High-power continuous wave deuterium fluoride/hydrogen fluoride chemical laser

A technology of hydrogen fluoride chemistry and deuterium fluoride, which is applied in the field of lasers, can solve the problems of thermal deformation of the mirror frame, large-angle lens misalignment, and heating of the mirror frame. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

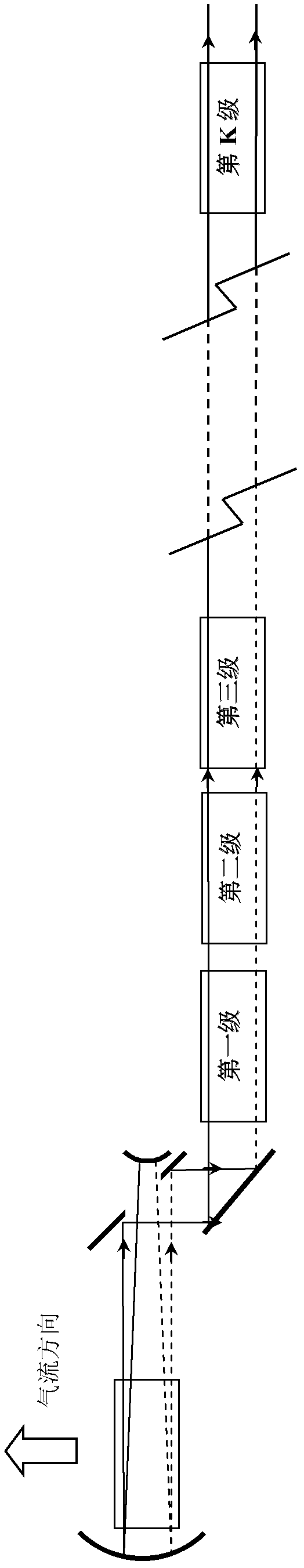

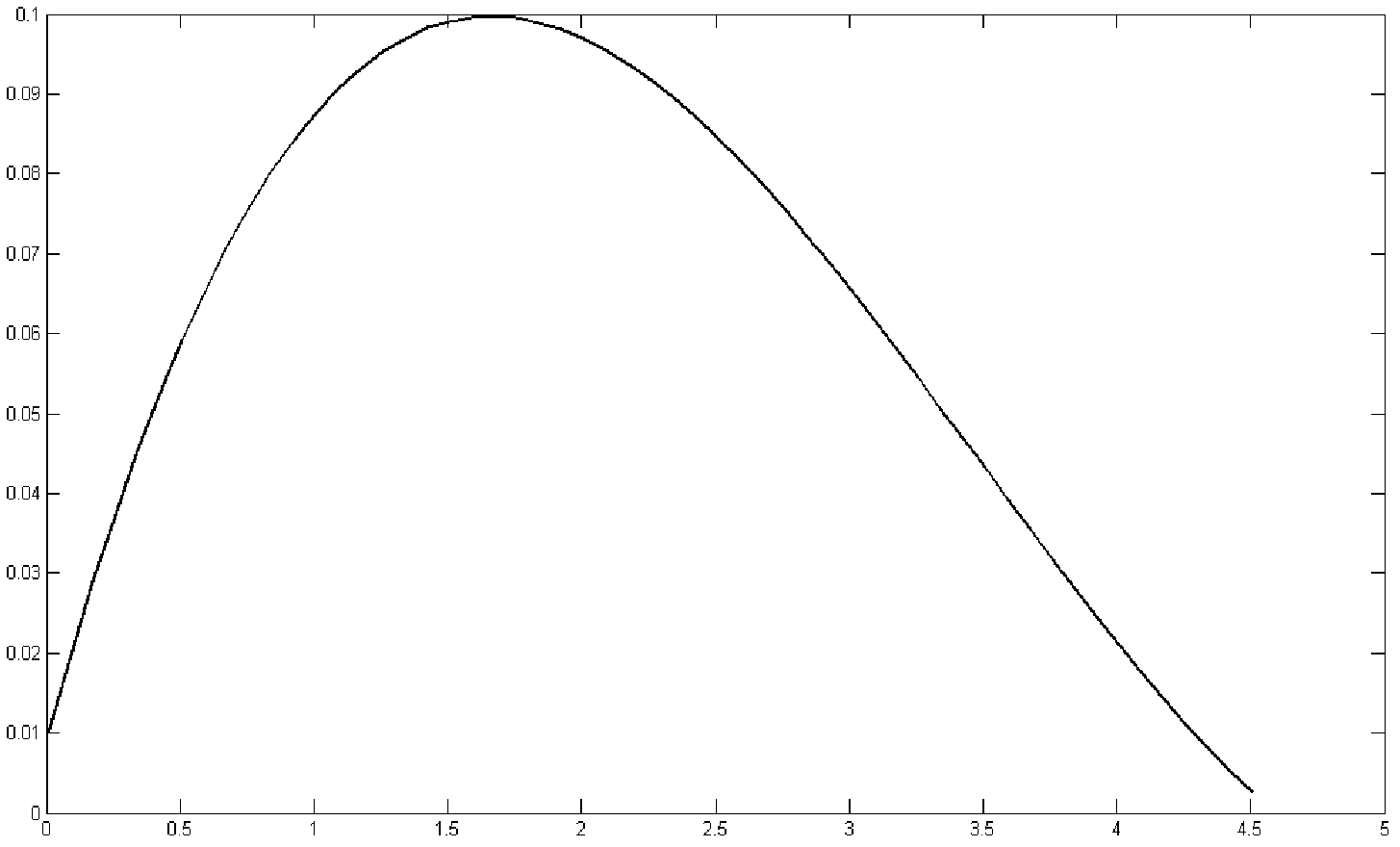

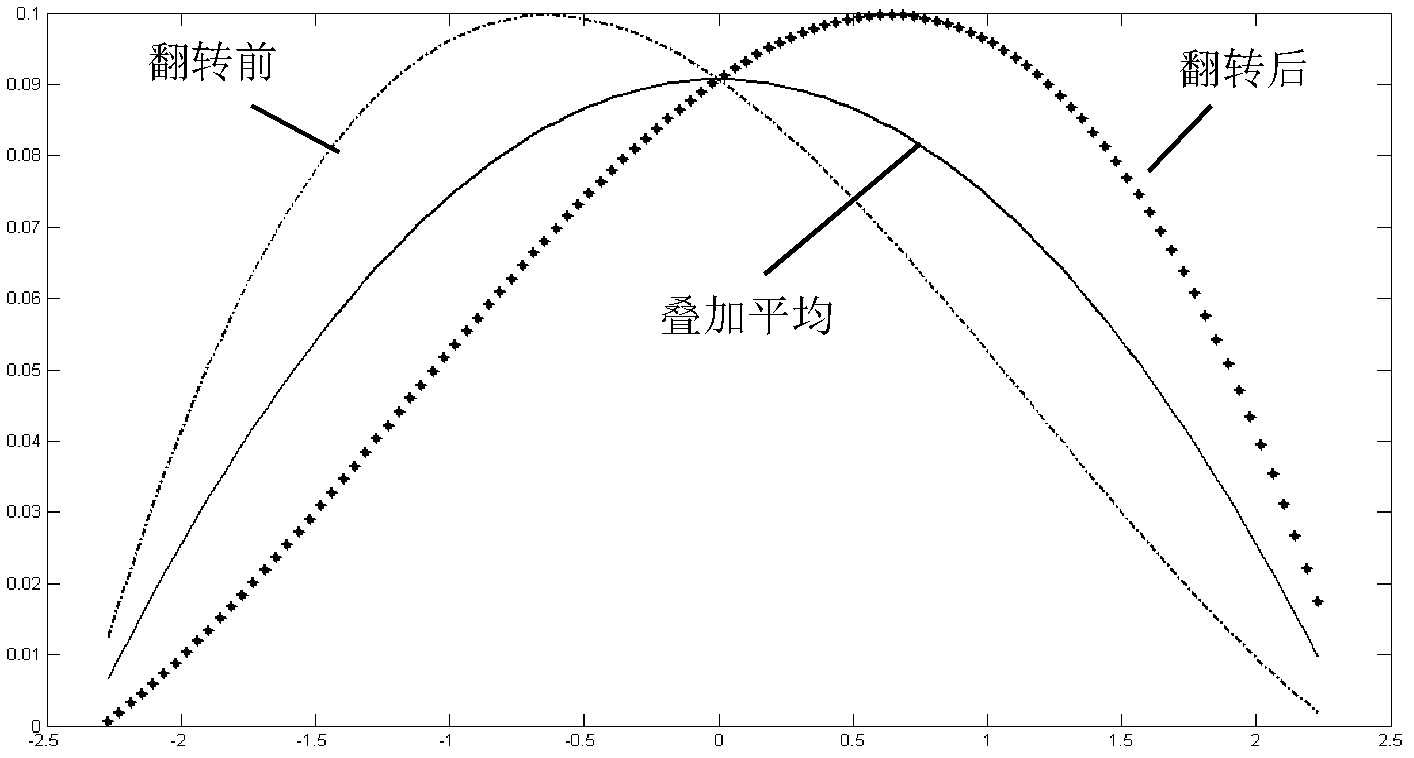

[0032] a kind of like Figure 4 The shown high-power continuous wave deuterium fluoride / hydrogen fluoride chemical laser of the present invention includes a main oscillator and 2N+1 amplification stages (N non-negative integers) behind the main oscillator, and the main oscillator is mainly composed of an unstable cavity mirror (positive branch confocal unstable cavity with output coupling mirror) and gain module 1. Gain module 1 is a device that generates excited deuterium fluoride / hydrogen fluoride molecules and accelerates them to supersonic flow. The gas flow direction is perpendicular to the optical axis 12 of the unstable cavity. Due to the flow characteristics of the gas, the gain medium is distributed along the direction of the flow field. is non-uniform, and the distribution of its small-signal gain coefficient along the direction of the flow field is as follows: figure 2shown. The unstable cavity mirror includes a concave mirror 2, an output coupling mirror 3 and a...

Embodiment 2

[0044] a kind of like Figure 6 Shown is for the inventive high power continuous wave deuterium fluoride / hydrogen fluoride chemical laser with 3 amplification stages. The laser includes a main oscillator and three amplification stages (i.e. N=1) behind the main oscillator. The main oscillator is mainly composed of an unstable cavity mirror (a positive branch confocal unstable cavity with an output coupling mirror) and a gain Module 1 constitutes. Gain module 1 is a device that generates excited deuterium fluoride / hydrogen fluoride molecules and accelerates them to supersonic flow. The gas flow direction is perpendicular to the optical axis 12 of the unstable cavity. Due to the flow characteristics of the gas, the gain medium is distributed along the direction of the flow field. is non-uniform. The unstable cavity mirror includes a concave mirror 2, an output coupling mirror 3 and a convex mirror 4, the gain module 1 is placed between the concave mirror 2 and the convex mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com