Sway-prevention control method for crane

A control method and crane technology, applied in the directions of load hanging components, transportation and packaging, can solve the problems of unsatisfactory application effect and crane anti-sway control technology not being widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

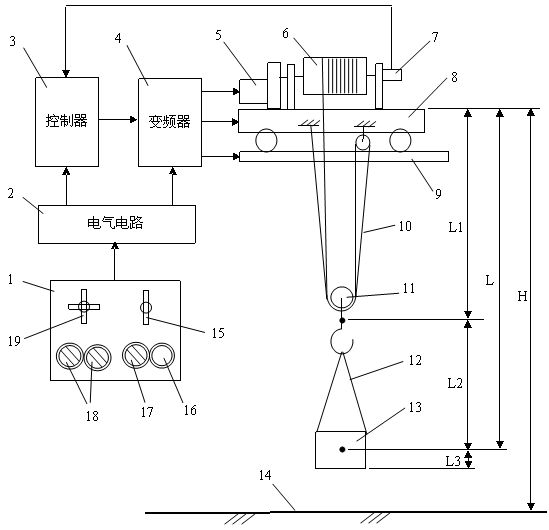

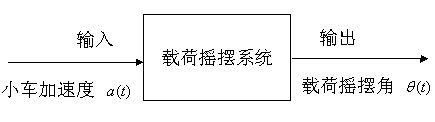

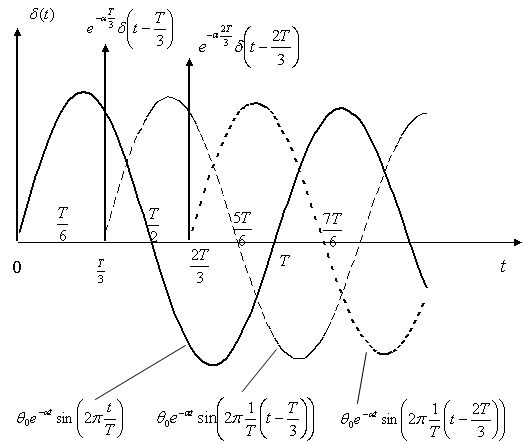

[0021] The crane anti-sway control method is mainly to enable the crane control system to automatically adjust and control the running speed of the trolley in real time, and eliminate the swing of the crane load in the shortest possible time. This control method is suitable for all methods of hanging loads with ropes Lifting equipment to carry loads. figure 1 An example of the crane anti-sway control method applied to a bridge (or gantry) crane is described.

[0022] Such as figure 1 Shown, bridge type (or gantry) crane has cart (bridge frame or portal frame) 9 and trolley 8. The cart 9 carries the dolly 8 and runs on the fixed track, and the dolly 8 runs on the track of the cart 9. The manipulator 1 is an operation console (or remote control device). The manipulator 1 is equipped with a horizontal operation lever 19, a lifting operation lever 15, a "lanyard calibration" button 16, a "empty hook / lanyard A / lanyard B" multi-position selection button 17, and other electrical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com