Method for preparing modified loess with high adsorption performance

A high-adsorption, loess technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of non-economic long-term, secondary environmental pollution, and economical problems , to achieve the effect of low cost, large adsorption capacity and clear wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

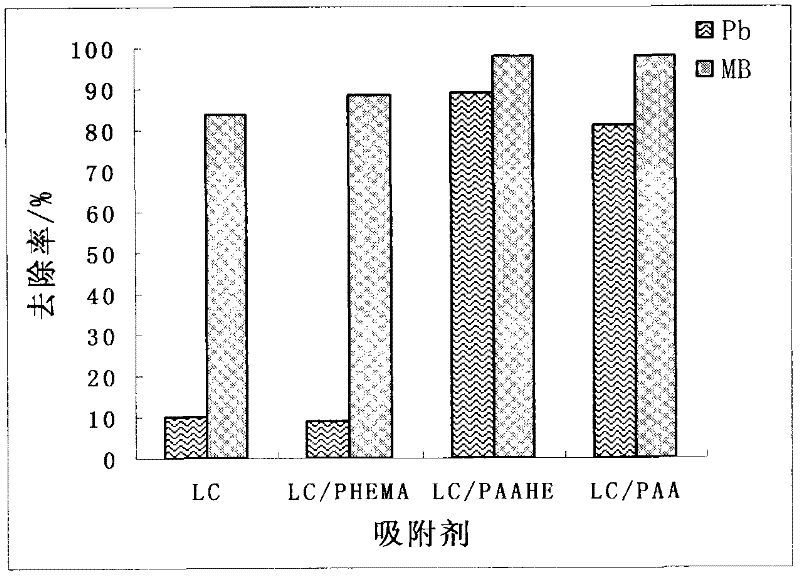

Embodiment 1

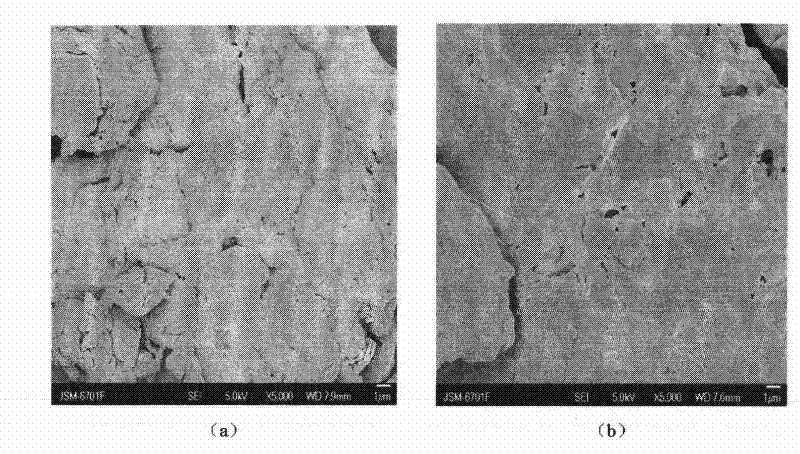

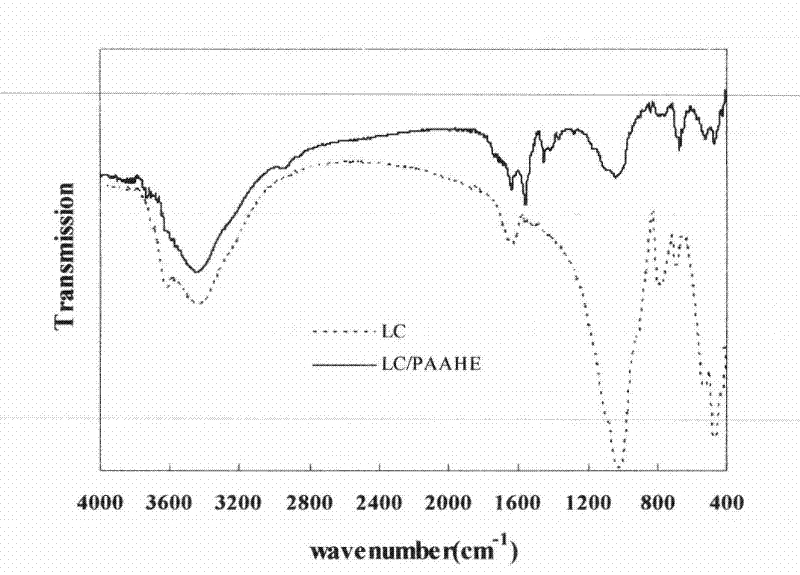

[0025] Embodiment 1 A kind of preparation method of the modified loess with high adsorption performance, comprises the following steps:

[0026] (1) Add 5 g of loess into a three-necked flask equipped with a stirring bar, a reflux condenser, and a gas conduit, add 10 mL of distilled water, and 0 g of acrylic acid and stir evenly at room temperature.

[0027] (2) Then add 8 g of hydroxyethyl methacrylate to the above solution and stir for 30 minutes to obtain a mixed solution after uniformity.

[0028] (3) Add 3g of cross-linking agent glycidyl methacrylate to the mixed liquid, vacuumize, pass inert gas and heat to 40°C, finally add 1g of initiator ammonium persulfate, heat up to 50°C and stir for 20min, that is, To form a complex, the complex is first washed with distilled water, and then dried at 50-100° C. to a constant weight to obtain a loess-based polymer composite adsorbent (LC / PHEMA).

Embodiment 2

[0029] Embodiment 2 A kind of preparation method of the modified loess with high adsorption performance, comprises the following steps:

[0030] (1) Add 4g of loess to a three-necked flask equipped with a stirring rod, a reflux condenser, and a gas conduit, add 20mL of distilled water and 8g of acrylic acid and stir for 50min at room temperature, and then dropwise add the NaOH solution with a neutralization degree of 40%. and, to obtain a neutralized solution.

[0031] (2) Add 0 g of hydroxyethyl methacrylate.

[0032] (3) Add 1g of crosslinking agent glycidyl methacrylate to the neutralization solution, vacuumize, pass inert gas and heat to 60°C, finally add 0.5g of initiator ammonium persulfate, heat up to 70°C and stir for 30min, That is, a complex is formed. The complex is first washed with distilled water, then dried at 50-100°C to constant weight, and ground through a 100-mesh sieve to obtain the loess-based polymer composite adsorbent (LC / PAA).

Embodiment 3

[0033] Embodiment 3 A kind of preparation method of the modified loess with high adsorption performance, comprises the following steps:

[0034] (1) Add 10g of loess to a three-necked flask equipped with a stirring rod, a reflux condenser, and a gas conduit, add 40mL of distilled water and 5g of acrylic acid and stir for 40min at room temperature, and then dropwise add the NaOH solution with a neutralization degree of 60%. and, to obtain a neutralized solution.

[0035] (2) Then add 0.5 g of hydroxyethyl methacrylate to the neutralization solution and stir for 40 minutes to obtain a mixed solution after uniformity.

[0036](3) Add 2g of cross-linking agent glycidyl methacrylate to the mixed solution, vacuumize, pass inert gas and heat to 50°C, finally add 0.3g of initiator ammonium persulfate, stir for 40min when the temperature rises to 80°C, that is When a complex is formed, the complex is first washed with distilled water, then dried to constant weight at 50-100°C, and gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com