Method for producing one or more concave cut-outs on a main body which is, in particular, substantially cylindrical, armature, keeper plate, and electromagnetic actuator

An electromagnetic actuator and retaining plate technology, which is applied in the manufacture of electromagnets with armatures, electromagnets, inductors/transformers/magnets, etc., can solve the problem of impossible secondary processing, separate milling, and inability to use through-grinding process and other issues to achieve the effect of horizontal precision and high horizontal precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

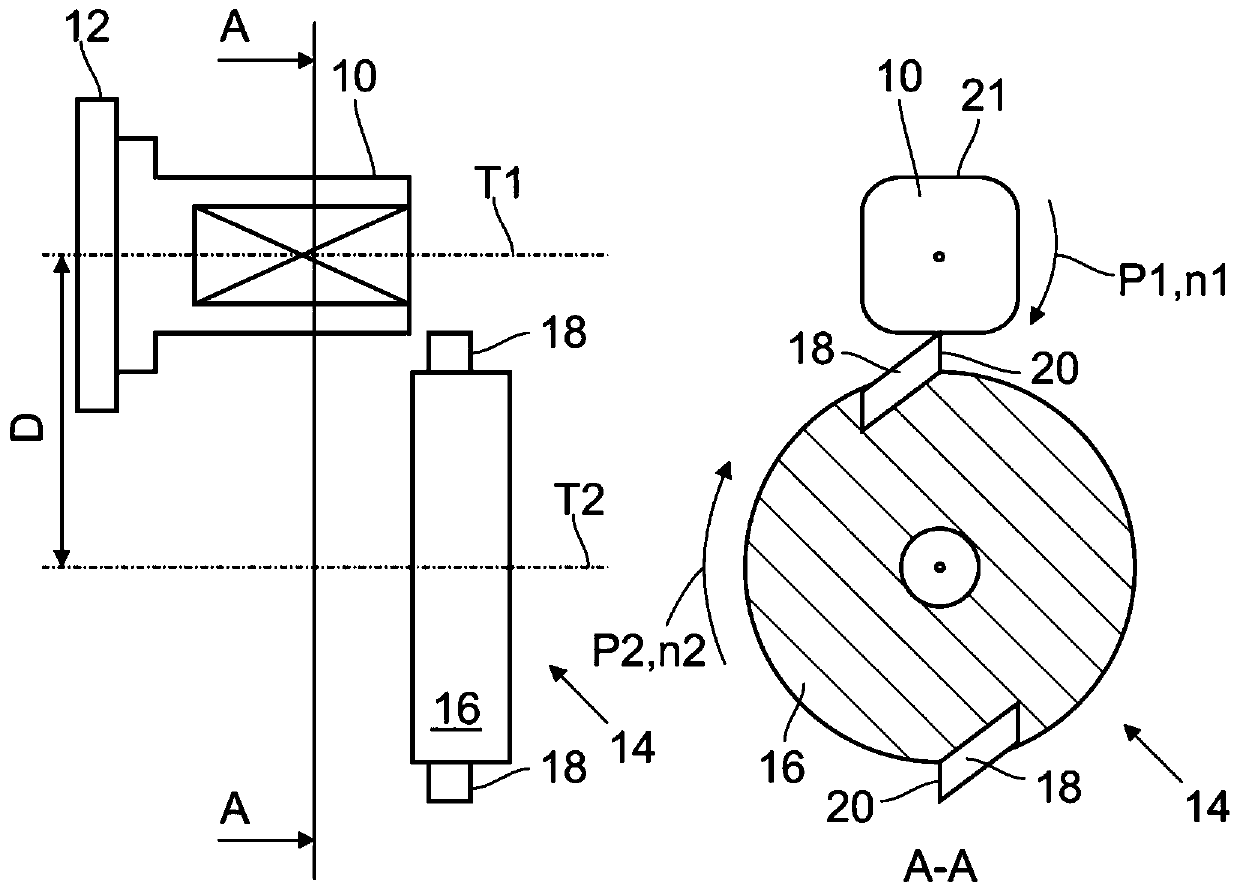

[0051] figure 1 The polygon turning known from the prior art is shown on the basis of a schematic diagram. Here, the substantially cylindrical body 10 in the initial state is clamped in a lathe 12 and rotated at a first rotational speed n1 about a first rotational axis T1 . Furthermore, the turning tool 14 has a disc-shaped receiving body 16 to which two high-speed cutting tools are fixed, rotating at a second rotational speed n2 about a second rotational axis T2. The second axis of rotation T2 extends parallel and is offset by a distance D from the first axis of rotation T1. The main body 10 rotates in a first rotational direction, while the turning tool 14 rotates in a second rotational direction, which is indicated by arrows P1 and P2. based on figure 1 In the illustration selected in , the main body 10 and the turning tool 14 are rotated to the right. The distance D between the first axis of rotation T1 and the second axis of rotation T2 is selected such that the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com