Pile cap foundation for offshore wind turbine and construction method thereof

A technology for wind turbines and pile caps, which is applied to the assembly of wind turbines, wind power generation, installation/support configuration of wind turbines, etc. It can solve problems such as low construction efficiency, low reliability, and high construction difficulty, and achieve Installation and removal are easy to operate, ensure horizontal accuracy requirements, and reduce the effect of offshore operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

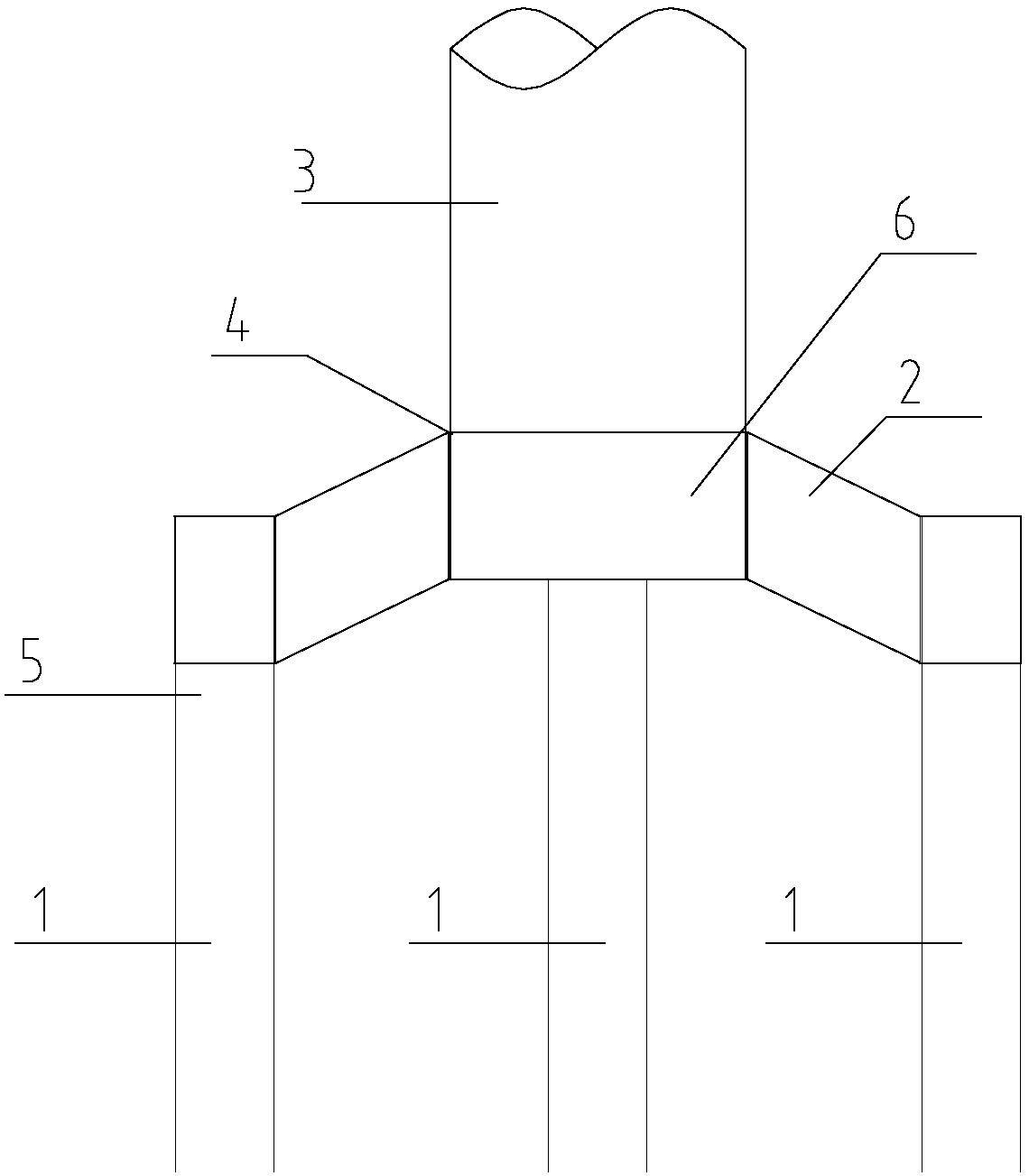

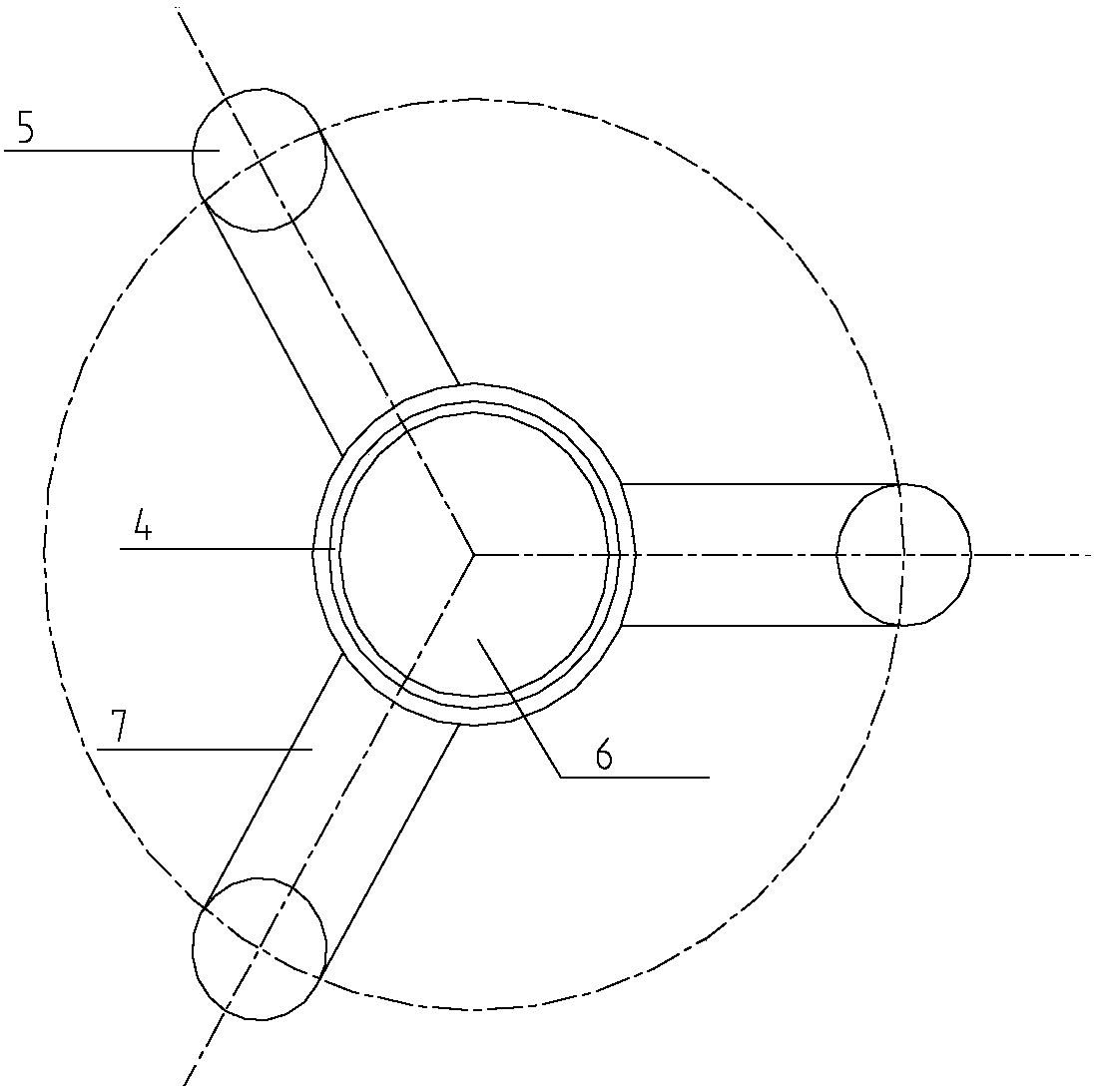

[0039] Such as figure 1 As shown, it is the foundation of the offshore wind power generating set of the present invention, which includes three steel pipe piles 1 and a steel cap 2 . The upper part of the steel cap 2 is provided with a flange 4 connected to the wind turbine tower 3. The steel cap has a central box 6 and several steel box girders 7 extending outward from the central box. The top of the central box 6 There is a flange 4 connected to the tower 3 of the wind power generating set, and vertical and horizontal reinforced steel ribs are arranged in the box.

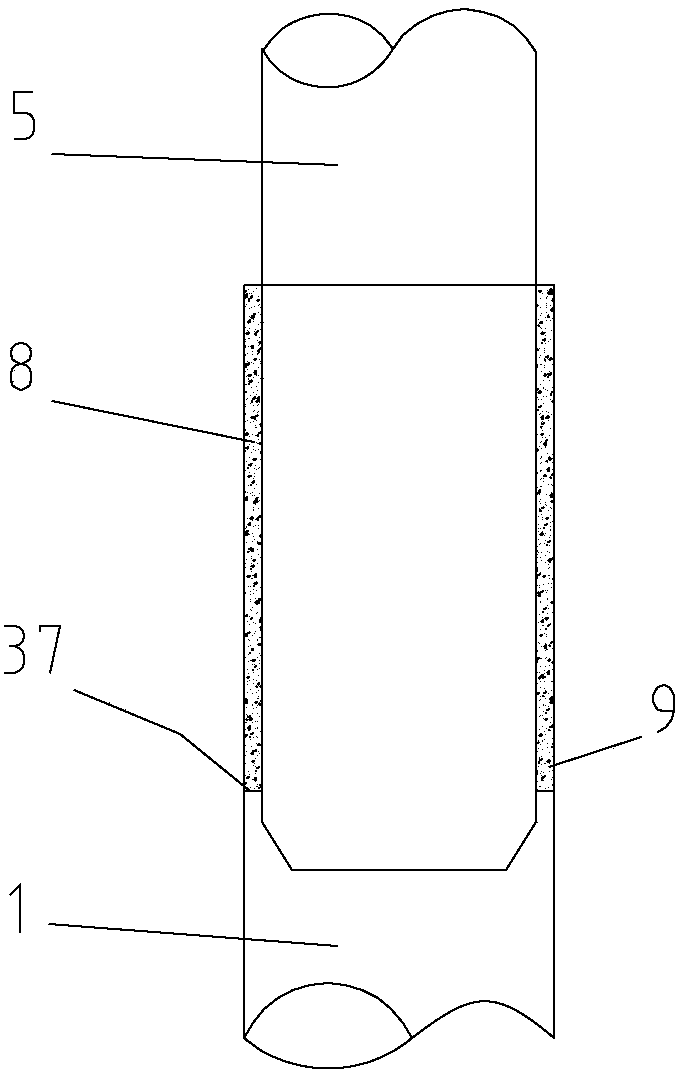

[0040] The end of each steel box girder away from the central box body is provided with steel cap pile legs 5, the number of steel cap pile legs matches the number of steel pipe piles and is socketed in the corresponding steel pipe piles.

[0041] Such as Figure 9 As shown, the steel pipe pile 1 is provided with a steel corbel 13 extending outward from the outer wall of the pile leg of the steel cap. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com