Lifting appliance anti-swaying device of rotary crane and control method of anti-swaying device

A hoisting equipment, slewing technology, applied in cranes, transportation and packaging, load hoisting components, etc., can solve the problem that PID self-tuning and fuzzy control cannot be realized, and the real-time speed of slewing and pitching cannot be known, and real-time detection and control. Insufficient capacity and other problems, to achieve the effect of strong anti-shake reliability, outstanding stability and efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

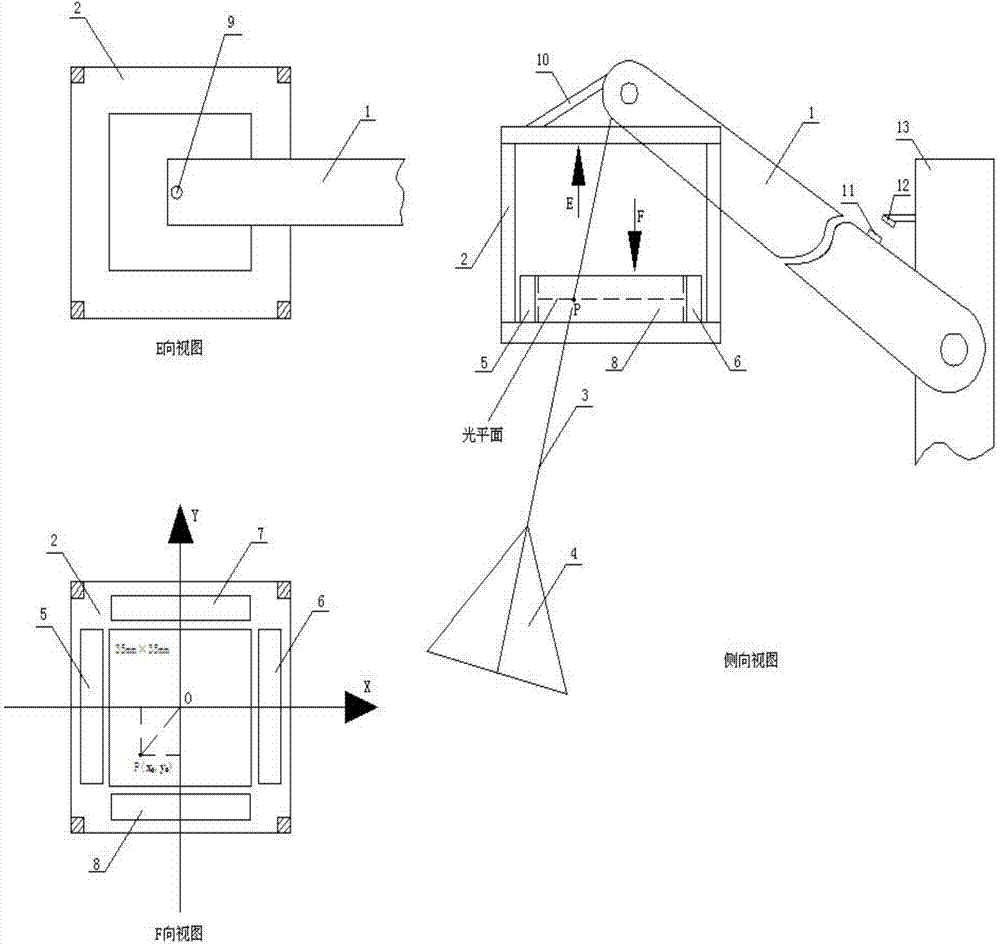

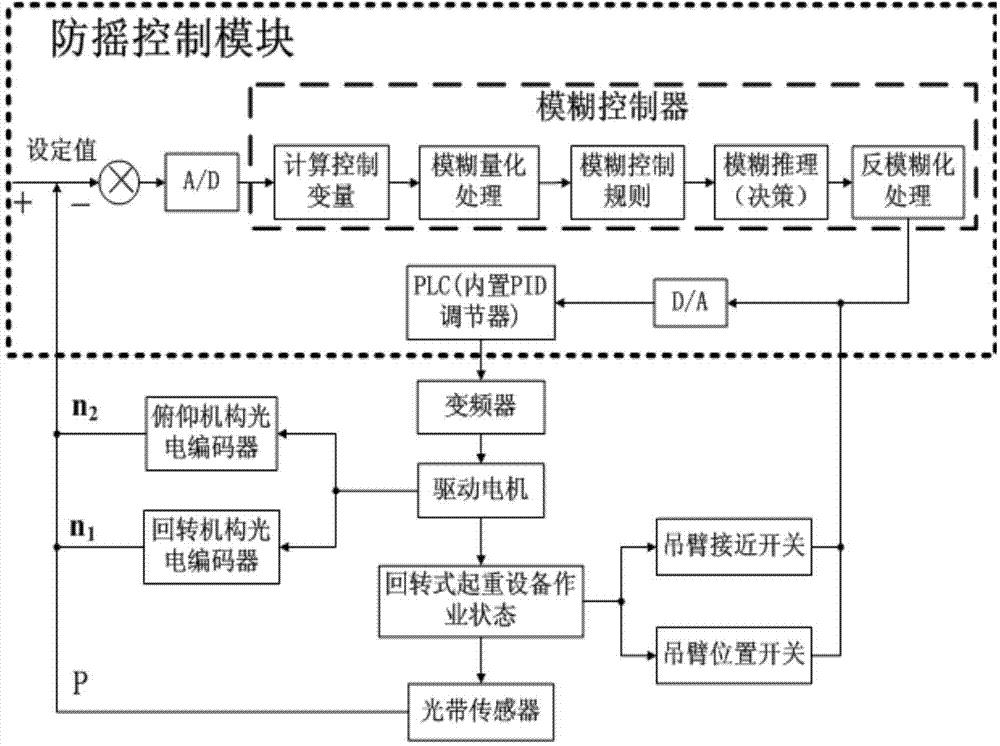

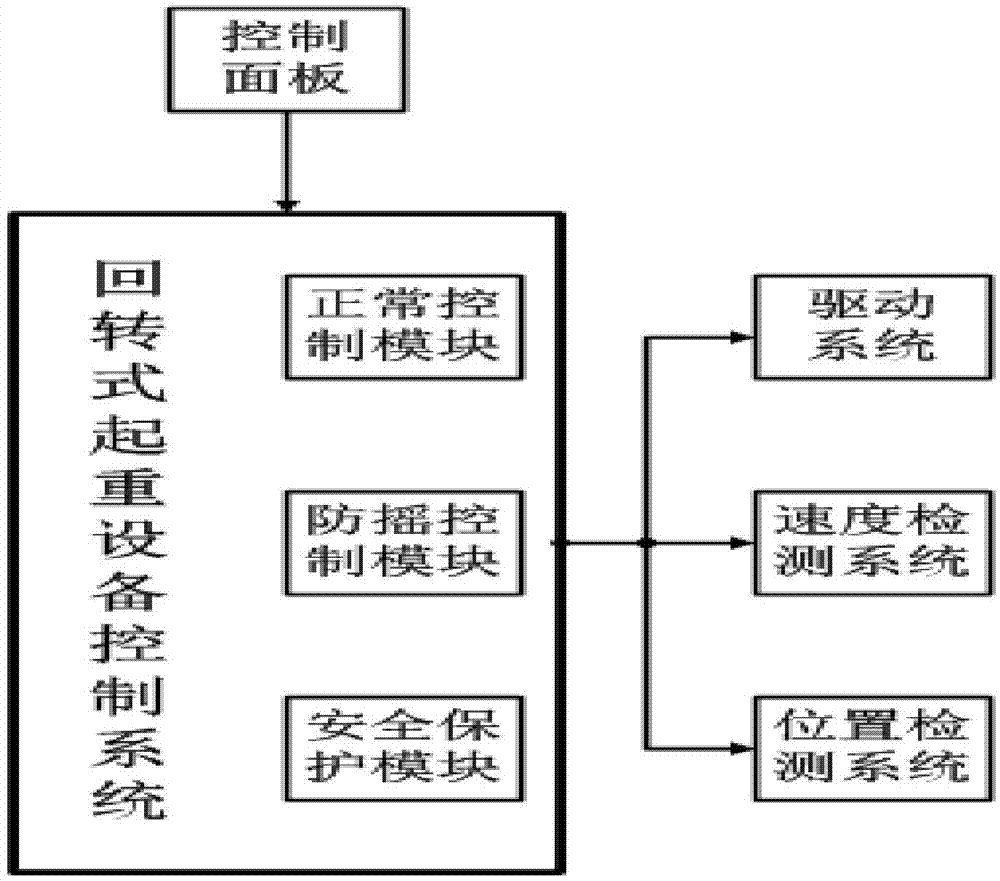

[0038] Such as figure 1 and 2 As shown, the present invention adds an anti-sway control module on the basis of the rotary hoisting equipment control system. In the anti-sway control module, a fuzzy controller and a PLC with a built-in PID regulator are programmed as independent modules and built into the rotary hoisting equipment control system, and a fuzzy self-tuning PID anti-sway control scheme is constructed. The output end of the anti-sway control module is connected with the frequency converter of the driving motor of the slewing mechanism and the pitching mechanism, and the driving motor of the slewing mechanism and the pitching mechanism of the rotary hoisting equipment is directly connected with the frequency converter; the slewing mechanism and The driving mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com