Global sliding-mode control method for bridge crane system

A technology of bridge crane and control method, which is applied in the direction of load hanging components, transportation and packaging, etc., and can solve the problems of not being robust in the whole process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

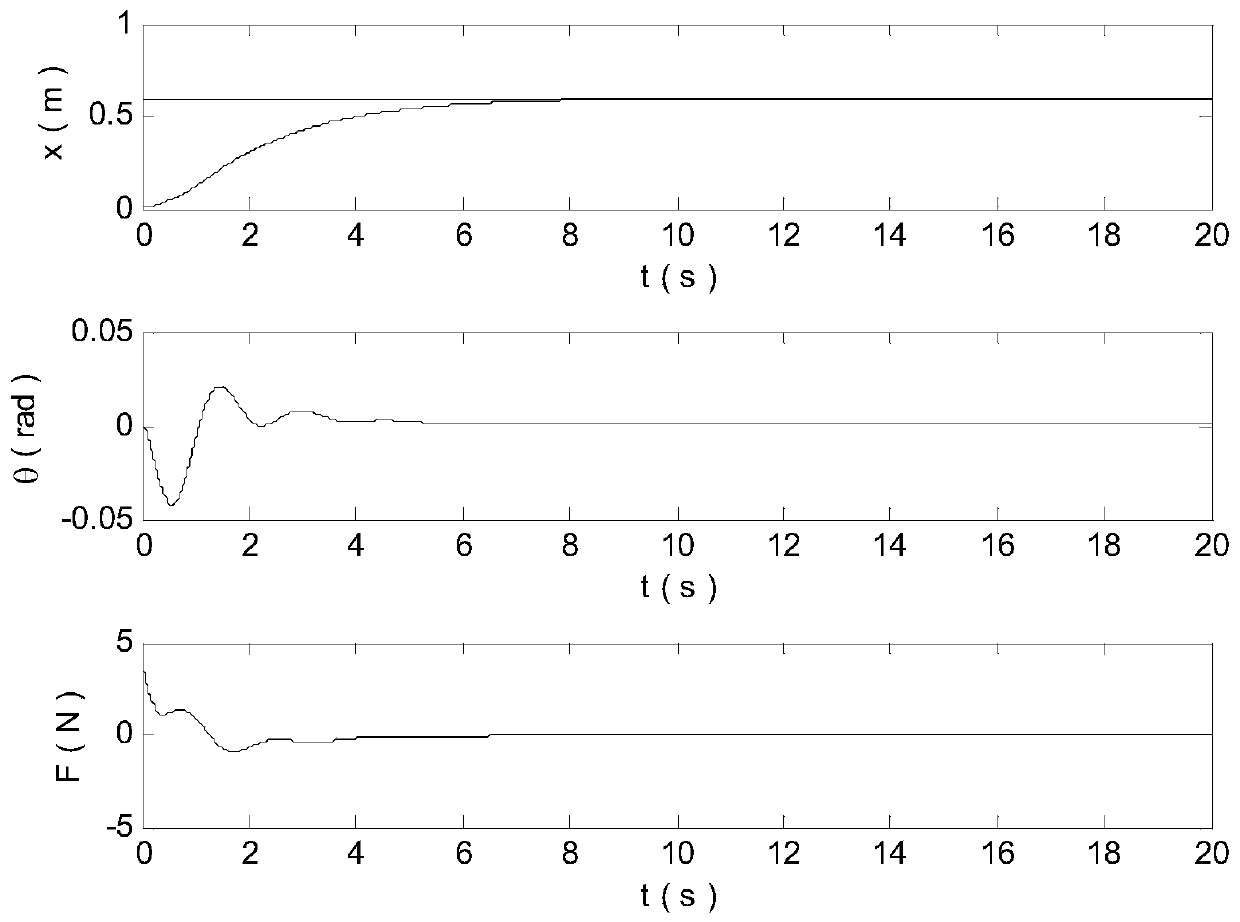

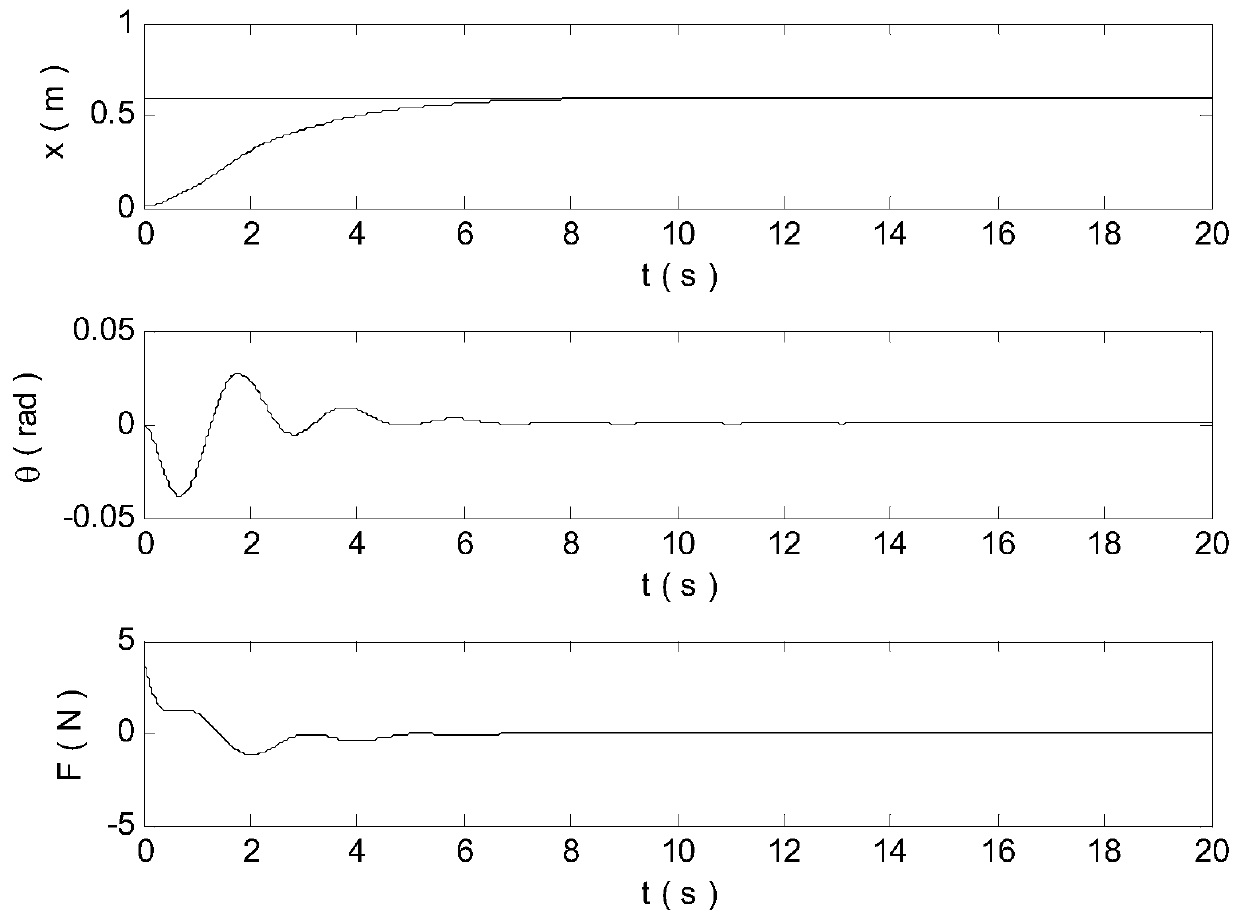

Examples

Embodiment 1

[0117] Embodiment 1, the global sliding mode control method of overhead crane system, comprises the following steps:

[0118] Step 1, determine the kinetic model;

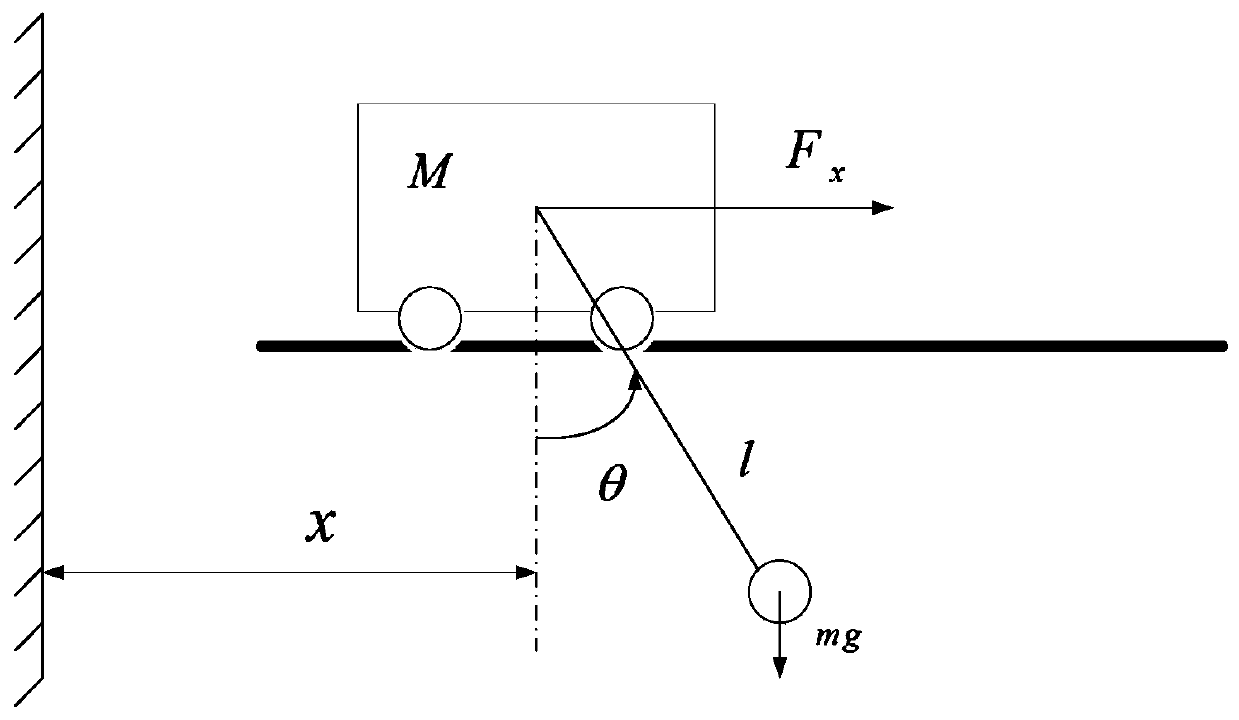

[0119] The present invention contemplates an overhead crane system comprising a trolley capable of one-dimensional translational movement along the bridge frame and a load attached to the trolley by a fixed length of rope. Based on the Euler-Lagrangian equation, the dynamic equation of the overhead crane system is as follows:

[0120]

[0121]

[0122] Among them, M and m are the masses of the trolley and the load respectively, the length of the fixed sling is l, g represents the acceleration of gravity; x represents the horizontal displacement of the trolley from the initial position, represents the speed of the trolley, Indicates the acceleration of the trolley; θ indicates the load swing angle, Indicates the angular velocity of the load swing angle, Indicates the angular acceleration of the load sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com