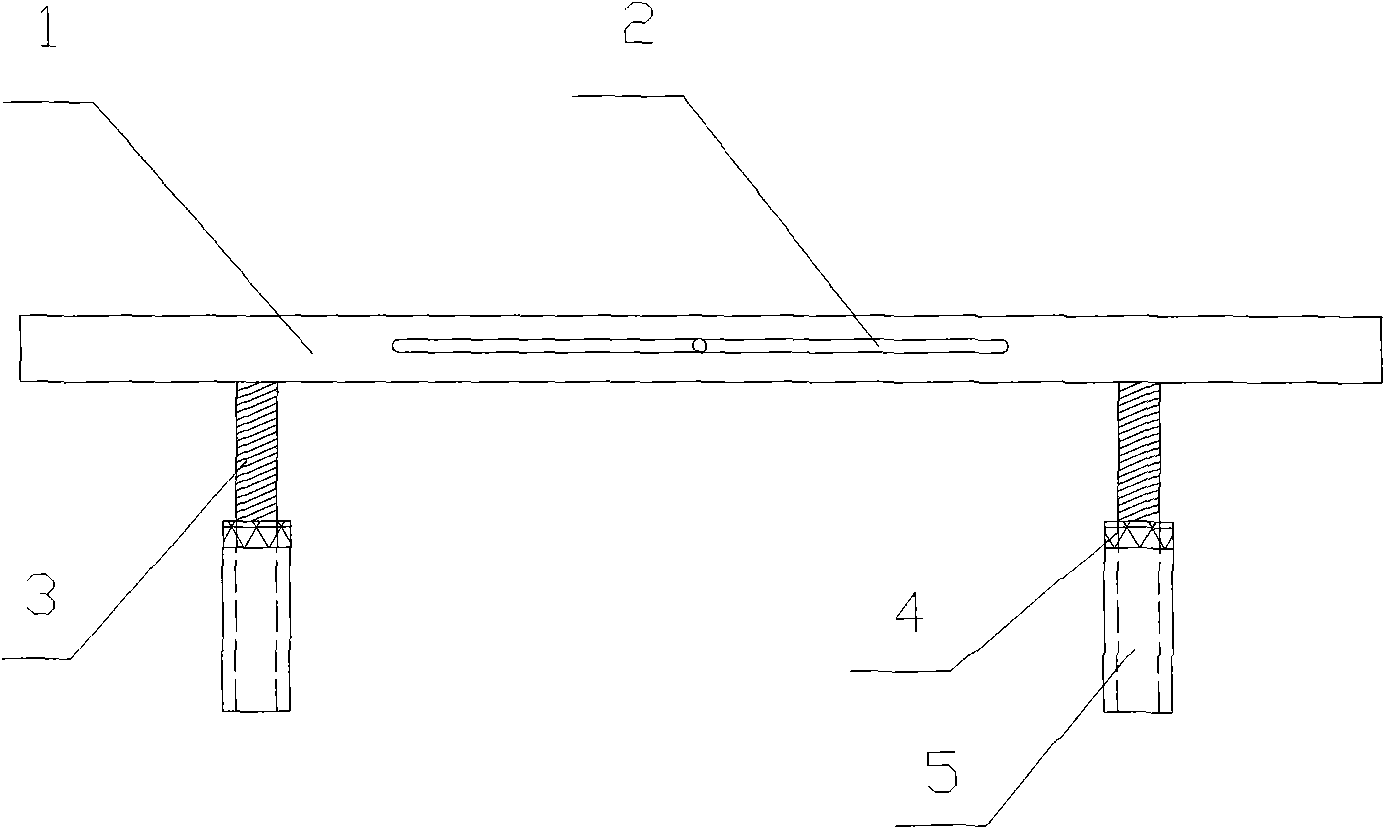

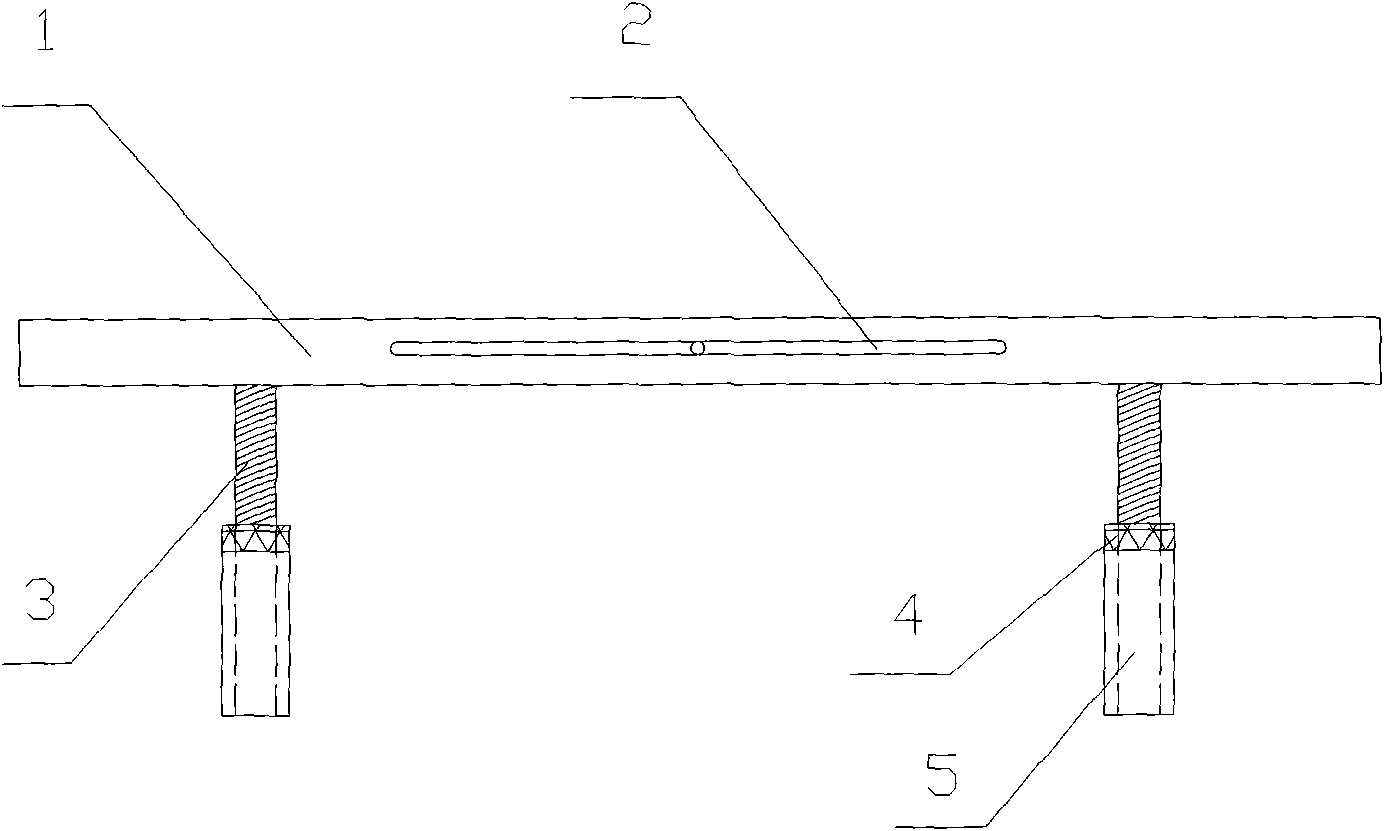

Knob type horizontal workbench

A workbench and knob-type technology, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of inconvenient adjustment and insufficient precision, and achieve the effect of high horizontal accuracy, convenient adjustment, and good horizontal working surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In the specific embodiment shown in the accompanying drawings, the knob-type horizontal workbench is composed of a table top (1), a horizontal pipe (2), a screw (3), a knob (4), and feet (5), wherein the table top (1) It is a flat rectangular parallelepiped with excellent flatness, and is made of stainless steel. There is a horizontal tube (2) on each of the four sides of the table (1), and the horizontal tube (2) is horizontally embedded in the side of the table (1). The length is 1 / 2 of the long side of the side rectangle. The horizontal tube (2) is made of plexiglass, and the inside is filled with water, leaving a blister. When the horizontal plane is completely horizontal, the four blisters are all at the central scale of the horizontal tube (2). Four identical precision screw rods (3) are fixed under the table top (1), with fine threads on the top, and a threaded knob (4) extends under the screw rod (3) into a sleeve-type foot (5), through the screw rod (3) Turn th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com