Patents

Literature

315 results about "Pid regulator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

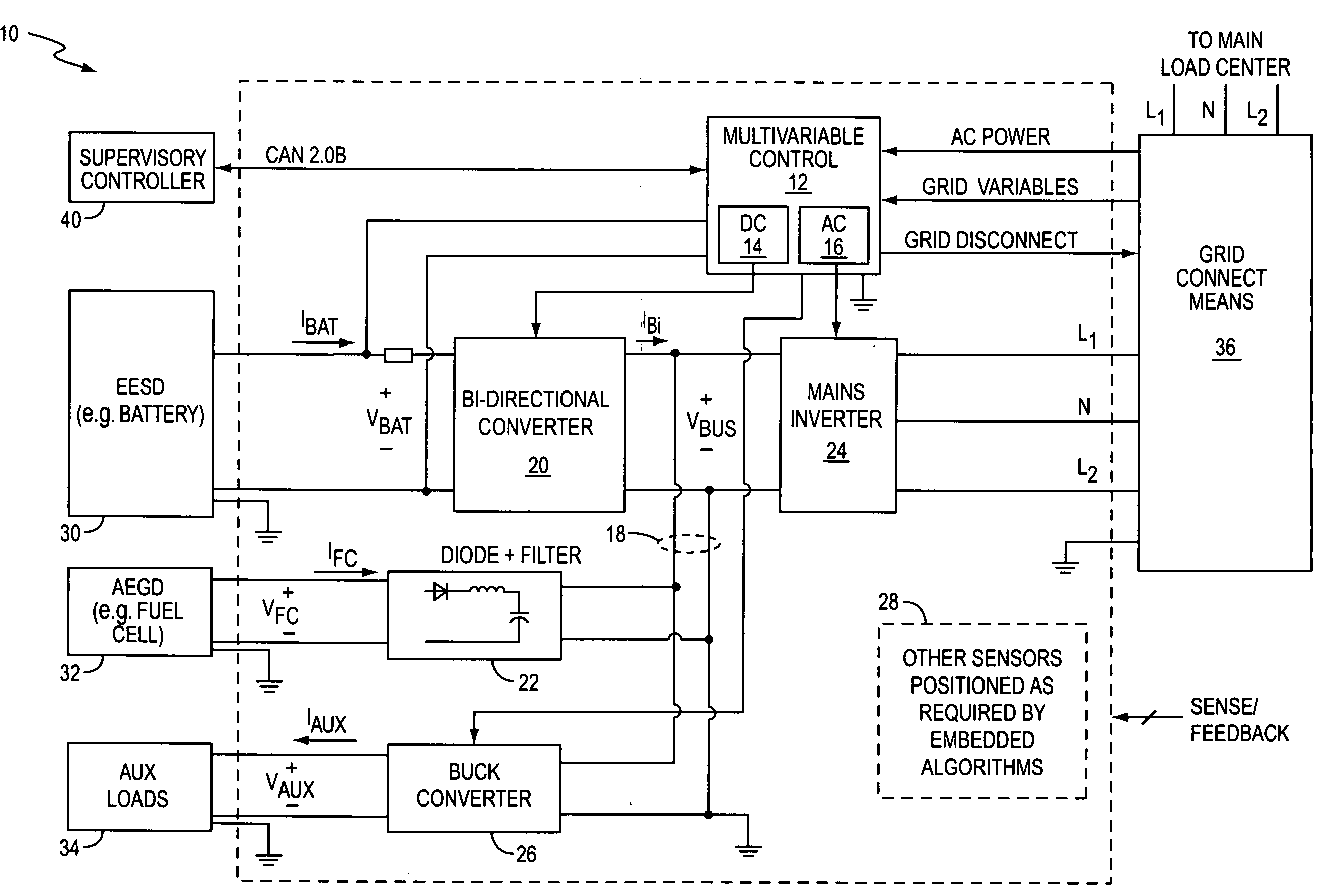

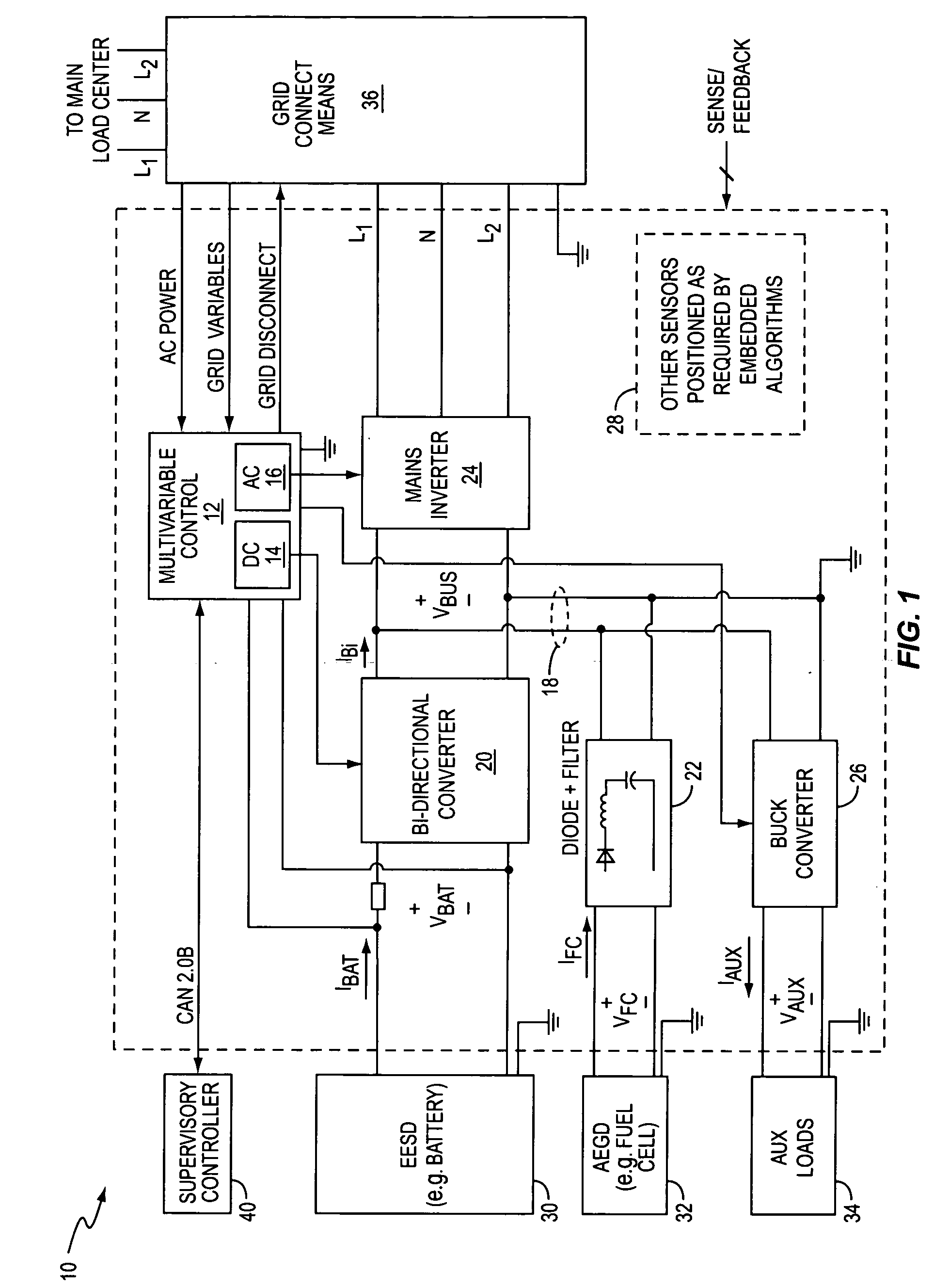

Alternative energy system control method and apparatus

ActiveUS7117044B2Mechanical power/torque controlSampled-variable control systemsPower flowControl power

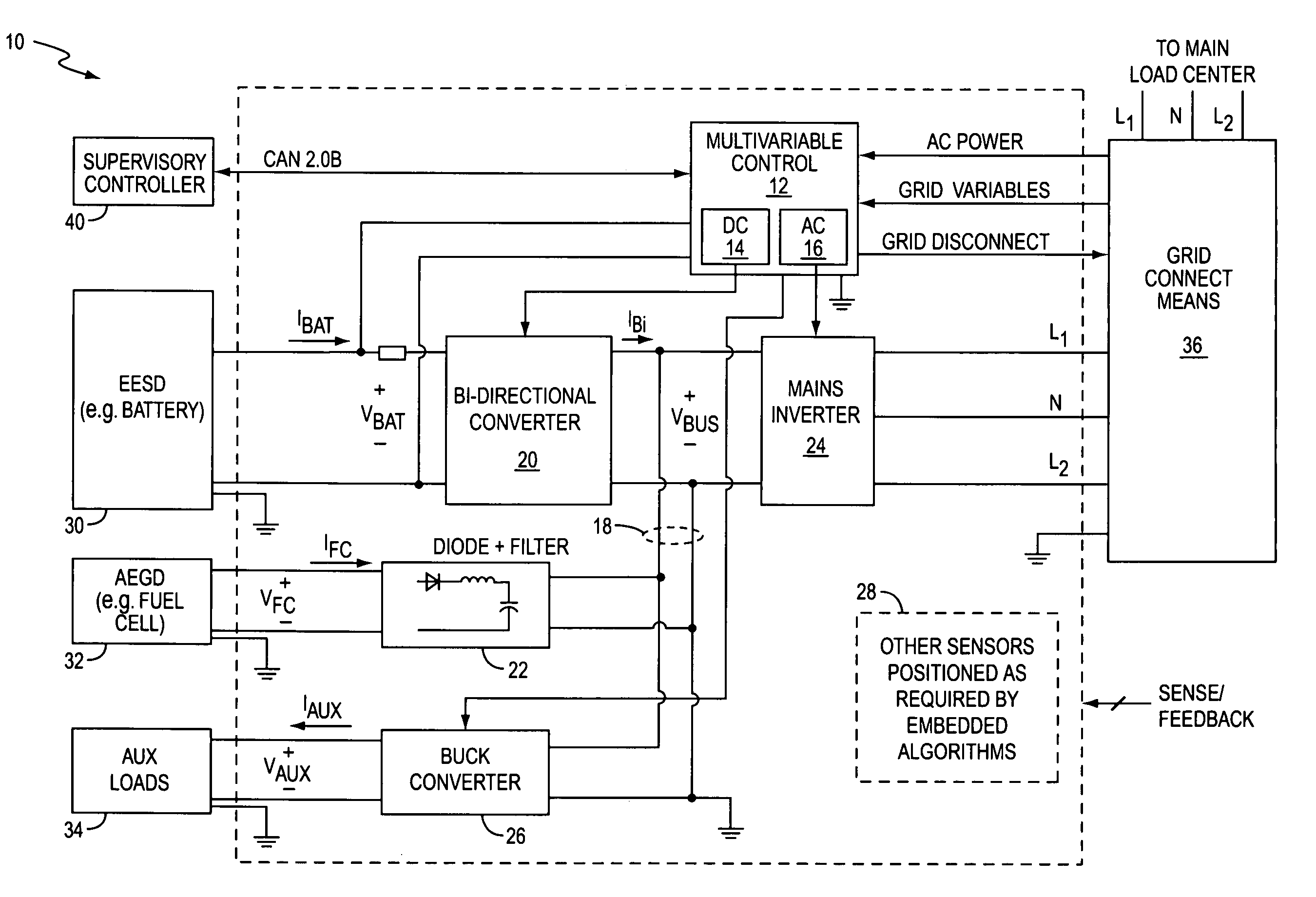

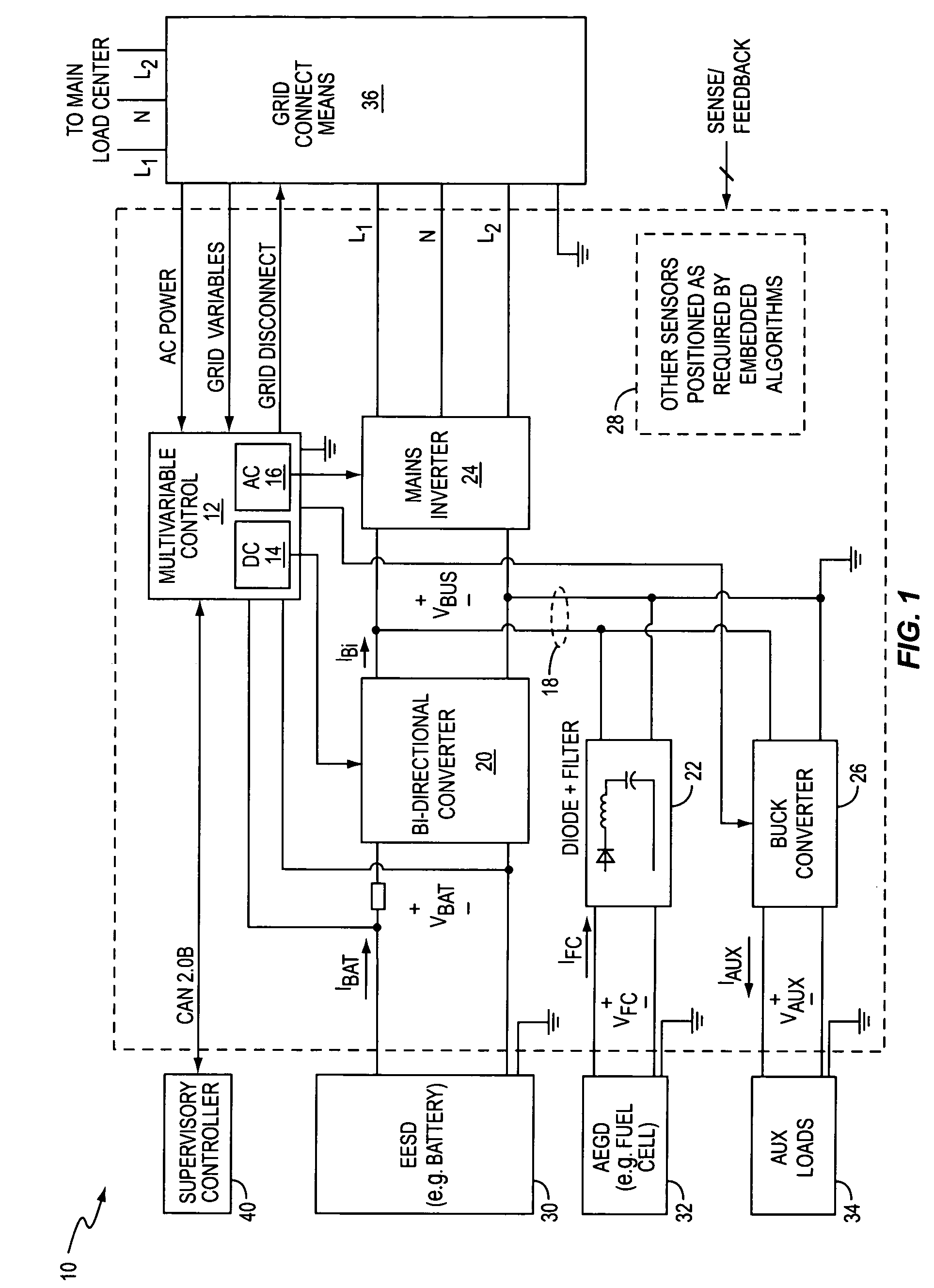

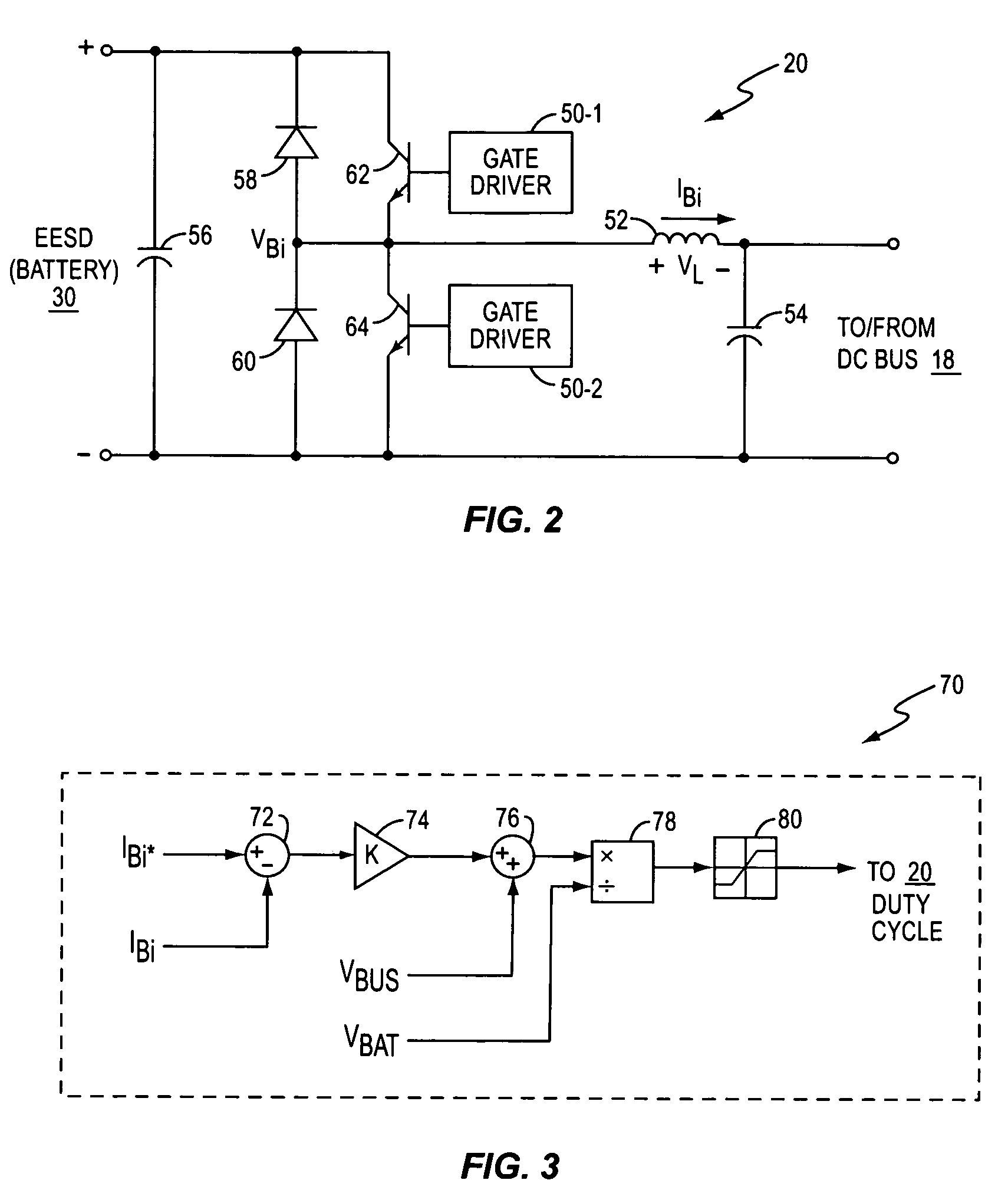

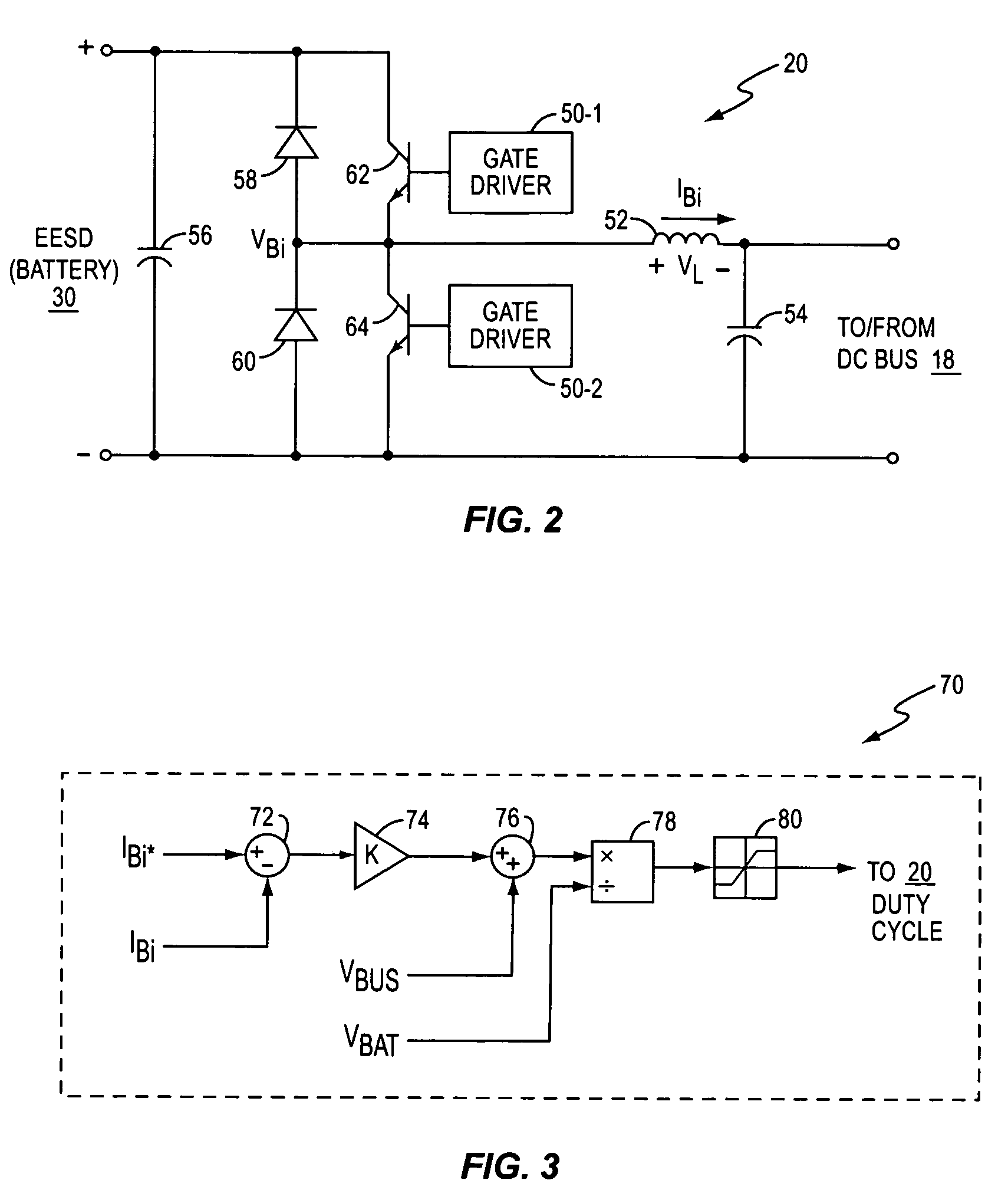

A multivariable control system provides regulation for a plurality of control variables of interest based on selecting a particular one of the variables for regulation relative to a corresponding setpoint, while continuing to monitor the other variables and switching regulation control over to another one of the variables as needed to maintain all of them within their allowed ranges. The system includes one or more PID regulators that tune themselves for the particular variables selected for regulation control. In an exemplary embodiment, the control system is configured for controlling an alternative energy system, wherein it includes one or more power flow devices that control power flow between electrical energy storage devices (EESDs) and a common dc bus and / or power flow between the dc bus and an external ac electrical system.

Owner:SQUARE D CO

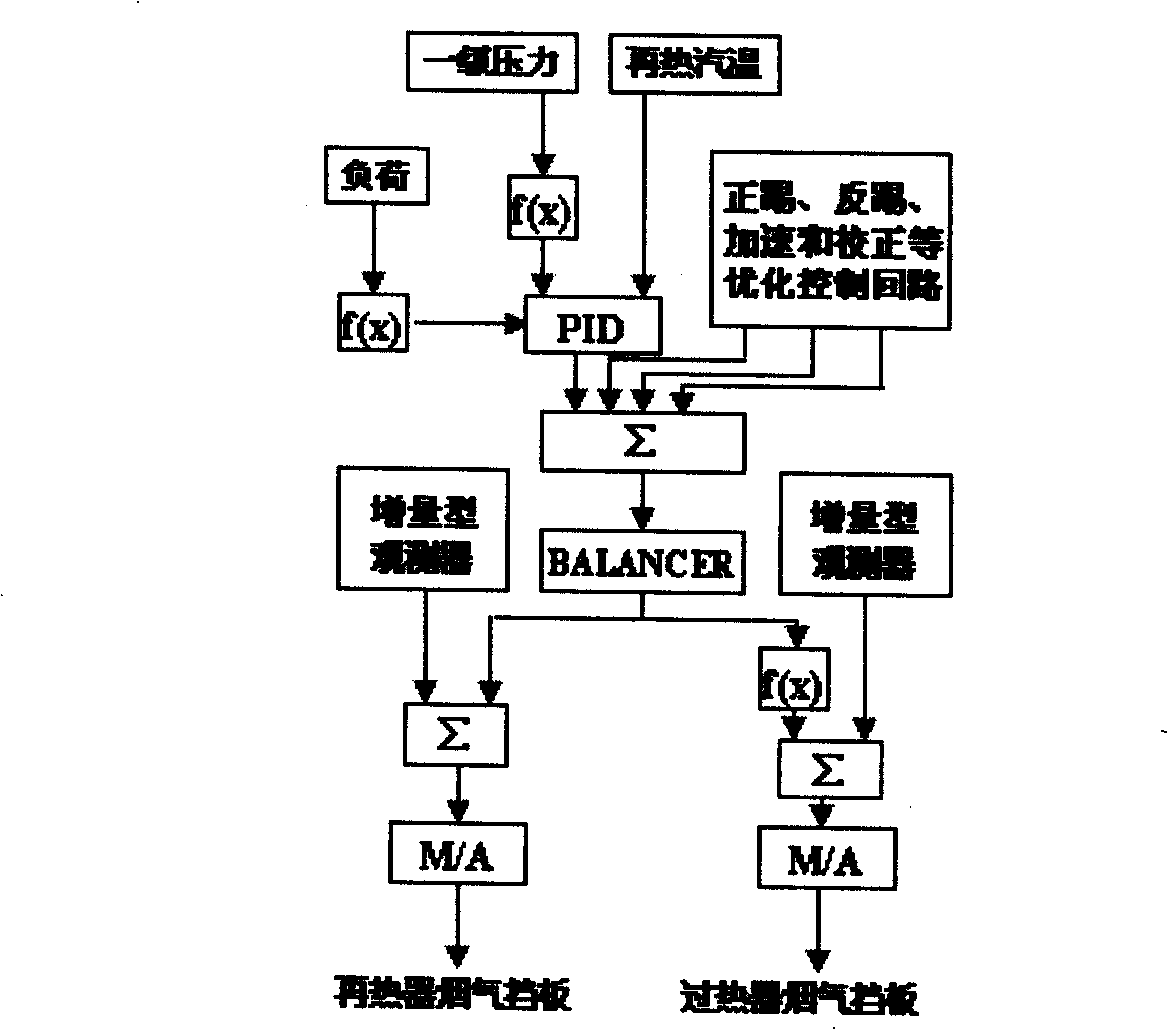

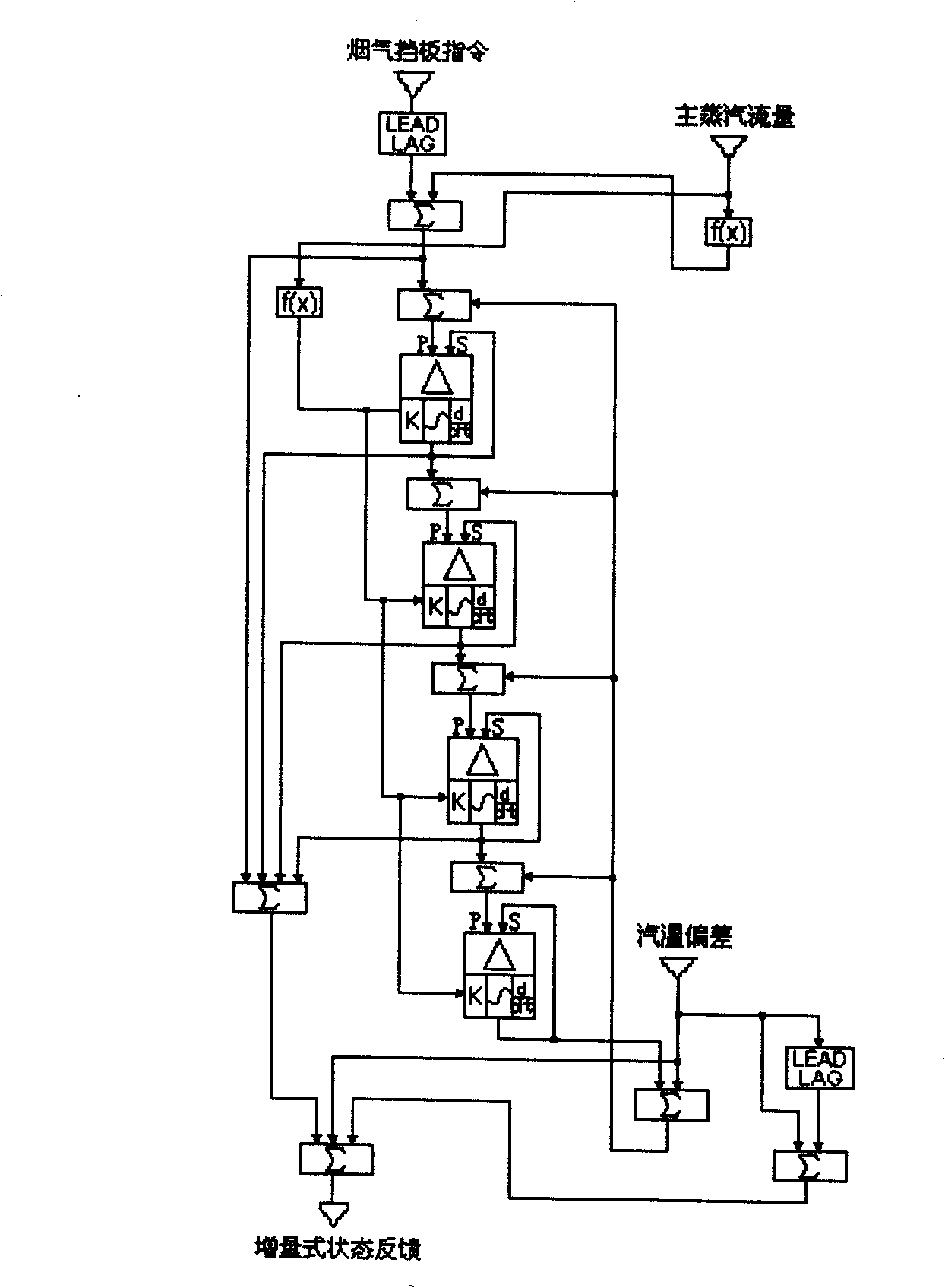

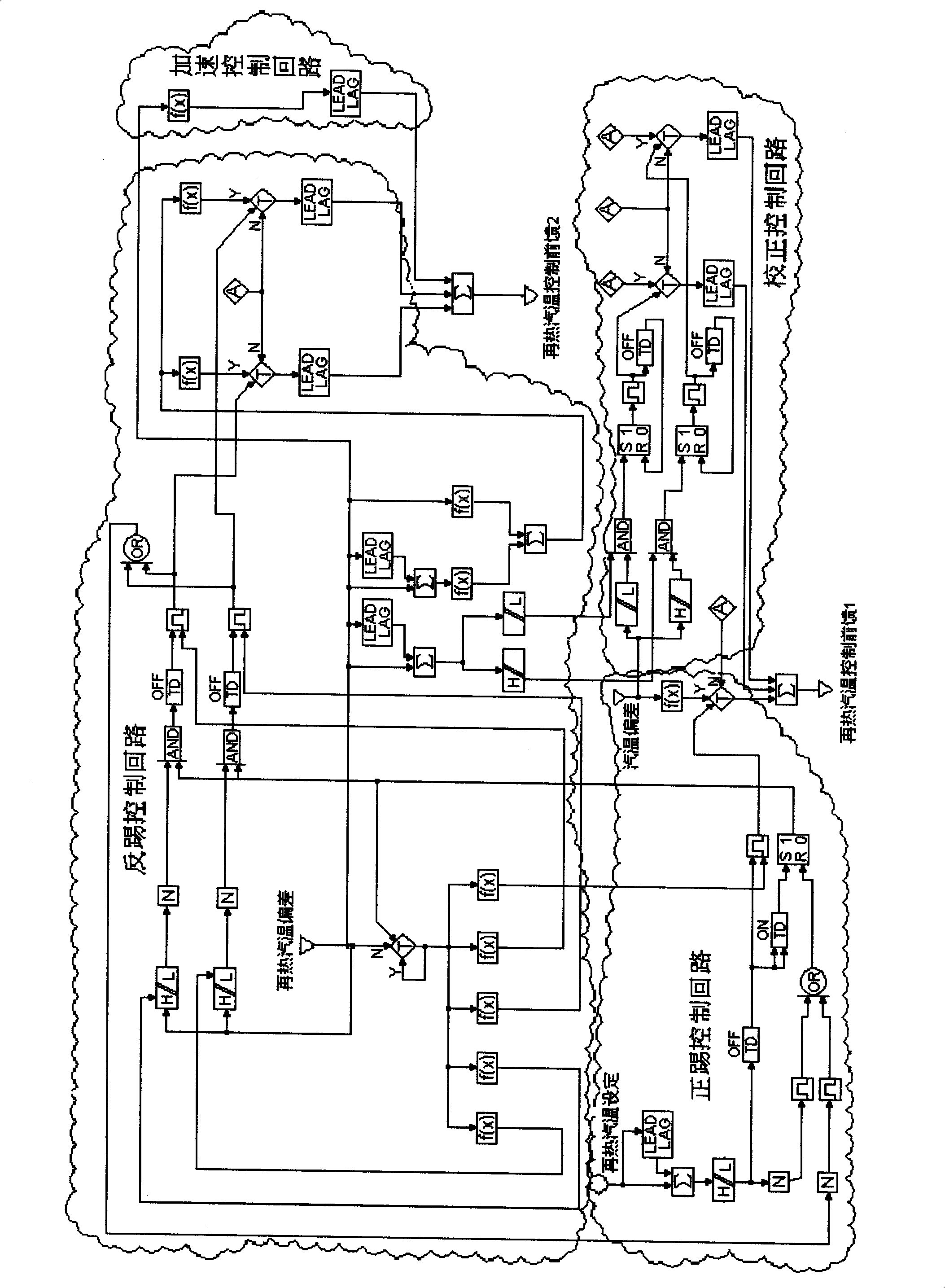

Thermal power unit reheated steam temperature control method

ActiveCN101338892APrevent overshootReduce Signal ErrorSuperheating controlTemperature control using electric meansFeedback controlLoad following power plant

The invention relates to a thermal power generating unit reheated steam temperature controlling method. According to the operating characteristics of the boiler reheater and the theoretic study on a steam-temperature control system, a state feedback control method based on incremental state observer is adopted, and the concept of an algebraically equivalence observer is used to direct the parameter setting of an incremental state observer; in addition, a special control circuit is arranged in the steam-temperature control circuit to resolve the problems that the process of steam-temperature adjustment is relatively long when the reheated steam temperature set value is changed, non-linearity exists during steam-temperature control, the process of steam-temperature variation is very slow, etc., and variation parameter PID regulator is combined to jointly form a comprehensive reheated temperature automatic adjusting system. The invention is capable to ensure reheated steam temperature control to escape spray water upon large-range load variation, and effectively overcomes the disadvantage of the poor effect of the traditional PID regulation on the control of big lagged object; the reheated temperature control effect is improved remarkably; and a sample is provided for controlling the controlled object with big inertia and serious lagging in relation to reheated steam temperature.

Owner:CHINA ELECTRIC POWER RES INST +2

Alternative energy system control method and apparatus

ActiveUS20050143846A1Mechanical power/torque controlSampled-variable control systemsControl powerPower flow

A multivariable control system provides regulation for a plurality of control variables of interest based on selecting a particular one of the variables for regulation relative to a corresponding setpoint, while continuing to monitor the other variables and switching regulation control over to another one of the variables as needed to maintain all of them within their allowed ranges. The system includes one or more PID regulators that tune themselves for the particular variables selected for regulation control. In an exemplary embodiment, the control system is configured for controlling an alternative energy system, wherein it includes one or more power flow devices that control power flow between electrical energy storage devices (EESDs) and a common dc bus and / or power flow between the dc bus and an external ac electrical system.

Owner:SQUARE D CO

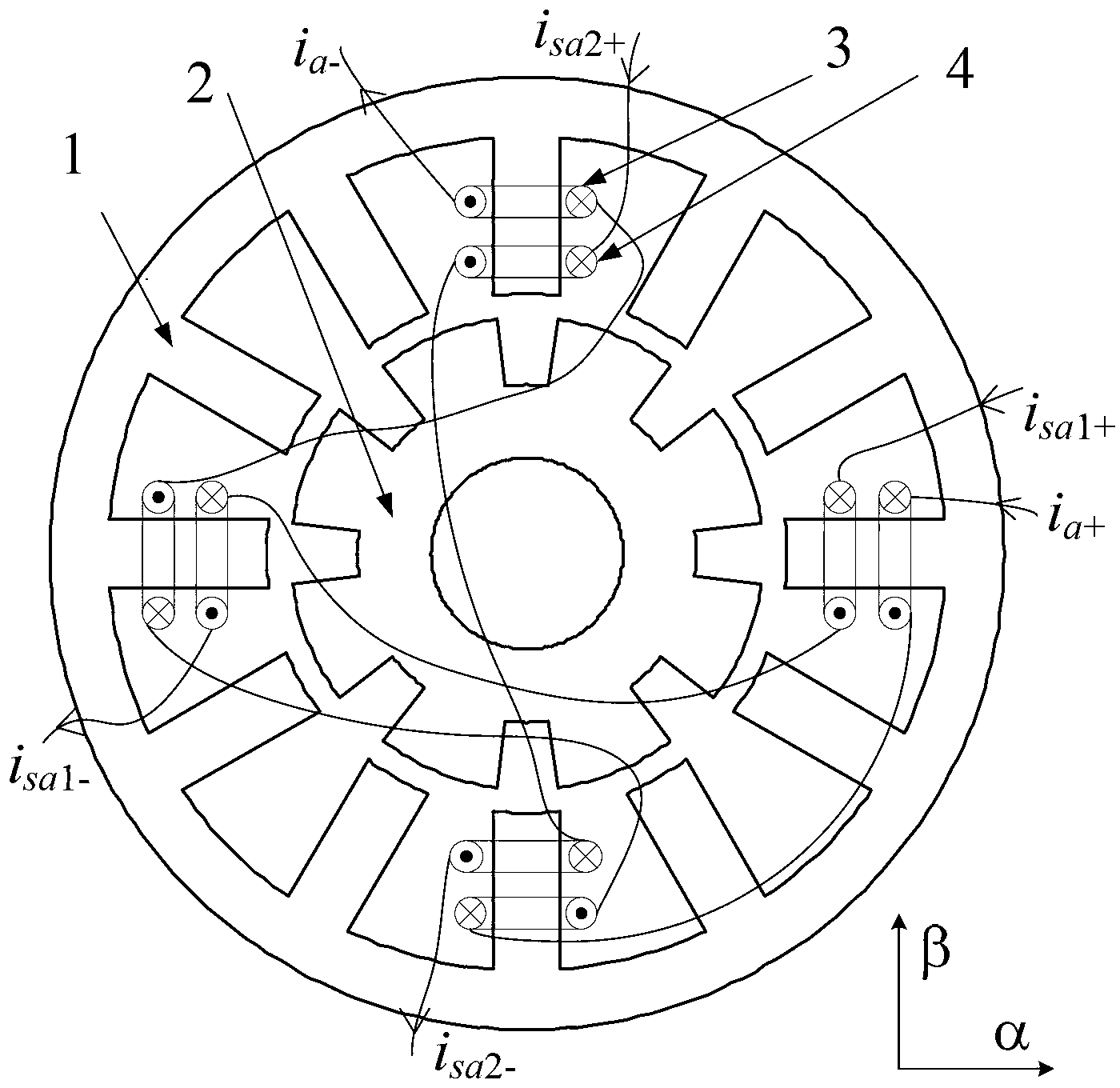

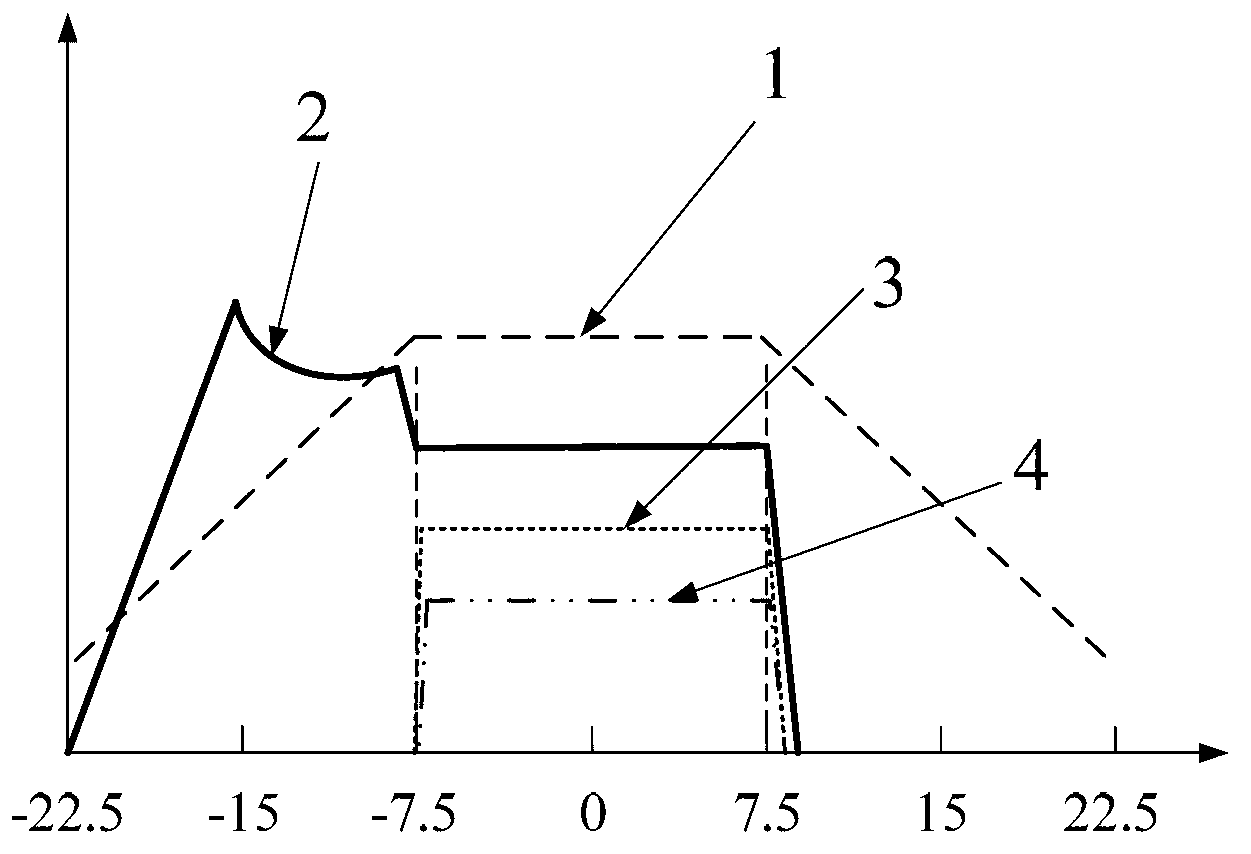

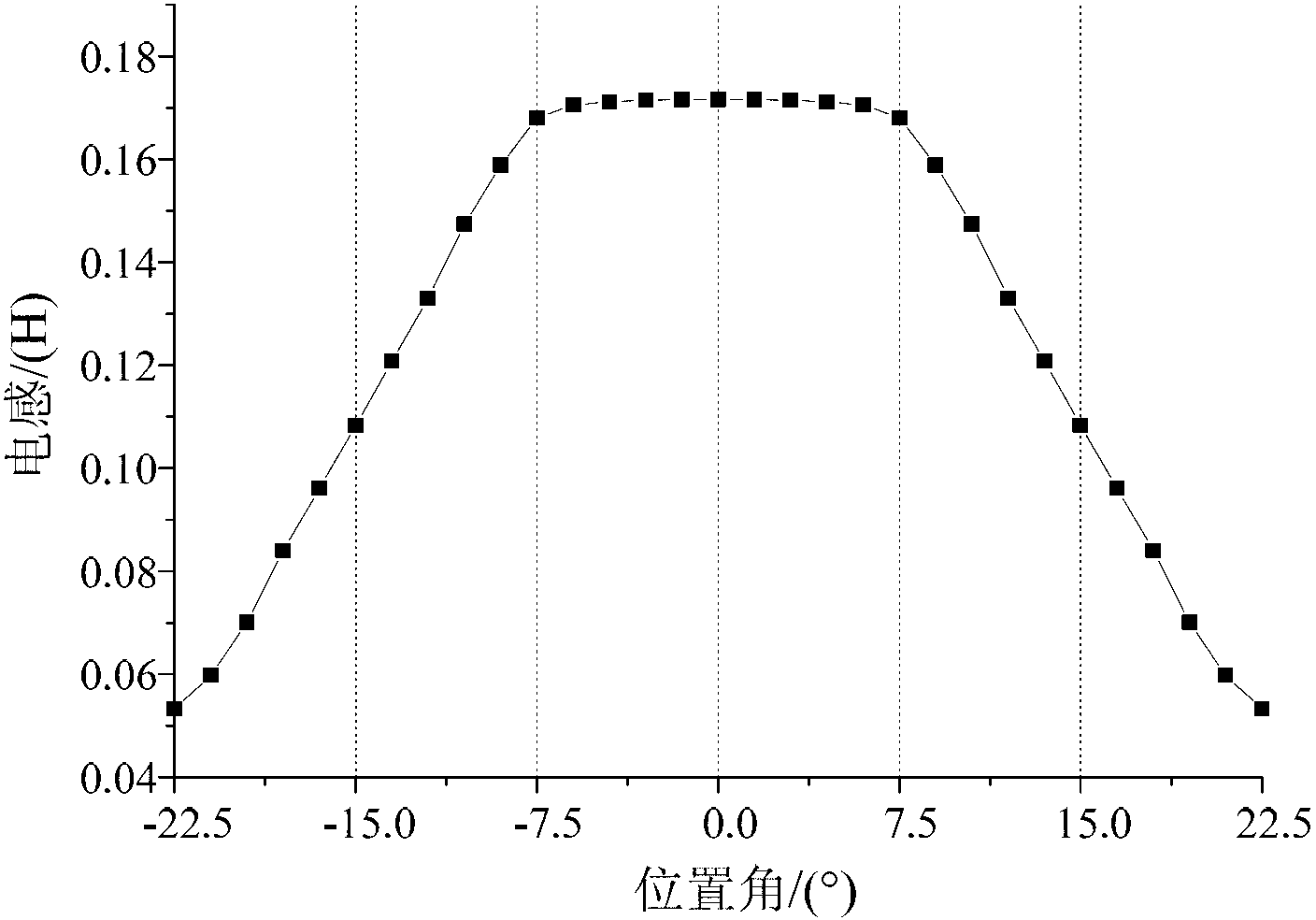

Bearingless switched reluctance motor and control method thereof

InactiveCN103296847AGive full play to high-speed adaptabilityReduce copper consumptionElectronic commutation motor controlAC motor controlLoop controlPower flow

The invention provides a bearingless switched reluctance motor and a control method thereof. The difference between a rotor pole arc angle and a stator pole arc angle of the motor is 15 degrees, current of torque windings and suspension windings are controlled to generate suspension force, the current of the torque windings is controlled so as to generate torque, and current of the torque winding of each phase and turn-on and turn-off angle of the torque winding are regulated to achieve a speed closed loop; radial displacement of a rotor is detection, and radial force needed for rotor suspension is outputted via PID (proportion integration differentiation) regulators, so that closed-loop control of radial displacement of the rotor is achieved. The suspension windings are only excited and conducted in a maximum-inductance flat-top area and do not generate torque, so that the torque and the suspension force can be decoupled in control, and current magnitude of the torque windings and the suspension windings is optimized to make copper loss of the windings to be minimum; in addition, counter potential of the suspension windings and the torque windings is zero in the maximum-inductance flat-top area, and high-speed suspended running of the bearingless switched reluctance motor is benefitted so as to give full play to high-speed adaptability of the switched reluctance motor.

Owner:NANJING UNIV OF POSTS & TELECOMM

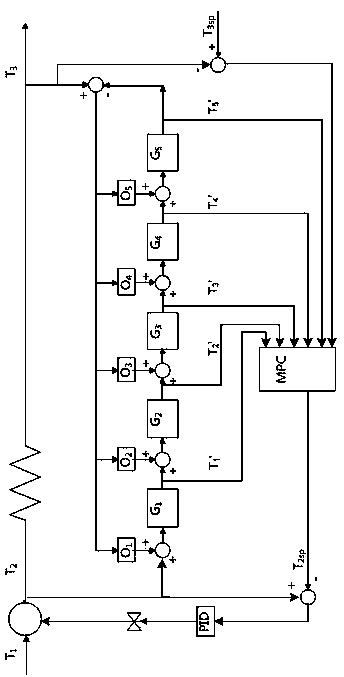

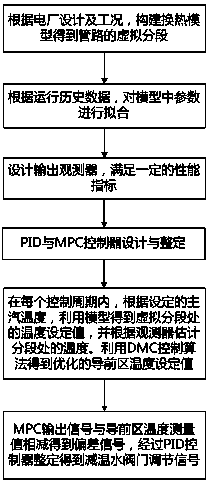

Method for predicting and controlling steam temperatures of boilers on basis of state observation model

ActiveCN103676651AReduced need for field trialsImprove object propertiesAdaptive controlControl signalMathematical model

The invention relates to a method for predicting and controlling steam temperatures of boilers on the basis of a state observation model. The method includes 1, replacing heat exchangers by multiple sections of concentration parameter links by a principle of natural segmentation or virtual segmentation, and using outlet parameters of media of various sections as representative parameters of the concentration links to build a mathematical model of enthalpy and temperature channels of the heat exchangers; 2, creating a state observer on the basis of output feedback and estimating outlet temperatures of the various sections; 3, connecting an MPC (multivariate model prediction controller) and a PID (proportion, integration and differentiation) regulator in a cascade manner to form a serial control circuit, acquiring step response coefficients according to the model of the enthalpy and temperature channels of the heat exchangers and acquiring set values of lead temperatures; 4, regulating the steam temperatures by the inner-loop PID regulator according to difference among the lead temperatures and output of the MPC and acquiring control signals of attemperation water valves. The method has the advantages that model building and verification are carried out, so that field test requirements can be reduced; states of inertial and lagged controlled objects are reconstructed via the state observer, so that characteristics of the objects can be modified; prediction and control are implemented, so that targets can be accurately and quickly controlled.

Owner:STATE GRID CORP OF CHINA +2

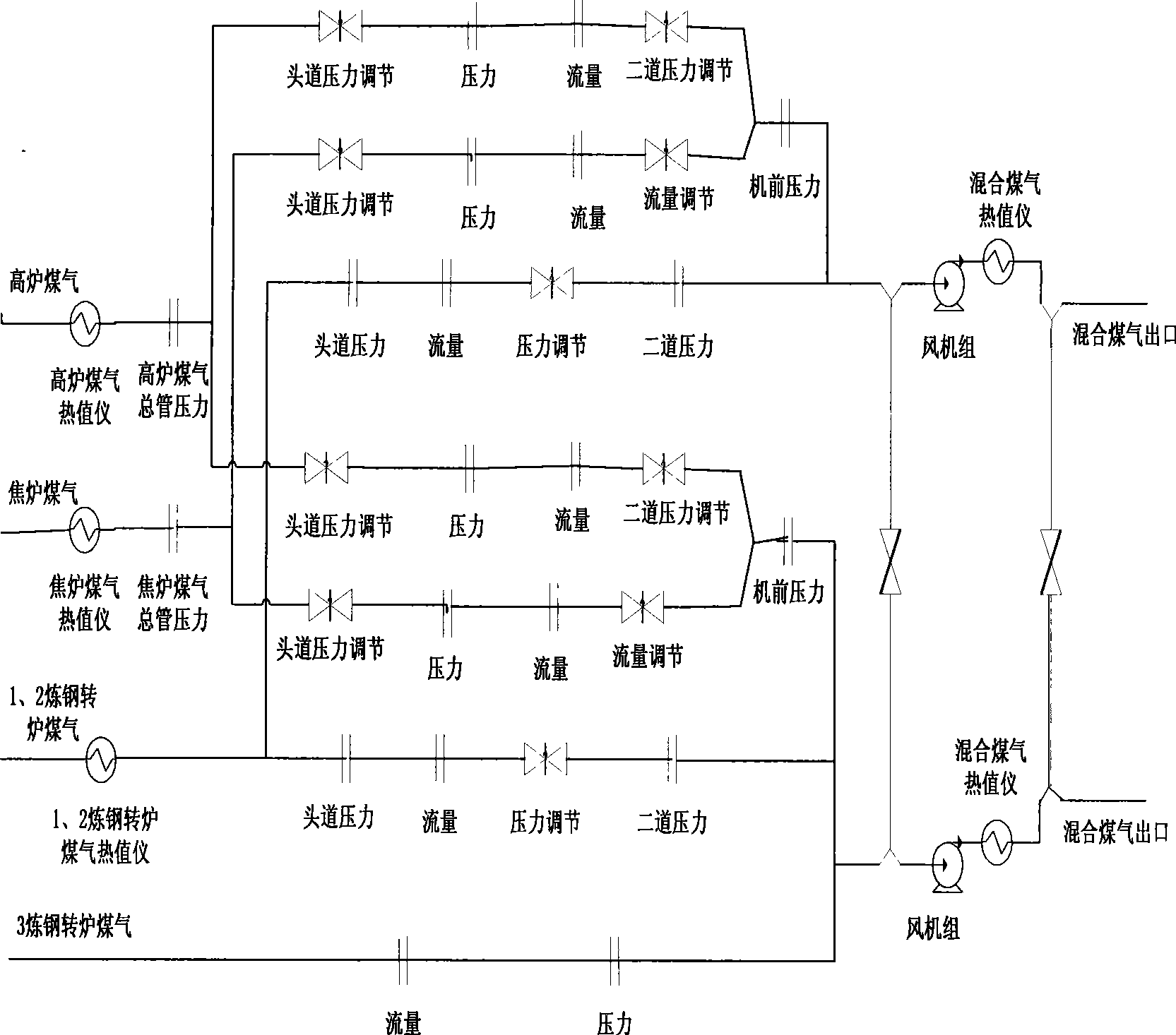

Mixed gas calorific value stabilization control method

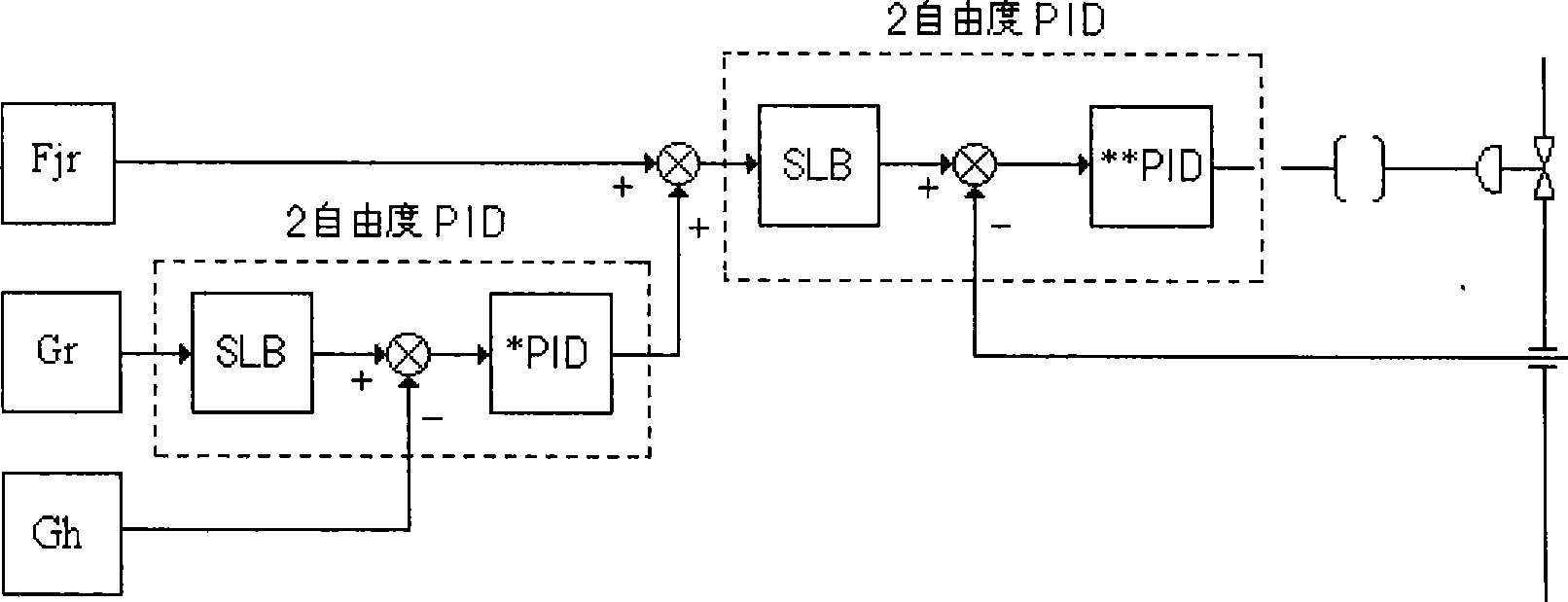

InactiveCN101482732AAdjust in timeAccurate adjustmentFuel supply regulationControllers with particular characteristicsEnergy balancingStabilization control

The invention relates to a control method for stabilizing the mixed gas heat value, the method comprises steps that: actual measuring heat values of blast furnace, coke oven and converter gas and the setting values of mixed gas heat values and various gas input amounts are taken as input parameters of a feedforward adjustment control loop, the required coke oven gas flows can be calculated by an energy balance formula; after feedforward adjustment, under the condition that the mixed gas heat value is not still to reach to the setting value, the difference value of the mixed gas actual measuring heat values and the setting values of the mixed gas heat value is taken as the input parameters of a feedback compensation adjustment, the difference value can be adjusted by the PID regulator to implement the compensation adjusting control; finally the coke oven gas flow output can be adjusted by the PID regulator. The invention can effectively control and adjust the mixed gas heat values and greatly improve the heating quality of the heating furnace steel billet.

Owner:ANGANG STEEL CO LTD

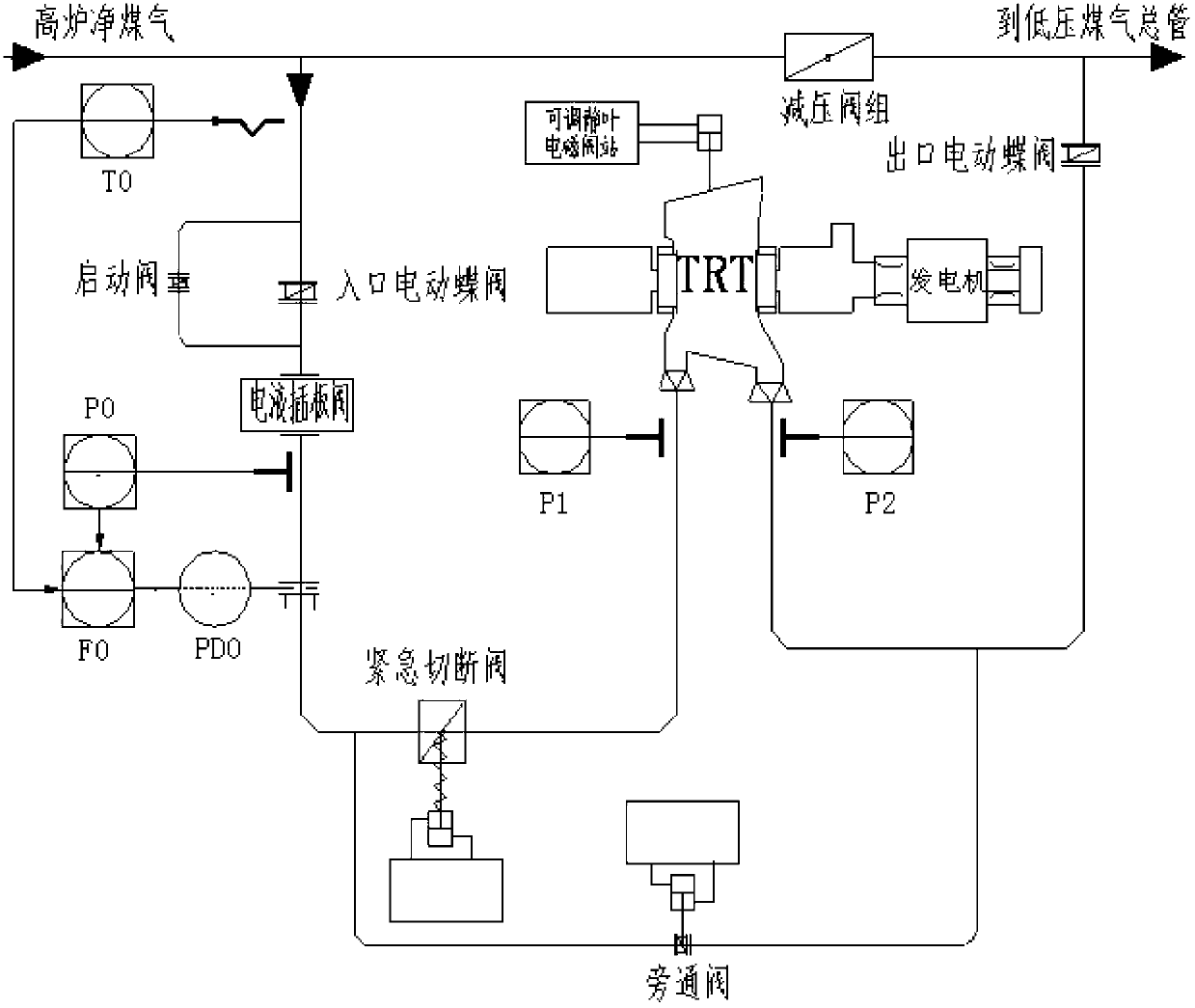

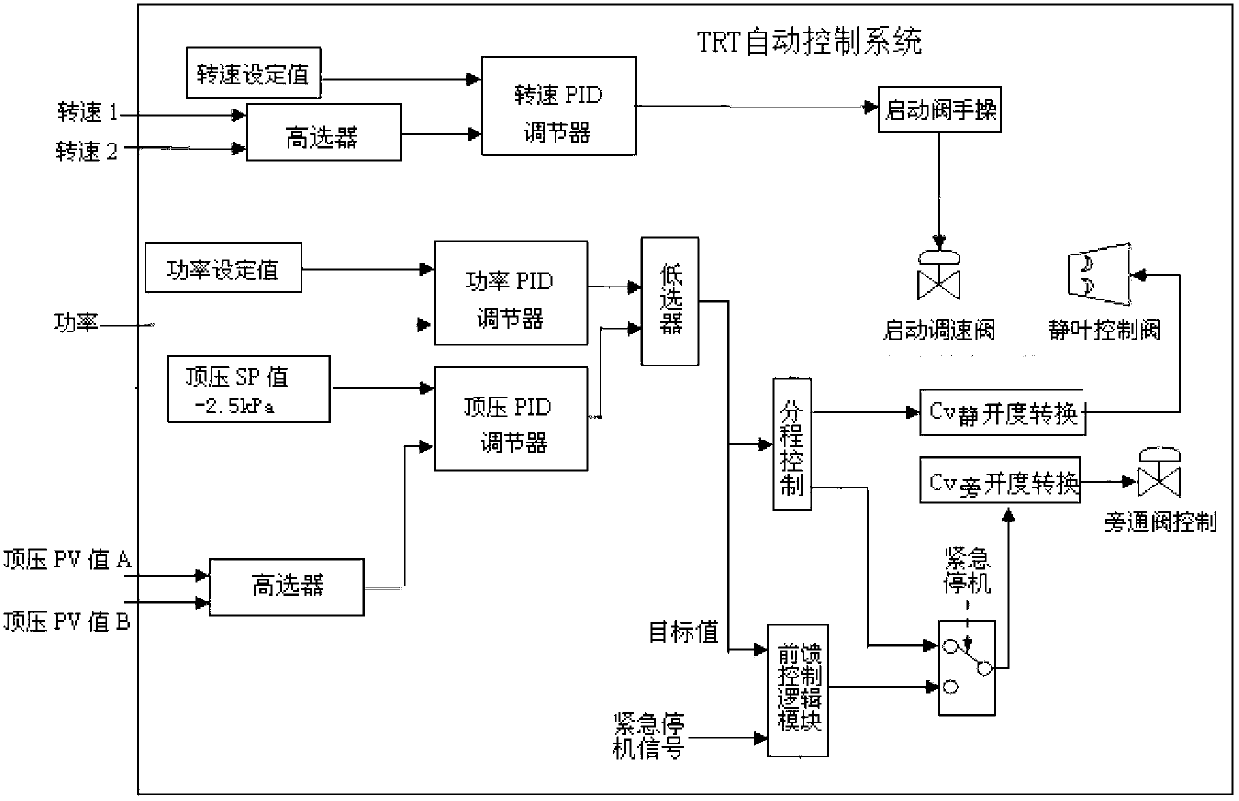

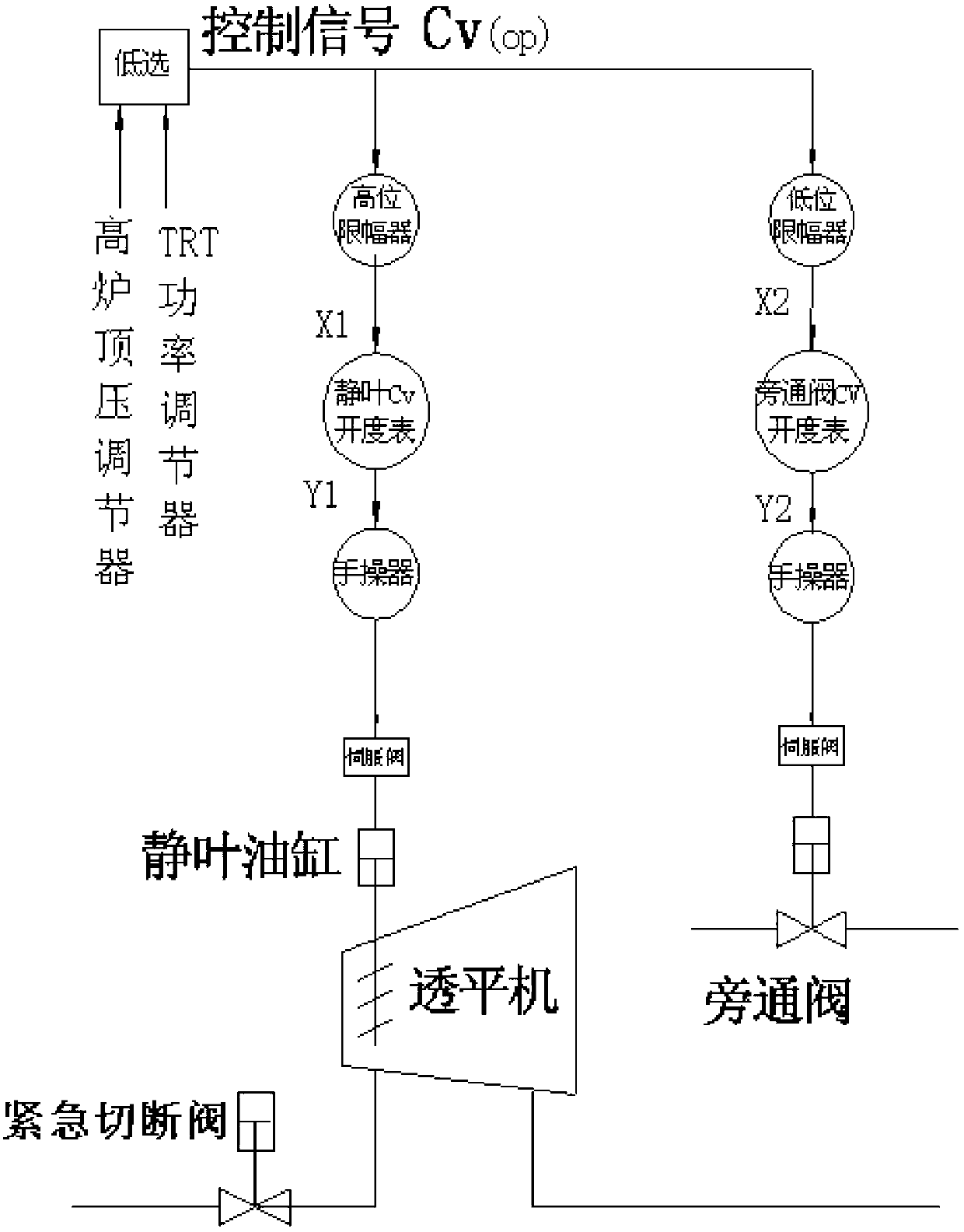

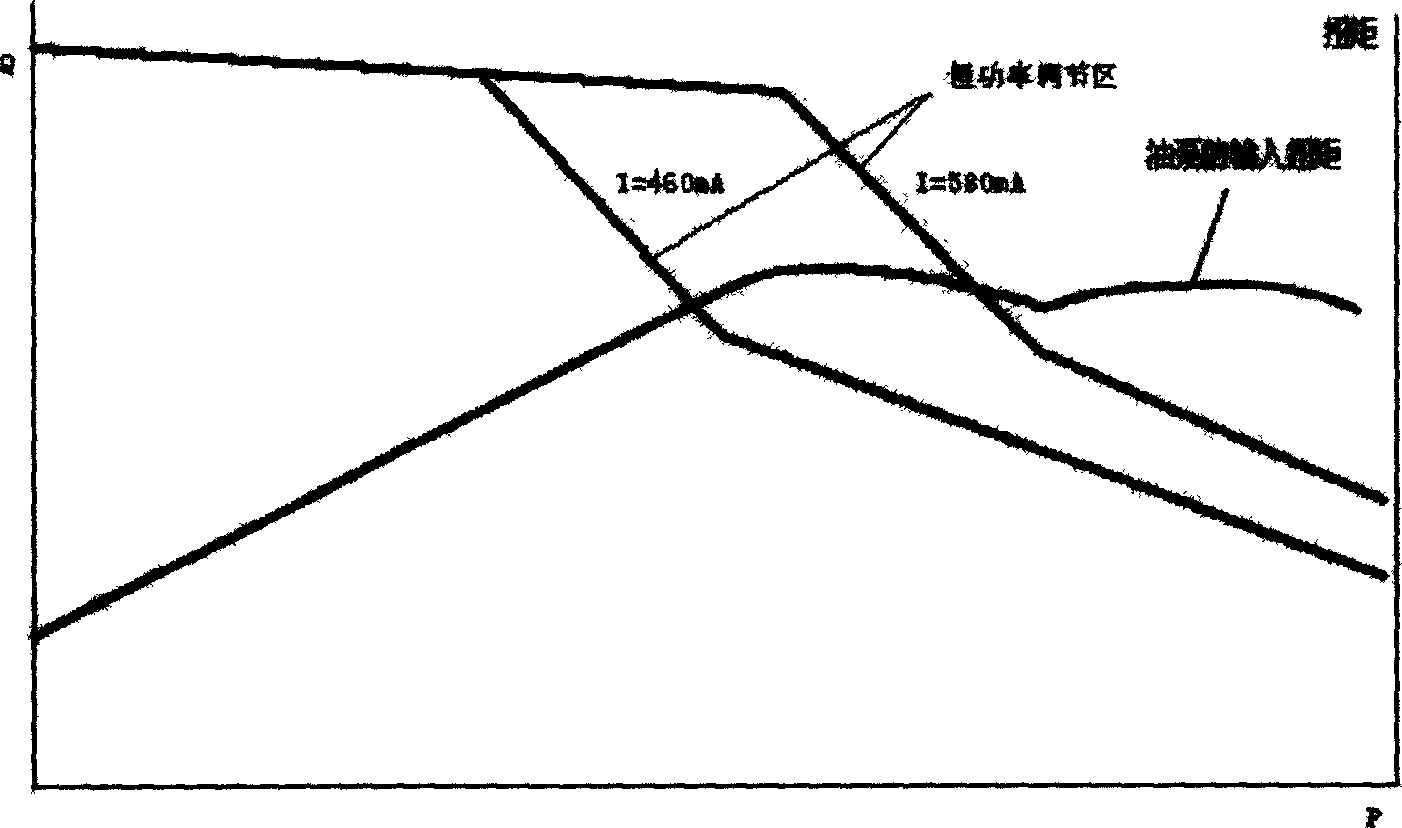

Automatic control method for top pressure of TRT (blast furnace top gas recovery turbine unit) system

InactiveCN102994672AA New Approach to SecurityA new way to be reliableBlast furnace detailsMachines/enginesAutomatic controlEngineering

The invention provides an automatic control method for the top pressure of a TRT (blast furnace top gas recovery turbine unit) system, which comprises the following steps of: converting the gas flow of the system into a Cv value, and creating a Cv-opening relation table of a stationary blade and a Cv-valve opening relation table of a bypass valve; controlling the TRT system by a speed PID regulator, a power PID regulator and a top pressure PID regulator respectively; controlling the top pressure in an operation stage of the TRT system, wherein the power PID regulator and the top pressure PID regulator of the system are connected to a split-ranging controller through a low selector; controlling the opening of the stationary blade and the opening of the bypass valve according to a split-ranging control principle; and after the system receives an emergency stop signal, closing an emergency cut-off valve, opening the bypass valve and controlling to slowly close the bypass valve, and regulating the pressure of the blast furnace by a pressure reducing valve group. The method provided by the invention solves the technical problems of low stability in regulating the top pressure of the blast furnace by the TRT, low generating efficiency, limited regulation ability, great fluctuation of pressure in the emergency stop process and the like caused by inaccurate performance data of the valve and insufficient circulation of TRT design.

Owner:武汉钢铁有限公司

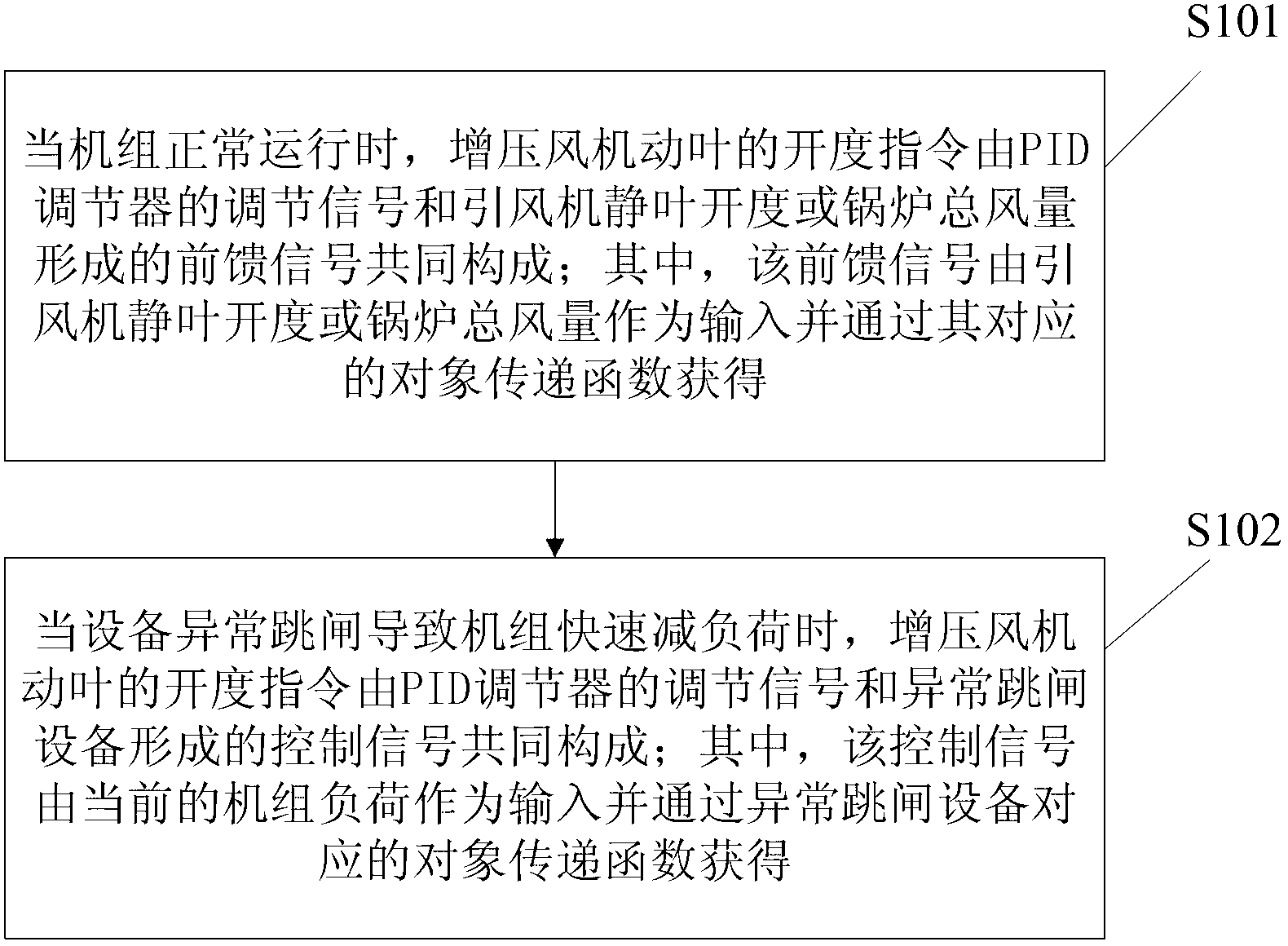

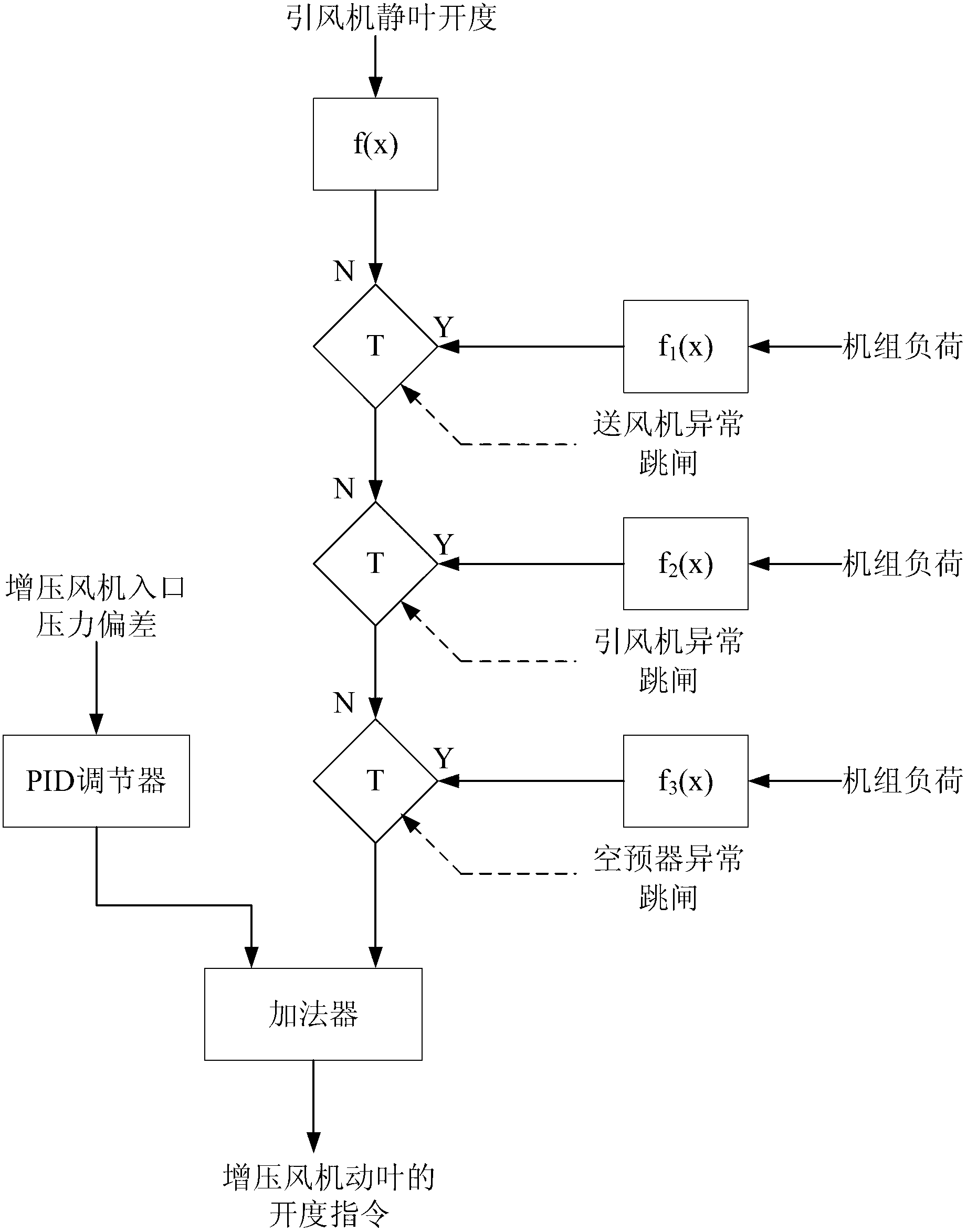

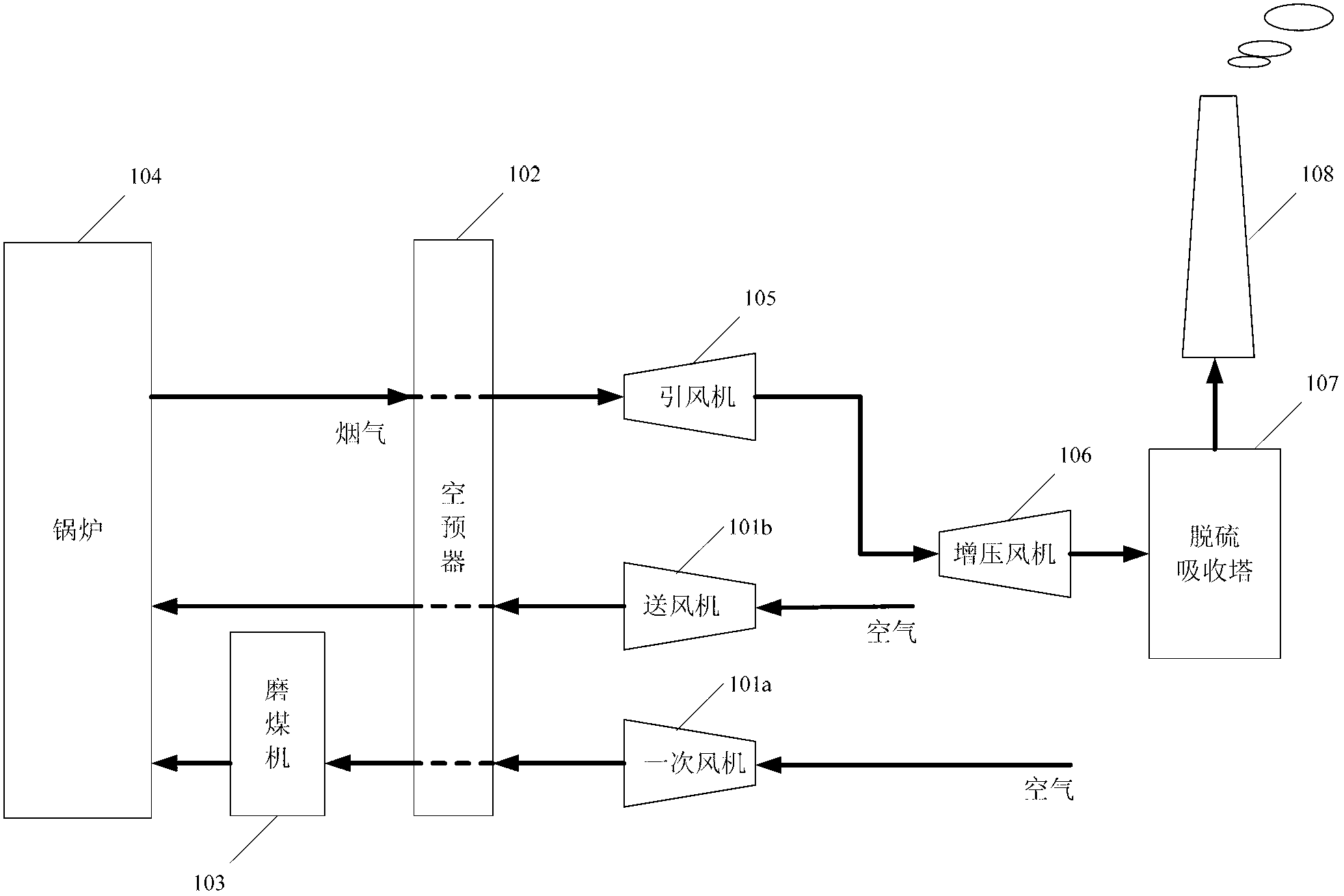

Control method for unbypassed booster fan of desulphurization system

InactiveCN103016379ASolve control problemsTrip will notPump controlNon-positive displacement fluid enginesProportion integration differentiationControl signal

The invention discloses a control method for an unbypassed booster fan of a desulphurization system. The control method for the unbypassed booster fan of the desulphurization system comprises the following working conditions: when a unit normally runs, an opening command of a moving blade of the booster fan jointly consists of a regulatory signal of a proportion integration differentiation (PID) regulator and a feedforward signal formed by opening of a stationary blade of a induced-draft fan or the total blast volume of a boiler, wherein the feedforward signal serves as input by the opening of the stationary blade of the induced-draft fan or the total blast volume of the boiler and is obtained through an object transfer function which corresponds to the opening of the stationary blade of the induced-draft fan or the total blast volume of the boiler; when runback (RB) is caused to the unit when equipment trips abnormally, the opening command of the moving blade of the booster fan jointly consists of the regulatory signal of the PID regulator and a control signal formed by the abnormally tripping equipment, wherein the control signal serves as input by current unit load and is obtained through an object transfer function which corresponds to the abnormally tripping equipment. Therefore, the control problem of the booster fan of the desulphurization system when the RB occurs on the unit is solved, so that the inlet pressure of the system can be controlled to be within a proper range by the booster fan when the RB occurs on the unit, and the unit cannot trip due to the fact that the pressure fluctuation is high.

Owner:广东红海湾发电有限公司

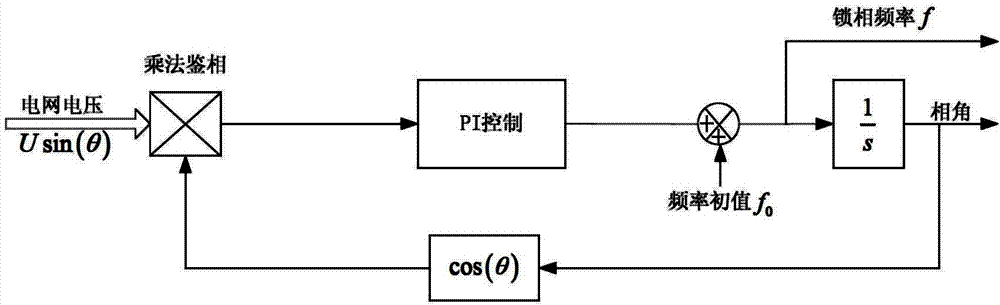

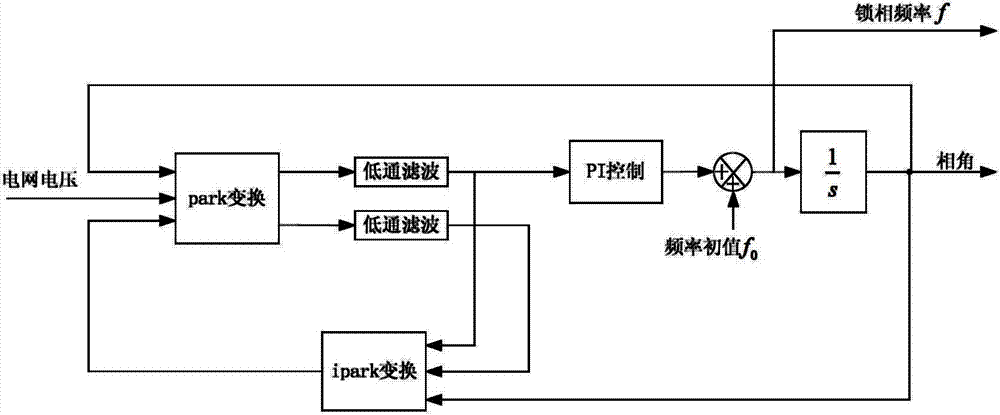

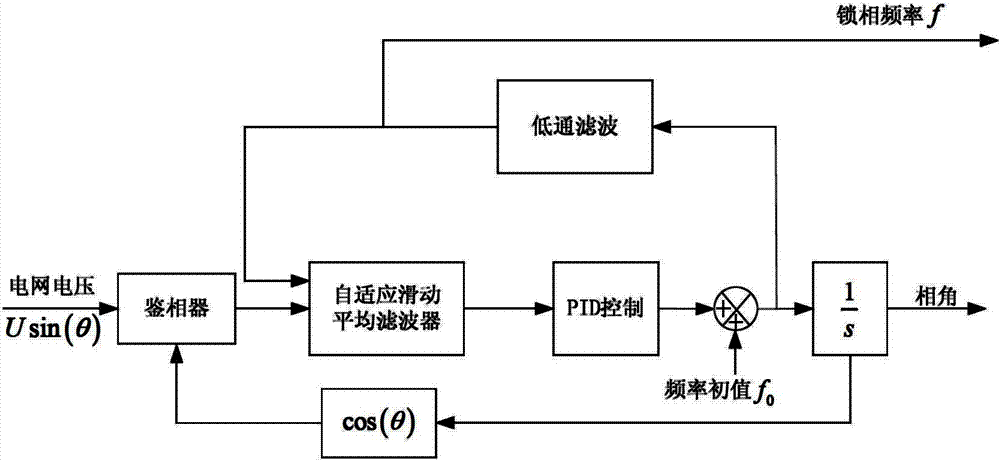

Self-adaptive grid-tied converter single phase soft phase-locked loop

ActiveCN102904568AGuaranteed speedGuaranteed dynamic performancePulse automatic controlMoving averageDiscriminator

The invention discloses a self-adaptive grid-tied converter single phase soft phase-locked loop. The self-adaptive grid-tied converter single phase soft phase-locked loop comprises a phase discriminator, a low pass filter, a loop filter and an integrator module, wherein the loop filter is composed of a self-adaptive moving average filter and a proportion integration differentiation (PID) regulator, the phase discriminator is a multiplication phase discriminator, an input signal is a trigonometric function of an output angle of power grid voltage and a phase-locked loop, and an output signal is transmitted into the moving average filter; an input signal of the moving average filter is output of the phase discriminator and output of the low pass filter, and the output signal is transmitted to the PID regulator; and an input signal of the PID regulator is an output signal of the moving average filter, and the output signal is transmitted into the low pass filter and the integrator module. The self-adaptive grid-tied converter single phase soft phase-locked loop has the advantages that the loop filter is improved, effects of secondary ripple and harmonic voltage on phase lock result in the steady state are eliminated, and simultaneously the rapidity of the phase lock is guaranteed.

Owner:西安奥特迅电力电子技术有限公司 +2

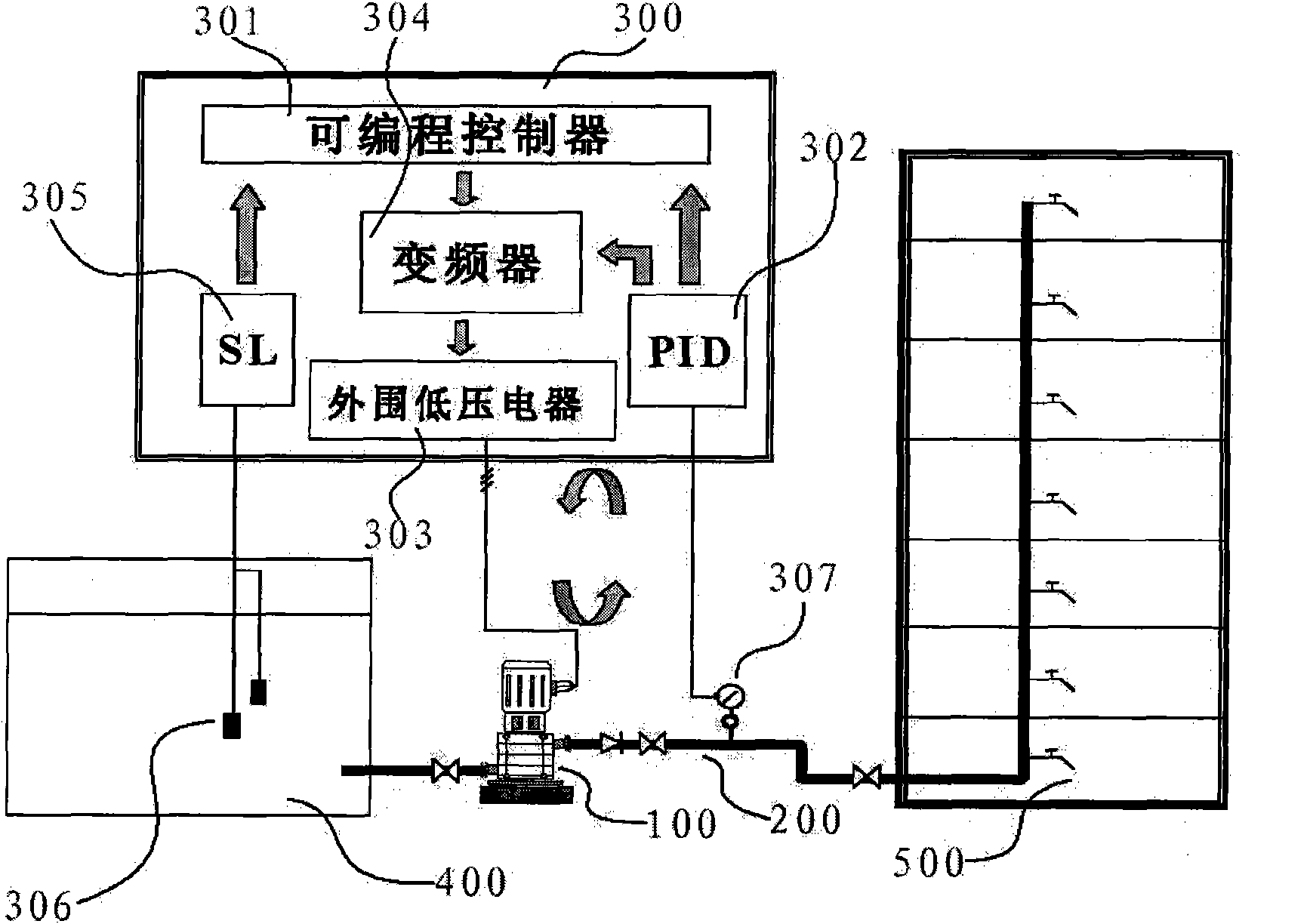

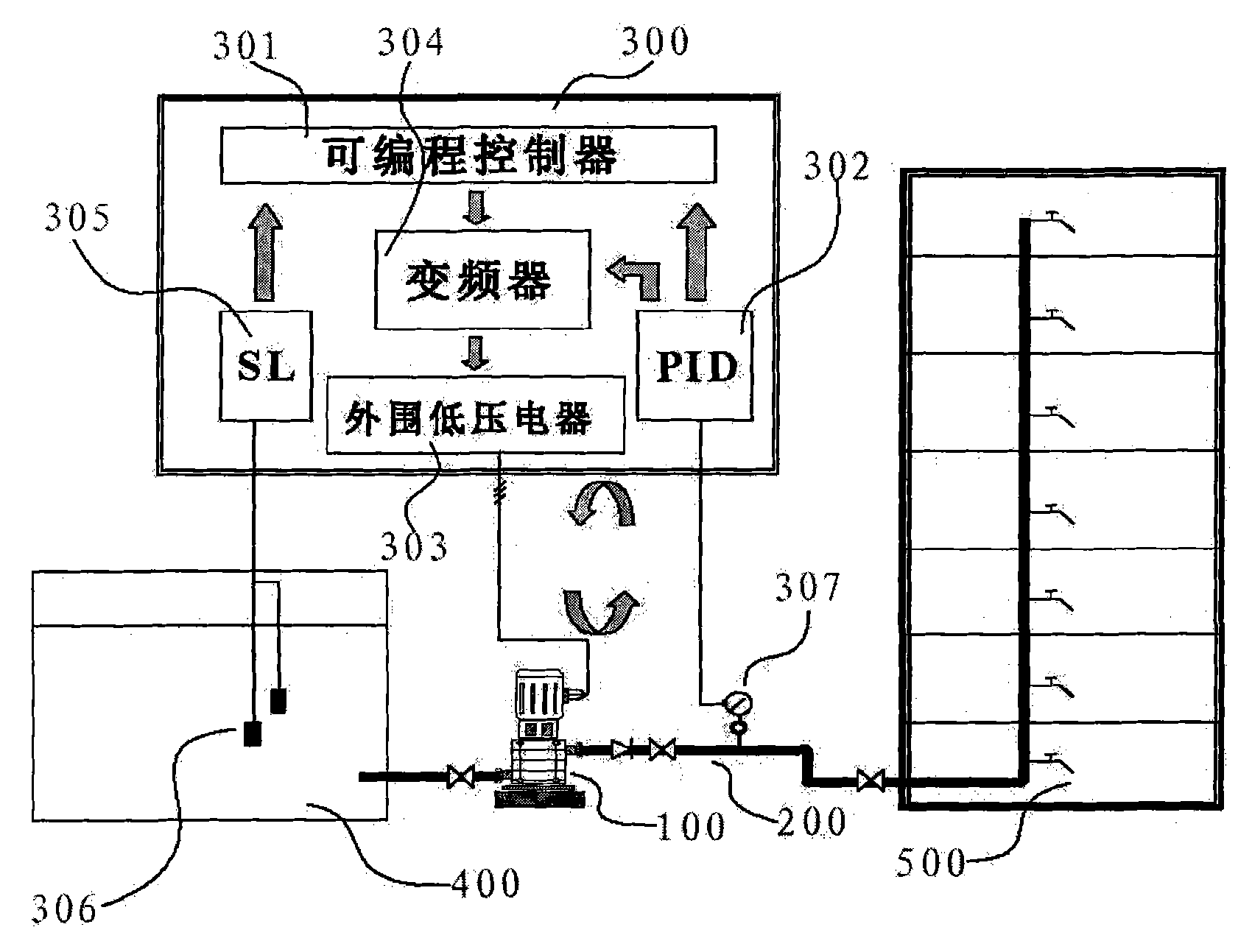

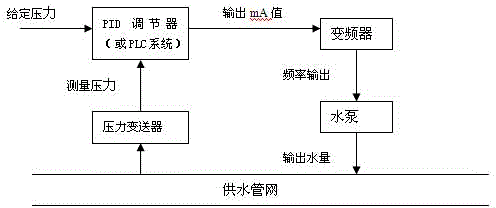

Frequency conversion constant-pressure water supply system and control method thereof

InactiveCN102116043AExtended service lifeNo impactWater supply tanksFrequency changerPore water pressure

The invention discloses a frequency conversion constant-pressure water supply system and a control method thereof. The frequency conversion constant-pressure water supply system is characterized in that a programmable controller and a frequency converter are connected with a PID (Proportion Integration Differentiation) regulator and control a water pump set; and the PID regulator detects water pressure through a pressure sensor. The control method of the frequency conversion constant-voltage water supply system comprises the following steps of: when water consumption is increased, enhancing the working frequency of a water pump, and accelerating the revolving speed of the water pump; when water consumption is decreased, reducing the working frequency of the water pump, and decelerating the revolving speed of the water pump. The invention regulates the revolving speed of various pumps in the living water supply system by adopting the frequency converter and can realize that one frequency converter simultaneously controls multiple water pumps, realize automatic constant-pressure water supply and additionally set a night small pump operating and fire-fighting function.

Owner:SHANGHAI EAST PUMP(GRP) CO LTD

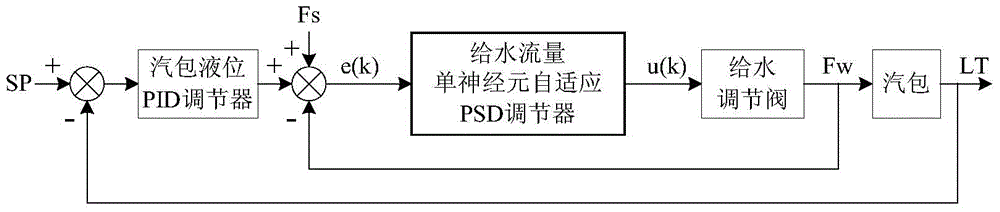

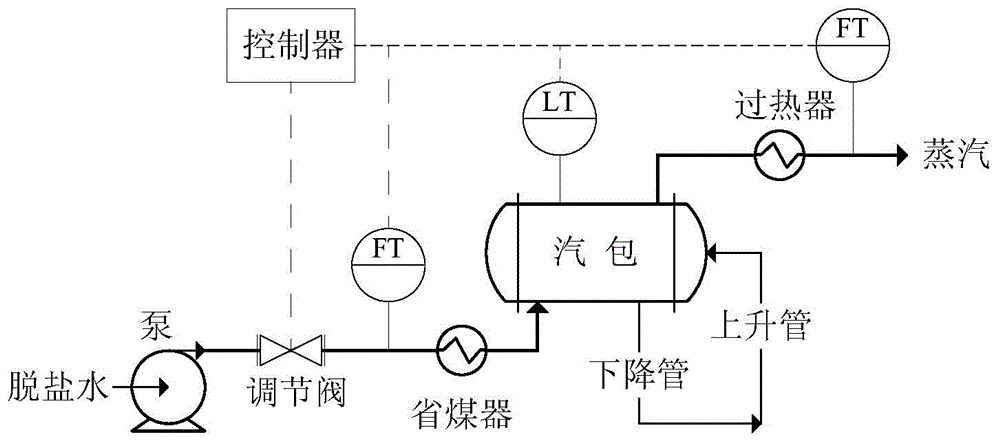

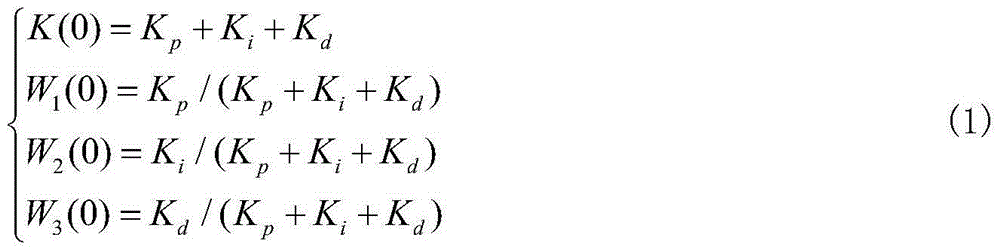

Thermoelectricity boiler drum liquid level control method

ActiveCN103558757AEfficient and stable productionAchieving Adaptive Optimal ControlAdaptive controlControl systemAdaptive optimization

The invention relates to a thermoelectricity boiler drum liquid level control method, three variables of a drum liquid level, feed water flow and steam flow are taken as processing objects, a feedforward and cascade stage structure is wholly adopted for a control system, a conventional PID adjuster with the drum liquid level as a detecting and controlling variable is adopted for a main adjustor, and the deviation between the set value SP of the drum liquid level and the actual measured value LT is calculated through the PID adjuster and output as the set value of the feed water flow; the measured value of the drum externally supplied steam flow is taken as a feedforward control variable; a single-neuron self-adaptive PSD adjuster with the feed water flow as a detecting and controlling variable is adopted for an auxiliary adjustor. Through the technical scheme, aiming at complex conditions of boiler drum operation, advanced, reliable and practical calculation is adopted to achieve self-adaptive optimum control over the boiler drum liquid level and ensure efficient and stable production of a boiler.

Owner:WISDRI ENG & RES INC LTD

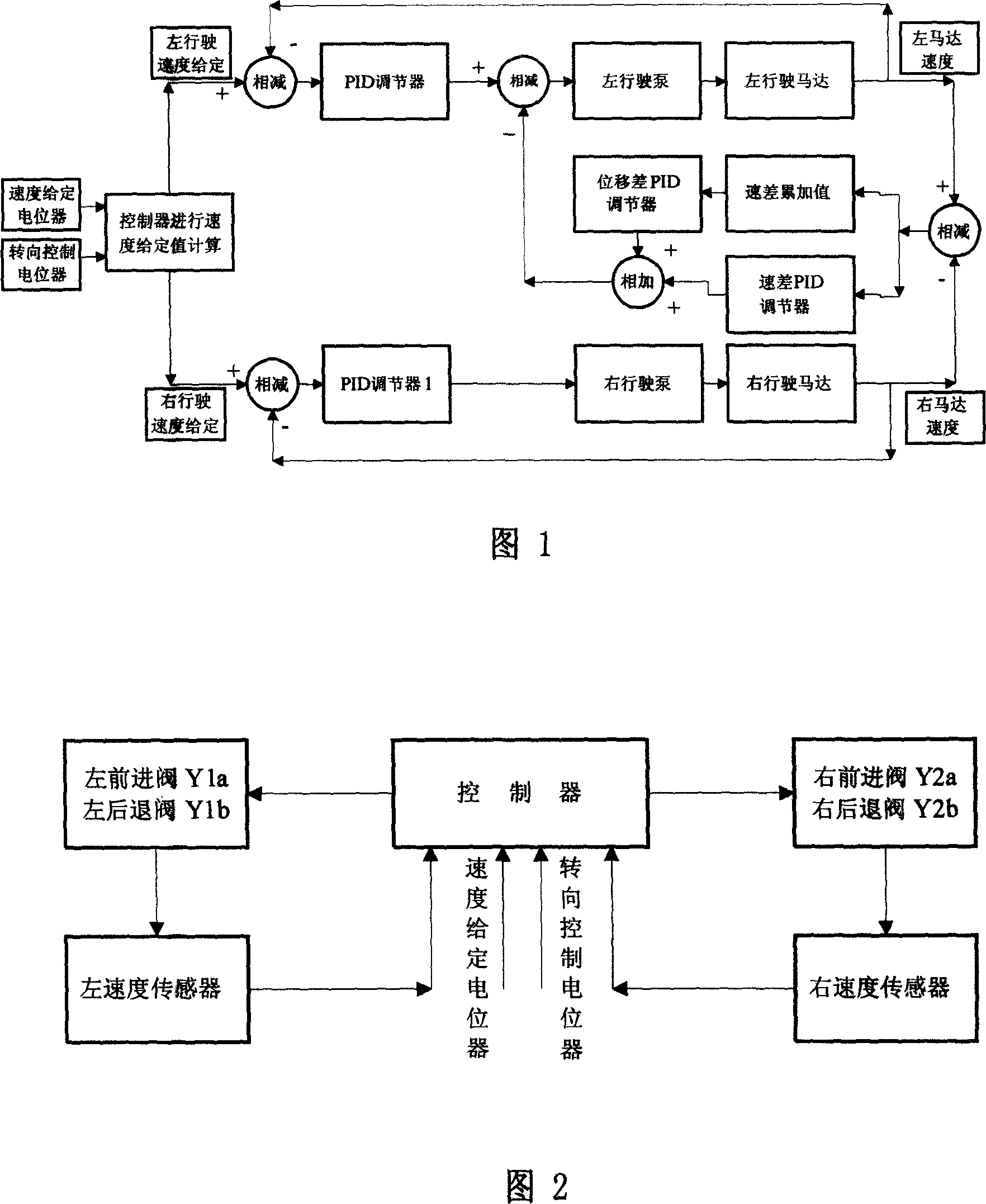

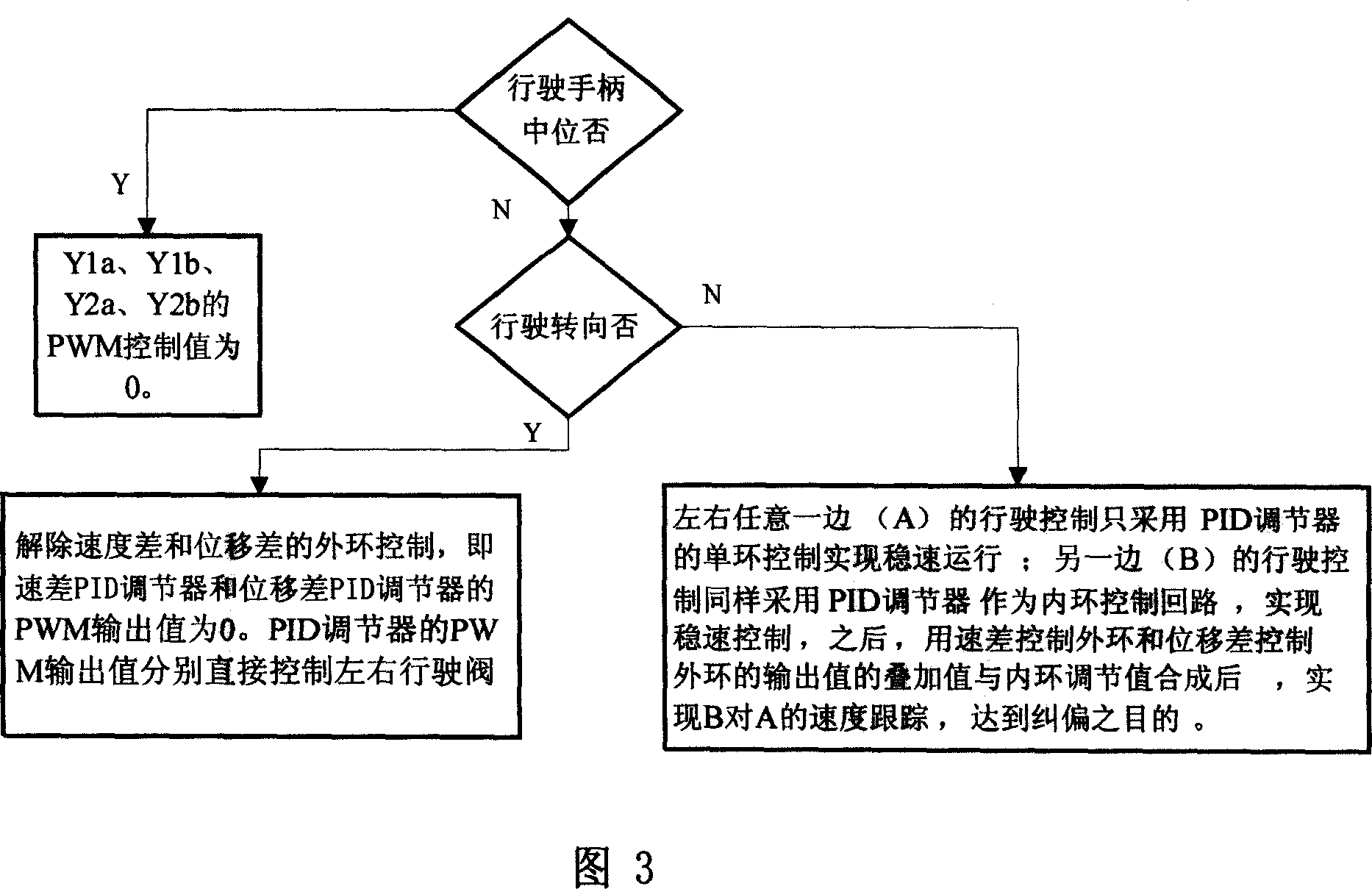

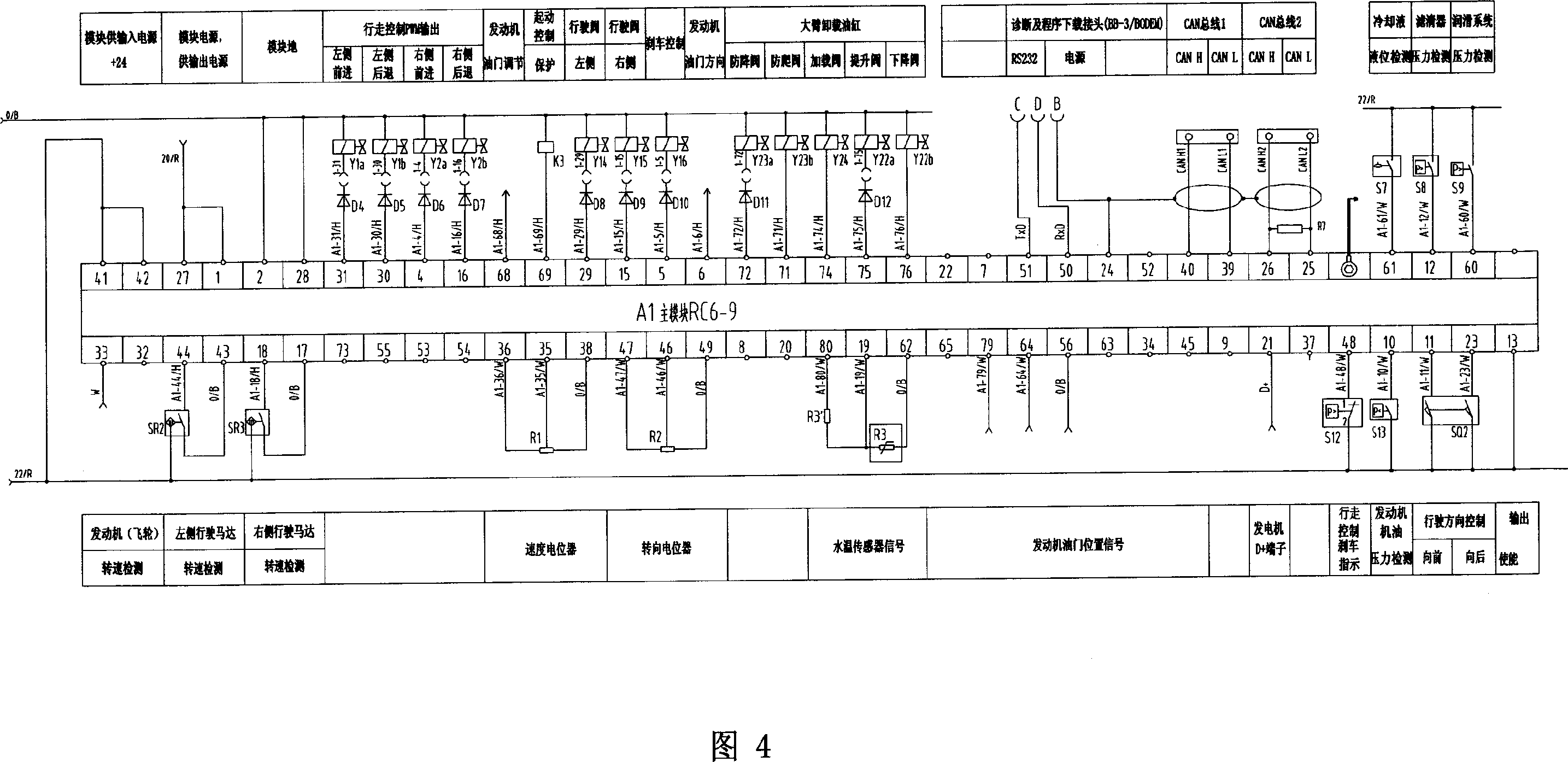

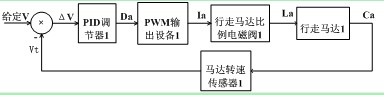

Control method and controller for walking system of spreader

ActiveCN101021054AControl deviationImprove walking performanceRoads maintainenceControllers with particular characteristicsControl systemClosed loop

The control method for walking system of spreader includes feeding the rotation speeds of both right and left motor for comparison with the given values, and controlling the rotation speeds via a PID regulator to form a core loop; feeding the speed difference of the right motor and left motor to trace zero target and controlling the speed of one motor via a speed difference PID regulator to constitute a speed difference tracing correction loop; and feeding the accumulated speed difference of the right motor and left motor to trace zero target and further regulate the speed in the speed difference tracing correction loop via a displacement difference PID regulator to form a displacement difference tracing correction loop. All the core loop, the speed difference tracing correction loop and the displacement difference tracing correction loop constitute one closed-loop control system for the walking system of spreader. The present invention has high operation comfortability and high construction quality.

Owner:益阳市科技成果转化服务中心 +1

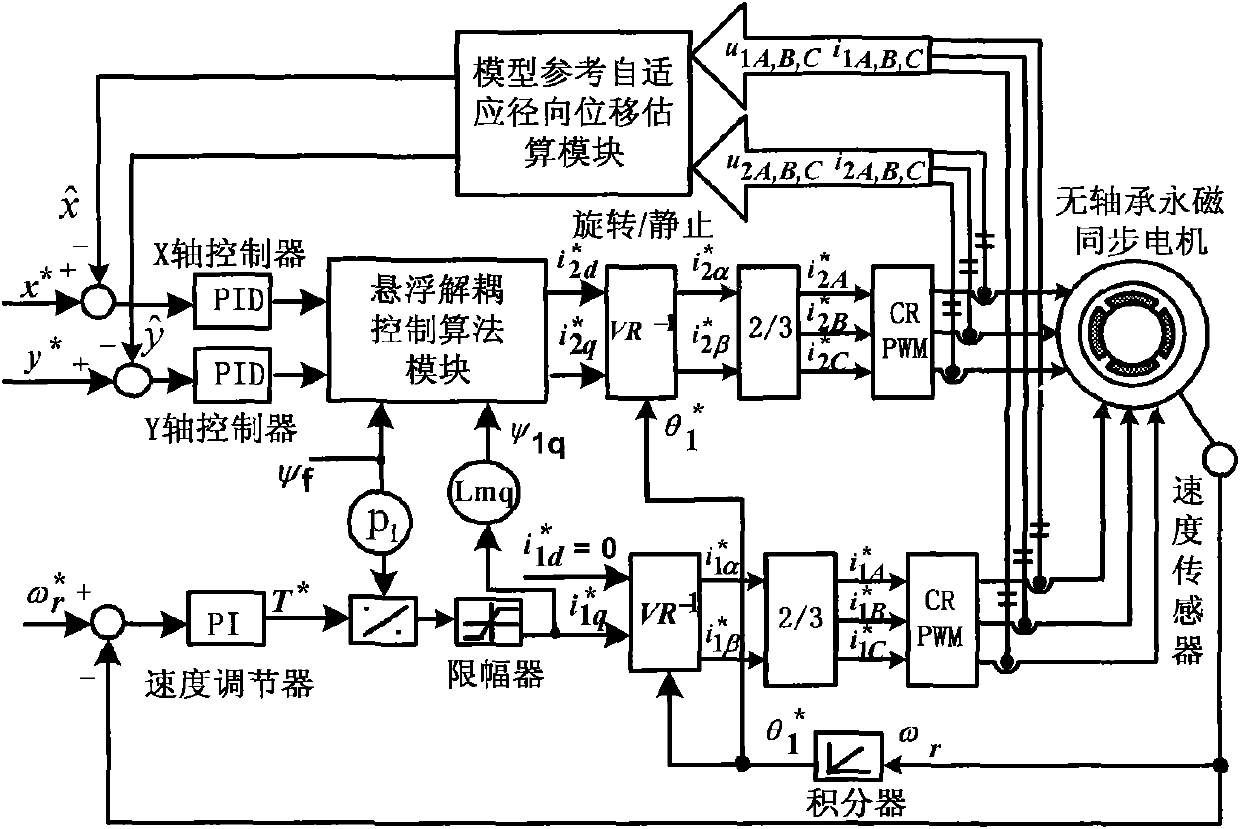

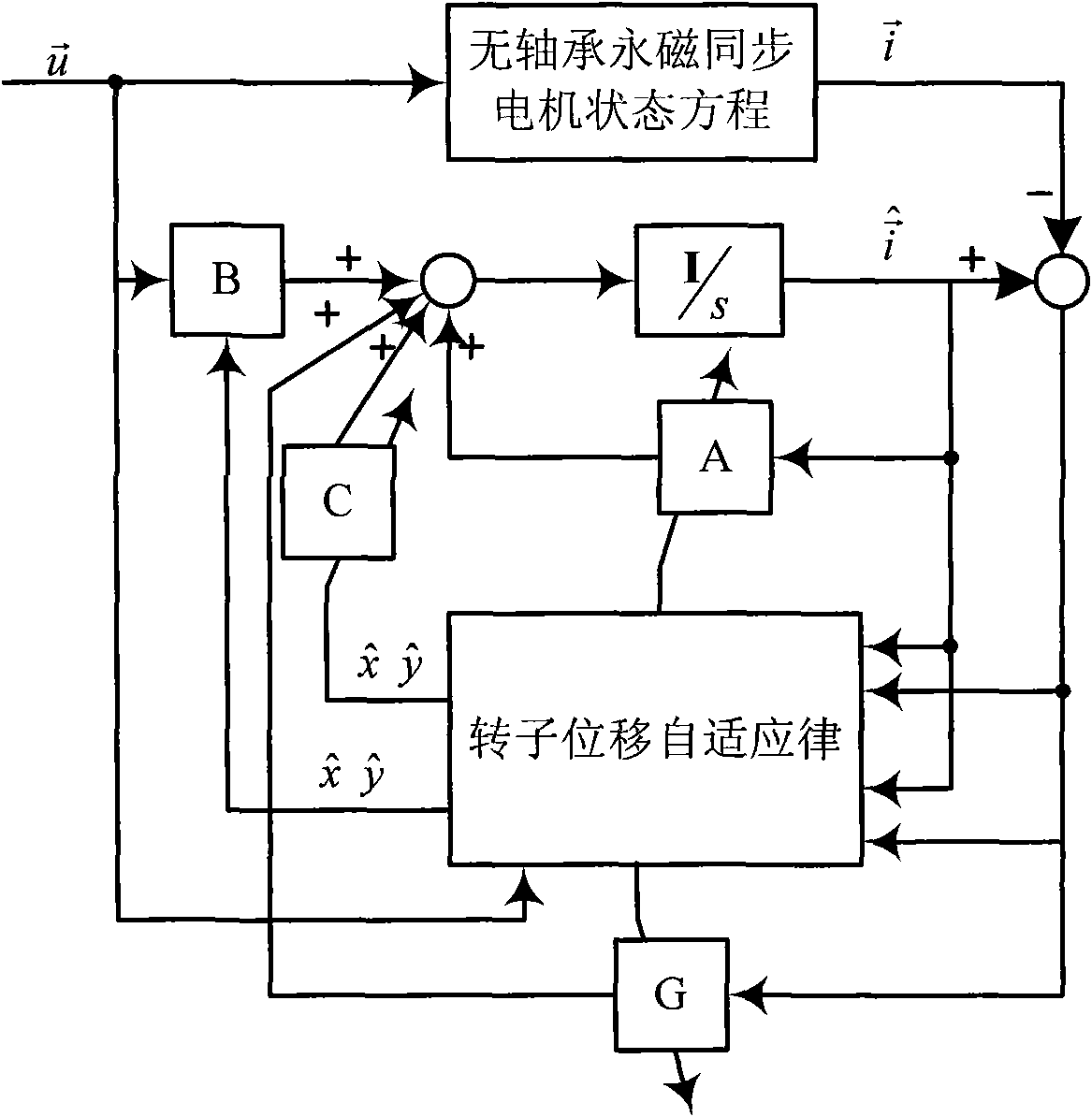

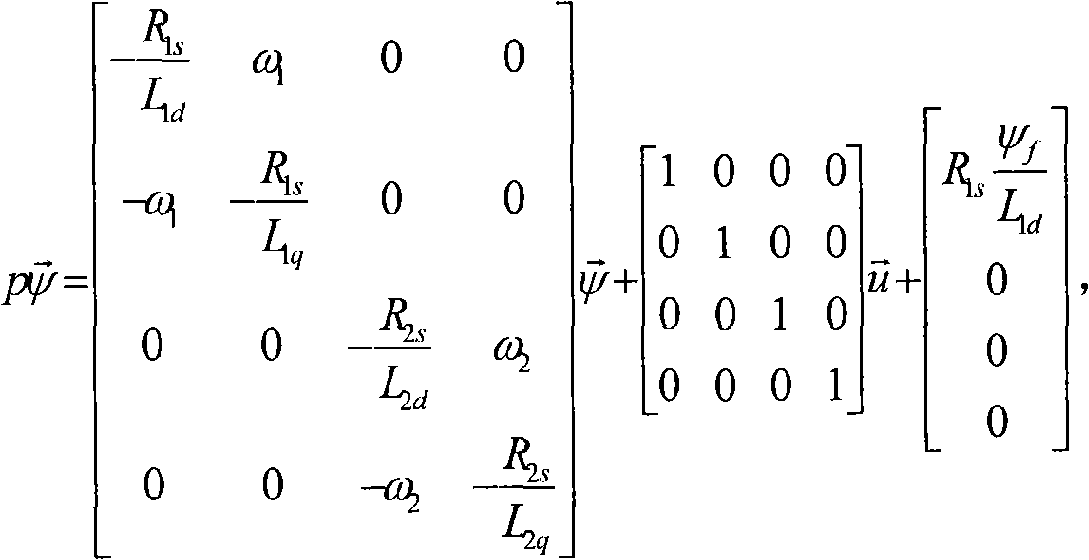

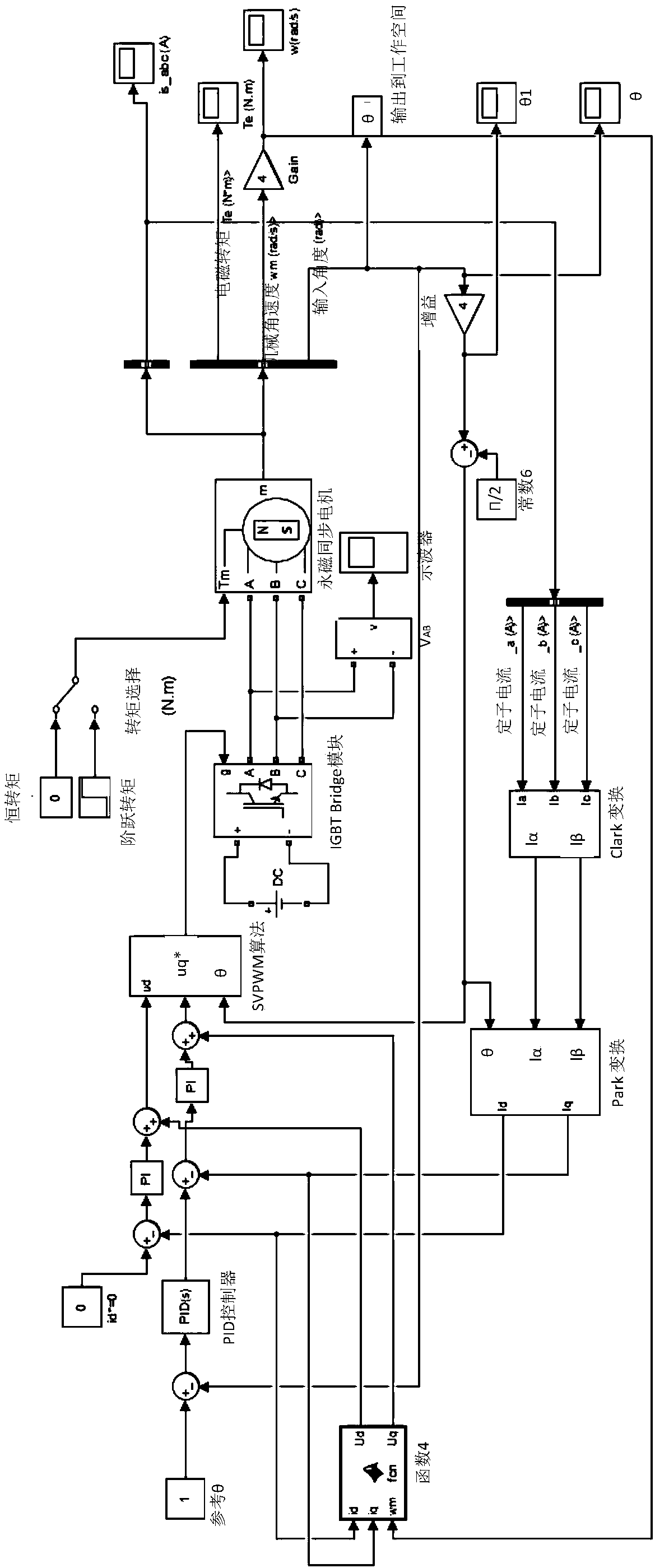

Control method of permanent magnetic bearing-free permanent magnetic synchronous motor non-radial displacement transducer

InactiveCN101667799AShorten the axial lengthLow costVector control systemsDynamo-electric converter controlSynchronous motorMagnetic bearing

The invention discloses a control method of a permanent magnetic bearing-free synchronous motor non-radial displacement transducer, comprising the steps of: building a model reference self-adapting radial displacement evaluating module by detecting the three-phase voltage and the electric current of a torque control winding and a suspension control winding with the model reference self-adapting theory; evaluating the radial displacement * and * by the model reference self-adapting radial displacement evaluating module; respectively comparing the displacement signals* and * with the reference displacement signals X<*> and Y<*>of a given permanent magnetic bearing-free motor rotor; adjusting with a displacement ring PID adjustor to respectively obtain the given suspending force Fx<*>and Fy<*>of the x axis and the y axis; obtaining the given three phase electric current signals i2A<*>, i2B<*>and i2C<*>for controlling the suspension by means of a suspend decoupling control algorithm; andobtaining real-time controlled three phase electric current i2A<*>, i2B<*>and i2C<*>by adjusting an electric current track type inverter. The control method of the non-radial displacement transducer reduces the cost of the system, shortens the axial length of the bearing-free motor, reduces the volume of the system, and improves the reliability of the system.

Owner:SHANGHAI UNIV

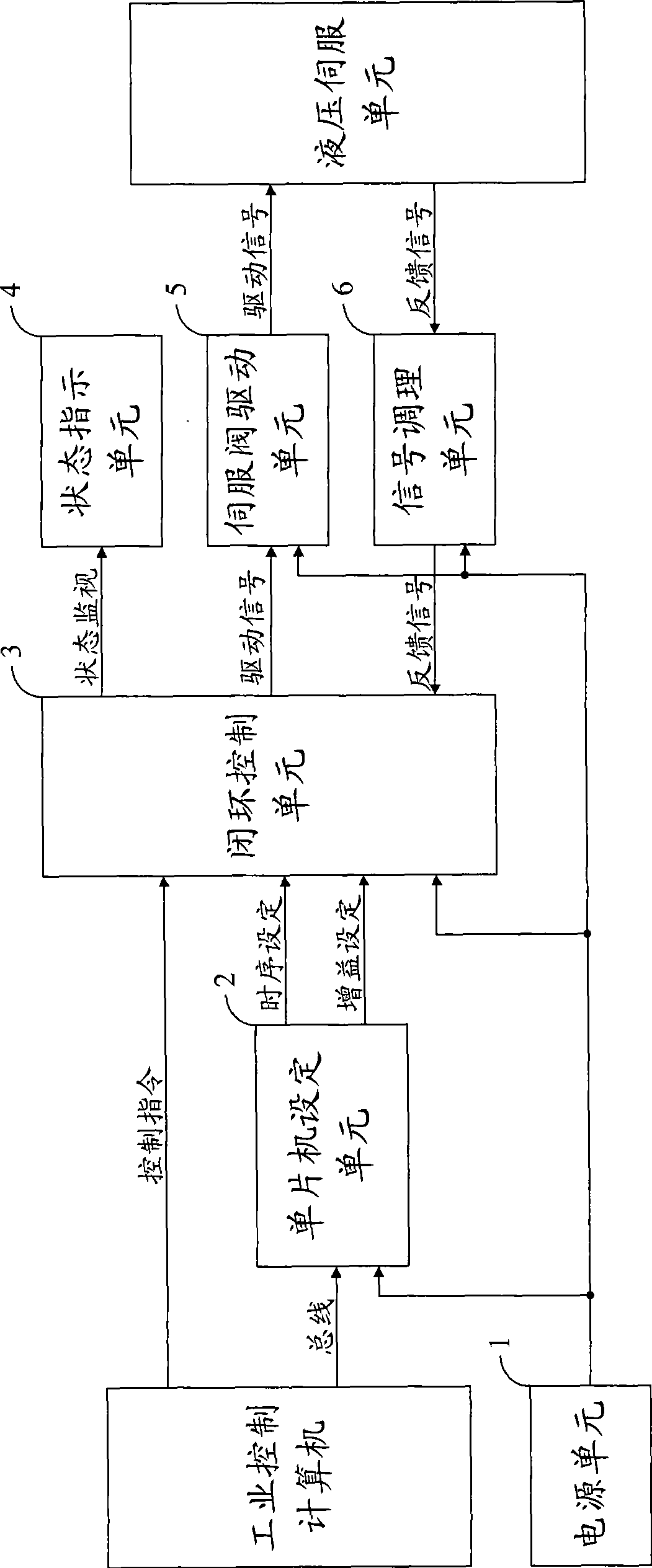

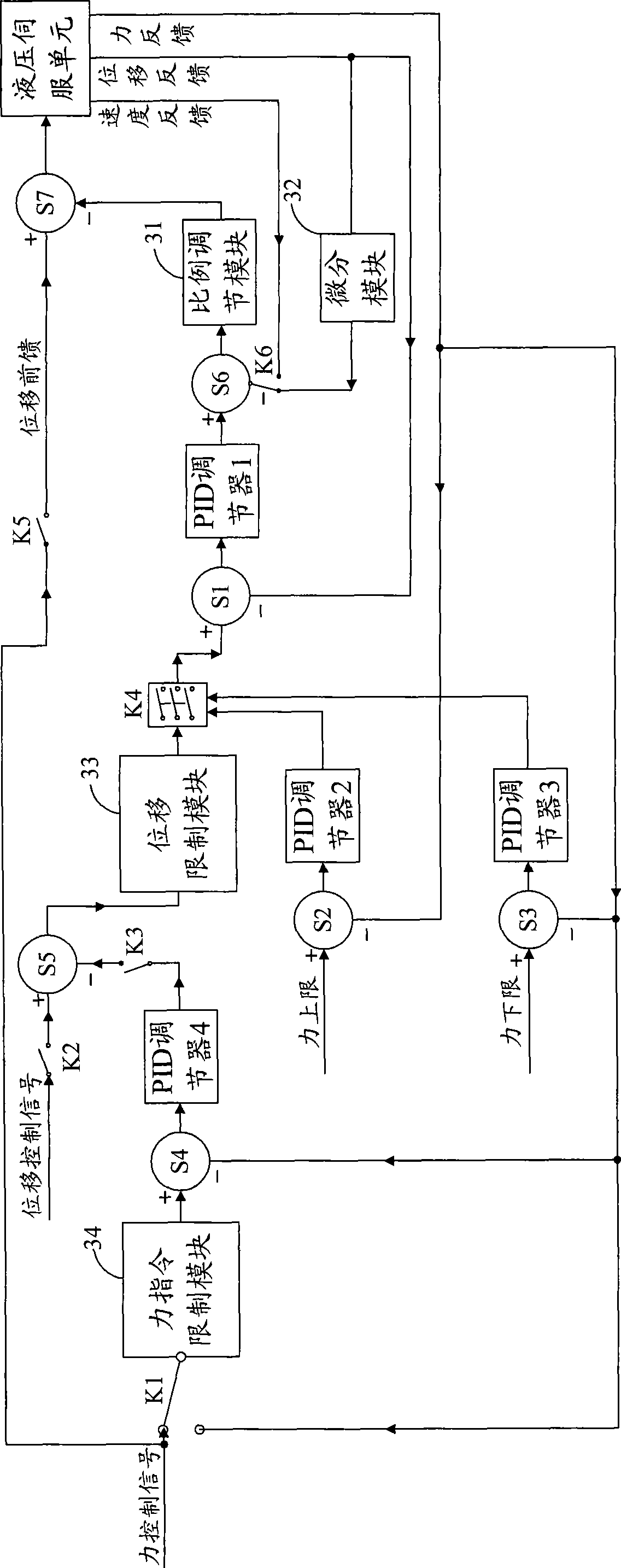

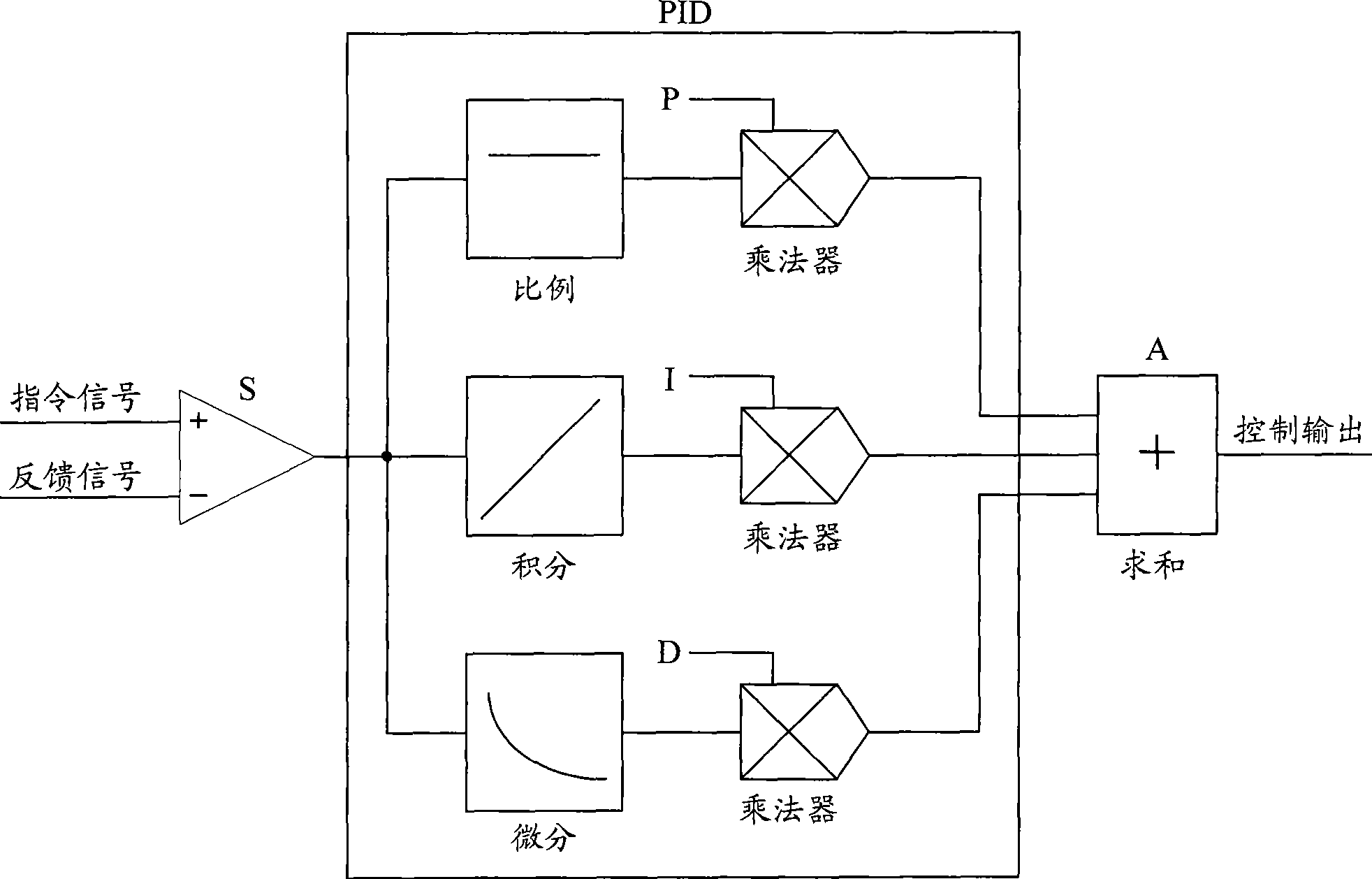

Servo controller and electrohydraulic servo system

ActiveCN101464681AHigh precisionStrong real-timeControllers with particular characteristicsTotal factory controlMicrocontrollerLoop control

The invention is applicable to the servo control filed and provides a servo controller and an electro-fluid servo system. The servo controller comprises a closed-loop control unit used for adopting the PIDF control algorithm to generate driving signals according to the received control signals and feedback signals, a servo valve driving unit used for controlling the movement of an external servo device according to the driving signals generated by the closed-loop control unit, a single chip setting unit used for conducing the parameter setting on the closed-loop control unit, and a power supply unit used for supplying the power to the closed-loop control unit, the servo valve driving unit, and the single chip setting unit. In the invention, the closed-loop control unit adopts the PIDF control algorithm, a PID adjuster is utilized to realize the automatic control gain, the single chip setting unit is utilized to simply, flexibly, and precisely adjust the gain parameters, Therefore, the real-time performance and the interchangeability of the servo controller are improved.

Owner:BYD CO LTD

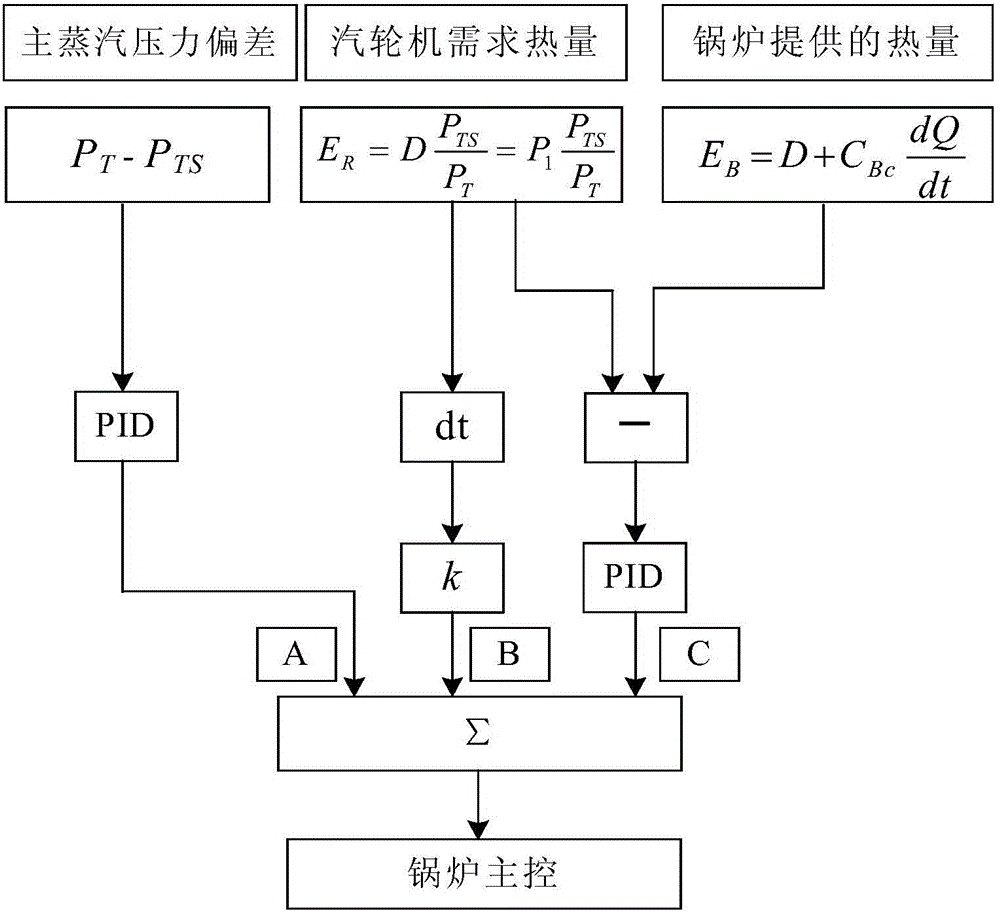

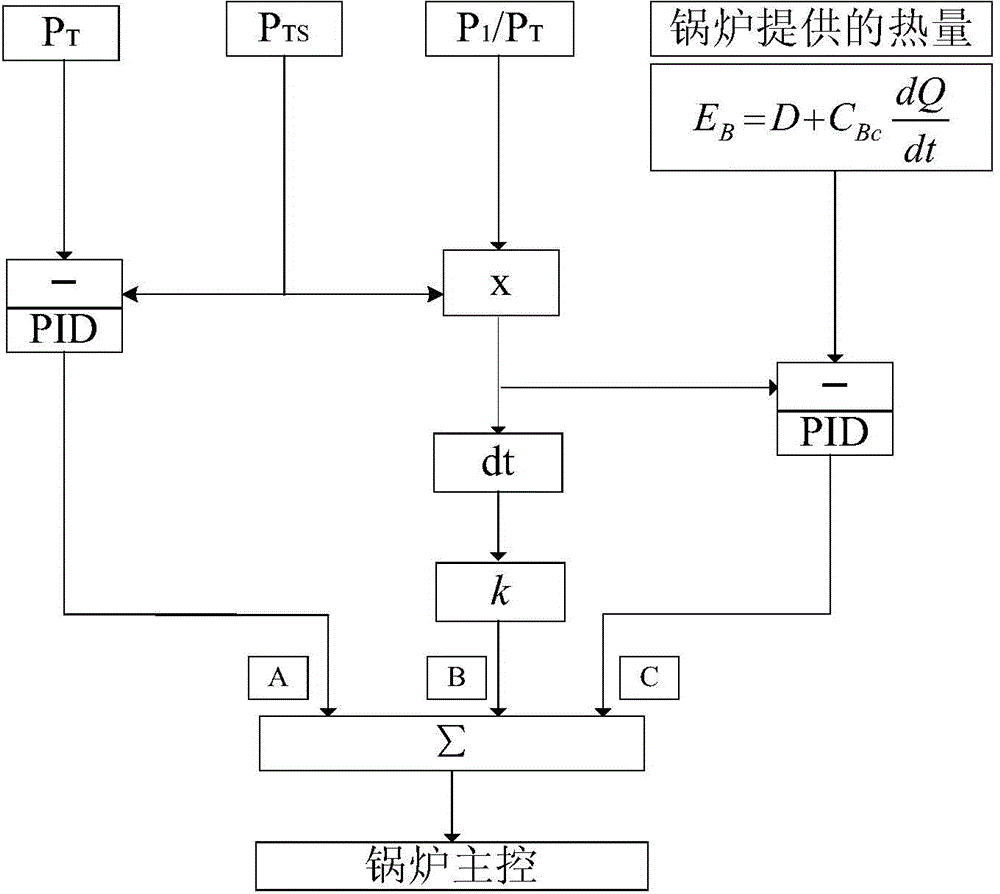

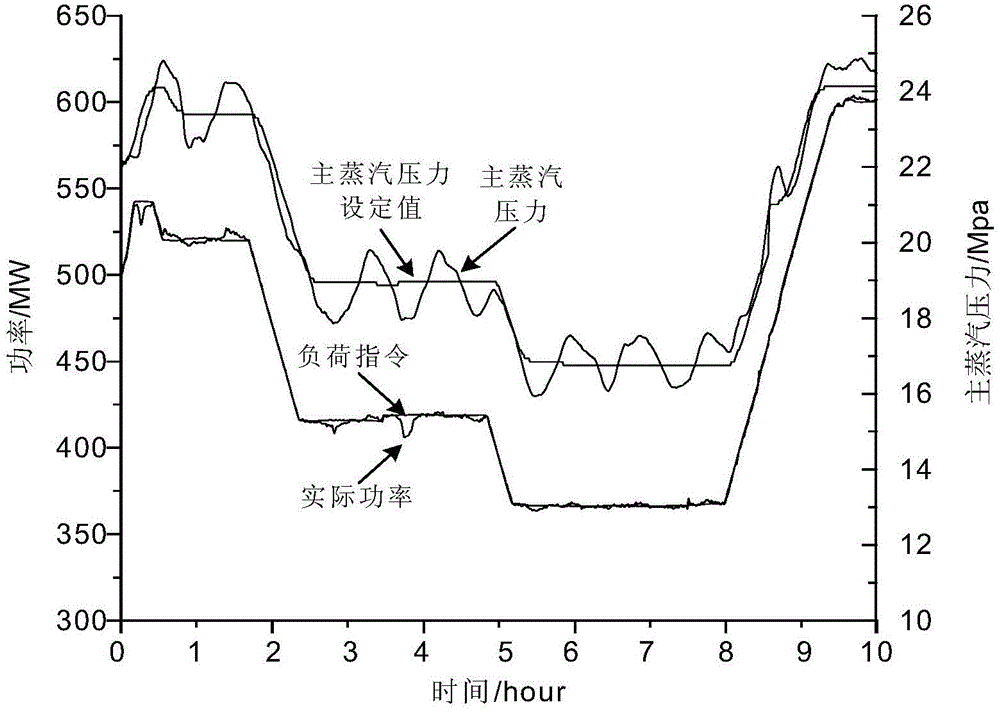

Energy balance-based control method of main steam pressure of supercritical CFB (circulating fluidized bed) boiler

ActiveCN104676574AOvercome stressOvercoming demandsFluidized bed combustionBoiler controlSteam pressureEnergy balanced

An energy balance-based control method of main steam pressure of a supercritical CFB (circulating fluidized bed) boiler includes the steps: S1, after a main steam pressure deviation signal P<T>-P<TS> of a unit is regulated by a PID (proportion integration differentiation) regulator, a signal A is output; S2: a steam turbine demanded heat signal is acquired through a steam turbine energy demand model; S3, a heat signal provided by boiler energy is acquired through an instant carbon mechanism model; S4, subtracting the steam turbine demanded heat signal E<R> by the heat signal E provided by boiler energy is performed, regulating is performed with the PID regulator, and a signal C is output; S5, after subjected to time differentiation, the steam turbine demanded heat signal E<R> is multiplied by a proportional gain k so as to obtain an output signal B, and a sum of the signals B, A and C is output to a boiler master controller; S6, coal feed is regulated according to master control output of a boiler so as to control the main steam pressure. The method has the advantages that regulating quality of the unit can be improved, stability of a main steam pressure control system of the supercritical CFB boiler is improved and ability to respond to load response of the unit is satisfied.

Owner:TSINGHUA UNIV

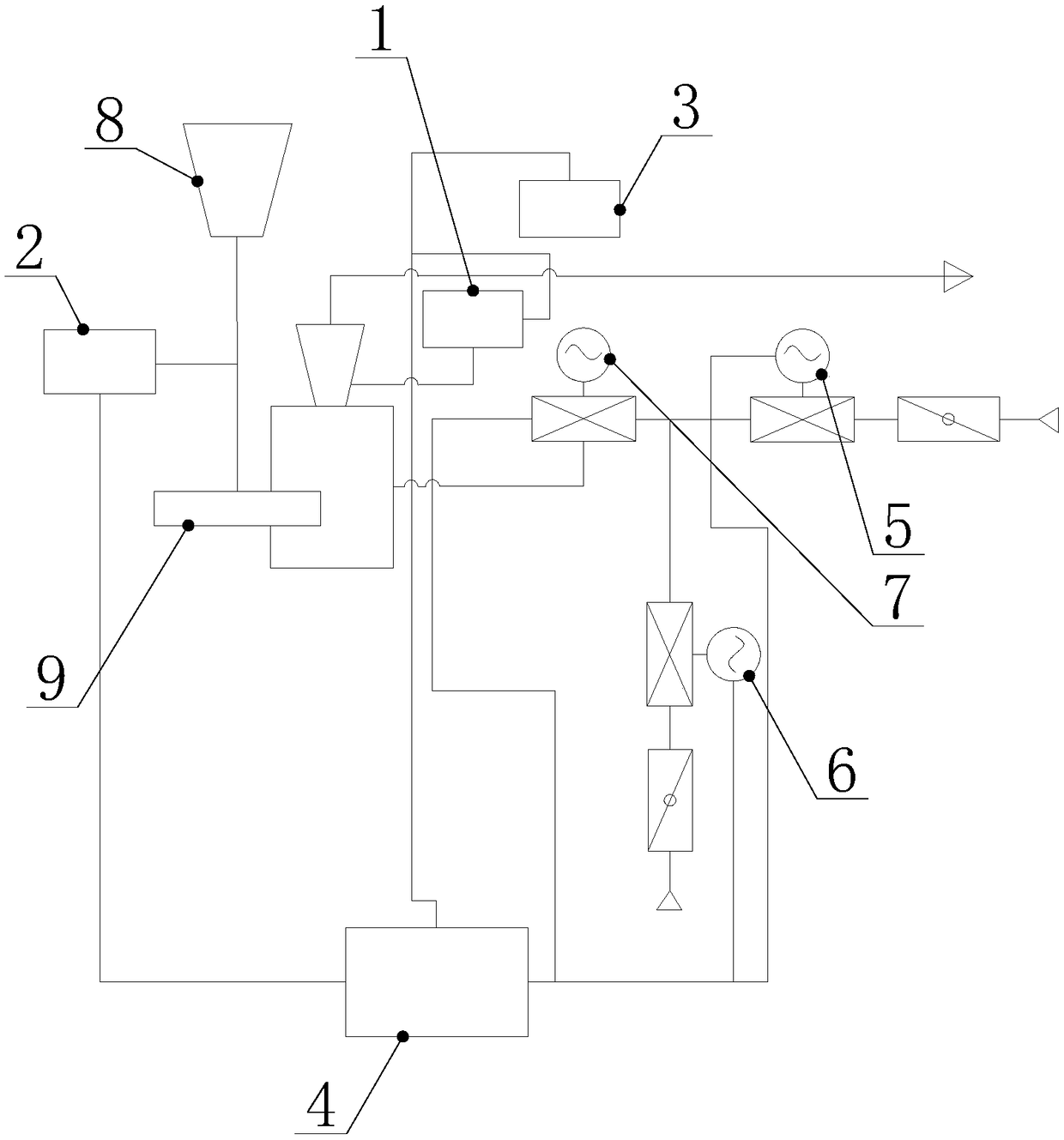

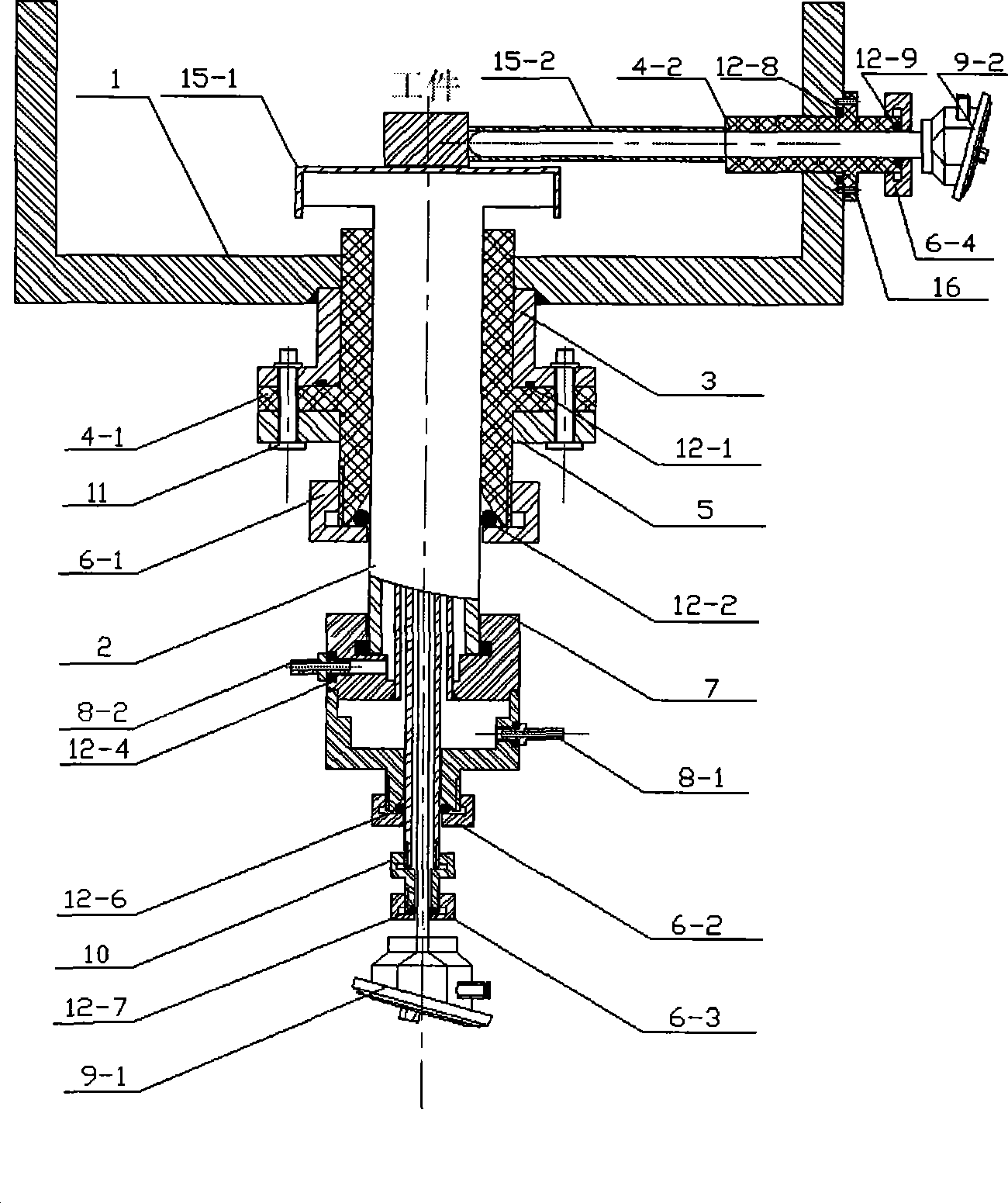

Mechanical digger full power control system and method

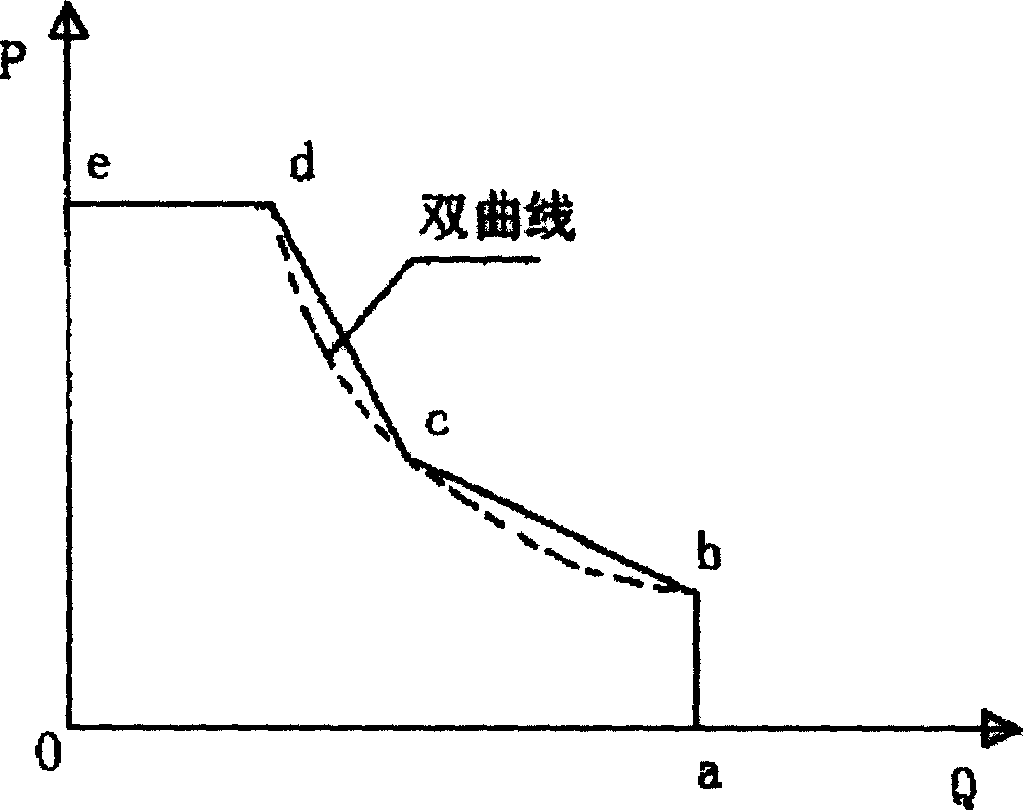

InactiveCN1651665AImprove smoothnessAbsorbed power can be adjustedSoil-shifting machines/dredgersPower control systemControl system

The present invention relates to an excavator all-power control system and its method. Said system mainly includes the following components: main pump, feedforward-feedback regulator, PID regulator and electro-hydraulic proportional valve. Said invention also provides the concrete steps of its control method. Said system not only can save energy, but also can raise power utilization rate, and can implement completely matching of absorption power of oil pump and output power of diesel engine.

Owner:GUANGXI LIUGONG MASCH CO LTD

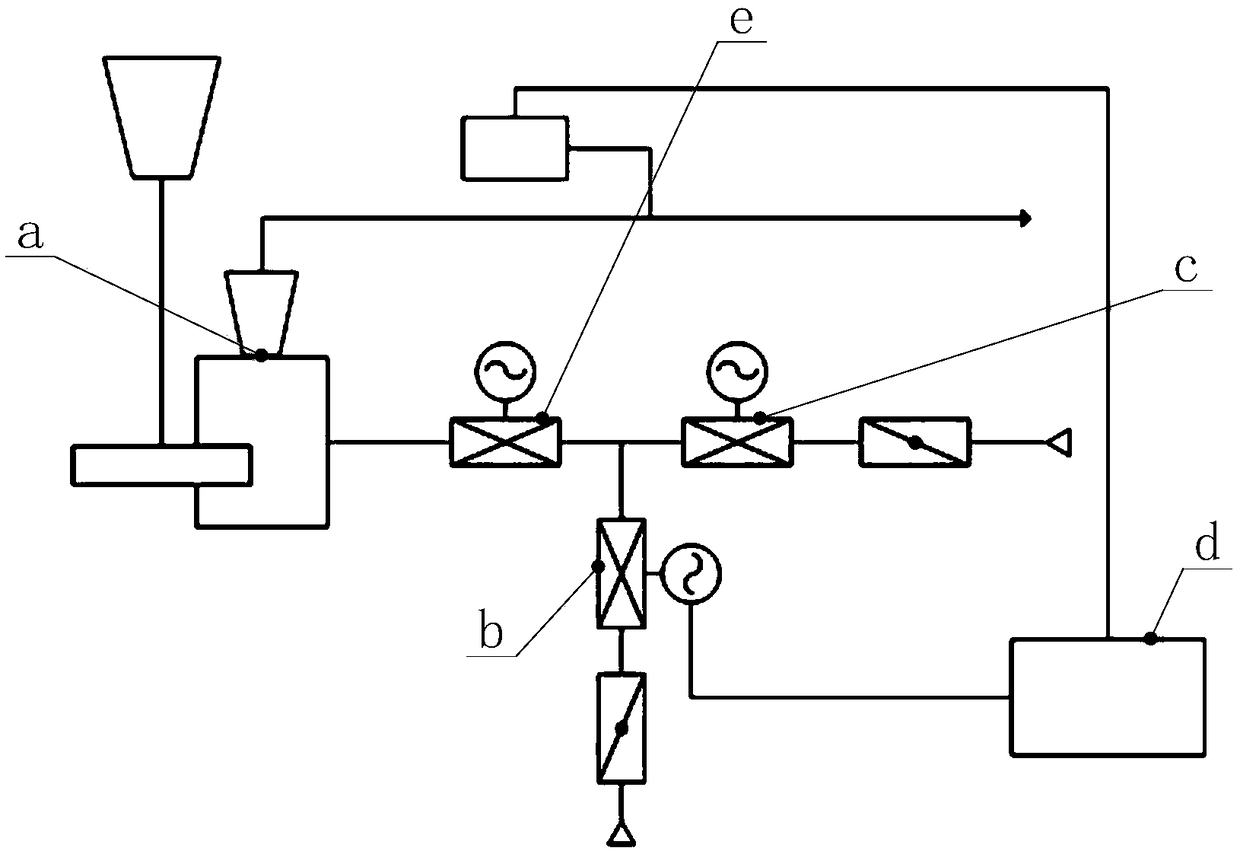

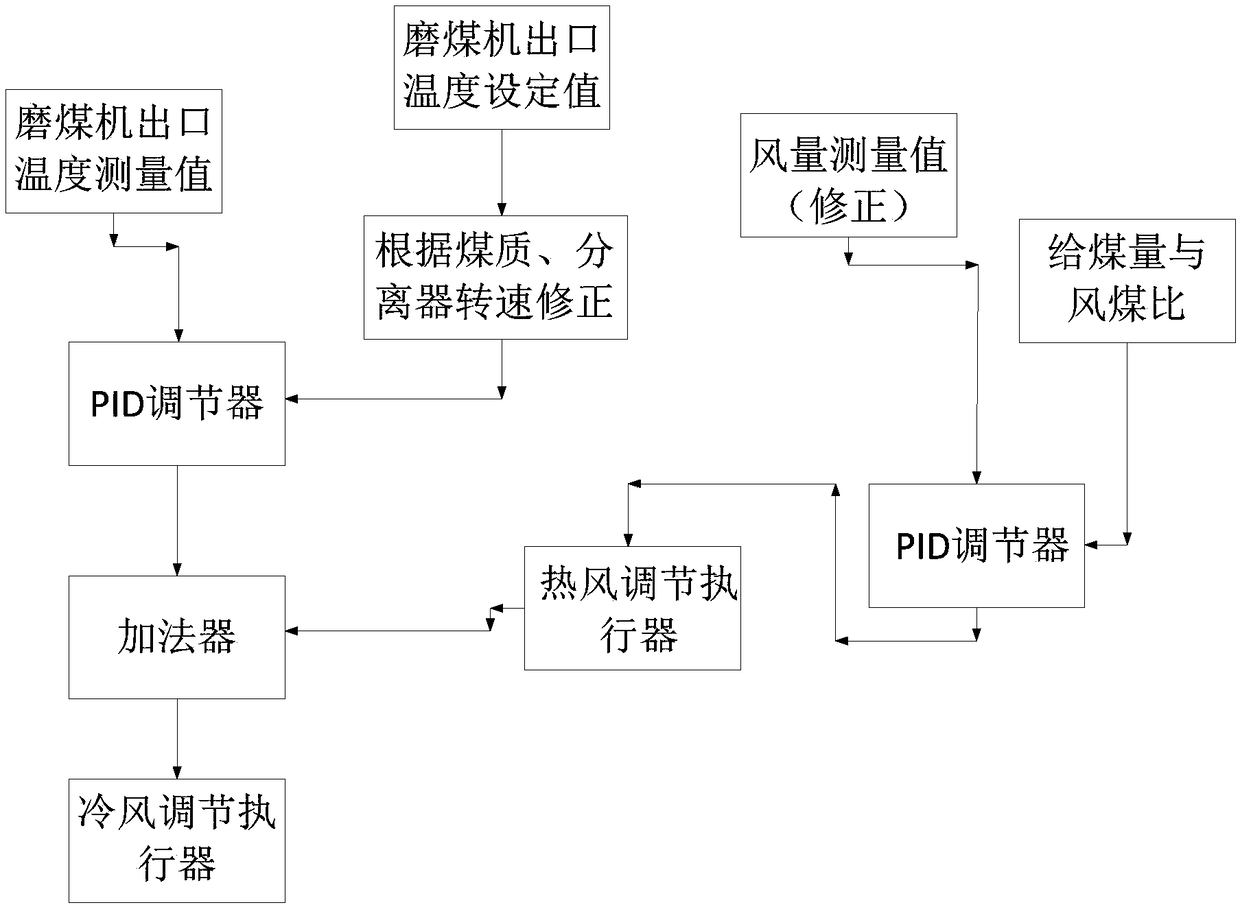

Coal mill outlet temperature control system and method based on pulverized coal fineness online adjustment

The invention provides a coal mill outlet temperature control system based on pulverized coal fineness online adjustment and provides a coal mill outlet temperature control method based on pulverizedcoal fineness online adjustment on the basis of the control system. The coal mill outlet temperature control system comprises a dynamic separator rotating speed measuring device, a coal quality analyzer, outlet temperature measuring devices, a damper adjusting device and a PID adjuster. The coal mill outlet temperature control system has the following control principles that the dynamic separatorrotating speed, the coal quality and the outlet temperature are measured by the dynamic separator rotating speed measuring device, the coal quality analyzer and the coal mill outlet temperature measuring devices, and dynamic separator rotating speed parameters, coal quality parameters and outlet temperature parameters are obtained to serve as control parameters to be sent to the PID adjuster; andthe PID adjuster adjusts a hot air adjusting damper, a cold air adjusting damper and a primary air adjusting damper according to coal quantity values obtained by a coal quantity measuring device, andthus the coal mill outlet temperature is stabilized at the set target temperature. Therefore, the coal mill outlet temperature control system based on the pulverized coal fineness online adjustment ishigh in control precision, and the control method is flexible.

Owner:GUODIAN LONGYUAN ENERGY SAVING TECH

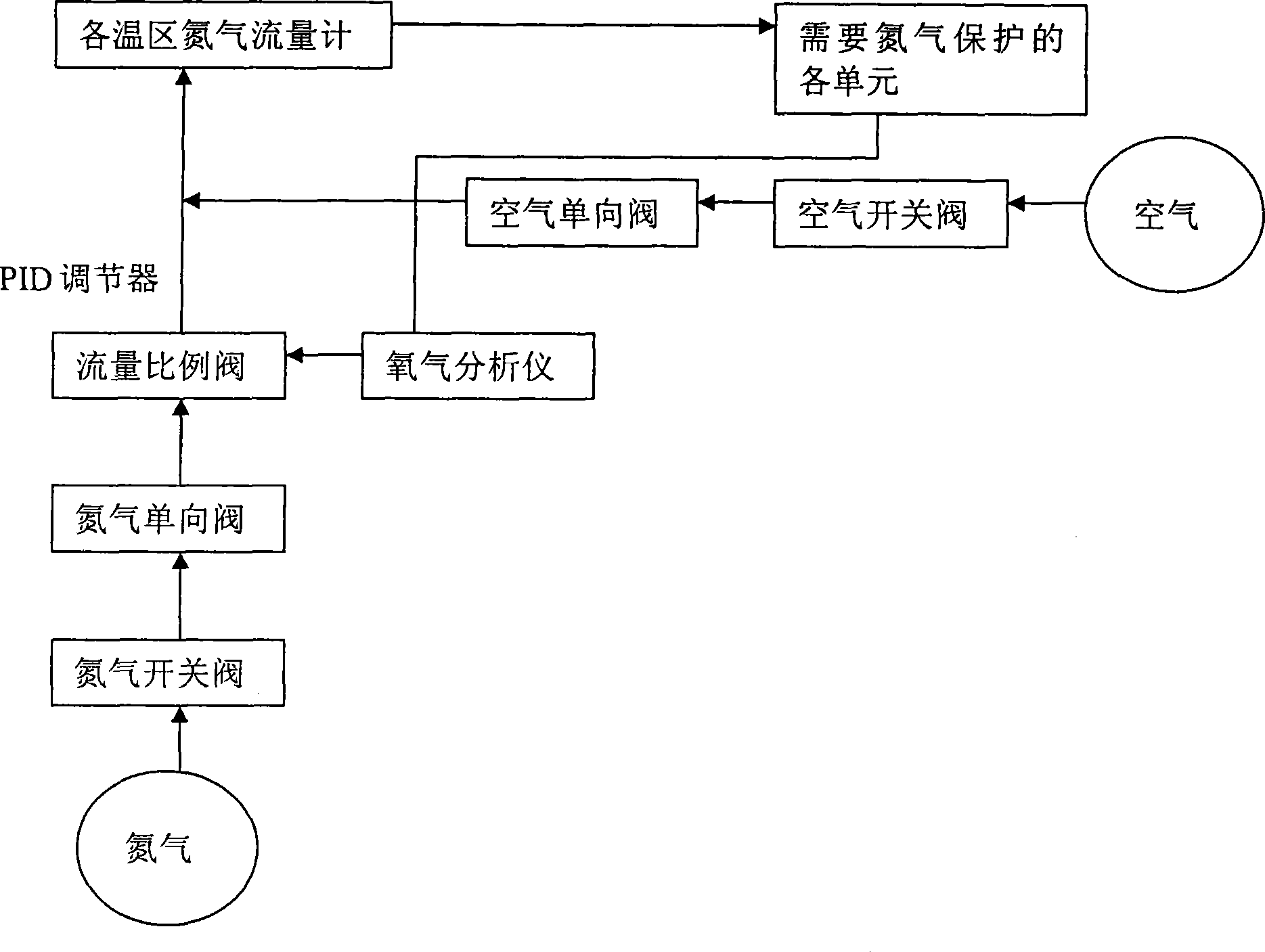

Nitrogen closed-loop control method and system

InactiveCN101364115AAdjust oxygen concentration in real timeGuaranteed normal consumptionControlling ratio of multiple fluid flowsSoldering apparatusProportional controlLoop control

The invention provides a nitrogen gas closed-loop control method and a system which are used for adjusting the oxygen concentration in the hot zone of each unit requiring nitrogen protection in a reflow soldering furnace. An oxygen content analyzer is used for the on-line detection of the oxygen content of the gas inside the reflow soldering furnace; and a PID adjustor periodically adjusts the opening degree of a proportional control valve based on the closed-loop feedback, thereby controlling the nitrogen flow. The control method and the system can automatically detect the gas environmental conditions inside the reflow soldering furnace, automatically control the oxygen concentration in each hot zone inside the reflow soldering furnace, ensure that the oxygen concentration reaches the desired preset value as quickly as possible, and maintain the oxygen concentration at the preset value. The control method and system have the advantages of stable soldering environment, high soldering quality, low nitrogen consumption and low production cost.

Owner:PANDA ELECTRONICS GROUP +1

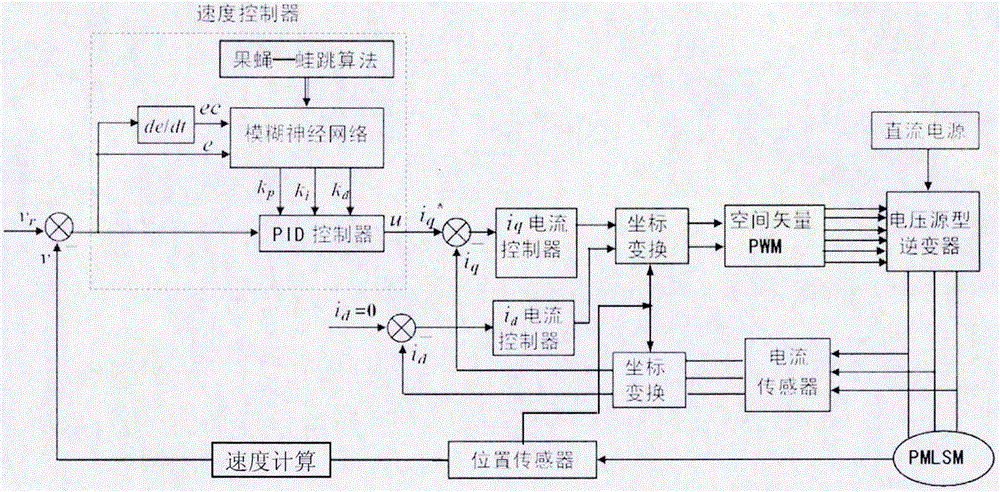

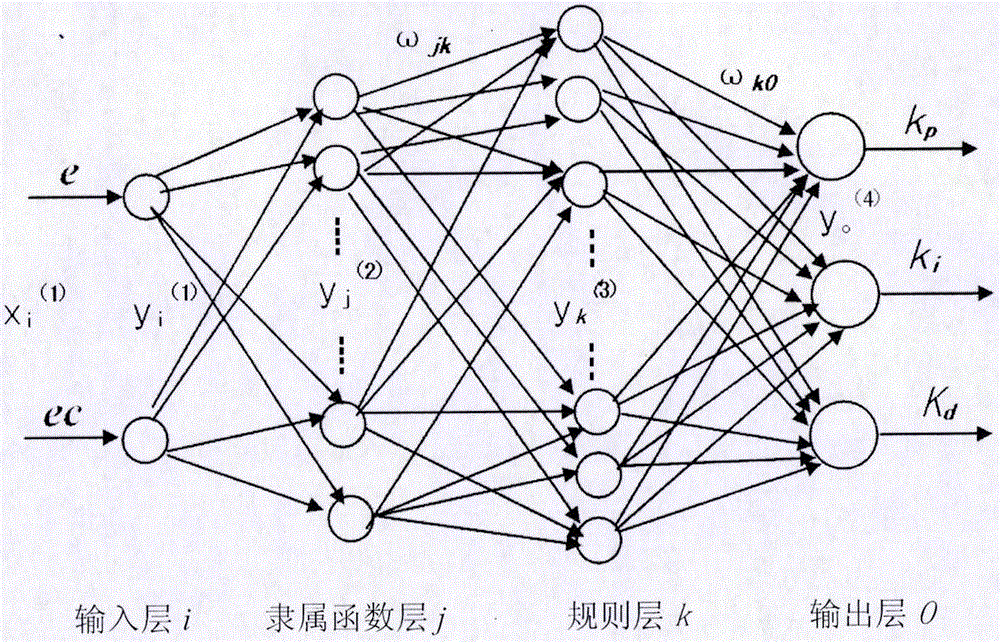

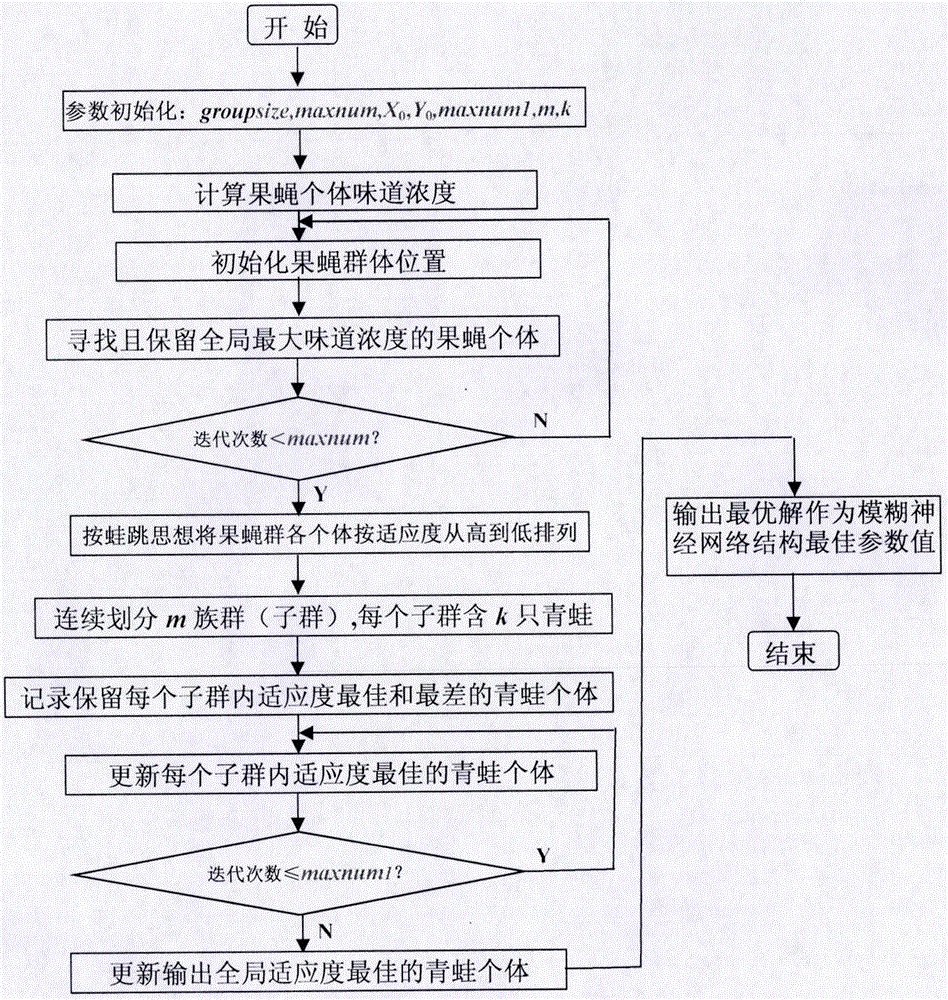

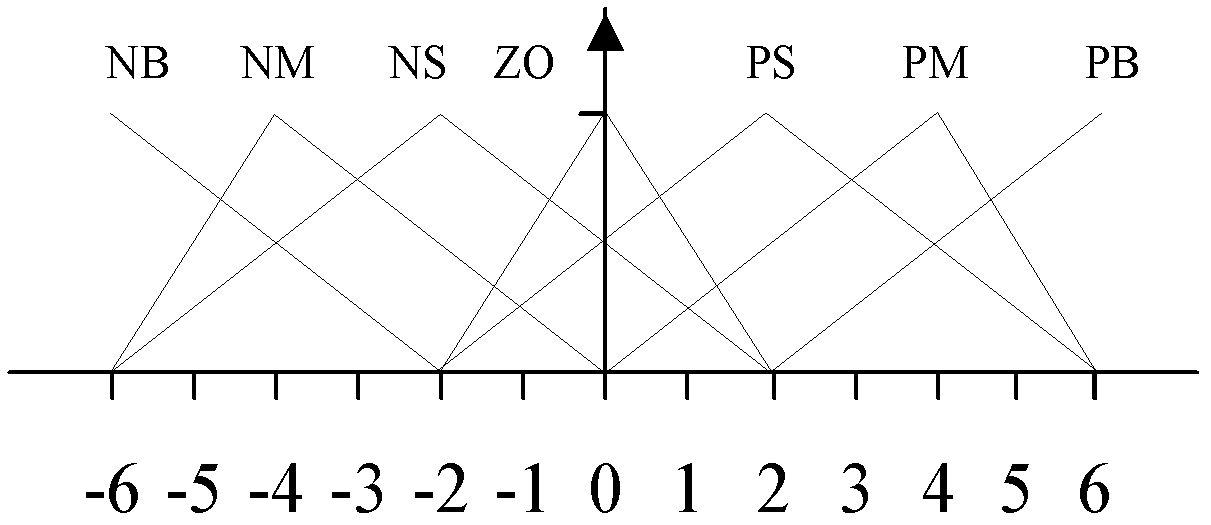

Fruit fly-leapfrog-based linear synchronous motor control method employing fuzzy neural network PID

InactiveCN106849814AStrong global search optimizationFast convergence performanceElectronic commutation motor controlAC motor controlControl systemSelf adaptive

The invention discloses a fruit fly-leapfrog-based linear synchronous motor control method employing a fuzzy neural network PID. A control system comprises an outer speed loop and an inner current loop, the current loop is designed into a traditional PID adjuster and the speed loop is designed into a fuzzy neural network PID speed controller; a fruit fly-leapfrog hybrid algorithm is formed through fusing a fruit fly optimization algorithm and a leapfrog algorithm; structure parameters of a fuzzy neural network are adjusted and optimized in real time, optimal parameters kp, ki and kd suitable for the PID controller are output and self-adaptation and intellectualization of speed control on a permanent-magnet linear synchronous motor are achieved. Simulation analysis and experiment results show that the control accuracy and the disturbance resistance of a permanent-magnet linear synchronous motor control system can be improved by adopting a fuzzy neural network PID speed control strategy optimized on the basis of the fruit fly-leapfrog hybrid algorithm, and an excellent control effect is achieved.

Owner:WUXI OPEN UNIV

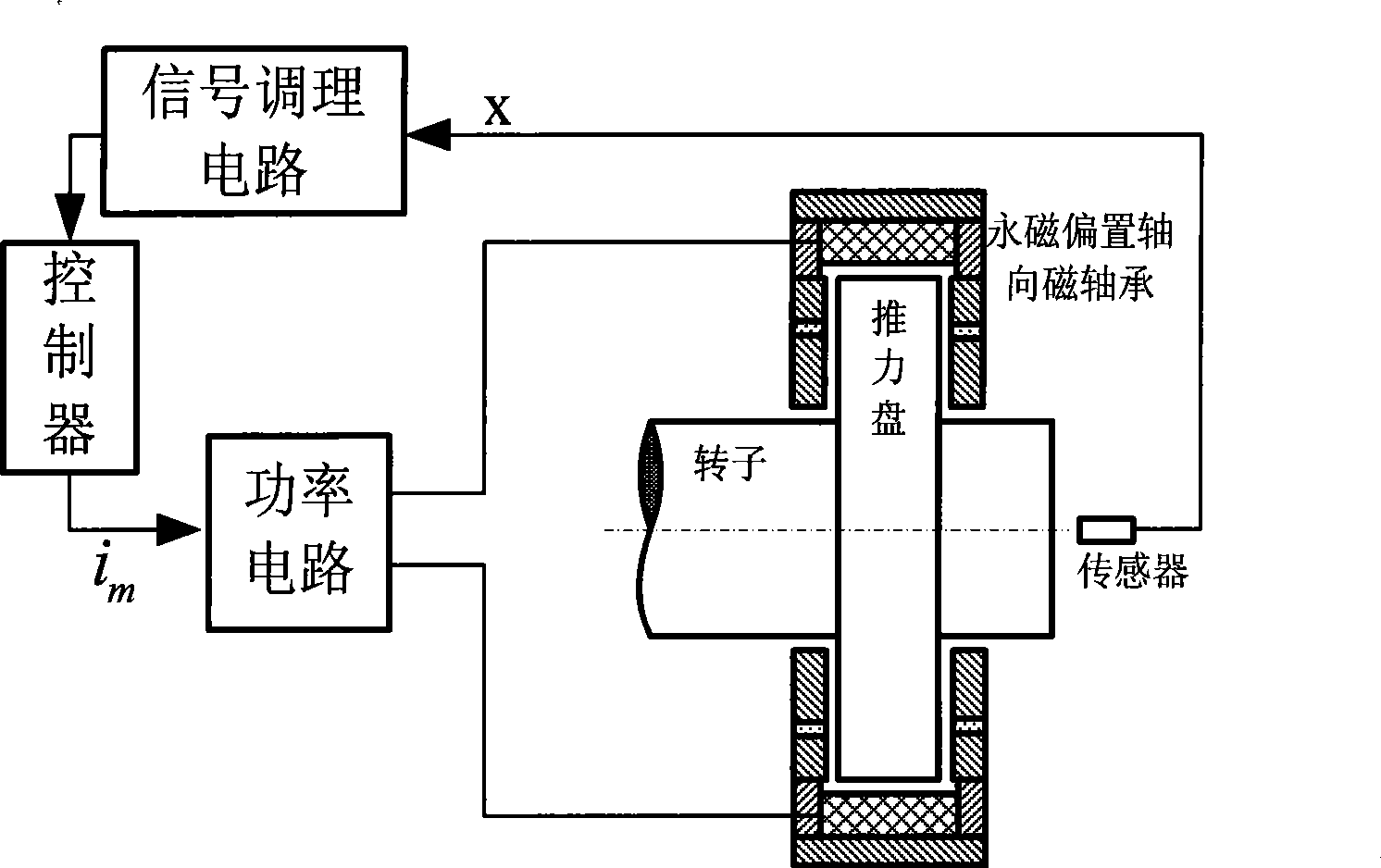

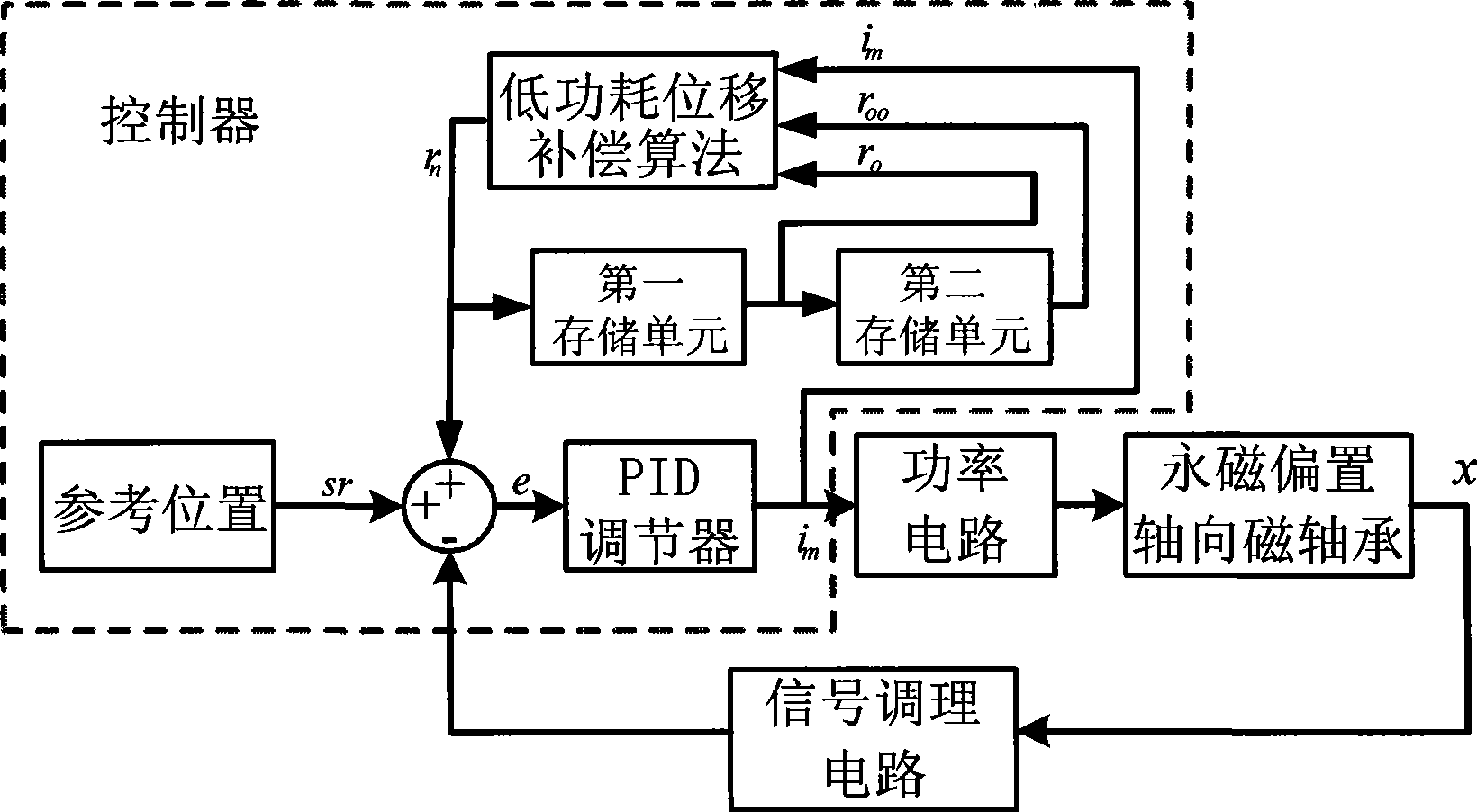

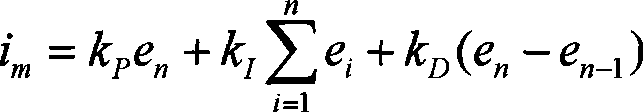

Method for implementing low power consumption suspension of five-freedom degree magnetic suspension system axial magnetic bearing

The invention discloses a method for realizing low power consumption suspension of an axial magnetic bearing, which comprises the following steps: (1) superposing a feedback displacement signal x of a rotor, a given reference position sr and a displacement compensating signal rn to obtain an error signal e; (2) adding the error signal e into a PID adjuster to obtain control current im; (3) amplifying the control current im and inputting the control current im to a permanent magnet biased magnetic bearing; (4) at the same time, adding the im as a feedback signal, a displacement compensating signal ro at the previous moment and a displacement compensating signal roo at the more previous moment output by a two-level storage unit into a low power consumption displacement compensating module to obtain a displacement compensating signal rn; and (5) stacking the rn, the sr and the x to generate the error signal e after the rn is obtained,; at the same time, putting the rn into the storage unit as the ro of the next moment, and putting the ro into the storage unit of next level as the roo of the next moment. Therefore, the whole control flow is circularly operated. The control current in an axial control coil reaches to be minimum, and the method realizes low power consumption.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

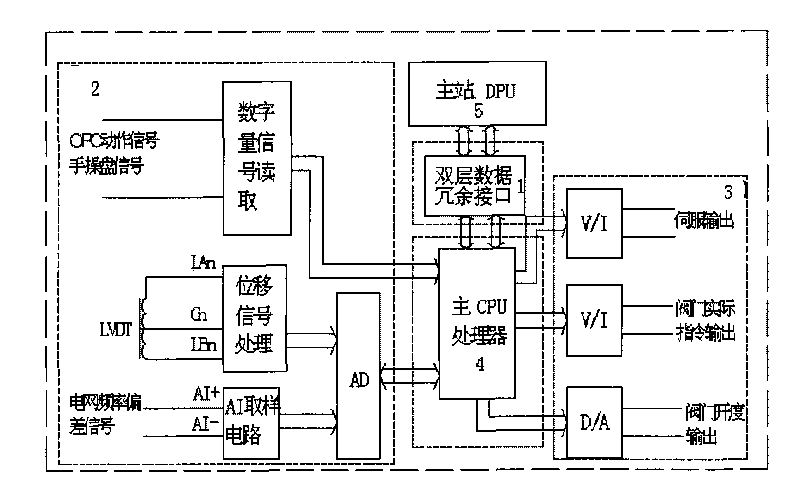

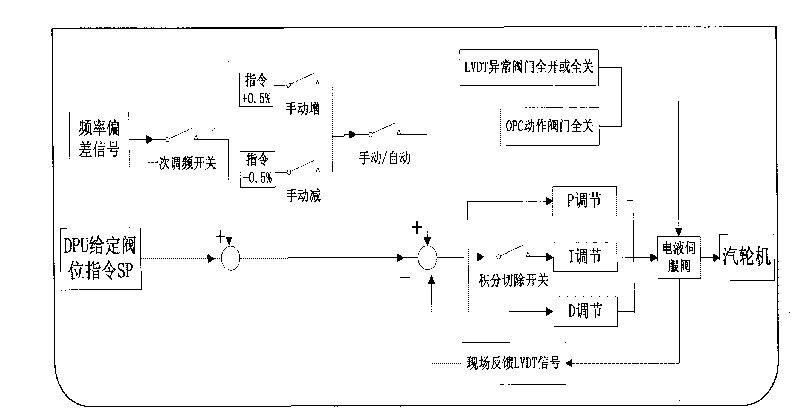

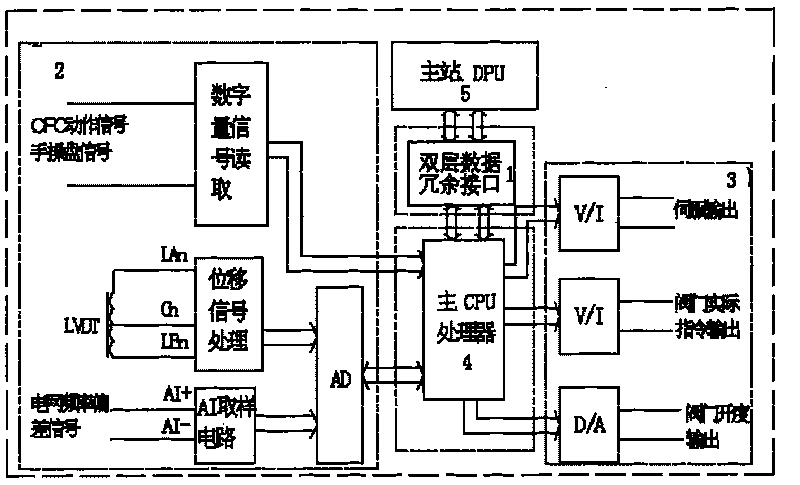

Single-channel servo control module

InactiveCN101725376AWith manual functionDoes not cause the door to vibrateServomotor componentsMachines/enginesIndustrial settingSoftware

The invention discloses a single-channel servo control module which comprises a double-layer data redundancy interface, a signal collecting detection interface, a servo driving interface, and a module main central processing unit (CPU). The data redundancy transmission interface forms a data transmission channel, and is connected with the module main central processing unit. The signal collecting detection interface collects the valve position and the handle operating panel information, and is connected with the main central processing unit. The servo driving interface drives the on-site electro-hydraulic servo valve, and is connected with the main central processing unit. The data redundancy transmission interface exchanges data with the main station DPU. A valve position given signal sent by the DPU and an LVDT feedback signal of the on-site oil motor are processed by a PID adjuster in the main central processing unit, the servo current is outputted to drive the electro-hydraulic servo valve, and then the valve-regulating travel of the turbine is controlled. The invention can reliably run in a long period under poor industry environments, and can monitor various working states in the clamping pieces through communication ports, and the interior software can be upgraded on line.

Owner:NANJING SCIYON AUTOMATION GRP

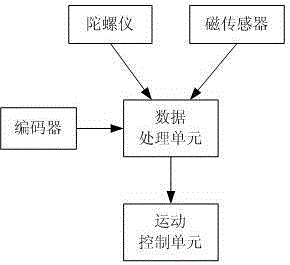

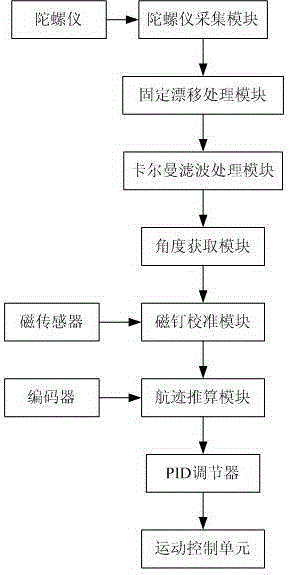

AGV inertial navigation system

InactiveCN105180930ALow costReduce laying workloadNavigation by speed/acceleration measurementsGyroscopeEngineering

The invention discloses an AGV (Automatic Guided Vehicle) inertial navigation system which comprises a gyroscope, a magnetic nail, an encoder, a magnetic sensor, a data processing unit and a motion control unit, wherein the gyroscope is arranged on an AGV vehicle; the magnetic nail is paved on a ground AGV channel; the magnetic sensor is arranged on a central line at the bottom of a vehicle head of the AGV vehicle; the gyroscope, the magnetic sensor, the encoder and the motion control unit are respectively connected with the data processing unit; the encoder, the data processing unit and the motion control unit are arranged in a control box on the AGV vehicle; the data processing unit comprises a gyroscope collecting module, a fixed shifting processing module, a Kalman filtering processing module, an angle acquiring module, a magnetic nail aligning module, a track plotting module and a PID (Proportion Integration Differentiation) regulator which are connected with each other in turn; the encoder is connected with the track plotting module; the PID regulator is connected with the motion control unit. The angle accuracy of the system is + / -0.1 degree, the track plotting accuracy is + / -5mm and the navigation precision is + / -10mm.

Owner:CHENGDU SIWI HIGH TECH IND GARDEN

Control system and method for improving the rapid boiler adjusting capability of unit generating set

ActiveCN104932566ASafe and stable operationPrevent vibration and divergenceFluid pressure control using electric meansEngineeringPid regulator

The invention discloses a control system and method for improving the rapid boiler adjusting capability of a unit generating set. The system comprises a deviation sampling module, an automatic boiler pressure PID regulator, an integrated calculation module, a feedforward generation module and a feedforward output amplitude limit module, one input signal of the automatic boiler pressure PID regulator is a signal directly from the deviation sampling module, the other input signal of the automatic boiler pressure PID regulator is a signal which is processed by the integrated calculation module, the feedforward generation module and the feedforward output amplitude limit module, and the output end of the automatic boiler pressure PID regulator is connected with a boiler control system. The control system of the invention can solve the problem that the working condition is instable for a long time due to wide fluctuation of the main vapor pressure of the set when the set adjusts the load rapidly, prevents the operational pressure of the set from oscillation and divergency, and ensures that the power generating set runs safely and stably.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Automatic adjusting method of water supply pressure

InactiveCN104675686ARelieve pressureConstant pressurePump controlPositive-displacement liquid enginesFrequency changerProportion integration differentiation

The invention belongs to the field of industrial water supply auto-control systems and provides an automatic adjusting method of water supply pressure. A pressure transmitter is mounted on a discharge master pipe of a water supply pump; a regulator is installed in a control room; a frequency converter is mounted in a pump control cabinet; an output signal of the pressure transmitter is connected to the input end of the regulator; the output signal subjected to constant pressure regulation by the regulator is connected to the input end of the frequency converter; output of the frequency converter is connected to a pump motor. A network pressure signal detected by the pressure transmitter is sent to a PID (proportion integration differentiation) regulator, a given pressure value is set in the regulator, actual pressure detected is compared with the given pressure value, a reverse mA value is output, the frequency converter is controlled to output proper frequency, running speed of the pump motor is changed, balance of water supply is adjusted, and constant pressure of a discharge network is achieved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

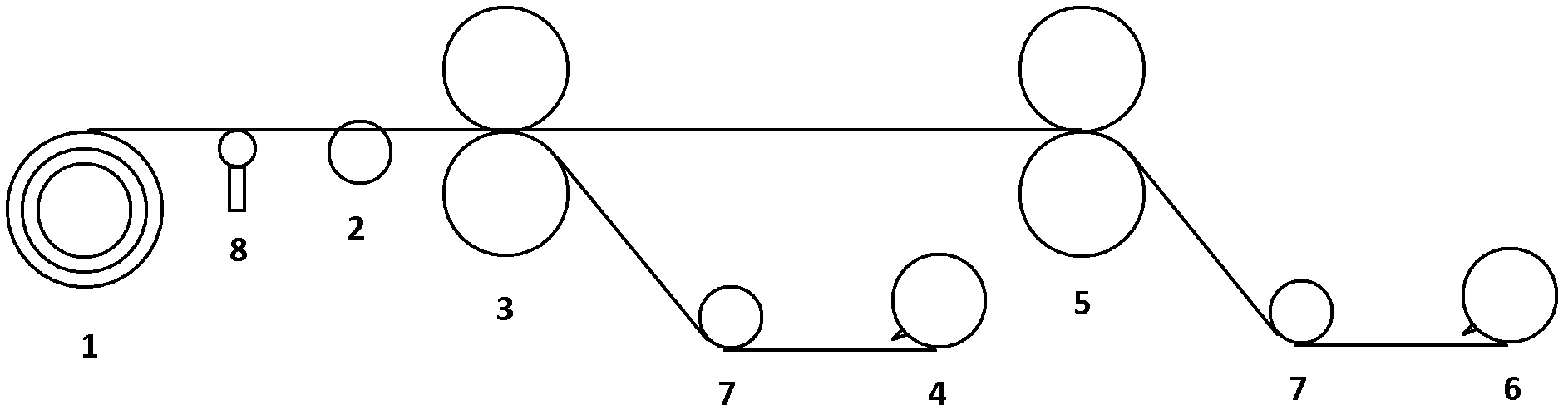

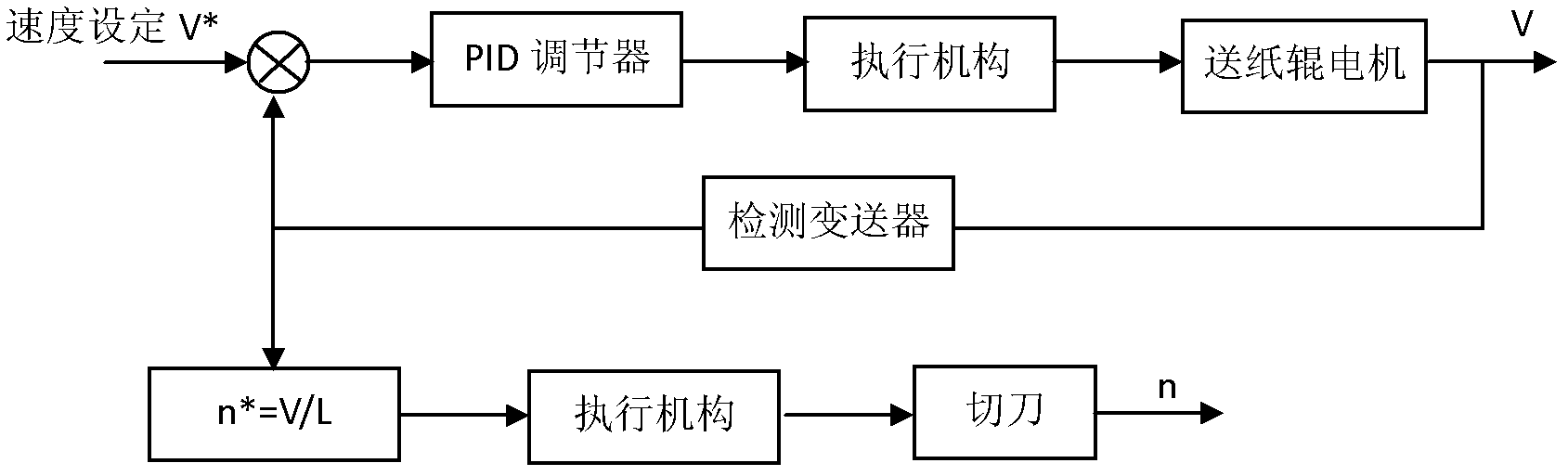

Feed-forward-fuzzy proportion integration differentiation (PID) control-based control method for paper cutting machine

InactiveCN102621882AImprove anti-interference abilityImprove dynamic performanceControllers with particular characteristicsMetal working apparatusProportion integration differentiationControl system

The invention relates to a feed-forward-fuzzy proportion integration differentiation (PID) control-based control method for a paper cutting machine. The method comprises the following steps of: setting a paper cutting length and the frequency of a cutter after system initialization, cutting paper under the control of a single-closed loop control and ratio control system, and stopping the paper cutting machine after the cutting of the paper is finished. The speed V of a paper feeding roller is controlled in a fuzzy PID control way on the basis of the conventional single-closed loop control andratio control over the speed of the cutter, so that the dynamic response and steady-state characteristics of a system are improved; namely, a fuzzy control mode is adopted, and a fuzzy controller is additionally arranged on a PID regulator, takes an error value E and an error change rate DeltaE as input language variables, and takes a proportional gain coefficient KP, an integral gain coefficientKI and a differential gain coefficient KD as output language variables, so that the PID regulator is controlled; and in addition, a feed-forward controller is arranged behind an execution mechanism, so that the problem that the speed V of the paper feeding roller is fluctuated by load disturbance is solved, and the fluctuation of the rotating speed n of the cutter is also alleviated.

Owner:QILU UNIV OF TECH

Intelligent air conditioner fresh air controlling device

InactiveCN103629786AReduce energy consumptionExtended service lifeEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsHysteresisElectricity

The invention discloses an intelligent air conditioner fresh air controlling device. The intelligent air conditioner fresh air controlling device comprises a fresh air pipe, an air return pipe, a waste heat recovery device and a PID adjusting device. An air inlet of the fresh air pipe is communicated with an outdoor air inlet air channel, and an air inlet of the air return pipe is communicated with an indoor air exhaust air channel. An air outlet of the fresh air pipe and an air outlet of the air return pipe are connected to the waste heat recovery device. The air inlet of the fresh air pipe and the air inlet of the air return pipe are provided with a plurality of sensors, and pipelines of the fresh air pipe and the air return pipe are provided with solenoid valves, and the sensors and the solenoid valves are electrically connected to the PID adjusting device. The waste heat recovery device is further connected with an air processor, an outlet of the air processor is communicated with the indoor part through an air supplying pipeline, and the air supplying pipeline is provided with an air feeder. According to the intelligent air conditioner fresh air controlling device, the purpose of operation in an energy-saving mode is achieved, the hysteresis of manual adjusting is avoided, a large number of manpower and material resources are omitted, and using and popularization are convenient.

Owner:昆山贝环电子技术服务有限公司

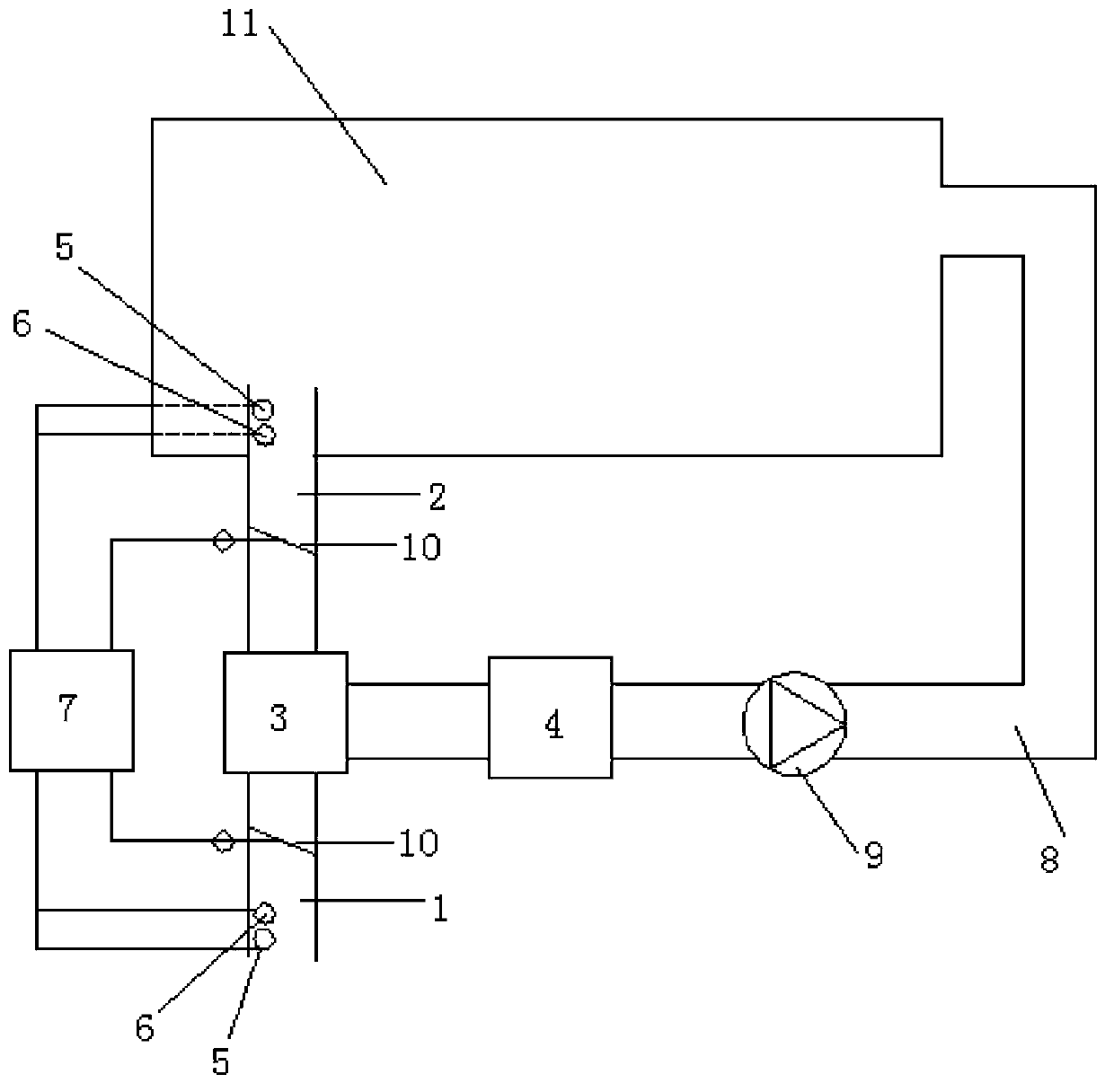

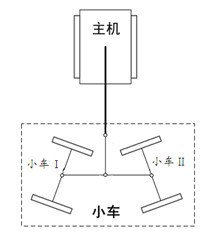

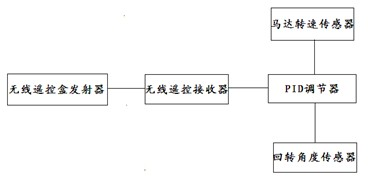

Wireless remotely-controlled deviation-checking device for crawler-type counterweight trolley and control method thereof

InactiveCN102060243AImprove work efficiencyGuaranteed synchronous controlCranesLoad-engaging elementsProportion integration differentiationRemote control

The invention provides a wireless remotely-controlled deviation-checking device for a crawler-type counterweight trolley, which comprises a wireless remote-control box transmitter, a wireless remote-control receiver, a PID (Proportion Integration Differentiation) regulator, a motor revolution speed sensor and a rotation angle sensor, wherein the wireless remote-control box transmitter is connected with the wireless remote-control receiver, the wireless remote-control receiver is connected with the PID regulator, and the motor revolution speed sensor and the rotation angle sensor are both connected with the PID regulator. In the wireless remotely-controlled deviation-checking device for the crawler-type counterweight trolley and a control method thereof, disclosed in the invention, the action type of the counterweight trolley is selected through the wireless remote-control box transmitter, and deviation-checking operation is executed for the crawler-type counterweight trolley through the wireless remote-control receiver, various corresponding sensors, PID regulator and other electric devices, and thus, the synchronous control of a crawler crane host machine and the counterweight trolley is ensured. The wireless remotely-controlled deviation-checking device for the crawler-type counterweight trolley and the control method thereof are easy to operate, have high accuracy and are favorable for effectively improving the working efficiency of crawler cranes.

Owner:SHANGHAI SANY TECH

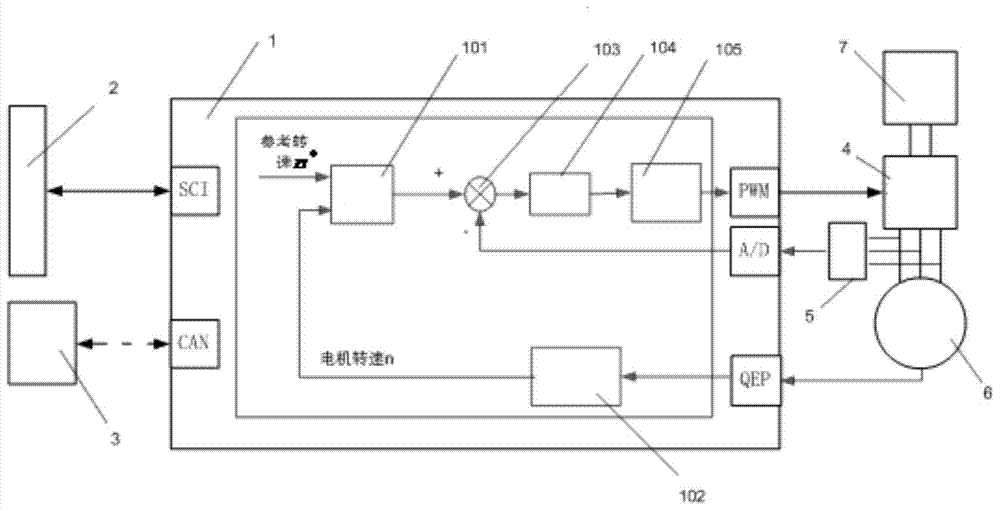

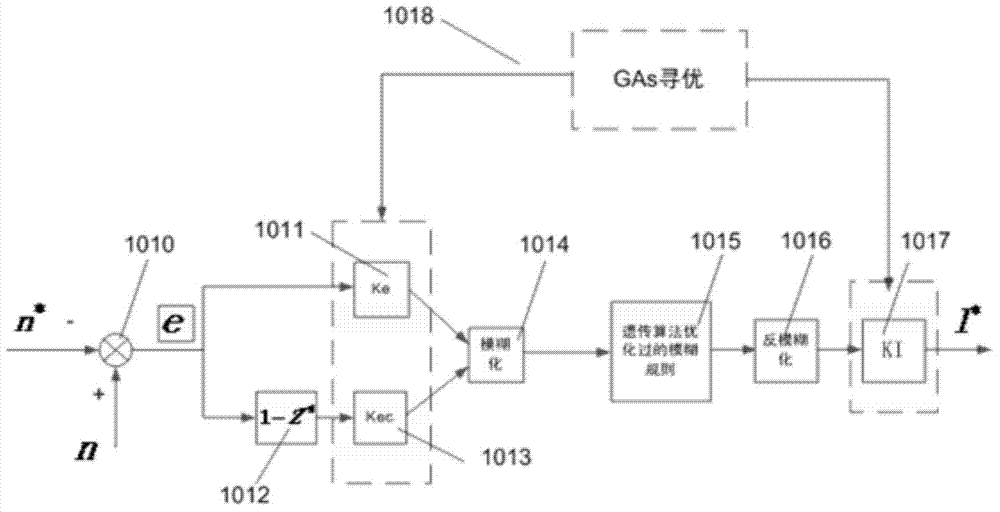

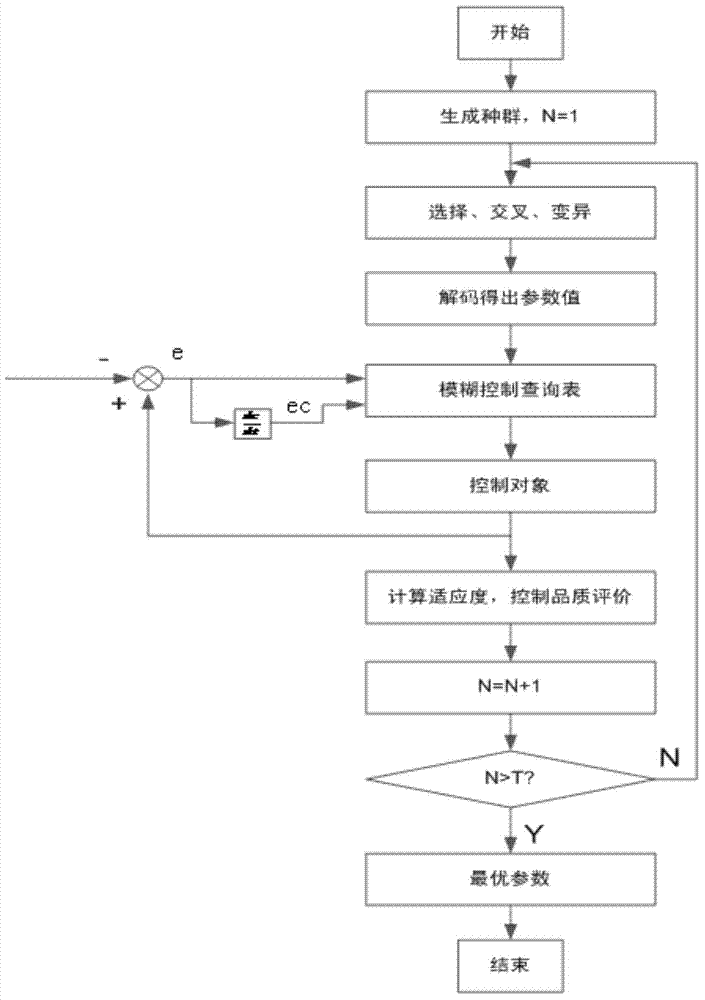

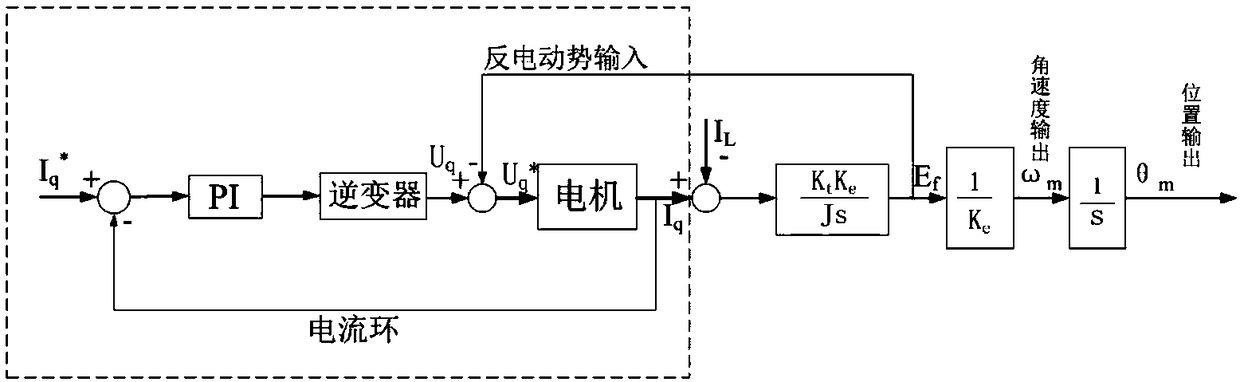

Method and system for fuzzy control over genetic algorithm optimization of shielded gate portal crane controller

The invention provides a method and system for fuzzy control over genetic algorithm optimization of a shielded gate portal crane controller. A reference rotation speed value n* and a brushless direct current motor measuring rotation speed value n serve as two input values of a fuzzy controller for genetic algorithm optimization; a current output by the fuzzy controller and a current output by a current sensor are input into a current comparator, an error current passes through a current PID regulator and is output to a PWM controller, and finally, the PWM controller controls the rotation speed of a motor through an inverter. By the adoption of rotation speed current double-closed-loop control, double-fuzzy control over genetic algorithm optimization is adopted by a rotation speed outer ring and traditional PI control is conducted on the currents. Compared with the prior art, the method and system for fuzzy control over genetic algorithm optimization of the shielded gate portal crane controller have the advantages that the tracking accuracy is high, the robustness is strong, parameter adjustment can be effectively conducted on system parameter drifting, the function of self-adaptation control is achieved, and the obvious superiority is achieved.

Owner:江苏新绿能科技有限公司

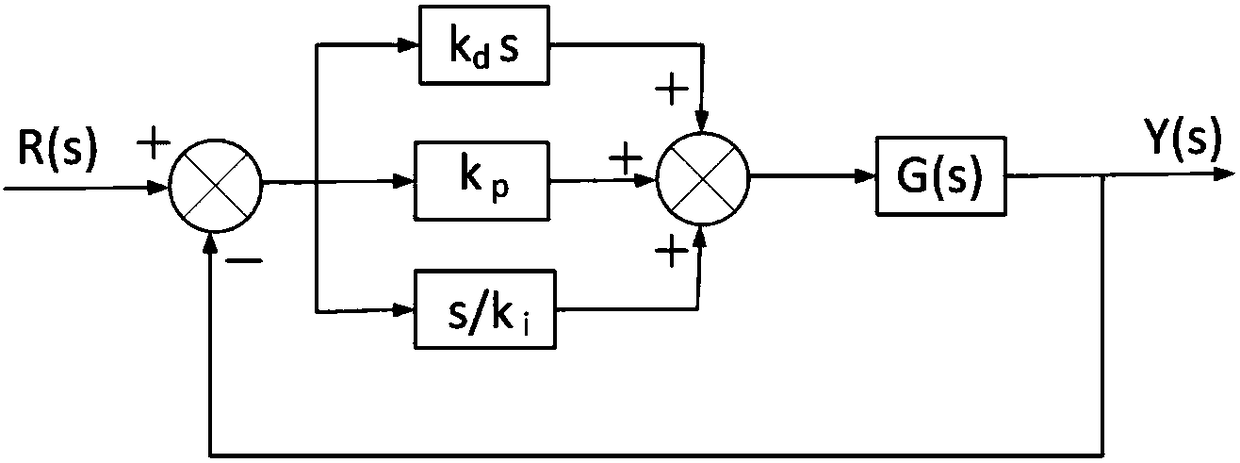

PMSM position servo system high-order object controller design and parameter determination method

InactiveCN108599649AIncrease reflectionReflect the impactElectronic commutation motor controlVector control systemsClosed loopPwm inverter

Owner:SUZHOU UNIV OF SCI & TECH

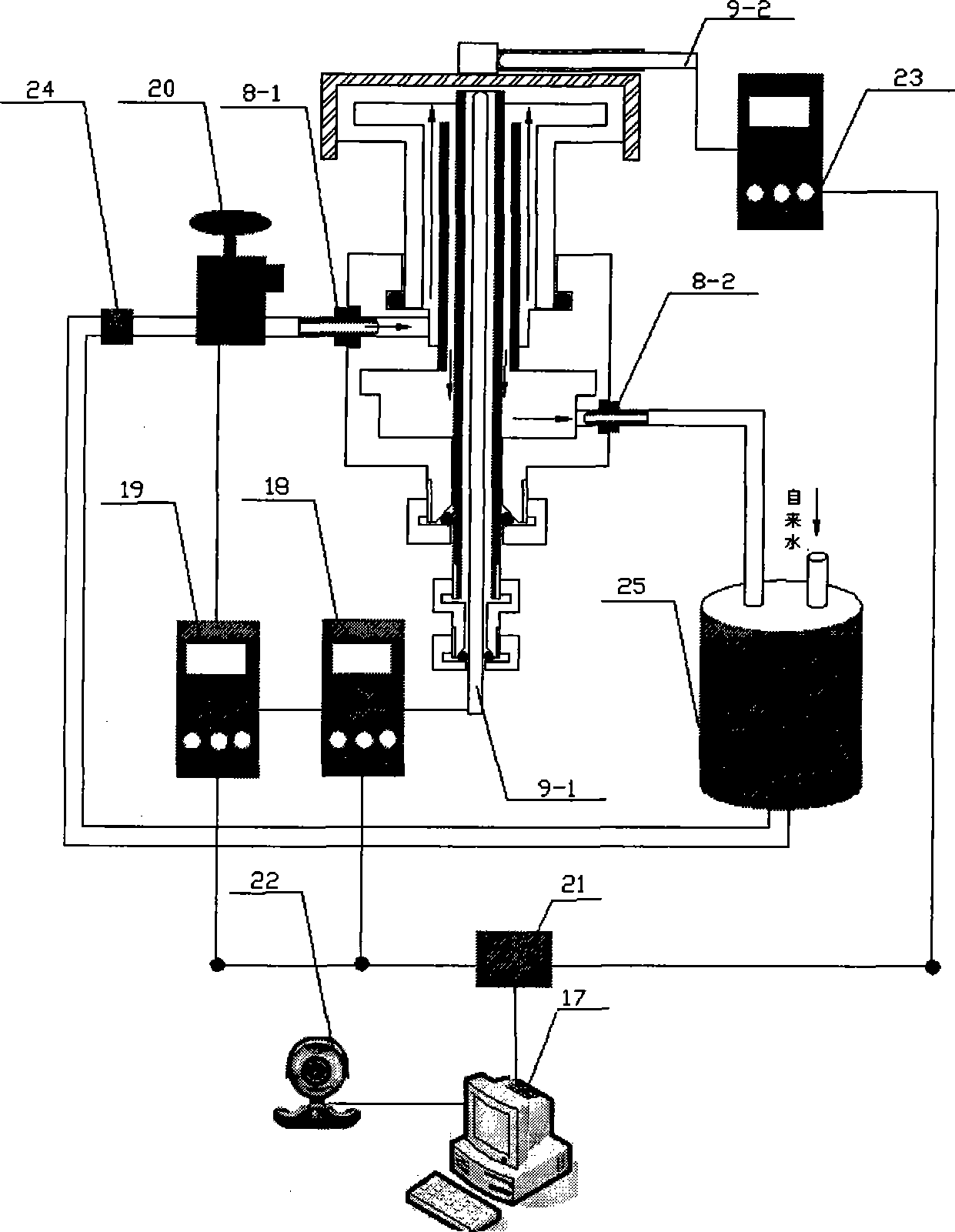

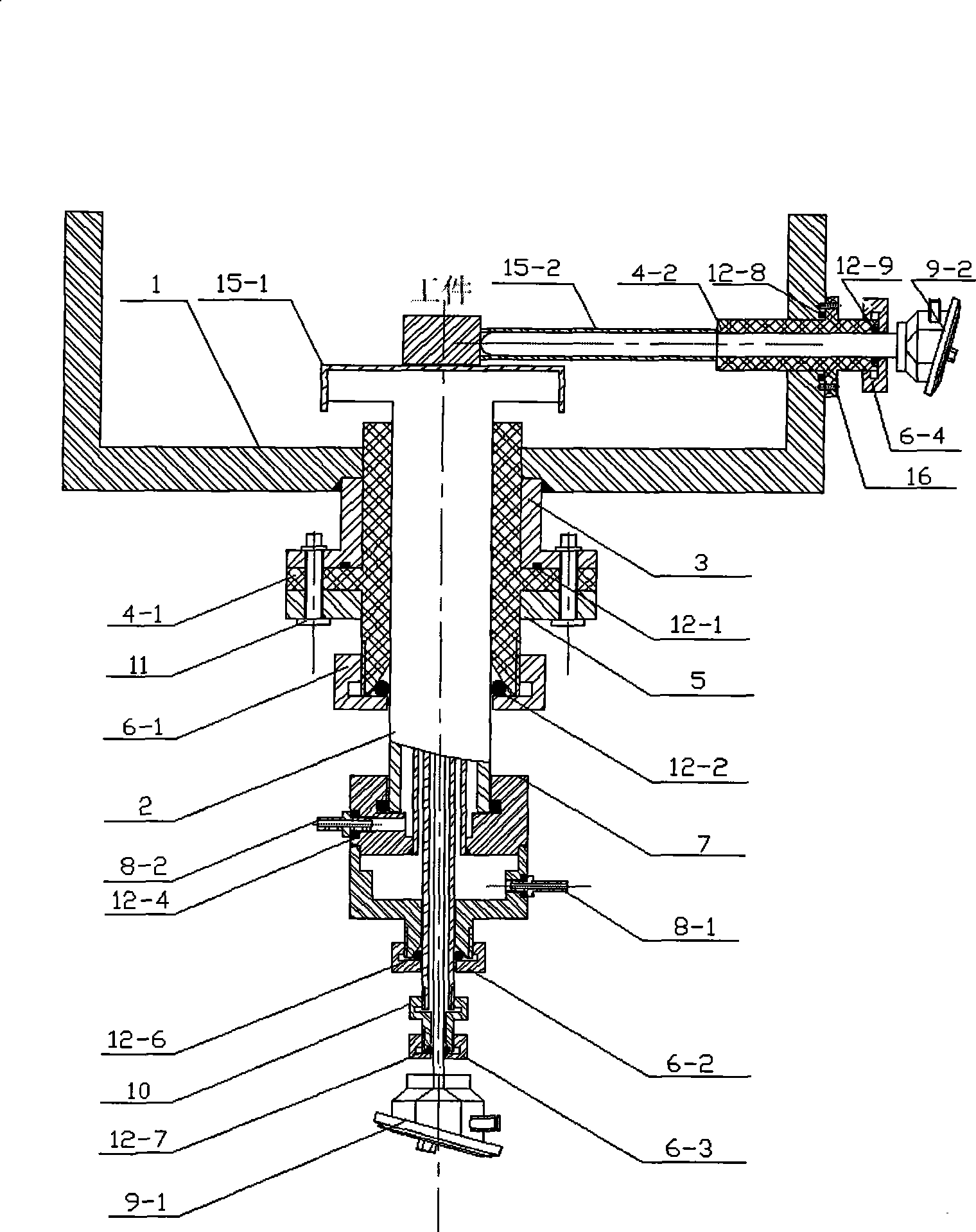

Substrate constant temperature technology for preparing direct current arc discharge PCVD diamond film

InactiveCN101413116AAccurate measurementPlay a security roleChemical vapor deposition coatingClosed loopData acquisition

The invention discloses a substrate automatic constant temperature technology for the preparation of a PCVD diamond film through direct current arc discharge, which is characterized by adopting a dual thermoelectric couple to measure and correct the temperature on the lateral surface and the back surface of a substrate respectively, using a closed loop control system consisting of a PID regulator with negative feedback function, a backup manipulator and an electric regulating valve to perform precise temperature control, and developing windows human-machine interaction interface based on a BT2000 industrial control configuration software platform for monitoring the temperature, the valve position and the depositing process, and acquiring and storing data. The technology has high control precision and convenient operation so that the technology is extremely suitable for preparing the plasma chemical vapor deposition (PCVD) diamond film through the direct current arc discharge.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com