Feed-forward-fuzzy proportion integration differentiation (PID) control-based control method for paper cutting machine

A control method, a technology of fuzzy control, applied in electric controllers, controllers with specific characteristics, metal processing, etc., can solve the problems of difficulty in ensuring the accuracy of cutting length L, easy to change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

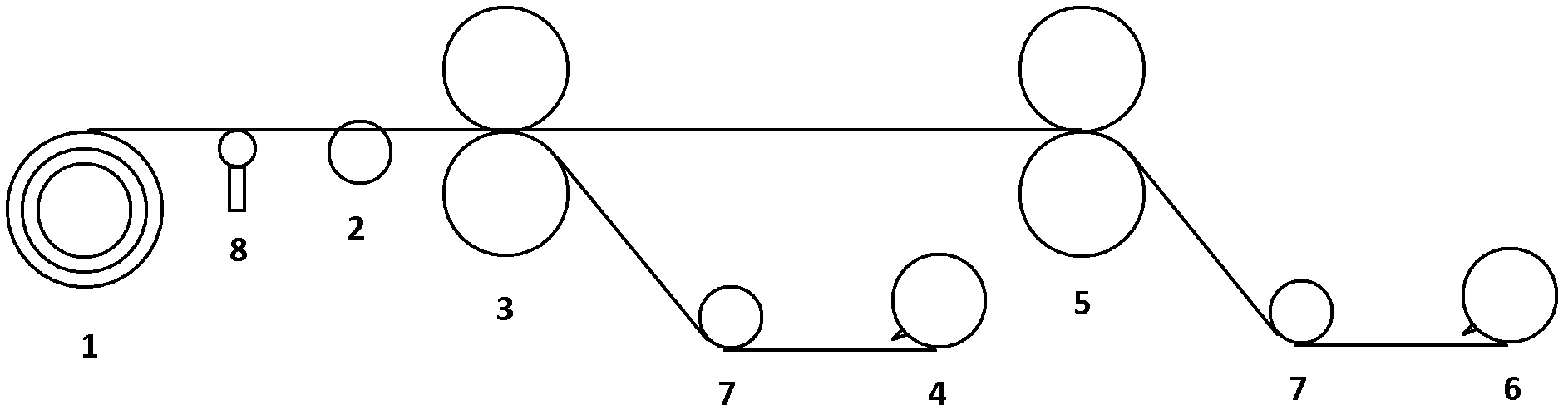

[0087] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

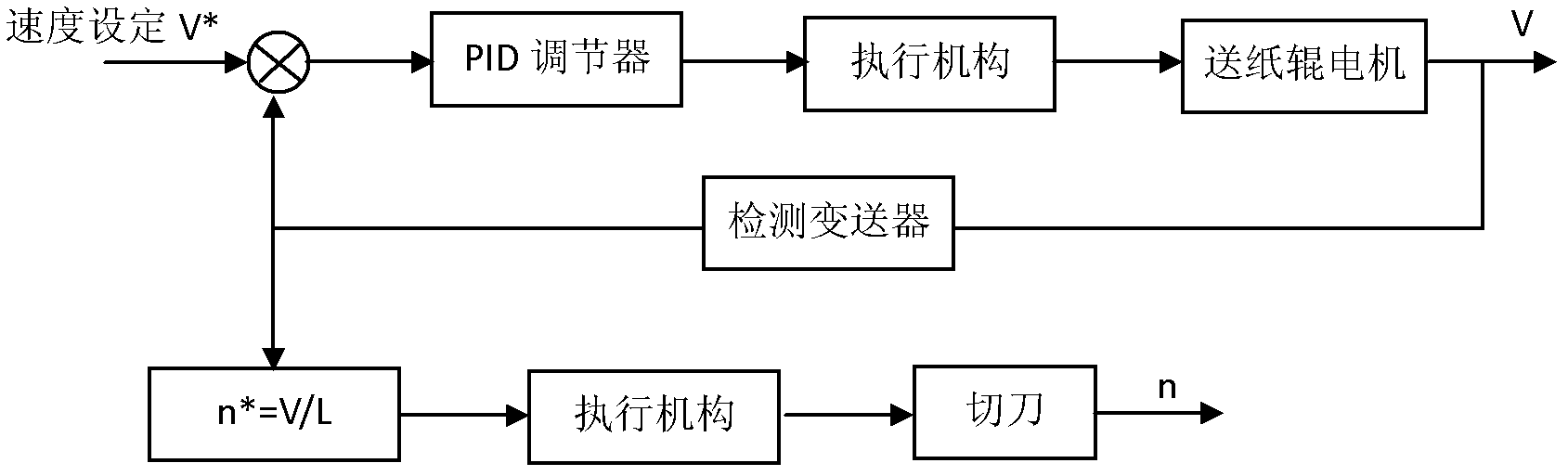

[0088] Figure 3-Figure 7 In the paper cutter control method based on feed-forward-fuzzy PID control, after the system is initialized, the paper cutting length and the cutter frequency are set, and the paper is cut under the control of the single closed-loop control plus the ratio control system. , shutdown;

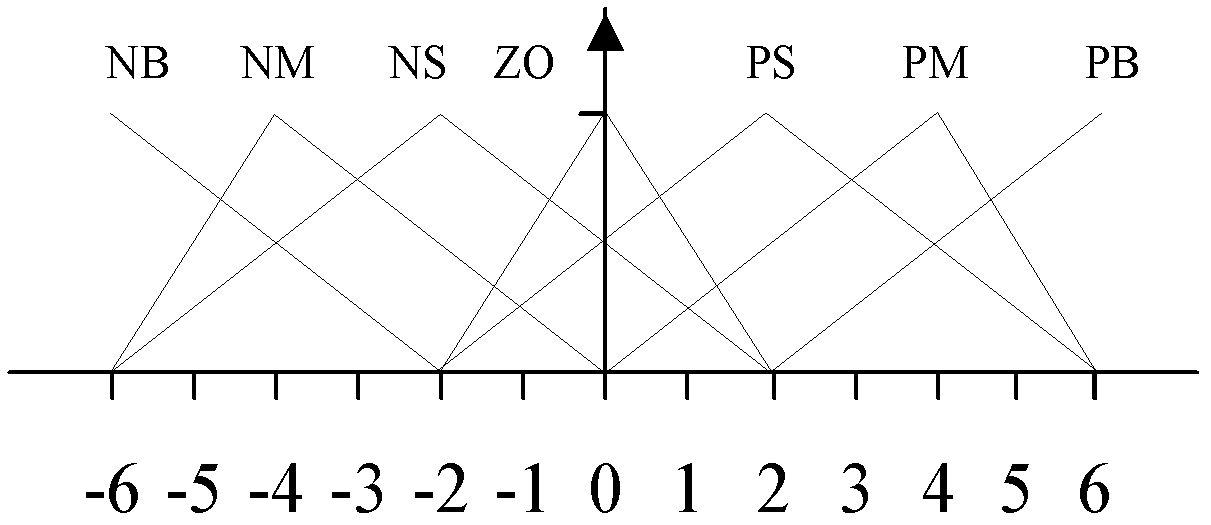

[0089] 1. On the basis of the original single closed-loop control plus ratio value to control the cutter speed, fuzzy PID control is used to control the speed V of the paper feed roller to improve the dynamic response and steady-state characteristics of the system, that is, to apply fuzzy control rules and adjust A fuzzy controller is added to the controller. The input language variables of the fuzzy controller are error value E and error change rate ΔE, and the output language variable is the proportional gain coefficient K of the PID controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com