Control method and controller for walking system of spreader

A walking system and control method technology, applied to controllers with specific characteristics, electric controllers, roads, etc., can solve problems such as inability to adjust steering operating devices, achieve simple and reliable operation, improve road construction quality, and improve stability and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

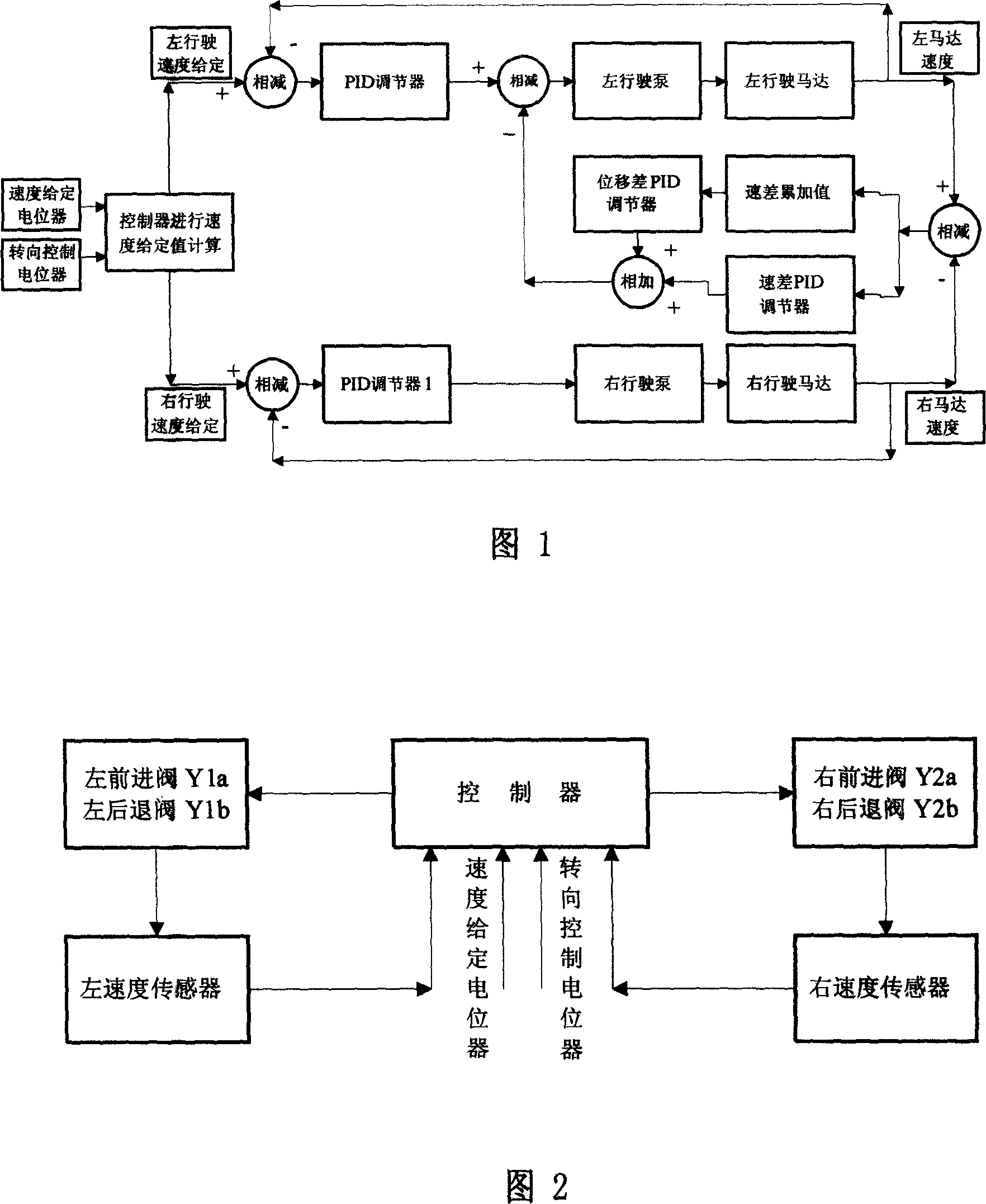

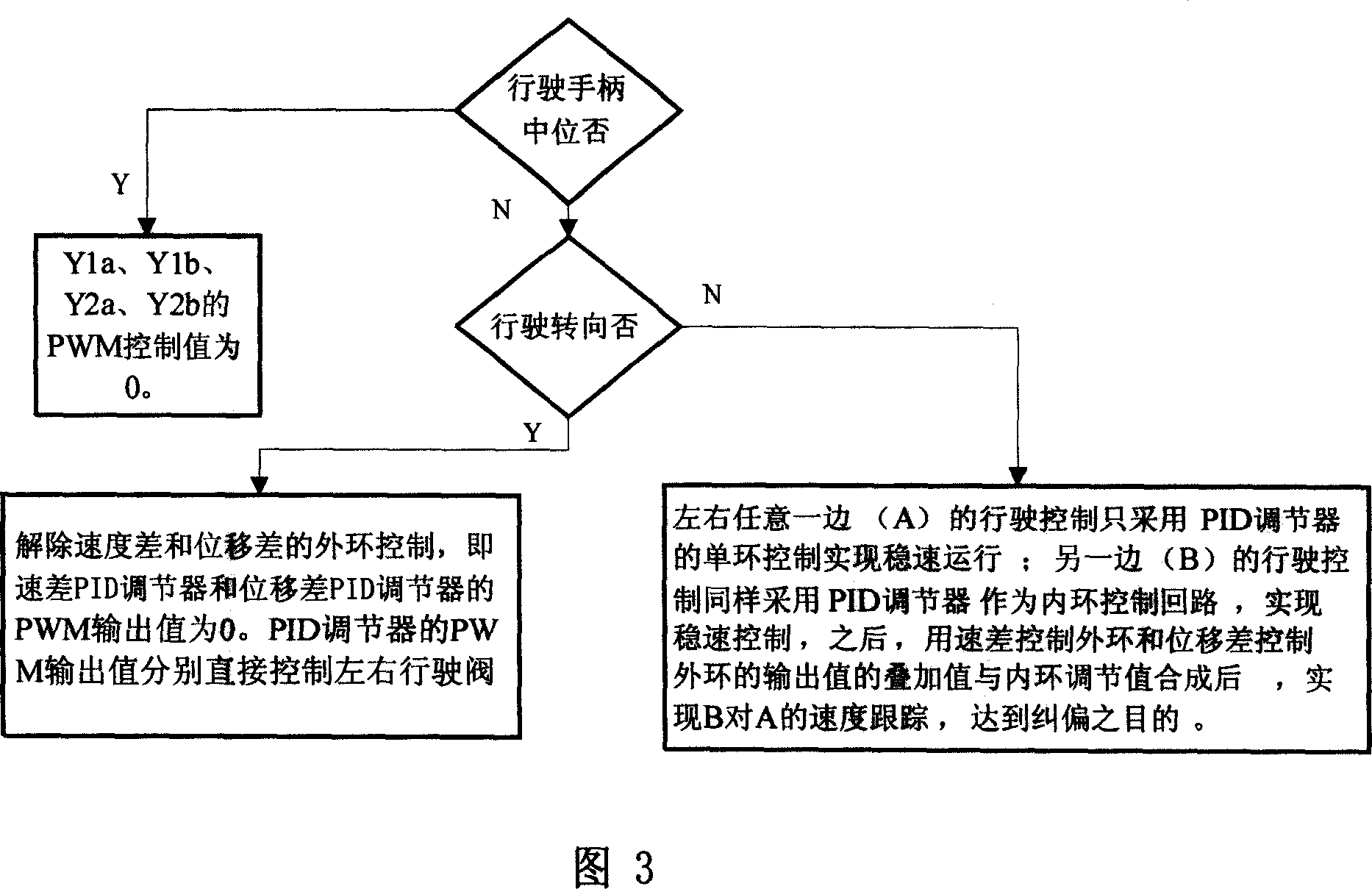

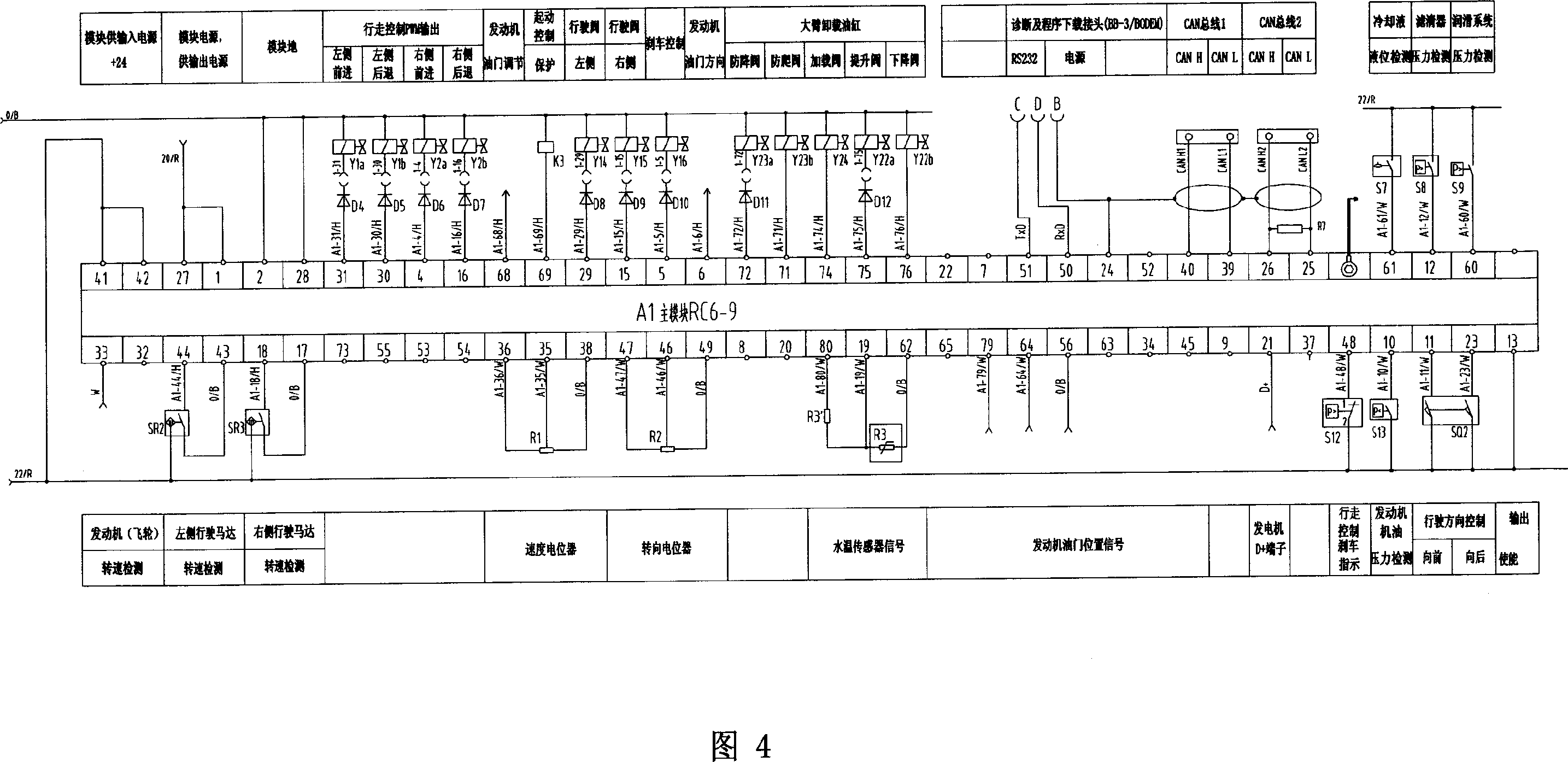

[0012] The control method of the walking system of the paver of the present invention is: the speed of the left motor is compared with the given speed value of the left motor as a feedback value, and the speed of the right motor is compared with the given speed value of the right motor as a feedback value. Compare, and independently control the speed of the left and right motors through the PID regulator to form a core loop; use the speed difference of the left and right motors as the feedback amount to track 0 as the goal, and control the amount formed by the speed difference PID regulator to one of them The speed of the motor is adjusted to form a speed difference tracking correction loop; the accumulated value of the speed difference between the left and right motors, that is, the left and right displacement difference, is used as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com