Anti-swinging control system of crane weight and control method of system

A control system and crane technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of reduced production efficiency, reduced operating efficiency, failures, etc., and achieve the effects of stable and reliable operation, convenient debugging, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

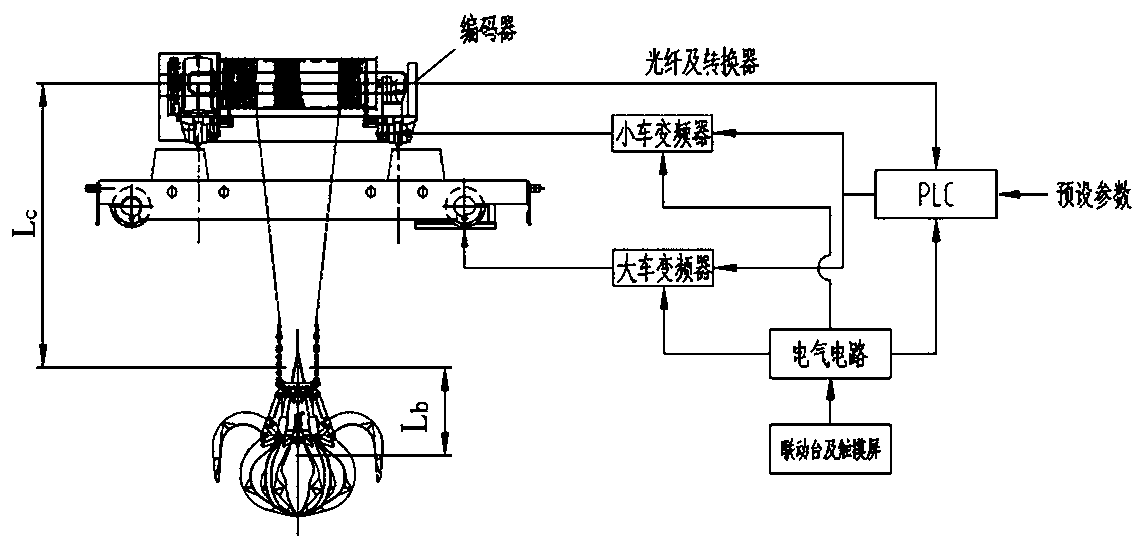

[0033] Example: such as figure 1 Shown is a schematic diagram of the implementation of the crane anti-sway control system and its control method of the present invention, which can be applied to indoor bridge cranes, gantry cranes, semi-gantry cranes and other cranes that do not have additional speed caused by wind.

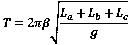

[0034]The crane in this embodiment includes an absolute encoder installed on the hoisting low-speed shaft, a communication module, a communication optical fiber, a programmable logic controller (PLC) installed in the control cabinet, a frequency converter for a cart, a frequency converter for a trolley, etc., and The inverter of the trolley drives the corresponding frequency conversion motor to move the heavy object suspended on the wire rope horizontally (X direction), and the trolley inverter drives the corresponding frequency conversion motor to make the weight suspended on the wire rope move horizontally (Y direction). Towards). The anti-sway control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com