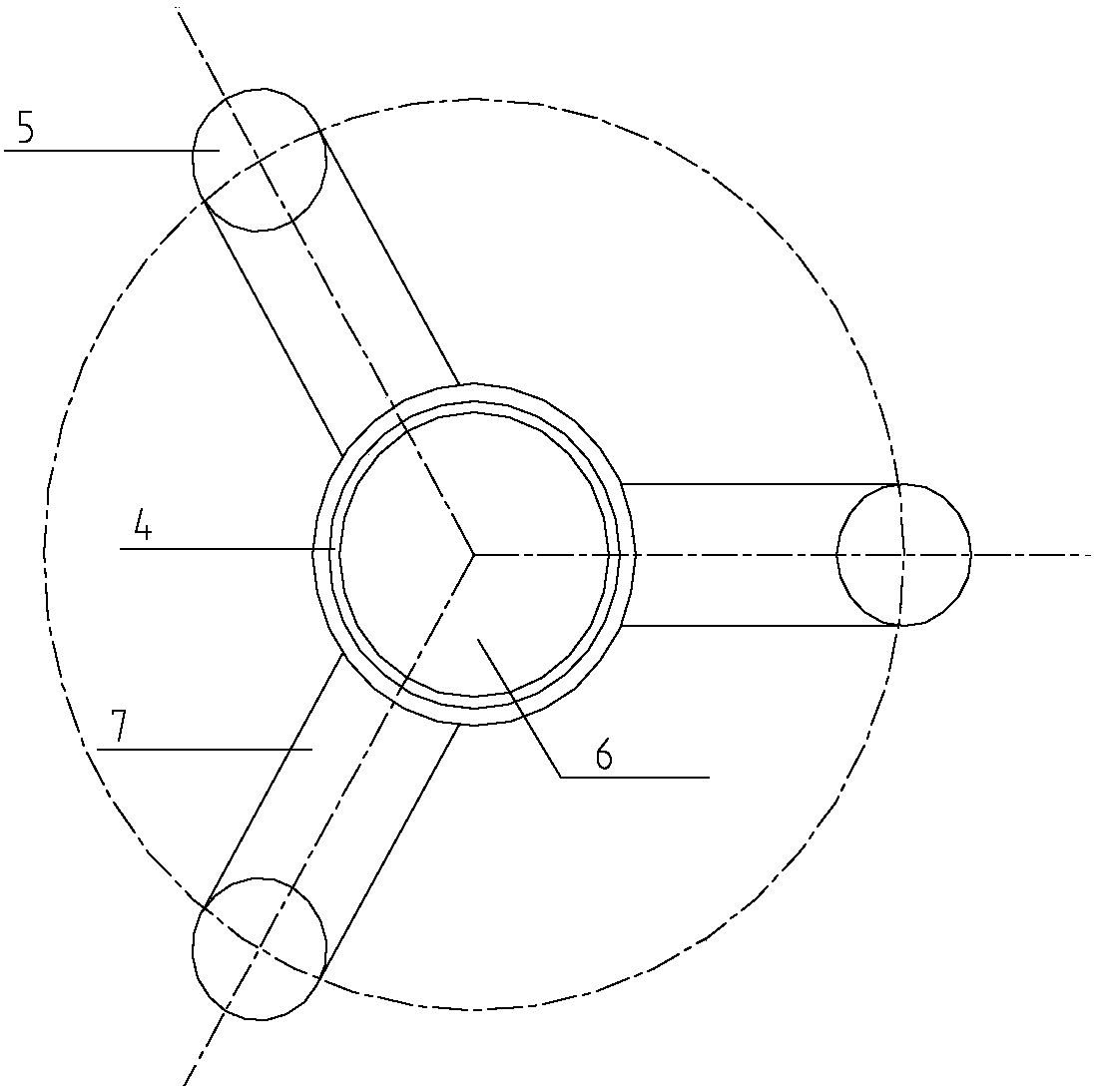

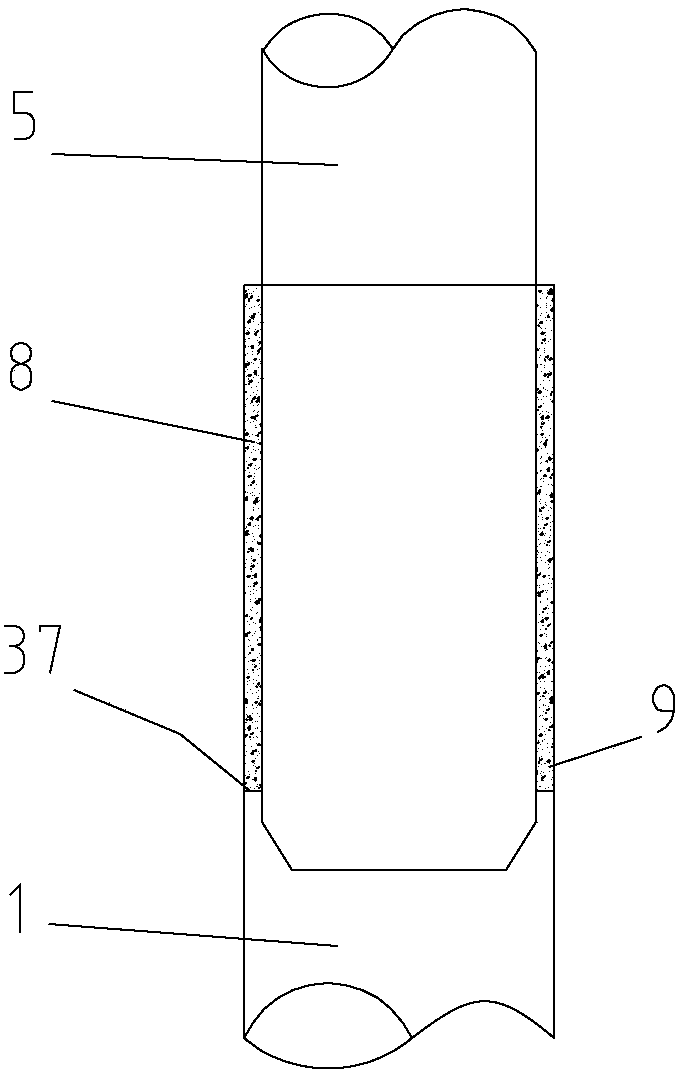

Pile cap foundation for offshore wind turbine and construction method thereof

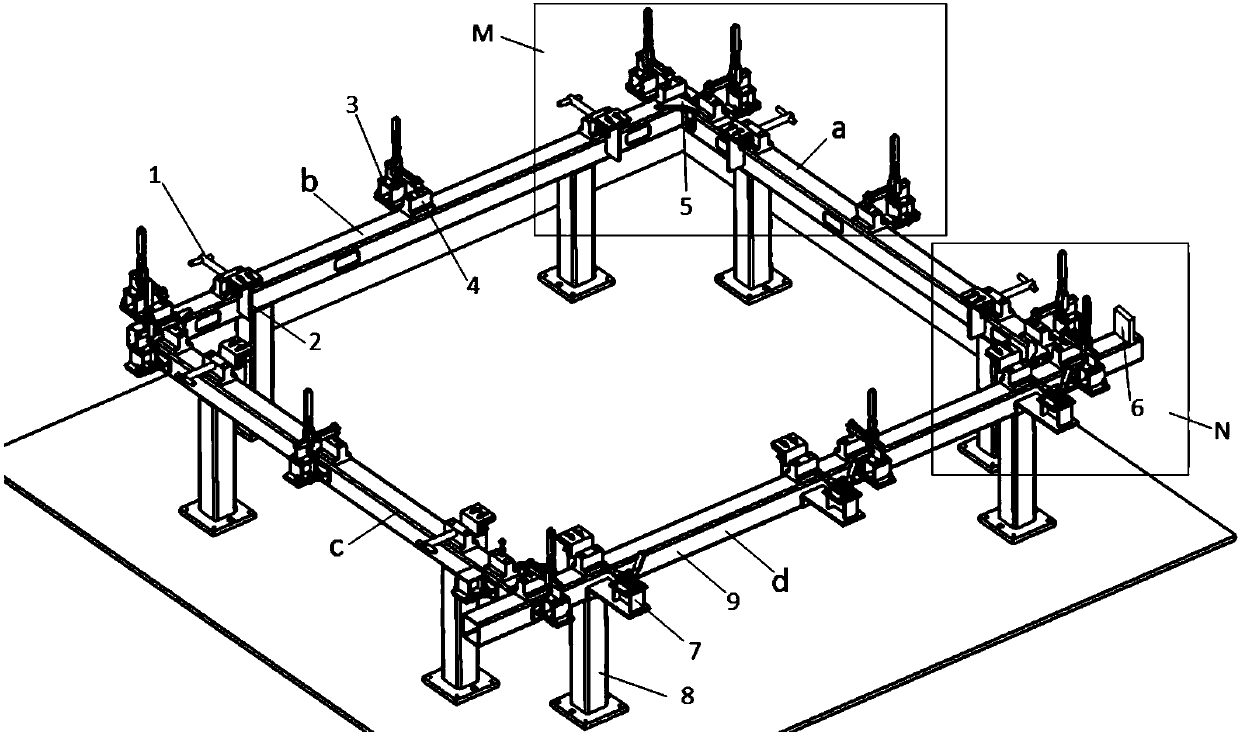

PendingCN108571425AHigh precision requirementsImprove horizontal accuracyWind motor assemblyWind motor supports/mountsPile capTurbine

The invention discloses a pile cap foundation for an offshore wind turbine. The pile cap foundation comprises a steel pipe pile and a steel pile cap, wherein a steel pile cap pile leg is arranged at aposition, which is arranged at one end of a steel box girder, of the steel pile cap; the steel pile cap pile leg sleeves in the steel pipe pile; the steel pipe pile is used for positioning a driven pile by adopting a positioning formwork; the positioning formwork comprises a truss supporting pile, a positioning truss and a double-layer steel sleeve; the positioning truss and the truss supportingpile are connected together by virtue of the double-layer steel sleeve; a closure gap used for containing the steel pipe pile is formed in the center of an outer end of each branch part of the positioning truss; upper and lower layers of pile hoops are at least arranged at each closure gap; the steel pipe pile is fixedly held by the pile hoops; and a grouting material is filled into an annular clearance at the connecting part of the steel pipe pile and the steel pile cap pile leg, so that the steel pipe pile and the steel pile cap pile leg are connected to form a whole. The steel pipe pile andthe steel pile cap can be made in a steel structure processing plant in advance, only operations of piling, mounting and grouting need to be performed in the offshore construction site, and the offshore operation volume is greatly reduced.

Owner:CCCC FOURTH HARBOR ENG CO LTD

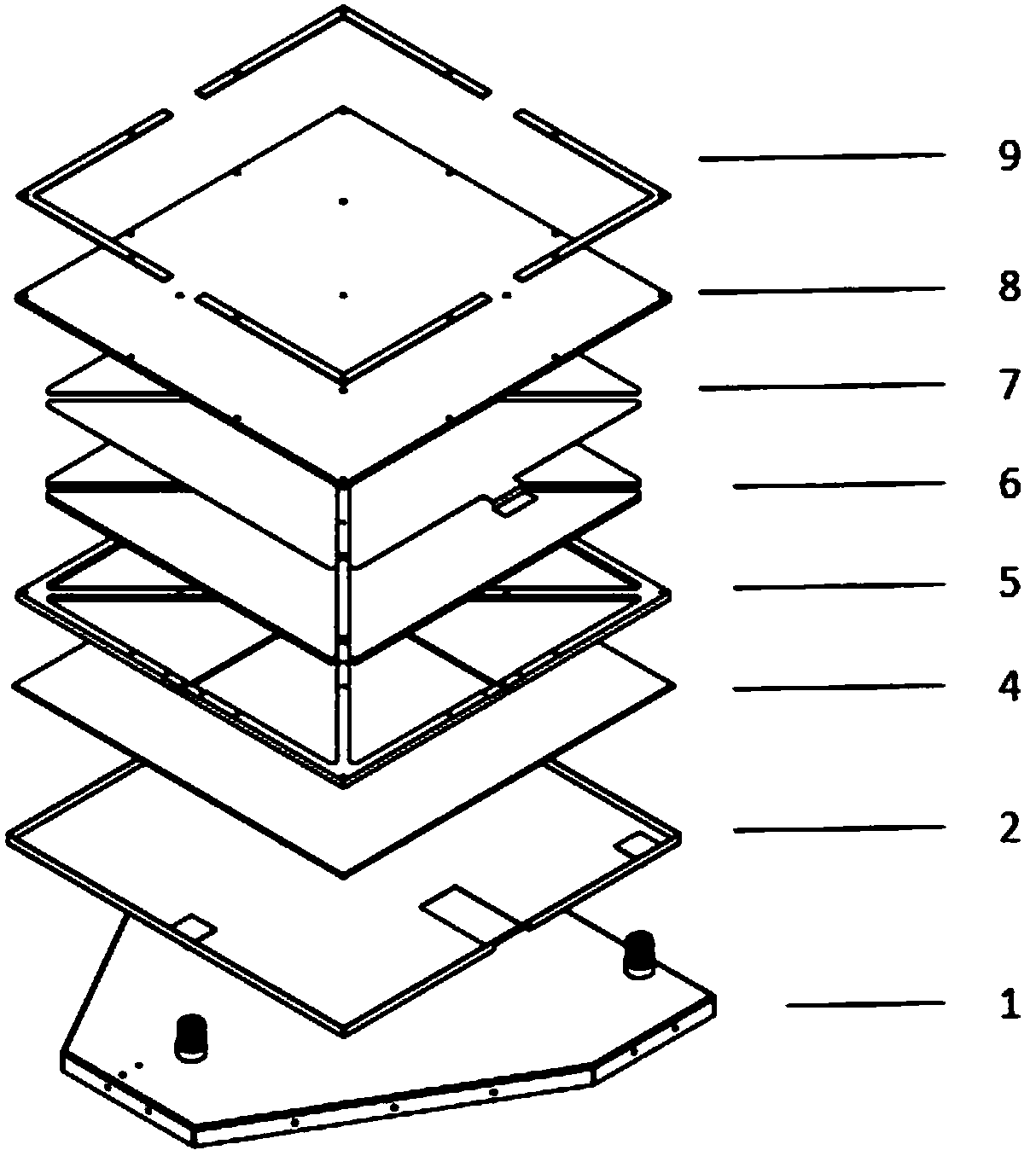

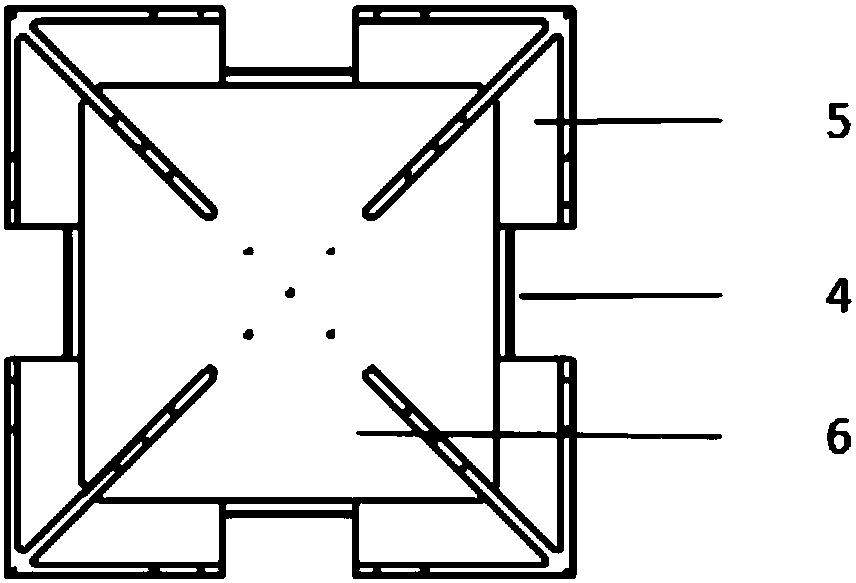

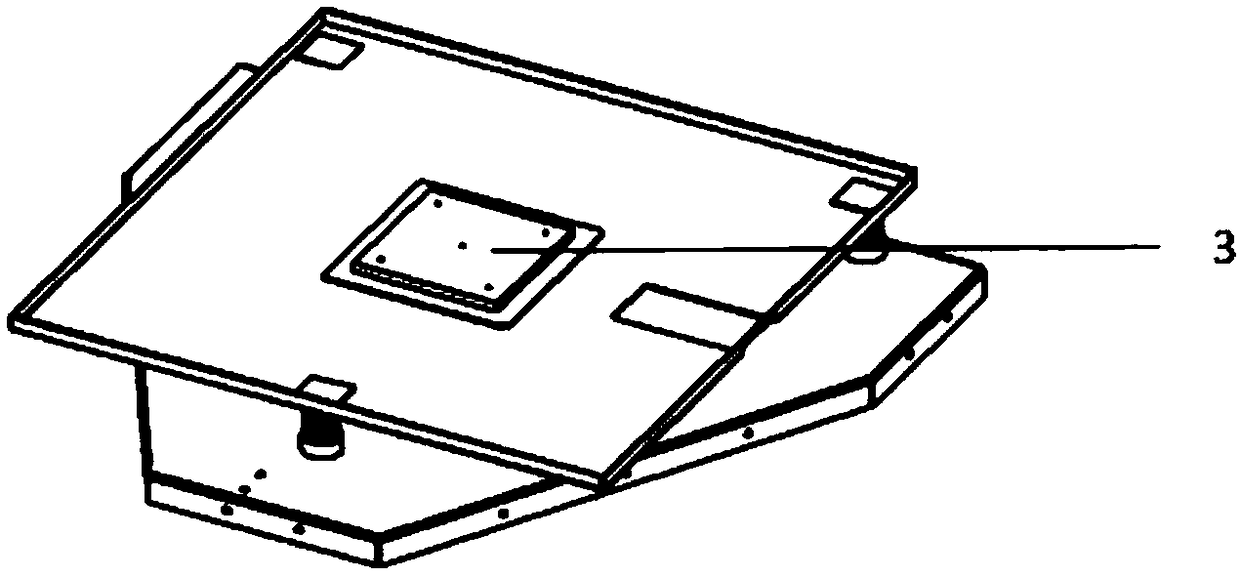

Self-adaption platform for high-temperature 3D printing

ActiveCN108284594AImprove scalabilityImprove horizontal accuracyManufacturing platforms/substrates3D object support structuresEngineeringSelf adaptive

The invention belongs to the technical field of 3D printing, and discloses a self-adaption platform for high-temperature 3D printing. The self-adaption platform comprises a support plate, a platform substrate, a glass plate, movable blocks, a rail plate, a heating film and a molding plate; the platform substrate is connected with the support plate, and a spring is arranged between the two for adjusting levelness of the platform substrate; the glass plate is used as a horizontal reference of the self-adaption platform; four movable blocks are provided; each diagonal line is provided with a convex edge; the rail plate is provided with rails cooperating with the convex edges; the convex edges move along the rails to realize outward translation unfolding of the movable blocks; the molding plate is fixedly connected with the rail plate, and the heating film is arranged between the two for heating the molding plate; and after the molding plate is heated to expand, the movable blocks realizeself-adaption outward translation unfolding to shift the molding plate for outward expansion to prevent local bulge deformation of the molding plate. The heated self-adaption unfolding of the self-adaption platform is realized; the local internal bulge or warpup problem of the molding plate is solved; and the molding precision is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

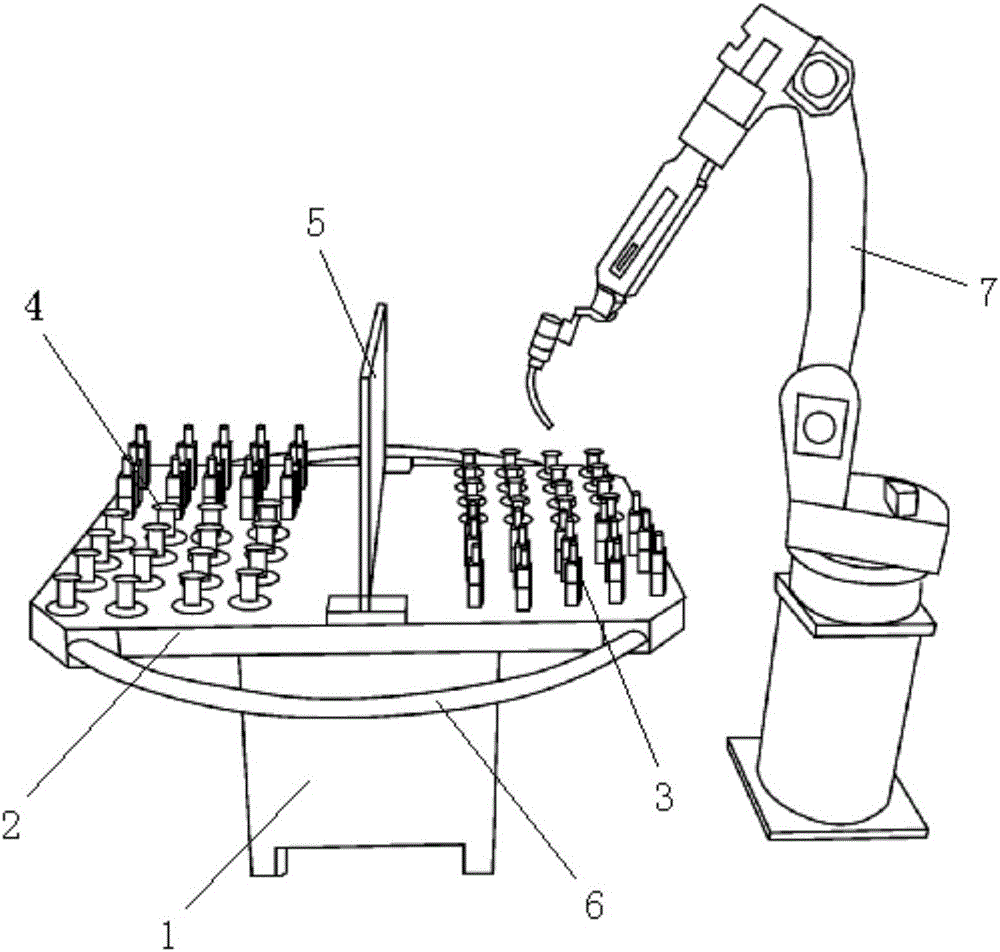

Keel welding production line and welding rotating device thereof

InactiveCN105728999ARealize automatic rotationRealize automatic controlWelding/cutting auxillary devicesAuxillary welding devicesProduction lineRotary stage

The invention discloses a keel welding production line and a welding rotating device thereof. The welding rotating device comprises a base, and a rotating table rotationally connected with the base through a rotating shaft; the rotating table is provided with a first welding spot set and a second welding spot set; the lower end surface of the base is slidingly connected with a line body of the production line through a slide block; and the rotating shaft is arranged in the vertical direction, the top end thereof is fixedly connected with the rotating table, and the outer peripheral direction thereof is rotationally connected with the base through a bearing. The welding rotating device further comprises a power element; and the rotating table rotates by 180 degrees in the horizontal plane around the rotating shaft under the effect of the power element. The welding rotating device can realize automatic rotation of the rotating table, so that the production efficiency is improved, the production takt is guaranteed, and the labor intensity of workers is reduced.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

3D printer supporting platform with polishing mechanism

InactiveCN107379544AImprove horizontal accuracyIncrease productivityManufacturing platforms/substratesManufacturing auxillary operationsEngineering3d printer

The invention discloses a 3D printer supporting platform with a polishing mechanism. The 3D printer supporting platform with the polishing mechanism comprises a base, a supporting platform body and an unloading box, wherein the output ends of electric lifting supporting rods are fixedly connected with the supporting platform body above the base; a cavity is formed in the center of the top of the supporting platform body; a rotary motor is installed in the center of the bottom of the supporting platform body through a bolt; an output shaft of the rotary motor extends into the cavity and is fixedly connected with a supporting board; the unloading box is arranged on the supporting board; cylinders are installed at four corners of the top of the supporting platform body; grooves are formed in the middles of the two sides of the top of the supporting platform body; polishing machines are arranged inside the grooves; auxiliary unloading boards are fixed to the two ends of the top of the supporting platform body; and rollers are evenly installed on the inner sides of the auxiliary unloading boards. As the grooves are formed in the two sides of the top of the supporting platform body and the polishing machines are arranged inside the grooves, after molding is finished, the polishing procedure is started directly, and the production efficiency is improved.

Owner:江苏天泽教育咨询有限公司

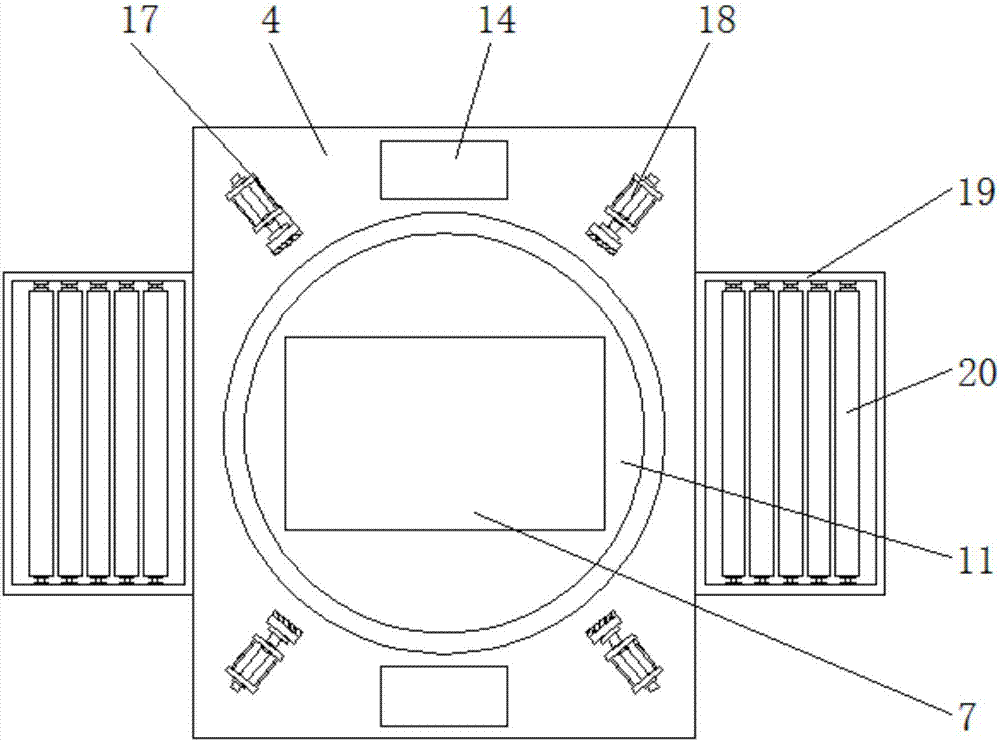

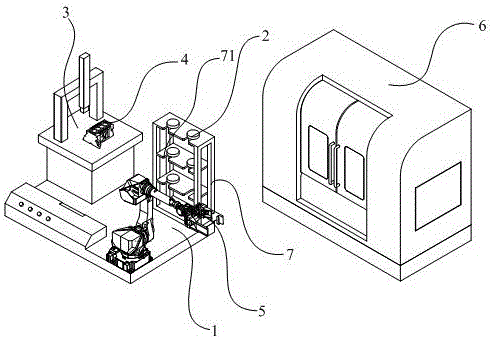

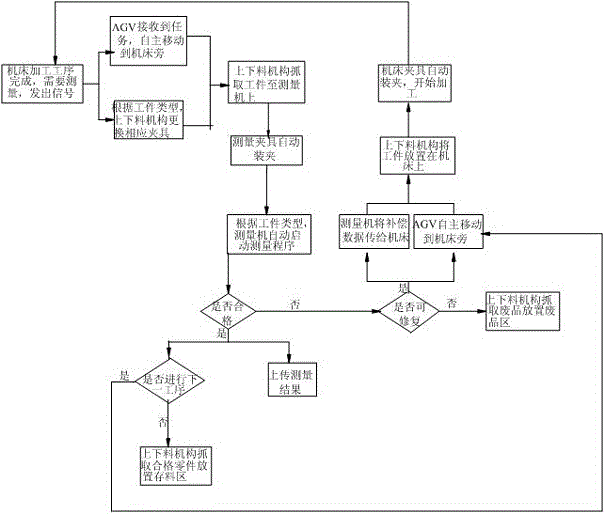

Real-time online measurement device and method thereof

InactiveCN106525116AReal-time analysis of machining errorsReduce measurement errorMeasurement devicesObservational errorMeasurement device

The invention provides a real-time online measurement device comprising a controller, an AGV navigation trolley, a set of clamp, a measuring machine and a material feeding and discharging mechanism capable of replacing the clamp and grabbing a workpiece. The measuring machine and the material feeding and discharging mechanism are arranged on the AGV navigation trolley. The controller is connected with the AGV navigation trolley, the material feeding and discharging mechanism and the measuring machine in a communication manner. The problems of high measurement error, high rejection rate, high cost, low processing efficiency and requiring artificial participation due to the fact that the quality of the processing workpiece cannot be monitored online in real time in workpiece measurement in the prior art can be solved.

Owner:HEXAGON METROLOGY QINGDAO

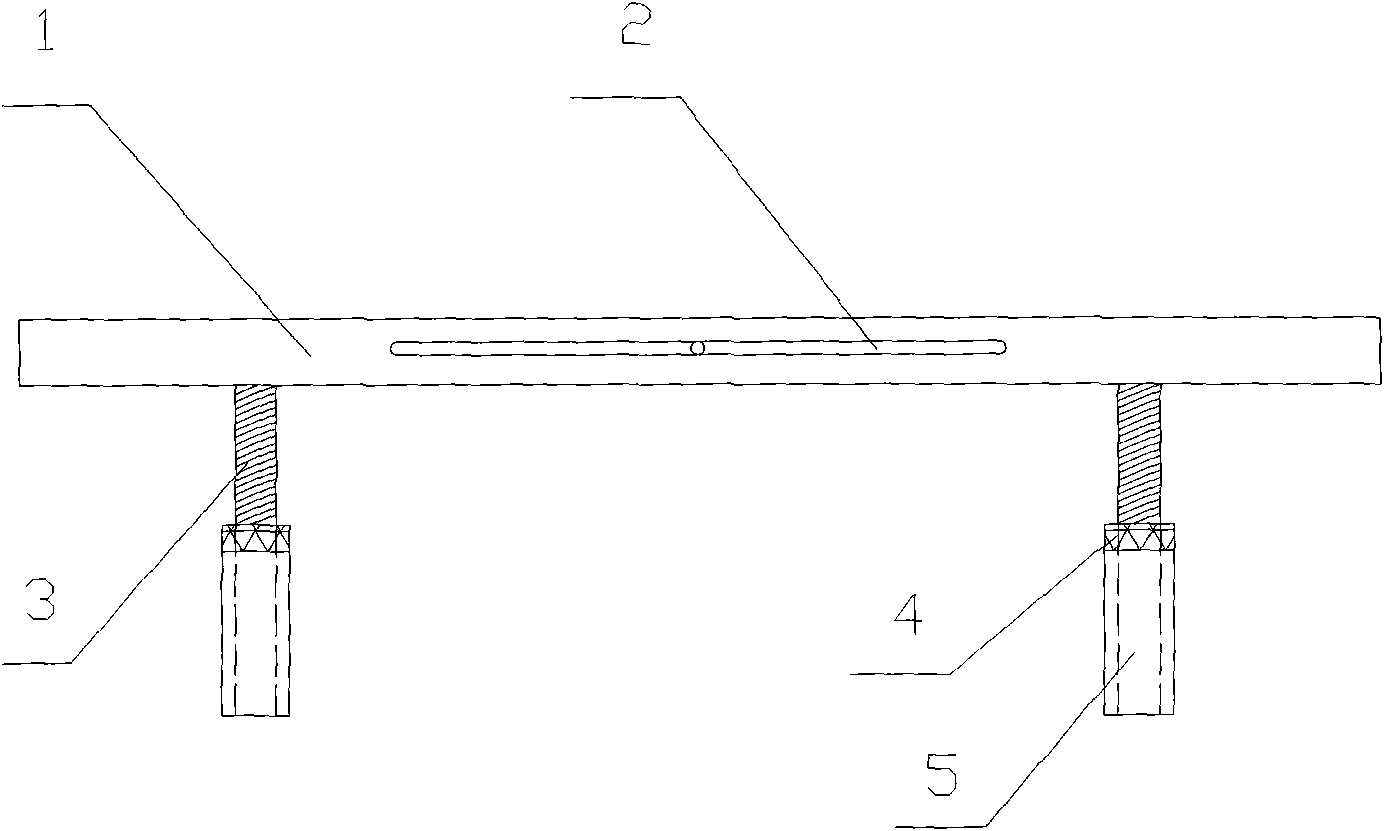

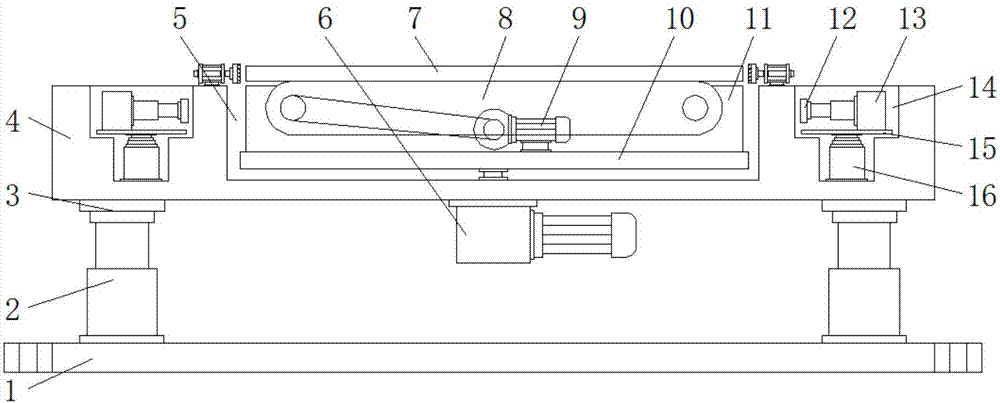

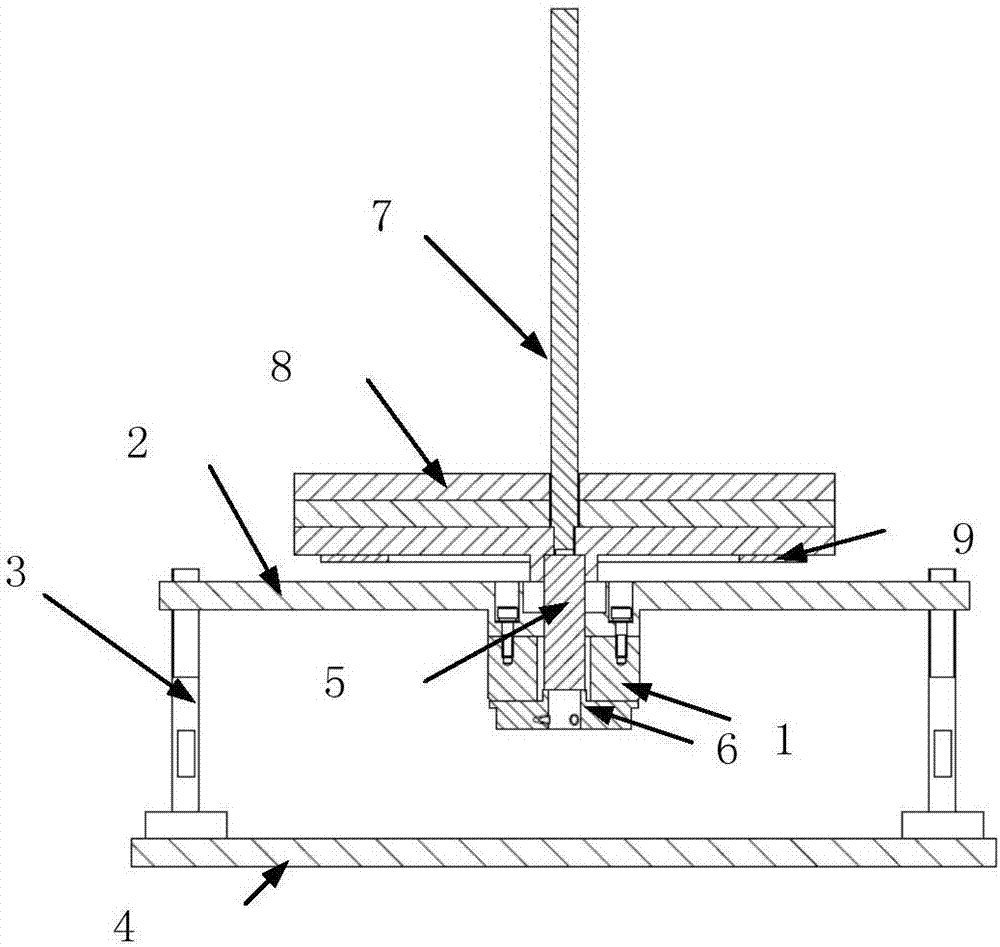

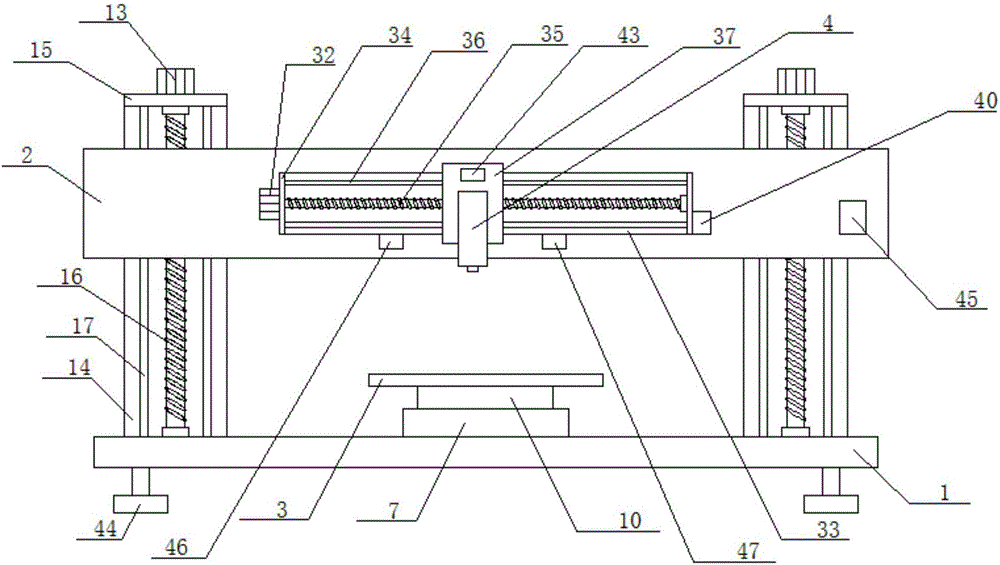

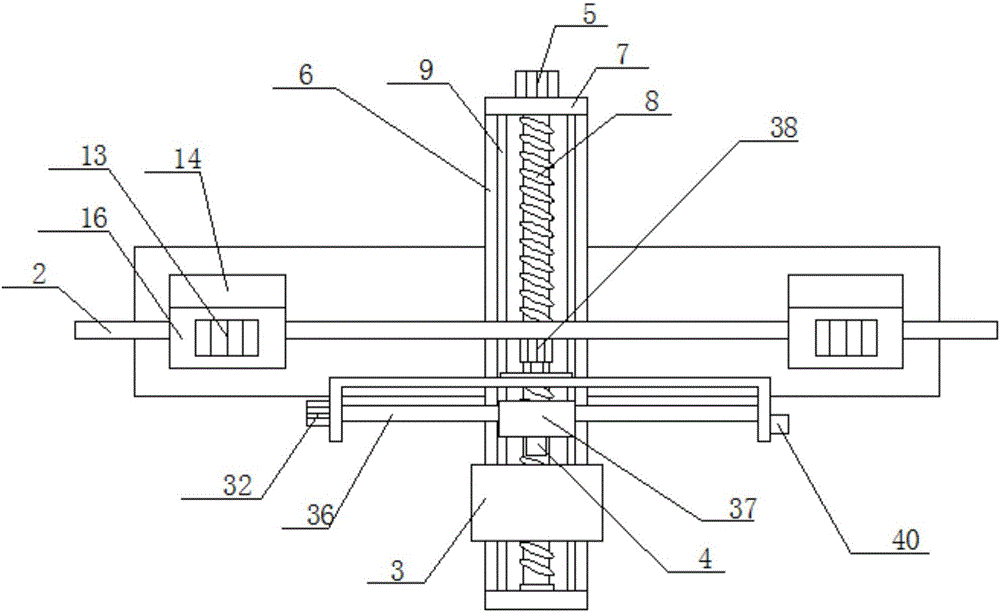

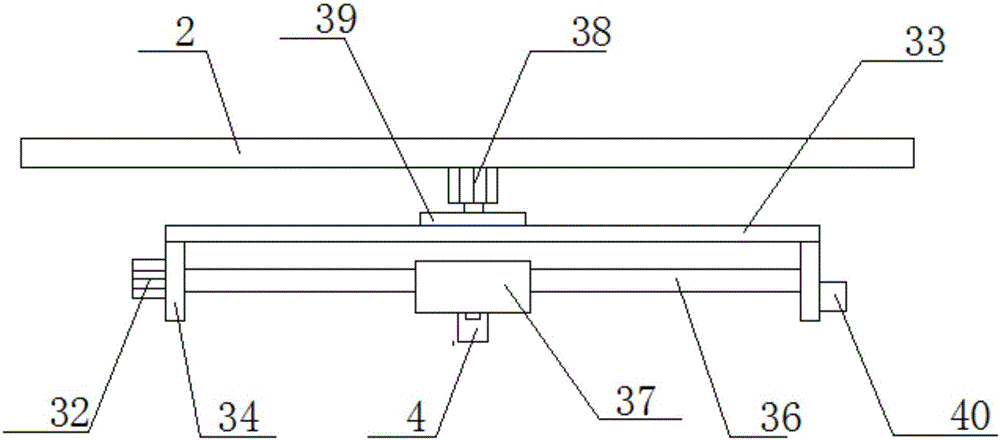

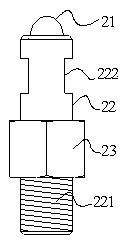

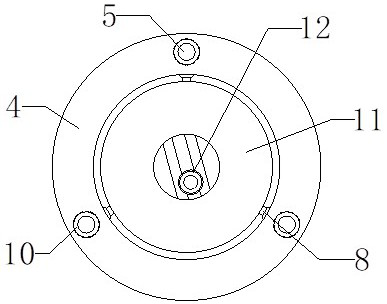

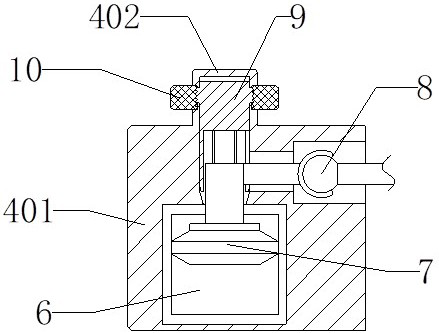

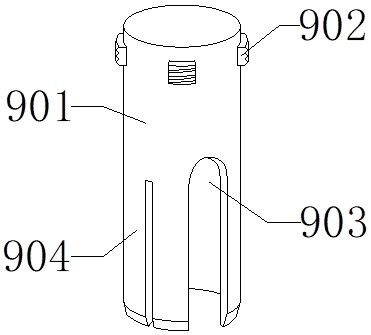

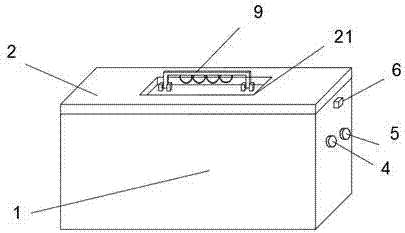

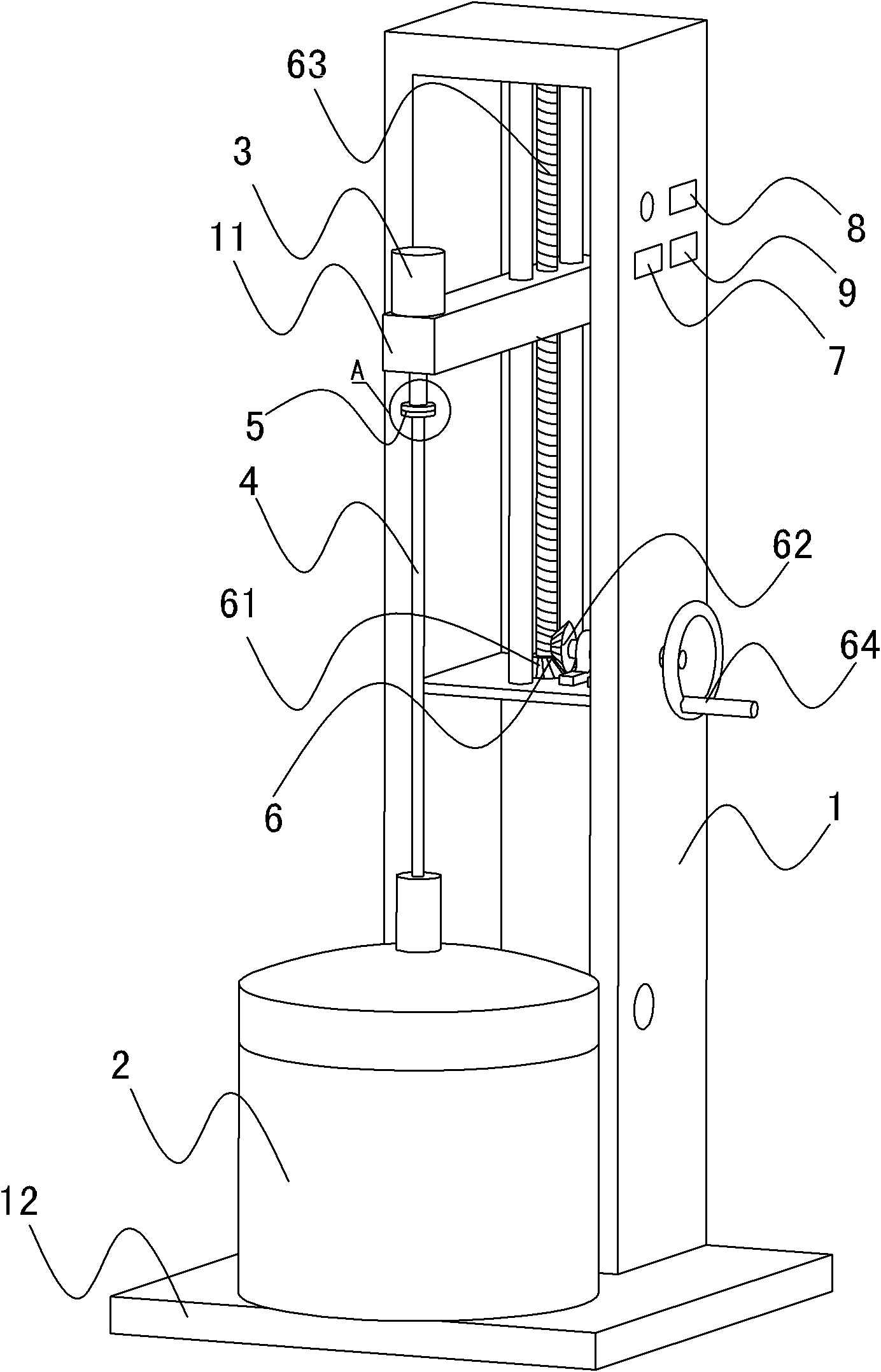

Permanent magnetic brake unit electromagnetic suction force test testing device

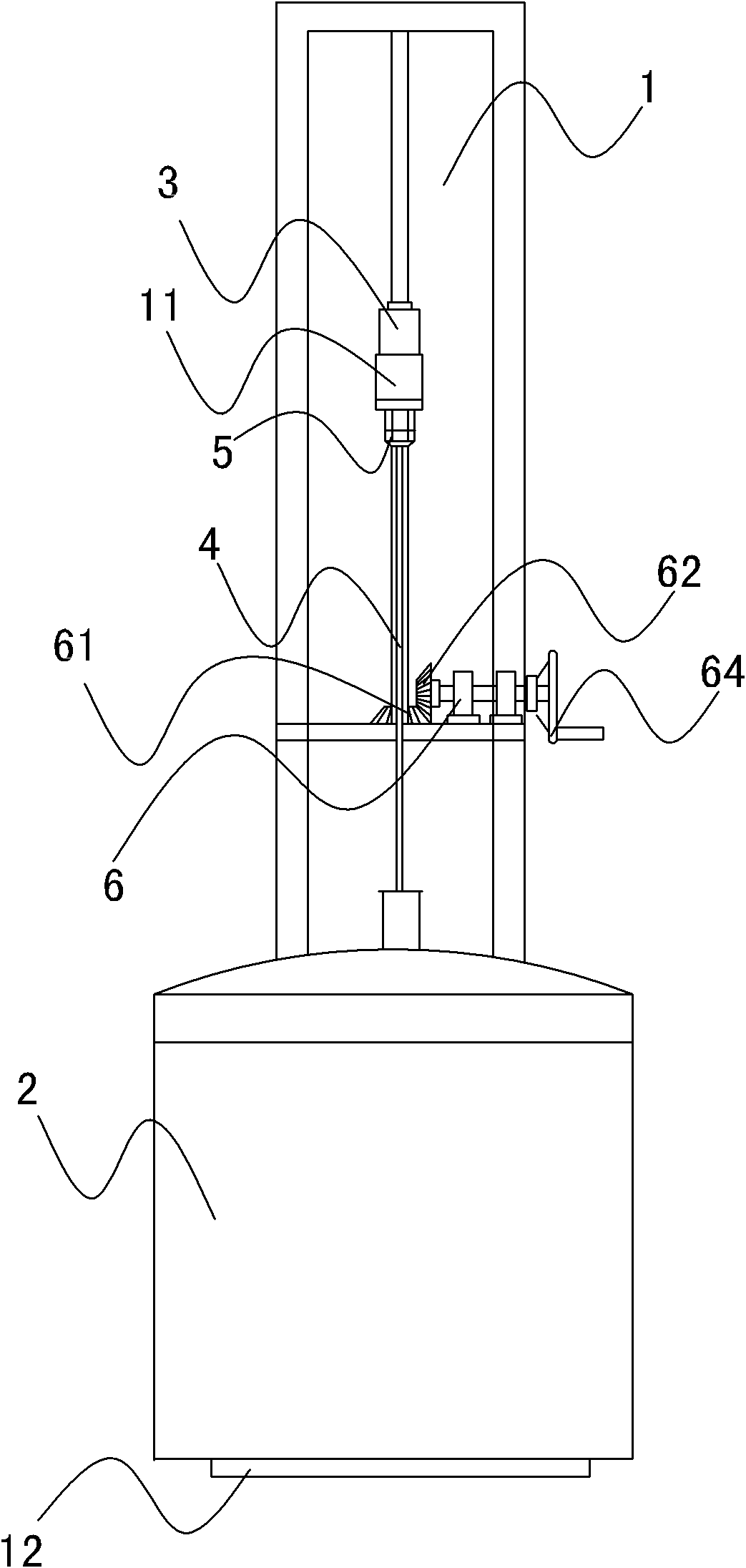

InactiveCN107478372AImprove horizontal accuracyRealize measurementApparatus for force/torque/work measurementInterference fitSuction force

The present invention provides a permanent magnetic brake unit electromagnetic suction force test testing device. The device comprises: brake stators (1), a first support platform (2), height regulation rods (3), a second support platform (4), a guide bar (5), a brake rotor (6), a mass block guide rod (7) and mass blocks (8). The brake stators (1) are connected with the first support platform (2); the first support platform (2) is connected with the second support platform (4) through the height regulation rods (3), and the height regulation rods (3) regulate the levelness of the first support platform (2) to regulate the levelness of the brake rotor (6); the lower end of the mass block guide rod (7) is connected with the mass blocks (8), and the lower end faces of the mass blocks (8) are in interference fit with the upper end face of the guide bar (5); and the guide bar (5), is located at the upper end face of the brake rotor (6) to conduct vertically downward loading force to the brake rotor (6).

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Accurate positioning 3D printer

ActiveCN106738916AIngenious designHigh feasibilityManufacturing driving meansEngineeringVertical displacement

The invention relates to an accurate positioning 3D printer. The accurate positioning 3D printer comprises a base, a support plate, a printing platform, a printing head, an X-axis movement mechanism, a Y-axis movement mechanism and a Z-axis movement mechanism, wherein the X-axis movement mechanism comprises a first motor, a first bottom plate, a first baffle, a first screw rod, a first limiting rod and a first sliding block, the Z-axis movement mechanism comprises a second motor, a second bottom plate, a second baffle, a second screw rod, a second limiting rod and a second sliding block assembly, the second sliding block assembly comprises a second sliding block, a correction unit and a control unit, and the Y-axis movement mechanism comprises a third motor, a third bottom plate, a third baffle, a third screw rod, a third limiting rod, a third sliding block and an adjustment assembly. According to the accurate positioning 3D printer, the positioning accuracy of a Y axis and a Z axis is increased, the adjustment assembly is additionally arranged in the Y-axis movement mechanism, so that the horizontal accuracy of the Y axis can be increased, and the control unit and the correction unit are additionally arranged in the Z-axis movement mechanism, so that the vertical displacement of the Z axis is stable and accurate.

Owner:嘉兴市永泰五金塑料有限责任公司

Satellite positioning enhancing method based on receiver clock offset generalized prolongation approach method

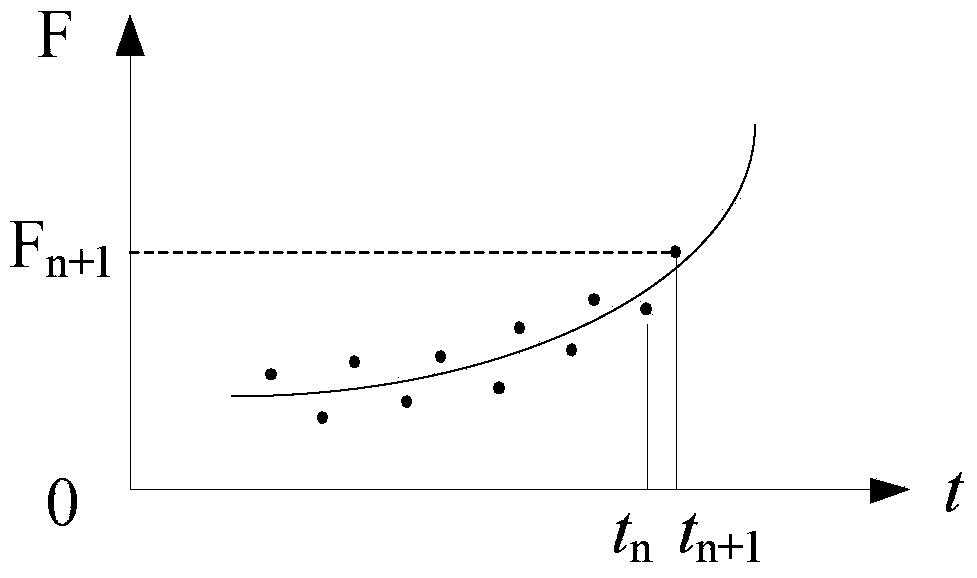

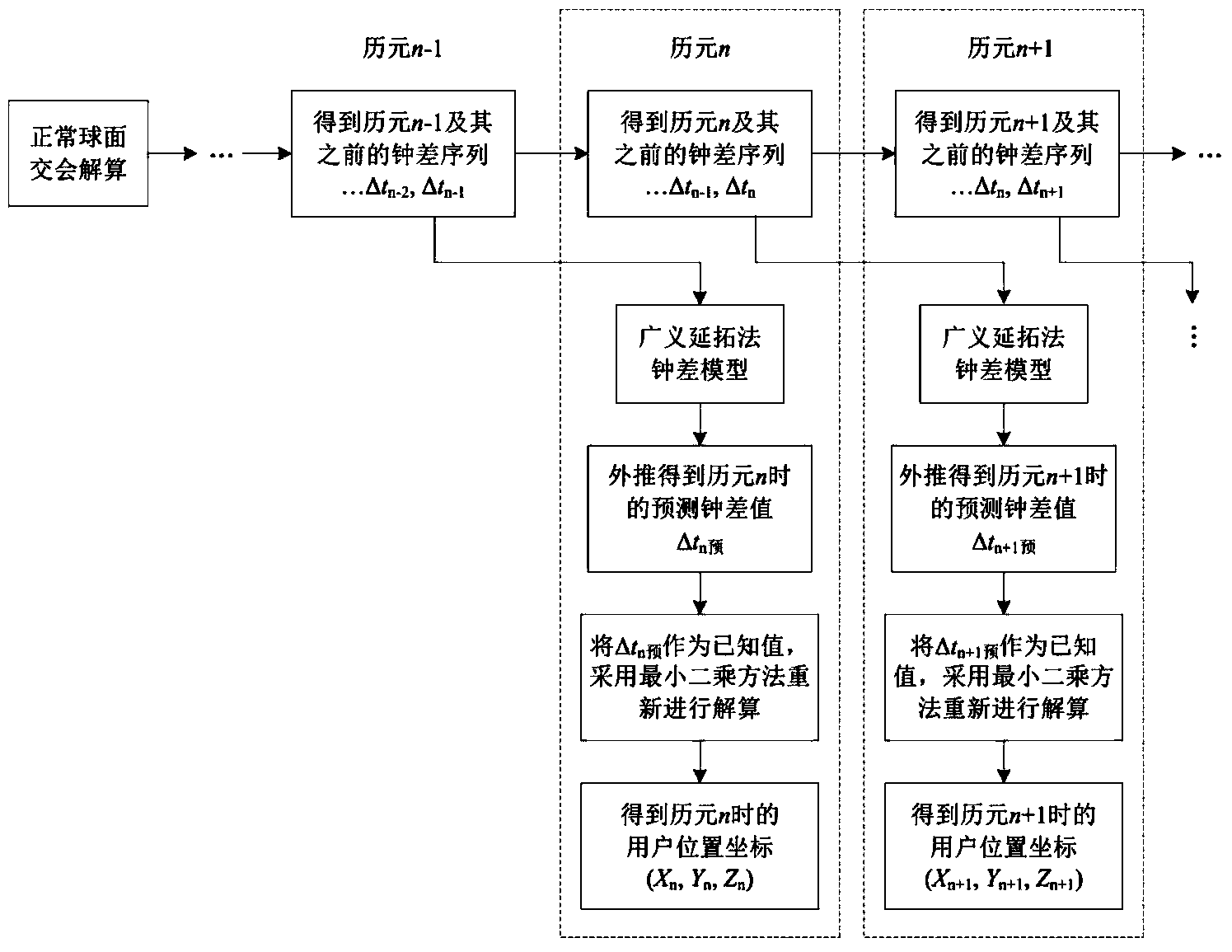

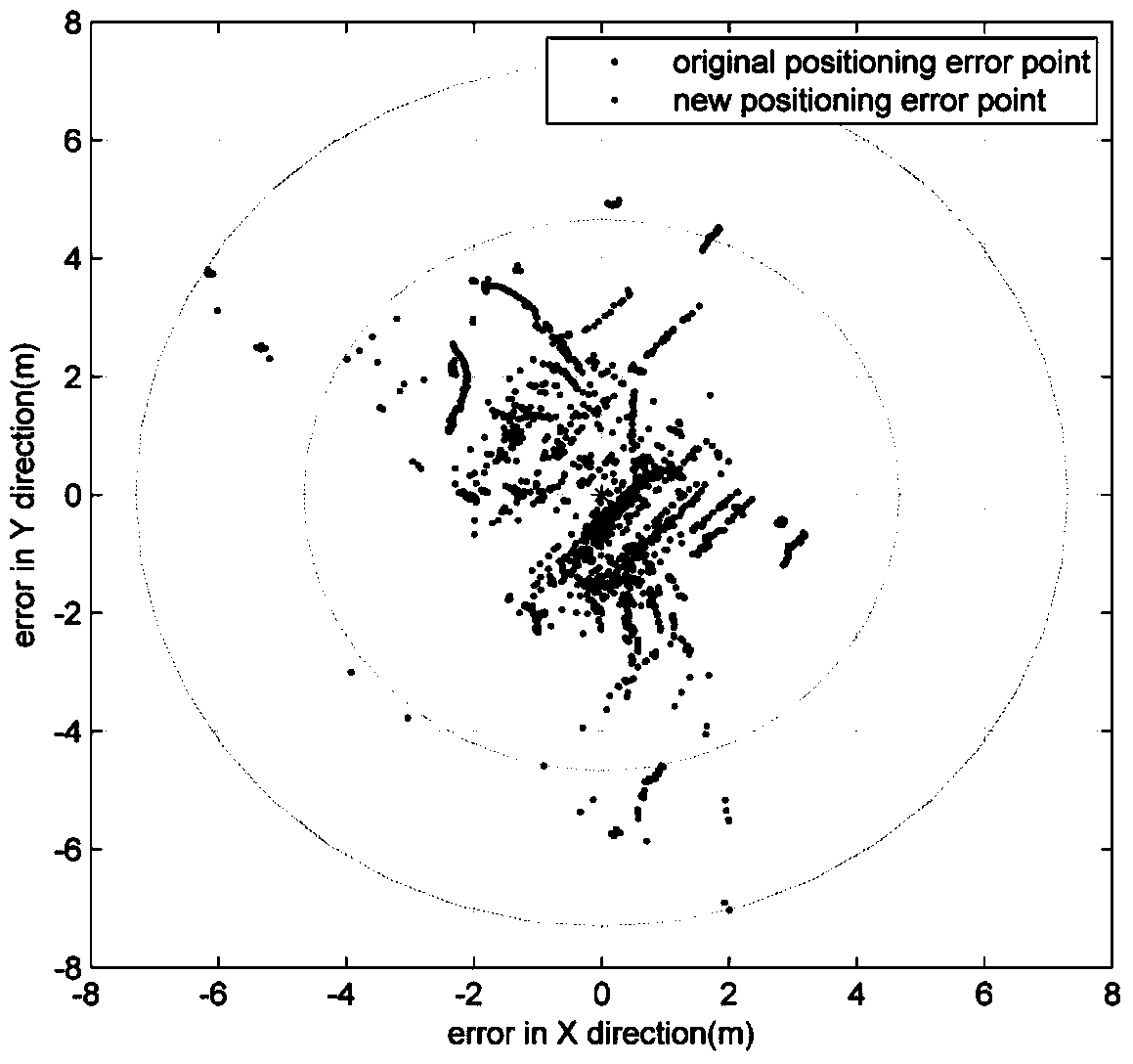

InactiveCN104280756ARealize 3D positioning solutionRealize redundant resolutionSatellite radio beaconingTime changesObservation data

The invention discloses a satellite positioning enhancing method based on a receiver clock offset generalized prolongation approach method. According to the method, a generalized prolongation approach mathematic model and a high-accuracy and high-sensitivity receiver clock offset extrapolation model are combined, a receiver clock offset is predicted and extrapolated to obtain a clock offset value of a receiver when satellite signals are blocked, and therefore three-dimensional positioning can still be achieved in an assisted mode on the condition of incomplete positioning; the generalized prolongation approach mathematic model is adopted to establish a high-accuracy clock offset calculation mathematic model, and a new constraint positioning enhancing method is established with the calculated clock offset as a constraint condition; the generalized prolongation clock offset approach model has both the advantages of an interpolation method and the advantages of a fitting method and can lock latest observation data, so that the clock offset model better conforms to the real-time change characteristics and law, and higher fitting and extrapolation accuracy is obtained. The satellite positioning enhancing method has high practical value and practical significance.

Owner:NAT ASTRONOMICAL OBSERVATORIES CHINESE ACAD OF SCI

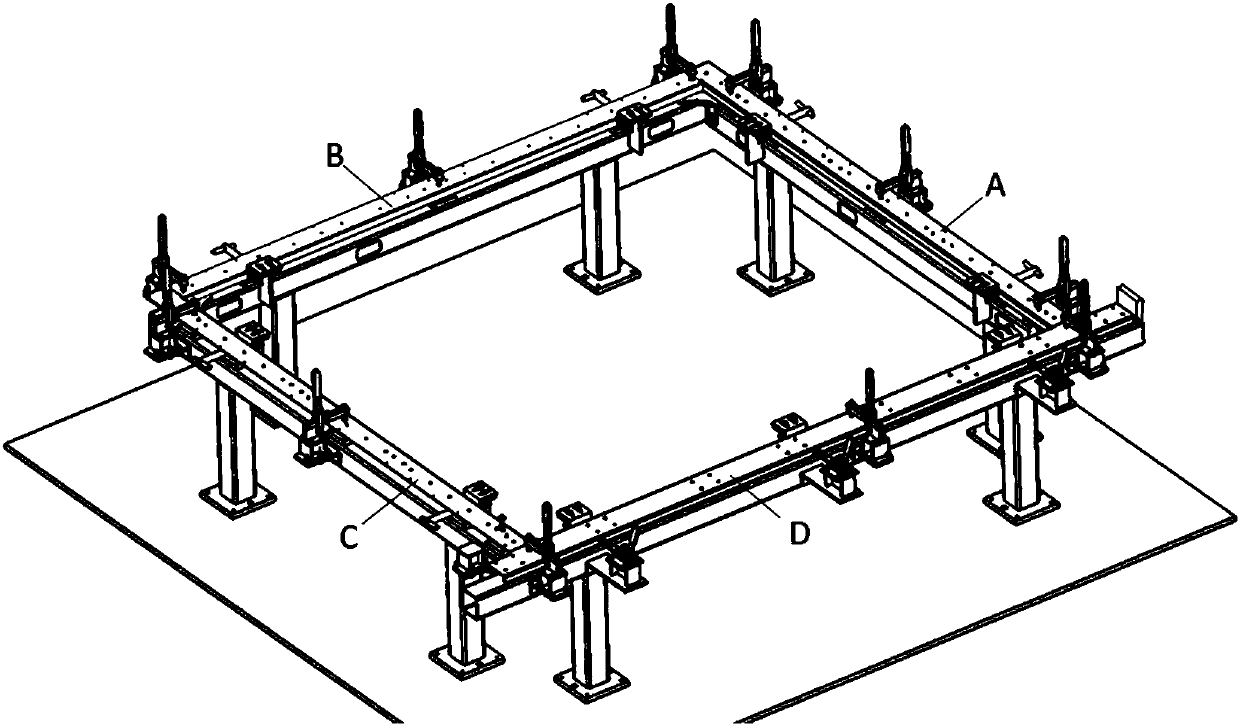

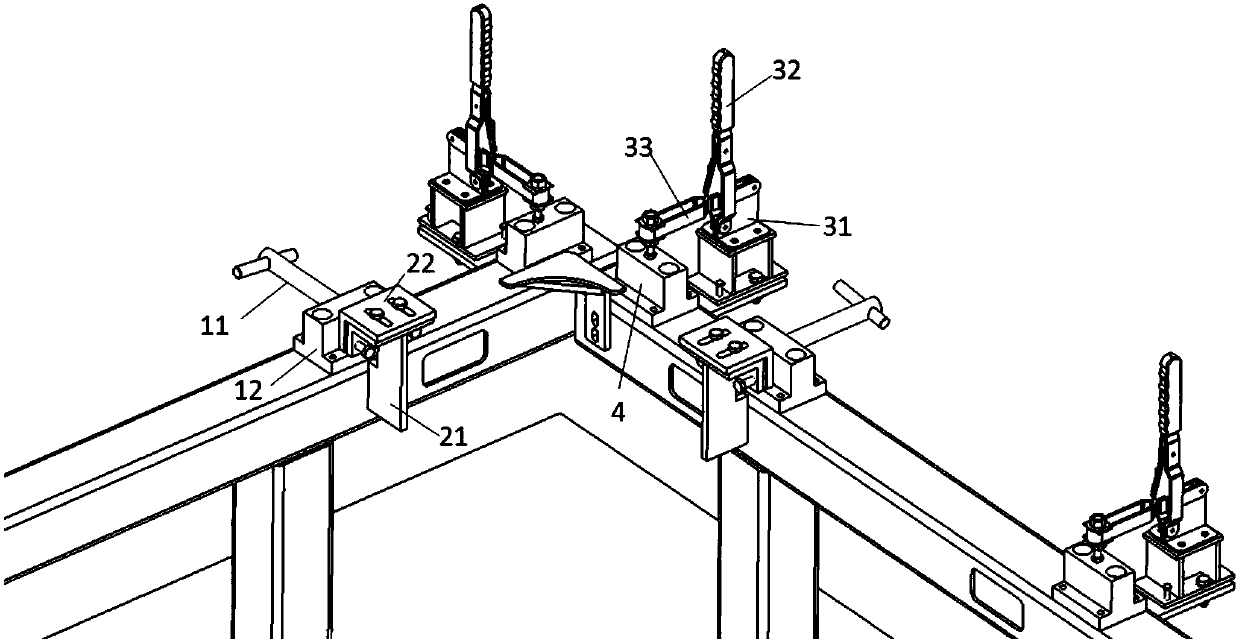

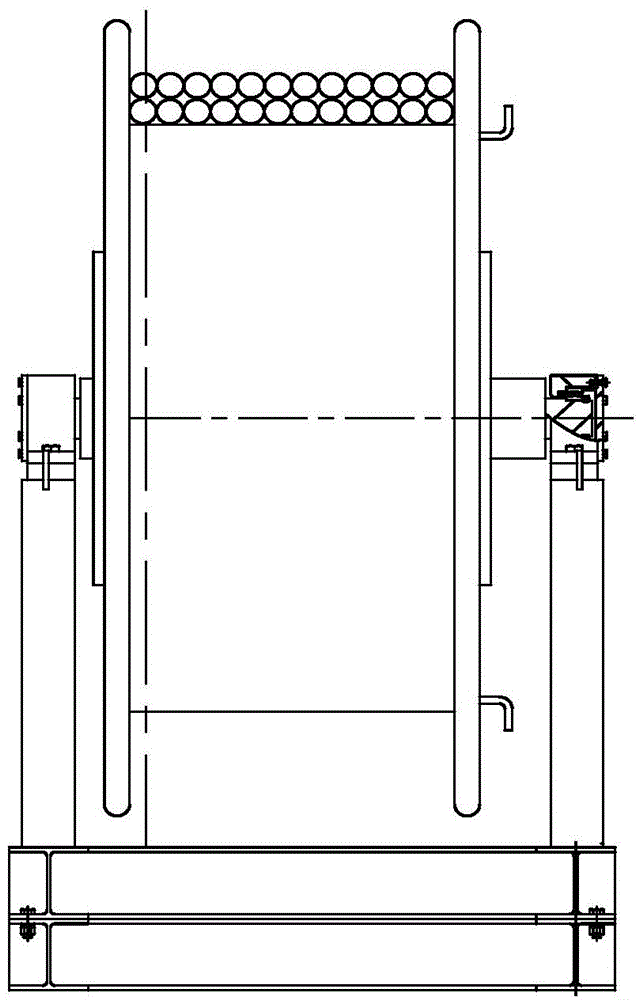

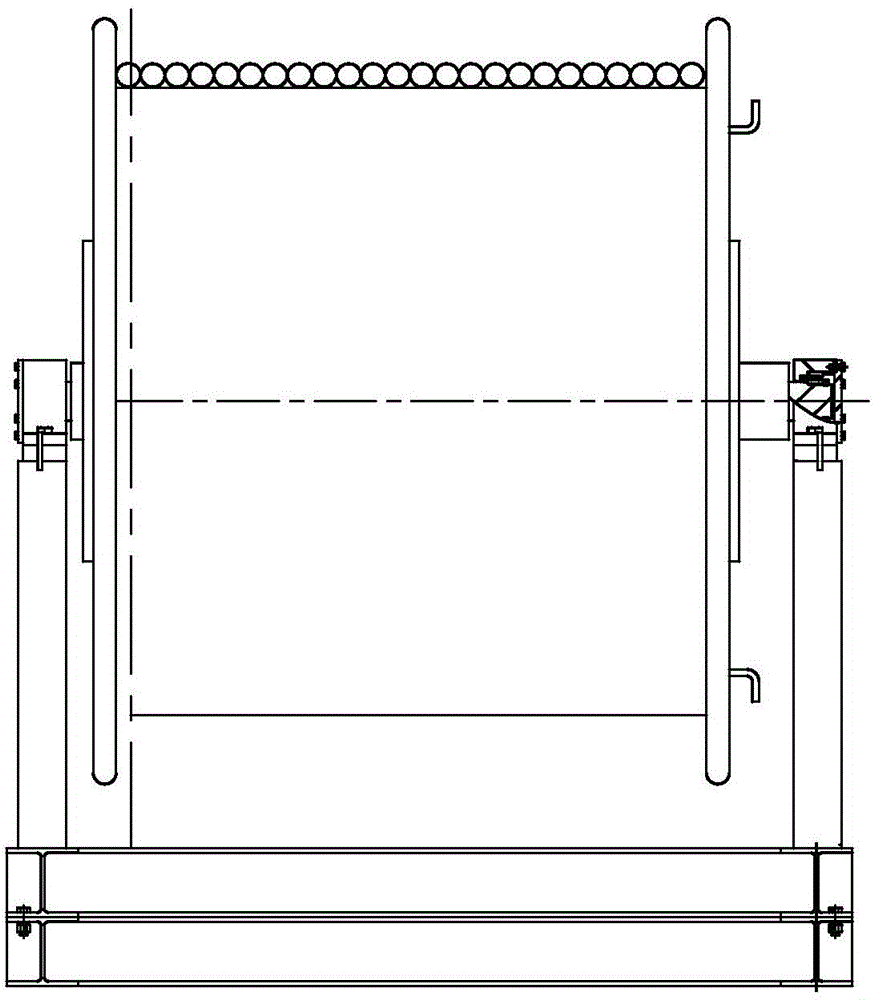

Right-side front door frame assembling and welding tool and installing and adjusting method thereof

PendingCN107649815AEffectively fixedSmall sizeWelding/cutting auxillary devicesAuxillary welding devicesPass rateEngineering

The invention discloses a right-side front door frame assembling and welding tool and an installing and adjusting method thereof, and is applied to the field of carbon steel welding. The right-side front door frame assembling and welding tool comprises a threaded jacking clamp, a limiting block, a down pressing quick clamp, a cushion block, a reinforcing plate gasket, a jacking quick clamp, a stand column and a cross beam. The installing and adjusting method is characterized in that components are installed, leveled and installed as a criterion. The method mainly solves the problems that the current right-side front door frame assembly is welded by manual assembly, the size of the assembly is determined by means of measurement of a measuring tape, the size of the assembly is not stable, the manual assembling speed is low, the production efficiency is low, no tool clamp is used to fix, and welding deformation is easily generated after welding. The ingenious design and effective installation and adjustment of the welding tool are realized so that the inner width, the inner height and the diagonal dimension of the right front door frame in the production process are controlled, the welding deformation is reduced, the size deviation is low, the product percent of pass is high and stable, and the production efficiency of the aluminum alloy container body is improved.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

Cable winch applied to submersible pump

The invention discloses a cable winch applied to a submersible pump. The cable winch applied to the submersible pump comprises a base, a supporting frame, an inserting pin and a winding drum, wherein the base is used for supporting the supporting frame and the winding drum, the supporting frame is fixedly connected with the base, the winding drum is arranged on the supporting frame and comprises a first circular baffle, a second circular baffle and a rolling shaft, the first circular baffle and the second circular baffle are fixedly connected with the two sides of the rolling shaft respectively, the inserting pin is detachably connected with the lateral surface of the supporting frame, a cable can be contained in the space between the first circular baffle and the second circular baffle, the base comprises a web and angle steel, and the web is fixedly connected to the bottom of the angle steel. The cable winch applied to the submersible pump can realize single-layer laying, saves the space, reduces the intensity and difficulty of on-site welding, and can effectively avoid the situation that as an operator forgets to pull out the inserting pin, the cable and a pump body are damaged.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

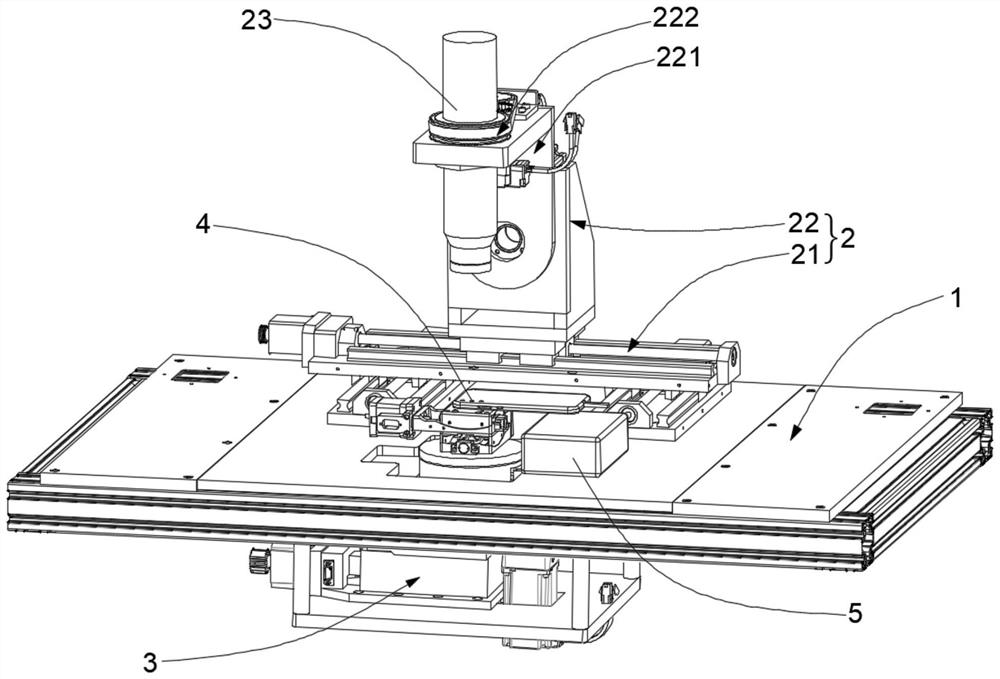

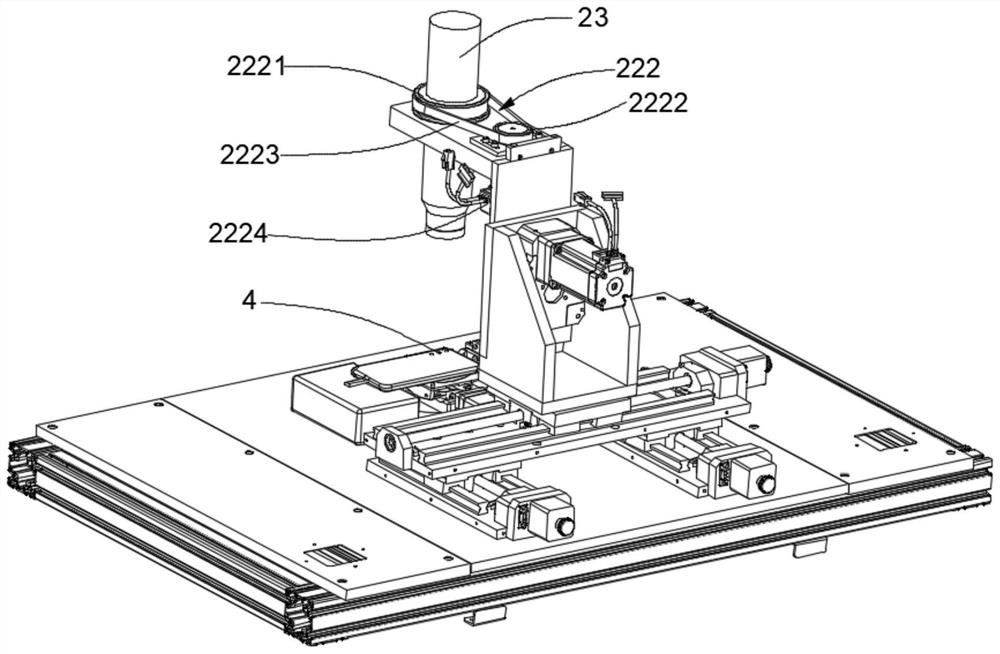

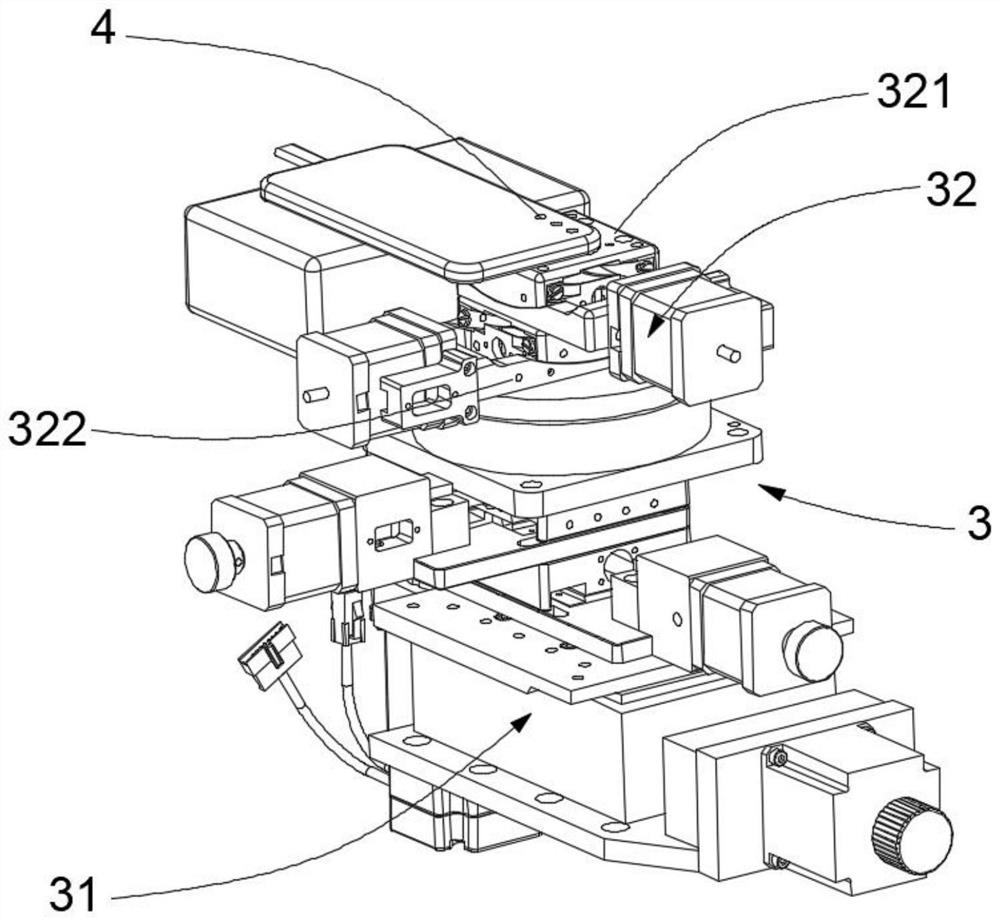

Camera test equipment and camera imaging test method

The invention relates to the technical field of camera testing, and particularly discloses camera testing equipment and a camera imaging testing method. The camera testing device comprises a supporting platform, a first adjusting module, a second adjusting module and an image receiving assembly. The first adjusting module comprises an XY moving platform and a rotating module arranged at the driving end of the XY moving platform, and the driving end of the rotating module is connected with the collimator; the second adjustment module comprises a moving module and a horizontal fine adjustment module arranged at the driving end of the moving module, and the camera is supported on the horizontal fine adjustment module; and the image receiving assembly is used for receiving image signals shot by the camera. Under the condition that the angle of the camera does not need to be adjusted, the imaging angle of the camera during image card shooting can be adjusted by adjusting the rotating module. Meanwhile, the horizontal precision of the camera adjusted by the horizontal fine adjustment module is high, so that the data detected by the method is accurate, the adjustment process is simple and convenient, and the test efficiency is improved.

Owner:上海研鼎信息技术有限公司

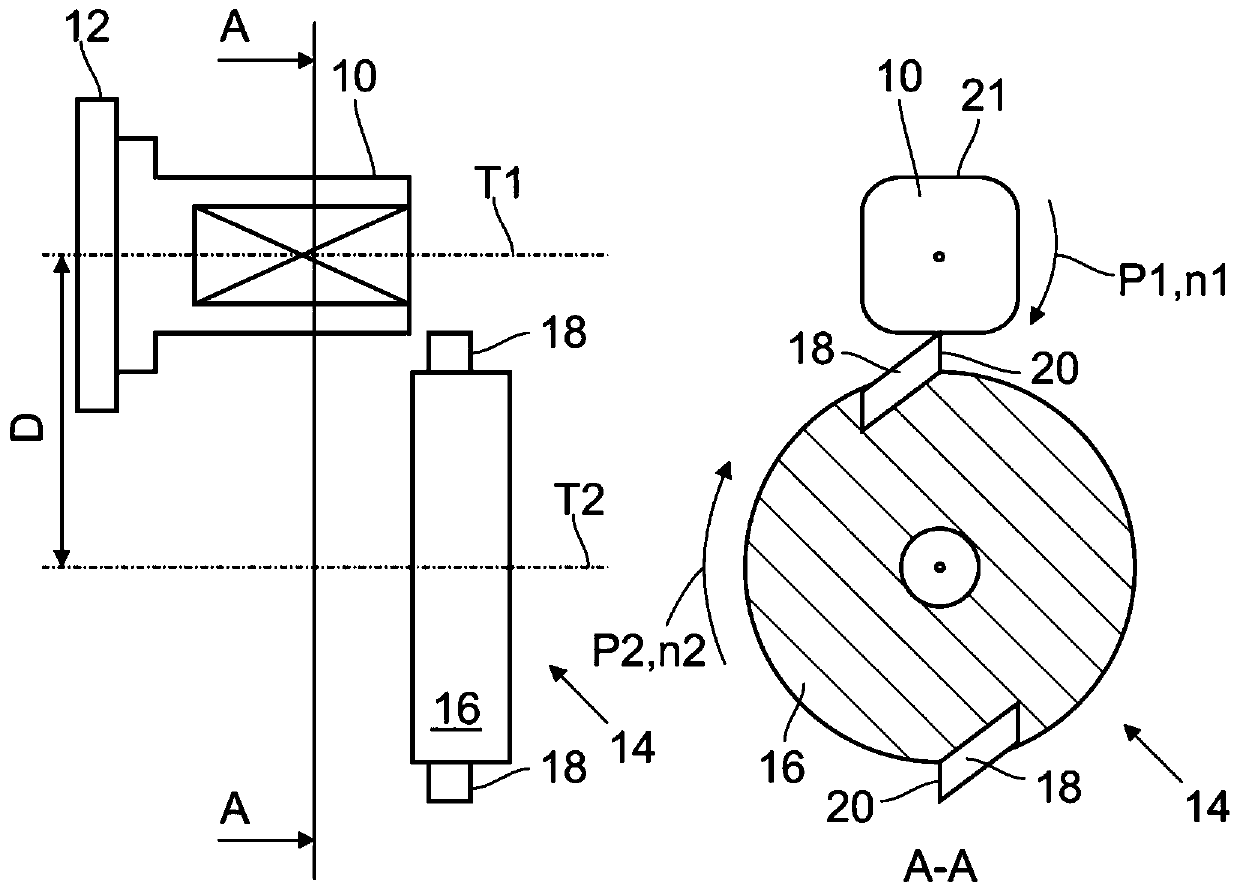

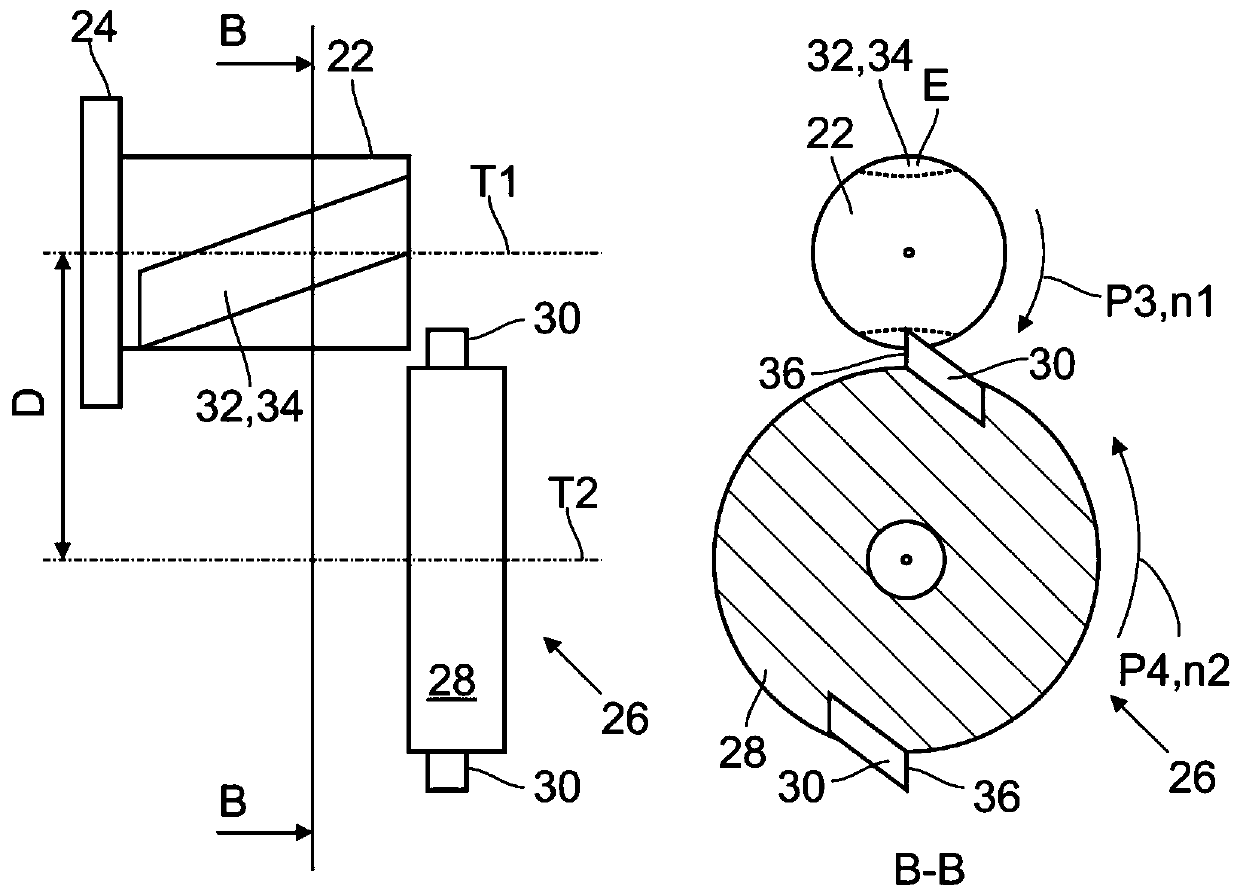

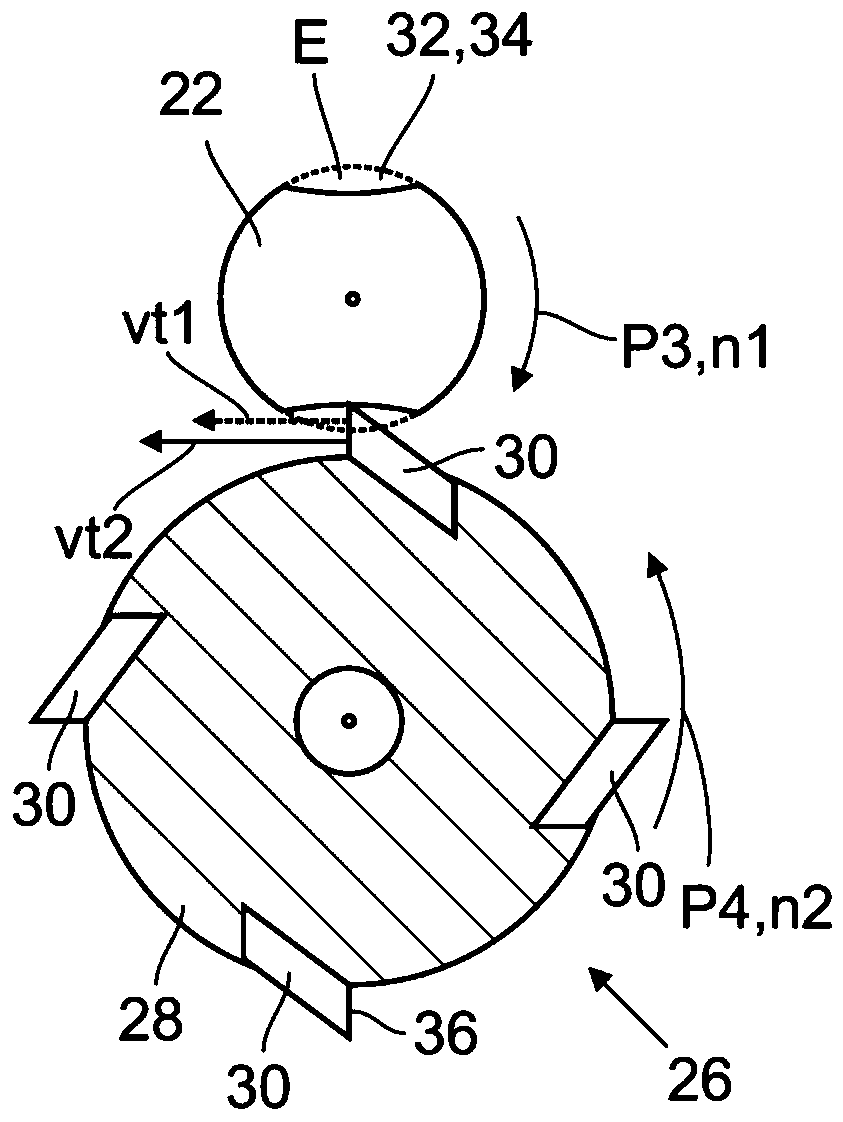

Method for producing one or more concave cut-outs on a main body which is, in particular, substantially cylindrical, armature, keeper plate, and electromagnetic actuator

InactiveCN111278592AImprove horizontal accuracyFull fluid balanceOperating means/releasing devices for valvesMilling equipment detailsRotational axisEngineering

The present invention relates to a method for producing one or more concave cut-outs (32) on a main body (22) which is, in particular, substantially cylindrical, more particularly for producing one ormore grooves (34) on an armature (40), a push rod (72), or a magnetic keeper plate, comprising the following steps: providing a substantially cylindrical main body (22) having a first axis of rotation (T1), rotating the cylindrical main body (22), by means of a lathe (24), about the first axis of rotation (T1) in a first rotational direction, and rotating a striking tool (26), provided witha number of fly cutters (30), about a second axis of rotation (T2) in a second rotational direction opposite to the first direction, said second axis running parallel and offset to the first axis ofrotation (T1), so that the fly cutter (30) engages stock-removably with the main body (22) in order to produce the cut-out (32). The invention also relates to an armature, a push rod and a magnetic keeper plate, having one or more cut-outs produced according to this method, and to an electromagnetic actuator comprising an armature of this type or a keeper plate of this type.

Owner:KENDRION VILLINGEN GMBH

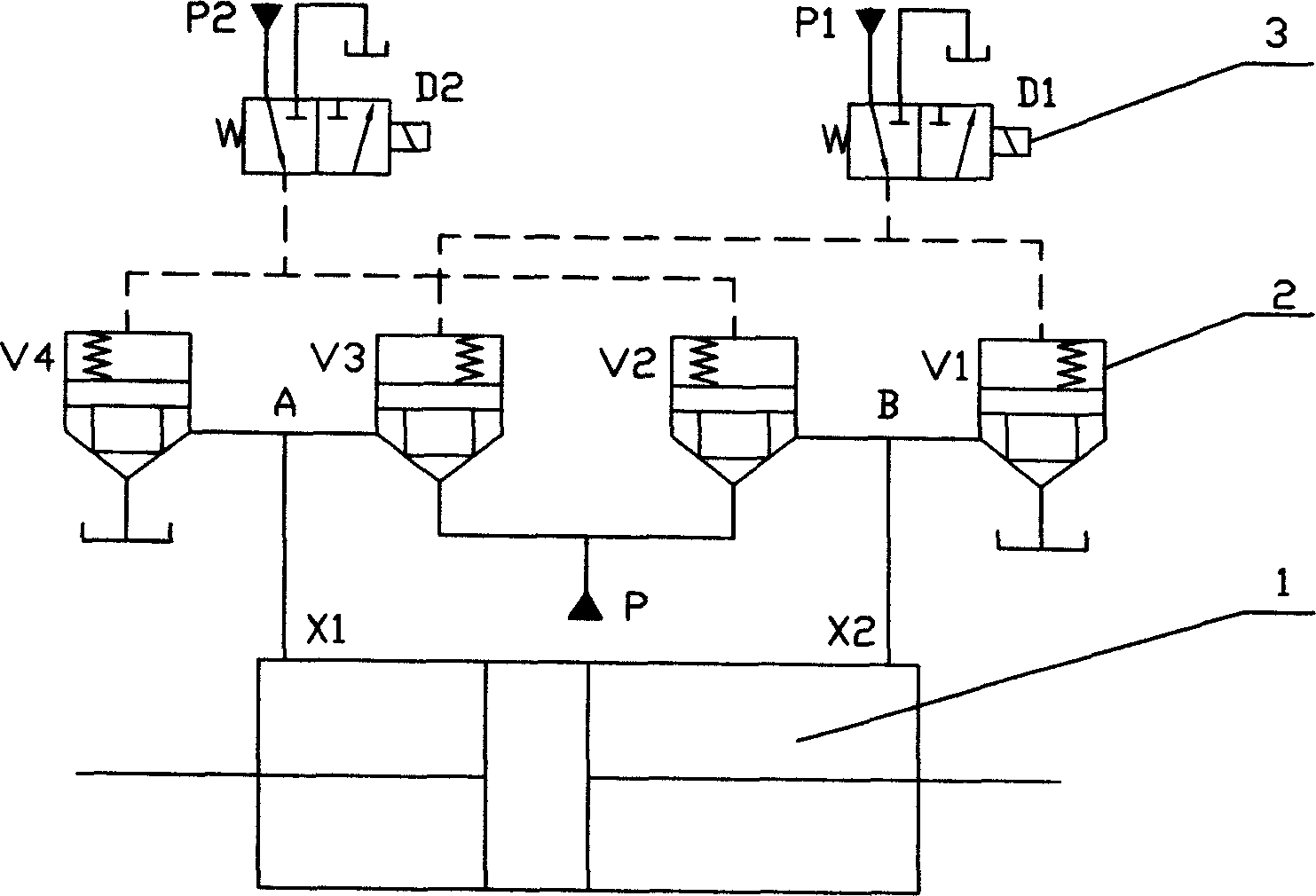

Hydraulic loop of ten thousand hydraulic press operation system

The hydraulic loop for ten thousand ton hydraulic press operation system includes oil cylinders, conic valves and two-position three way high speed solenoid valves, and has one three-position four way digital valve comprising 4 conic valves and 2 two-position three way high speed solenoid valves. The conic valves act as the main control valves, the high speed solenoid valve as the fore running valve, and the conic valves are controlled to open or close via the control of high speed solenoid valves. The high speed solenoid valves are controlled with industrial control computer to realize digital control. The fore running valve may have its oil supplying pressure from autonomous loop or other pressure source. The present invention realizes the digital design of the hydraulic loop for ten thousand ton hydraulic press operation system and has raised reliability, operation performance, automation level and control precision of the operation system.

Owner:CENT SOUTH UNIV

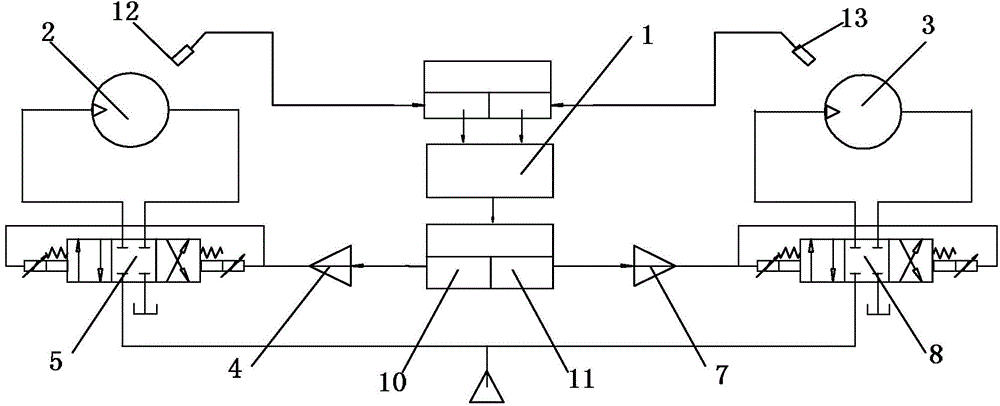

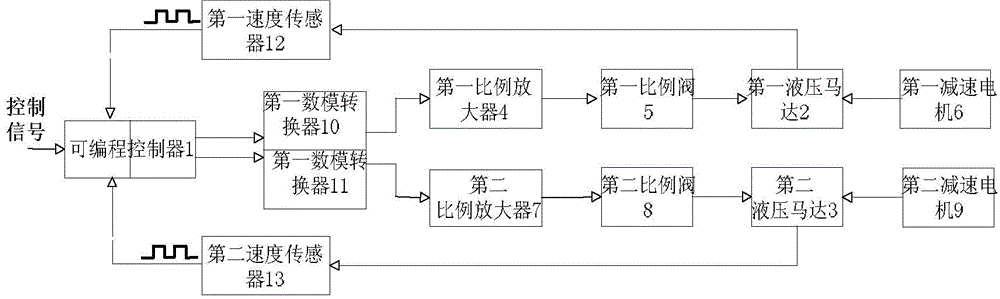

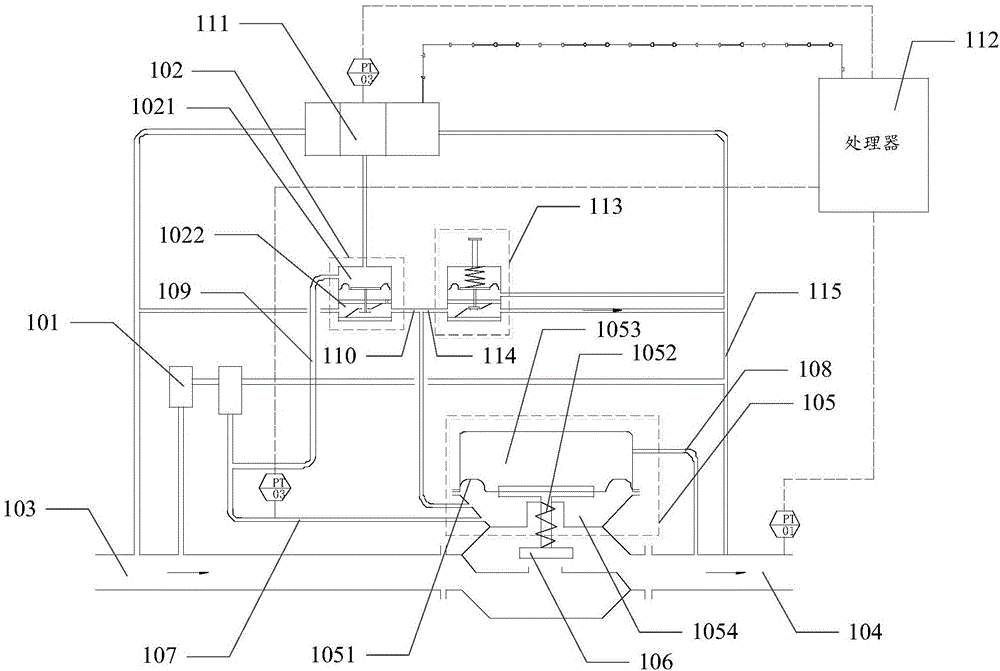

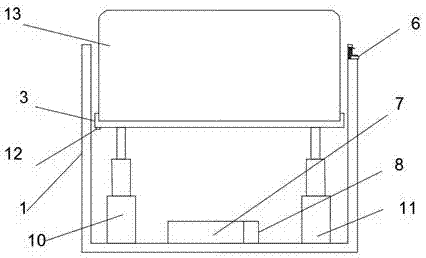

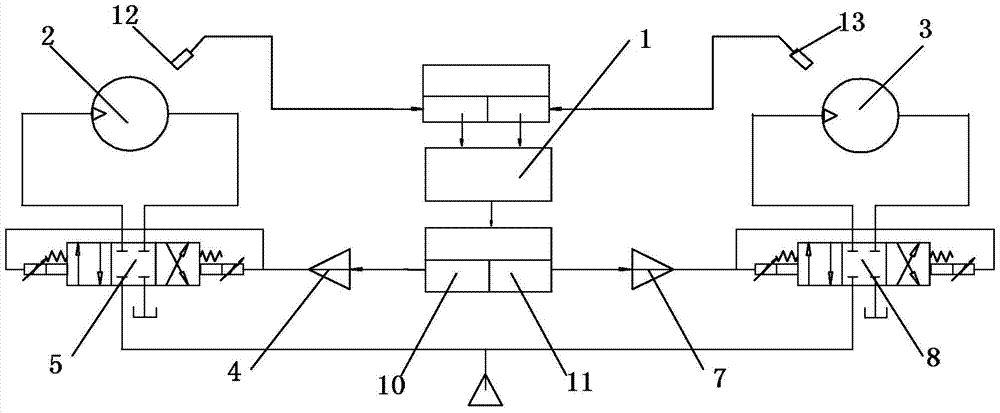

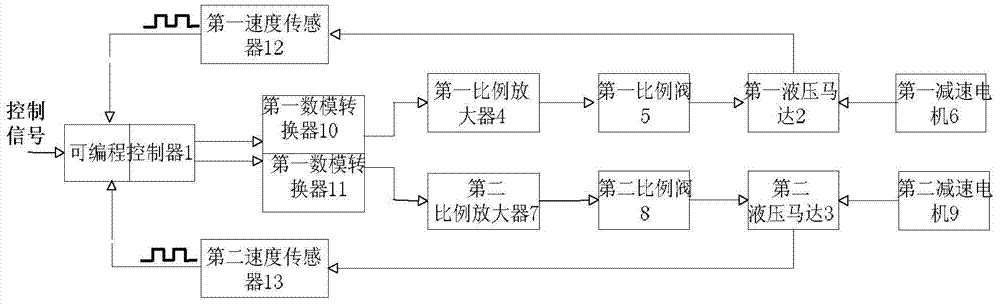

Control device and control method for automatic distribution of sea surface oil spilling oil containment boom

InactiveCN104454798AImprove efficiencyHigh precisionWater cleaningGeneral water supply conservationHydraulic motorAudio power amplifier

The invention discloses a control device for automatic distribution of a sea surface oil spilling oil containment boom. The control device comprises a programmable logic controller, and further comprises a first hydraulic motor and a second hydraulic motor. The programmable logic controller is connected with a first proportional valve through a first proportion amplifier, the first proportion amplifier is connected with the first hydraulic motor, and the first hydraulic motor is connected with a first reduction box; the programmable logic controller is connected with a second proportional valve through a second proportion amplifier, the second proportion amplifier is connected with the second hydraulic motor, and the second hydraulic motor is connected with a second reduction box. The invention further discloses a control method for automatic distribution of the sea surface oil spilling oil containment boom. Influences of stress unevenness of the two motors on a system can be effectively reduced by the adoption of an equivalent control mode, the anti-interference capability of the system is improved, finally, the purpose that speeds of the two hydraulic motors stressed unevenly are proportional to each other is achieved, coordination control over the revolving speeds of the two motors in an equivalent control mode is achieved, and the automation level and the control accuracy of the system are improved.

Owner:SHANDONG UNIV OF SCI & TECH

Driving pressure regulator

ActiveCN106802676AGuaranteed SensitivityGuaranteed control accuracyFluid pressure control using electric meansEngineeringPressure regulator

The invention discloses a driving pressure regulator. Through adoption of a second director that can input second driving air pressure to a driver, air pressure in a third cavity and loading force of an elastic device inside the driver can be balanced without increases of the area of a second isolated film in the driver when first air pressure has a high air pressure value or the flow of the first air pressure is large. The technical effects are that sensitivity and control precision of the driving pressure regulator are guaranteed while the application range of the driving pressure regulator is increased.

Owner:四川九门科技股份有限公司

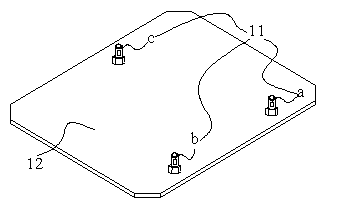

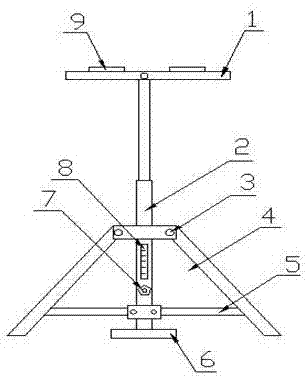

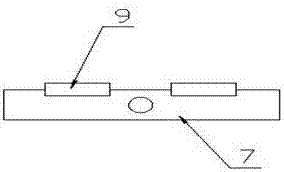

Three-point supporting platform

Owner:KUN SHAN POWER STENCIL

Building formwork supporting device convenient to transport and use

InactiveCN107288338AImprove support stabilityImprove horizontal accuracyForms/shuttering/falseworksArchitectural engineeringEngineering

The building formwork supporting device that is convenient to transport and use in the present invention is composed of a supporting plate, a pneumatic telescopic rod, a hinge screw, a triangle bracket, a connecting beam, a grounding wooden bracket, an air injection hole, a bracket leg, a hoop, a pressure display gauge and a pressure sensor. Composition, the support plate is tightly connected with the upper end of the pneumatic telescopic rod through hinge screws, the tripod is composed of bracket legs and hoops, the pneumatic telescopic rod passes through the hoop of the tripod bracket, and the pneumatic telescopic rod and hoop are connected by hinge screws Tightly connected, the bracket legs of the tripod are connected to each other through connecting beams, the grounded wooden support is solidly connected to the lower end of the pneumatic telescopic rod, the pneumatic telescopic rod is provided with an air injection hole, and the pressure sensor is provided with two, which are fixed to the support plate respectively. The pressure display gauge is fixedly connected to the lower end of the pneumatic expansion rod, and the pressure display gauge is electrically connected to the pressure sensor. The beneficial effects of the above-mentioned technical solution are high support stability, high level accuracy, high support effect, and the pressure between the support plate and the building formwork can be controlled at any time, the support effect can be enhanced, and the project quality can be guaranteed.

Owner:宋雪纯

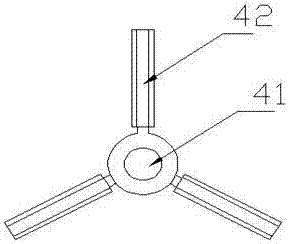

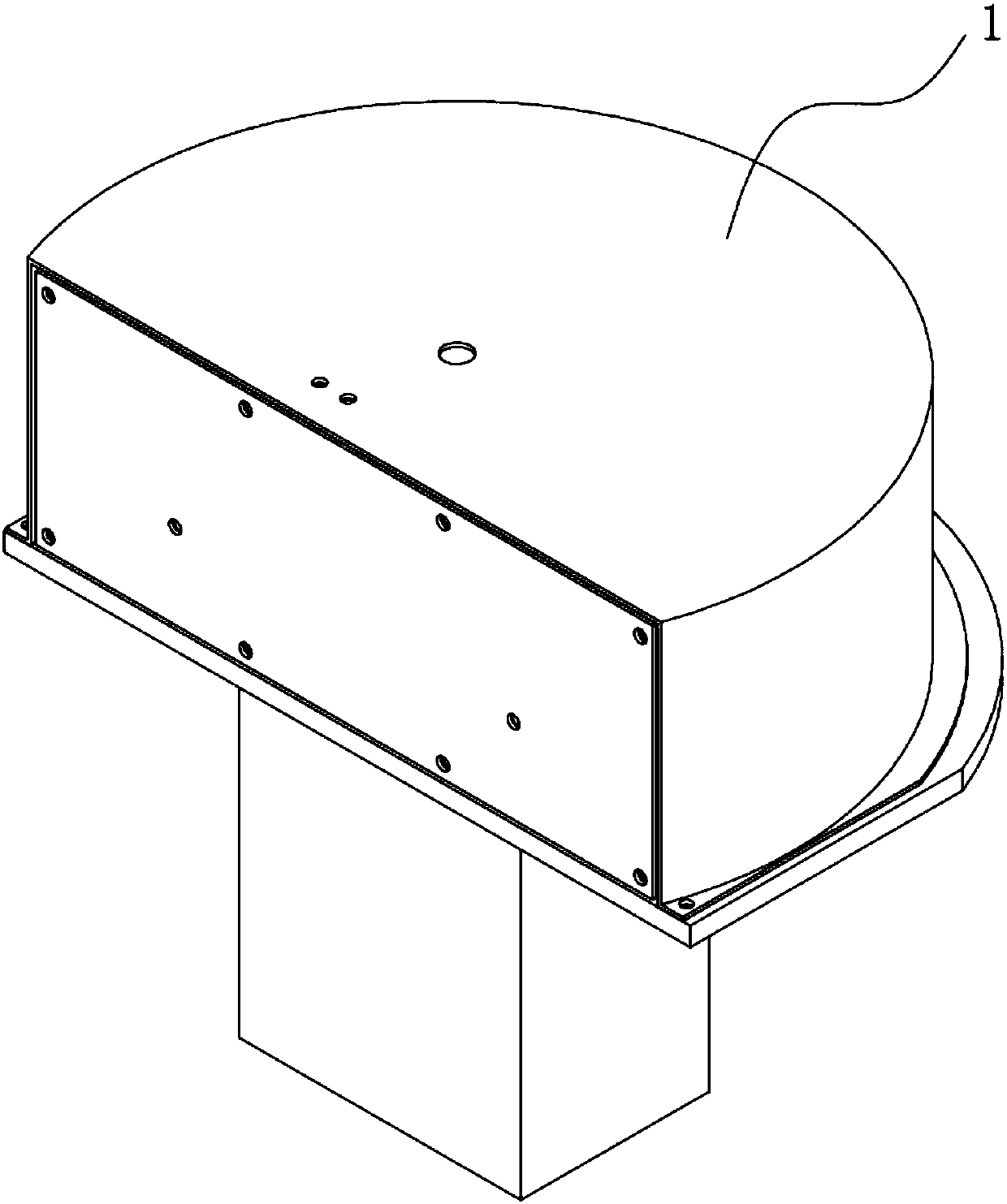

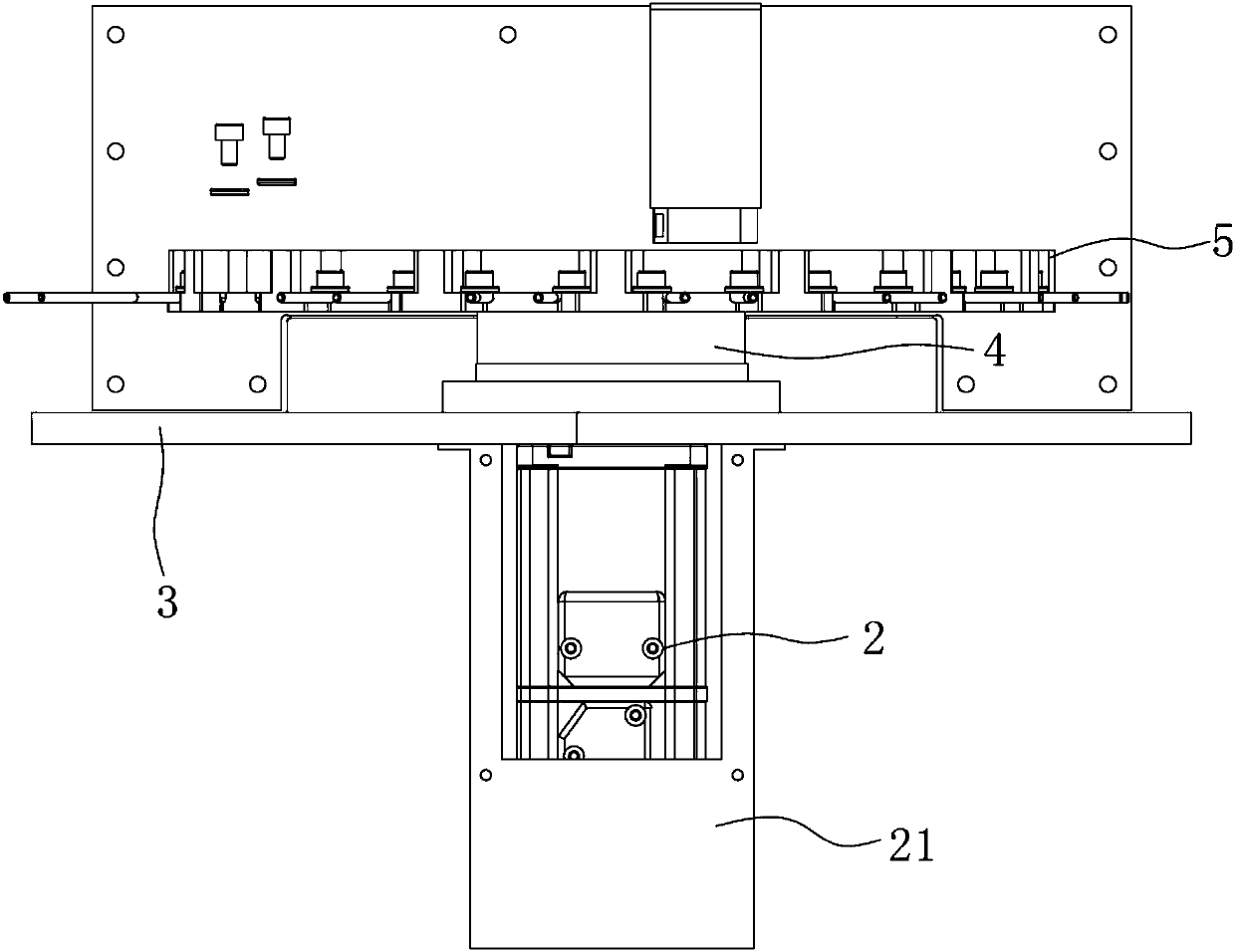

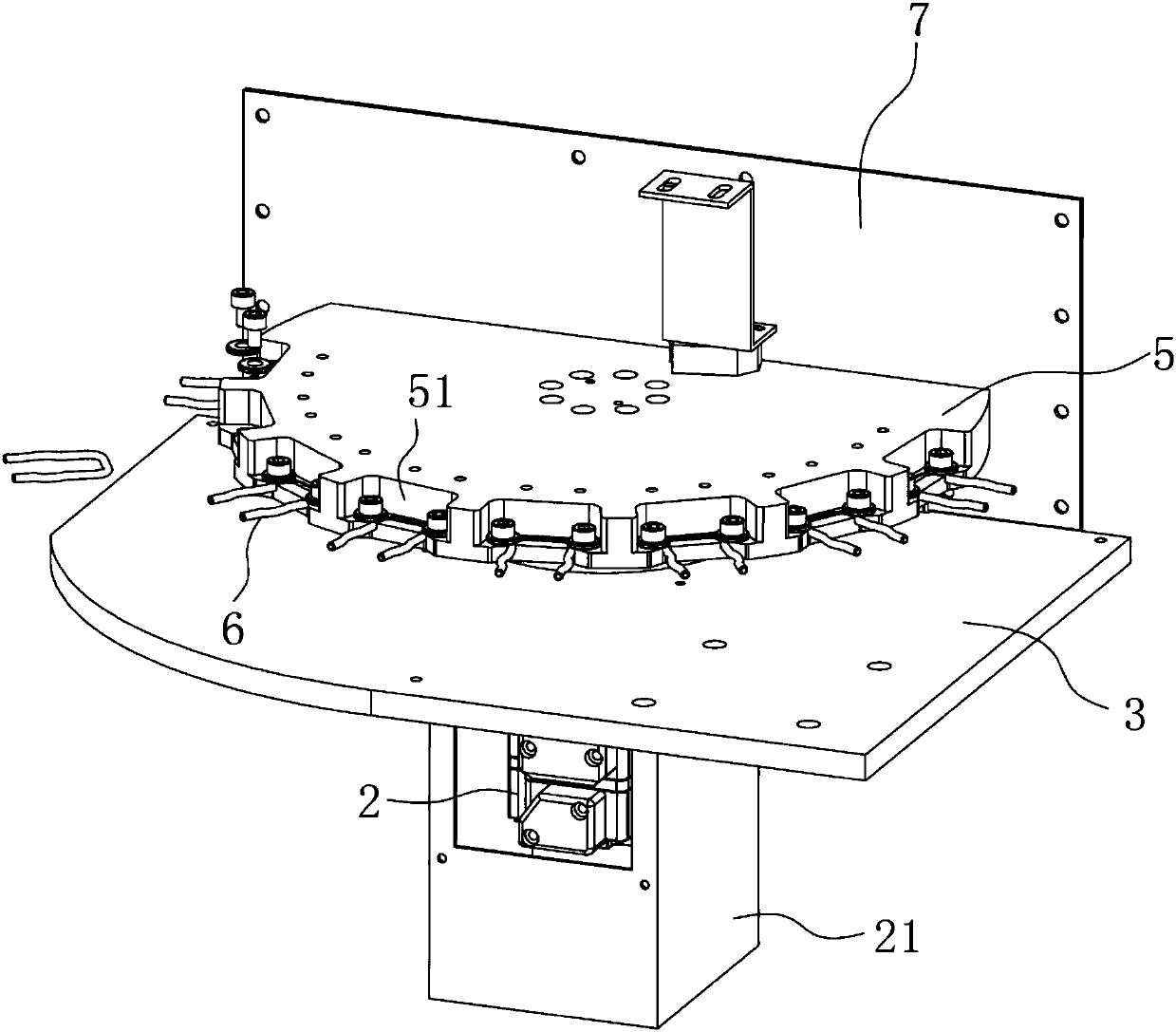

Half-moon type tool magazine structure

PendingCN107598637ASimple structureImprove horizontal accuracy and transmission stabilityPositioning apparatusMetal-working holdersDrive motorReducer

The invention discloses a half-moon type tool magazine structure. The half-moon type tool magazine structure comprises a tool magazine body, a driving device, a cutter disk and clamps, wherein the driving device comprises a driving motor and a harmonic reducer; a motor output shaft of the driving motor penetrates through the tool magazine body and then is connected with the harmonic reducer; the cutter disk is arranged at the top of the harmonic reducer and connected with the harmonic reducer; a plurality of cutter disk mounting tables are evenly arranged on the edge of the top face of the cutter disk; a tool mounting groove is formed in the table top of each cutter disk mounting table; the U-shaped bottoms of the clamps are clamped into the tool mounting grooves; and the two ends of the clamps extend out of the tool mounting grooves and can be used for clamping tools. According to the half-moon type tool magazine structure, the harmonic reducer is driven by the driving motor to act and directly drives the cutter disk to rotate, other extra transmission structures are not used indirectly, thus, the structure of a driving system is greatly simplified, the situation that the cutter disk bumps up and down during rotation can be avoided, the horizontal precision and transmission stability of the cutter disk during operation are improved, the positioning accuracy is improved, and the machining precision is ensured.

Owner:DEDA MACHINERY KUNSHAN

Precise surveying and mapping device for engineering surveying

ActiveCN112013223AReduce leveling difficultyImprove horizontal accuracySurveying instrumentsStands/trestlesSurvey instrumentSupport plane

The invention provides a precise surveying and mapping device for engineering surveying. The device comprises a support frame, wherein the support frame comprises a base and telescopic rods, at leastthree telescopic rods are annularly arranged on the bottom side of the base, the base is in an annular shape, a horizontal adjusting mechanism is arranged in the base, a mounting plate is arranged ata central through hole of an annular structure of the base, the mounting plate is movably connected with the base through a horizontal adjusting mechanism structure extending out of the side wall of the inner side of the base, connecting screws are arranged in the middle of the mounting plate, and surveying instrument is mounted at the upper end of the mounting plate through the connecting screws.According to the device, the base and the mounting plate are separately arranged, a floating block is movably connected with a ball cage connecting piece, and after fixation of the floating block isreleased, the floating block can drive the mounting plate to move under the action of buoyancy, so that the mounting plate is closer to a horizontal state, a more horizontal mounting environment is provided, the subsequent leveling difficulty of the surveying instrument is reduced, the horizontal precision of the surveying instrument is improved, more accurate surveying data is obtained, and the development prospect is good.

Owner:昆山市城乡房产测量有限公司

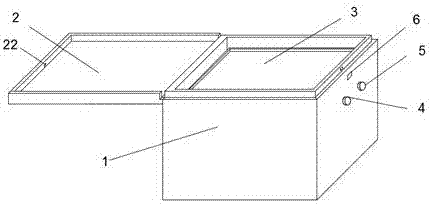

Portable 3D printer storage box

PendingCN107139477AImprove horizontal accuracyMeet job requirementsAdditive manufacturing apparatusManufacturing auxillary operationsComputer printingEngineering

Owner:山东同其智能科技有限公司

A control device and control method for automatic deployment of sea oil spill containment boom

InactiveCN104454798BImprove efficiencyHigh precisionWater cleaningGeneral water supply conservationHydraulic motorAudio power amplifier

Owner:SHANDONG UNIV OF SCI & TECH

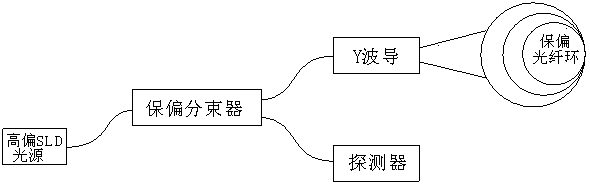

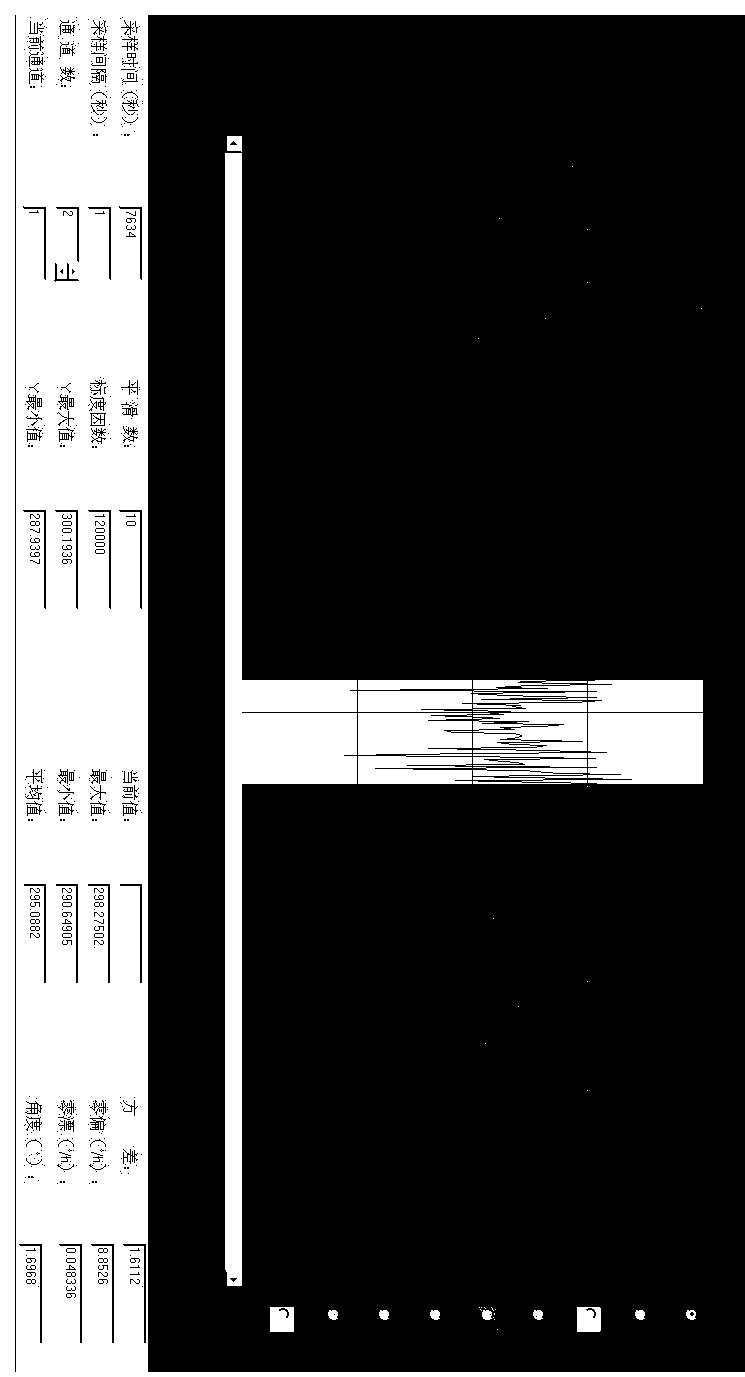

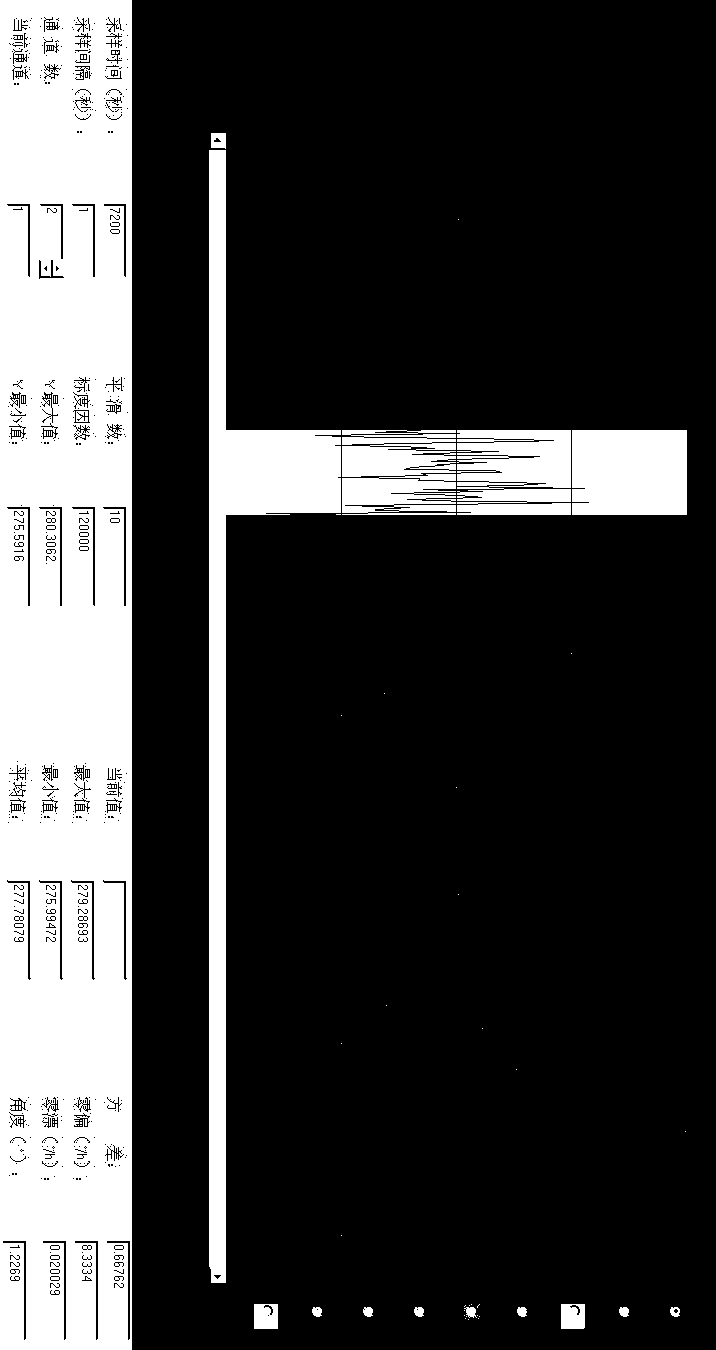

Full polarization-maintaining light path of optical fiber gyroscope

InactiveCN103398709AHigh polarization state purityIncrease profitSagnac effect gyrometersOptical pathLight wave

A disclosed full polarization-maintaining light path of an optical fiber gyroscope comprises a high polarizing SLD light source, a polarization-maintaining beam splitter, a Y waveguide and a polarization maintaining fiber coil; the high polarizing light source goes through the polarization-maintaining beam splitter and then is input to the Y waveguide; the two tail fibers of the Y waveguide are respectively connected with the two ends of the polarization maintaining fiber coil; and the polarization-maintaining beam splitter is connected with a detector, and is used to perform beam splitting on a light wave signal returned by the Y waveguide, so that the light wave signal returned by the Y waveguide is detected and converted into an electric signal which is resolved by a subsequent resolving circuit. The full polarization-maintaining light path of the optical fiber gyroscope is capable of inhibiting polarization cross-coupling in the whole light path, and thus polarization noise of the optical fiber gyroscope is inhibited, and the precision of the optical fiber gyroscope is improved.

Owner:CHONGQING HUAYU ELECTRIC GRP

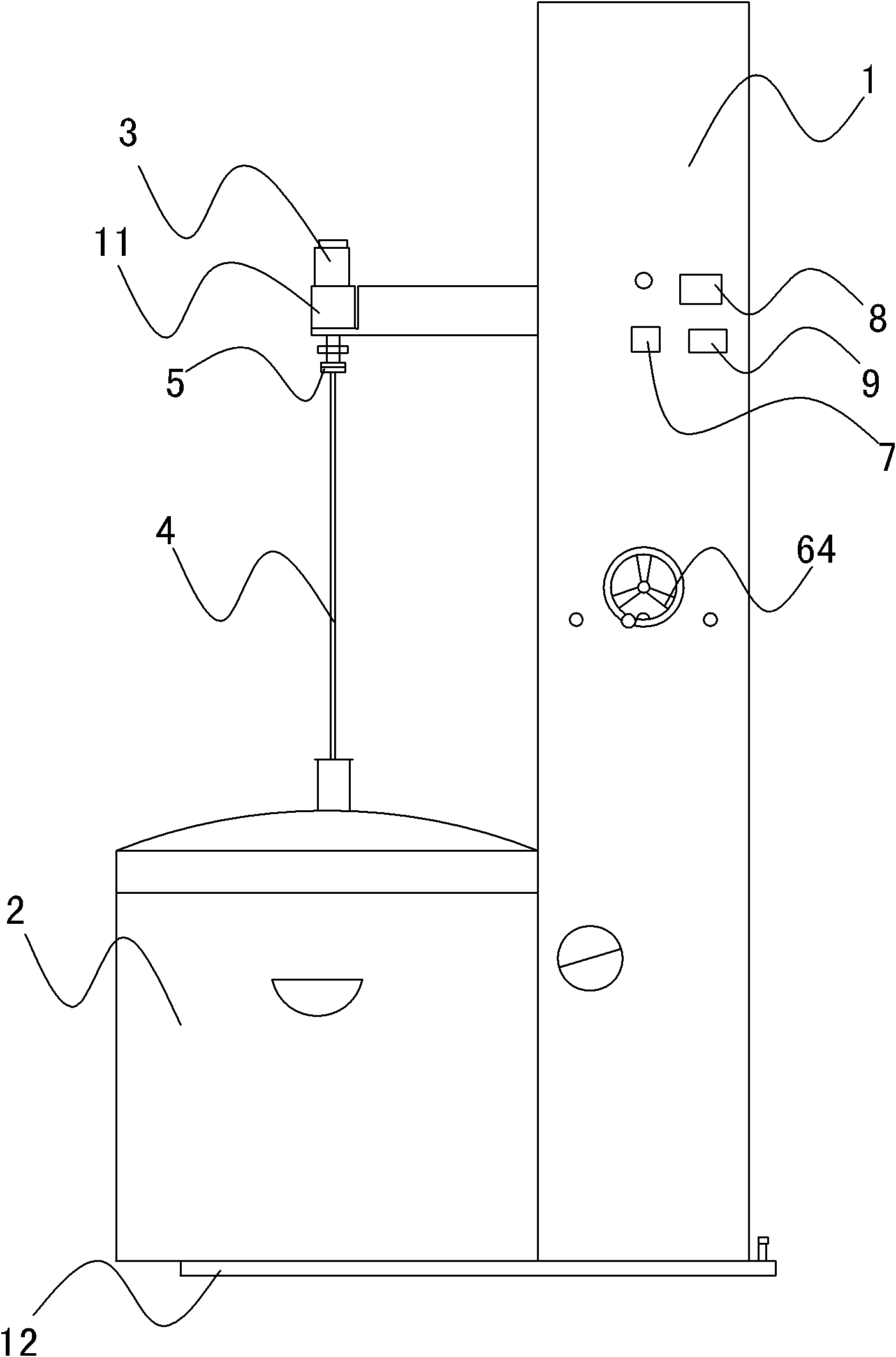

Potassium titanyl phosphate growth equipment

InactiveCN102277619ASmall mechanical error disturbanceImprove the uniformity of the temperature fieldPolycrystalline material growthBy pulling from meltControl systemPower switching

The present invention relates to the technical field of growing potassium titanyl phosphate by an additive method, and provides a freely adjustable seed crystal rotary rod to continuously rotate and stir the vertical precision required for KTP crystal growth, and the operation of pulling the seed crystal rotary rod is simple and convenient. Further, the growth equipment of potassium titanyl phosphate that improves the production yield and quality of potassium titanyl phosphate crystals includes a fuselage, a furnace barrel, a DC motor, a seed crystal rotating rod, a temperature sensor, a PLC control system and a power switch, and the power switch is set On the fuselage, the power switch is electrically connected to the DC motor, the DC motor, the temperature sensor and the power switch are all electrically connected to the PLC control system and controlled by the PLC control system, and a cross arm is arranged on the fuselage , the DC motor is arranged on the cross arm of the fuselage, the lifting device is arranged on the fuselage and connected with the cross arm of the fuselage, the DC motor is connected with the seed crystal rotating rod through the connecting seat, and the The free end of the seed crystal rotating rod is vertically installed in the furnace barrel.

Owner:FUJIAN ZHONGCE OPTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com