Isostatic suspension cylinder

An isostatic pressure, cylinder technology, applied in the direction of fluid pressure actuation devices, etc., can solve the problems of friction, energy consumption and wear, piston rod shaking or swaying, cylinder inner wall tolerance and shape and position tolerance deformation, material elastic erosion, etc. Achieve the effect of avoiding uncertain factors and interference factors, high accuracy and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

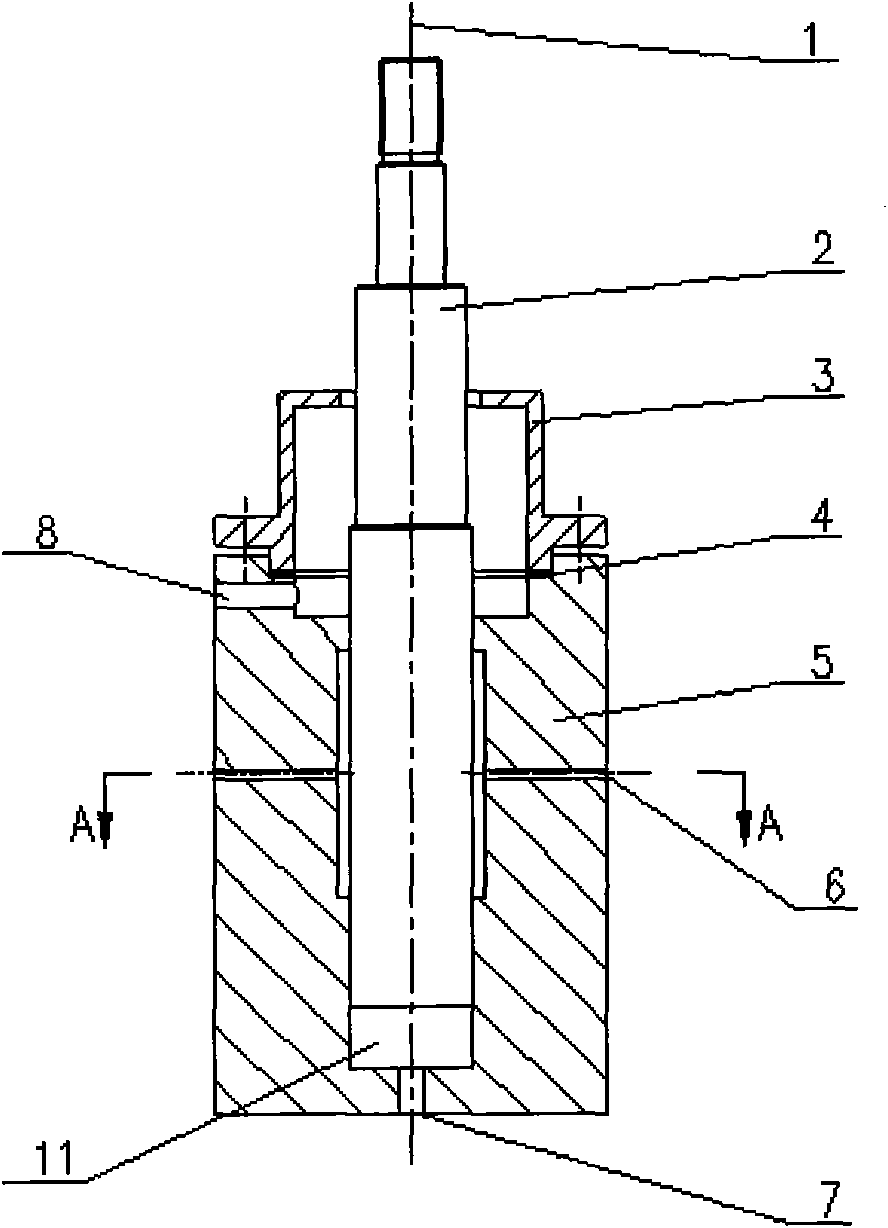

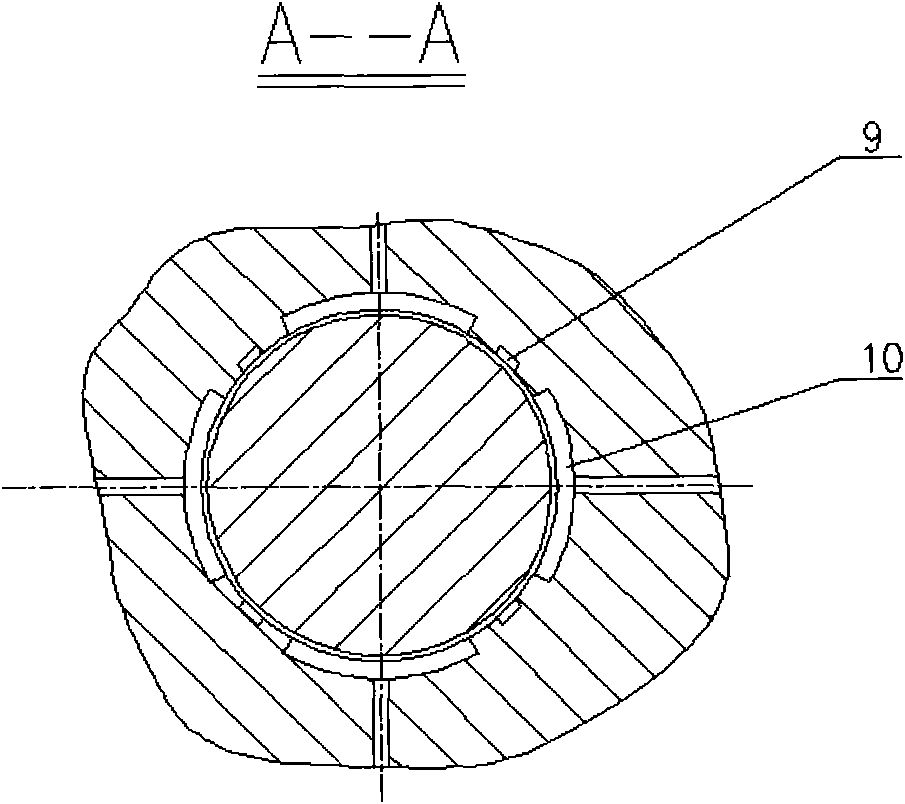

[0013] Such as Figure 1-2 As shown, the hydrostatic suspension cylinder in the present invention includes a cylinder body 5 , a plunger 2 and a sealing cover 3 .

[0014] The middle and upper area of the inner wall of the cylinder body 5 is radially provided with four isostatic pressure oil chambers 10 with the same area and symmetrically distributed and a small hole throttling oil inlet 6, and the small hole throttling oil inlet 6 is arranged along the The radial direction of the cylinder is arranged and communicated with the isostatic oil chamber 10; the plunger 2 is placed in the cylinder 5, one end of which extends out of the cylinder 5, and the other end is connected to the cylinder 5. A hydraulic working chamber 11 for making the plunger 2 reciprocate up and down is formed between the cylinder blocks 5 , and a hydraulic oil inlet 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com