Right-side front door frame assembling and welding tool and installing and adjusting method thereof

A technology for welding tooling and frame assembly, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The product size is qualified and stable, the production time is shortened, and the assembly process is efficient and fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

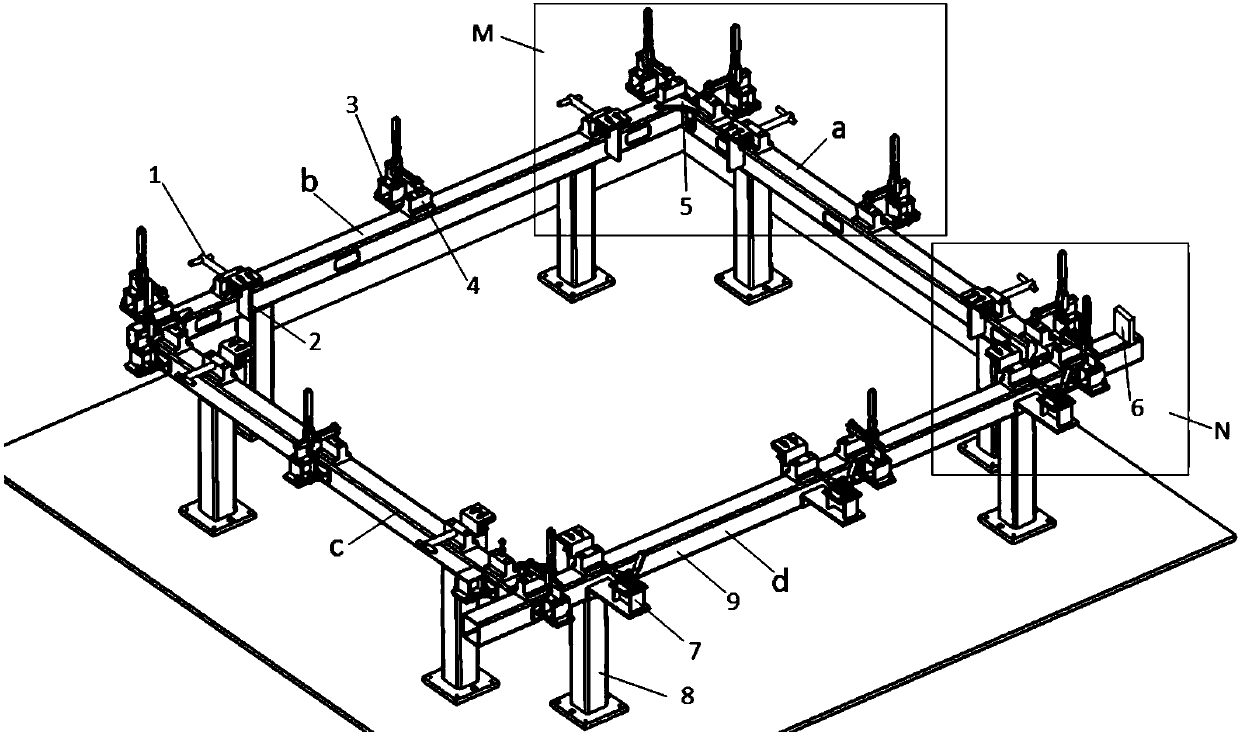

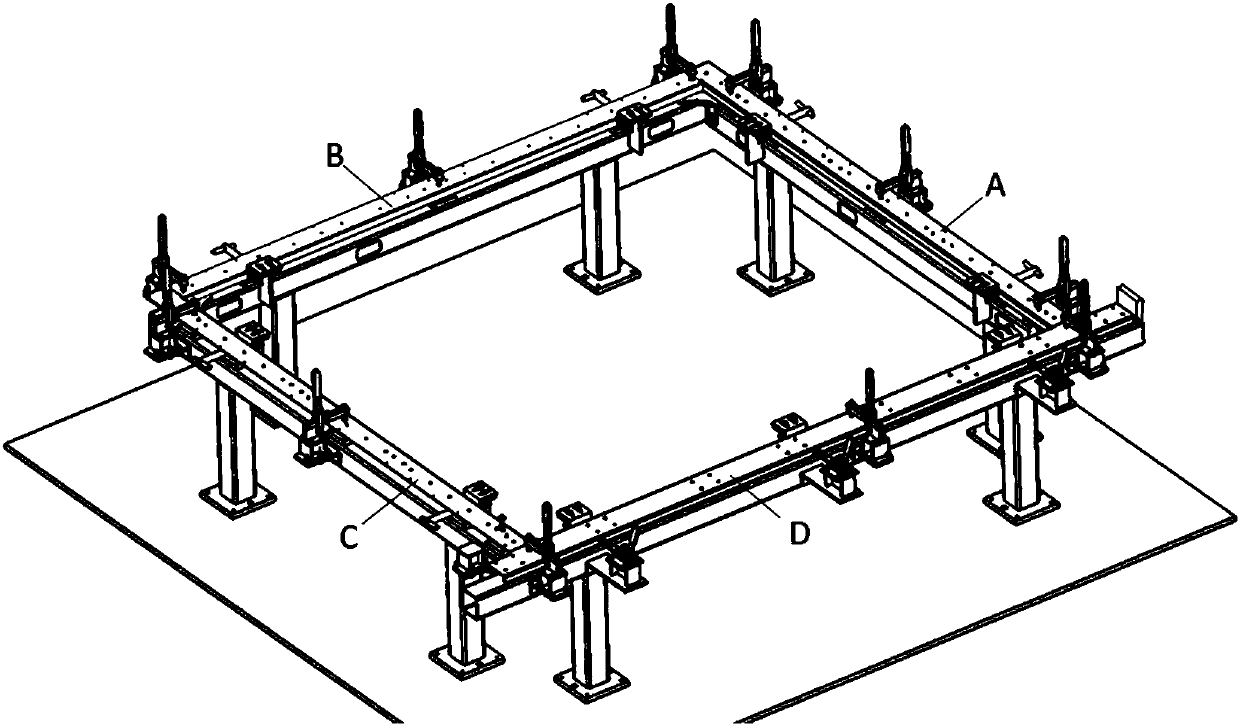

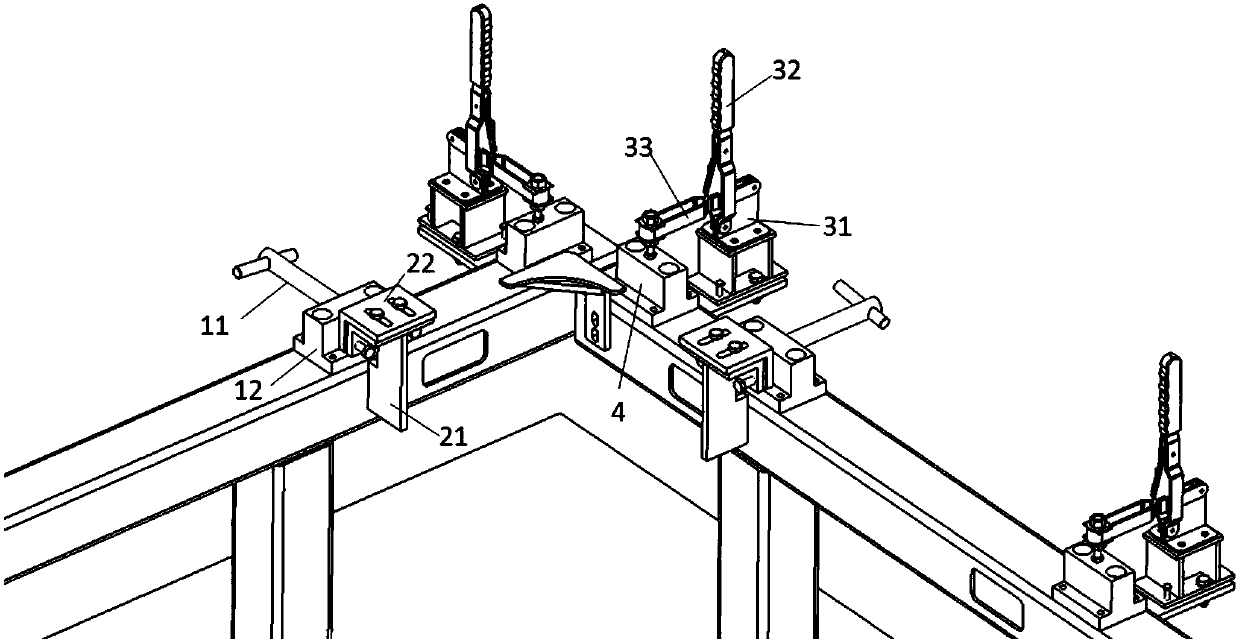

[0038] Such as Figure 1~2 , a right front door frame butt welding tool, including a threaded clamping clamp 1, a limit block 2, a pressing quick clamp 3, a spacer 4, a reinforcement plate gasket 5, a limiting block 6, and a clamping clamp 7 , column 8, beam 9; the column 8 has eight and is vertically fixed on the ground, the beam 9 has four abcd, each beam 9 is vertically connected with two columns 8, and the four beams are formed end to end The structure corresponding to the ABCD four sides of the front door frame on the right side; there are six pairs of threaded clamping fixtures 1, and two pairs are respectively arranged on the three crossbeams of abc; There are three pairs on the root crossbeam; there are three pairs of fast clamps 7, which are all arranged on the d crossbeam; four pairs of the reinforcing plate gasket 5 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com