Patents

Literature

101 results about "Sway control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

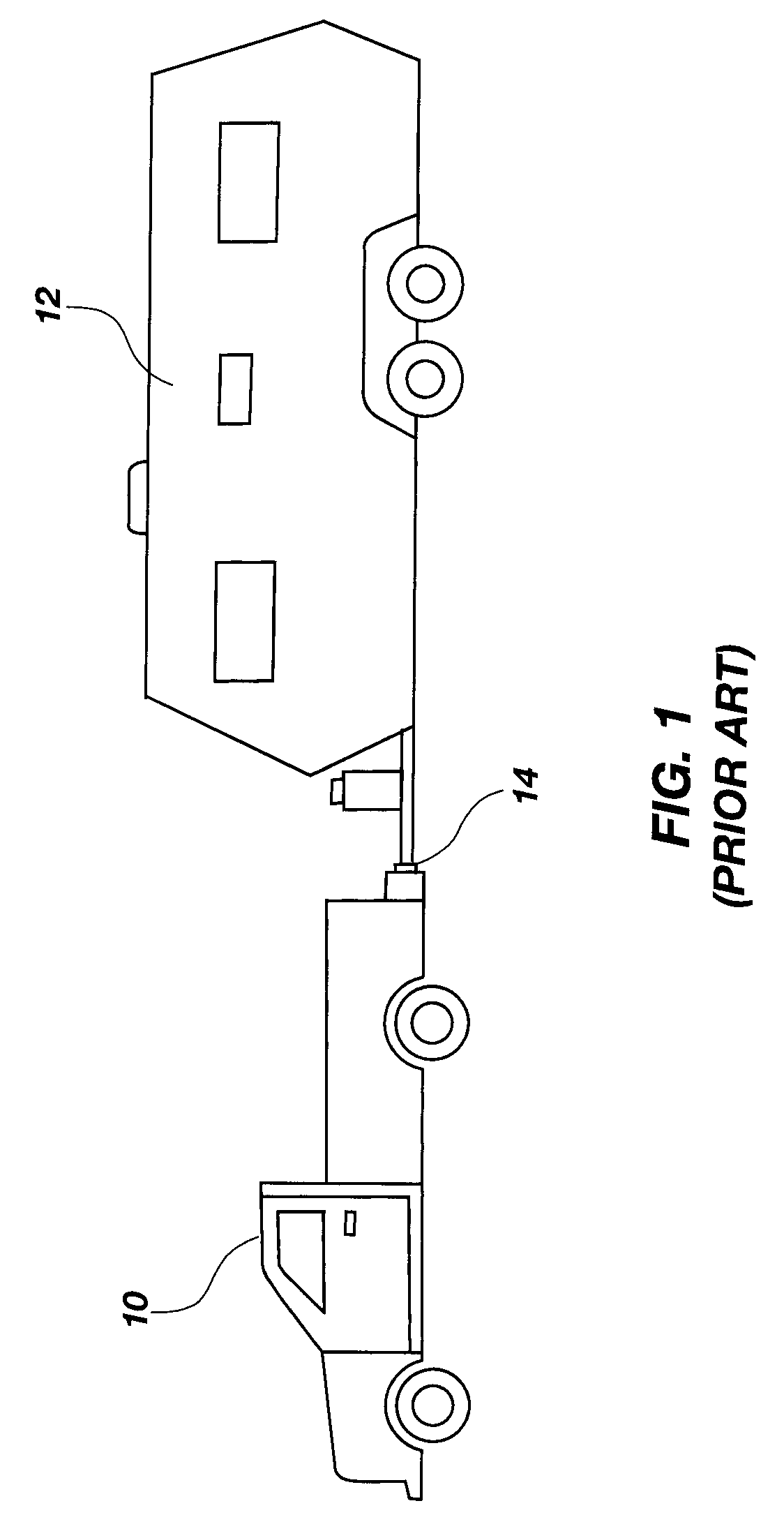

Trailer sway control with reverse sensors

InactiveUS20090198425A1Furthers stabilizationHand manipulated computer devicesAnalogue computers for trafficProximity sensorSteering wheel

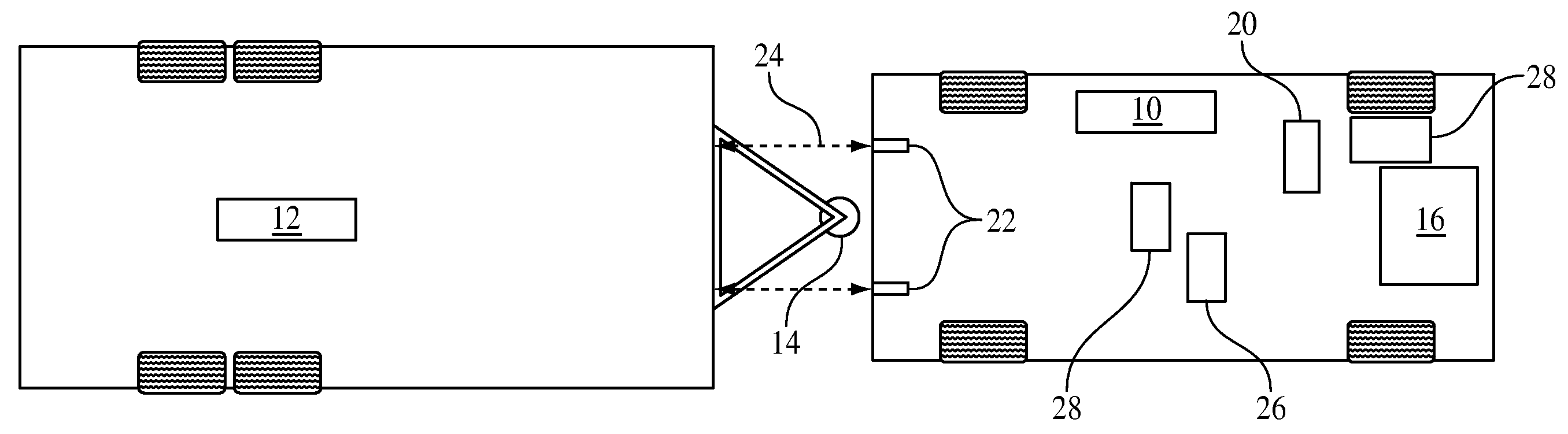

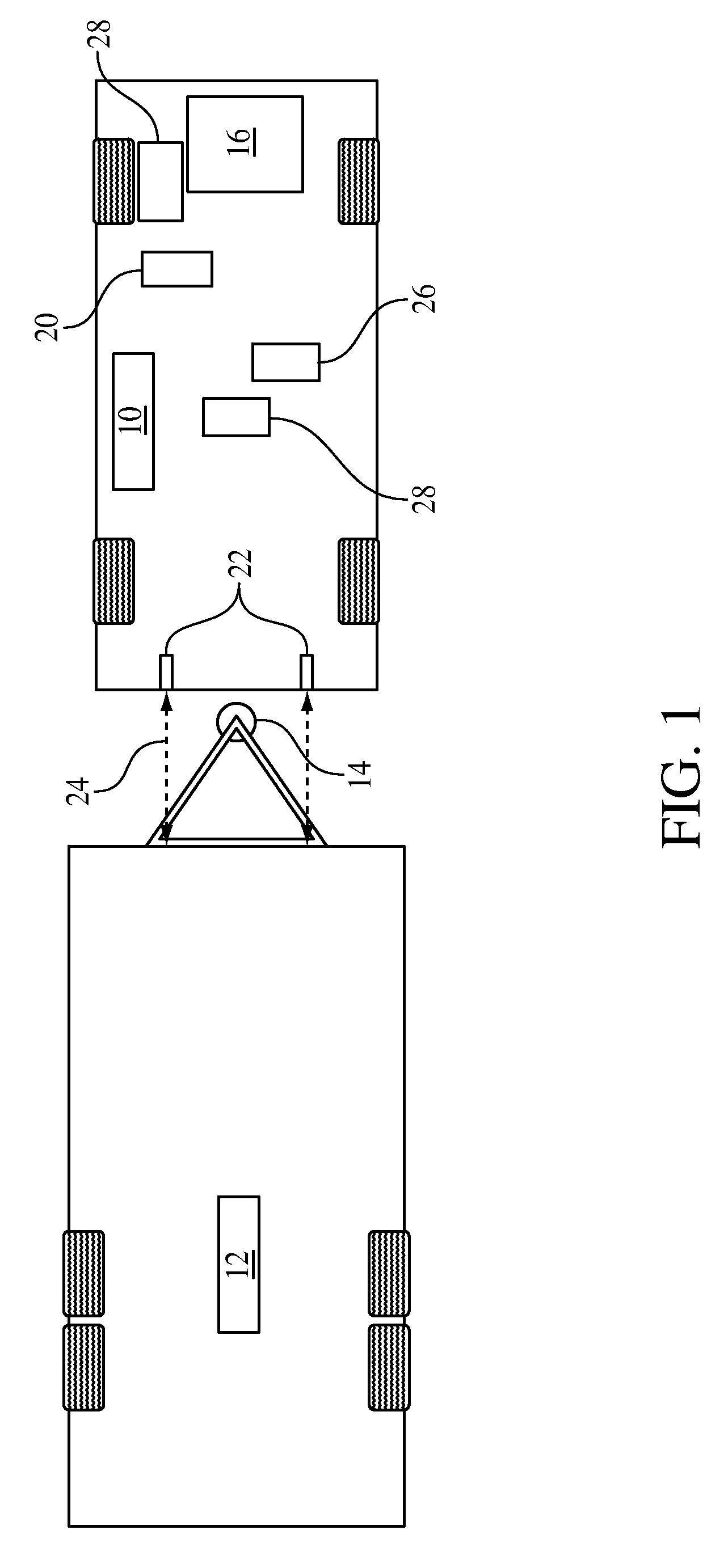

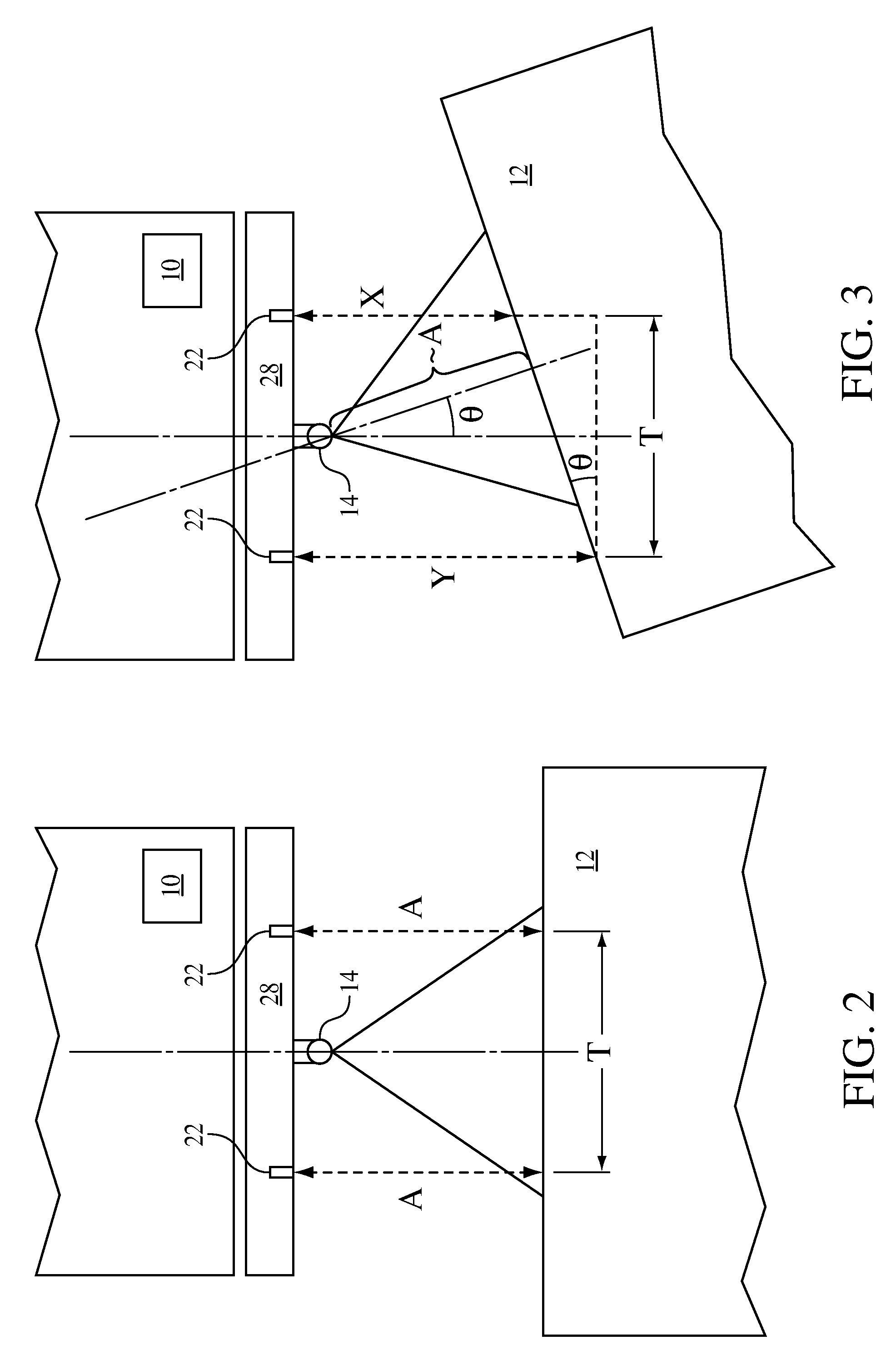

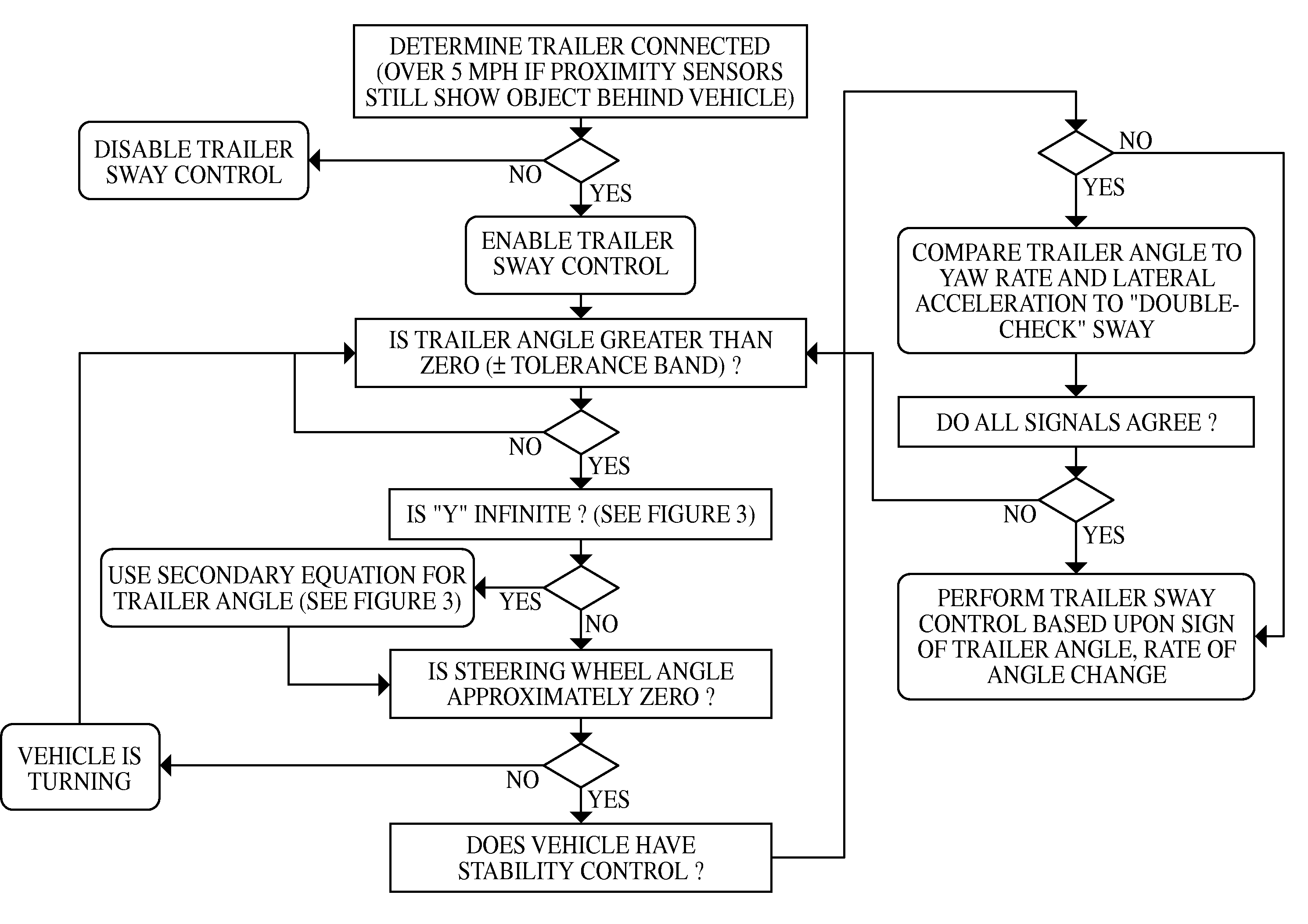

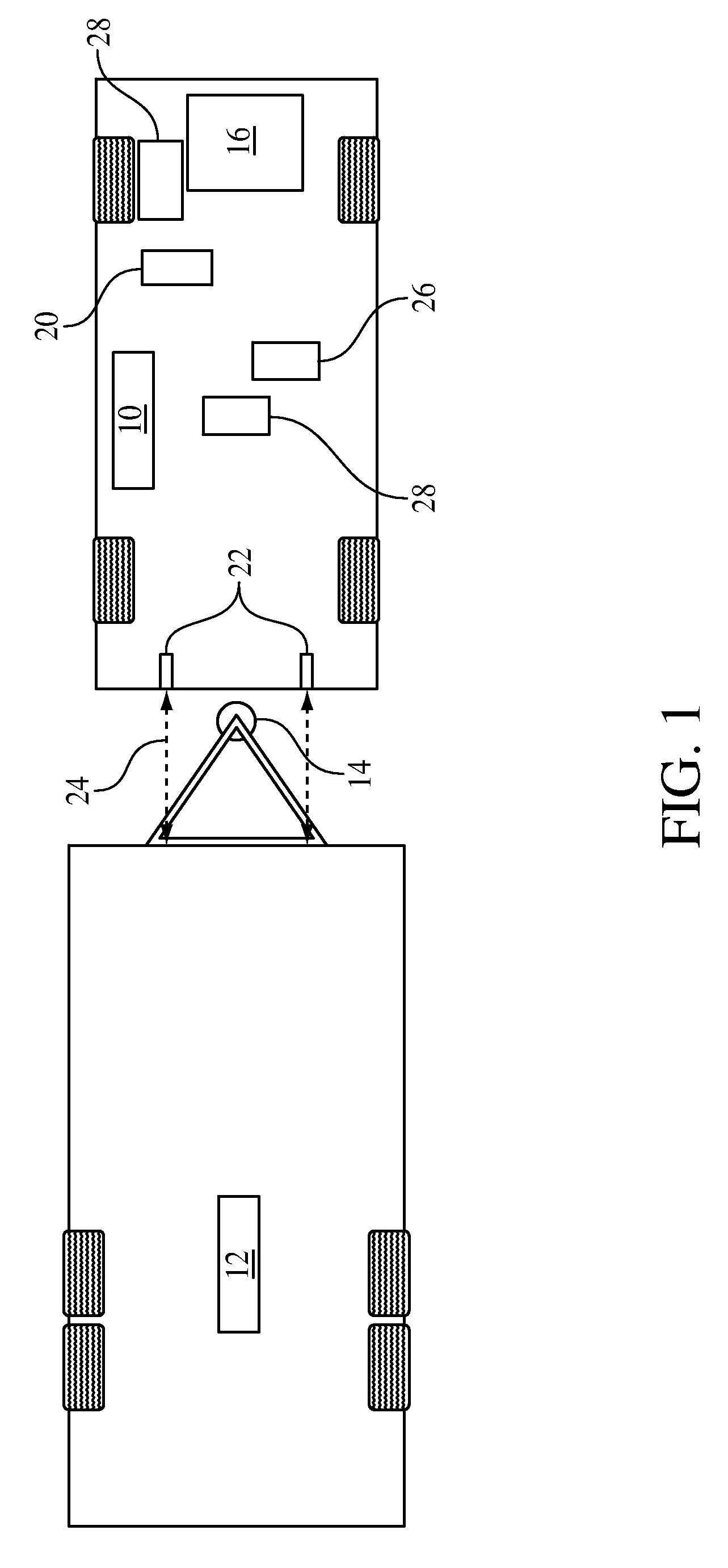

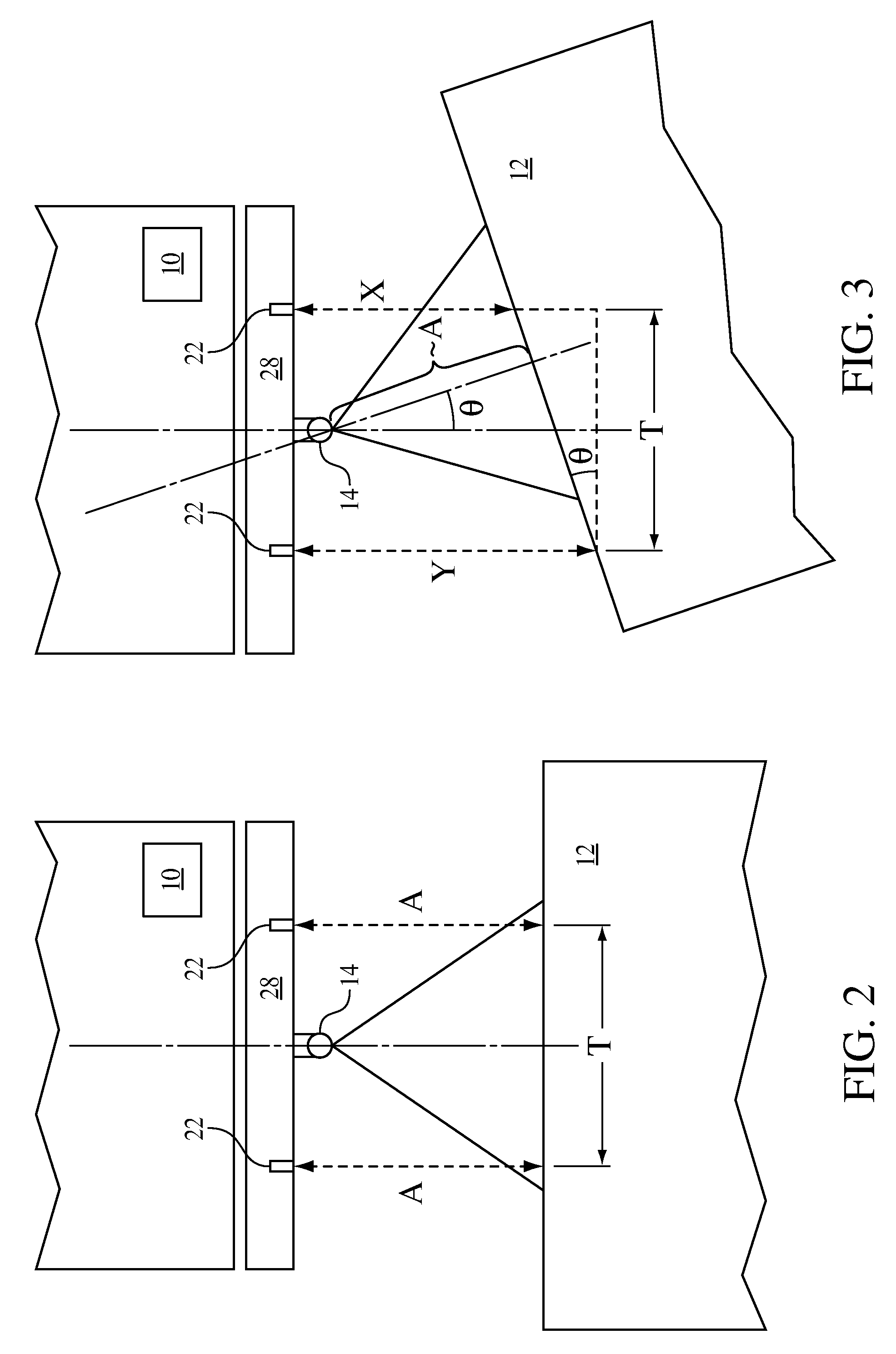

Reverse proximity sensors are used to determine an angle between a towed trailer and the towing vehicle. The trailer sway control determines a trailer angle of sway based upon proximity sensor readings from the reverse proximity sensors and from a sensor reading of an angle of turn of a steering wheel of the towing vehicle. Provided the determined trailer angle of sway exceeds a range that can be tolerated, a controller sends instructions to apply necessary braking to the vehicle or trailer to mitigate the trailer sway.

Owner:FORD GLOBAL TECH LLC

Trailer sway control with reverse sensors

InactiveUS8260518B2Furthers stabilizationHand manipulated computer devicesAnalogue computers for trafficProximity sensorSteering wheel

Reverse proximity sensors are used to determine an angle between a towed trailer and the towing vehicle. The trailer sway control determines a trailer angle of sway based upon proximity sensor readings from the reverse proximity sensors and from a sensor reading of an angle of turn of a steering wheel of the towing vehicle. Provided the determined trailer angle of sway exceeds a range that can be tolerated, a controller sends instructions to apply necessary braking to the vehicle or trailer to mitigate the trailer sway.

Owner:FORD GLOBAL TECH LLC

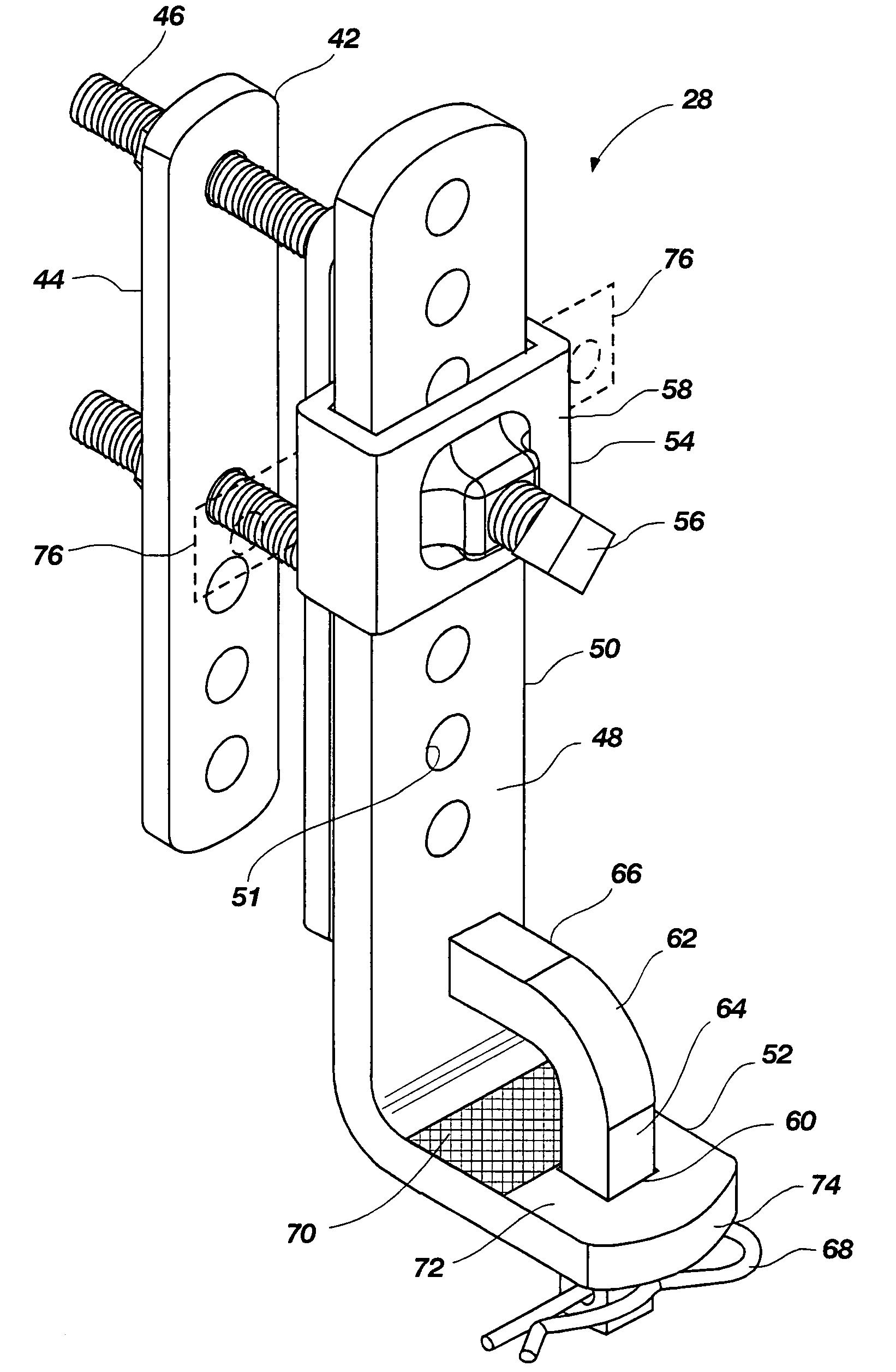

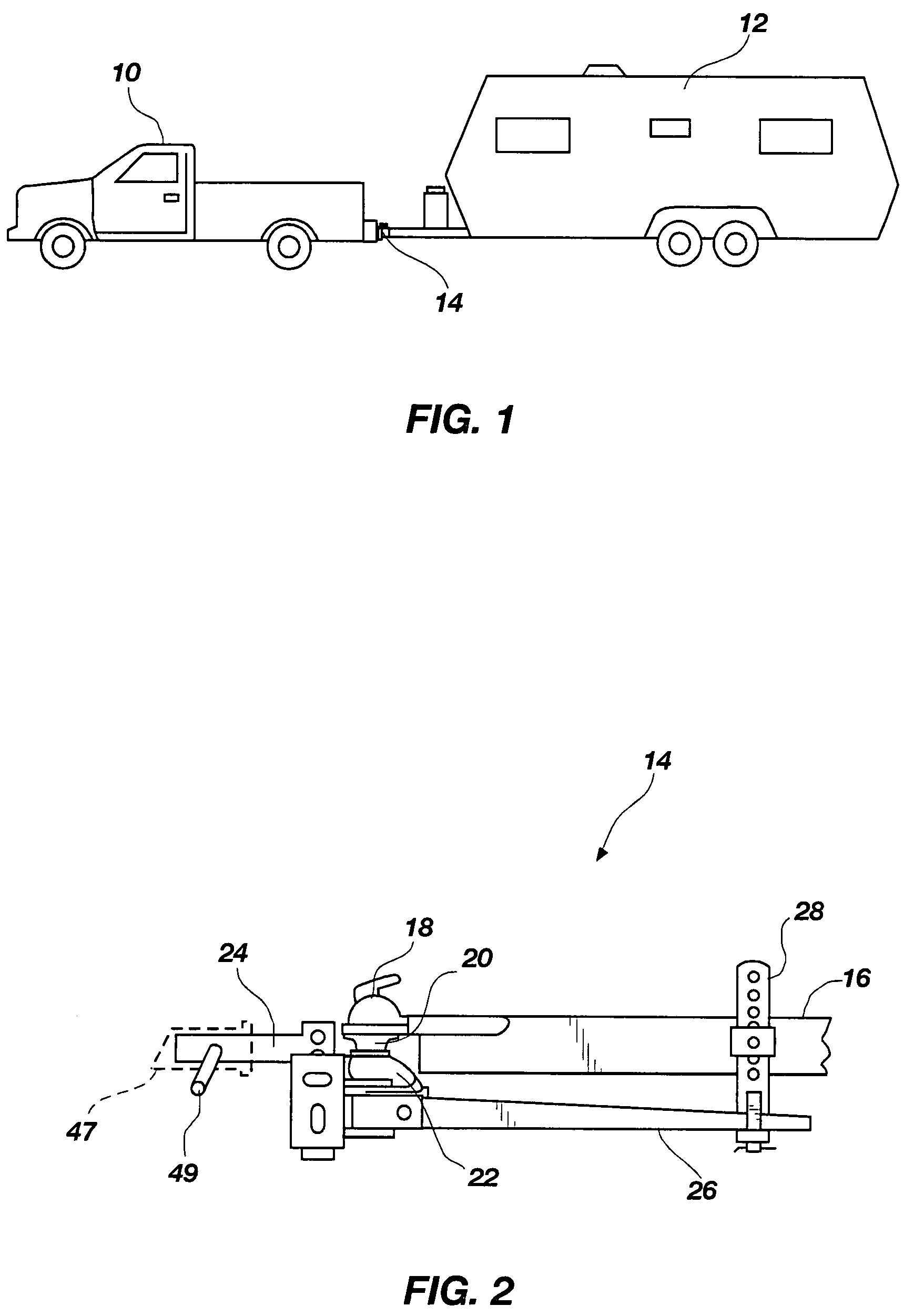

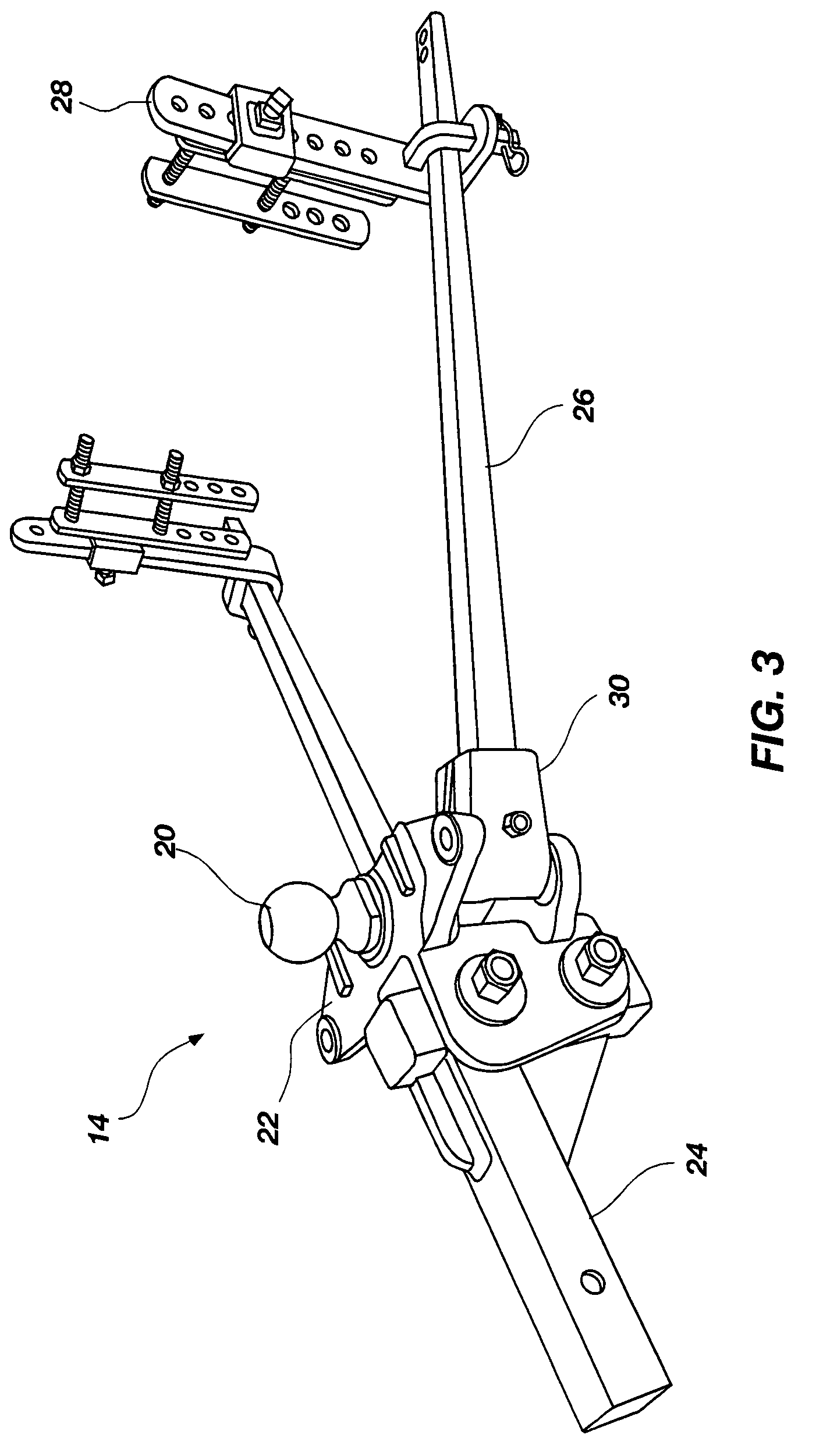

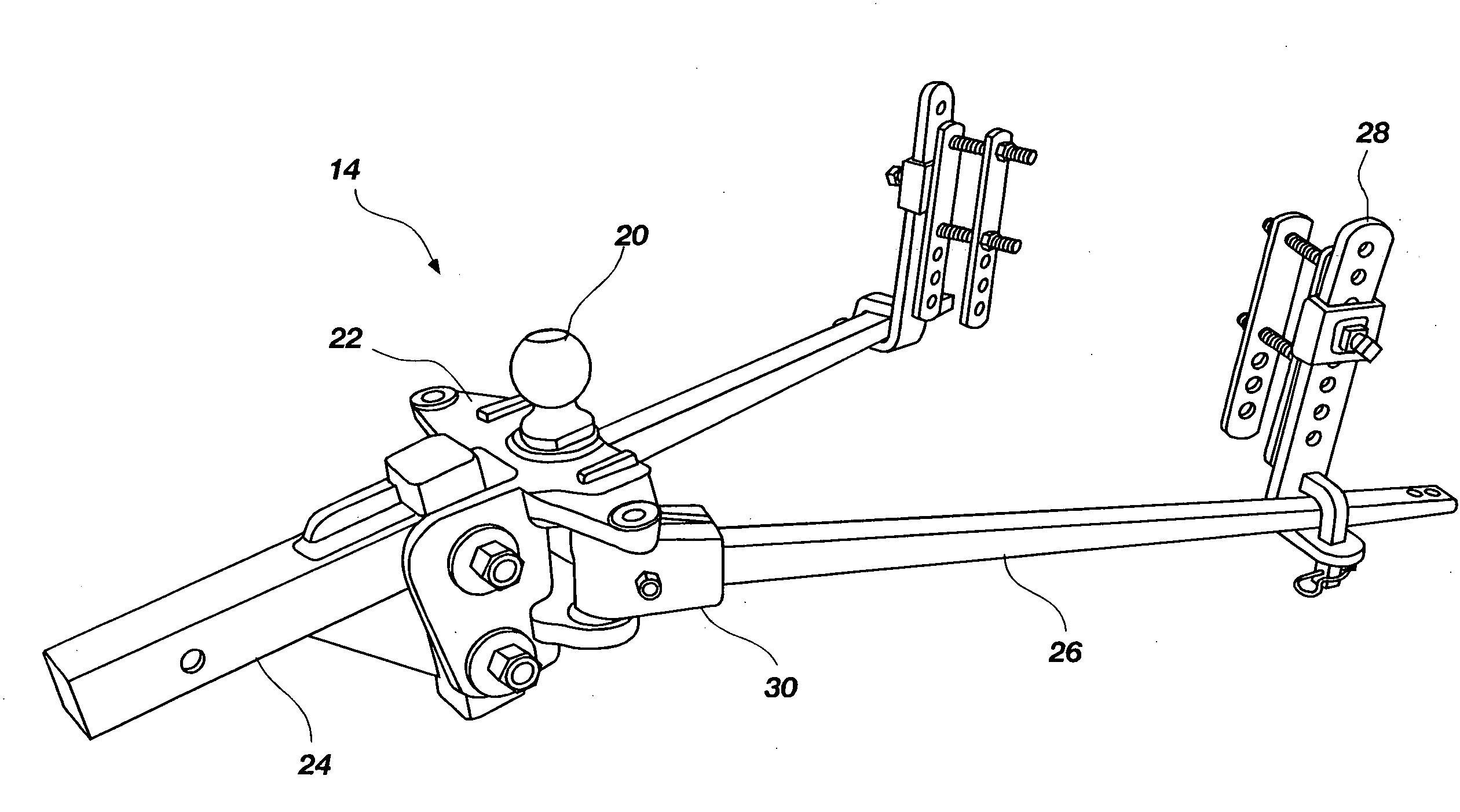

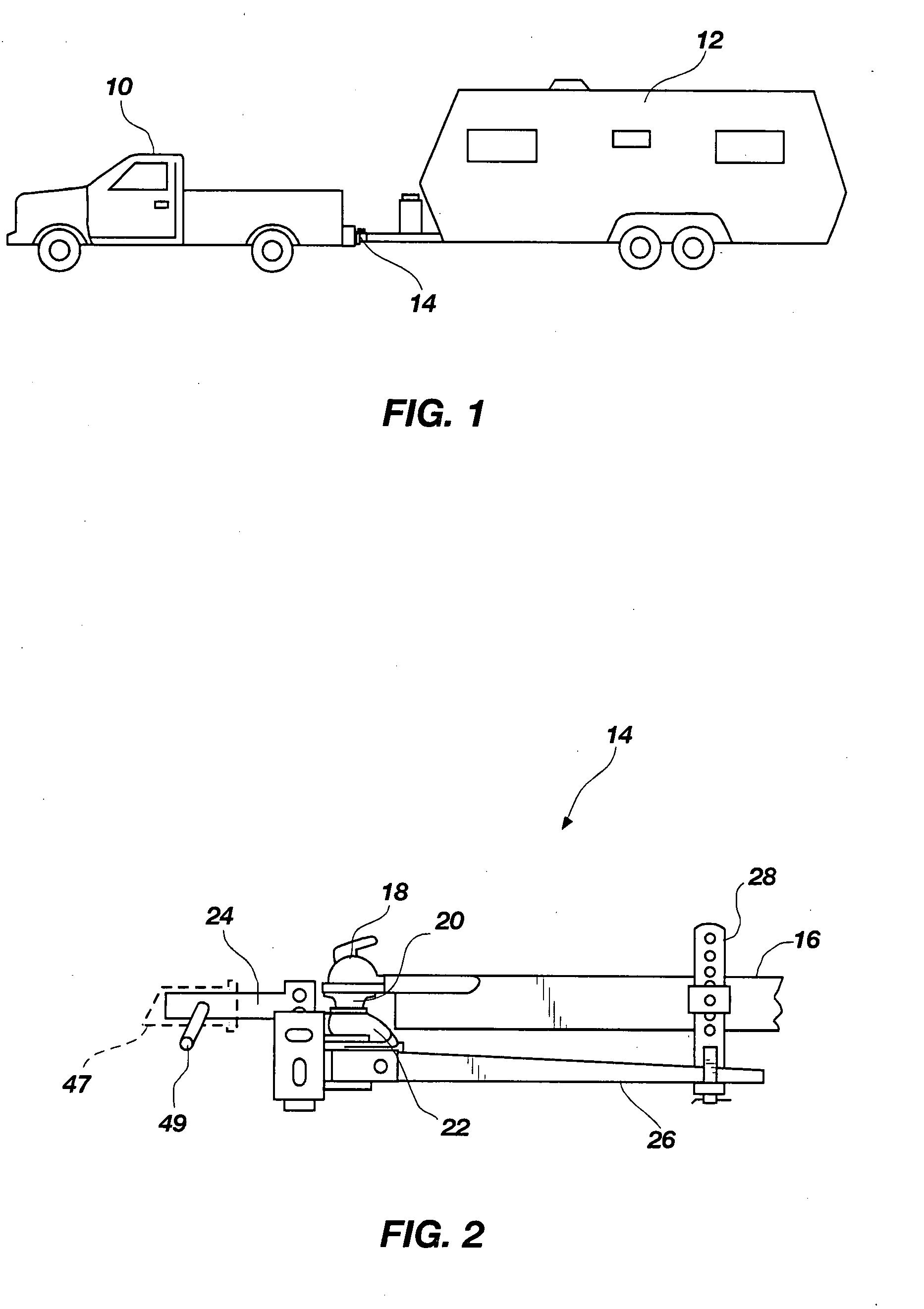

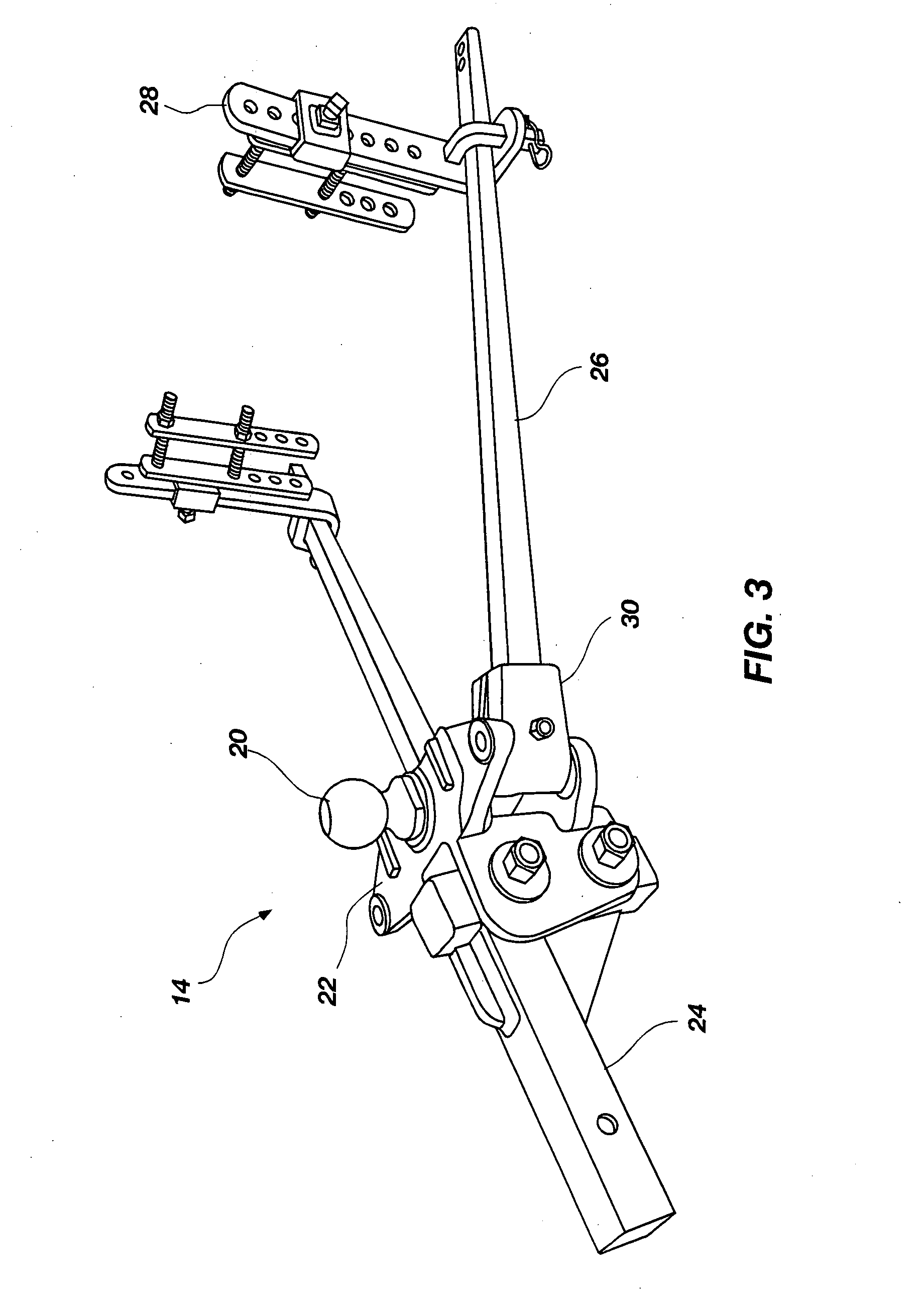

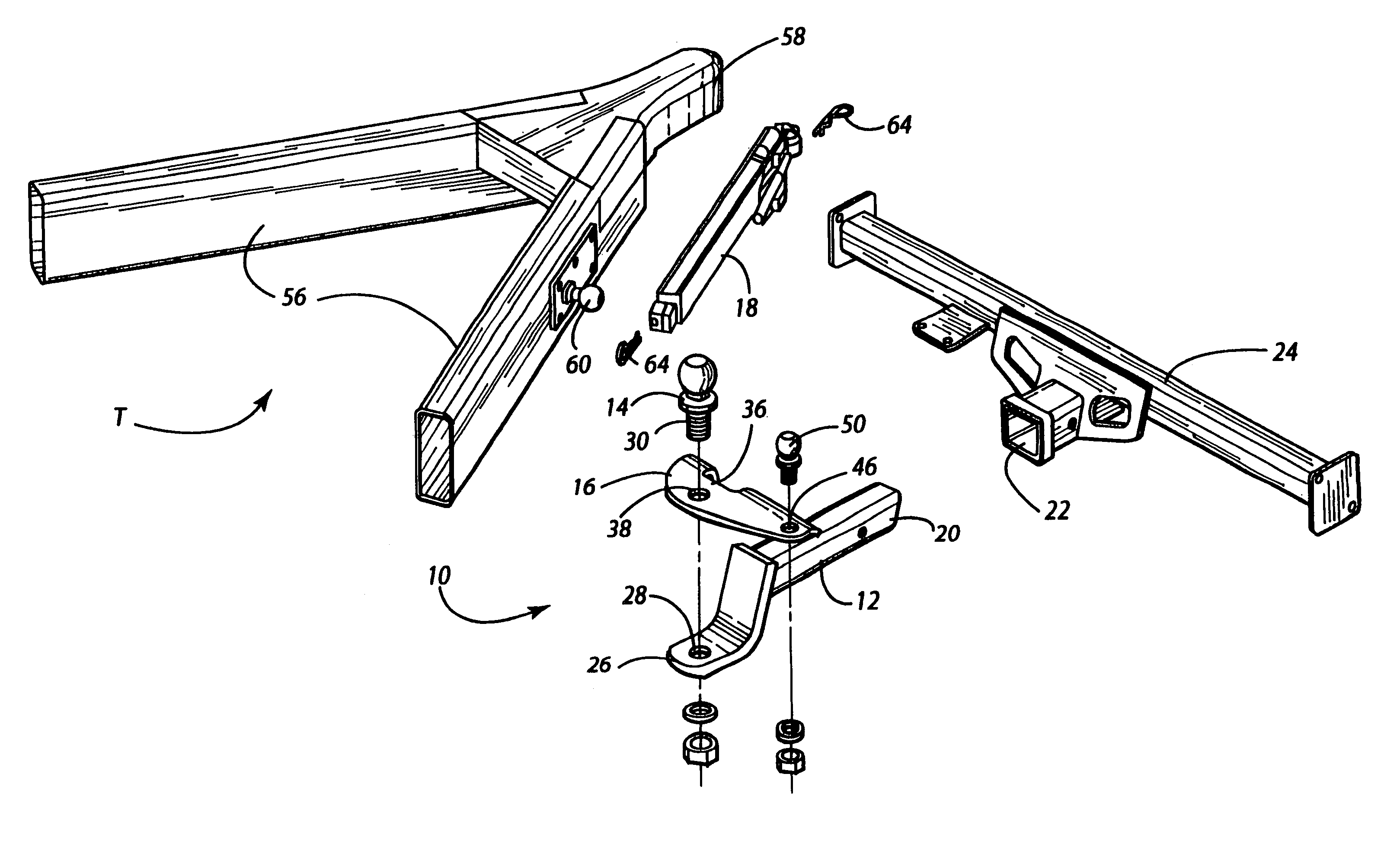

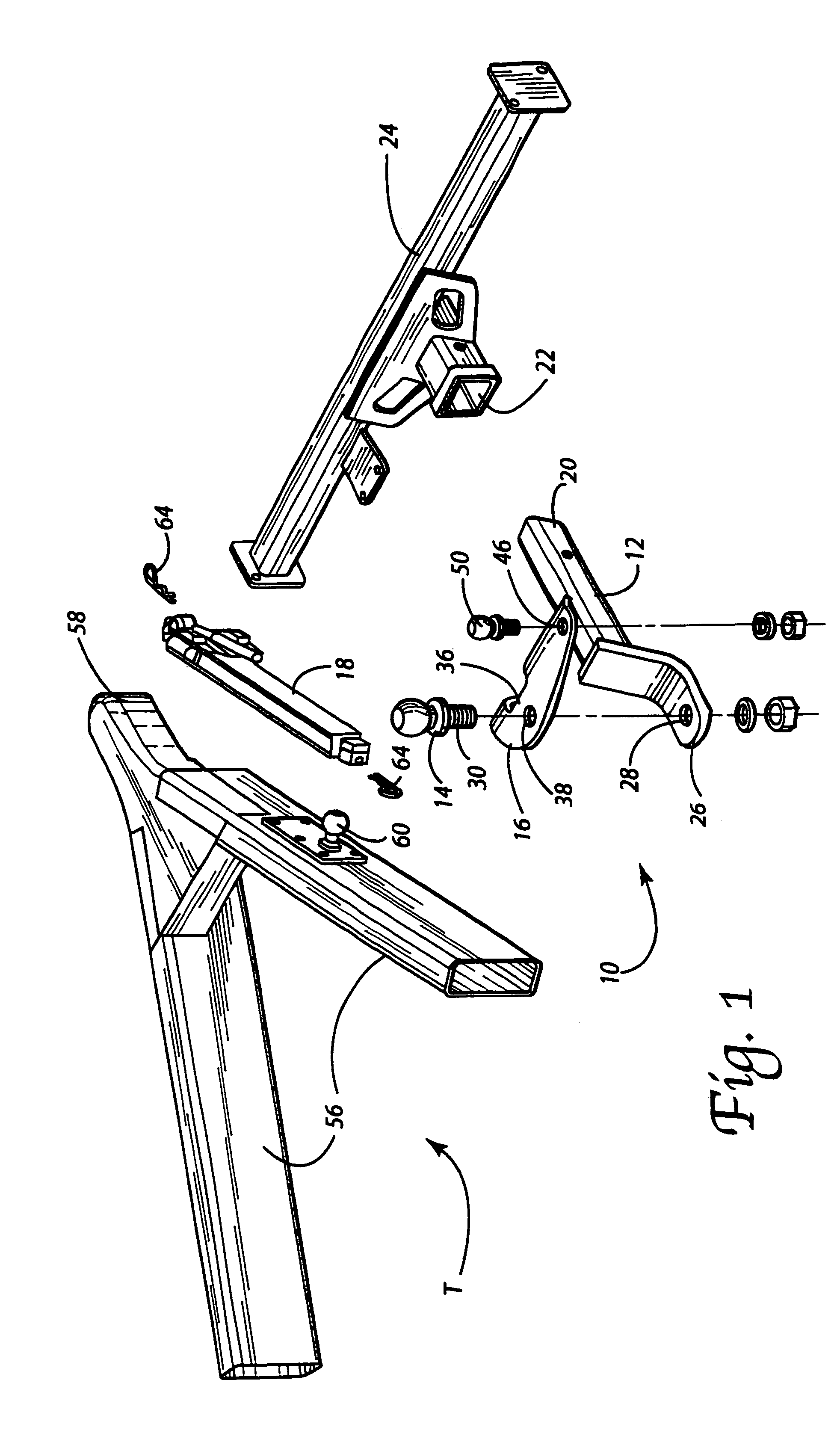

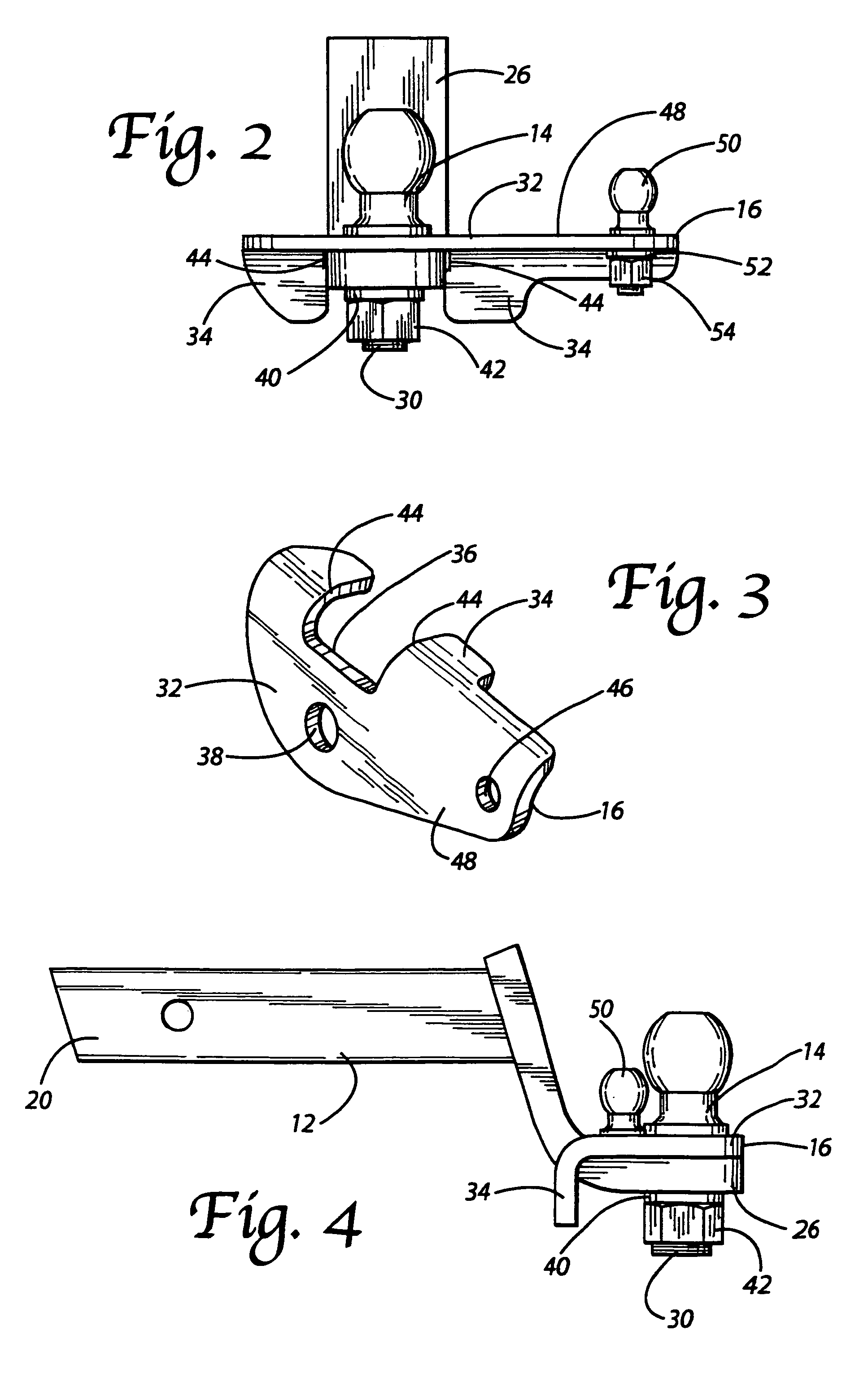

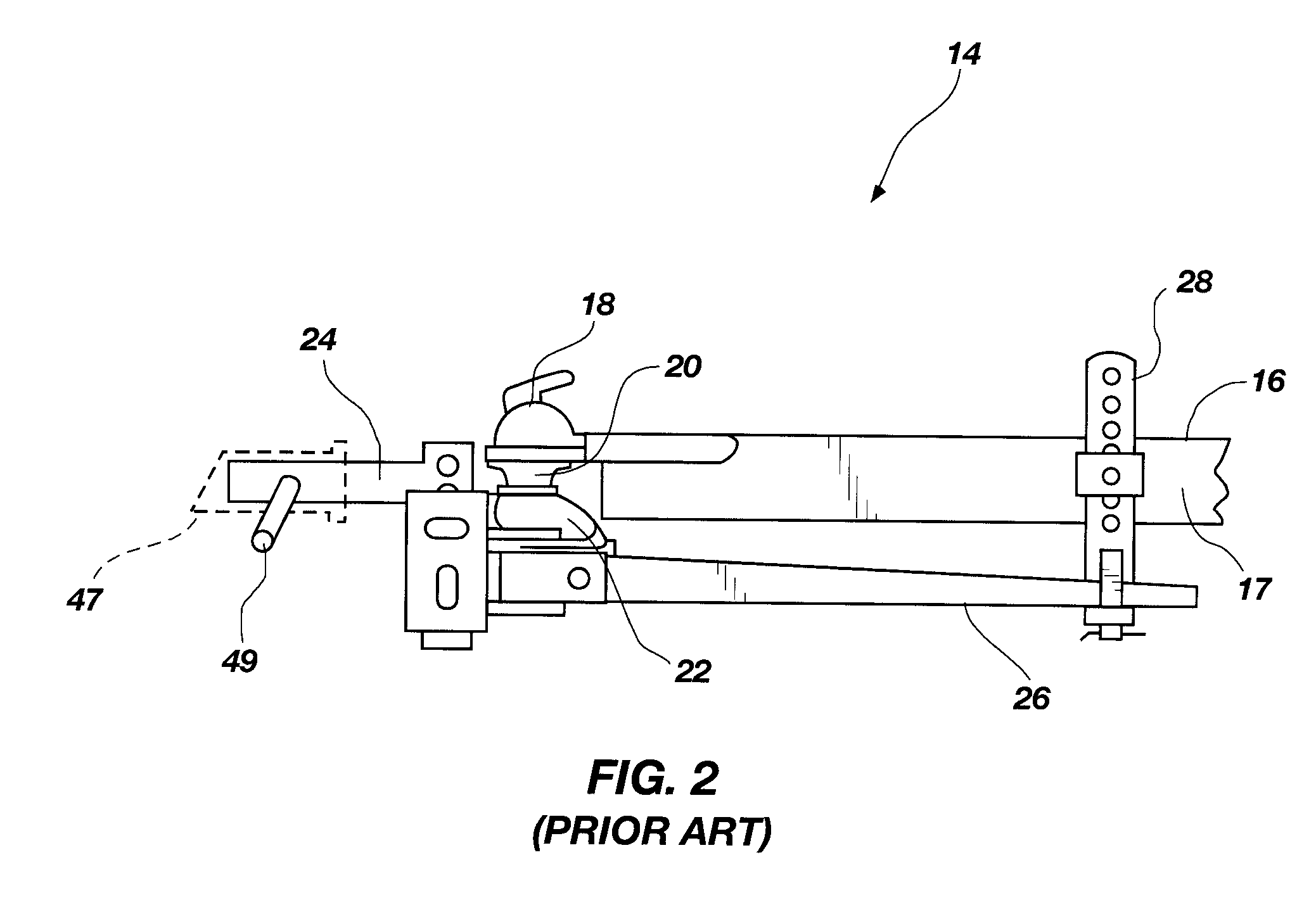

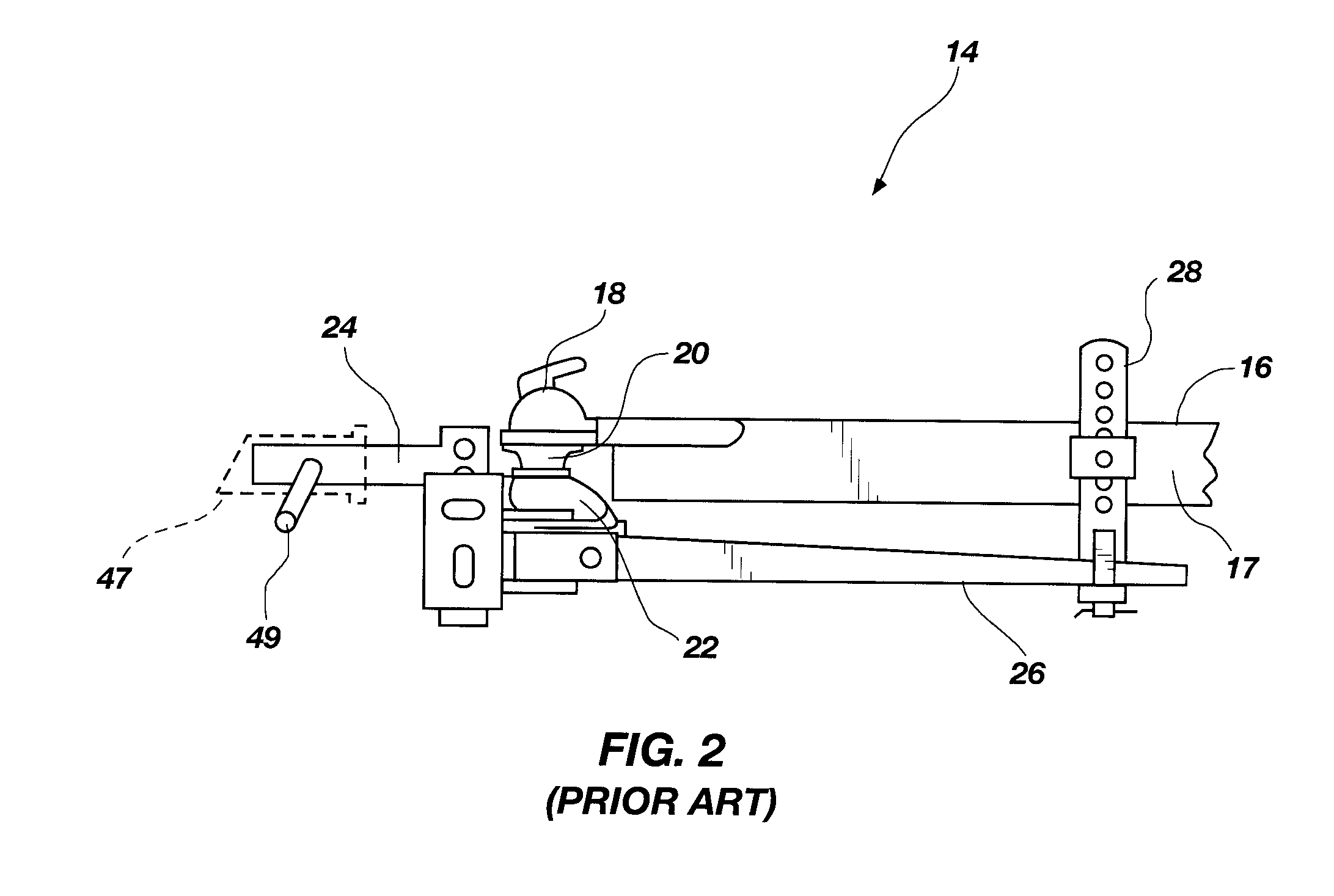

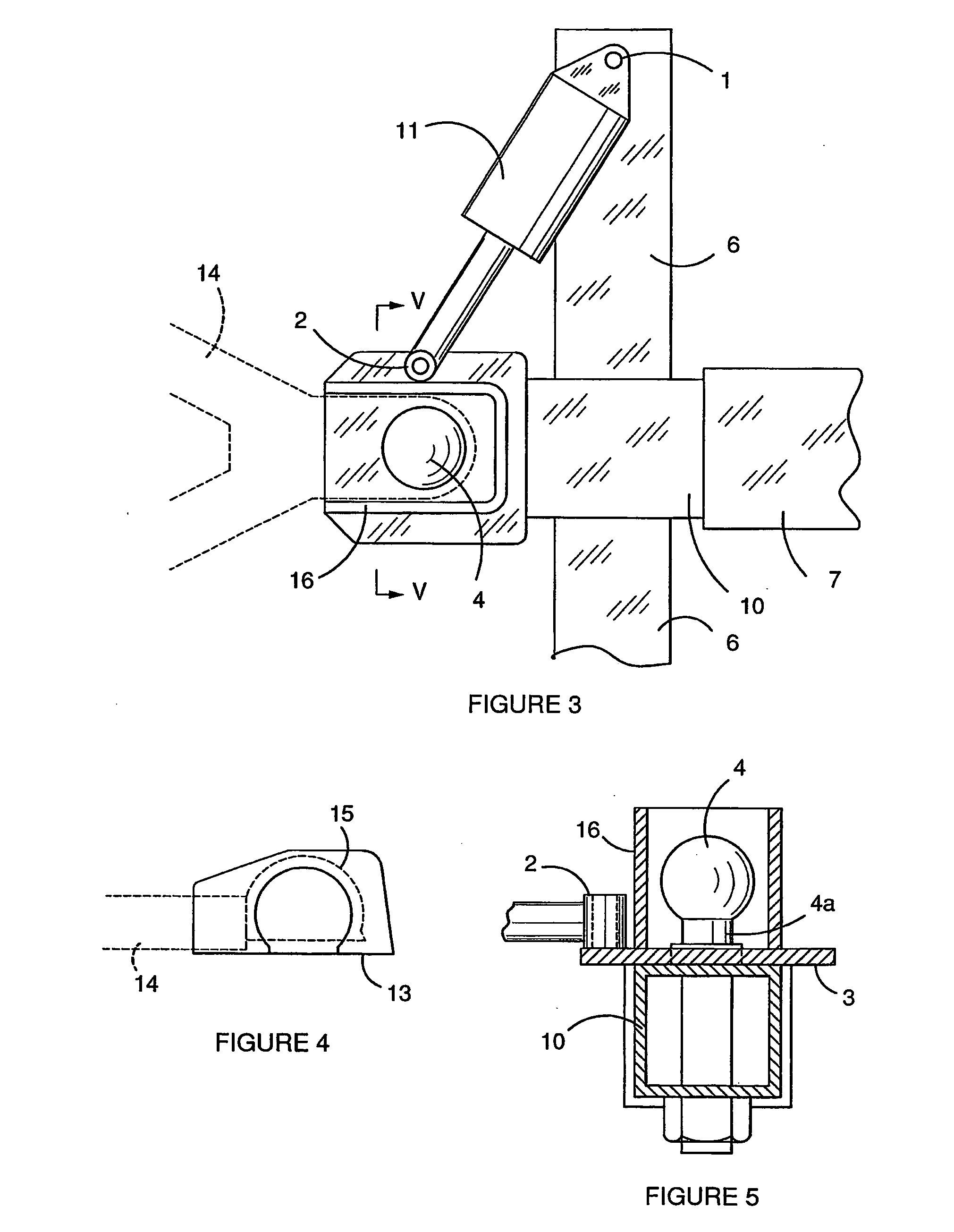

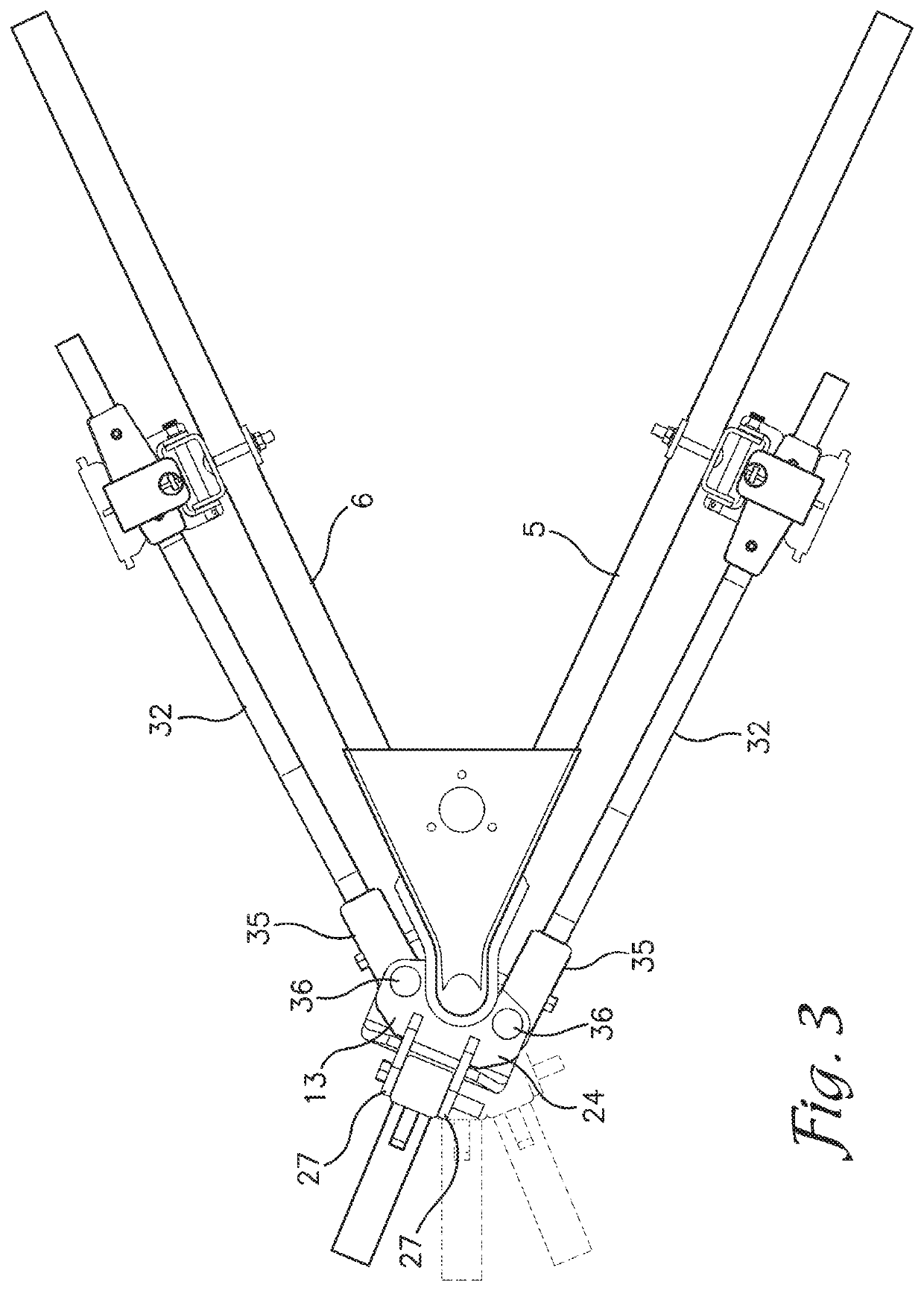

Sway control hitch

A trailer hitch system for equalizing trailer loads and reducing trailer sway. The trailer hitch system may include spring bars that may be attached to a hitch head using a trunnion style connection. The spring bars may be attached to the trailer using rigid brackets that reduce swinging of the spring bars. The rigid brackets may include an upward extending portion for attaching to the trailer tongue, and a lateral extending portion for receiving the spring bars thereupon. The brackets may have a contact surface on the lateral extending portion that may be free from a coating such that a metal on metal contact is made between the spring bars and the brackets. Portions of the brackets beyond the contact surface may be covered with a protective coating.

Owner:PROGRESS MFG LLC

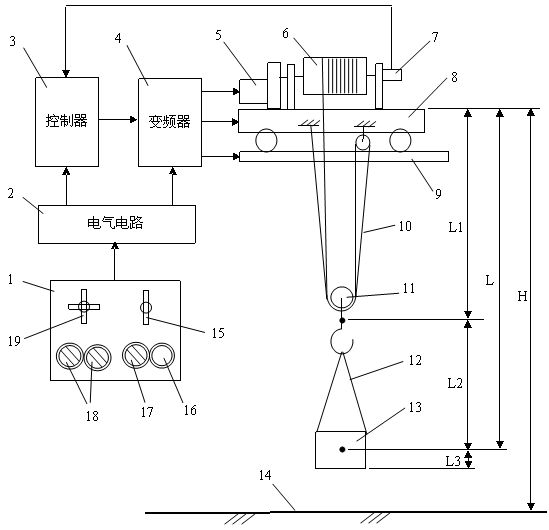

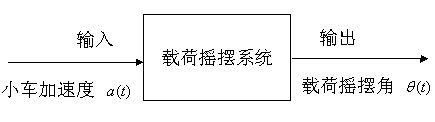

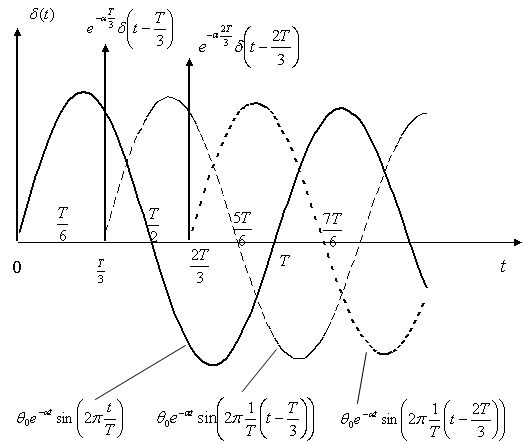

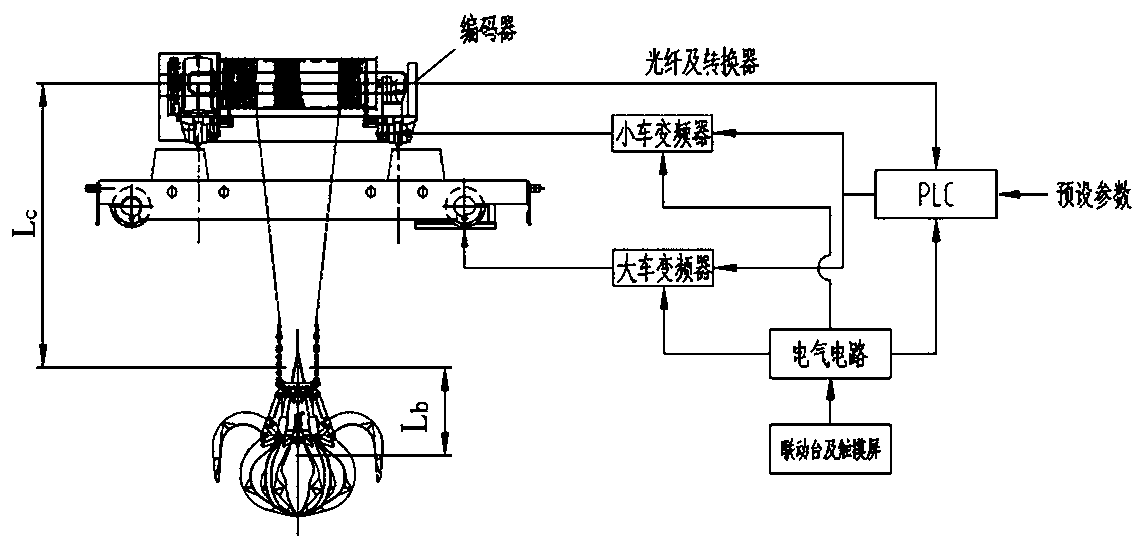

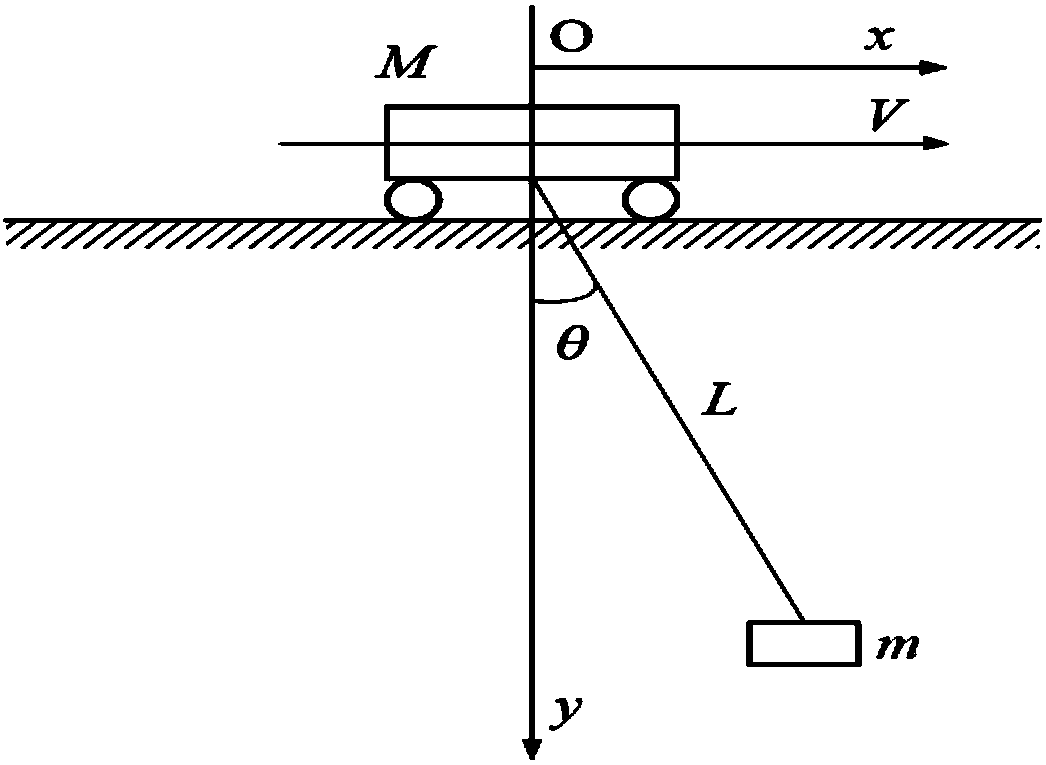

Sway-prevention control method for crane

ActiveCN102502403ASwing does not produceShort control adjustment timeLoad-engaging elementsOperating instructionPrevention control

The invention relates to a sway-prevention control method for a crane, which is characterized in that according to the operation demand of the crane, an operating instruction related to a trolley is sent to a controller by an operator; the controller works out the operating speed of the trolley according to a trolley acceleration and deceleration formula; and the operating speed of the trolley is controlled through a frequency converter and a trolley driving motor to realize the sway-prevention control on the crane. According to the sway-prevention control method for the crane, after the crane reaches a uniform motion performed at a specified speed from a stop state, a lifting hook and a load do not sway, and after the crane reaches the stop state from the uniform motion, the lifting hook and the load do not sway as well. Moreover, the control adjustment time of the dynamic process of the crane from a static state to the uniform motion and from the uniform motion to the stop state is the shortest.

Owner:HENAN WEIHUA HEAVY MACHINE

Anti-sway control of a crane under operator's command

InactiveCN1505590AMake sure it works correctlyResidual Swing EliminationTrolley cranesLoad-engaging elementsEngineeringKey factors

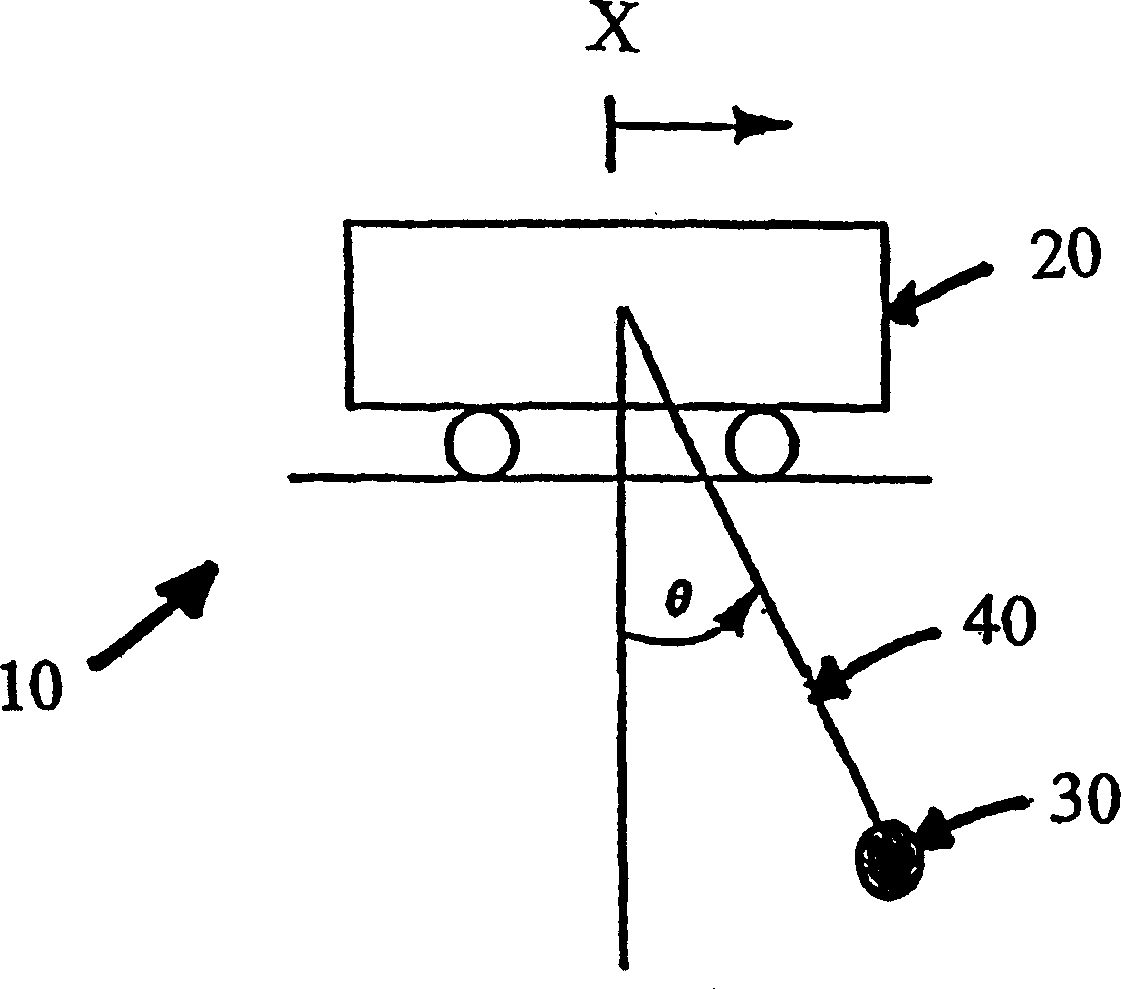

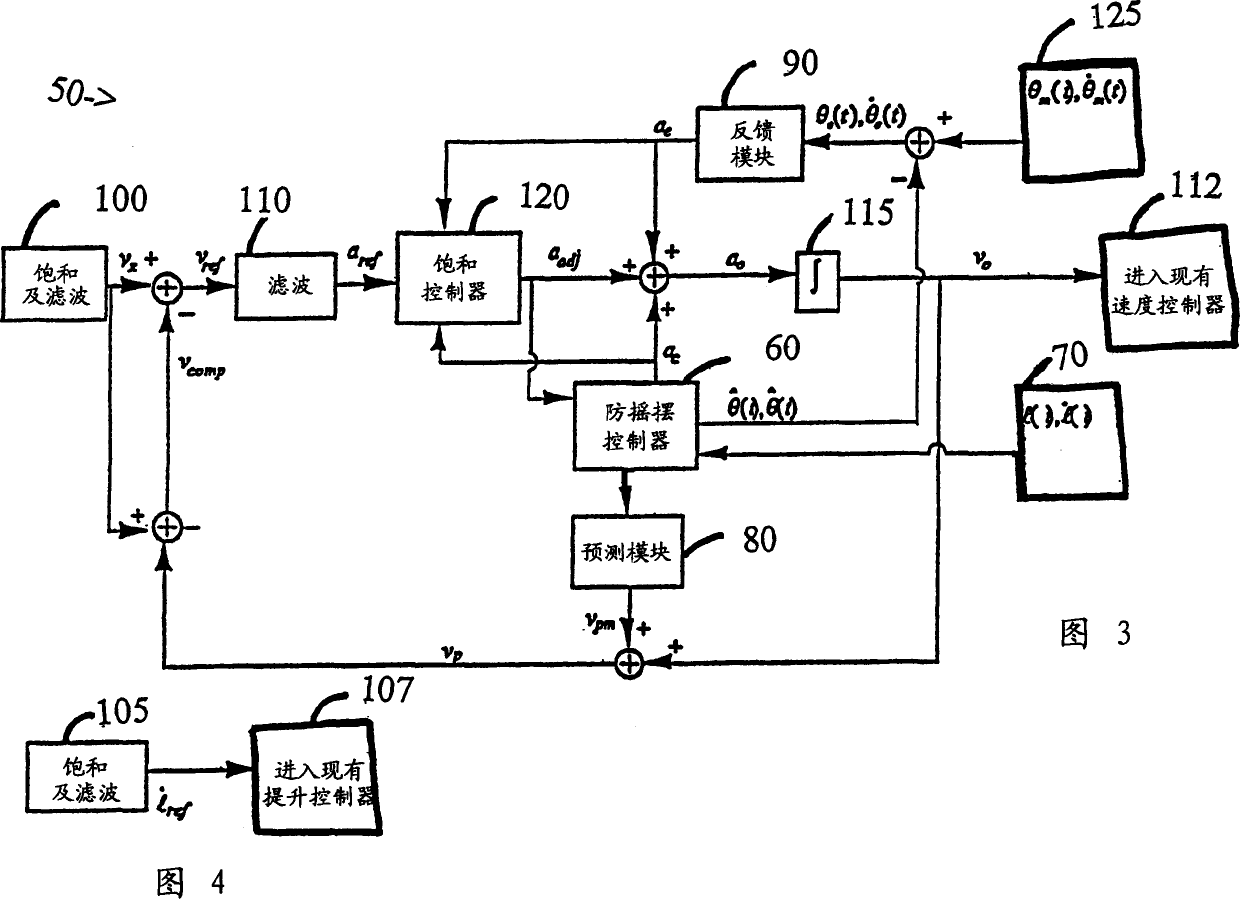

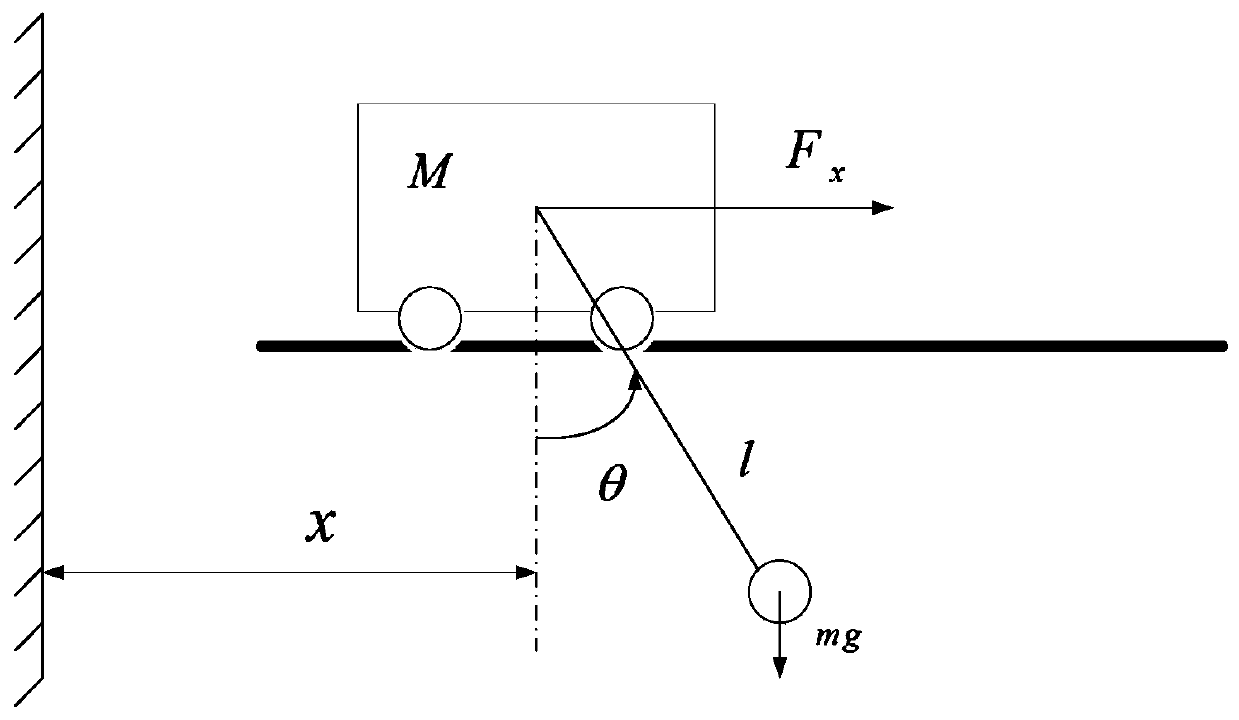

A system (10) is disclosed for eliminating sway of a load (30) in a crane or crane-like system subject to operator's command. The load is suspended by a cable (40) from a horizontally movable trolley (20) and can be hoisted vertically. The system uses the principle of cancellation to eliminate sway even when the crane has simultaneous trolley and hoisting motions. The system takes into account the full dynamical effect in computing cancellation signals. The use of a family of ordinary differential equations for the computation of the cancellation controls is a key component of the invention. In computing these controls, the differential equations are solved in real time using sensory measurement of the cable length and its time derivative. The cancellation controls handle the sway induced by the operator's command. Sway can also be induced by other factors, like wind load and external disturbances. This system also includes a feedback mechanism for eliminating sway due to such factors. The system ensures saturation limits, corresponding to the velocity and acceleration limits of the drive system of the trolley are not exceeded for proper functioning of the system.

Owner:NAT UNIV OF SINGAPORE

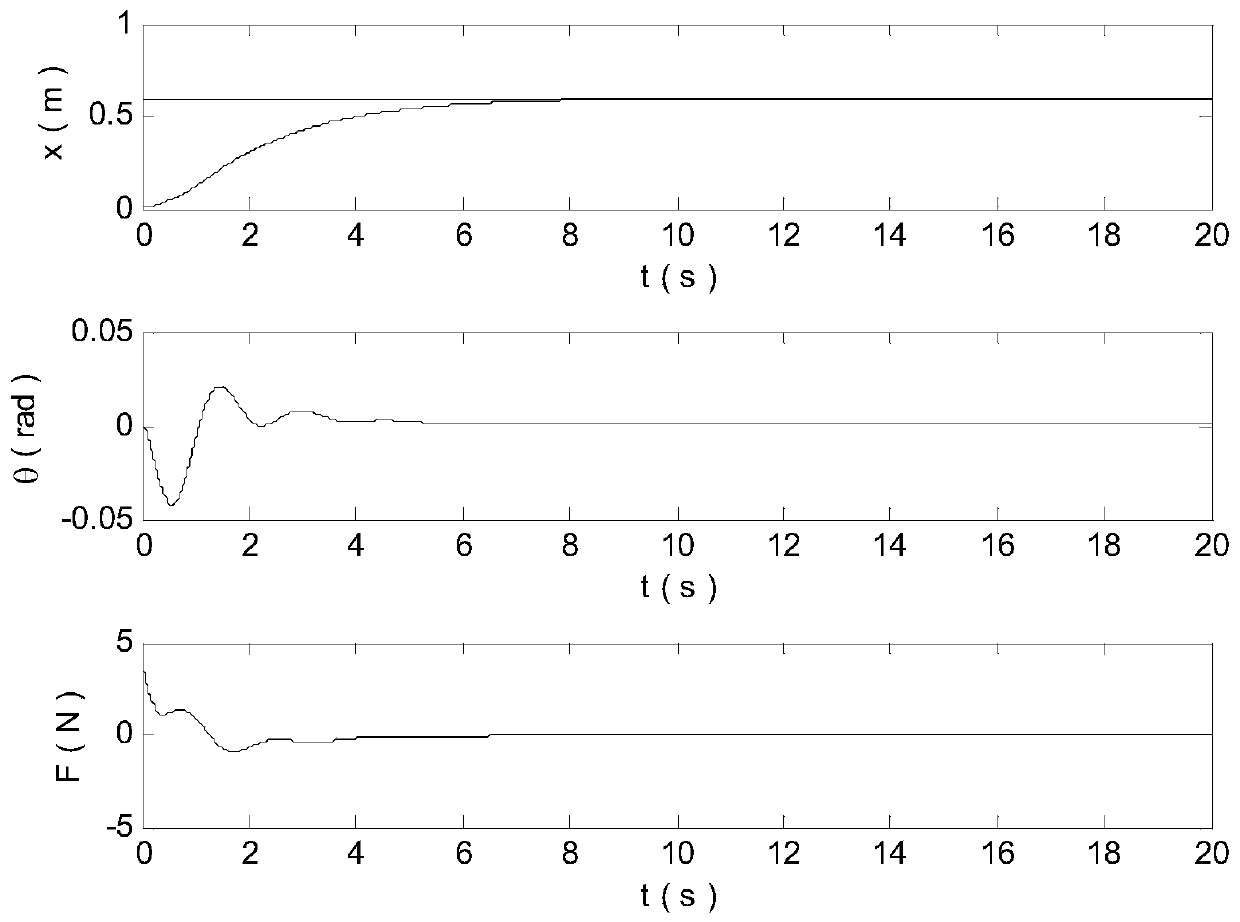

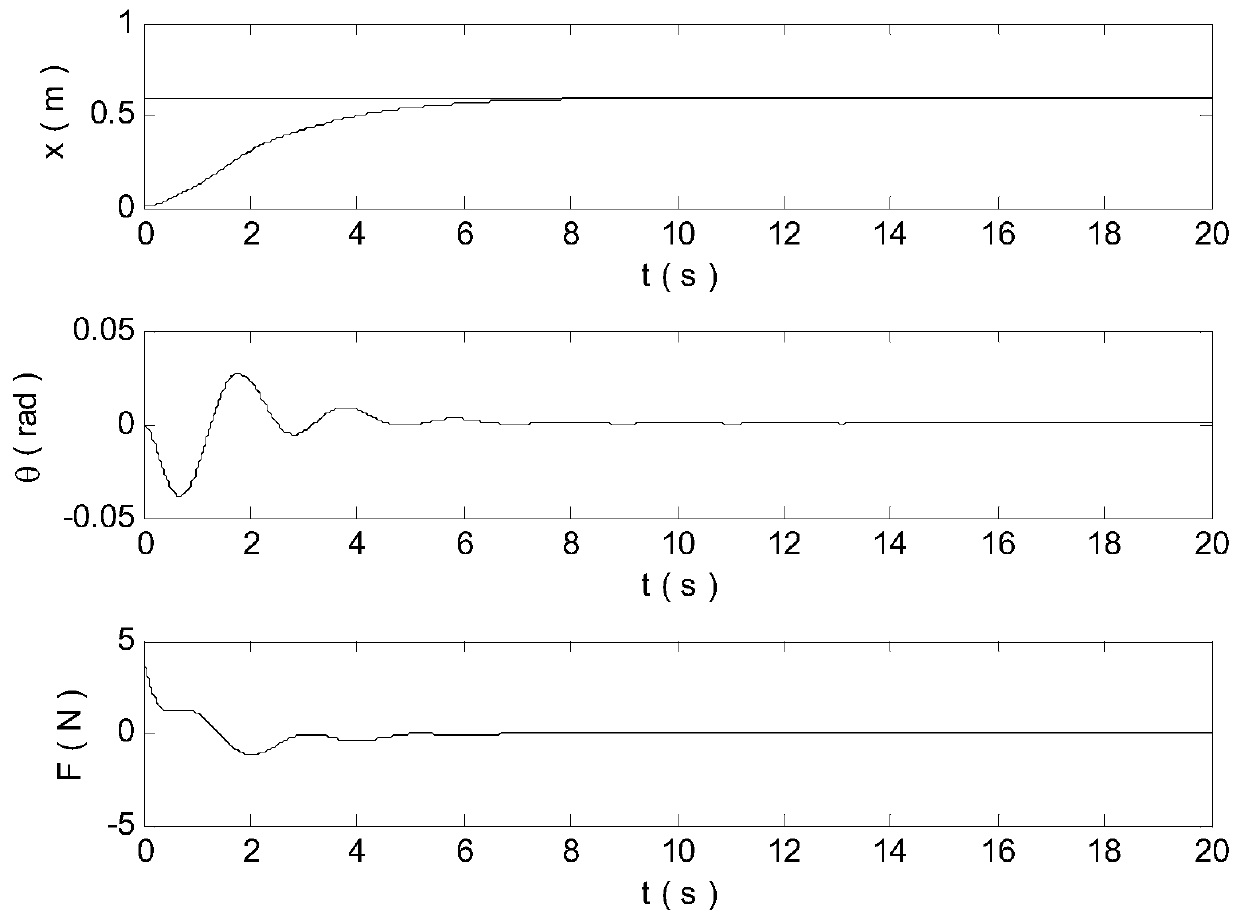

Global sliding-mode control method for bridge crane system

ActiveCN110203831AImprove control efficiencyReduce safety concernsLoad-engaging elementsDesign controlPosition control

The invention provides a global sliding-mode control method for a bridge crane system. The method comprises the following steps: determining a kinetic model; determining a control target; designing adamping signal and transforming a kinetic equation; designing a control rule; and implementing the control method. According to the control method, the bridge crane system has good robustness in the whole operating process while positioning control and anti-sway control of a trolley of the bridge crane system are implemented, so that the control efficiency of the bridge crane is improved, and theprobability of safety problems of the bridge crane system in actual operation caused by external disturbance and uncertain parameters. The global sliding-mode control method has good application prospect and economical benefit.

Owner:ZHEJIANG SCI-TECH UNIV

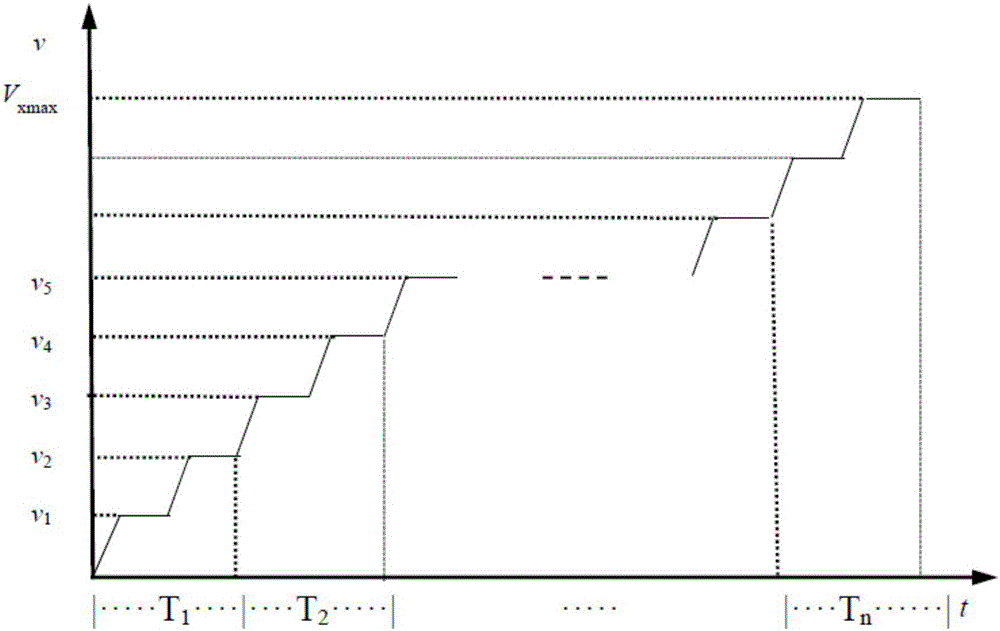

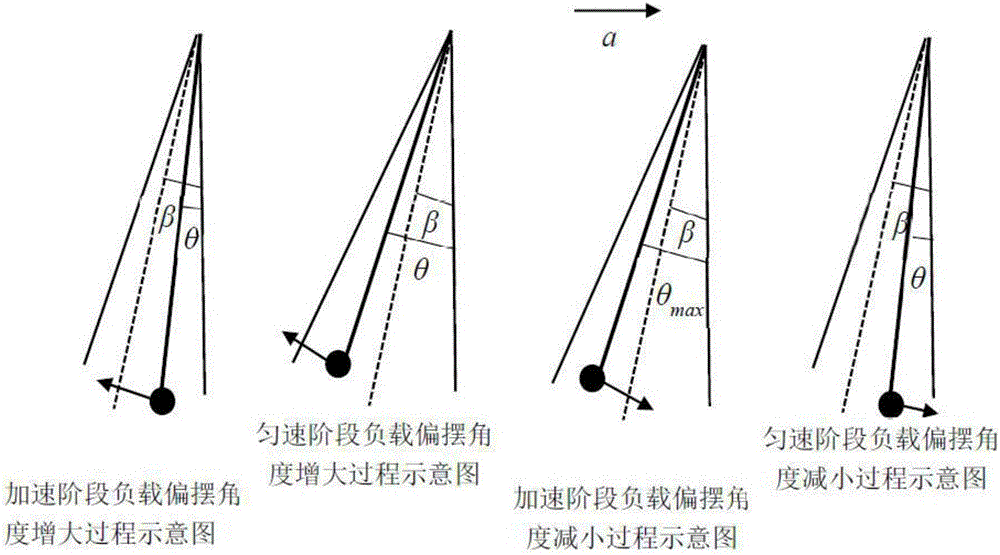

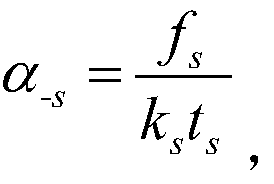

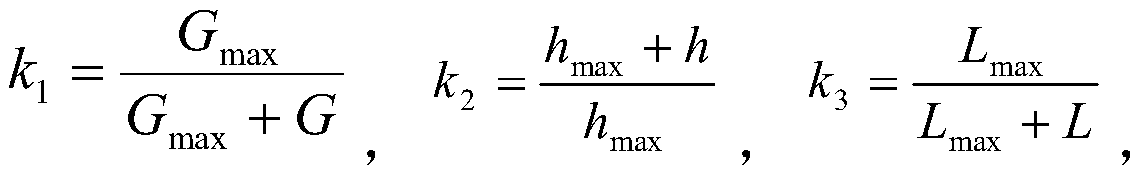

Intelligent anti-swing control method for multi-section uniformly-variable-speed crane

ActiveCN105883615AFully consider the use of securityImprove horizontal accuracyLoad-engaging elementsEngineeringLoad deflection

The invention discloses an intelligent anti-swing control method for a multi-section uniformly-variable-speed crane. The acceleration process of a running mechanism is divided into multiple sections of the uniform acceleration processes or the deceleration process of the running mechanism is divided into multiple sections of the uniform deceleration processes by taking the preset maximum allowable load swing amplitude and the lifting rope length as input variables on the basis of the system dynamics analysis rule of the crane through the input shaping principle of a two-order oscillation system according to the load deflection cycle, and load deflection is finally inhibited by controlling running of the running mechanism; meanwhile, multiple sections of the uniformly variable speed processes are optimized through an interpolation method. According to the method, by taking the maximum allowable load swing amplitude as the input variable, the safety of the crane in the running process is fully taken into account, the precision is controlled, and the safety and the working efficiency of the crane are significantly improved.

Owner:SHANDONG ZHONGYANG MACHINERY CO LTD +1

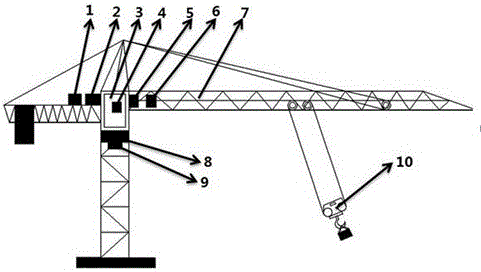

Tower crane, and anti-swing controlling method, device and system of lifting hook of the tower crane

ActiveCN103991801AGuaranteed uptimeAchieve sway controlCranesLoad-engaging elementsEngineeringTower crane

The invention discloses a tower crane, and an anti-swing controlling method, a device and a system for a lifting hook of the tower crane. The anti-swing controlling method for the lifting hook includes: acquiring present operation status parameters of the lifting hook in real time during the operation condition of the lifting hook; and when receiving a command of stopping the lifting hook operation, acquiring rotation control parameters and amplitude variation control parameters according to the acquired operation status parameters at present and a preset control role, and controlling a rotation mechanism and an amplitude variation mechanism of the tower cane to be operated reversely to the rotation control parameters and the amplitude variation control parameters, so as to reduce the horizontal shift between the lifting hook and a rotating arm support of the tower cane. Through the technical scheme, swing control of the lifting hook in the rotation direction and the amplitude variation direction can be achieved so that the tower cane can be operated stably, accidents caused by collision caused by swing of a lifted object are reduced, the working safety is improved and the working efficiency is increased.

Owner:ZOOMLION HEAVY IND CO LTD

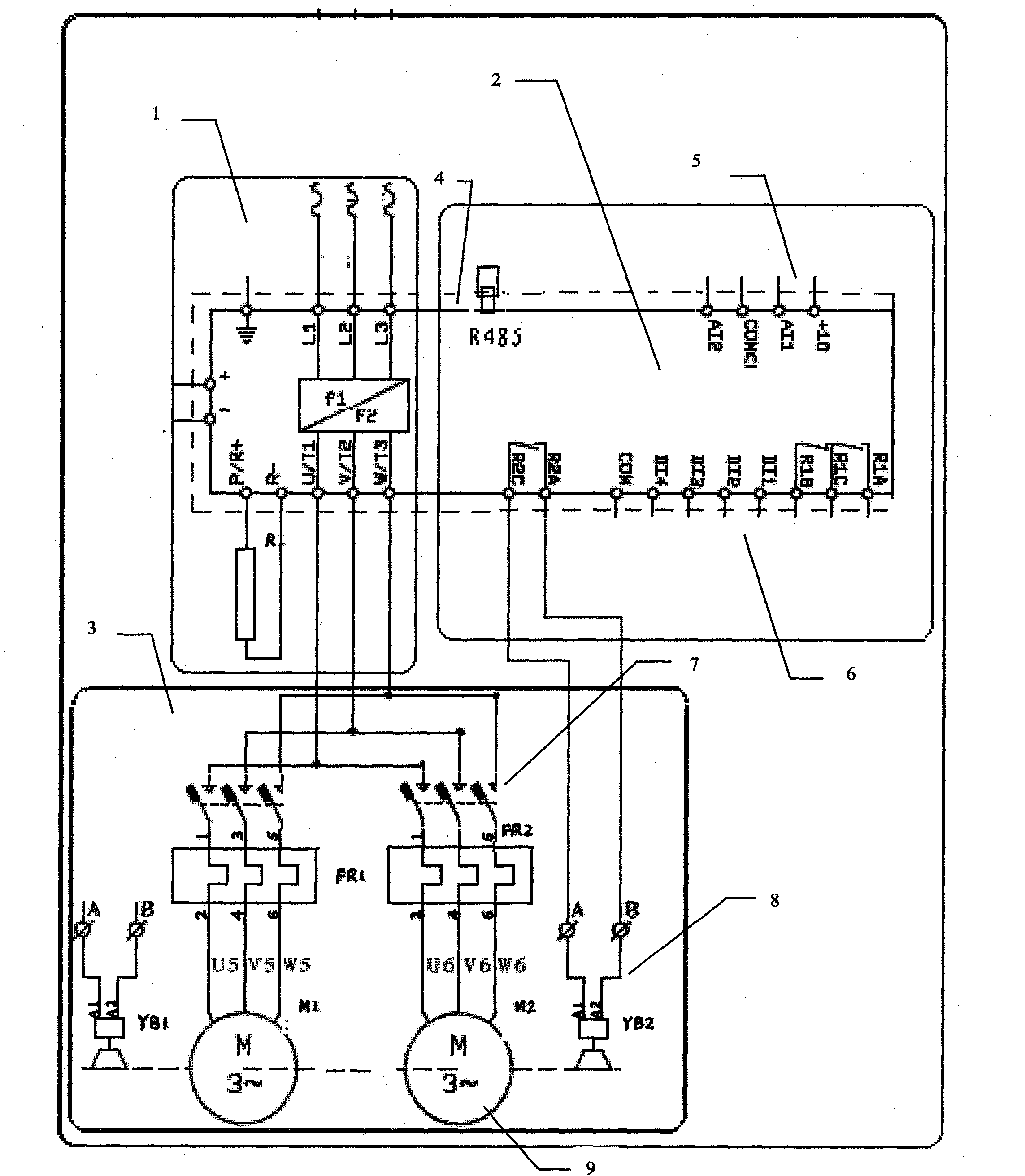

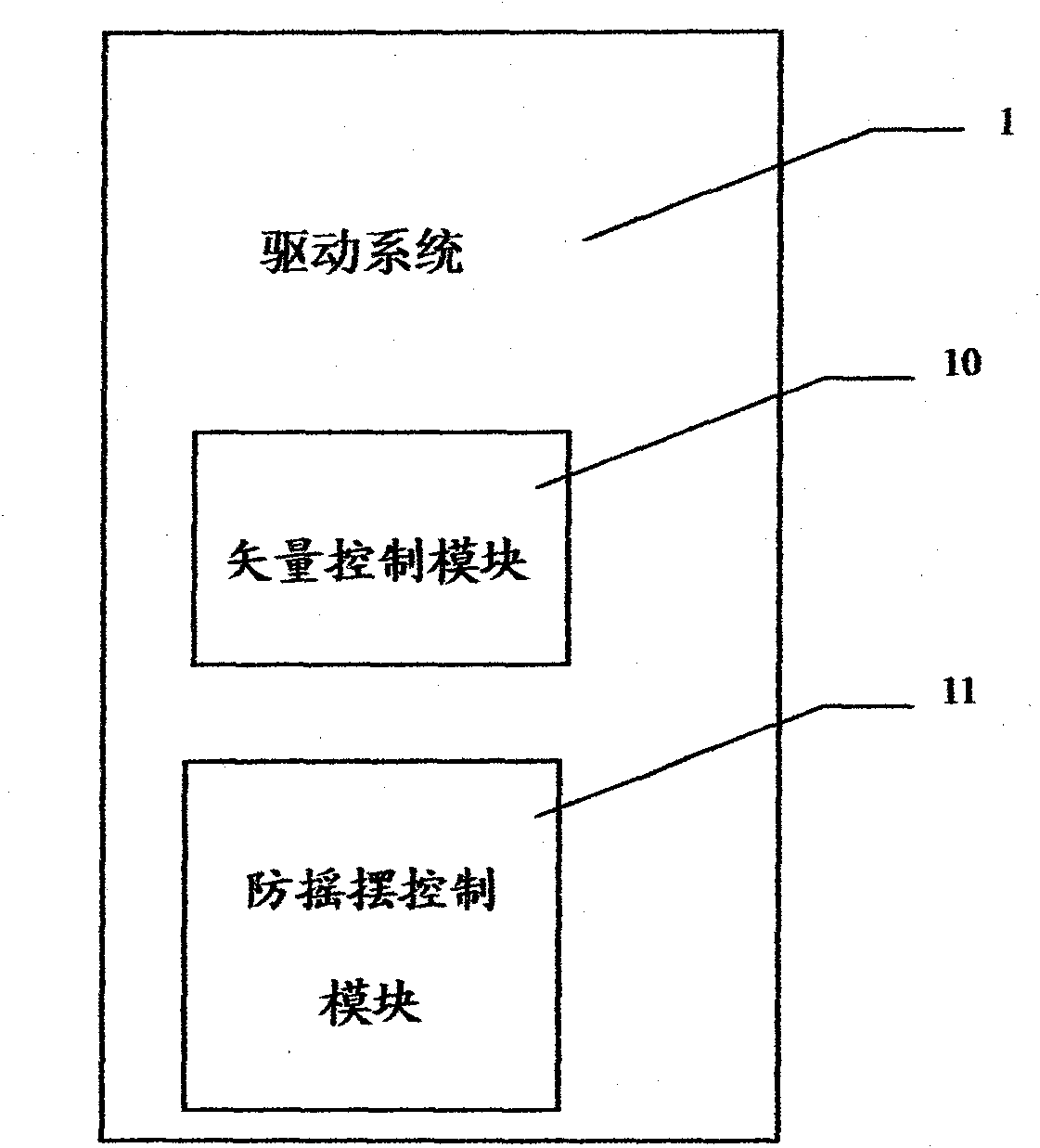

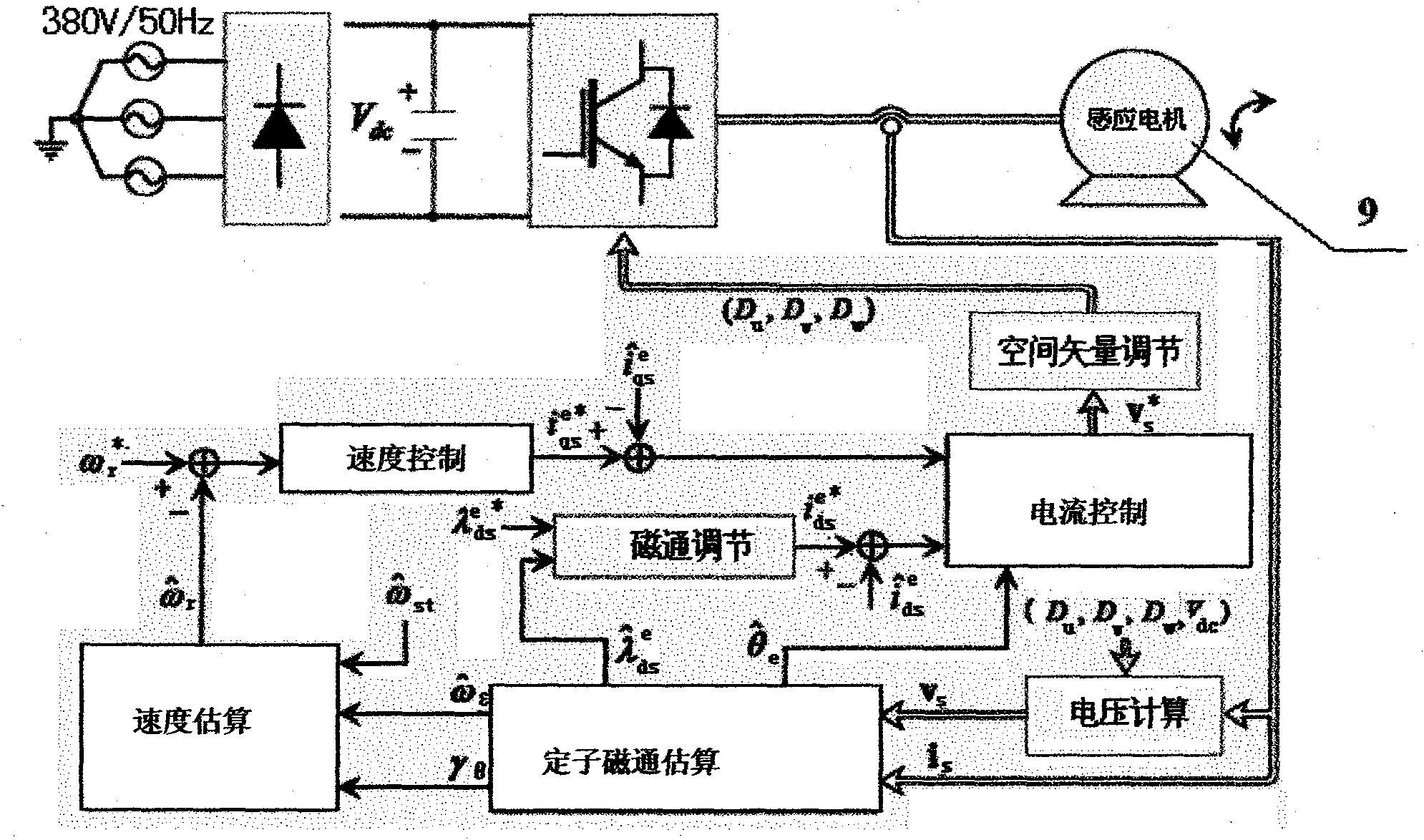

Swing mechanism control system for tower crane

InactiveCN101780920AReduce jitterThere is no problem of sudden changes in speedCranesLoad-engaging elementsControl vectorCommunications system

The invention provides a swing mechanism control system for a tower crane, comprising a motor system, a driving system and a communication system. The motor system comprises two motors, two brake controllers and two breakers, wherein one end of each breaker is connected with the driving system through three power lines, and the other end is connected with each motor; one end of each brake controller is connected with the output end of the communication system through two brake communication lines, and the other end is connected with each motor through a power line. The driving system comprises a vector control module and an anti-swing control module, wherein the vector control module drives and brakes the motors by adopting a vector control mode. In the invention, uniform acceleration can be realized in the process of starting and stopping, anti-swinging control and location control can be achieved, and adjustable control of the motor in the process from operating to stopping can be realized. The invention avoids the shaking of the tower body caused by sudden releasing of stress to the maximum and has the advantages of safety, convenience, energy saving, environment protection, little noise and convenient use.

Owner:青岛立邦达工控技术有限公司

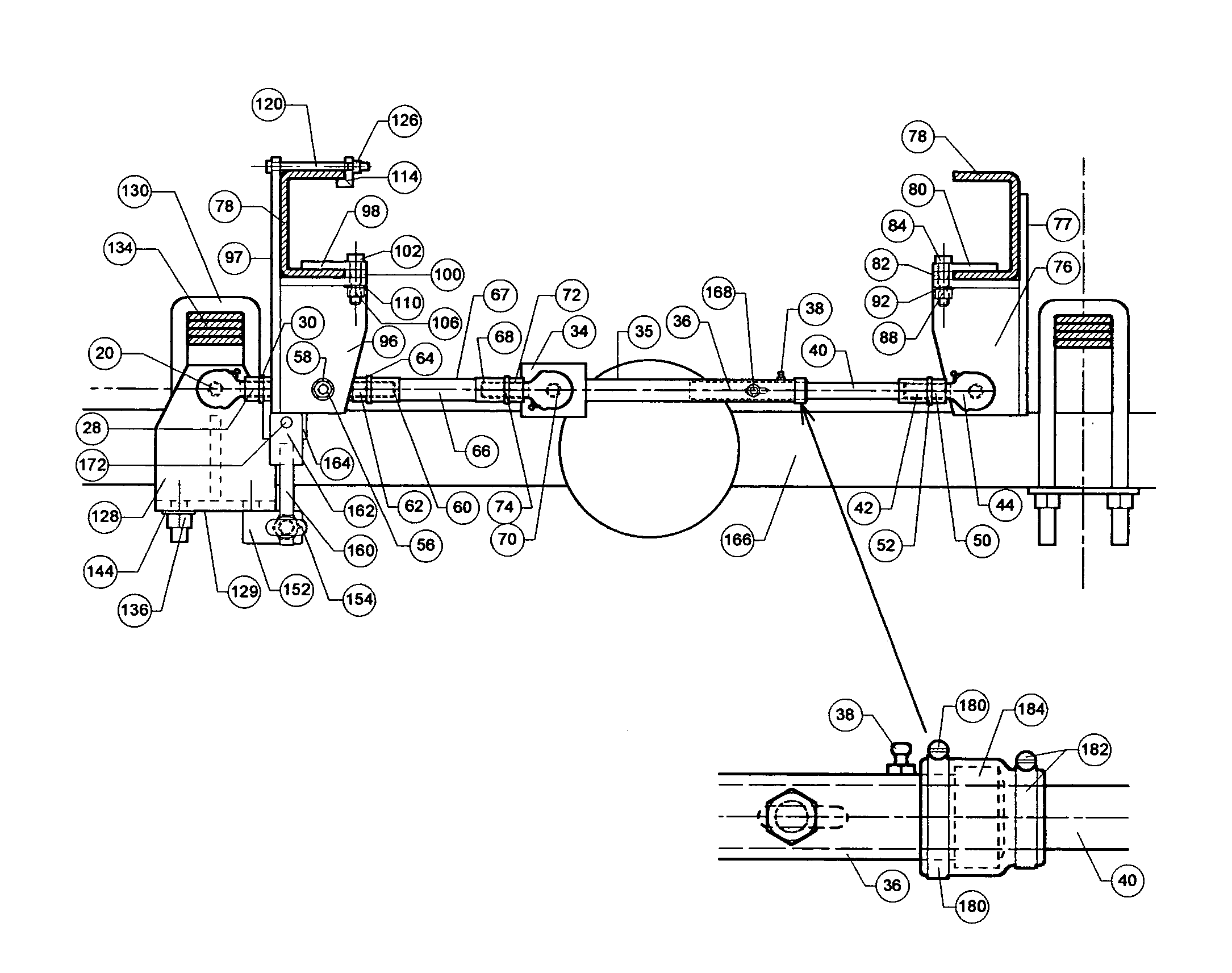

Motor vehicle sway control assembly

InactiveUS7229086B1Reduce driver fatigueEasy maintenanceInterconnection systemsResilient suspensionsMobile vehicleMotor vehicle part

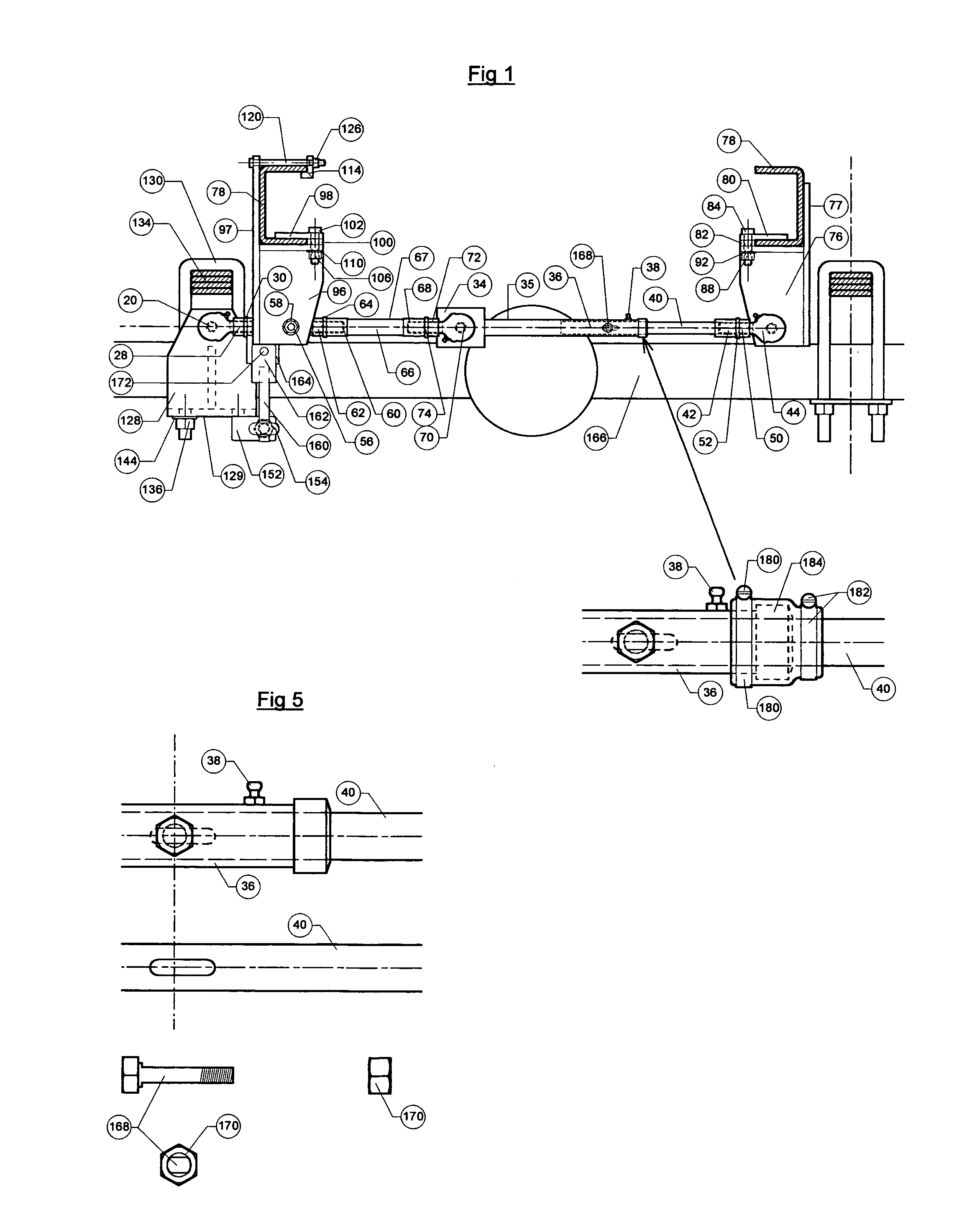

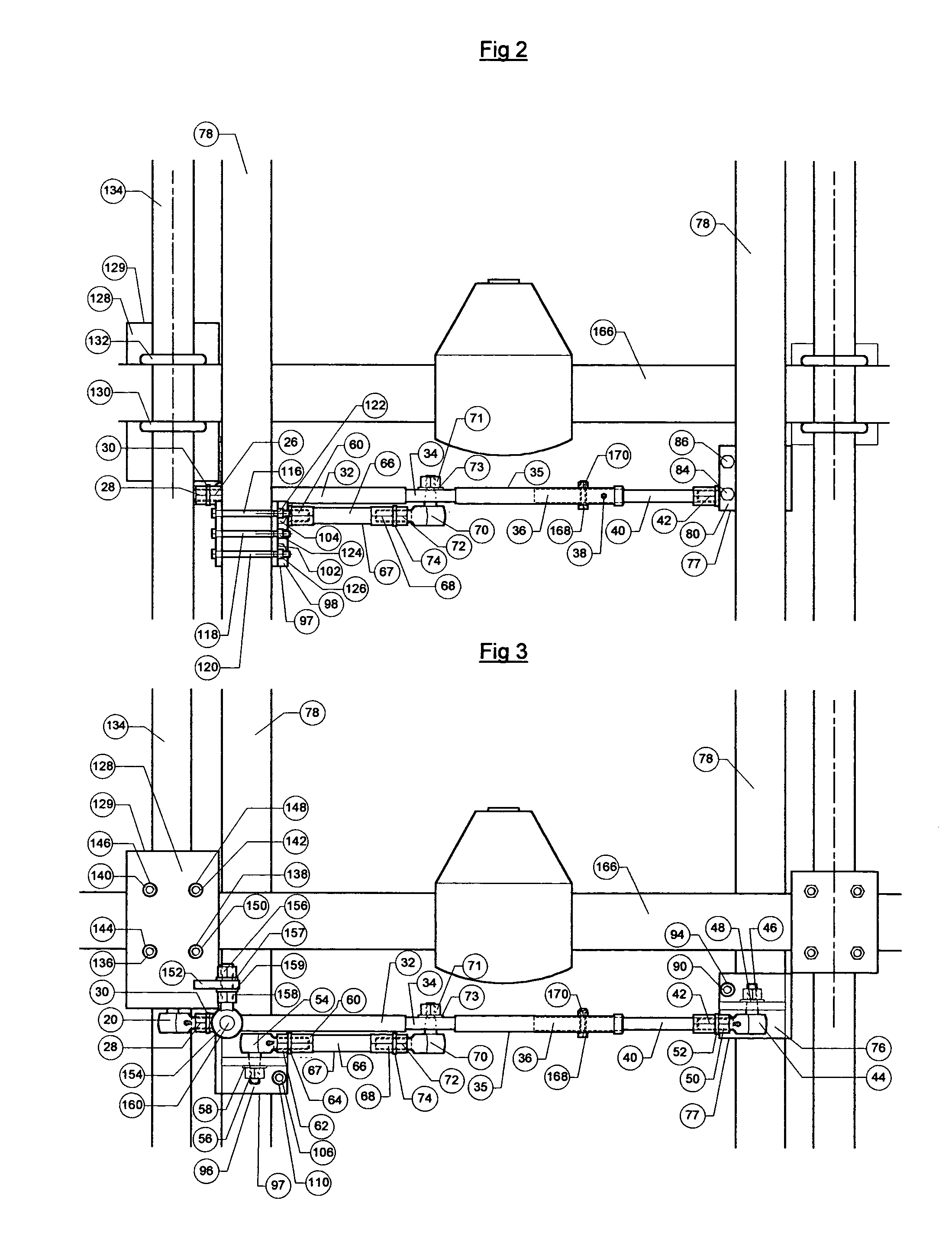

An improved vehicle sway control assembly designed to limit excessive side swaying of front engine rear axle driven motor vehicles during all driving conditions. The system utilizes two frame brackets (77), (97), one axle / spring bracket (129), and two rods (35), (67). The first rod (35) has one end attached to a frame bracket (77) and the other end to the axle / spring bracket (129). It incorporates a telescoping feature allowing the rod end nearest the frame bracket (77) to telescope. The second rod (67) is attached on the opposite side to a frame bracket (97) on one end and a mid section plate (34) on the telescoping rod (35) on the other end. The counter rotational arch of the second rod (67) will force the telescoping rod (35) to extend thus canceling the telescoping rod (35) arch curve travel if it were a solid rod. The overall design will limit axle (166) to frame (78) side movement while providing near straight vertical axle (166) travel.

Owner:ROGERS ROBERT LOUIS

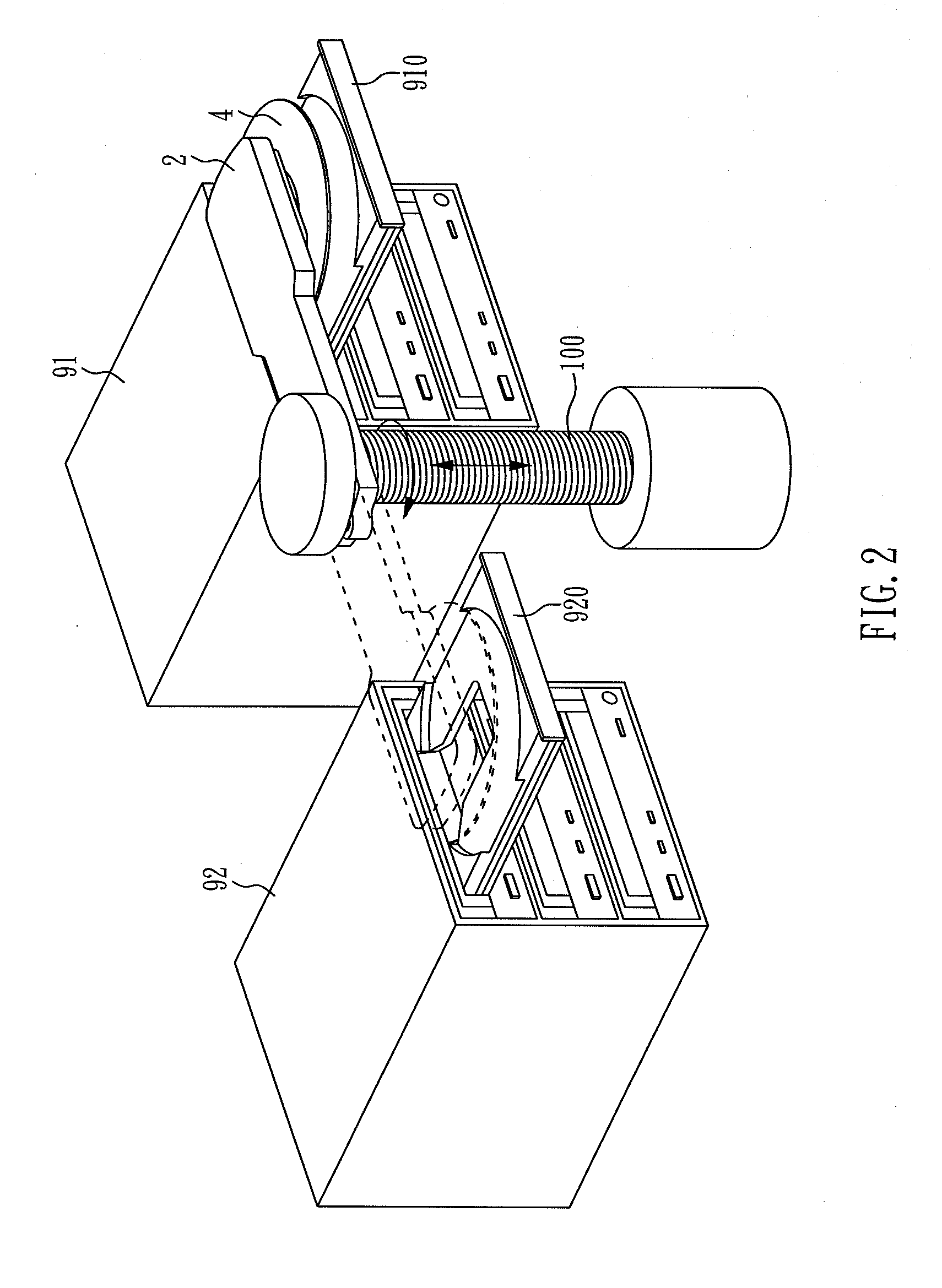

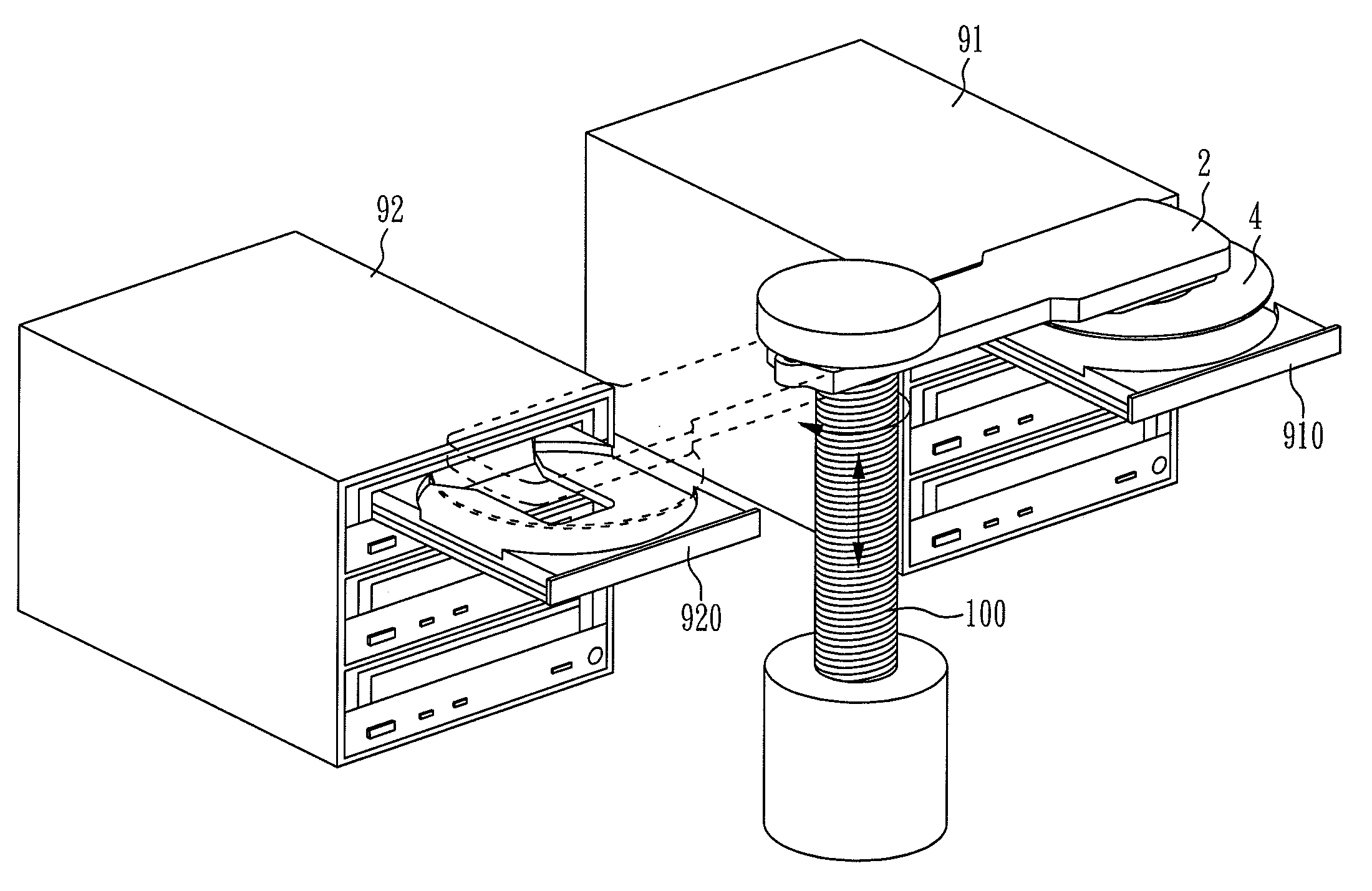

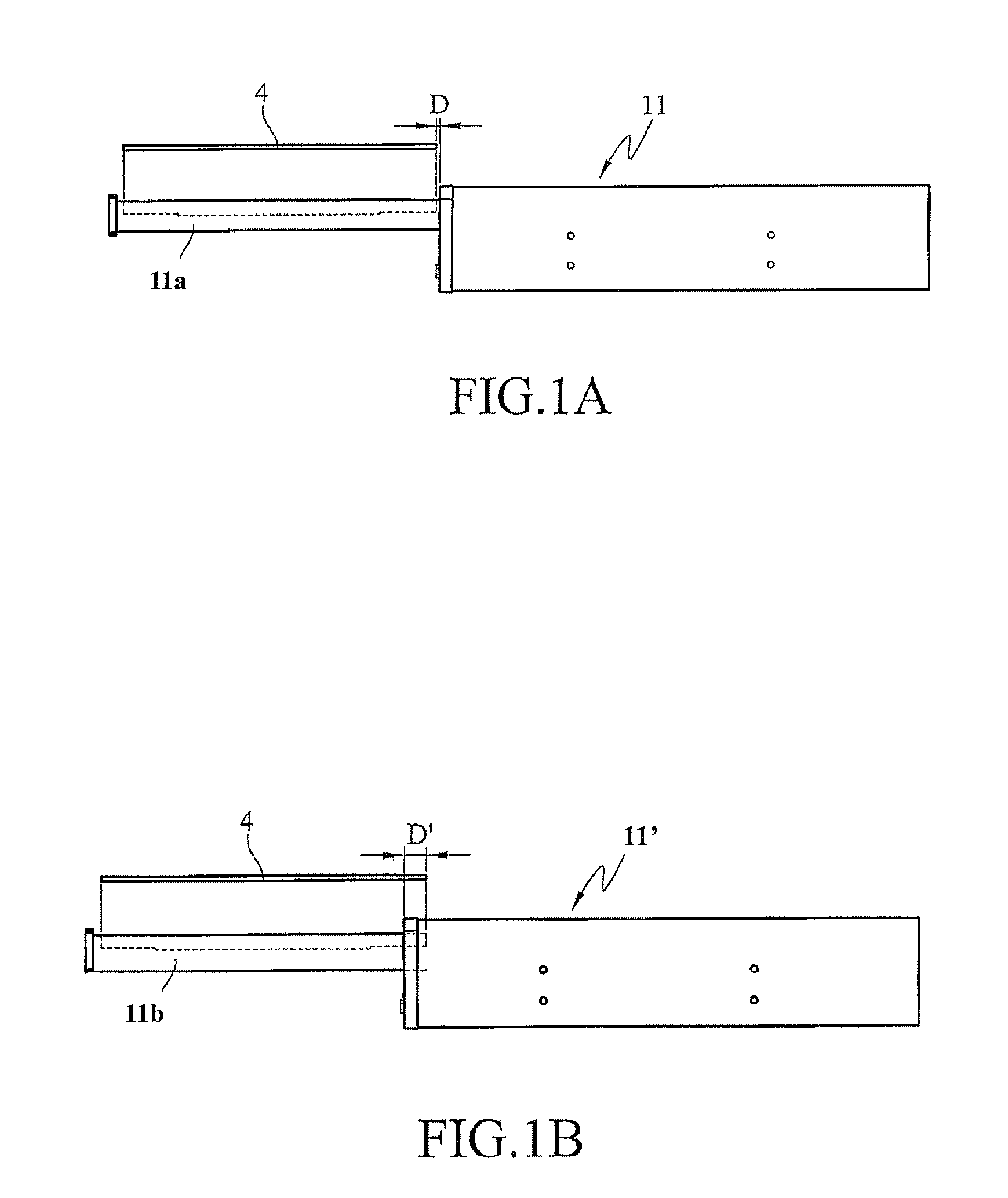

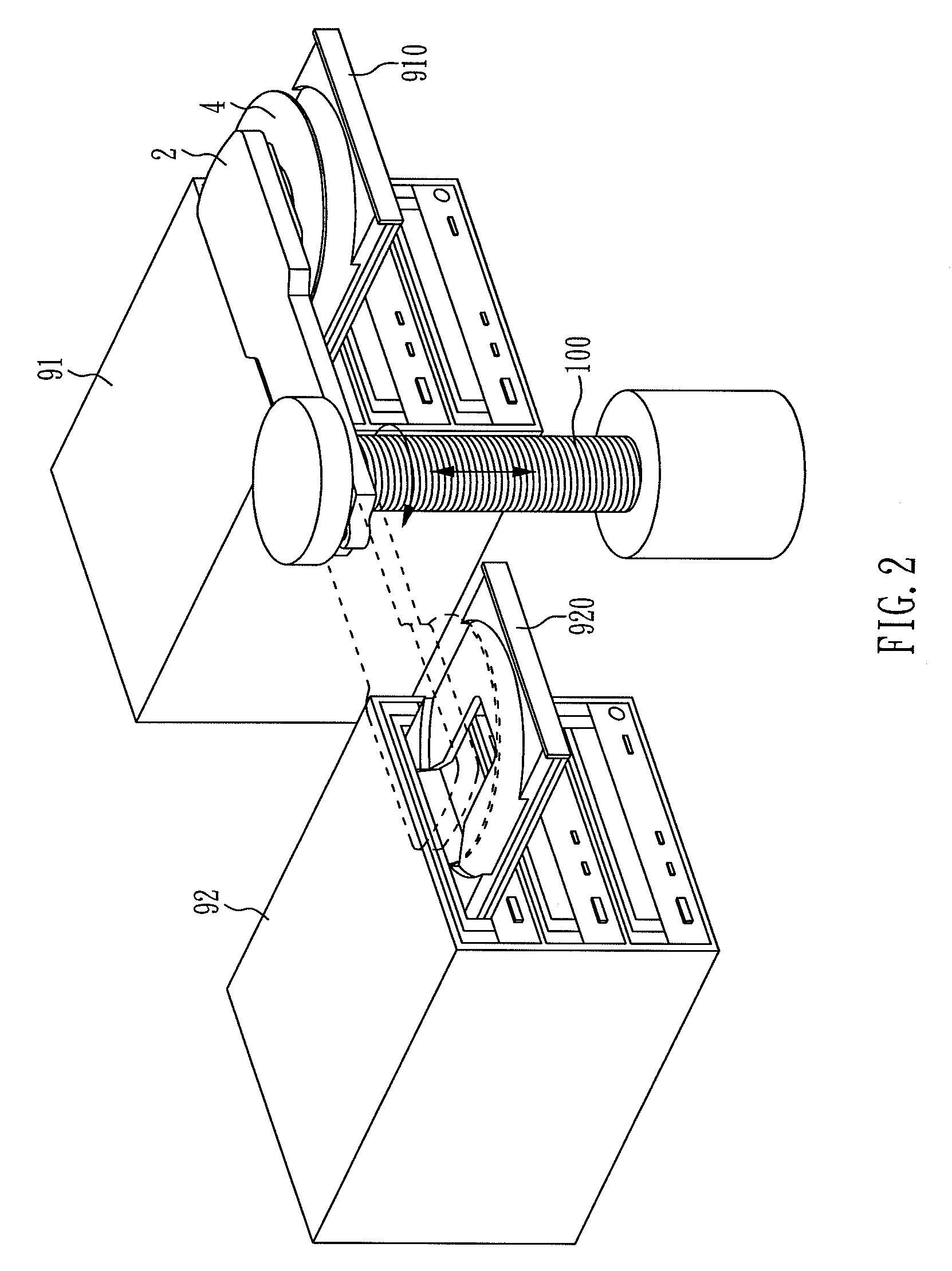

Transportation Arm Device for Carrying Discs

InactiveUS20090178066A1Provide flexibilityRecord information storageRecord carrier contruction detailsEngineeringSway control

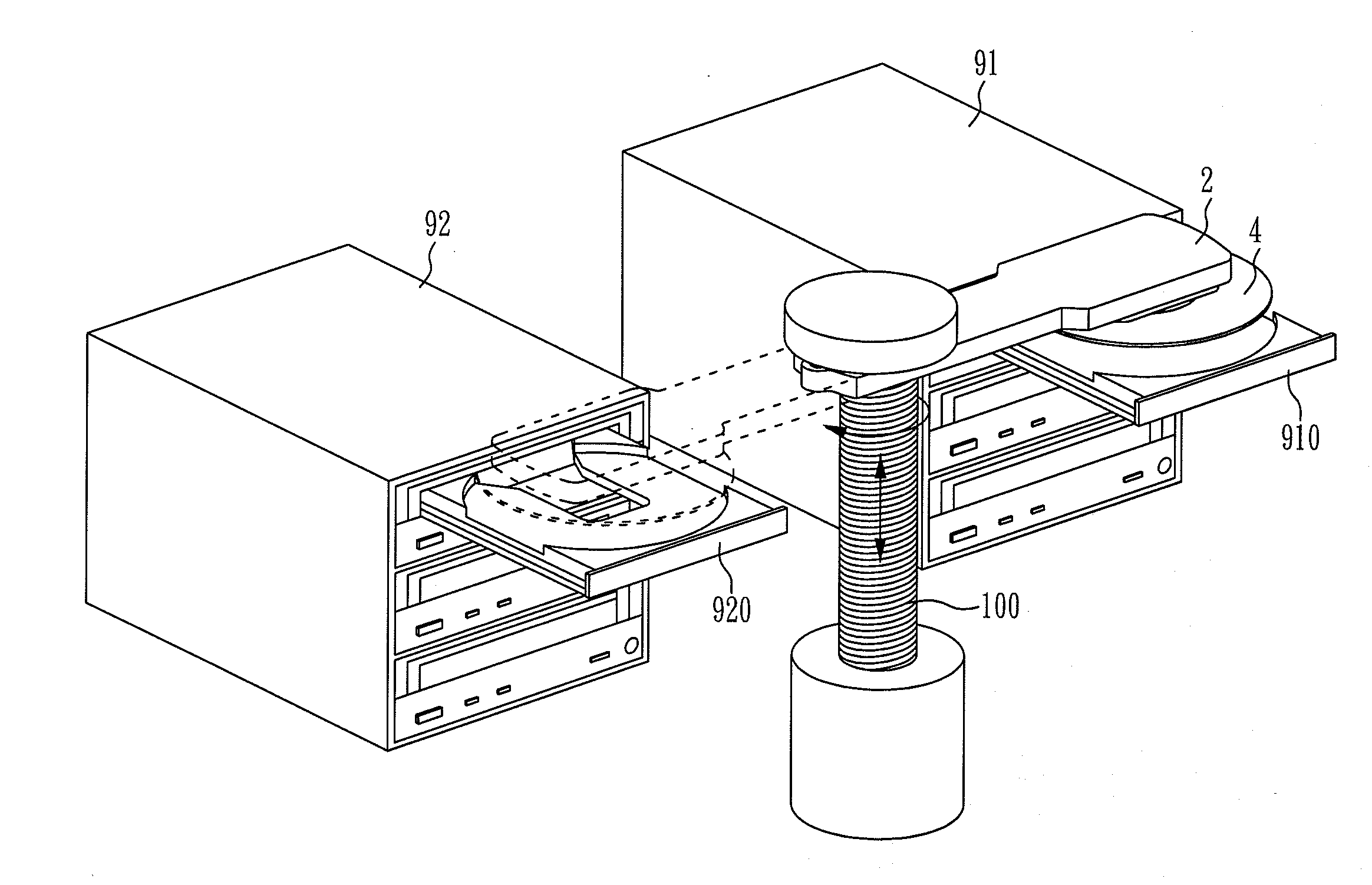

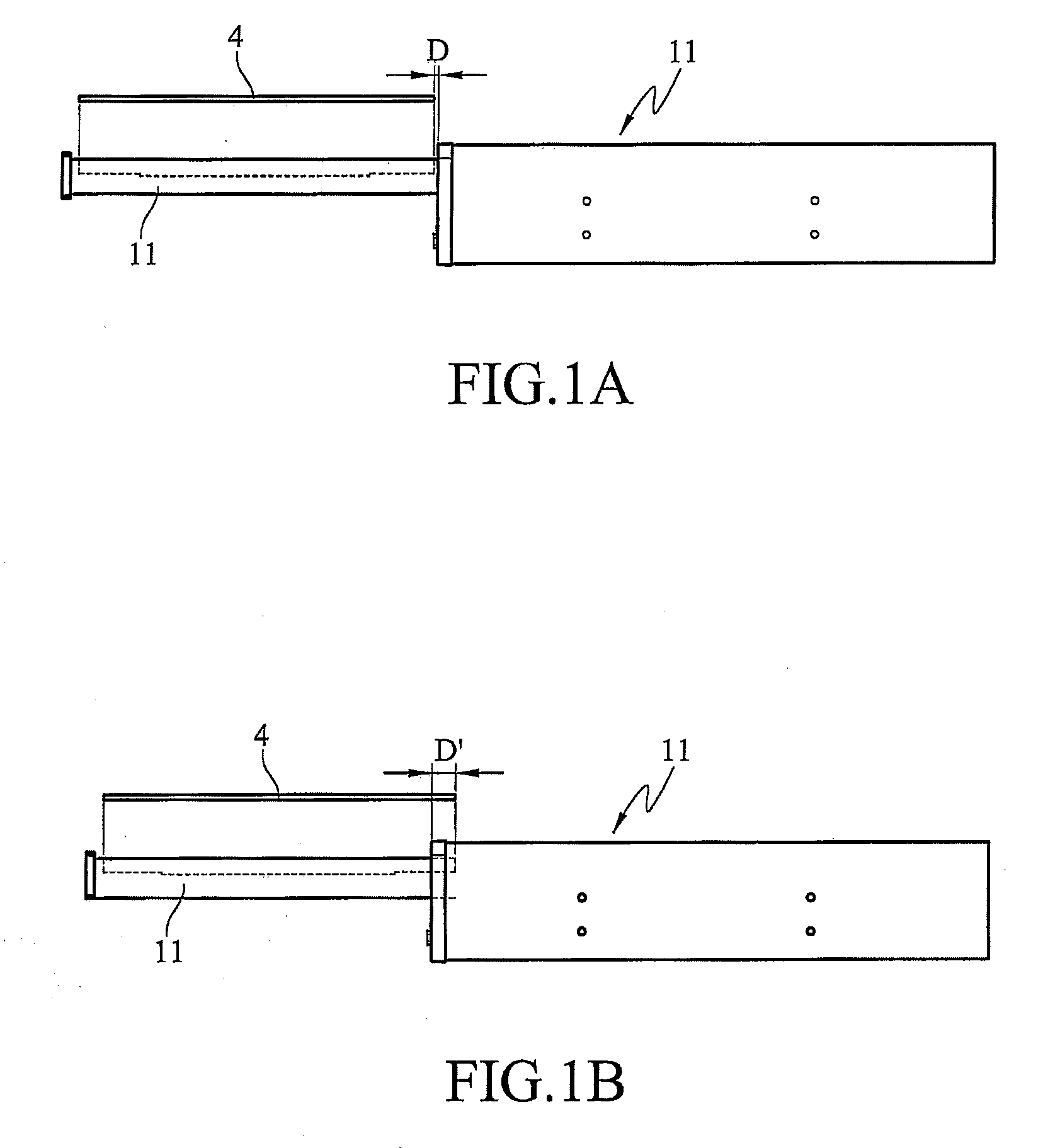

A transport arm device for carrying at least one disc comprising a driving means, a sway control member, and a swaying mechanism is disclosed. The sway control member comprises a hole in substantial middle of the sway control member for receiving a portion of the driving means and two leaf springs extending up from two sides of the sway control member respectively. The swaying mechanism is capable of grabbing the discs. The swaying mechanism comprises a rotating connection for engaging with a suspension of the transport arm device, wherein the two leaf springs are contacted with the swaying mechanism. The sway control member is moved by the driving means so as to rotate the swaying mechanism along a rotary axis on the rotating connection, and the two leaf springs provide elasticity for the swaying mechanism rotating back.

Owner:DATATRONICS TECH

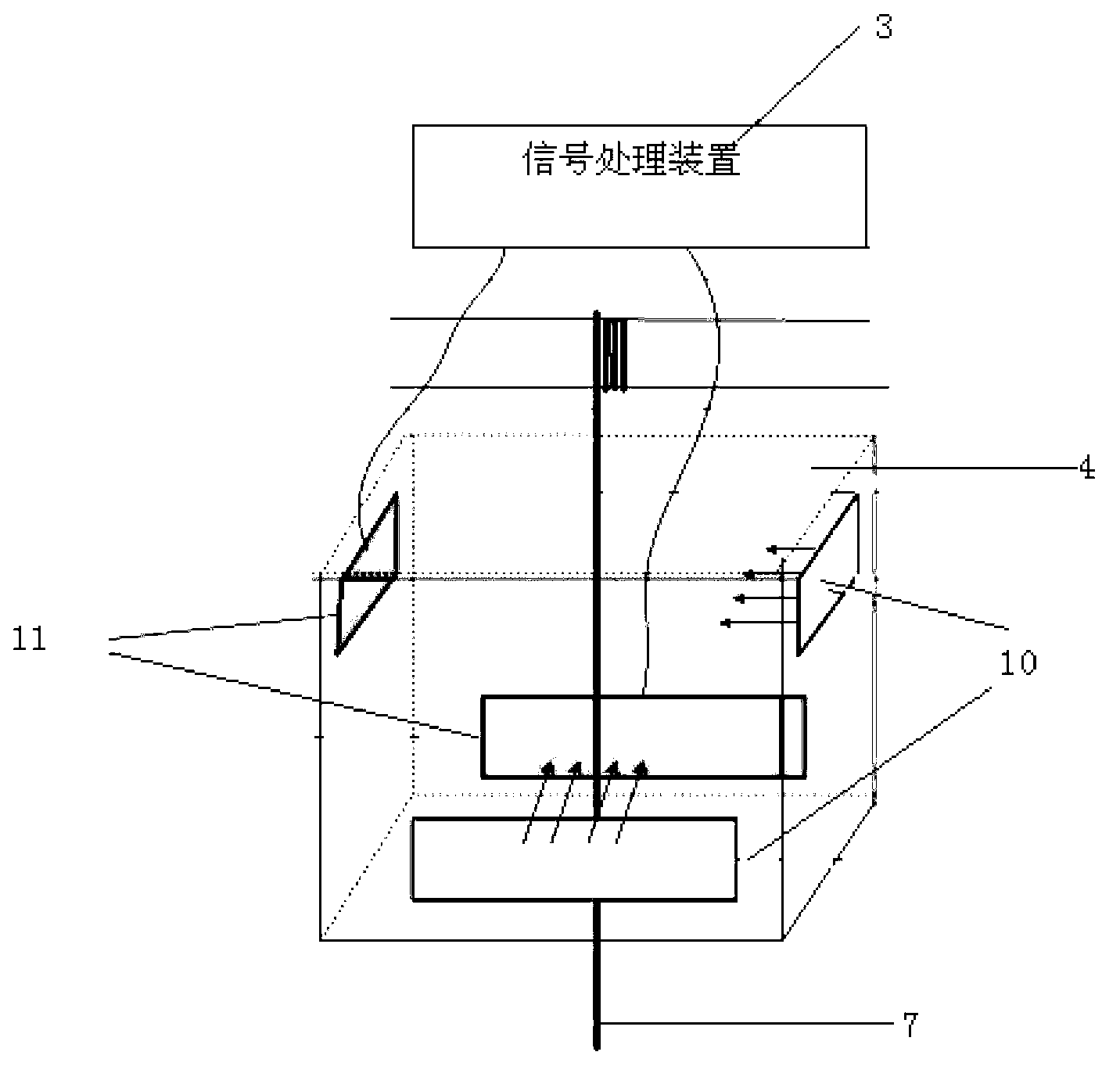

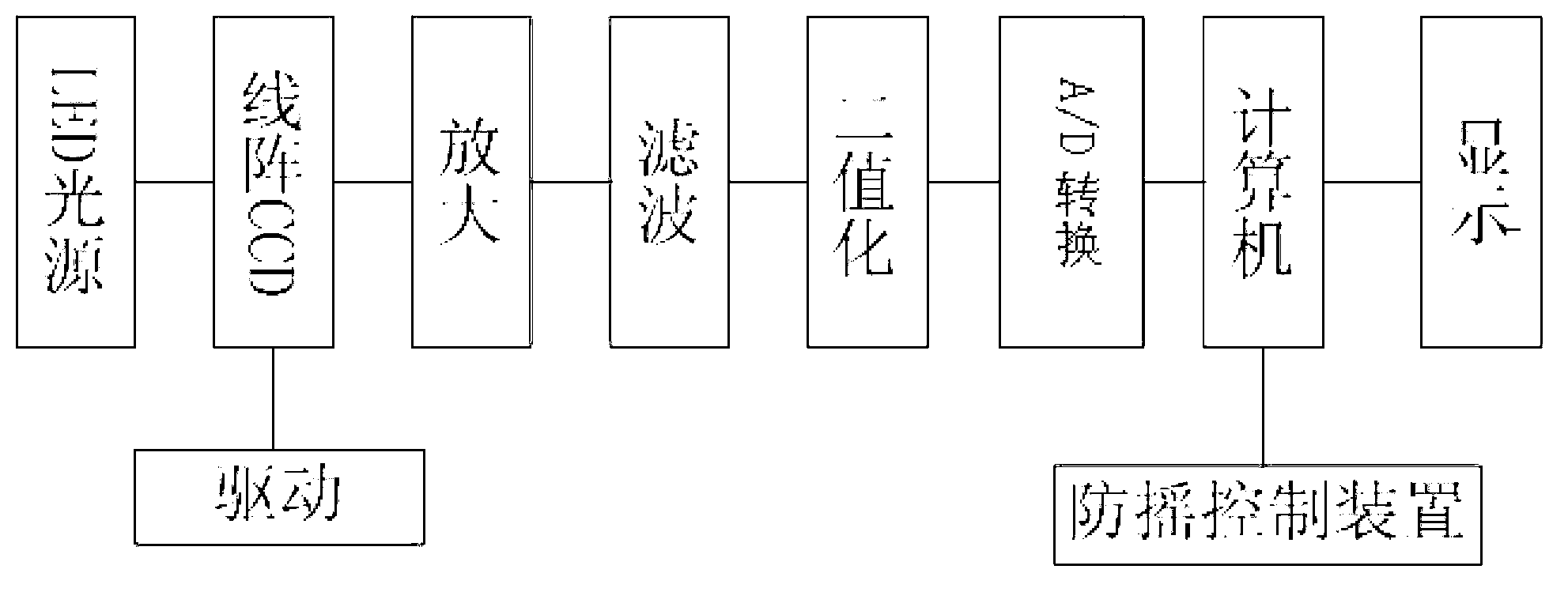

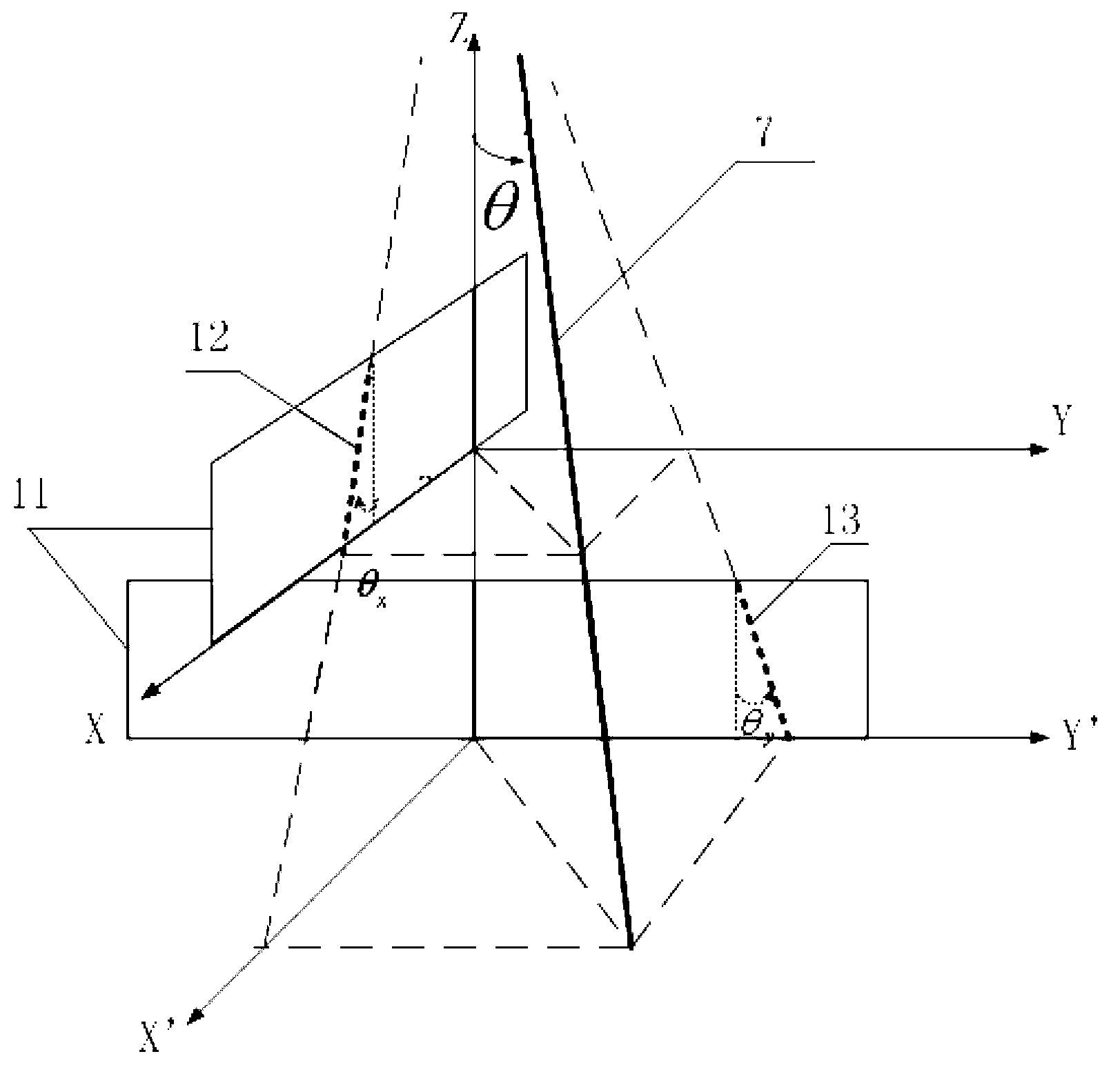

Device and method for measuring swing angle of double-hanger bridge crane on basis of image detection

InactiveCN102701078ALow costSimple structureUsing optical meansLoad-engaging elementsMachine visionMeasurement device

The invention discloses a device and a method for measuring a swing angle of a double-hanger bridge crane on the basis of the image detection. A lamp box is used as a main body of the device; four lateral surfaces of the lamp box are provided with linear array CCD (Charge Coupled Device) devices and LED (Light-Emitting Diode) lamps; the linear array CCD devices and the LED lamps are oppositely arranged; a lifting rope is arranged at the middle position of the lamp box; the linear array CCD devices are connected with a CCD shallow measurement device by wires; and two groups of linear array CCD devices are provided. According to a vision principle of a machine, double hangers process and calculate obtained pulsed signals to obtain the swing angle by two sets of illuminating devices and the linear array CCD shadow measurement device; and the obtained data can be used as feedback information for the anti-sway control of the bridge crane and can also be directly shown to a cab of the bridge crane. The device and the method for measuring the swing angle of the double-hanger bridge crane on the basis of the image detection have the advantages of simple structure, high accuracy, strong anti-interference capacity and the like.

Owner:SHANGHAI MARITIME UNIVERSITY

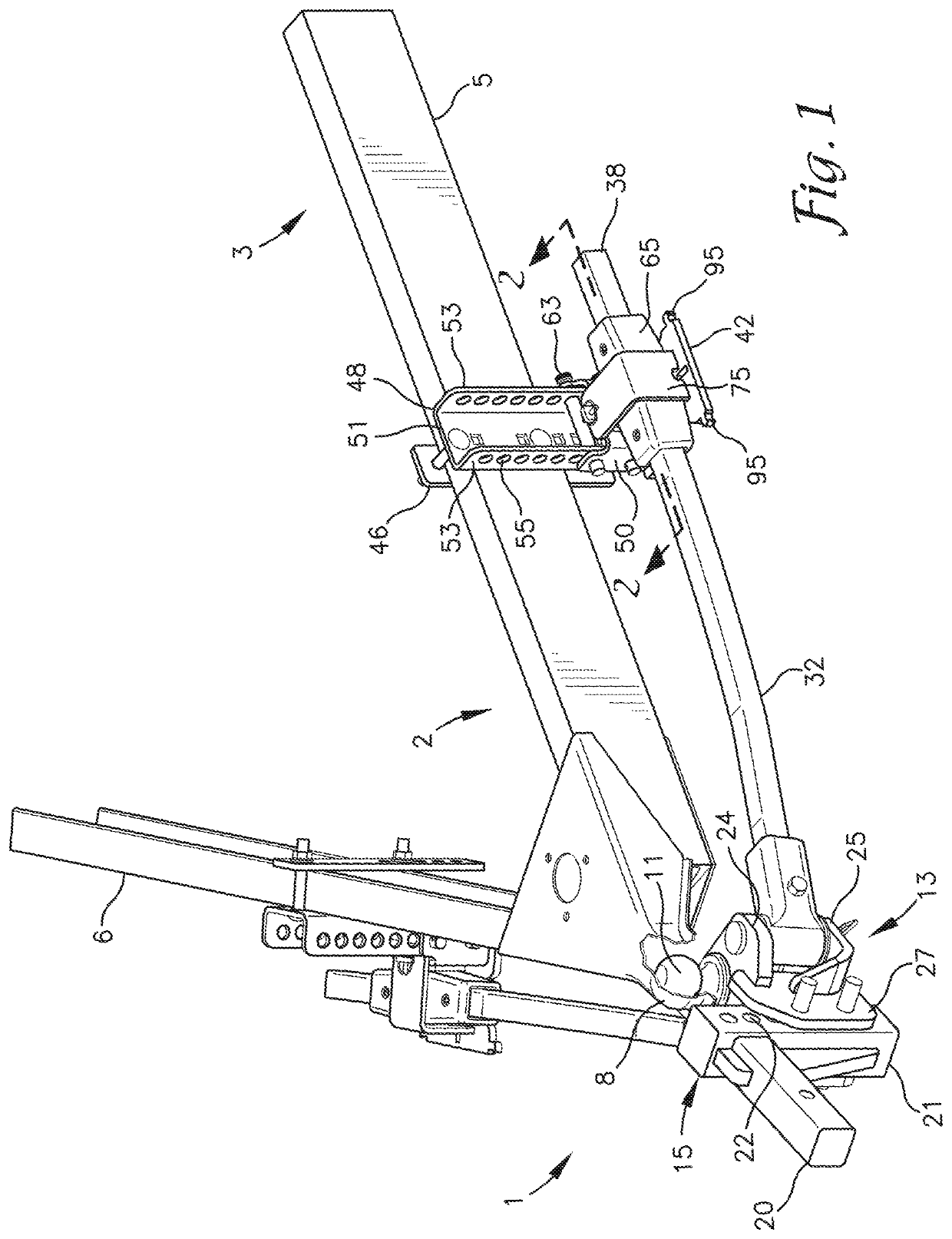

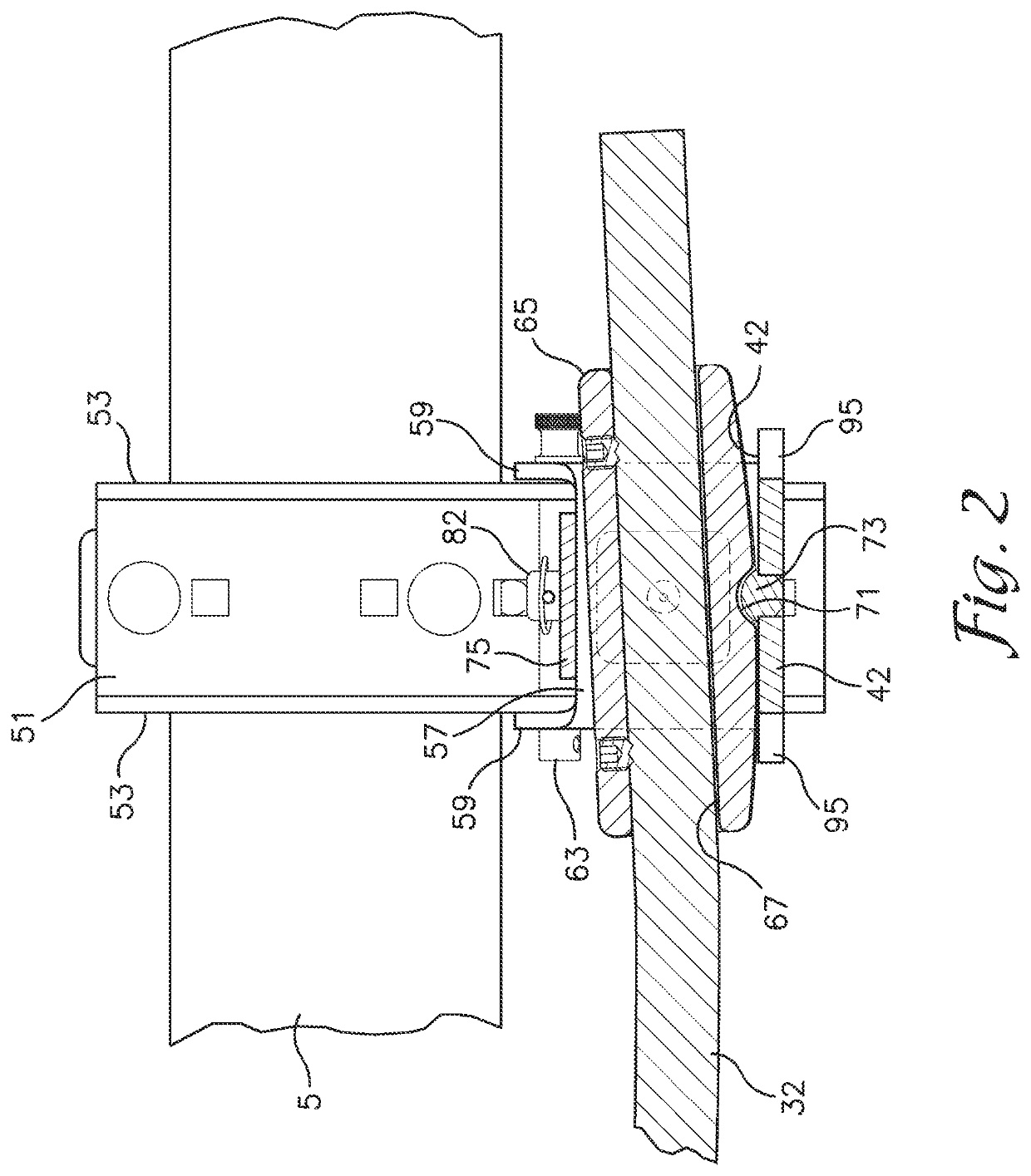

Sway control hitch

A trailer hitch system for equalizing trailer loads and reducing trailer sway. The trailer hitch system may include spring bars that may be attached to a hitch head using a trunnion style connection. The spring bars may be attached to the trailer using rigid brackets that reduce swinging of the spring bars. The rigid brackets may include an upward extending portion for attaching to the trailer tongue, and a lateral extending portion for receiving the spring bars thereupon. The brackets may have a contact surface on the lateral extending portion that may be free from a coating such that a metal on metal contact is made between the spring bars and the brackets. Portions of the brackets beyond the contact surface may be covered with a protective coating.

Owner:PROGRESS MFG LLC

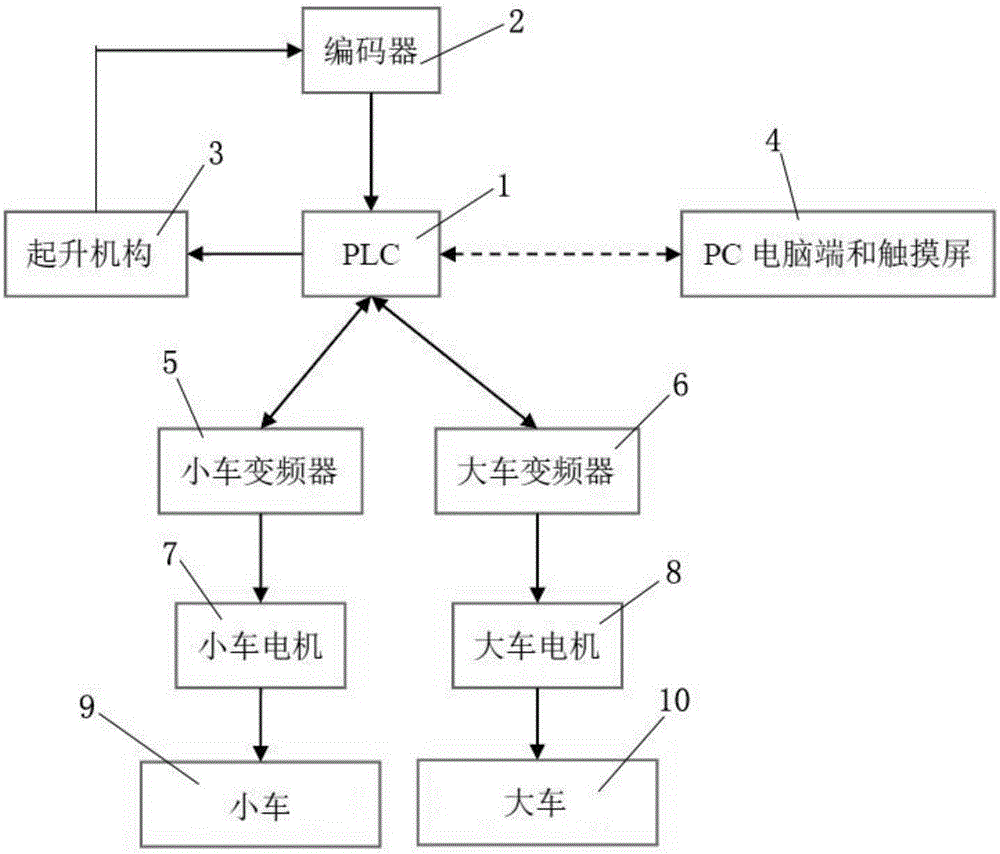

Anti-swinging control system of crane weight and control method of system

PendingCN110316657AEliminate swaySimple structureLoad-engaging elementsFrequency changerGravity center

The invention relates to the technical field of crane control, in particular to an anti-swinging control system of a crane weight and a control method of the system. The system comprises a steel wirerope length measuring unit, a pre-treatment module, an anti-swinging operation module and a frequency converter control unit, wherein the steel wire rope length measuring unit is used for accurately measuring the steel wire rope length in real time; a signal of an encoder is in communication through an optical fiber, a measuring signal is transmitted to a PLC, and communication with the PLC is achieved; the pre-treatment module and the anti-swinging operation module are used for calculating a set frequency parameter of a frequency converter according to the distance from the gravity center ofa steel wire rope length superposition gripper (or a lifting appliance) to a steel wire rope unloading buckle, data are output at right time in segments, large and small trolley speeds are controlled,and the large and small trolley speed decreasing anti-swinging purpose is achieved; and the frequency converter control unit achieves speed increasing or decreasing operation according to an output instruction of the PLC. According to the anti-swinging control system, due to production validation, swinging of a load crane during starting and stopping can be eliminated, stability and reliability are achieved, and the swinging reducing amplitude is larger than 95%.

Owner:SHANGHAI ANGFENG EQUIP TECH CO LTD +1

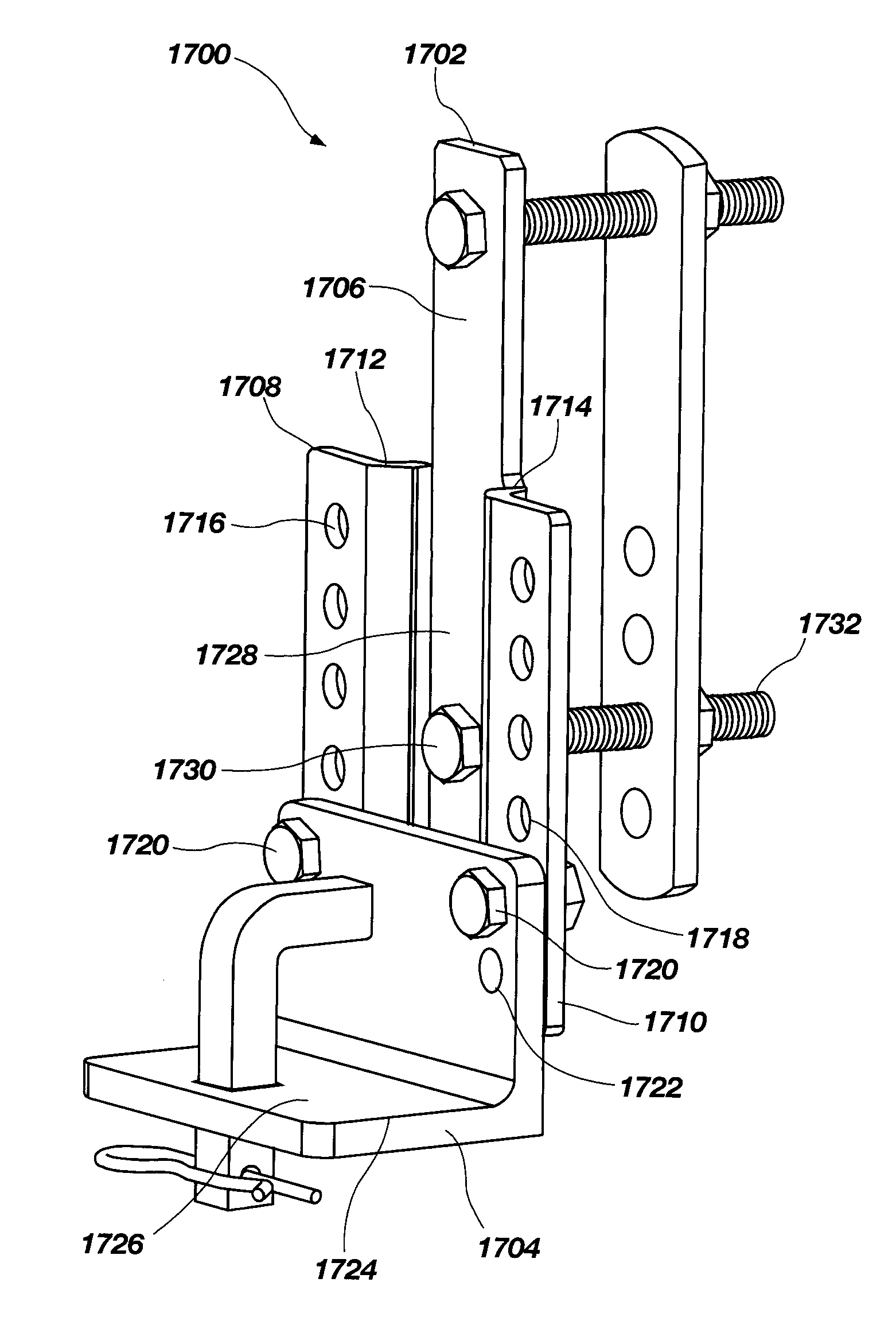

Sway control conversion bracket

A bracket, apparatus and method are provided for adapting a simple draw bar and hitch ball arrangement to allow connection to a sway control device. The bracket includes an aperture for receiving the threaded stem of the hitch ball, a notch for receiving and engaging the draw bar and a second aperture for receiving a sway control device connector such as a sway control ball. The bracket allows connection to any number of sway control devices available in the industry so that a simple draw bar and hitch ball may be converted for sway control capability.

Owner:COQUENT TOWING PRODS

Dual-attachment system for a sway control hitch

A trailer hitch system for equalizing trailer loads and reducing trailer sway. The trailer hitch system may include spring bars that may be attached to a hitch head using a trunnion style connection. The spring bars may be attached to the trailer using rigid brackets that reduce swinging of the spring bars. The rigid brackets having a plurality of contact points may include an upward extending portion for attaching to the trailer tongue, and a lateral extending portion for receiving the spring bars thereupon. The rigid brackets may include a spacing member and an attachment member.

Owner:PROGRESS MFG LLC

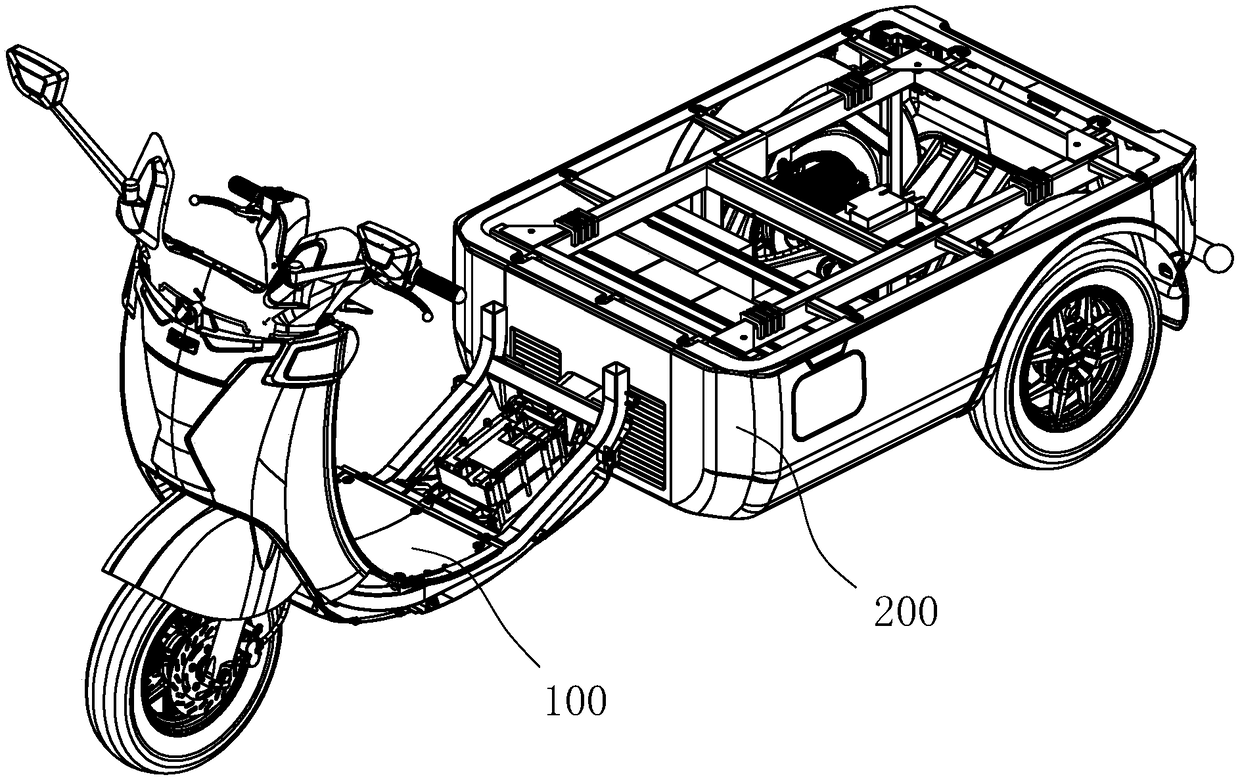

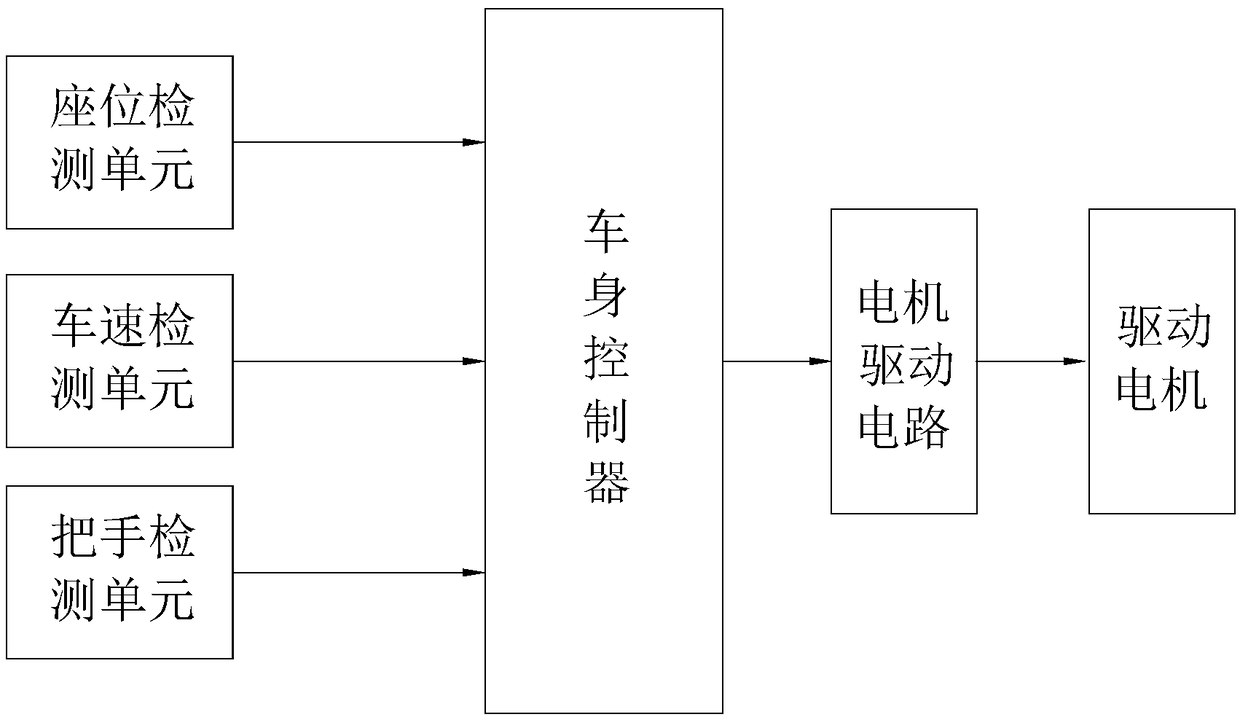

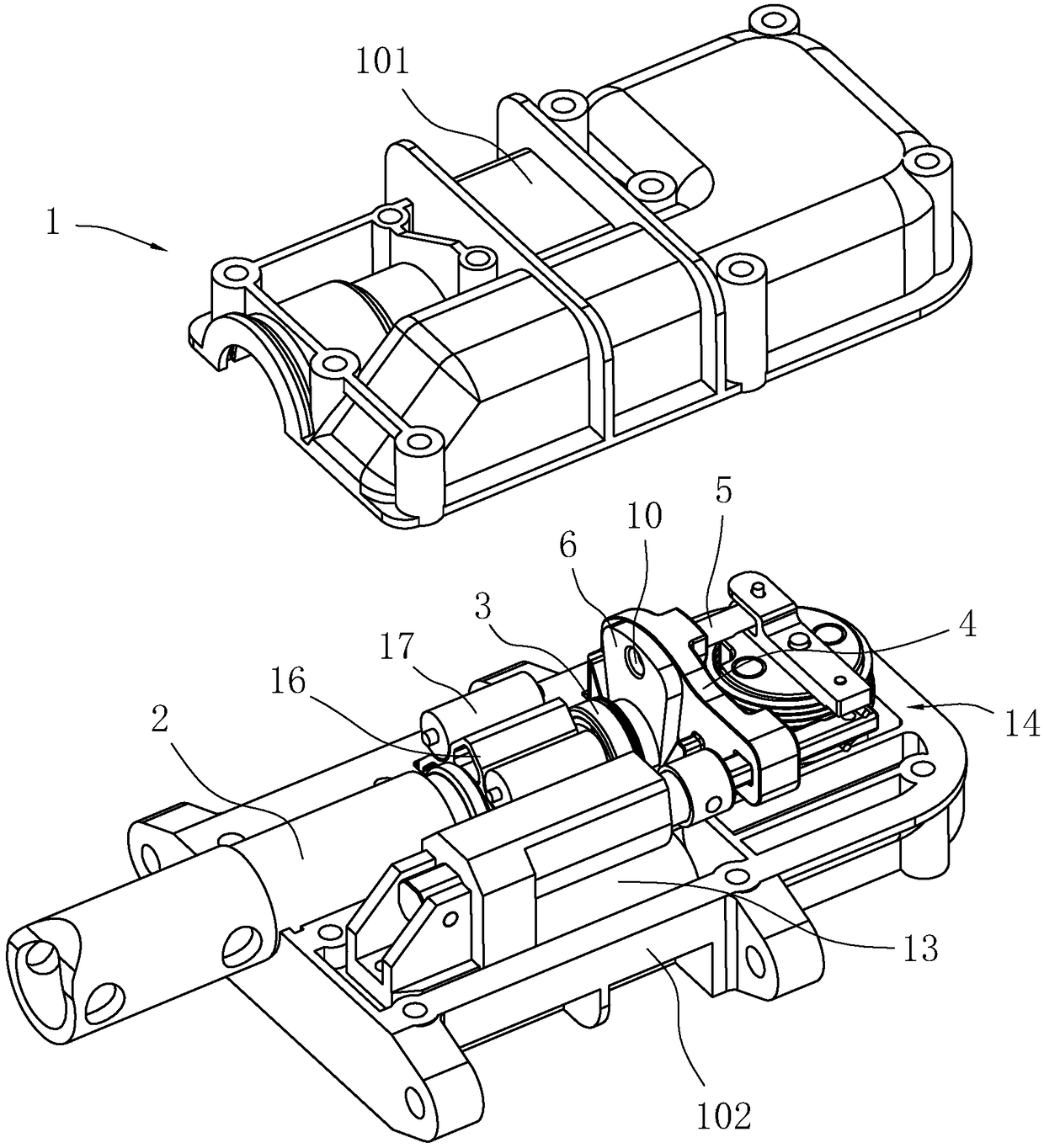

Logistics vehicle swing control mechanism based on man-machine interaction

ActiveCN109466672AImprove ease of useImprove sway stabilityPassenger cyclesLogistics managementDrive motor

The invention discloses a logistics vehicle swing control mechanism based on man-machine interaction, which is characterized by comprising a front vehicle body, a rear vehicle body, a swing mechanism,a driving motor, a signal acquisition part and a vehicle body controller, wherein the signal acquisition part comprises a seat detection unit, a vehicle speed detection unit and a handle detection unit; the vehicle body controller is used for receiving the seat signal, the vehicle speed signal and an angle signal and carrying out judgment; when the logistics vehicle is ridden, the vehicle body controller controls the driving motor to enter a pre-separation state, and judges one by one that when the vehicle speed is larger than a preset value and the rotation angle of the handle is larger thana threshold value, the vehicle body controller controls the driving motor to act so as to drive a locking rod to separate from a locking hole. The data in the logistics vehicle is acquired by the signal acquisition part, the acquired data is judged by the vehicle body controller, and the control mechanism of whether the front vehicle body swings or not is established so as to effectively improvethe use convenience of the logistics vehicle.

Owner:ZHEJIANG RAP INTELLIGENT VEHIGLE CO LTD

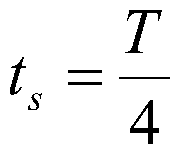

Crane period anti-swing control method

InactiveCN108249303AEasy to implementEasy anti-sway controlLoad-engaging elementsKinematicsSway control

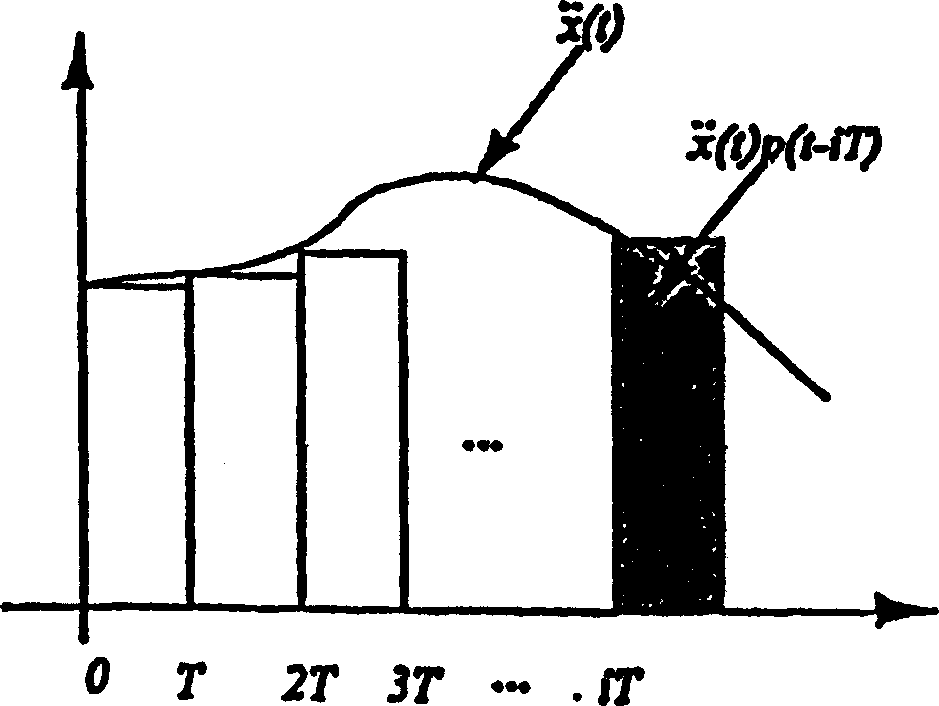

A crane period anti-swing control method is characterized in that the crane hoisting process is divided into a constant acceleration process, a constant speed process and a constant deceleration process, and the load swing angle is zero in the constant speed process and during stopping; in the constant acceleration process, a trolley adopts the accelerated speed a as the input, the acceleration duration is a period or an integral number of periods nT, T is the swing period, n is a natural number, the accelerated speed a=garctan (theta<max> / 2), and the constraint condition of the maximum allowable swing angle theta<max> is met; in the constant speed process, the trolley carries out hoisting at the constant speed of V<constant>=naT; and the constant deceleration process is the inverse process of the constant acceleration process, that is, the trolley adopts the accelerated speed -a as the input, and the lasting duration is the same as the acceleration duration. The crane period anti-swing control method starts with the kinematics, it can be theoretically achieved that the load swing angle is zero during constant-speed running and stopping, no swing angle senor is needed, engineeringimplementation is easy, and cost is low. When the limiting conditions such as the swing angle, the expected constant speed and the stroke are given, the specific acceleration and deceleration processes meeting all expected conditions can be planned easily.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

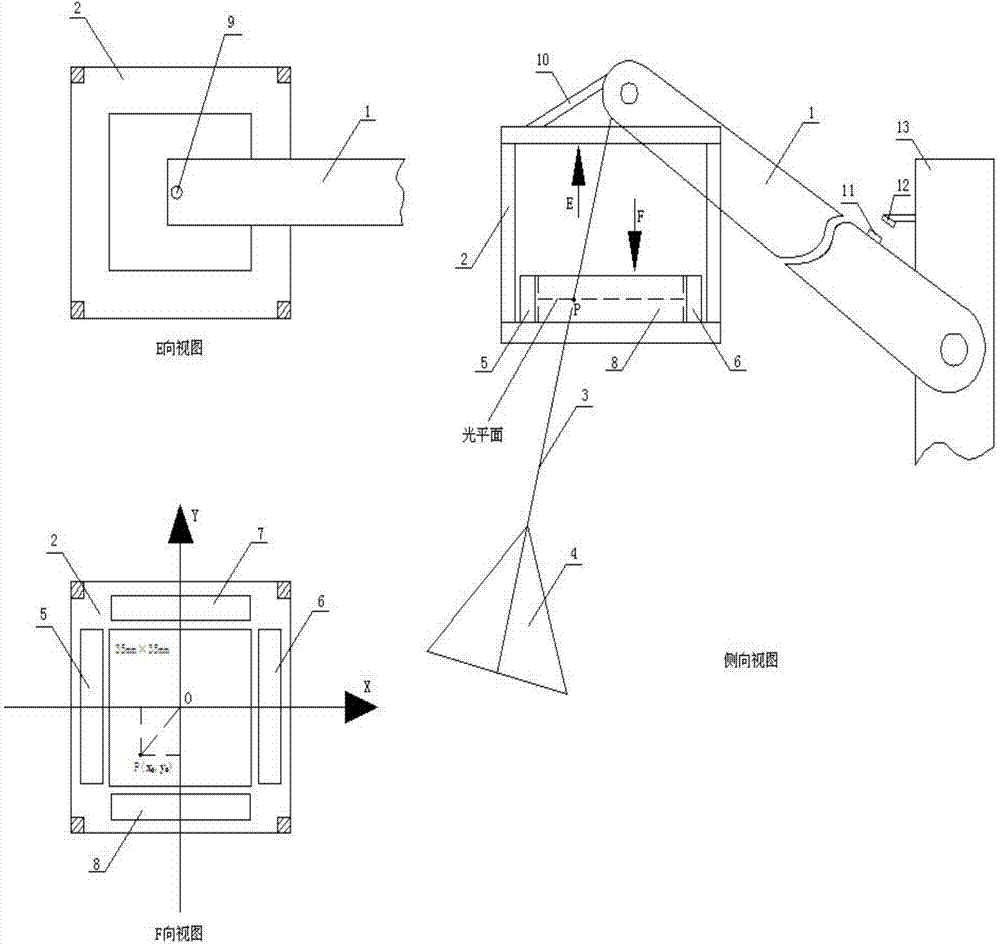

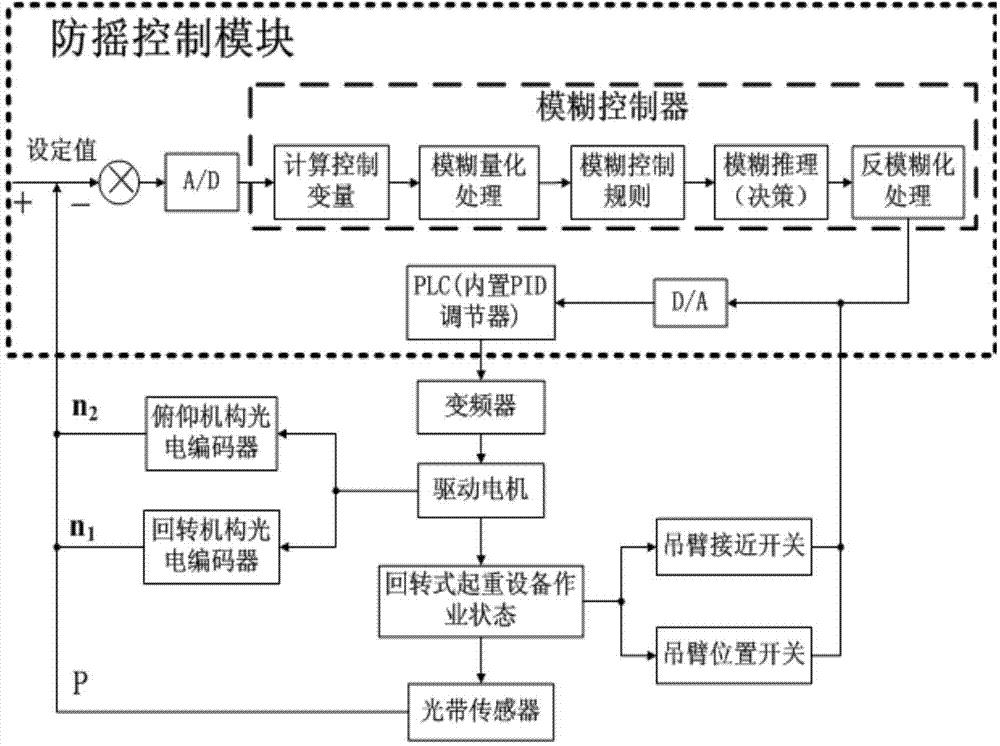

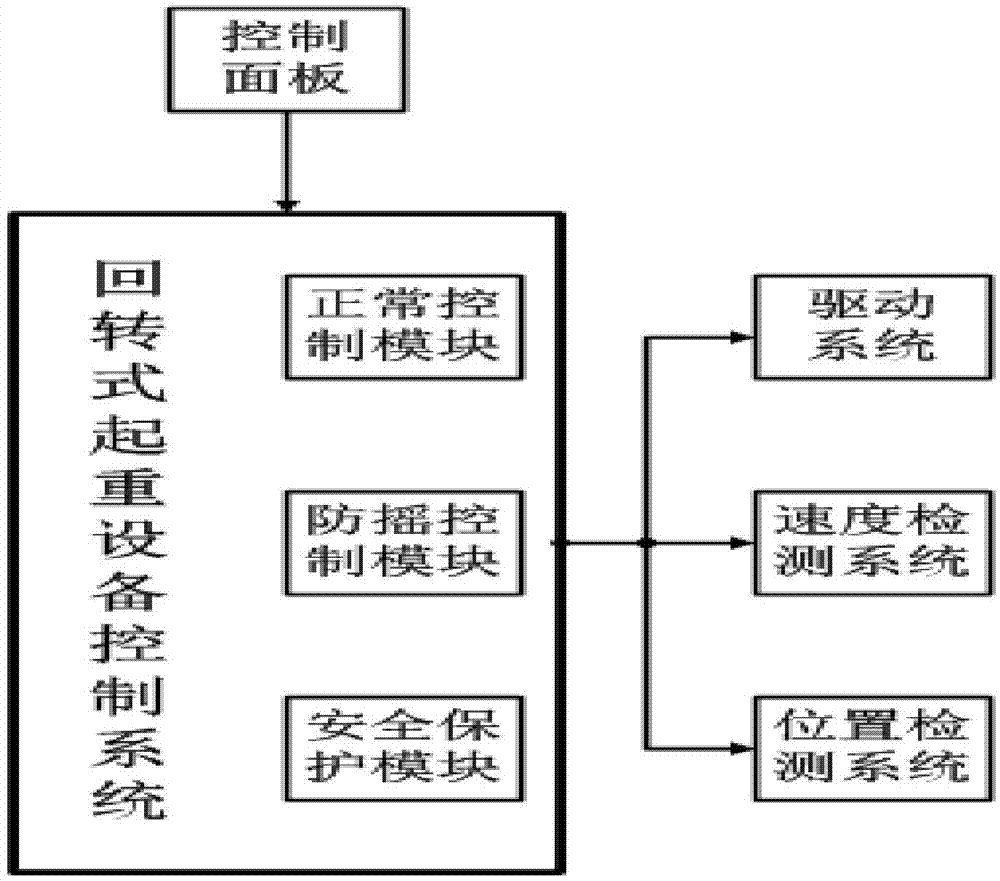

Lifting appliance anti-swaying device of rotary crane and control method of anti-swaying device

ActiveCN104760890ARealize anti-shake functionStrong anti-shake reliabilityLoad-engaging elementsCranesControl systemComputer module

The invention relates to the field of engineering machinery and particularly relates to a lifting appliance anti-swaying device of a rotary crane and a control method of the anti-swaying device. An anti-swaying control module is additionally arranged on the basis of a control system of the rotary crane; a light band sensor capable of continuously measuring the coordinate of a lifting appliance in a light plane in real time, a rotary mechanism photoelectric encoder for detecting the rotating speed of a rotary mechanism, a pitching mechanism photoelectric encoder for detecting the pitching speed of a pitching mechanism and a jib approaching switch and a jib position switch for detecting the specific operation height of a jib are simultaneously adopted; the spatial coordinate of a steel wire rope connected with the lifting appliance in the light plane during swaying is measured in real time through the light band sensor and then coordinate information is transmitted to the anti-swaying control module of the control system for analysis and comparison; by changing parameters of a frequency converter to control the speed, the swaying angle of the lifting appliance can be reduced to the range of a set value; the problem that the lifting appliance sways at a large amplitude during the operation of the rotary crane is solved and stable and reliable operation of the lifting appliance is guaranteed.

Owner:JIANGSU DINSON HEAVY IND +1

Transportation arm device for carrying discs

InactiveUS7650612B2Provide flexibilityRecord information storageRecord carrier contruction detailsEngineeringSway control

A transport arm device for carrying at least one disc includes a driving mechanism, a sway control member, and a swaying mechanism. The sway control member comprises a hole substantially in the middle of the sway control member for receiving a portion of the driving mechanism and two leaf springs extending up from two sides of the sway control member respectively. The swaying mechanism is capable of grabbing the discs. The swaying mechanism comprises a rotating connection for engaging with a suspension of the transport arm device. The two leaf springs are contacted with the swaying mechanism. The sway control member is moved by the driving mechanism so as to rotate the swaying mechanism along a rotary axis on the rotating connection, and the two leaf springs provide elasticity for the swaying mechanism rotating back.

Owner:DATATRONICS TECH

Dual-attachment system for a sway control hitch

A trailer hitch system for equalizing trailer loads and reducing trailer sway. The trailer hitch system may include spring bars that may be attached to a hitch head using a trunnion style connection. The spring bars may be attached to the trailer using rigid brackets that reduce swinging of the spring bars. The rigid brackets having a plurality of contact points may include an upward extending portion for attaching to the trailer tongue, and a lateral extending portion for receiving the spring bars thereupon. The rigid brackets may include a spacing member and an attachment member.

Owner:PROGRESS MFG LLC

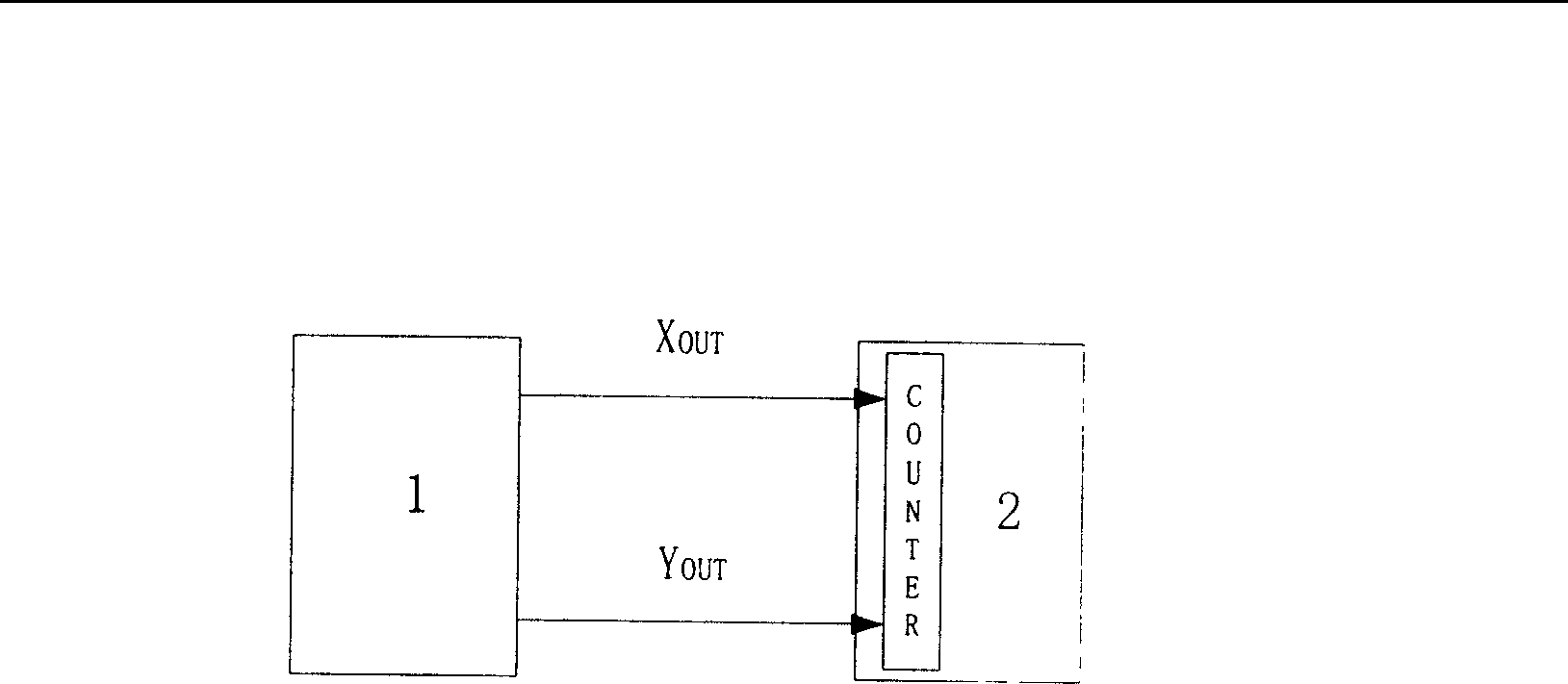

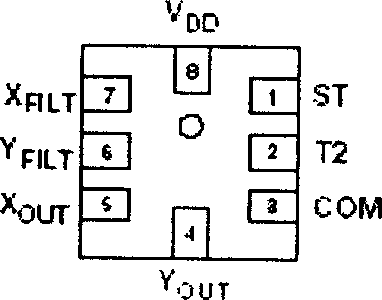

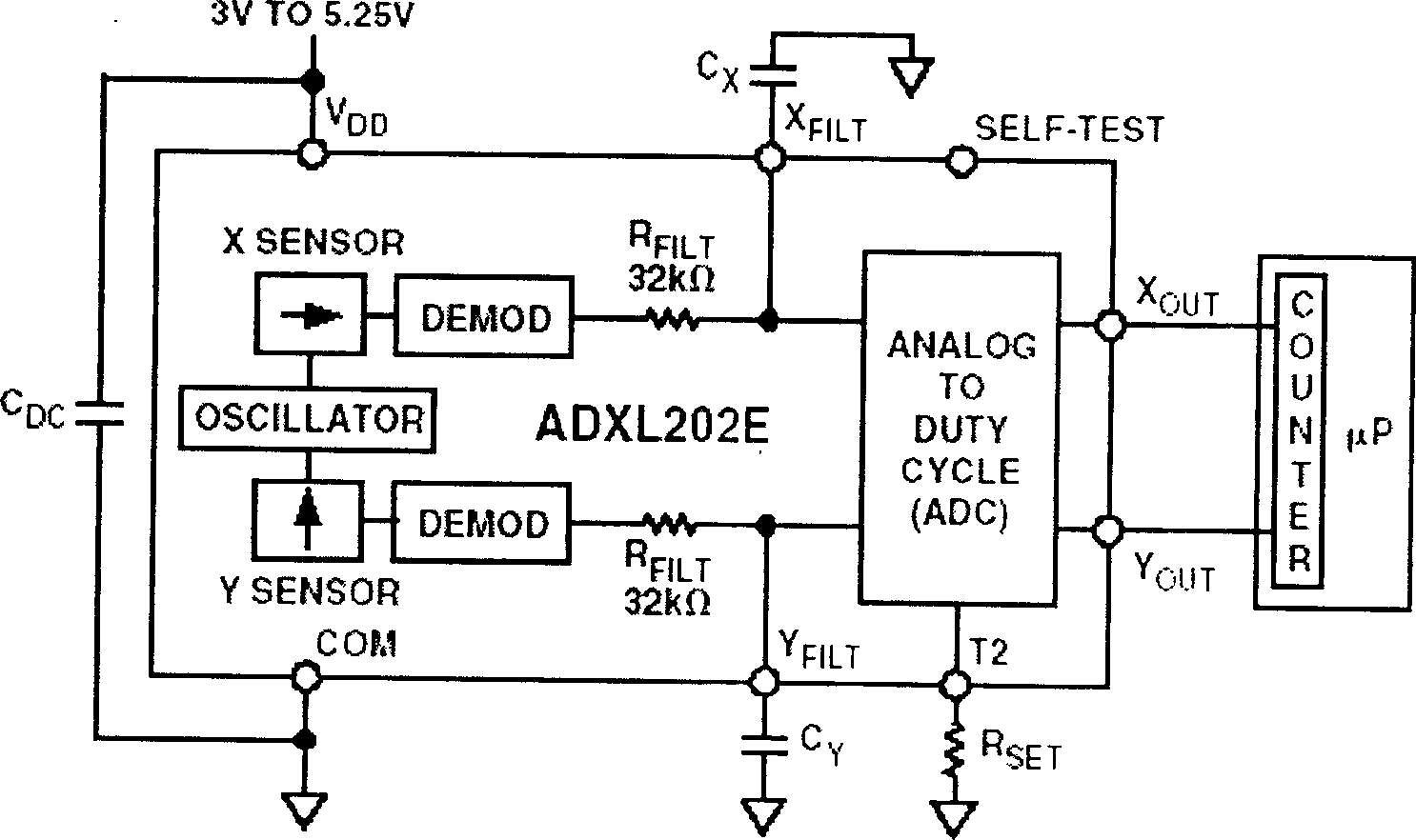

Gradient induction encrypted method

InactiveCN1598750ADoes not compromise portabilityImplement password protectionInput/output processes for data processingComputer usersDependability

The invention discloses a gradient induction encrypting method, it is mainly composed of sensor chip 1 and microprocessor 2, the balancing induction signal of sensor chip is transmitted to timer / counter port of microprocessor, the microprocessor decodes the balancing induction signal, and records the moving trail of cursor as keyword of moving intelligent terminal, the keyword is inputted by swaying control panel of intelligent terminal, compares the new cursor moving trail with stored keyword in memory to complete encrypting. The excellence of the invention is using the cursor moving trail as keyword of intelligent terminal, which replaces the traditional key-press or touch screen, avoids the shortage of number and letter being not easy to remember, reduces many unnecessary trouble due to forgetting keyword. The encrypting method do not influence portability of moving intelligent terminal, so it has the characters such as simple structure, strong operating reliability, it is a ideal moving intelligent terminal for all computer users.

Owner:TIANJIN UNIV

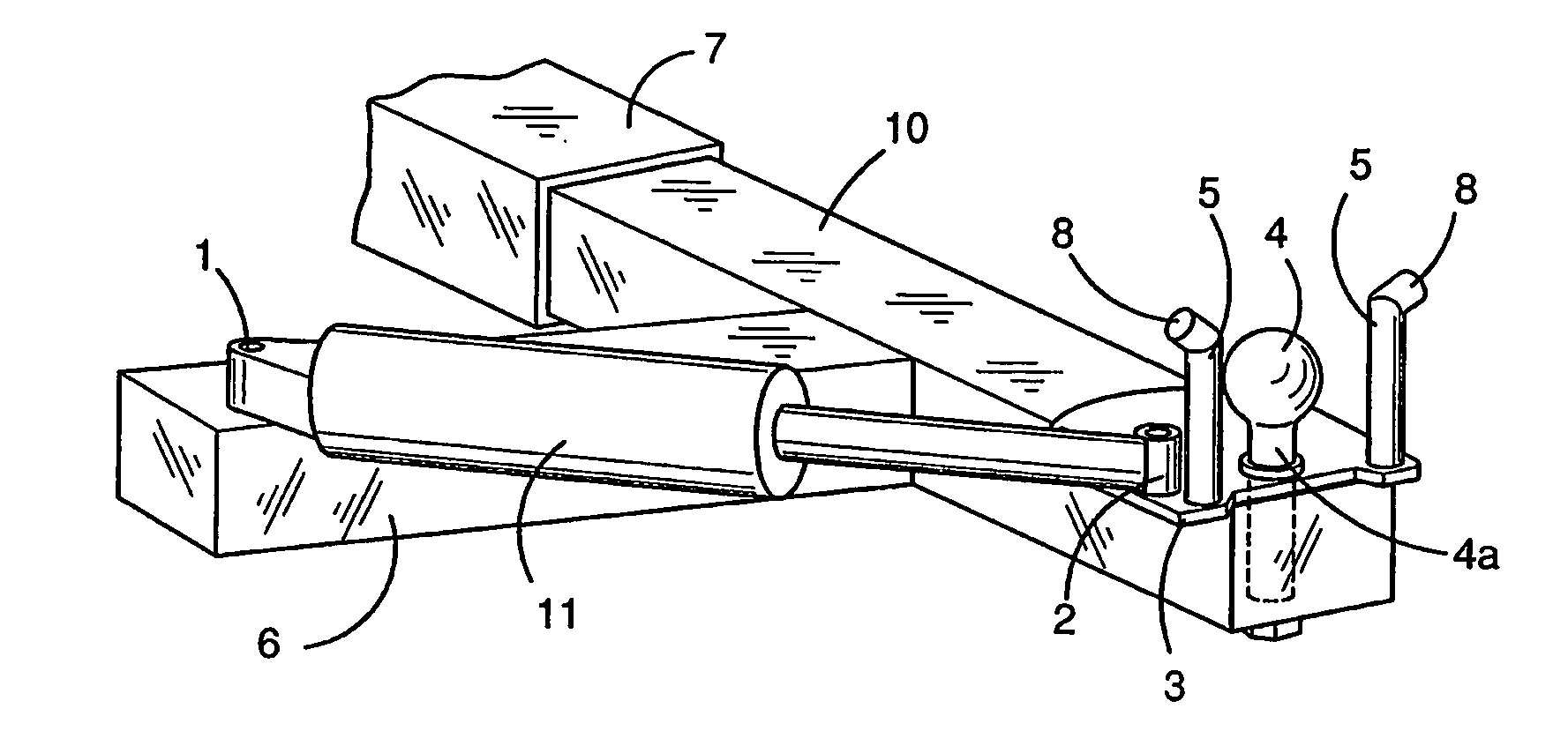

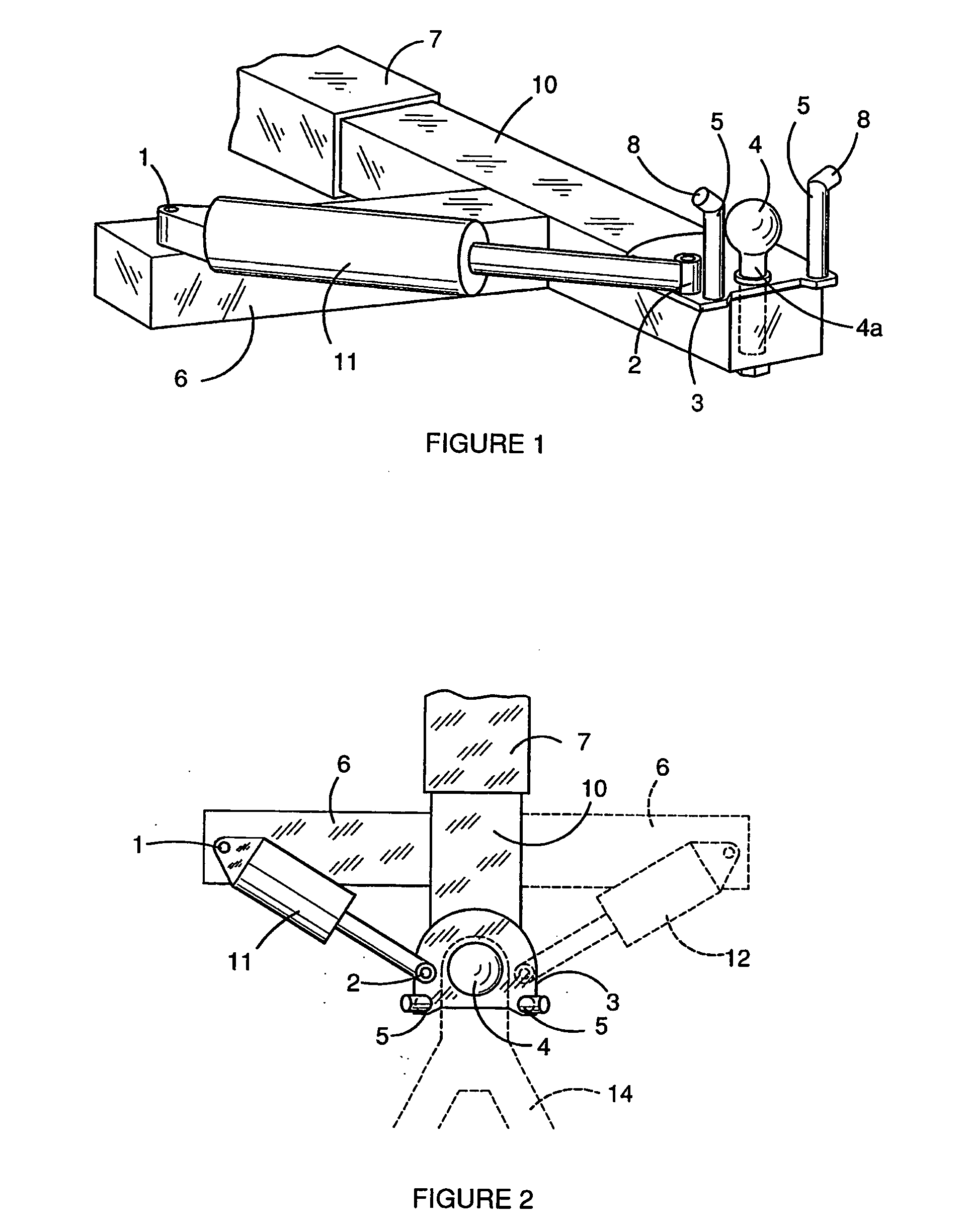

Sway Control Device for Trailers

The present invention relates to an apparatus for reducing sway of a trailer towed by a towing vehicle. The apparatus comprises a draw bar for linking a trailer to a vehicle and means for hitching the trailer to the draw bar and for hitching the draw bar to the vehicle. The apparatus also comprises a body associated with the hitching means such that horizontal angular movement of the draw arm relative to the draw bar causes a substantially equivalent horizontal angular movement of the body relative to the draw bar. The apparatus further comprises means linked to the body for dampening horizontal angular movement of the body and, thereby, dampening horizontal angular movement of the trailer.

Owner:MCCUNE BERNARD JOHN

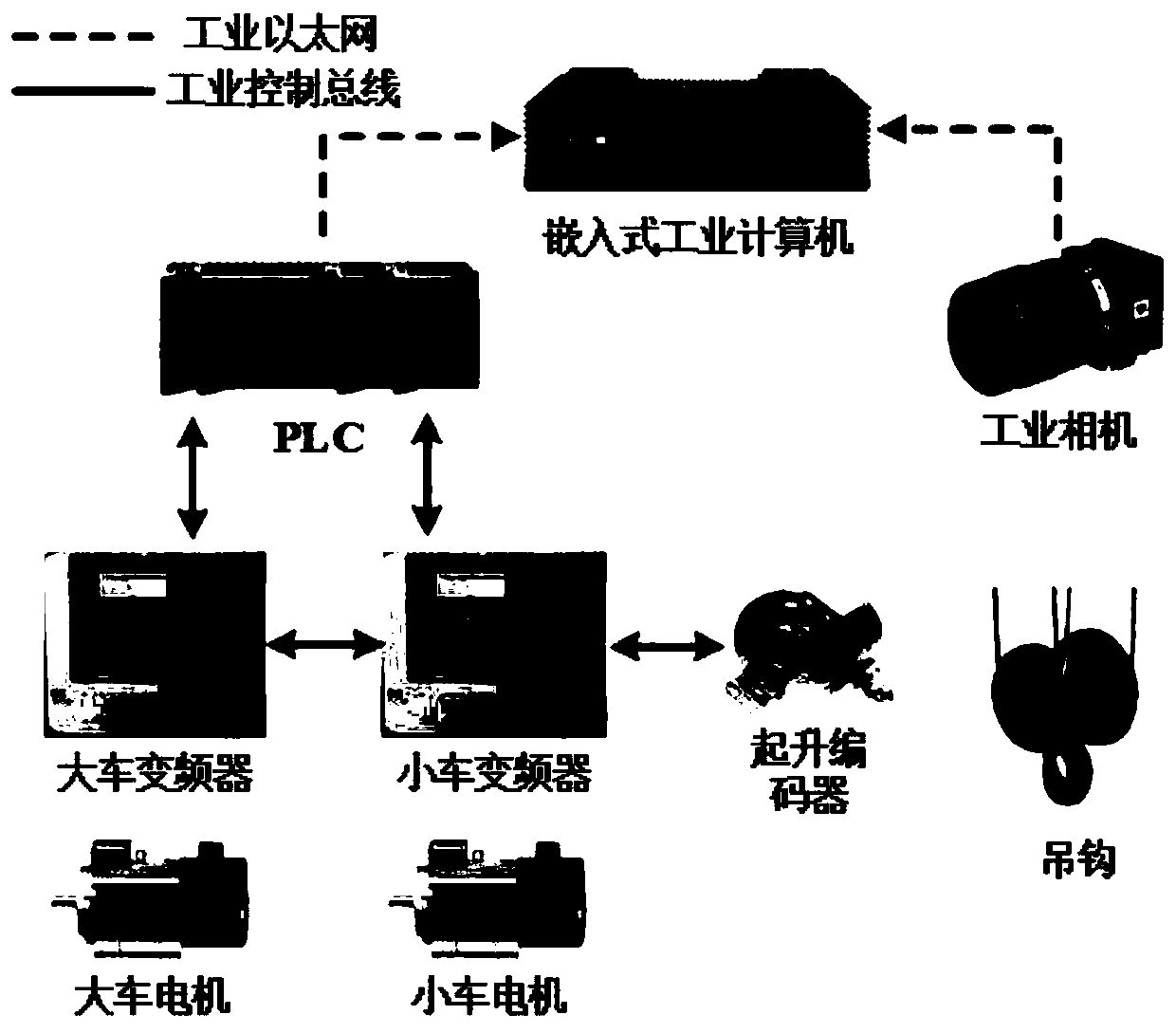

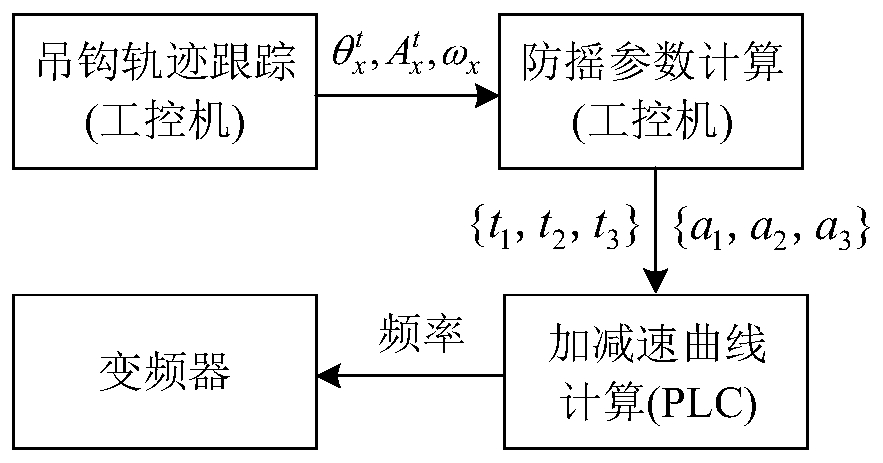

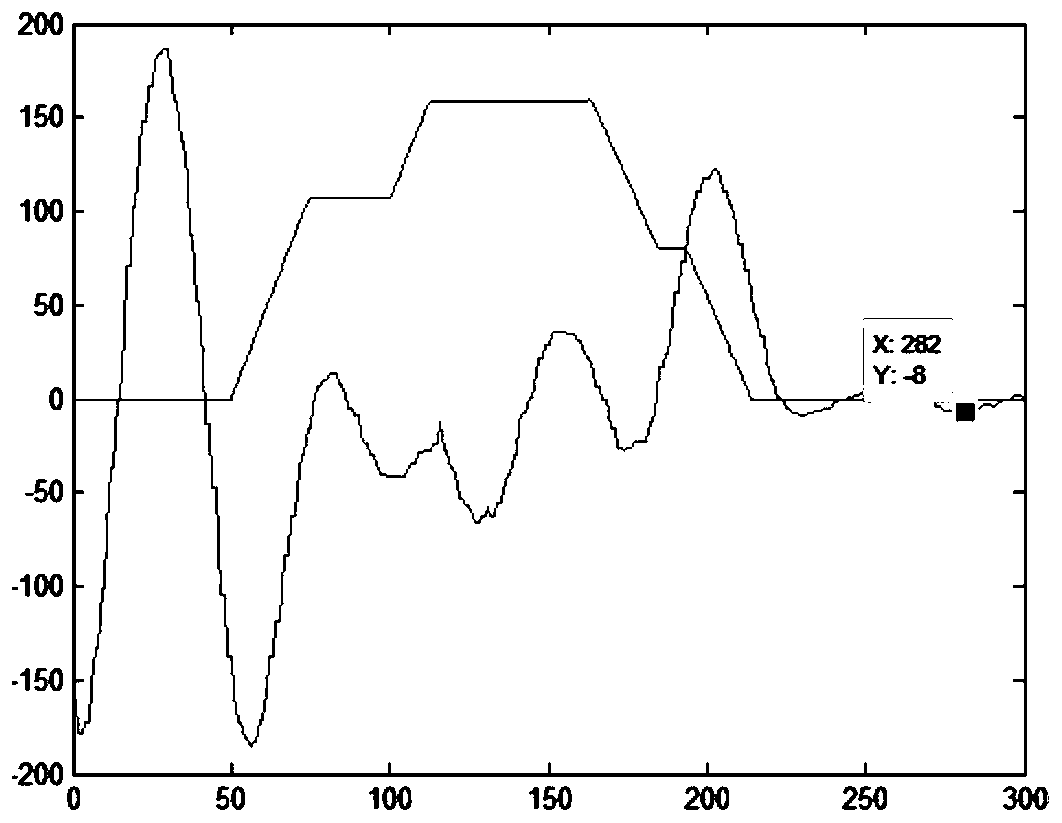

Crane anti-swing control method based on machine vision

ActiveCN110775818AAdaptableGood anti-shake effect in working conditionsLoad-engaging elementsMachine visionMachine

The invention discloses a crane anti-swing control method based on machine vision, and the method is used for identifying and tracking the swing track of a lifting hook in real time, self-adaptively controlling and adjusting an acceleration and deceleration frequency curve of a large car and a small car when the large car and the small car accelerate or decelerate according to the swing angle, amplitude and frequency of the lifting hook, and realizing an intelligent anti-swing function. The crane anti-swing control method aims at the real-time anti-swing of the closed loop of a load, and is strong in adaptability and good in anti-swing effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

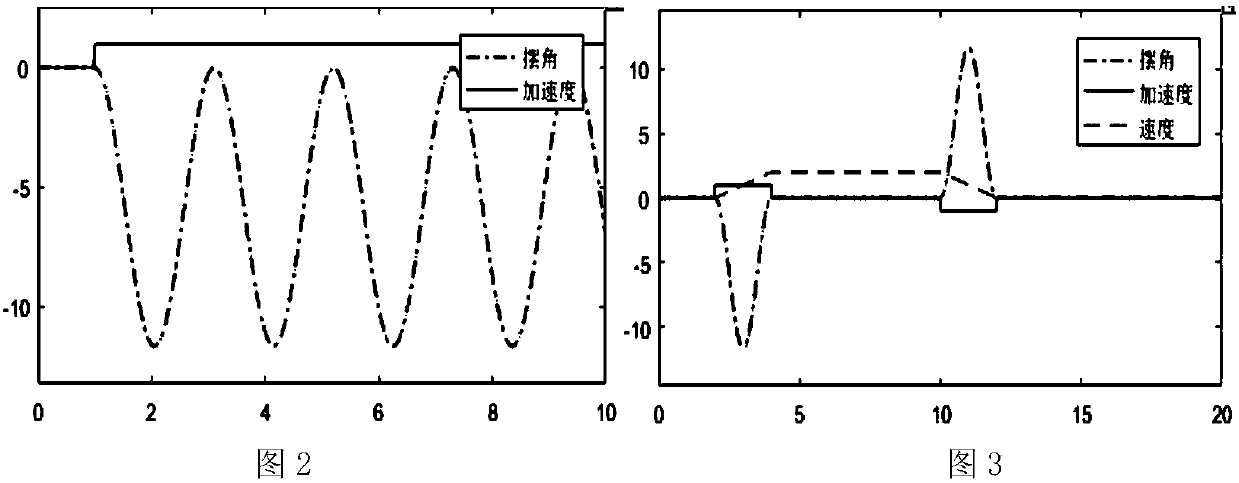

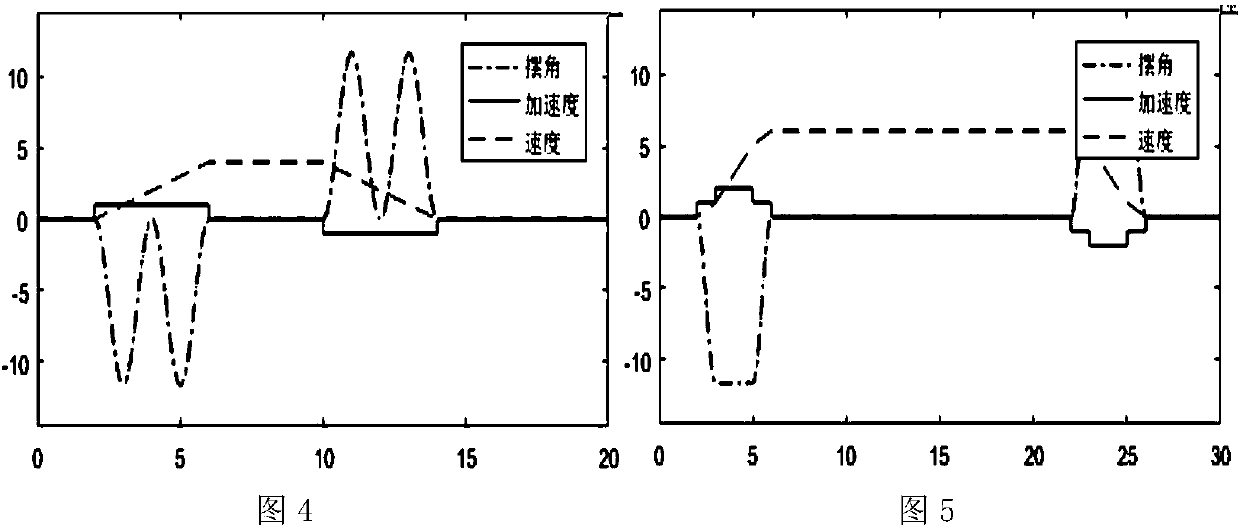

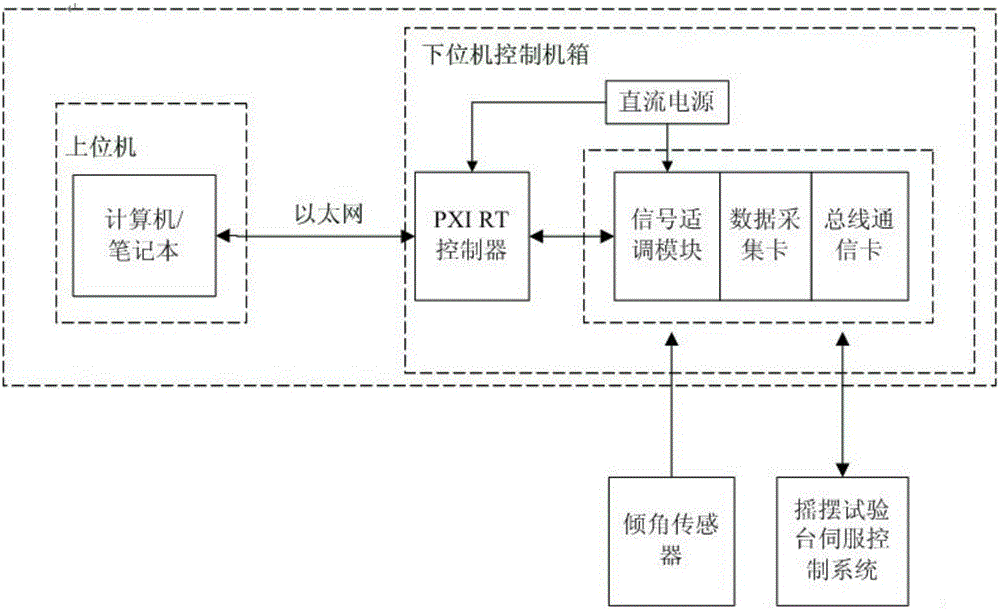

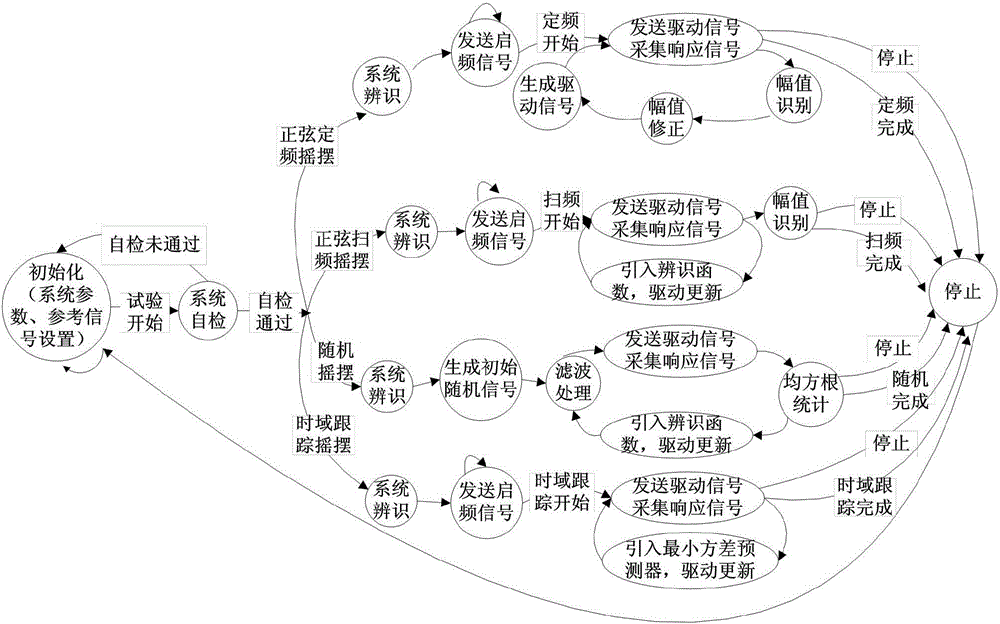

Multifunctional control method and control device for swaying testing stand

The invention discloses a multifunctional control device for a swaying testing stand. The multifunctional control device for a swaying testing stand comprises a host computer, a lower computer, a control sensor, and a servo control system for the swaying testing stand, wherein the host computer and the lower computer are connected through the Ethernet; both the control sensor and the servo control system are electrically connected with the lower computer; and an inclination angle sensor is arranged on the swaying testing stand. The invention also discloses a multifunctional control method for a swaying testing stand. The multifunctional control method for a swaying testing stand comprises a sine frequency fixing swaying control method, a sine frequency sweeping control method, a random swaying control method and a time domain tracking swaying control method. The multifunctional control method and control device for a swaying testing stand of the invention can realize sine frequency fixing, sine frequency sweeping, random and time domain tracking swaying control, and at the same time the control device has the advantages of being simple in system, having few modules, being easy to install and being convenient to maintain, and is suitable for the swaying control field.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

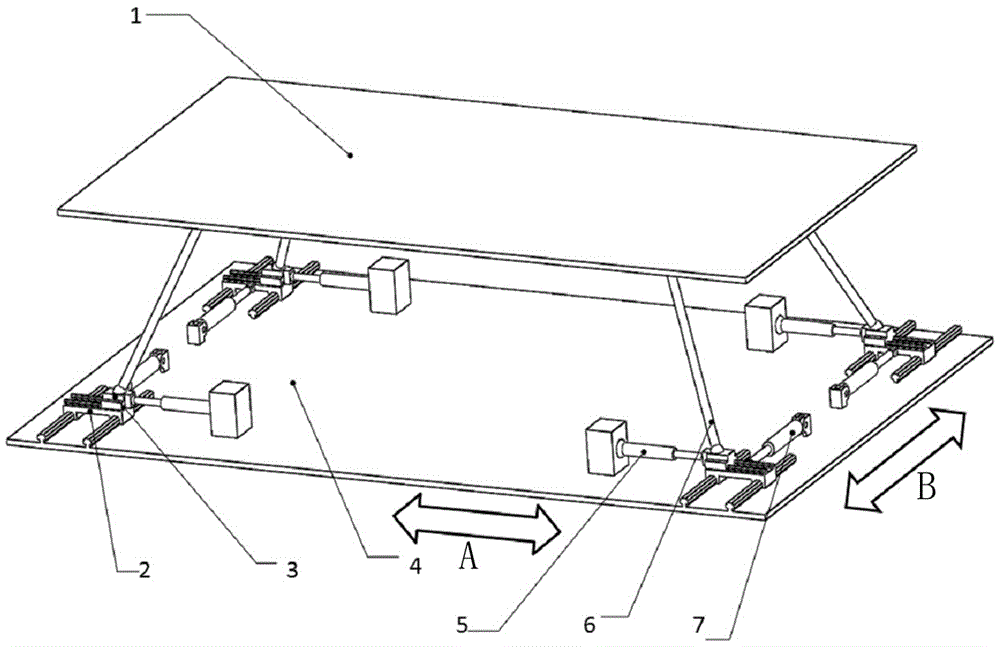

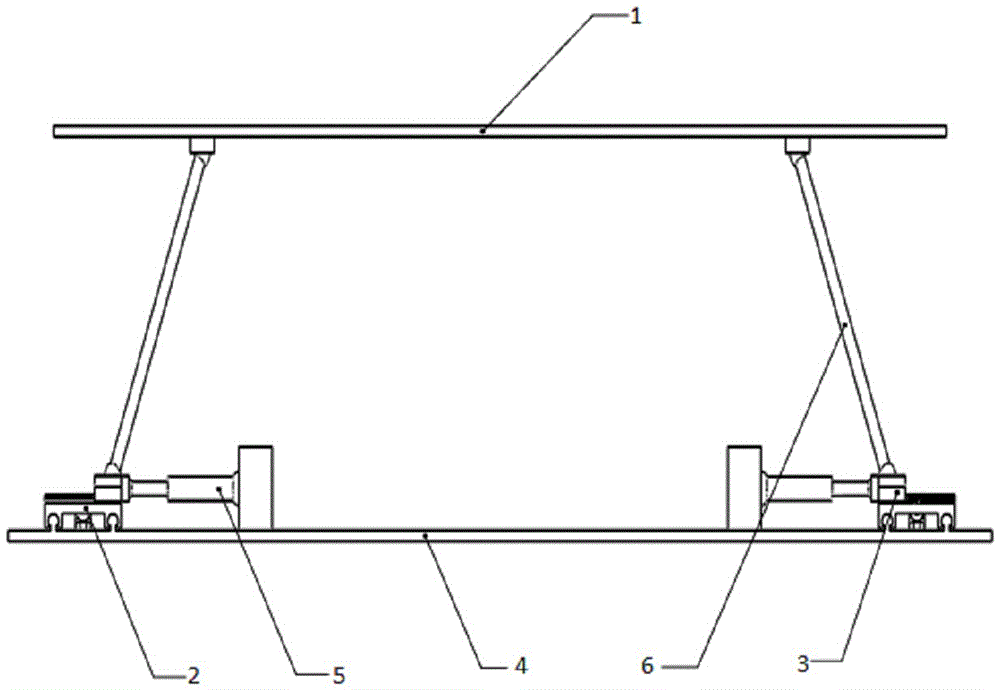

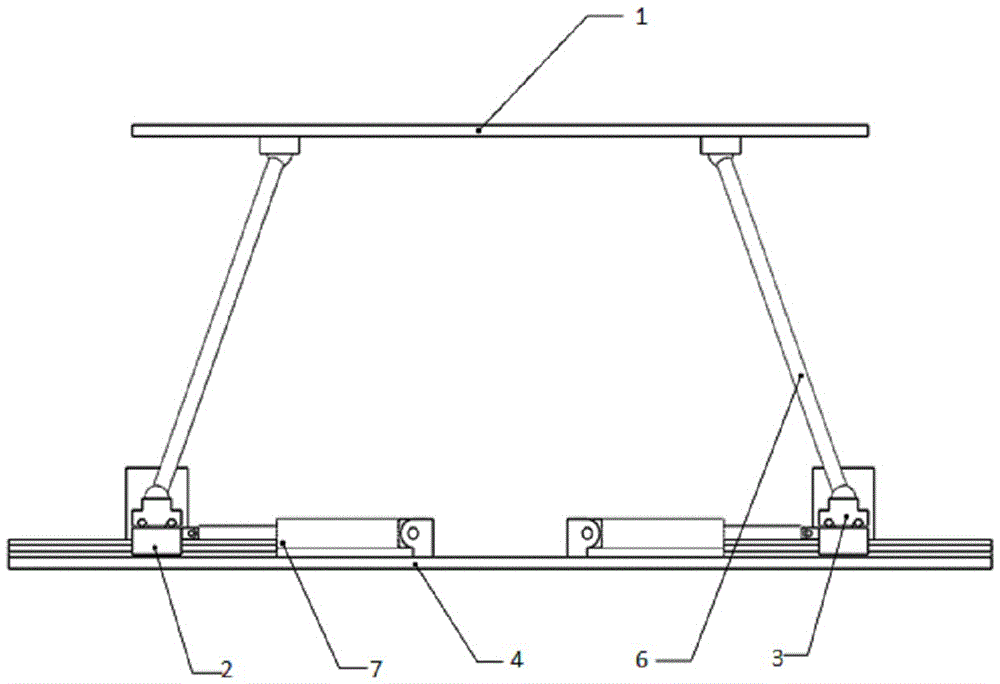

Swaying platform under control of cross-shaped sliding table and swaying control method

InactiveCN106652648AReduce the effects of inertial forcesSimple structureCosmonautic condition simulationsSimulatorsHydraulic cylinderEngineering

The invention provides a swaying platform under the control of a cross-shaped sliding table. The swaying platform under the control of the cross-shaped sliding table mainly comprises a training platform, cross-shaped sliding rails, sliding blocks, a bottom board, longitudinal hydraulic cylinders, support rods and horizontal hydraulic cylinders. Compared with the scheme of the traditional swaying platform, the scheme provided by the invention has the advantage that the integral height of the swaying platform provided by the invention is greatly reduced, and thus the influences of the inertia force when the swaying platform sways are reduced; compared with other schemes, the scheme provided by the invention has the advantage that the swaying platform can truly simulate various swaying postures; compared with the similar swaying platforms, the swaying platform provided by the invention has the advantages that the weight of the swaying platform under the control of the cross-shaped sliding table is reduced, meanwhile, the weight of the training platform is born by the support rods but not the hydraulic cylinders, thus most of the work of the hydraulic cylinders is used for realizing the swaying of the swaying platform, and therefore, the burden of a hydraulic device is alleviated.

Owner:SHENYANG POLYTECHNIC UNIV

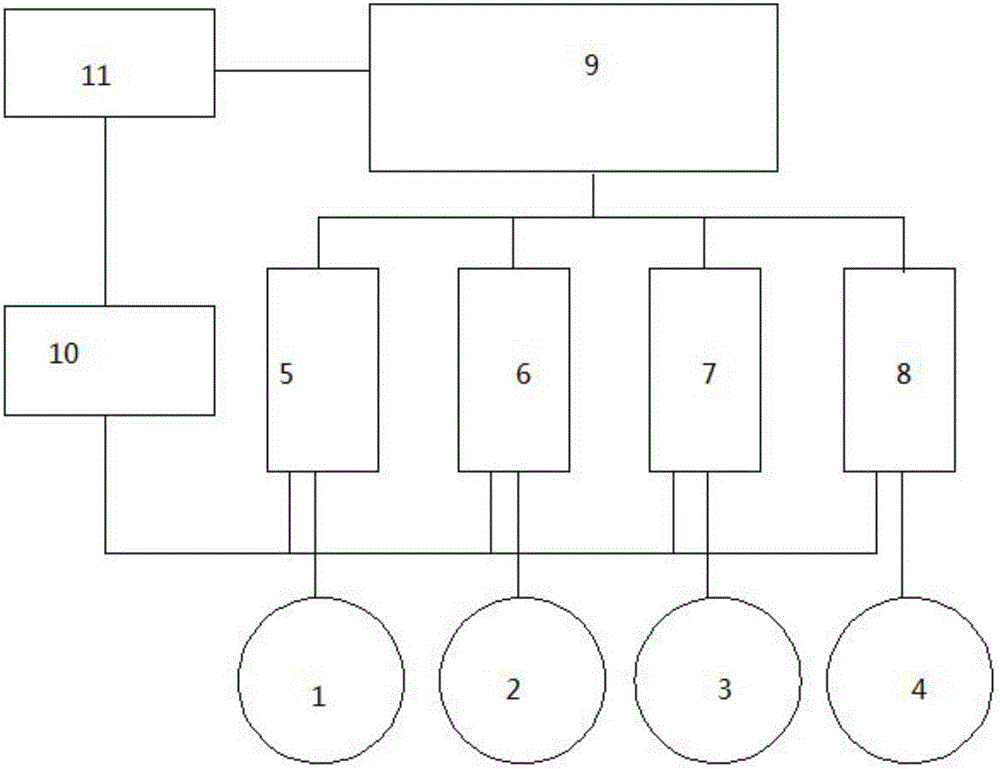

Built-in crane anti-sway control system

InactiveCN106586833AEliminate load swayEliminate running speedLoad-engaging elementsOperating instructionElectric machine

The invention provides a built-in crane anti-sway control system. The system comprises a crane, the crane is formed by a main lifting motor, an auxiliary lifting motor, a cargo motor and a trolley motor, the main lifting motor is provided with a main lifting frequency converter, the auxiliary lifting motor is provided with an auxiliary lifting frequency converter, the cargo motor is provided with a cargo frequency converter, and the trolley motor is provided with a trolley frequency converter; the main lifting frequency converter, the auxiliary lifting frequency converter, the cargo frequency converter and the trolley frequency converter communicate with and are connected to a built-in sway controller through a CAN bus; the main lifting frequency converter, the auxiliary lifting frequency converter, the cargo frequency converter and the trolley frequency converter are respectively connected to an electric appliance controller through wires, and the electric appliance controller is connected to an operating platform; and the operating platform transmits a signal to the built-in sway controller. The anti-sway control system calculates the running speeds of the cargo and the trolley of the sway eliminated crane through the built-in anti-swing controller according to an operating instruction and the real-time running condition of the crane in order to accurately eliminate the load sway phenomenon of the crane.

Owner:合肥市春华起重机械有限公司

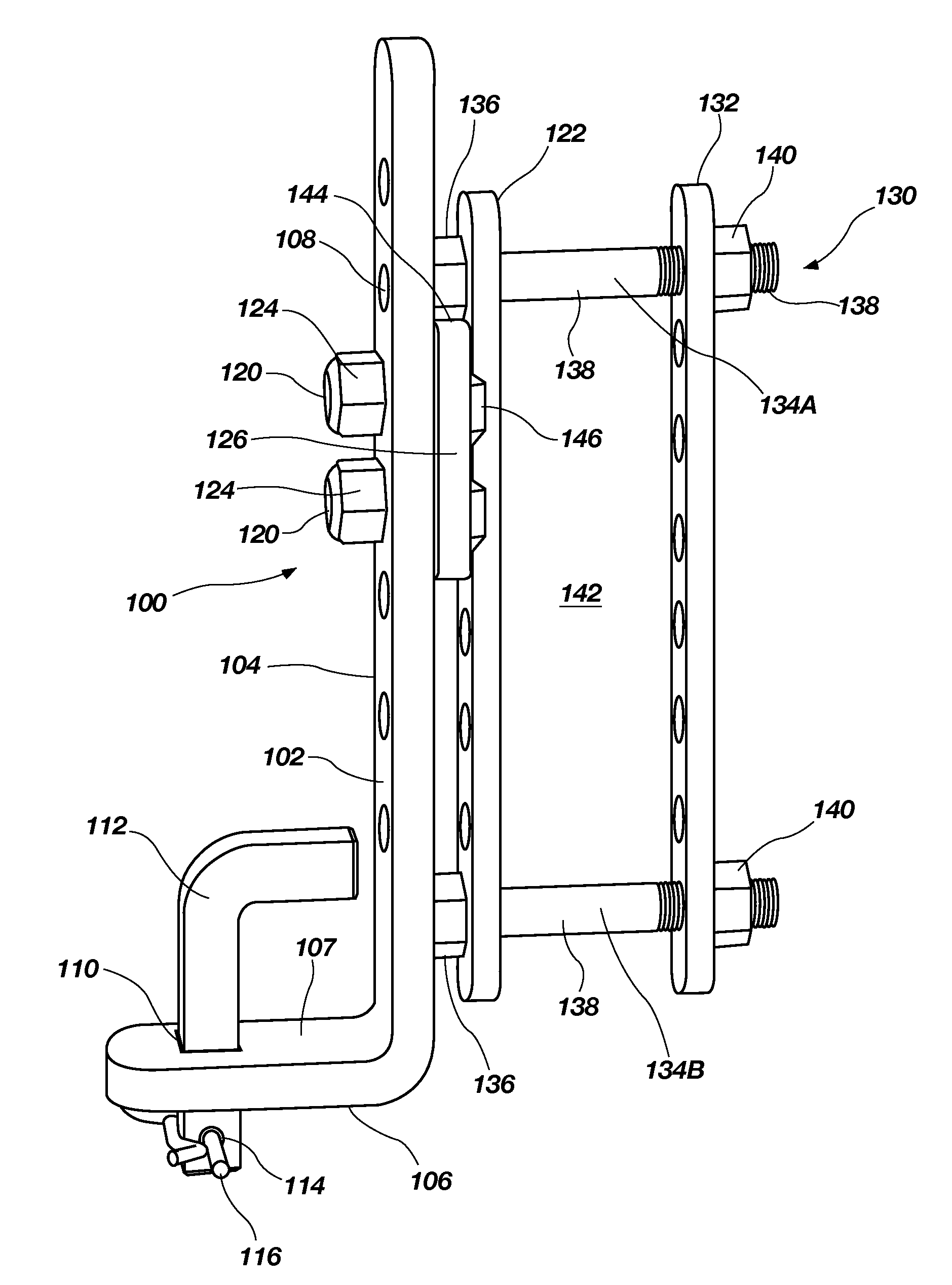

Weight distributing and sway control hitch

A weight distributing hitch for towing a trailer includes a pair of deflection bars extending rearward from a ball mount head. A distal end of each deflection bar is supported by a deflection bar support connected to the frame by a height adjustable bracket assembly. A first resistance feature on the deflection bar support engages a second resistance feature associated with the deflection bar to restrain the deflection bar from sliding relative to the deflection bar support and thereby preventing swaying of the trailer relative to the towing vehicle. A longitudinal position of the second resistance feature relative to the deflection bar or a longitudinal position of the first resistance feature relative to said deflection bar supported by said deflection bar support is adjustable to position the second resistance feature in engagement with the first resistance feature when the deflection bar is supported on the deflection bar support.

Owner:B & W CUSTOM TRUCK BEDS

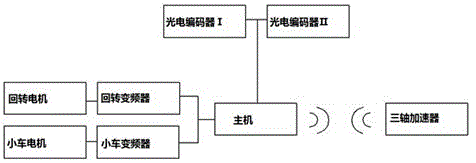

Building tower type crane anti-swing device

A building tower type crane anti-swing device is an indispensable tool for vertical transportation. Due to the fact that a lifting tool and a lifting load are likely to swing, the unloading work period is prolonged, even unhooking happens and serious accidents are caused. The building tower type crane anti-swing device comprises a main machine, a three-axis accelerometer, a photoelectric encoder I, a photoelectric encoder II, a rotary frequency converter, a trolley frequency converter, a rotary motor, a trolley motor, a rotary mechanism and a wireless communication device. The building tower type crane anti-swing device is characterized in that the main machine is connected with the photoelectric encoder I and the photoelectric encoder II; the photoelectric encoder I is connected with the rotary frequency converter; the photoelectric encoder II is connected with the trolley frequency converter; and the rotary frequency converter is connected with the rotary motor, and the trolley frequency converter is connected with the trolley motor.

Owner:HARBIN UNIV OF SCI & TECH

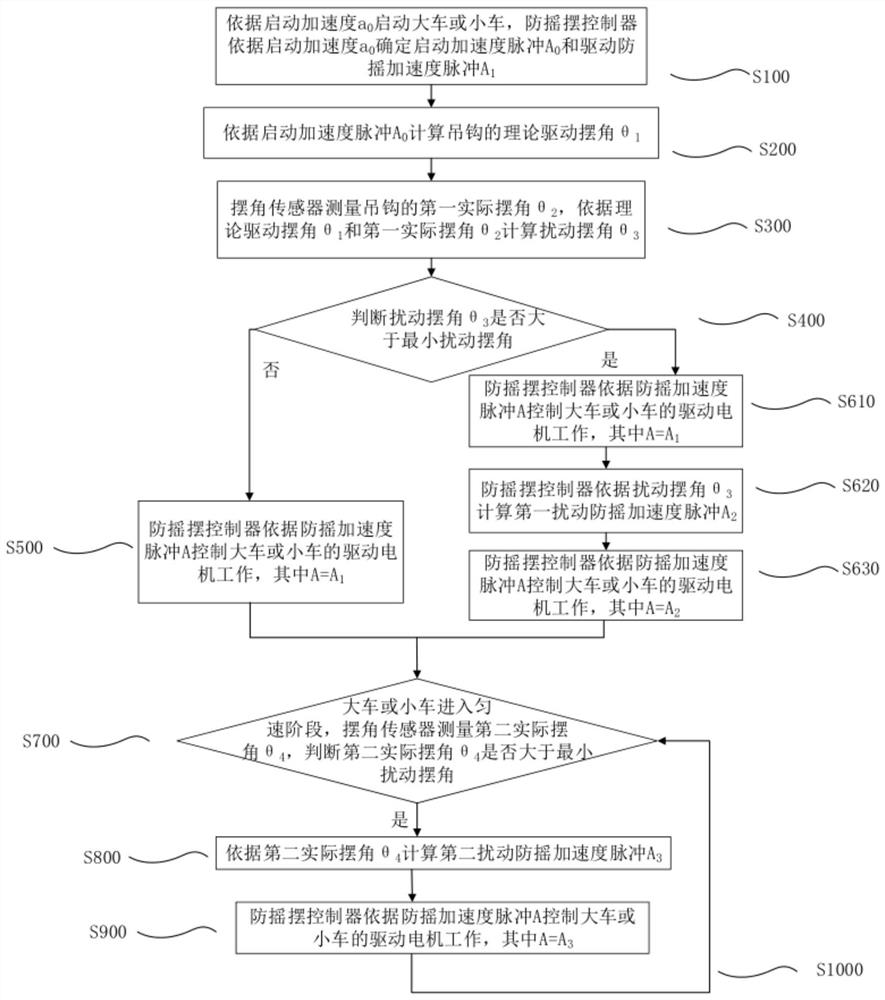

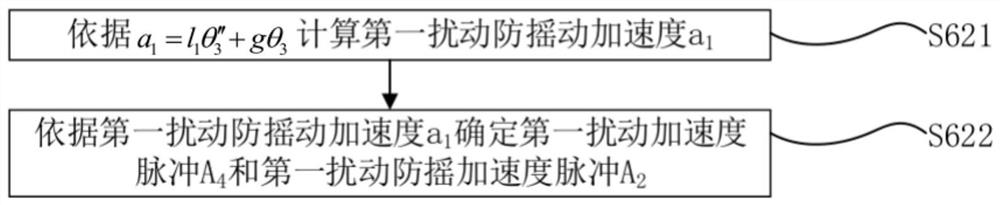

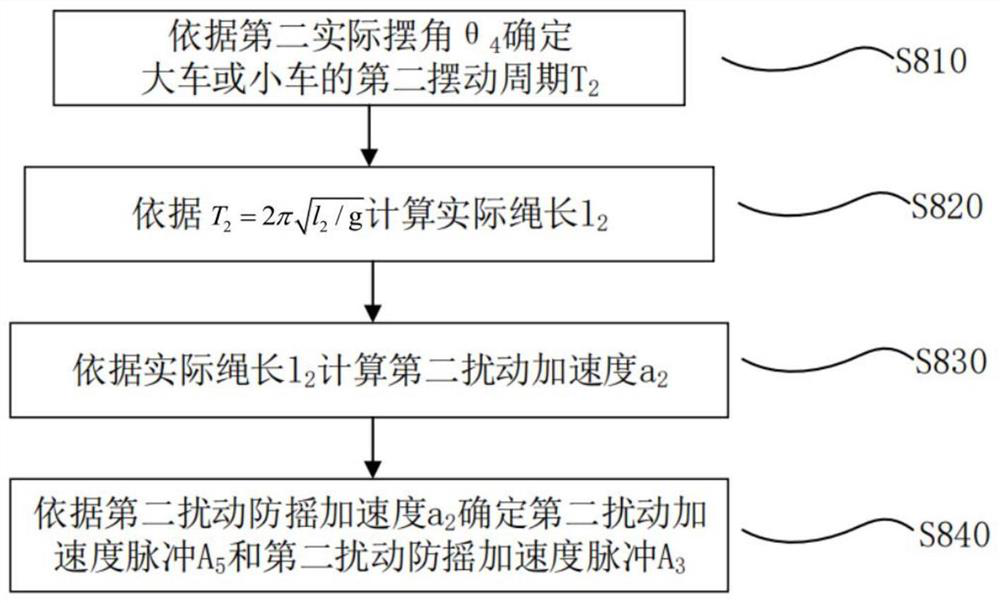

Anti-swing control method and travelling crane

ActiveCN113200451AStable jobWobble Phenomenon ReducedTravelling cranesLoad-engaging elementsLoop controlEngineering

The invention provides an anti-swing control method and a travelling crane. The anti-swing control method comprises the steps that a cart or a trolley is started, and a starting acceleration pulse A0 and a driving anti-swing acceleration pulse A1 are determined; a theoretical driving swing angle theta1 is calculated; a first actual swing angle theta2 is measured, a disturbance swing angle theta3 is calculated and whether the disturbance swing angle theta3 is larger than the minimum disturbance swing angle or not is judged, and if not, the cart or the trolley is controlled to work according to the driving anti-swing acceleration pulse A1; if yes, the cart or the trolley is controlled to work according to the driving anti-swing acceleration pulse A1, a first disturbance anti-swing acceleration pulse A2 is calculated, and then the cart or the trolley is controlled to work according to the first disturbance anti-swing acceleration pulse A2; in the constant speed stage, a second actual swing angle theta3 is measured and whether the second actual swing angle theta3 is larger than the minimum disturbance swing angle or not is judged, if yes, a second disturbance anti-swing acceleration pulse A3 is calculated, and the cart or the trolley is controlled to work according to the second disturbance anti-swing acceleration pulse A3; and the steps of the constant speed stage are repeated. According to the anti-swing control method, swing closed-loop control of a lifting hook can be achieved, the control precision is high, and the working efficiency of the travelling crane is high.

Owner:EUROCRANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com