Intelligent anti-swing control method for multi-section uniformly-variable-speed crane

A control method and crane technology, applied in the directions of load hanging components, transportation and packaging, can solve the problems of unsuitability for wide application, less combination and high cost, and achieve the effects of low cost, good stability and elimination of load deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

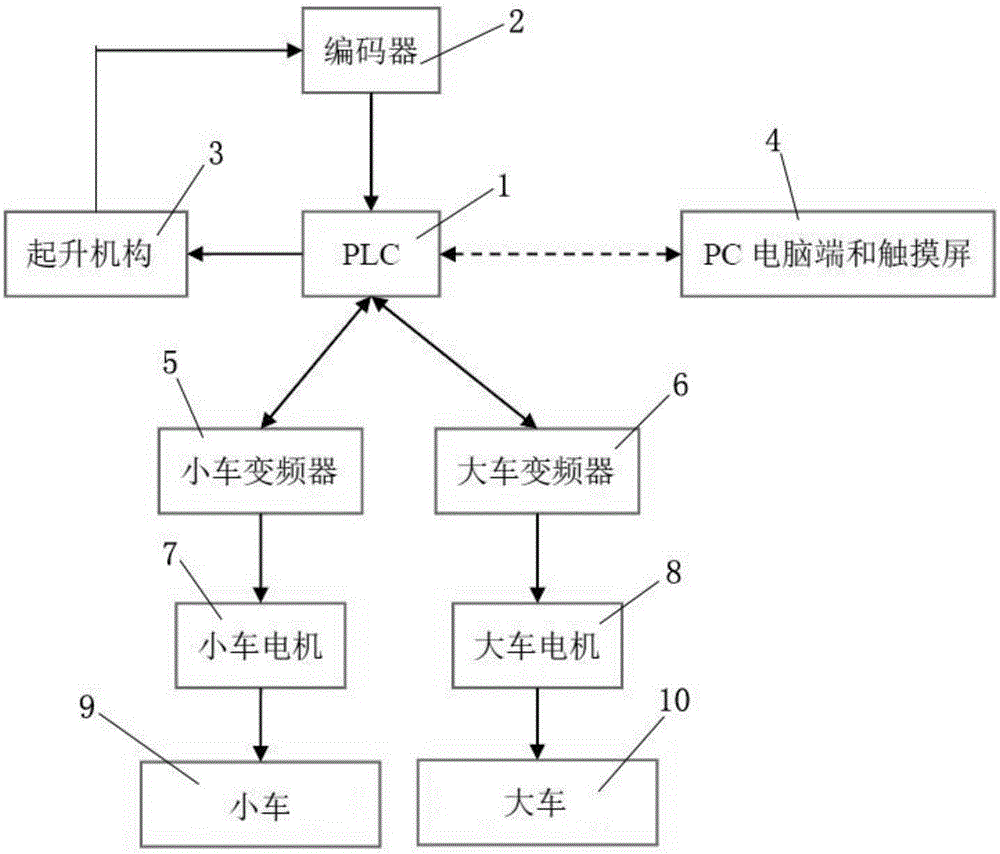

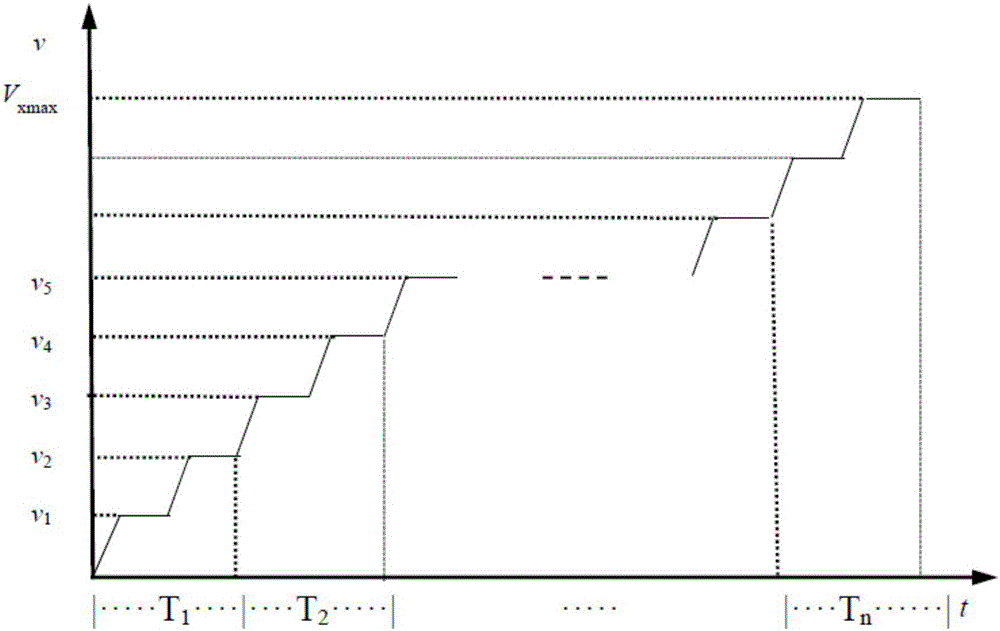

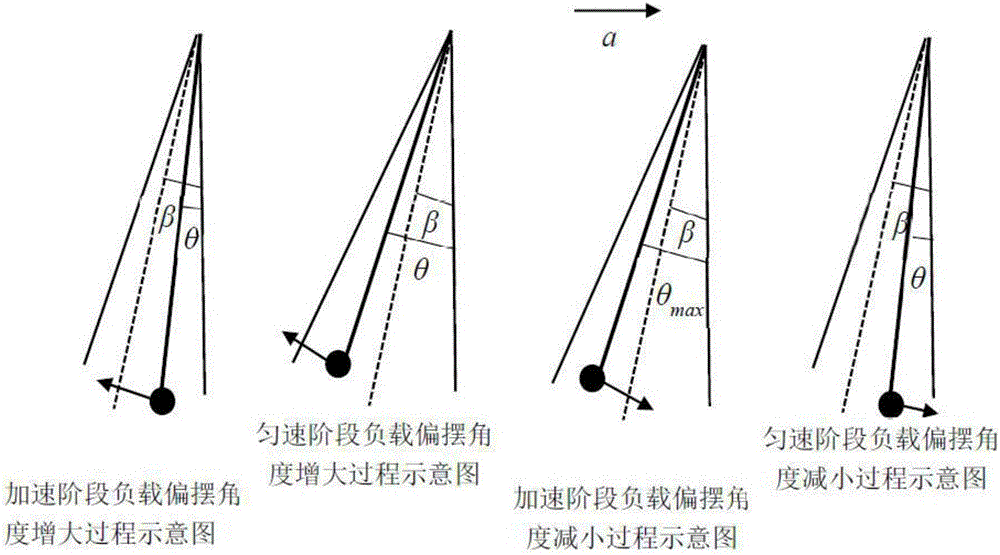

[0043] The intelligent anti-sway control system of the multi-stage uniform speed crane adopts dynamics and control software for joint simulation, that is, establishes the dynamics model of the crane through Adams, and the dynamics model of the crane is as attached Figure 4 As shown, the control model of the anti-swing control system is established through Matlab. Because the crane is large and the anti-sway control principle is the same during the operation of the trolley, the anti-sway simulation of the load during the multi-stage uniform acceleration of the trolley is taken as an example to illustrate the anti-sway control process. The specific main setting parameters are: the maximum allowable swing of the load is x=0.16m, and the maximum running speed of the trolley is v xmax =1m / s, the length of the hoisting rope is l=1.725m. The specific control process of the intelligent anti-sway control system for multi-stage uniform speed cranes is as follows:

[0044] 1. Establis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com