Elastic swing roller mechanism for sliding door

A technology of roller mechanism and sliding door, which is applied in the direction of switches with braking devices, door/window accessories, building structures, etc. It can solve the problems of inability to interact, unable to meet user needs, and sliding doors that cannot be opened and closed directly. problems, to achieve the effect of convenient operation, simple and reasonable structure, and small opening and closing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

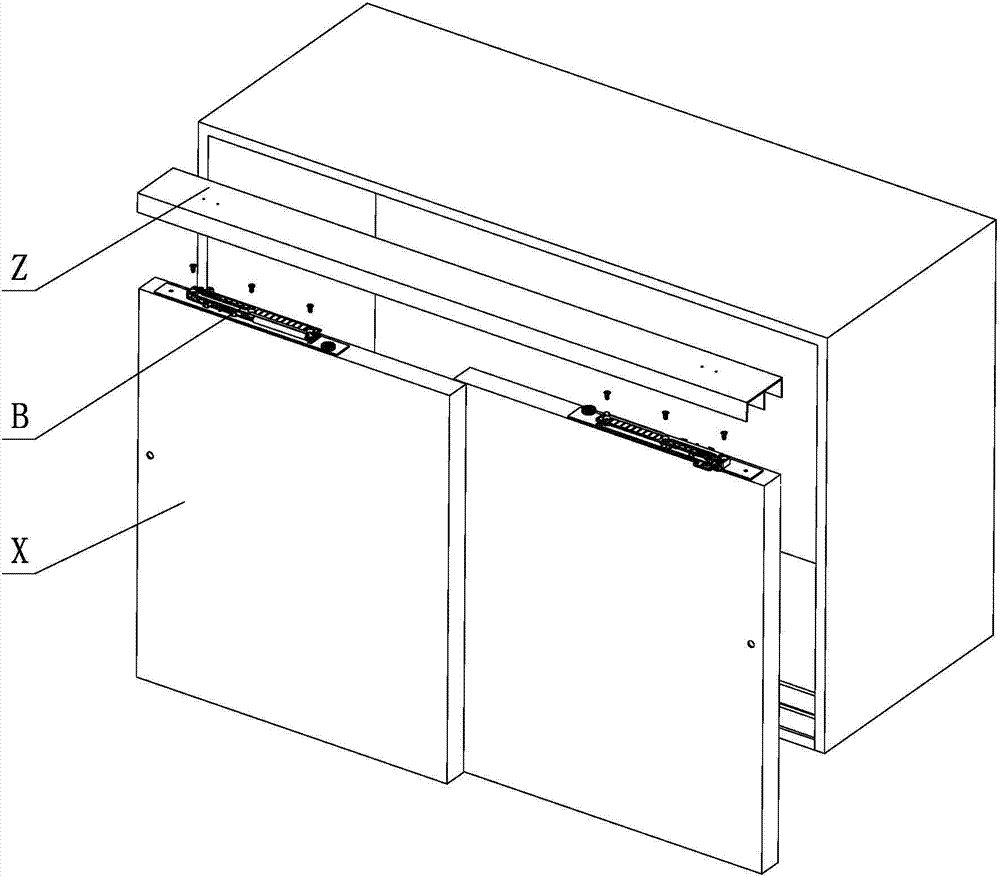

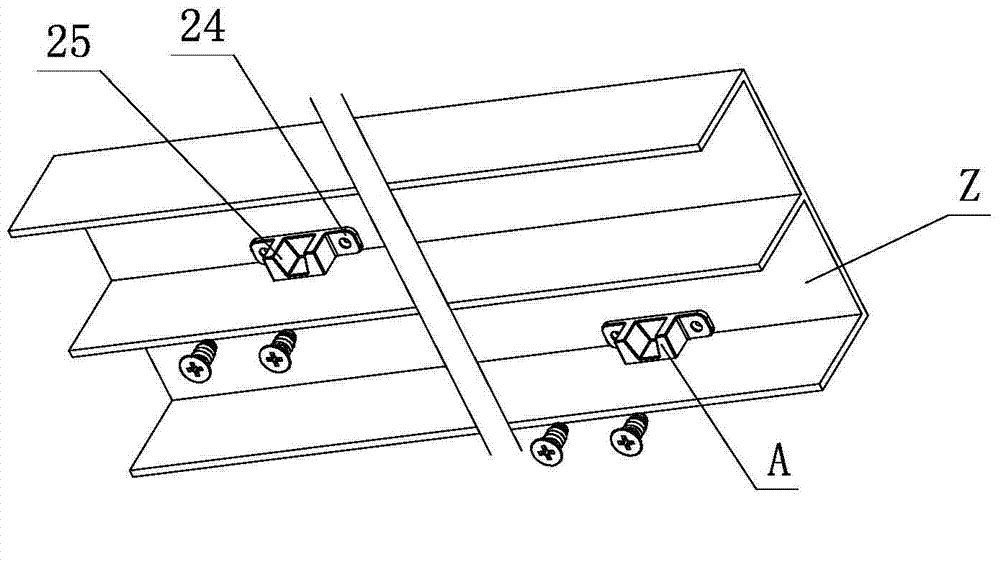

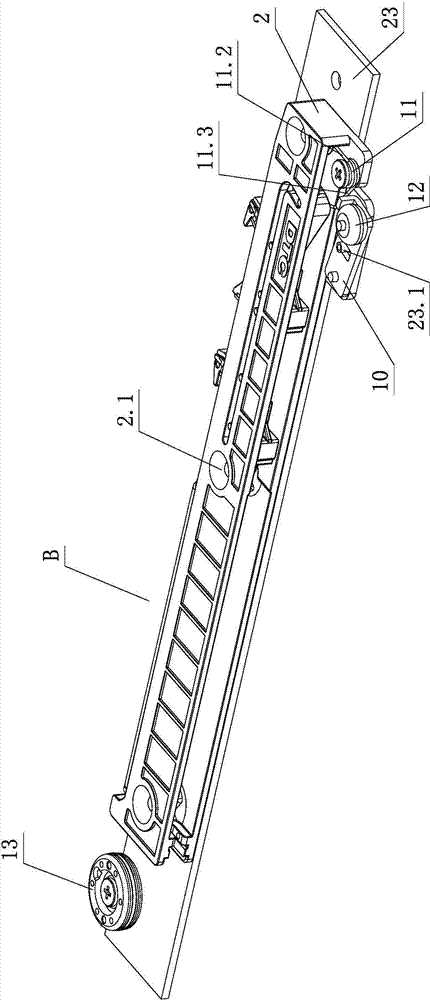

[0021] see Figure 1-Figure 5 , the elastic swing roller mechanism used for sliding doors, including fixed parts, movable parts and interacting toggle device A, reverse push and / or damping device B, the movable part is at least sliding door X, the fixed part At least the chute piece Z or the cabinet body; the toggle device A is set on the chute piece Z or the cabinet body, the reverse thrust and / or damping device B is set on the sliding door X, or the toggle device A is set on the On the sliding door X, the reverse thrust and / or damping device B is arranged on the chute member Z or the cabinet body; the reverse thrust and / or damping device B is provided with a fixed seat 23, and the fixed seat 23 is provided with a bracket 2 And the adapter 10 for positioning and swinging, wherein, the support 2 is provided with an elastic member 11, and the adapter 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com