Pit pump long-distance-suspended pump pipe swinging concreting construction technology for high-rise buildings

A technology for pouring concrete and high-rise buildings. It is used in construction, building structure, and building material processing. It can solve problems affecting construction safety and formwork installation quality, limitations on the height and amplitude of automobile pumping, and weakening of steel bars and concrete. It can improve the overhead span, ensure construction quality and safety, and ensure the effect of structural quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

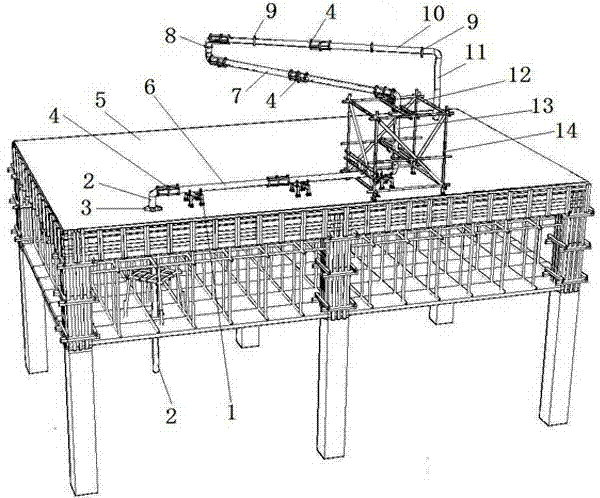

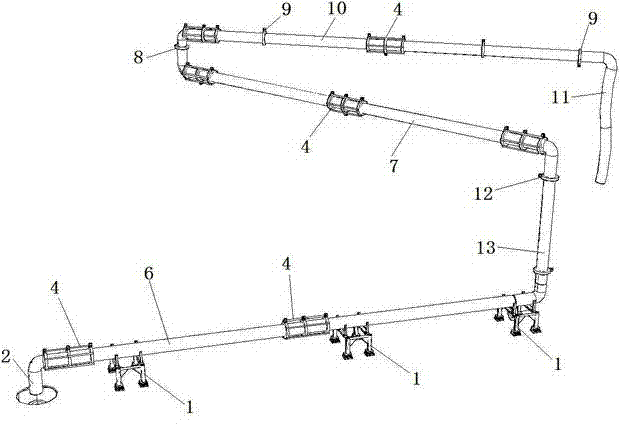

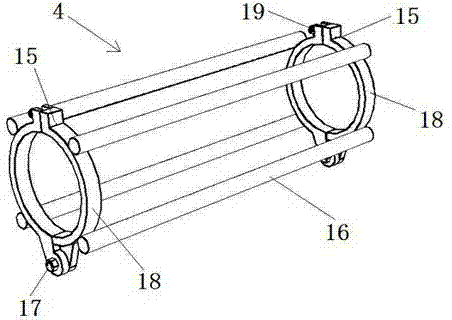

[0023] Such as figure 1 , figure 2 As shown, the pump pipe of the high-rise building of the present invention is suspended at a long distance and the construction technology of swinging concrete is poured, and the technology includes the following construction steps:

[0024] (1) Install the pump pipe 2 through the floor panel: when the floor formwork 5 is installed, reserve the reserved port 3 for the pump pipe 2 through the floor panel according to the position of the pump tube 2 through the floor panel in the pump tube layout diagram, and the pump tube through the floor panel 2. Use the reserved ground anchors to fix in four directions. The height of the protruding floor is generally 150mm plus the thickness of the plate, which is convenient for the installation of the horizontal pump pipe 6. The reserved opening 3 of the floor template 5 extends to the upper side of the floor template 5 to be poured.

[0025] (2) Install the horizontal pump pipe 6 on the upper side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com