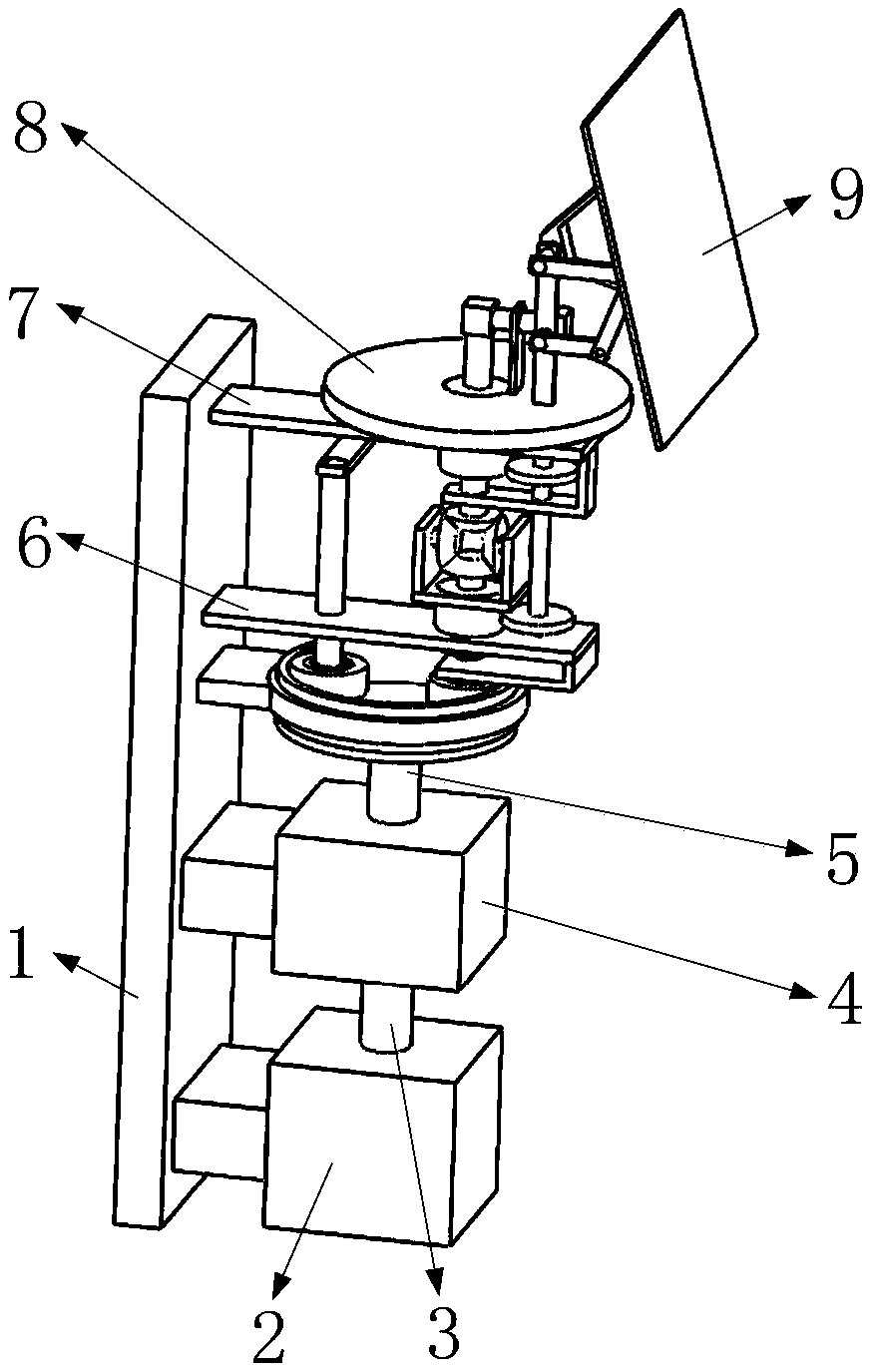

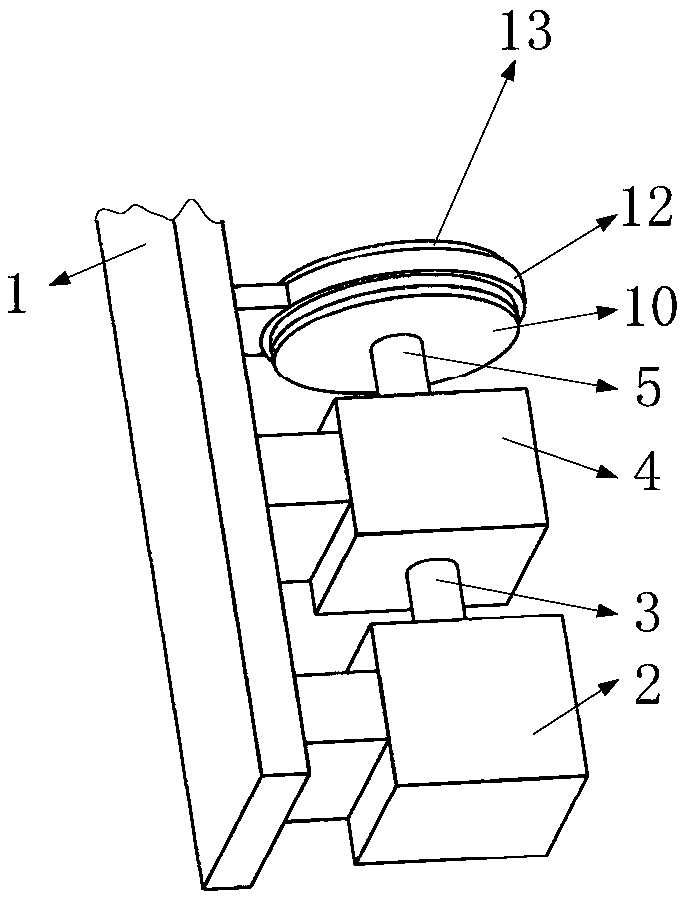

Heliostat used by solar power generating system

A power generation system and heliostat technology, applied in the field of heliostats, can solve problems such as increasing economic costs, and achieve the effects of reducing economic costs and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

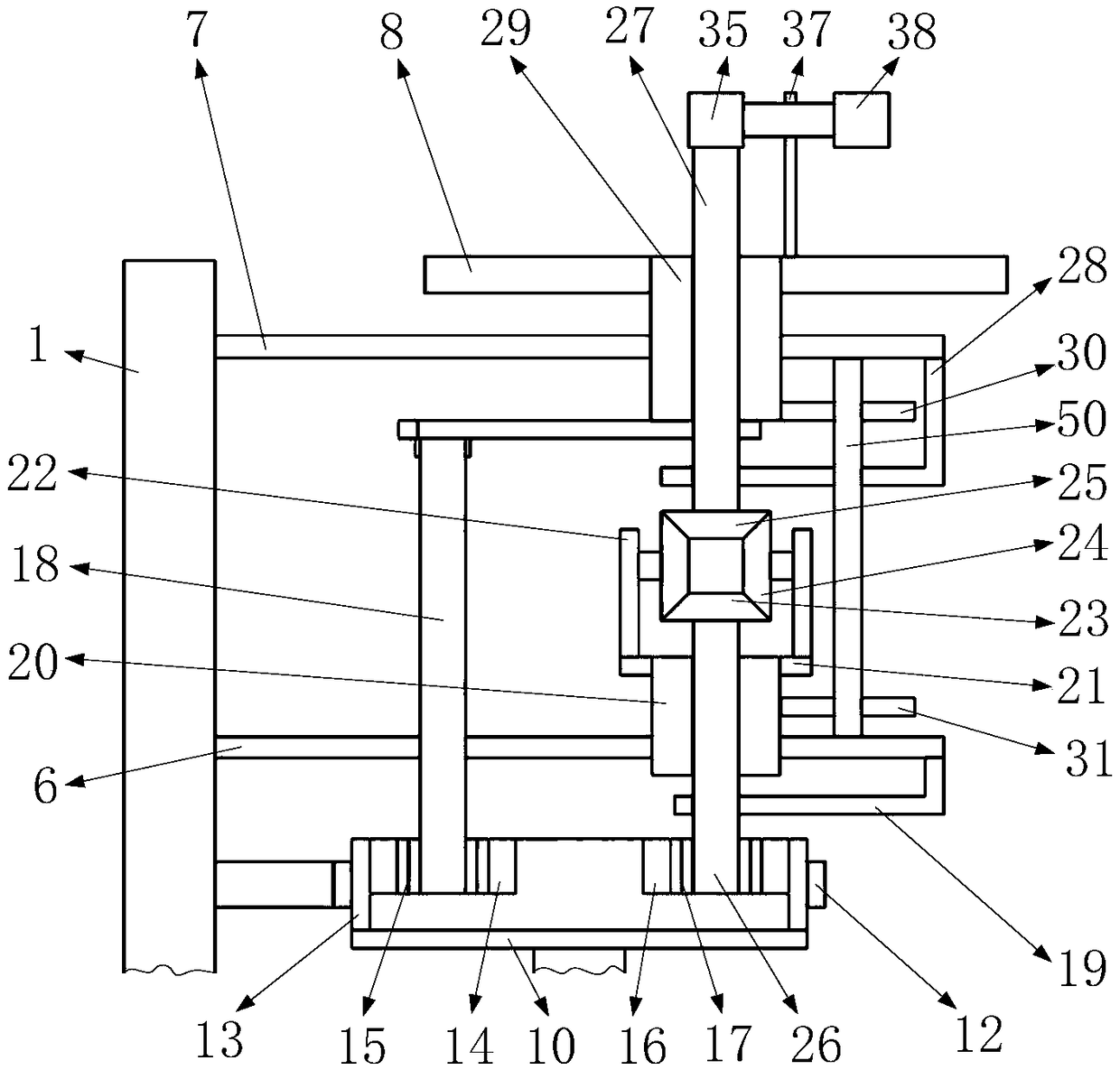

[0055] Specific implementation method: when the chip records through the sensor that the azimuth angle of the heliostat 9 is not suitable for the angle of the sun, the chip controls the motor 2 to make the motor 2 rotate clockwise, and the motor 2 is input through the drive shaft 3, the reducer 4, The shaft 5 drives the disc 10 to rotate clockwise, and the disc 10 drives the ring gear 13 to rotate clockwise; the first drive gear 14 and the second drive gear 16 rotate clockwise, and under the action of the first one-way clutch ring 15, the first The driving gear 14 can drive the first shaft 18 to rotate clockwise through the first one-way clutch ring 15, and under the action of the second one-way clutch ring 17, the second driving gear 16 cannot drive the second one-way clutch ring 17 to drive the second The shaft 26 rotates; the first shaft 18 can drive the second shaft sleeve 29 to reciprocate through the first crank rocker mechanism, and the second shaft sleeve 29 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com