Circuit board

A technology of circuit board and conductive paste, which is applied in the direction of printed circuit, printed circuit, circuit device, etc., can solve the problems of poor accuracy of the area, contamination, leakage, etc., and achieve the goal of eliminating deviation, large line width, and increasing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

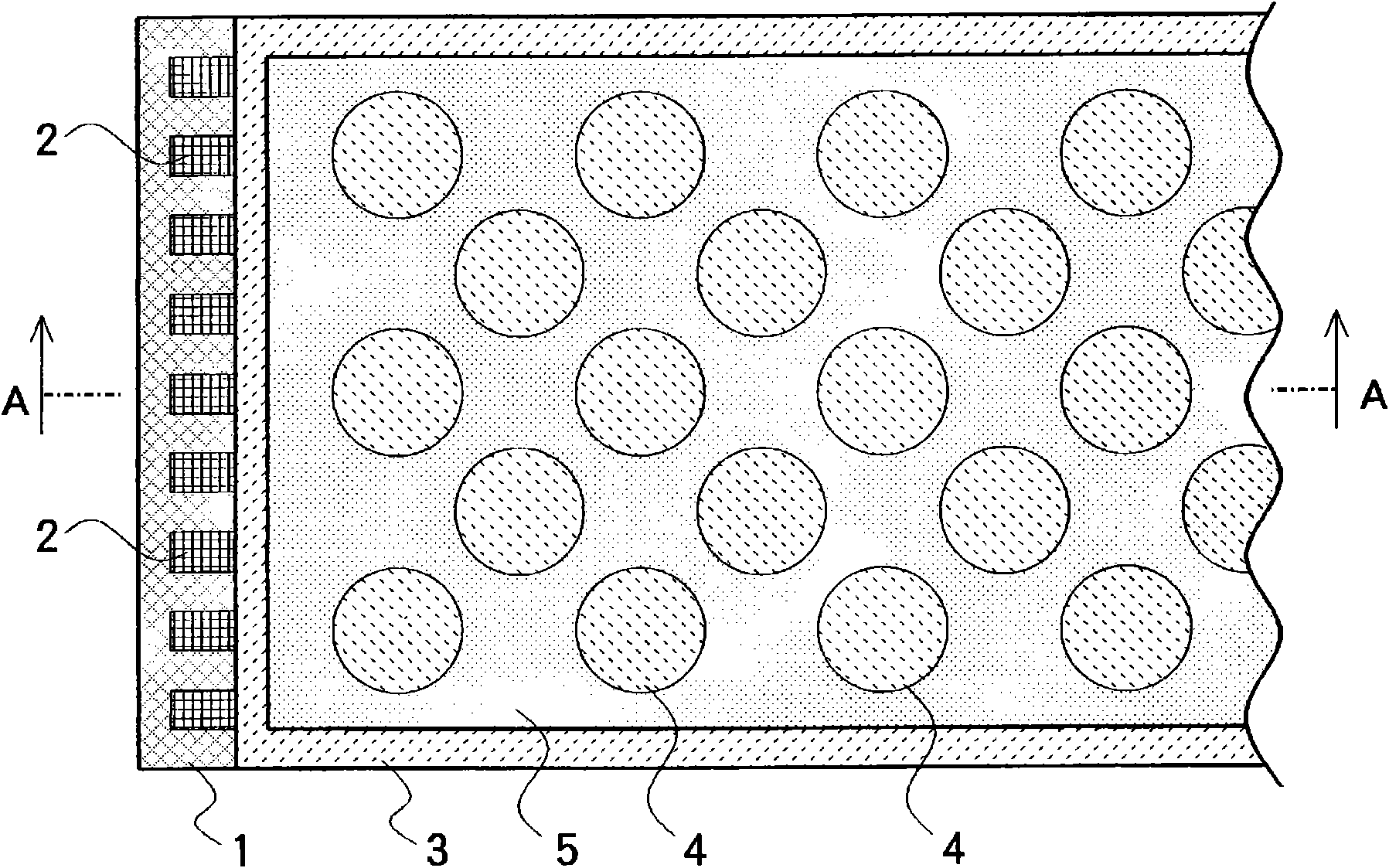

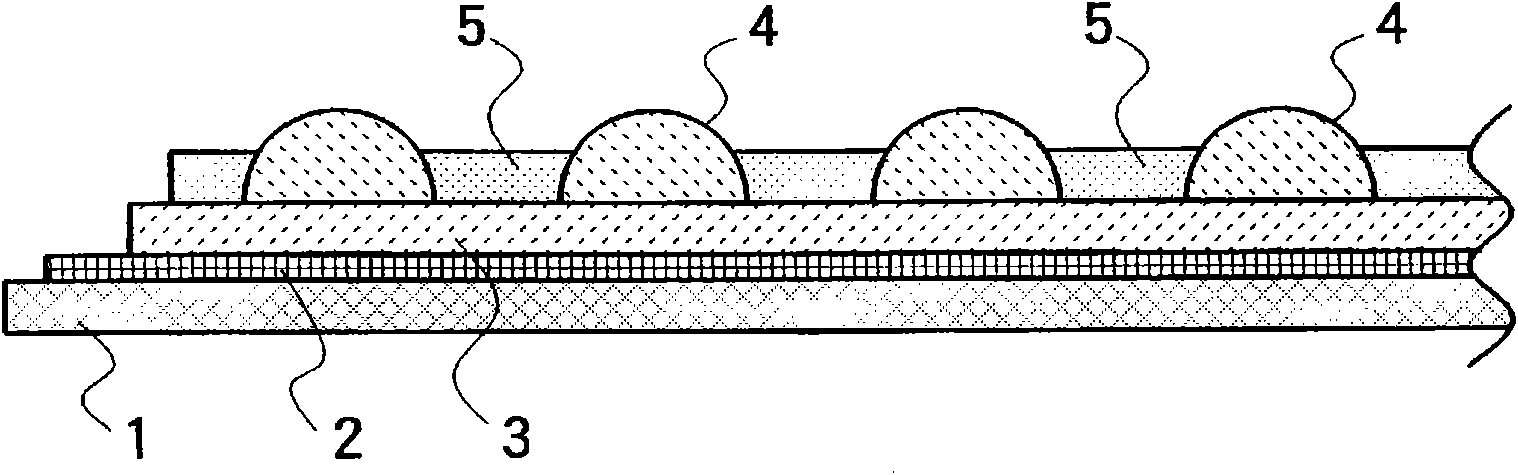

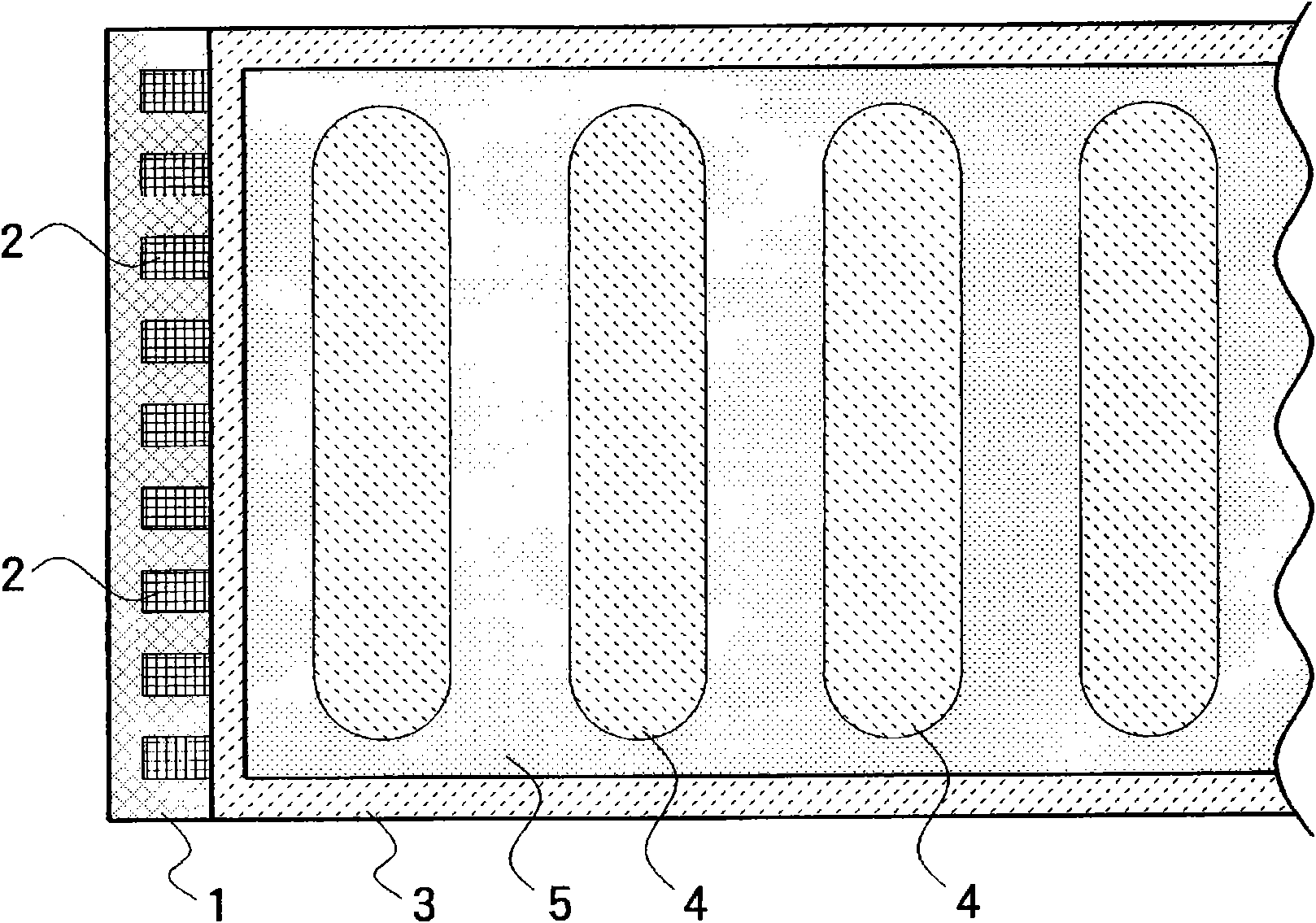

[0046] figure 1 with figure 2 is a schematic diagram showing a first preferred embodiment in which a circuit board according to the present invention is applied to a flexible printed circuit board, figure 1 shows the floor plan of the board, figure 2 along figure 1 The arrow direction of the A-A line in the figure shows the circuit board in a cross-sectional view.

[0047] figure 1 with figure 2 The reference numeral 1 in represents a film-shaped base substrate formed of an insulating material, and a plurality of signal lines 2 formed of copper foil are arranged on one surface of the base substrate 1 ( figure 2 upper surface shown). Furthermore, an insulating layer 3 is stacked to the base substrate 1 so as to cover the above-mentioned signal line 2 .

[0048] For example, a polyester film, a polyimide film, a liquid crystal polymer film, or the like can be used as the above-mentioned base substrate 1 . Among these films, polyimide film is ideal because it has high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com