Patents

Literature

59 results about "Cylinder cutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

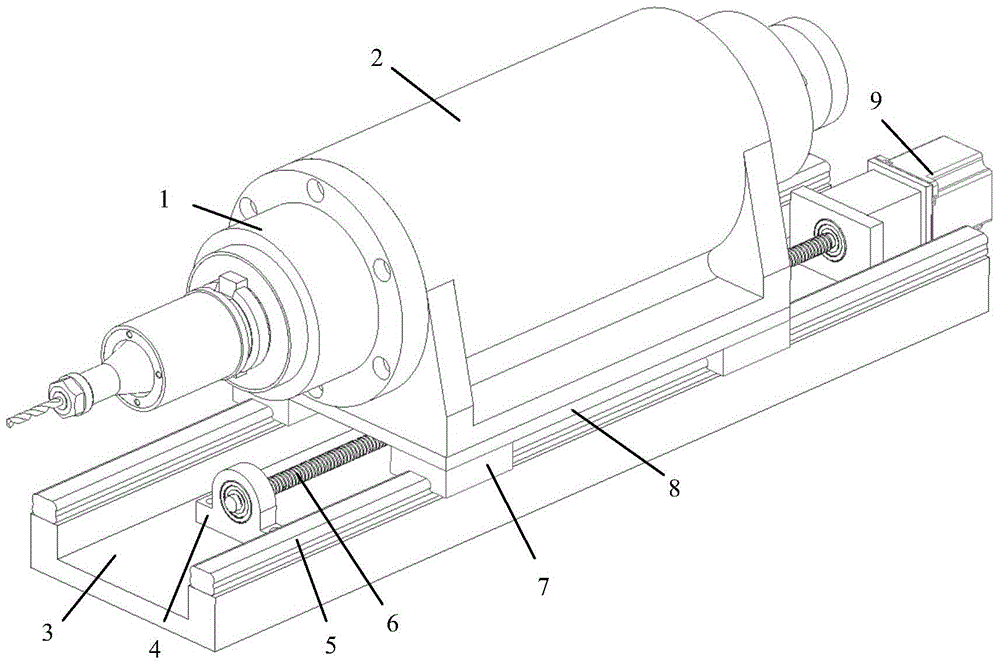

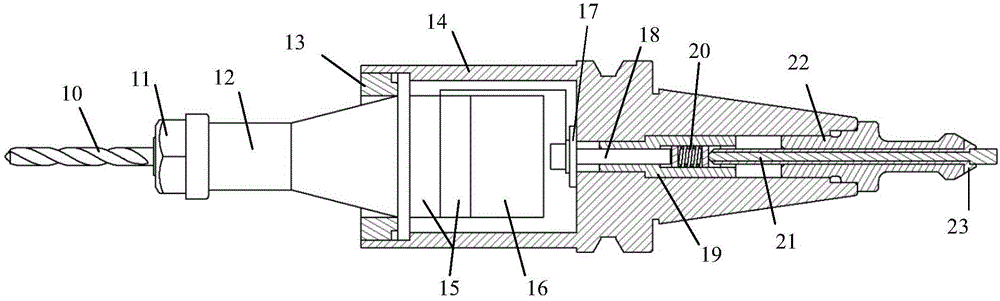

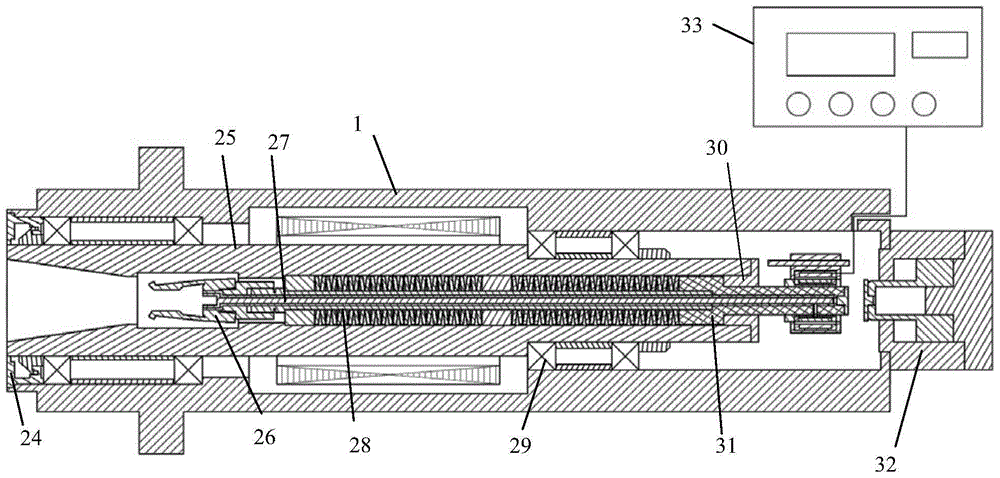

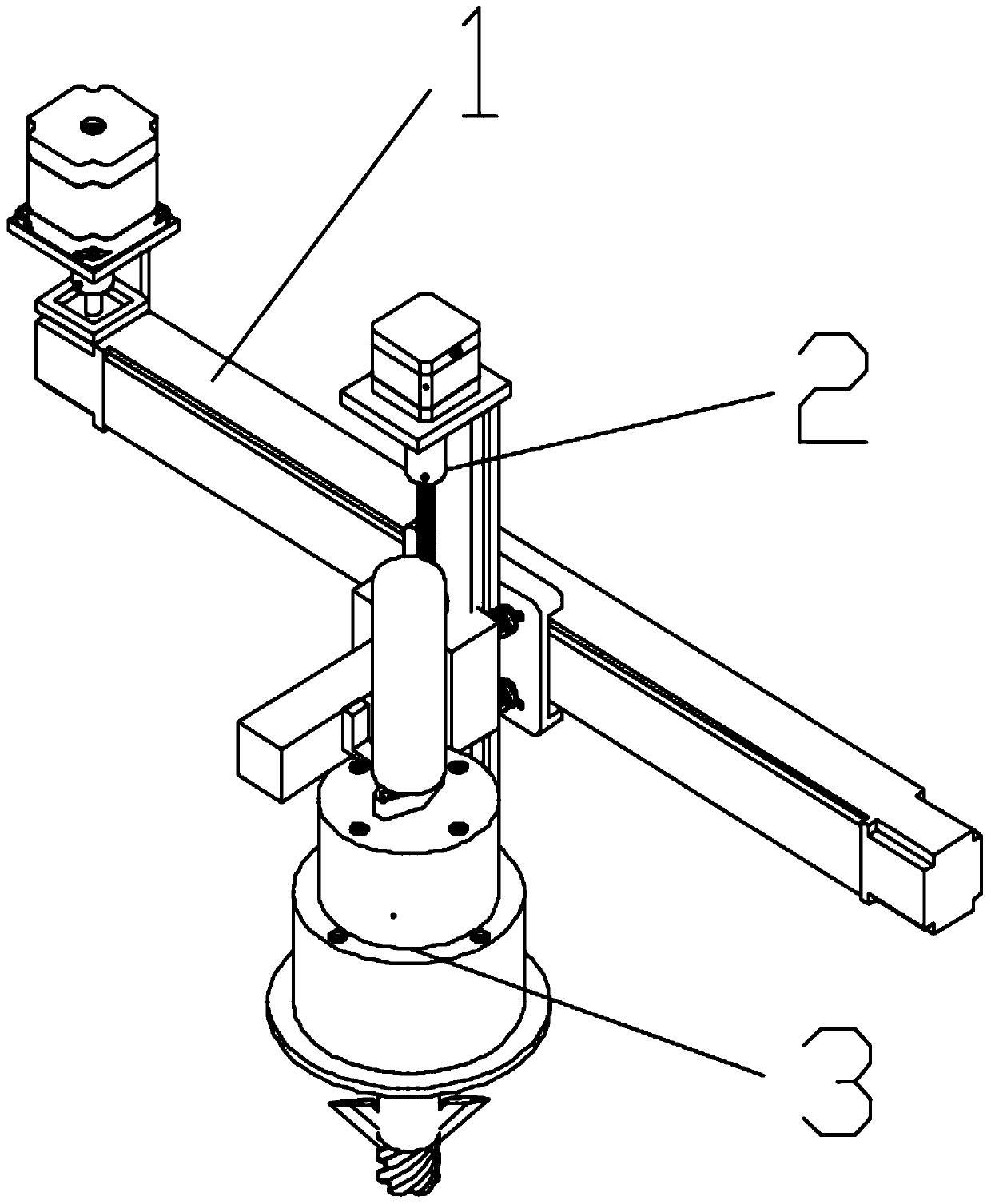

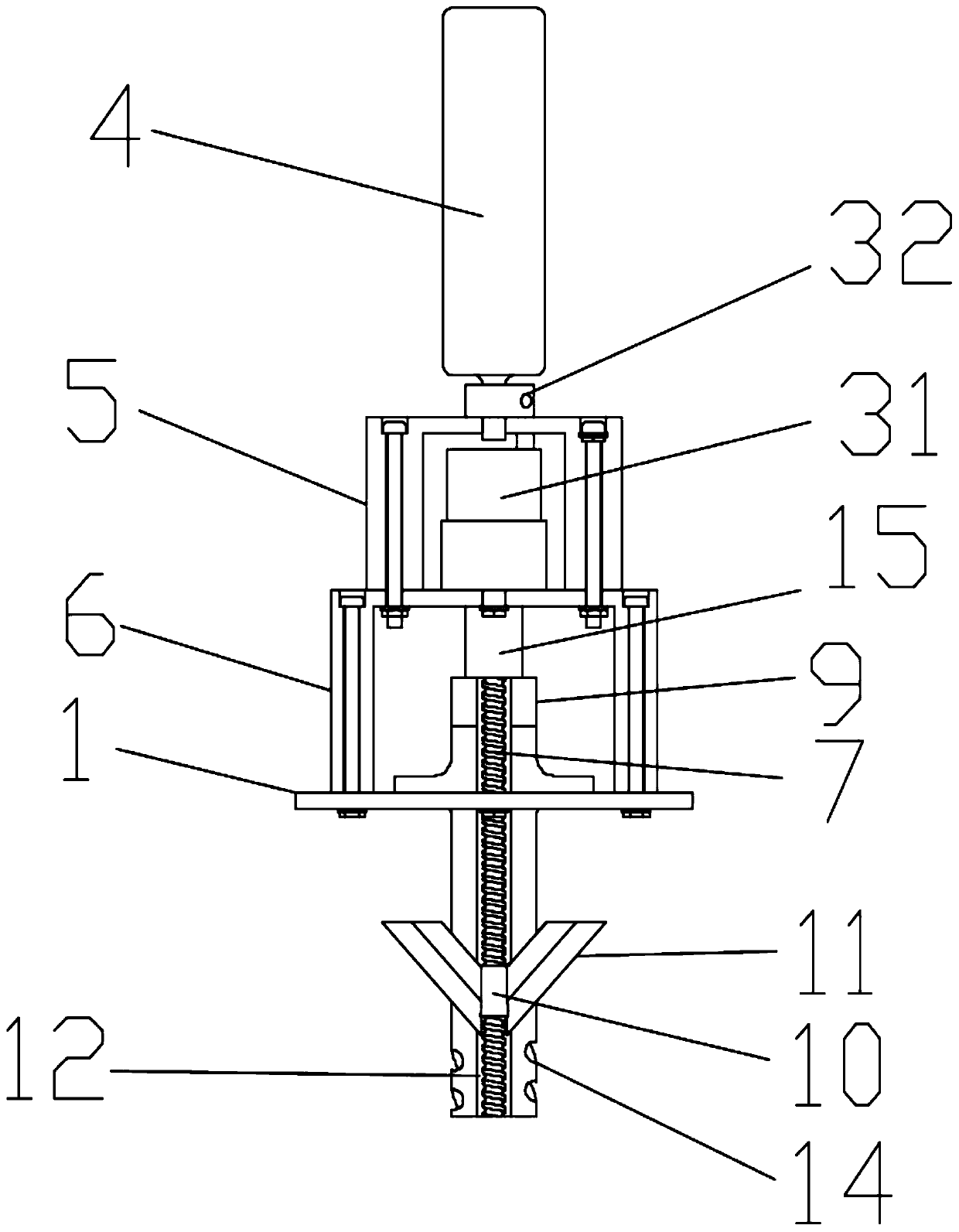

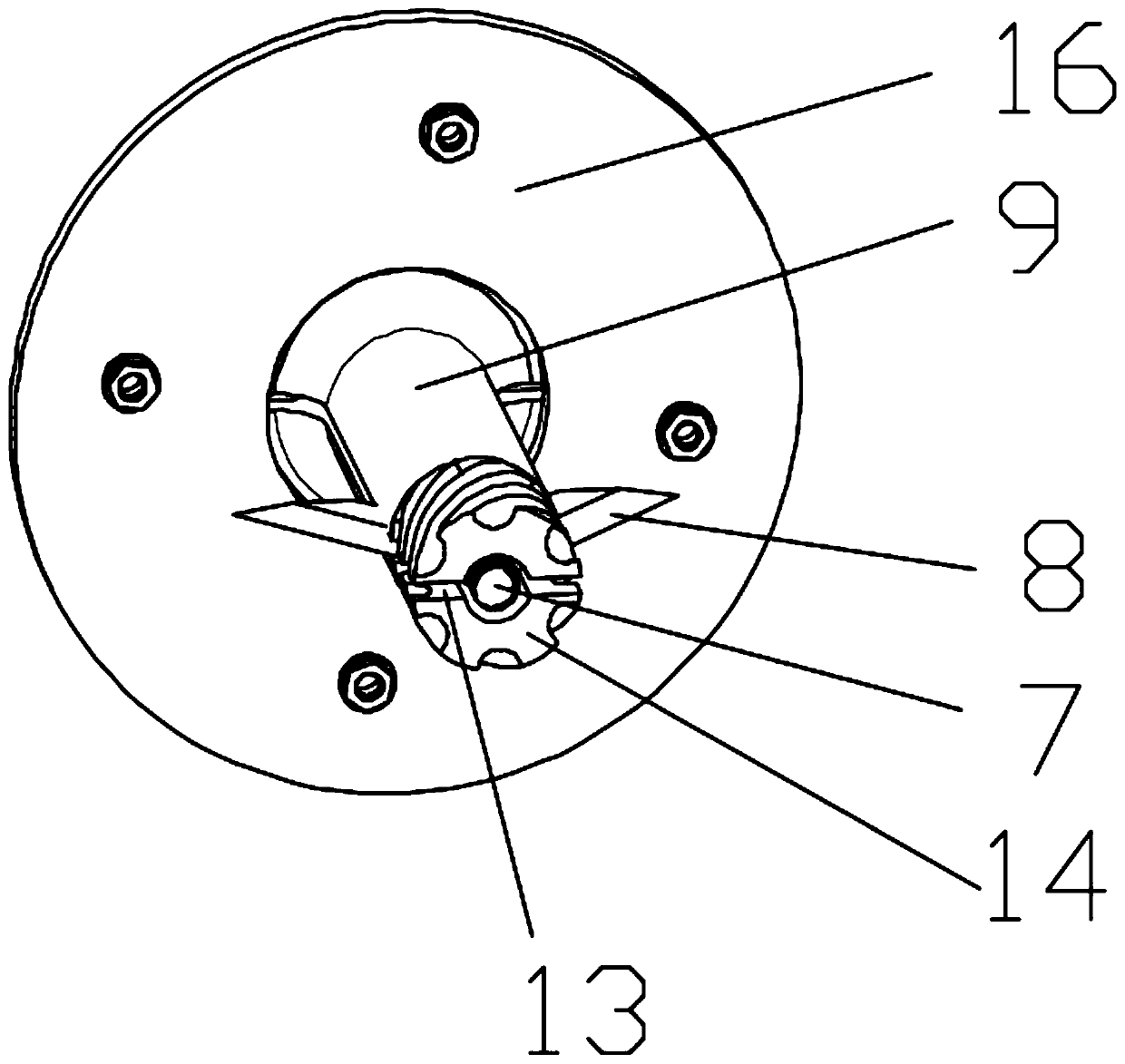

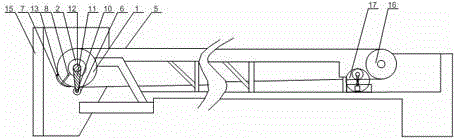

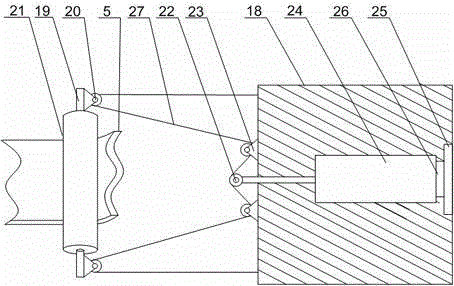

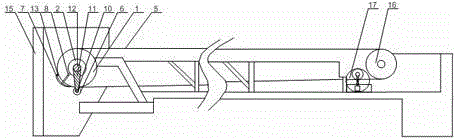

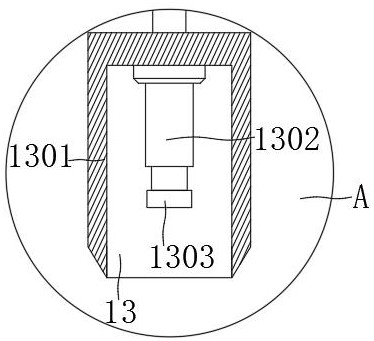

Ultrasonic vibration drill hole tail end actuator

The invention discloses an ultrasonic vibration drill hole tail end actuator which comprises a main shaft unit, an ultrasonic knife handle unit and a feeding unit. The ultrasonic vibration drill hole tail end actuator overcomes the defects of a traditional drilling technique, an ultrasonic vibration drilling technique is utilized for conducting drilling on aluminum alloy, titanium alloy, carbon fiber composite materials and other materials difficult to process through robots, especially for conducting drilling on small holes with the diameter being less than 6 mm, and the machining quality and efficiency are improved. A radial wireless transmission mode is adopted for the tail end of a rotor to transmit ultrasonic signals, interference with oil cylinder cutter movement and spindle rotation does not occur, a copper electrode penetrates through a spring rod inner hole to be connected with a knife handle inner copper electrode in cooperation with an elastic pin shaft in the knife assembling process so as to transmit ultrasonic signals, a carbon brush does not need to be replaced, device durability is improved, all power transmission devices are arranged in a main shaft, and a robot can achieve multi-angle drilling. Multiple ultrasonic knife handles can be replaced quickly, and machining efficiency is improved.

Owner:DALIAN UNIV OF TECH

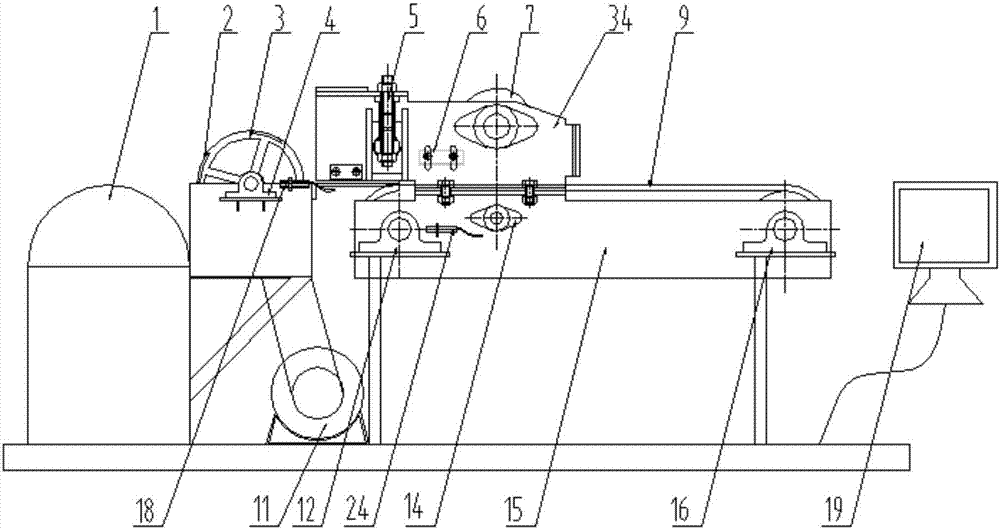

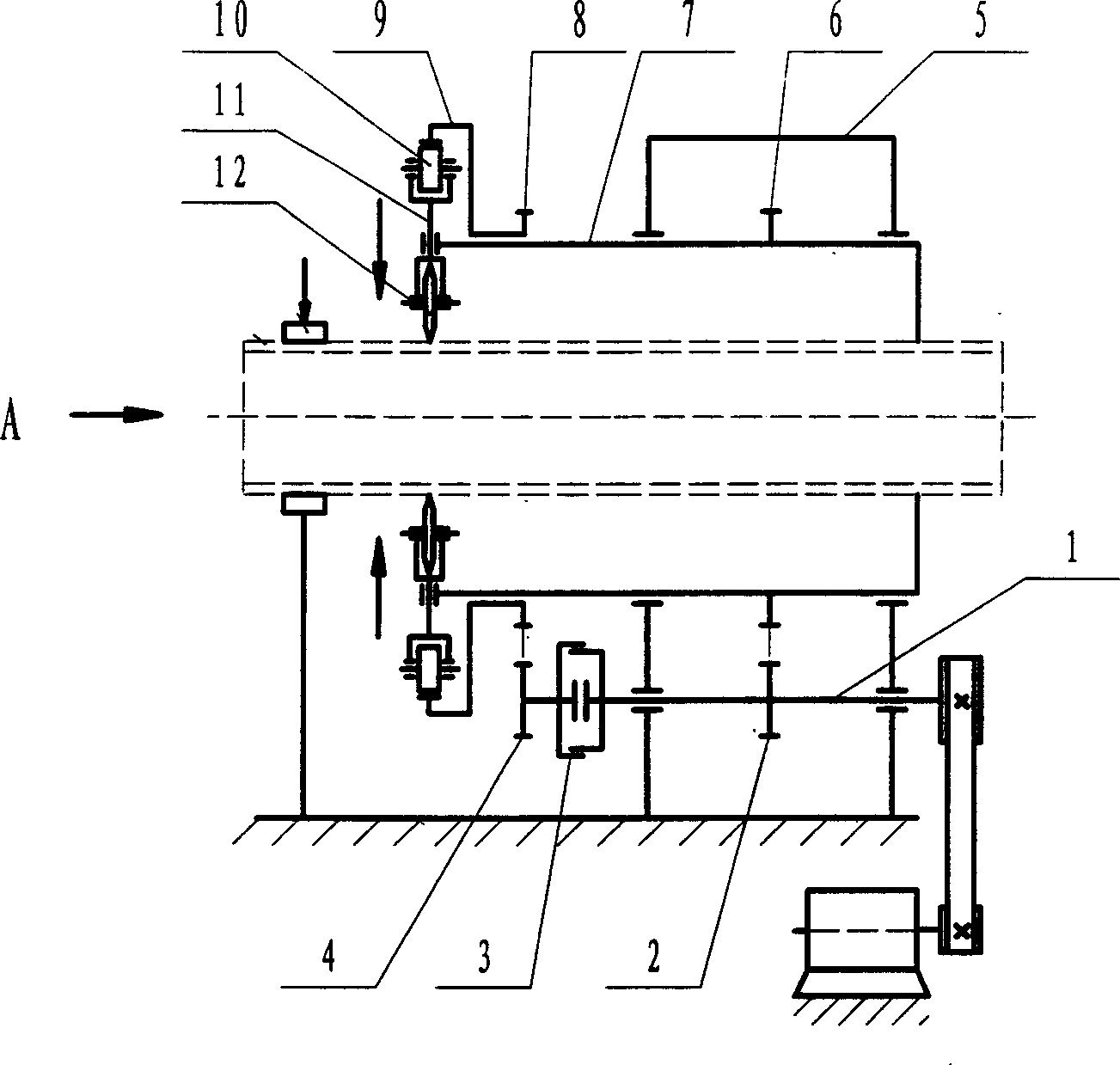

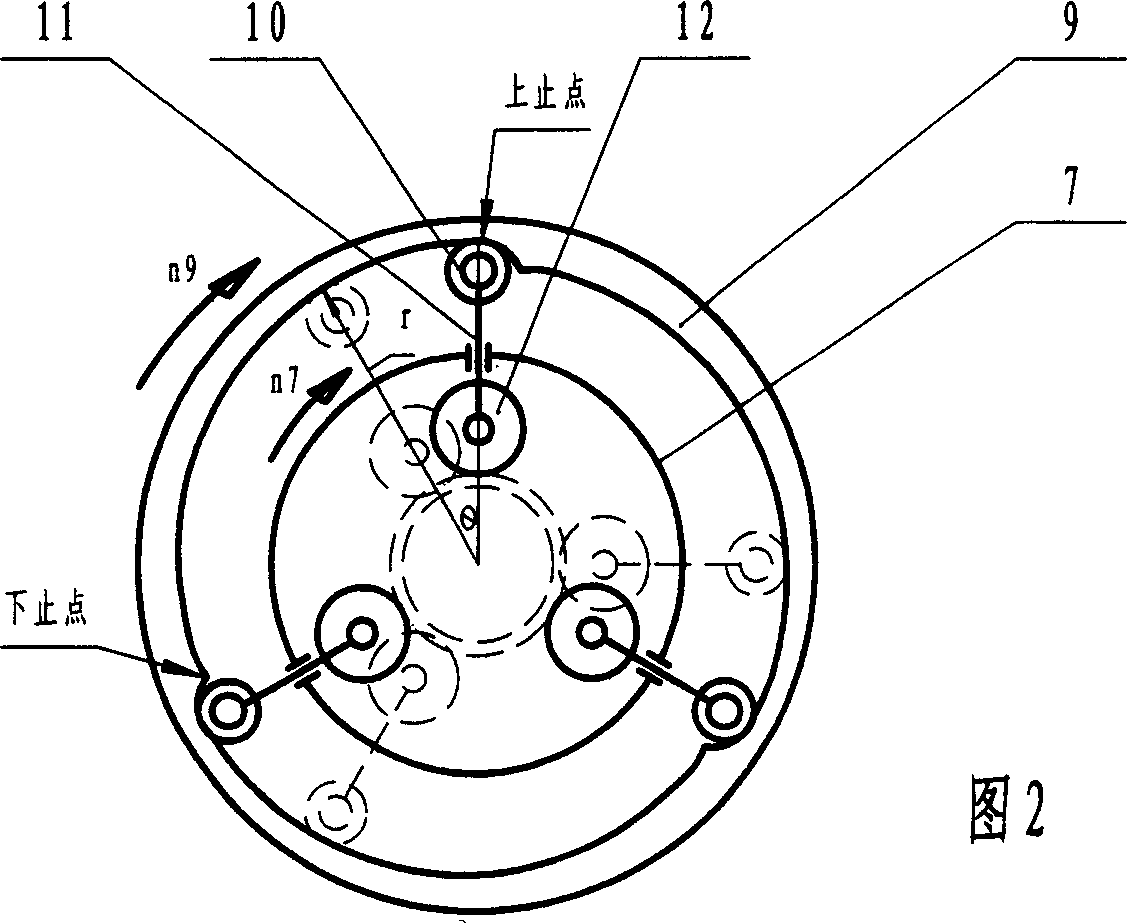

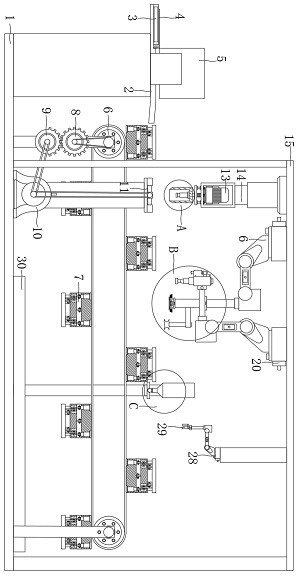

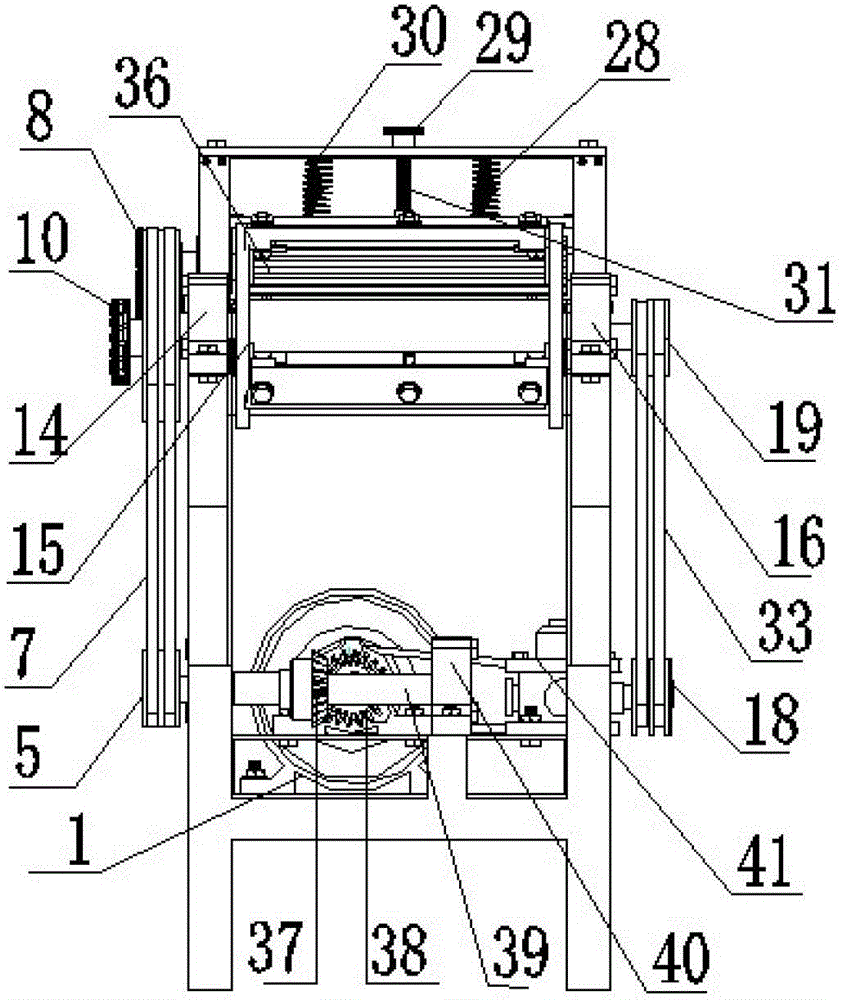

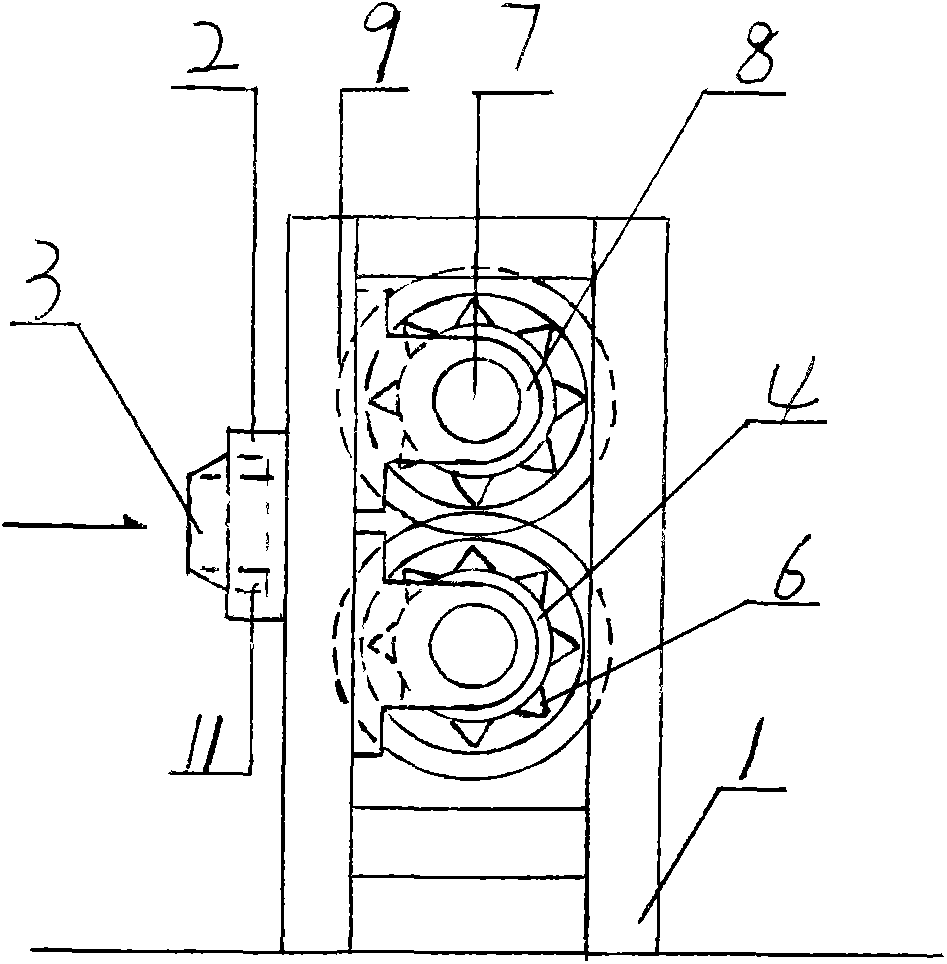

Slicing and chopping machine for household crops

InactiveCN102729276ASave spaceReduce the number of motorsCuttersMetal working apparatusCylinder cutterCrop

The invention discloses a slicing and chopping machine for household crops. The slicing and chopping machine mainly comprises a motor, a transmission part, an automatic conveying and automatic adjusting device and a slicing and chopping cylinder cutter. The slicing and chopping machine is ingenious and compact in design, reasonable in spatial arrangement, practical and efficient, safe and reliable, and low in cost, can realize the slicing and chopping of different crops, has automatic conveying and automatic adjusting functions, and is suitable for processing semi-finished products of the crops and chopping stalks of the crops, thus being capable of greatly promoting the development of the breeding industry, and having very wide application and generalization prospects.

Owner:GUANGXI UNIV

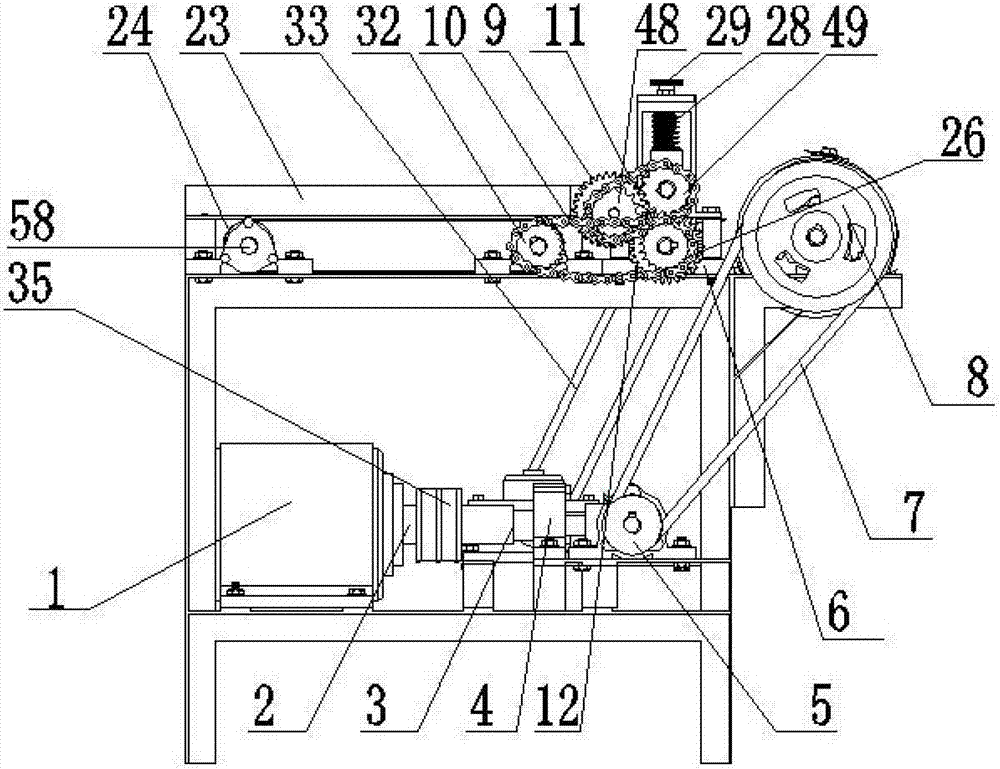

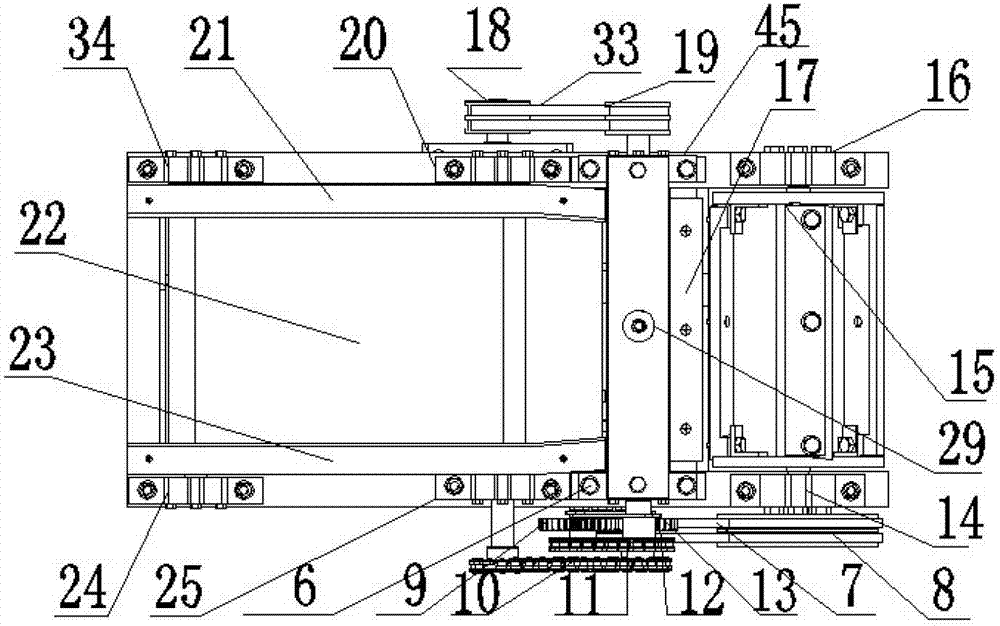

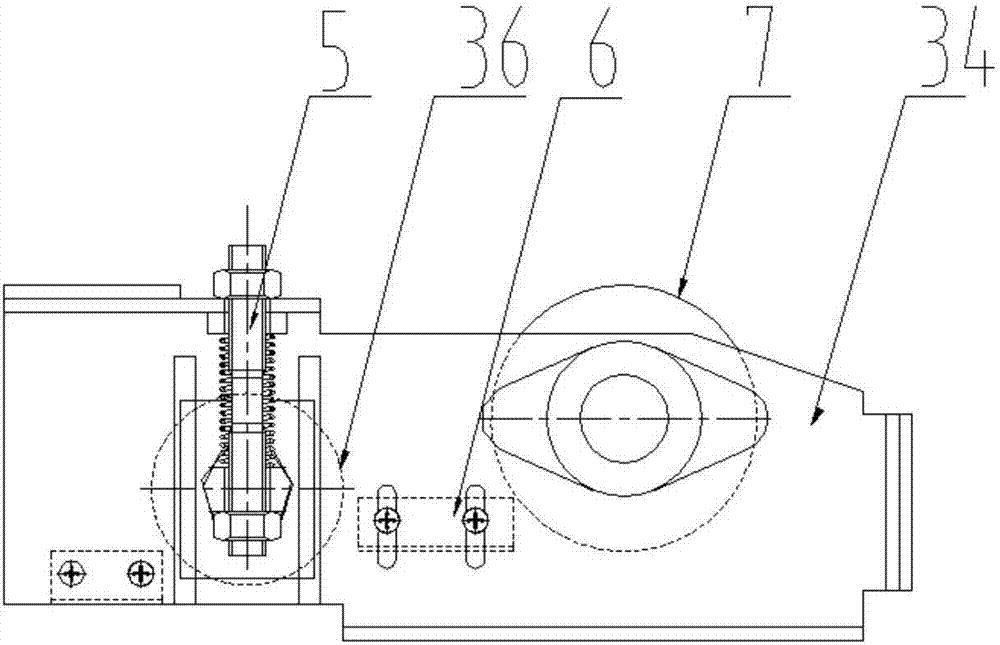

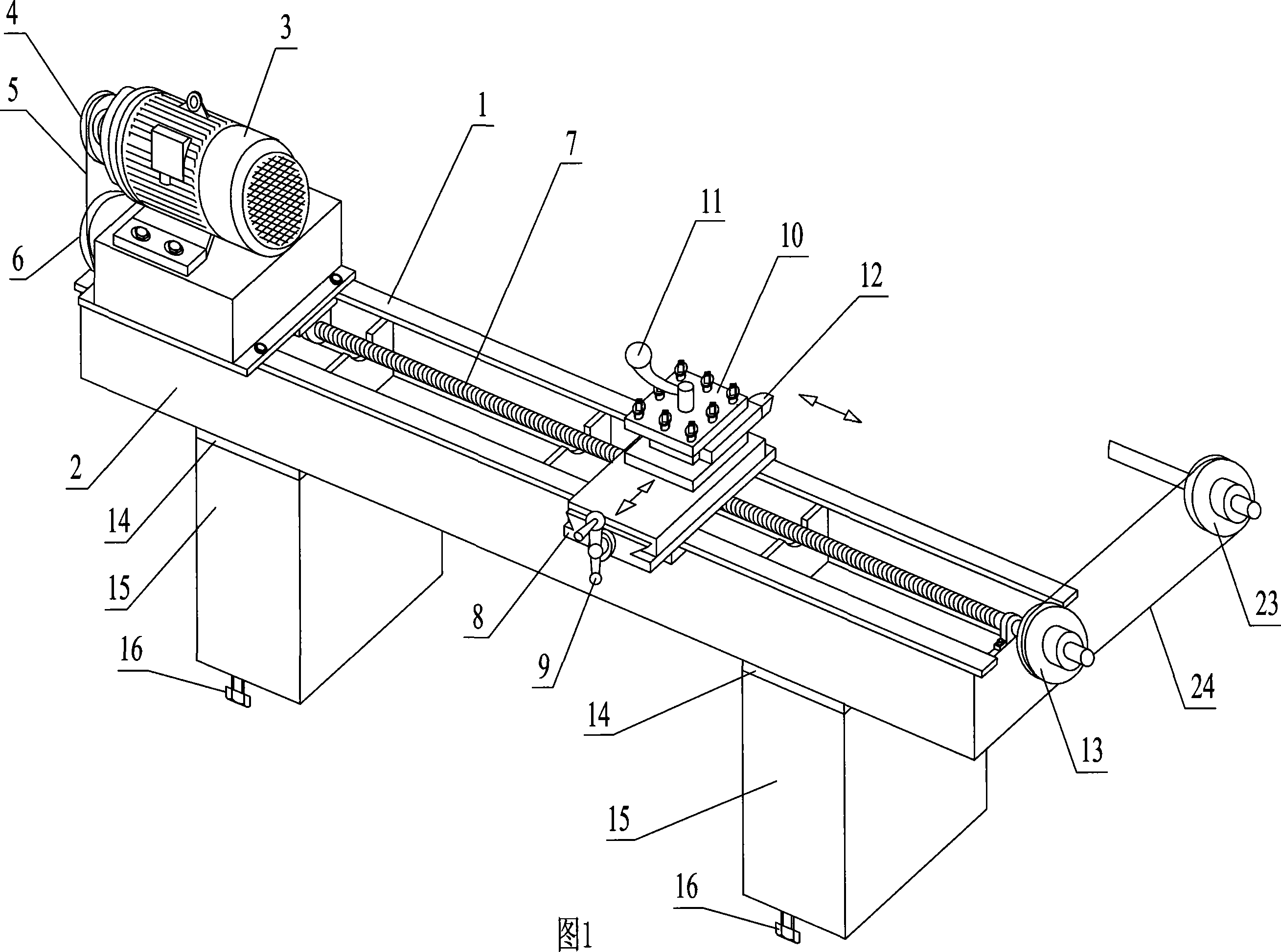

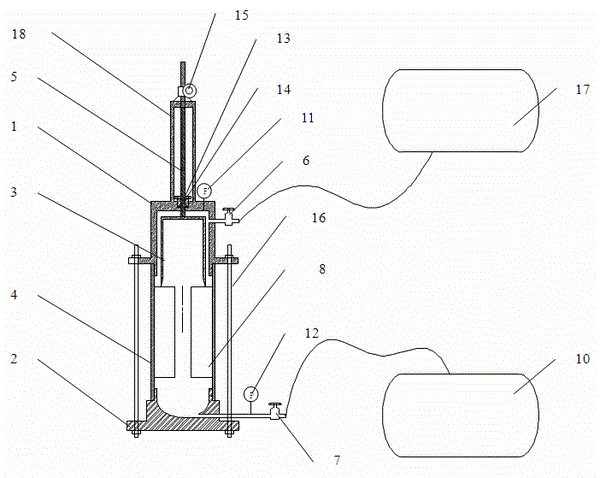

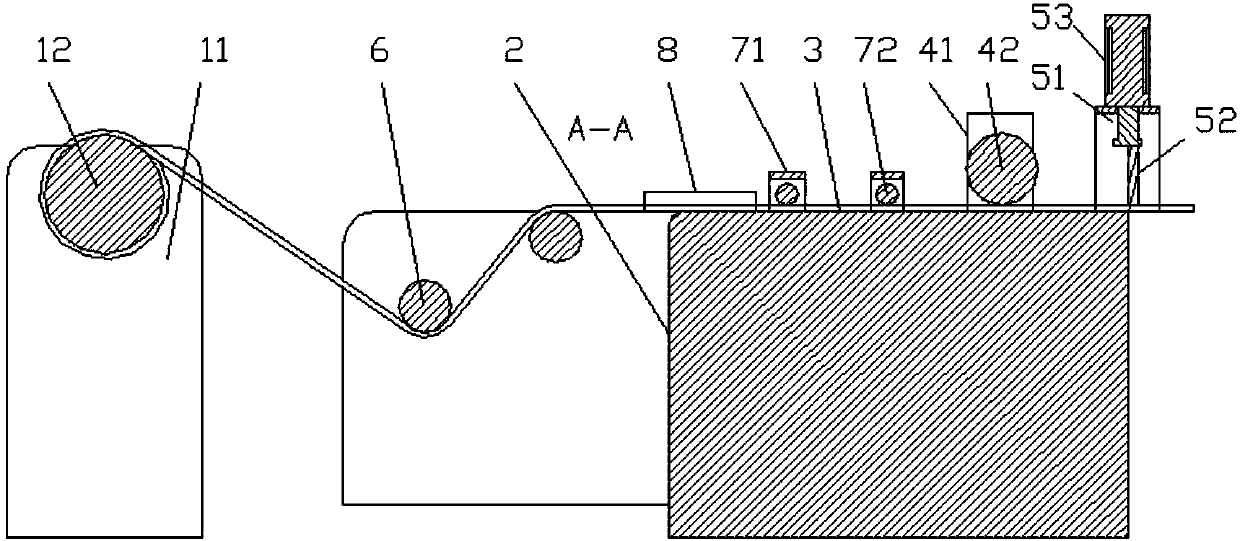

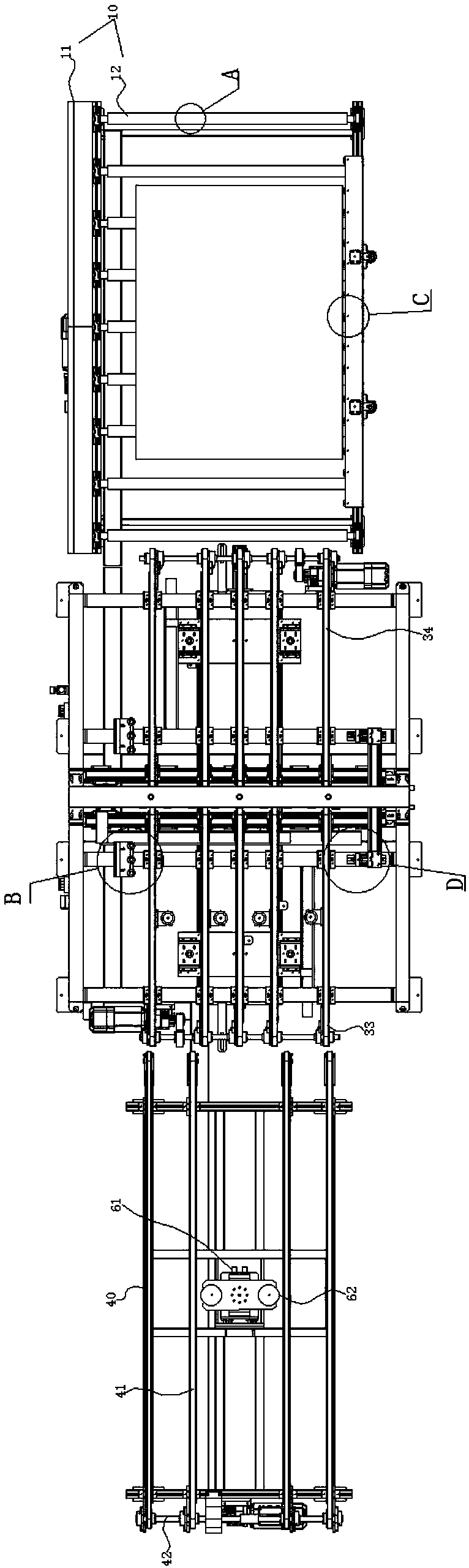

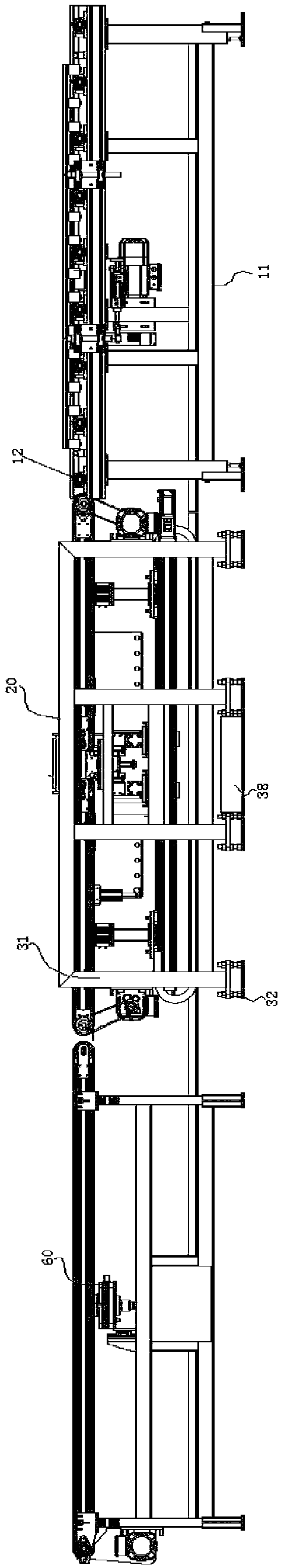

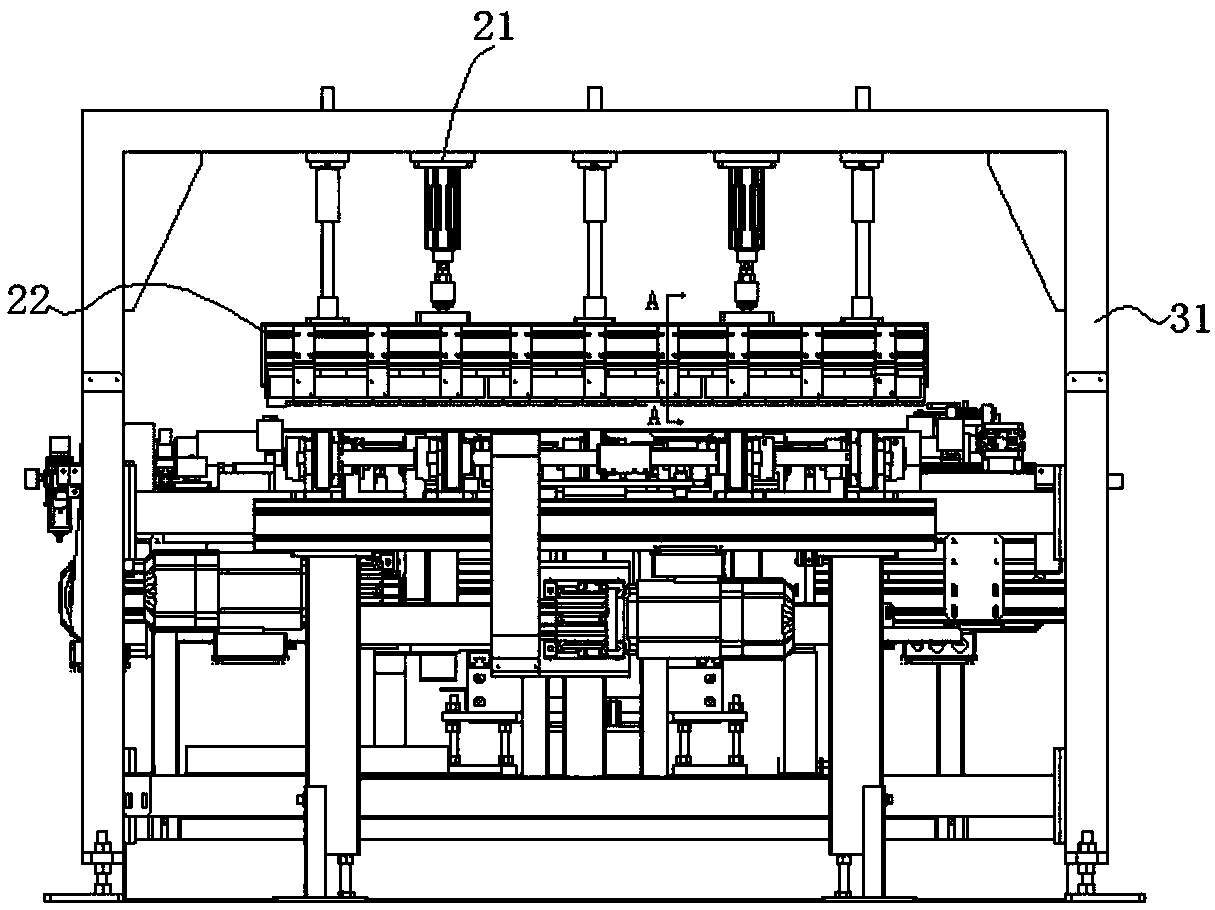

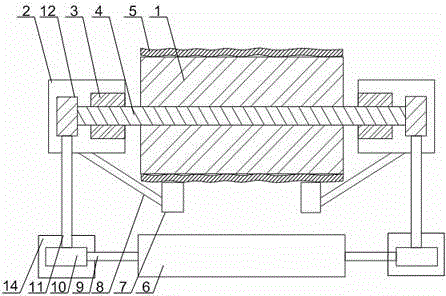

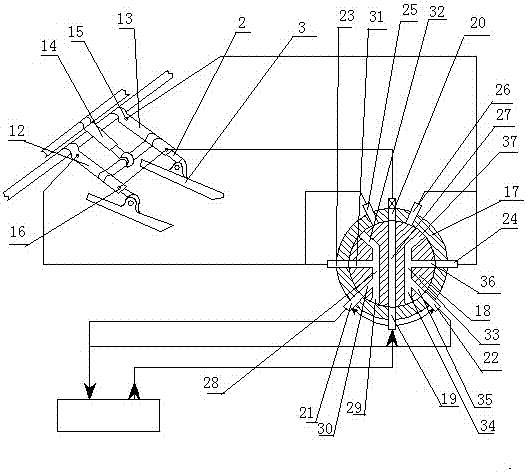

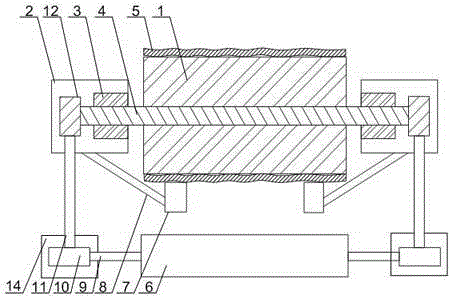

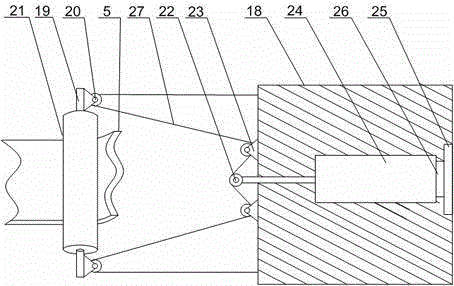

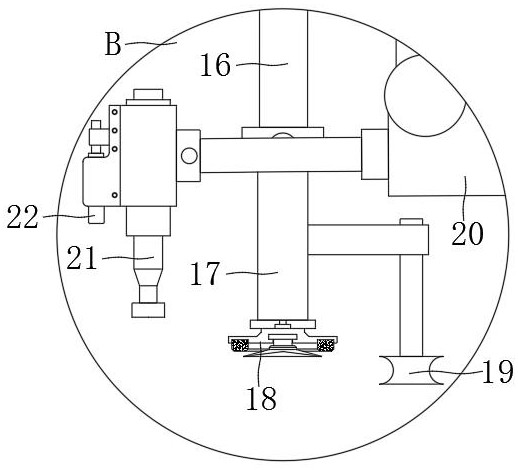

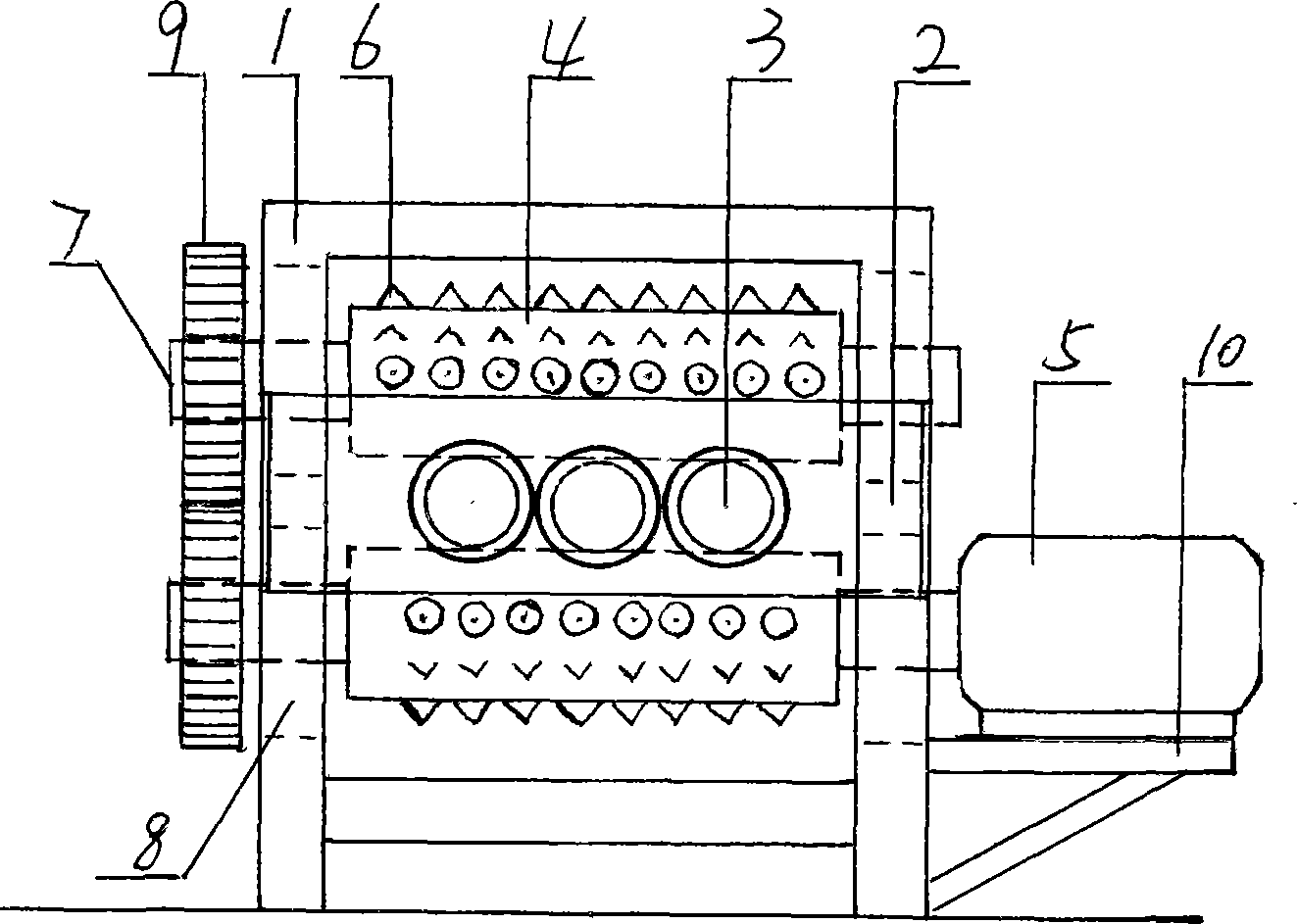

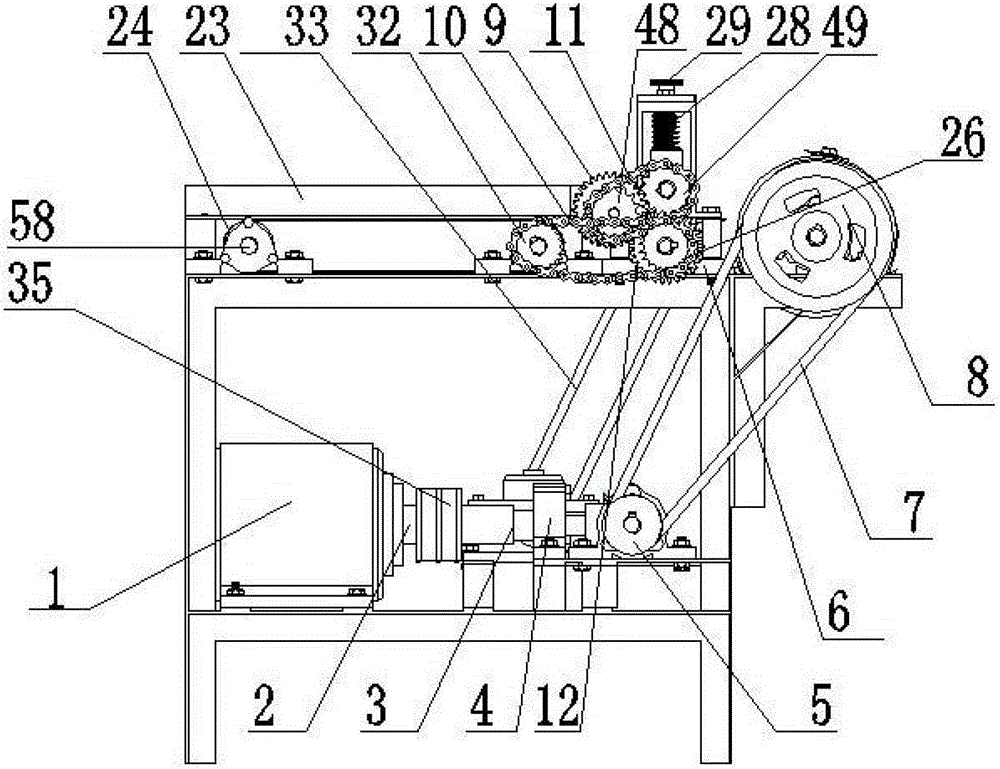

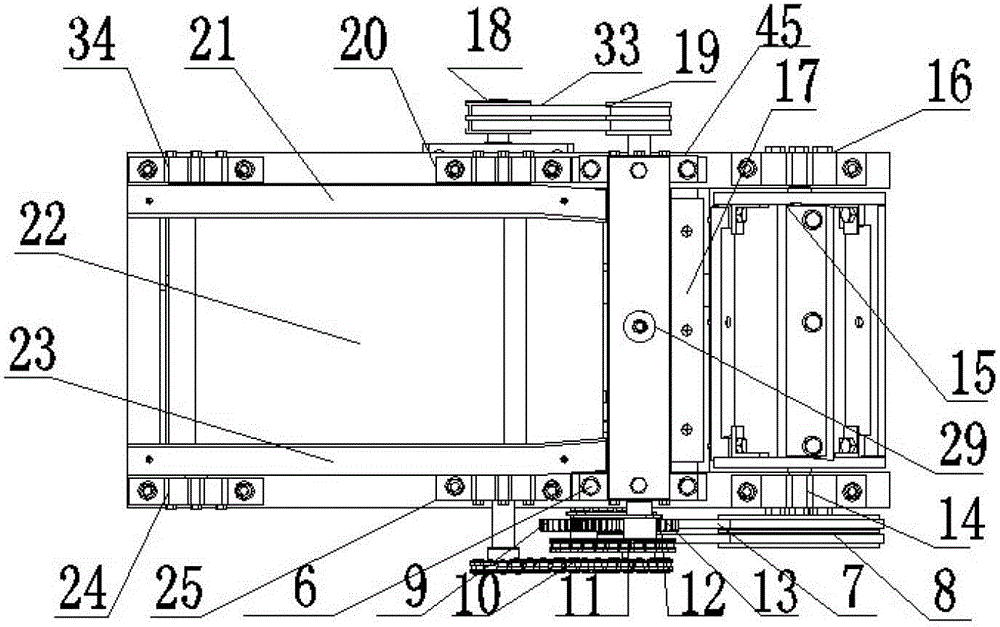

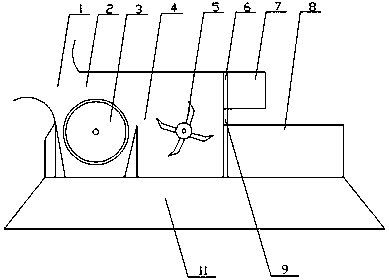

Straw cutting speed and length adjustable cylinder cutter

ActiveCN107046962AAdjust the speed in real timeControllable cutting speedCuttersControllers with particular characteristicsHelical lineResource utilization

The invention discloses a straw cutting speed and length adjustable cylinder cutter, belongs to the technical field of a straw resource utilization device, and is mainly used for rapidly and efficiently cutting a straw according to the required cutting length at the low power consumption. The cylinder cutter comprises a cylinder cutting device, a material pressing type feed device and a control display unit. The cylinder cutting device comprises a helical line type cutting moving blade, a horizontal cutting stationary blade and a rotating cylinder for installing the moving blade; the material pressing type feed device comprises an upper floating type material pressing roller, an upper fixing material pressing roller and a belt conveying platform; the cutting length is controlled through the belt conveying speed, and the cutting speed and the cutting efficiency are controlled through the belt conveying speed and the rotating speed of the rotating cylinder together. A controller acquires data through an acquisition test unit, the belt conveying speed and the rotating speed of the rotating cylinder are respectively controlled through calculation according to the set cutting length and the set cutting speed, and the straw is accurately efficiently cut at the low power consumption.

Owner:JIANGSU UNIV

Round section tubing slitting mill

The invention discloses round section tubes slitting mill, comprising drive axle, drive mechanism comprising rotating cylinder and driving medium, and cylinder cutting mechanism installed on the radial rotating cylinder. The inner ring of rotating cylinder is inner cam which is composed by many curved line; the driving device controlled unit which is composed by driving medium and clutch is installed on the drive axle to control cylinder cutter. The unit possesses the advantages of simple structure and continuous work. The unit is suit for producing tubes production line.

Owner:刘庆国

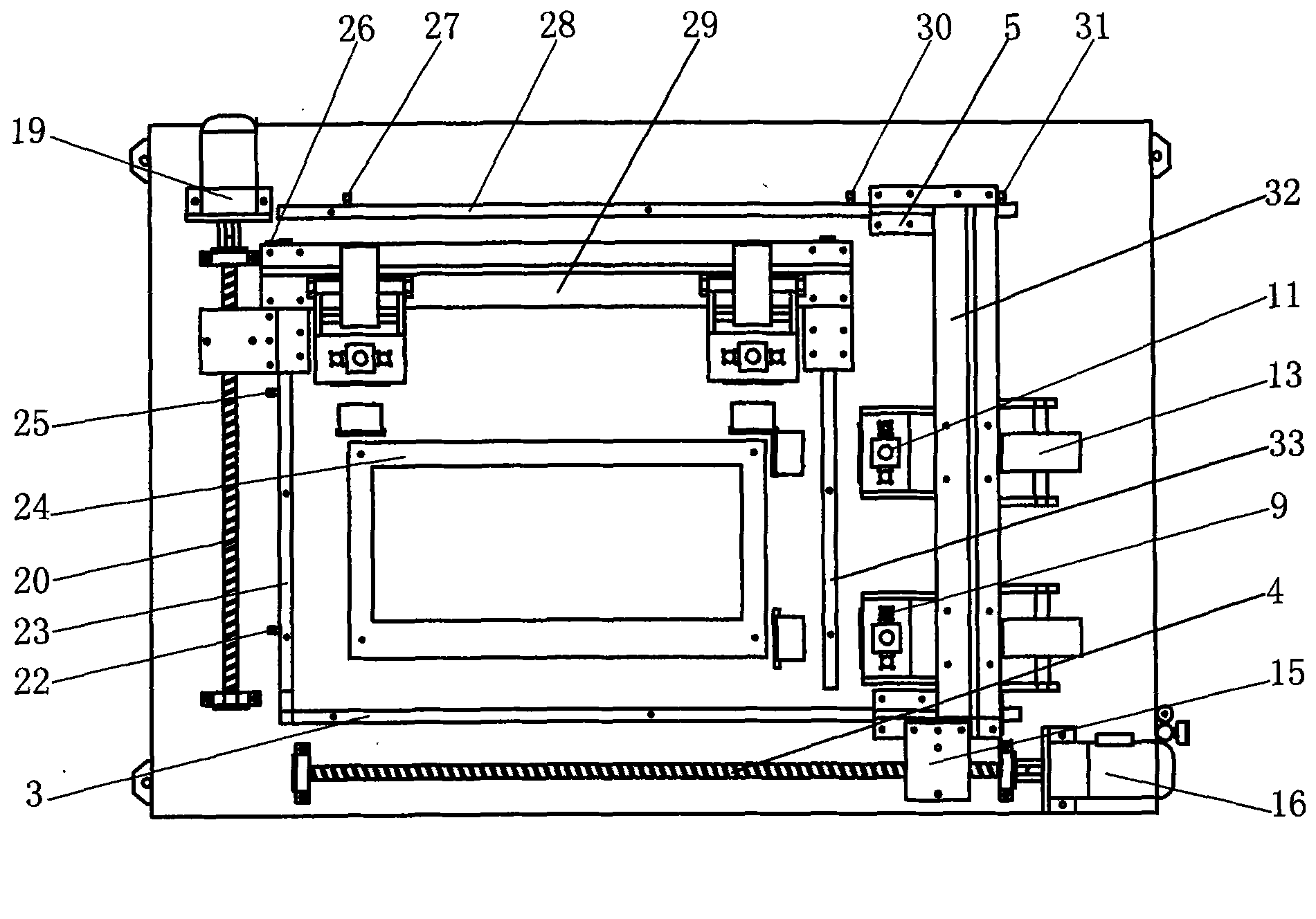

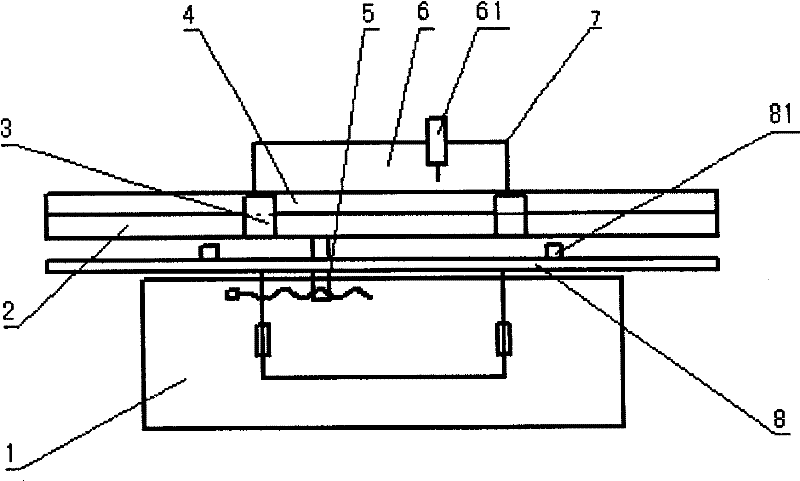

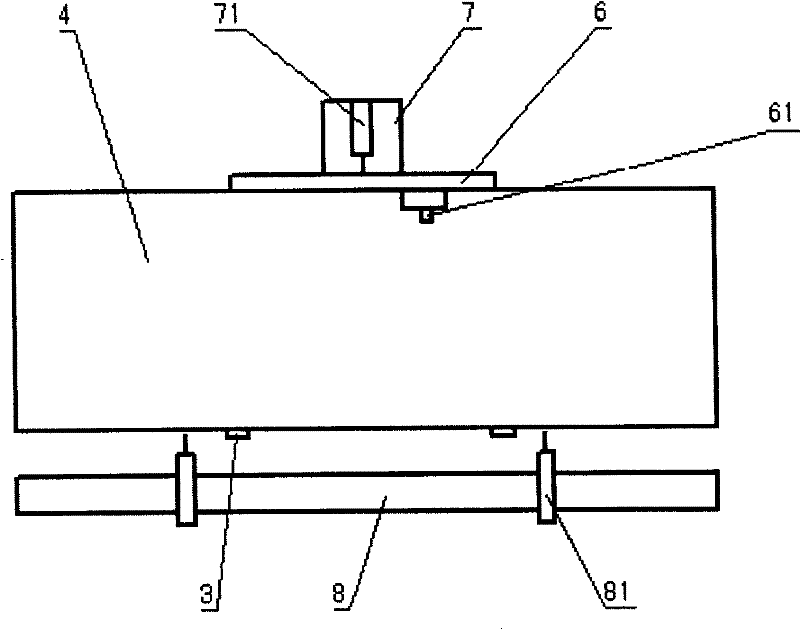

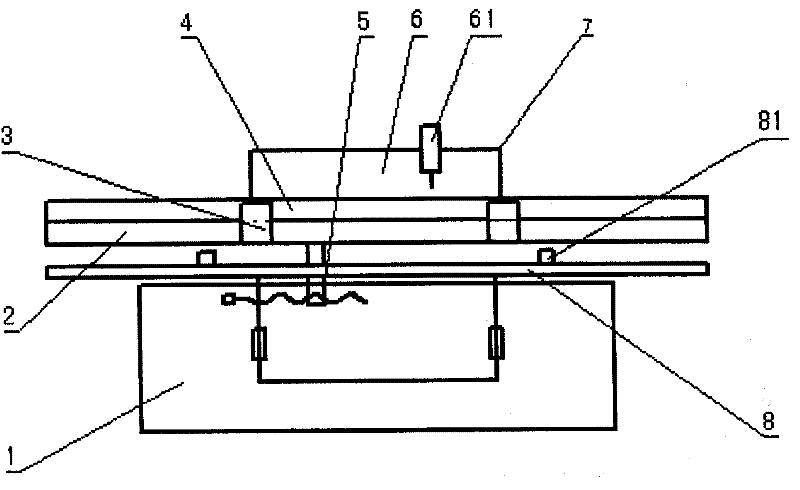

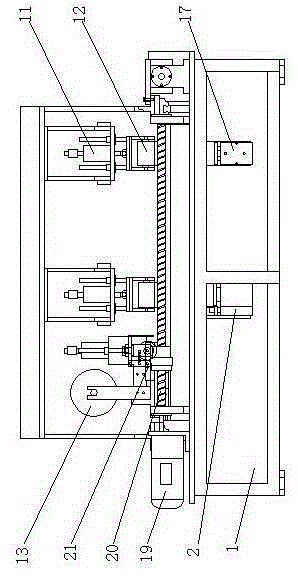

Four-side film laminator

InactiveCN102642374AEasy to useBeautiful processingLaminationLamination apparatusEngineeringPlastic film

A four-side film laminator is characterized in that a mould, a front guide rail, a rear guide rail, a left guide rail and a right guide rail are mounted on a bottom box, guide rail sliders are mounted on the guide rails, a transverse push rod is mounted between the sliders of the front guide rail and the rear guide rail, a longitudinal push rod is mounted between the sliders of the left guide rail and the right guide rail, a front laminating roller frame and a rear laminating roller frame are mounted on the lower portion of the transverse push rod, and a left laminating roller frame and a right laminating roller frame are mounted on the upper portion of the longitudinal push rod. A transverse lead screw is mounted on the outer side of the front guide rail, a longitudinal lead screw is mounted on the outer side of the left guide rail, the longitudinal lead screw, a lead screw nut and the transverse push rod are connected with a nut of the transverse lead screw, the longitudinal push rod is connected with a nut of the longitudinal lead screw, and the transverse lead screw and the longitudinal lead screw are provided with motors. A longitudinal cylinder cutter and a transverse cylinder cutter are mounted on the inner upper portion of the bottom box. The four-side film laminator solves the problem that materials are wasted when a laminating machine is used for totally closing the surface of an article, and the four-side film laminator is particularly applicable to covering plastic films for articles such as plastics, paper and the like.

Owner:江敦景

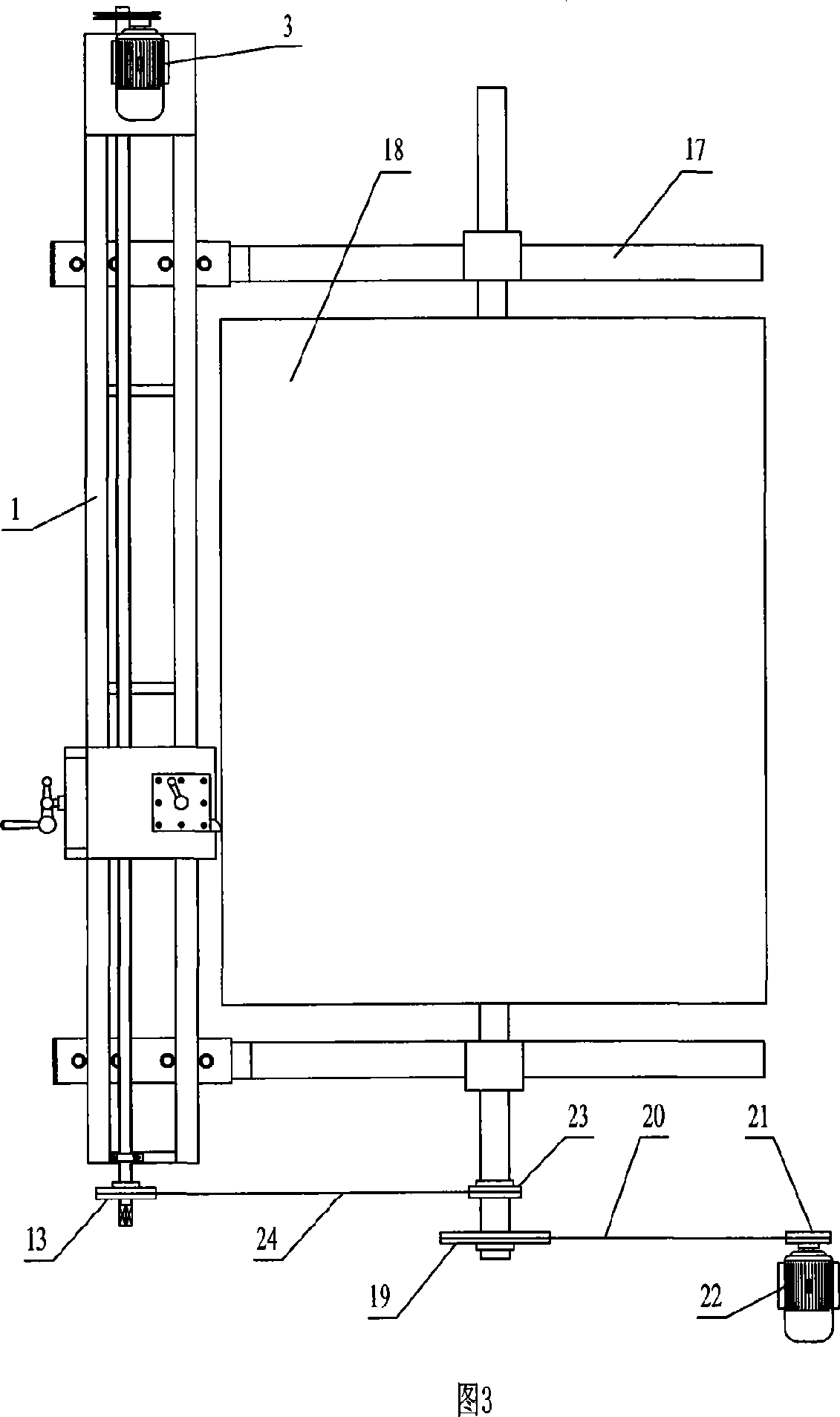

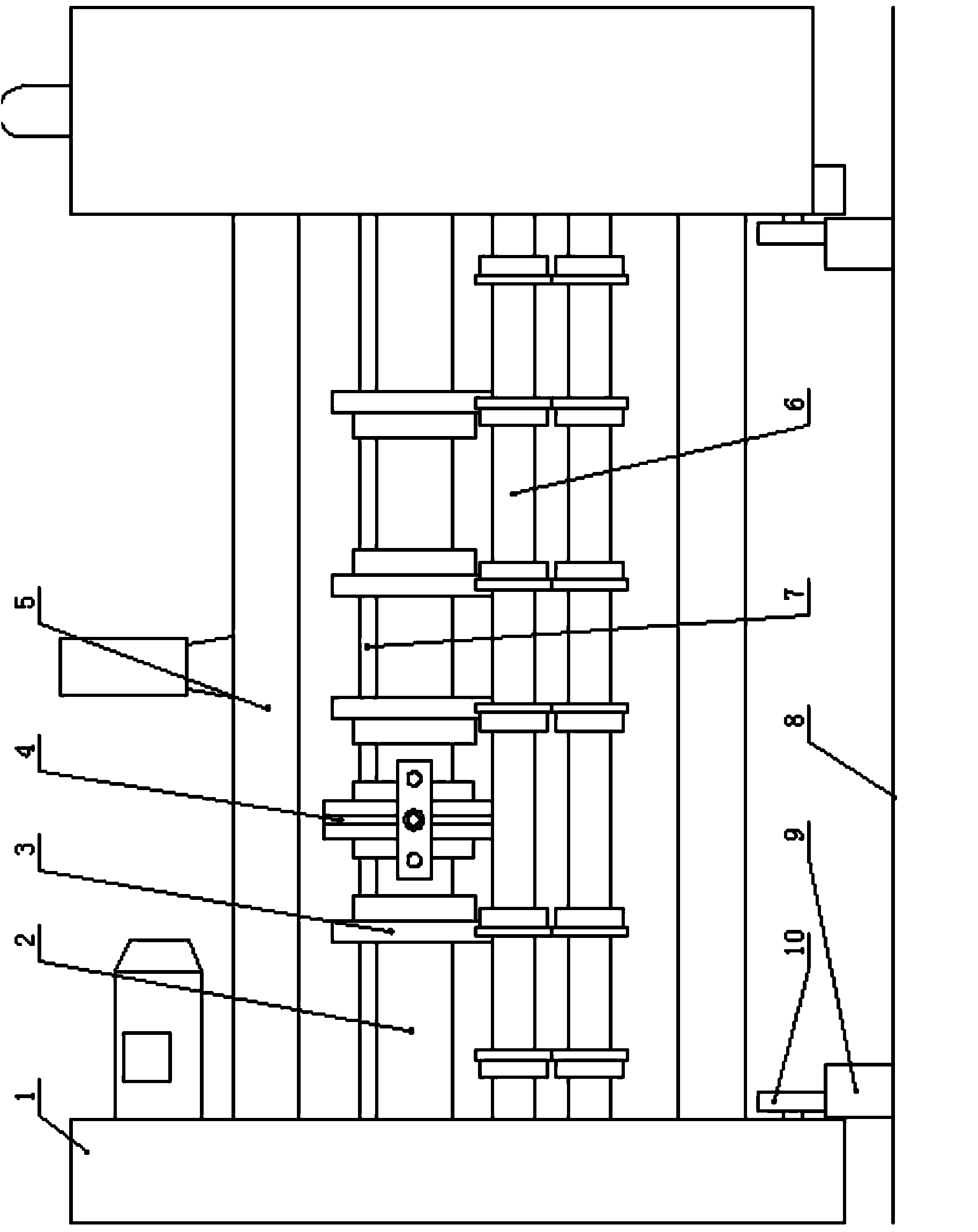

Special movable device for barrel cutting

InactiveCN101085468AHigh precisionReduce the workload of disassembly and assemblyFeeding apparatusLarge fixed membersSprocketEngineering

The movable cylinder cutter comprises the guide track cushion installed on the alight base, frame with guide track, bottom of the alight base having adjustable alighting device, left of the guide track installed with frequency changing generator with belt wheel, leather belt wheel and sprocket silk bar installed at left and right ends of the frame, with the belt wheel connecting with the triangle belt and frequency changing generator, the sprocket connected to the one on the cutting cylinder shaft through chains, with support plates installed on the thread bar along the guide track and handle knife base on the support plate with handle adjustable knife knob installed on the knife base. It can fine cut the surface of the cylinder to improve the precision of the hackling parts.

Owner:宋晓波

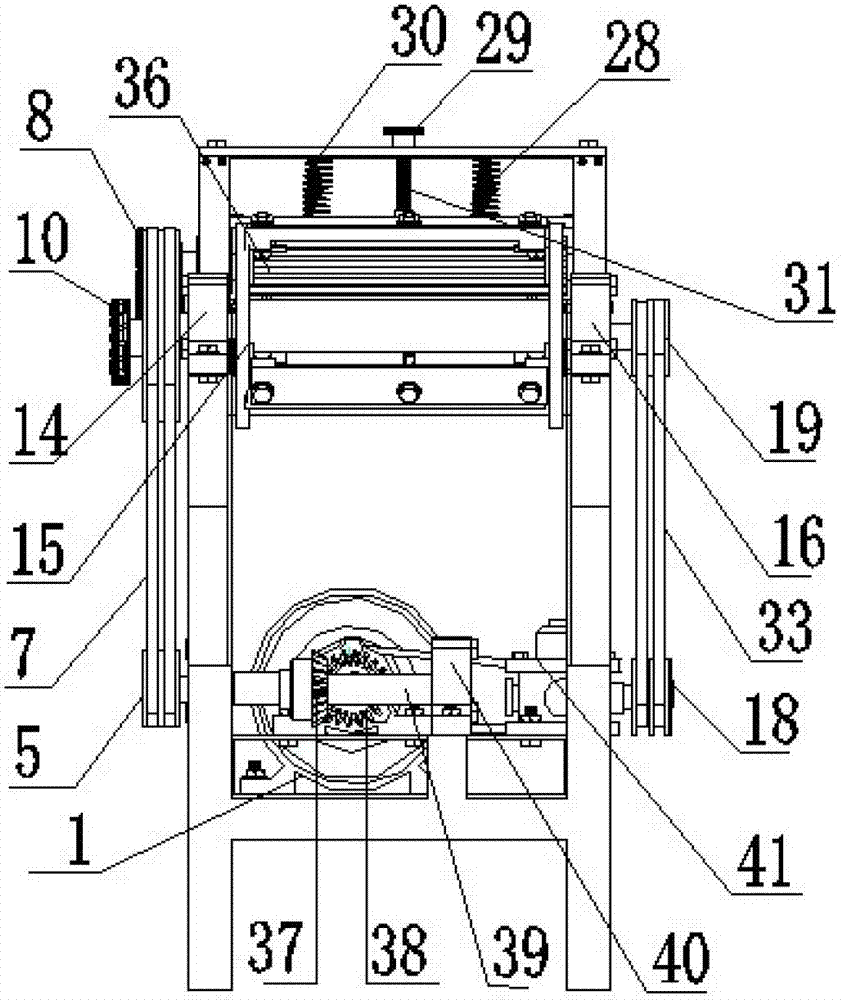

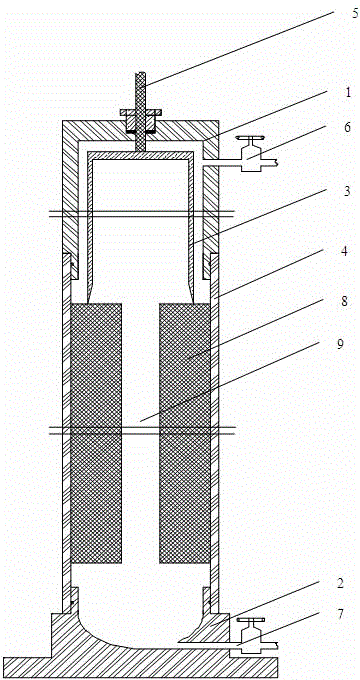

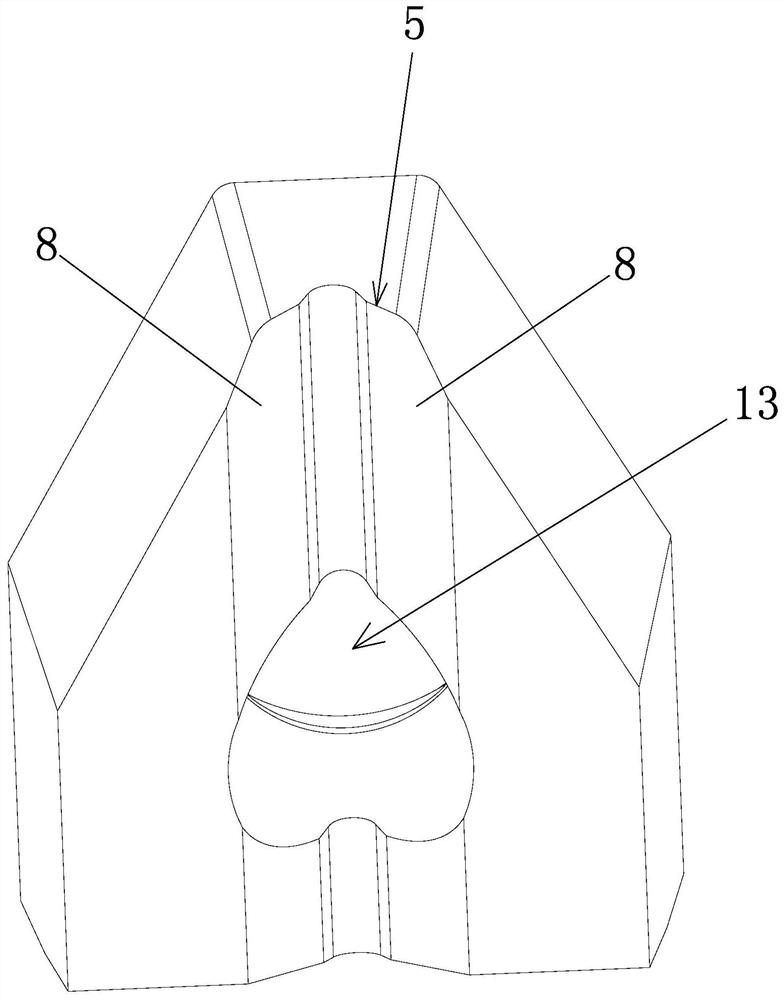

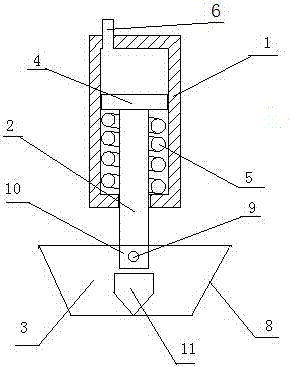

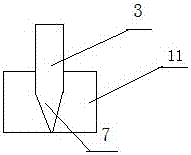

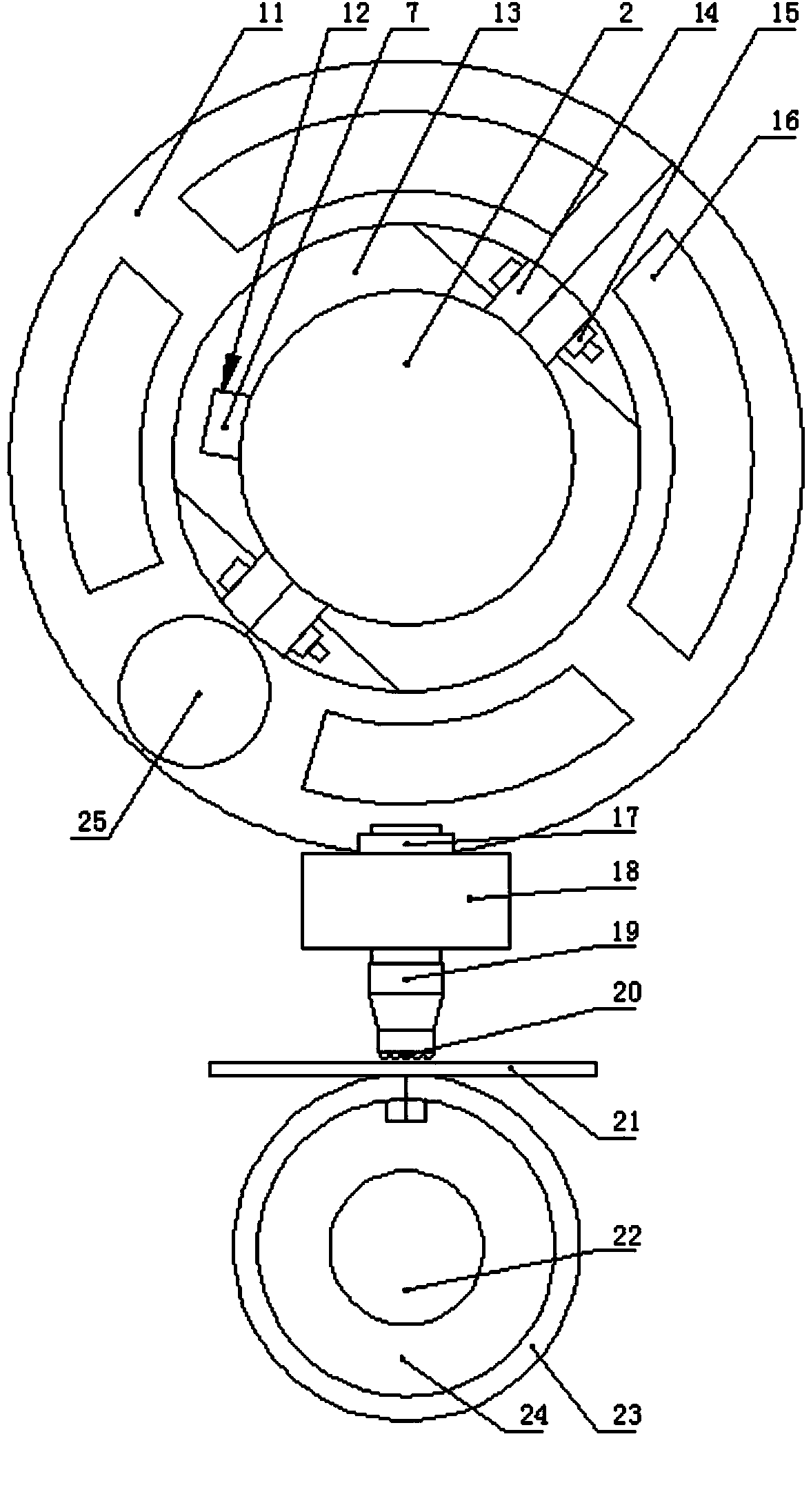

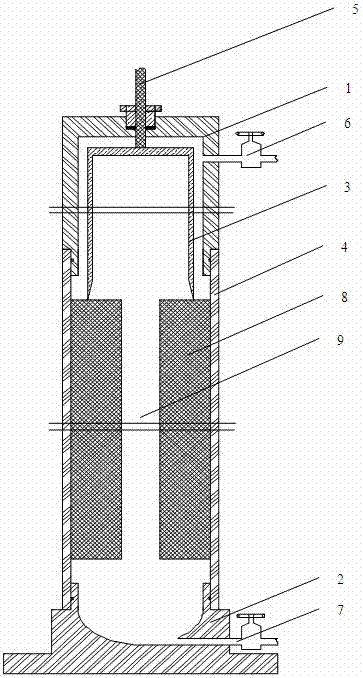

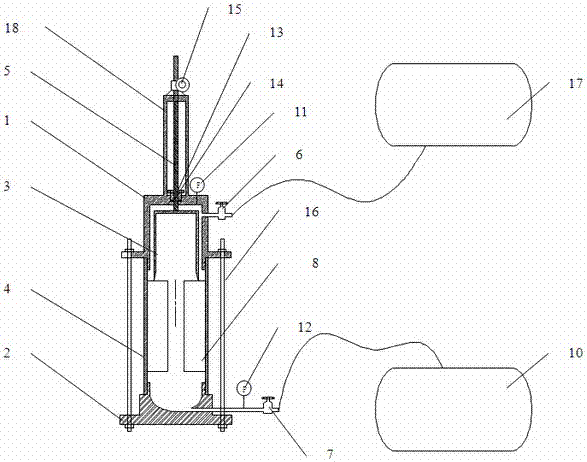

Safety separating device for shell and grain of small-sized composite solid rocket engine

A safety separating device for a shell and a grain of a small-sized composite solid rocket engine comprises an upper sealing seat and a lower sealing seat which are mounted at the upper end and the lower end of an engine shell to be processed in a sealing mode. A liquid inlet is formed in the upper sealing seat, and a liquid inlet valve used for regulating the flow quantity of sense reducing liquid entering the engine shell to be processed is connected to the liquid inlet. A liquid outlet is formed in the lower sealing seat, and a liquid outlet valve used for regulating the flow quantity of sense reducing liquid flowing out of the engine shell to be processed is connected to the liquid outlet. A cylinder cutter used for cutting the grain in the engine shell to be processed is arranged in the upper sealing seat, and is of a cylindrical structure with the closed upper end and a cutting edge at the lower end. A push rod used for pushing the cylinder cutter to cut the grain downwards penetrates through the upper sealing seat to be connected with the cylinder cutter. The position, making contact with the upper sealing seat, of the push rod is dynamically sealed. The safety separating device has the advantages of being safe, high in efficiency, small in equipment investment and suitable for recovery processing of small-sized scrapped solid rocket engines.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

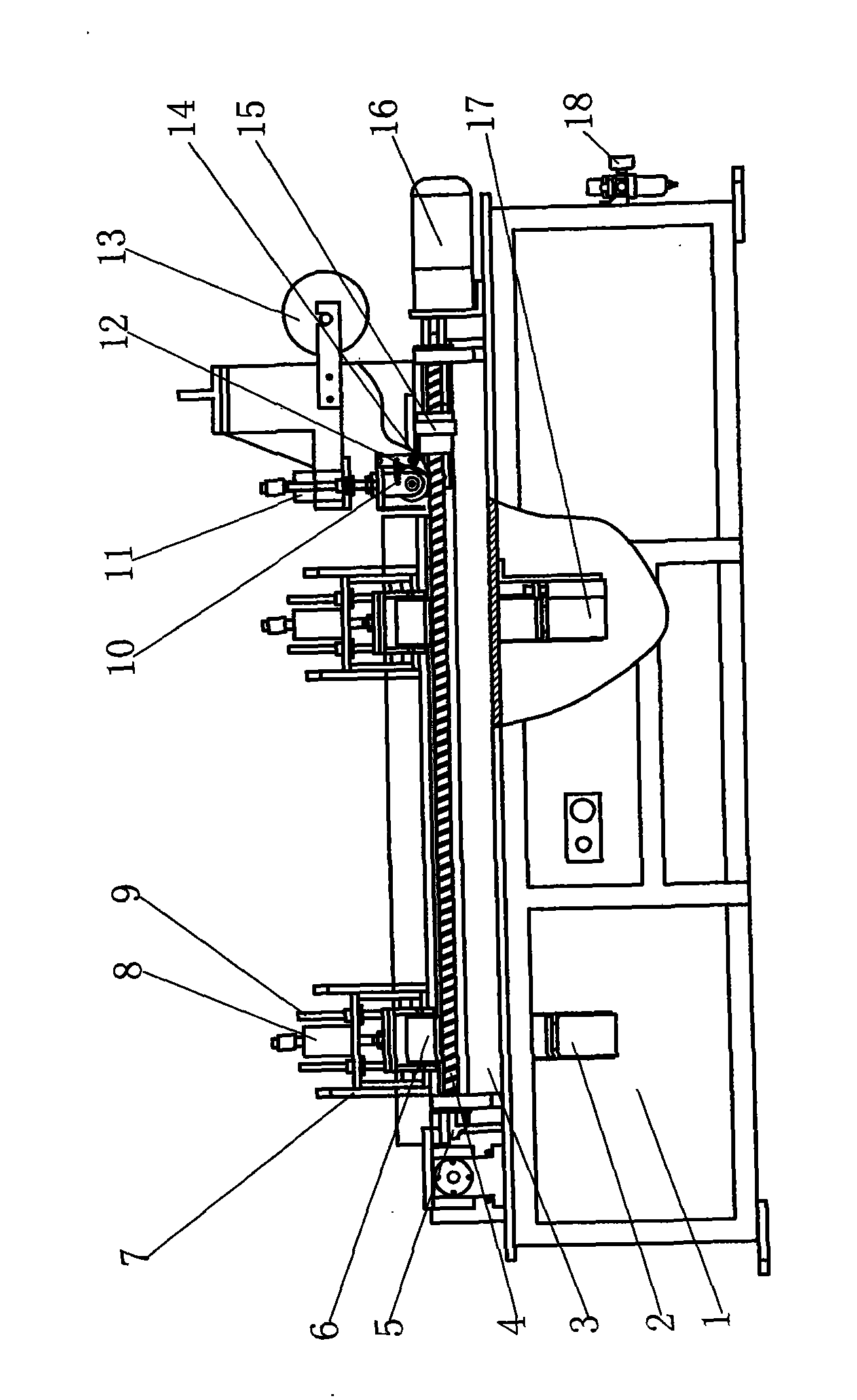

Cutting device used for iridescent printing paper

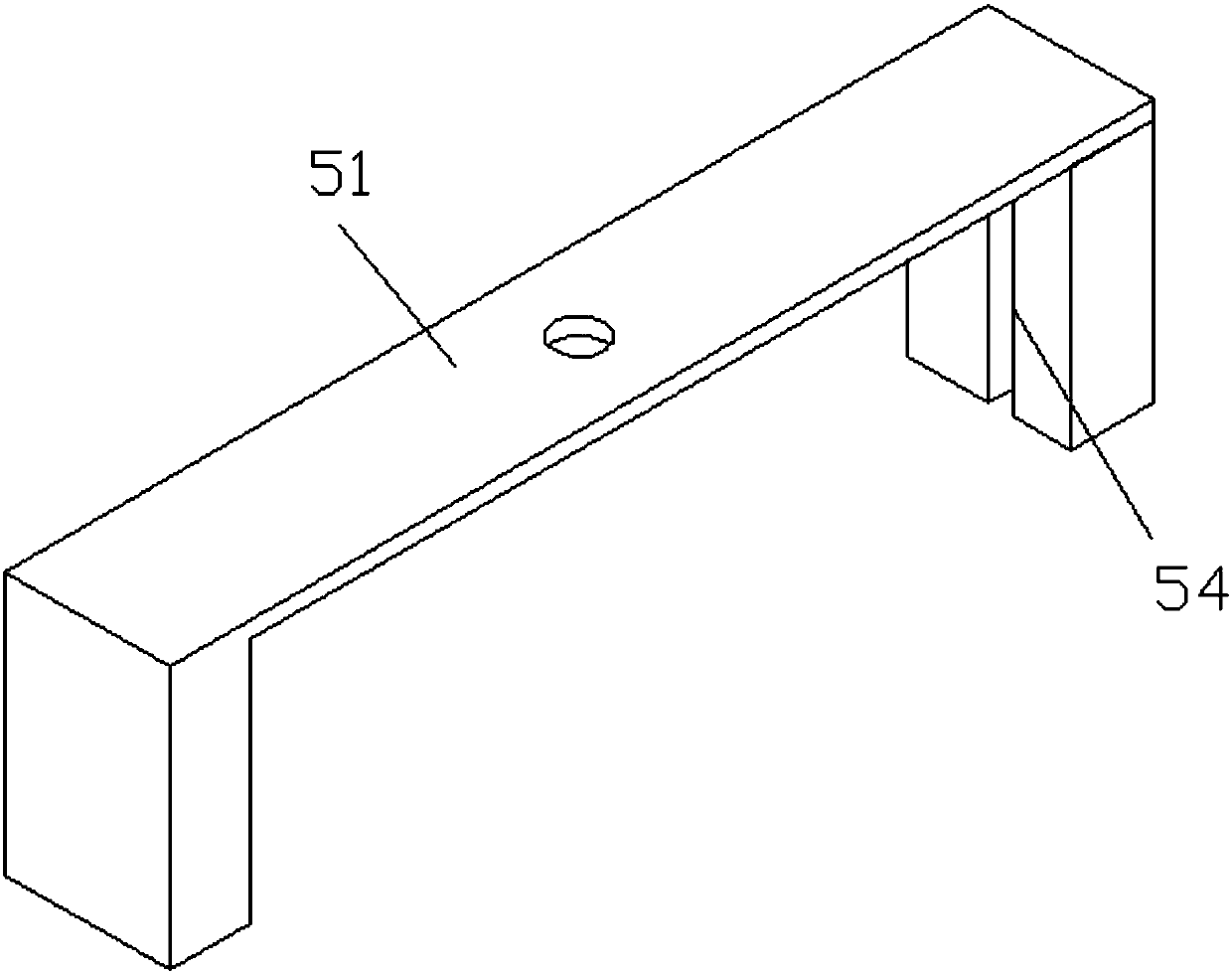

PendingCN107932569ARealize fixed-size cutting workHigh degree of automationMetal working apparatusWebs handlingInsertion stentPulp and paper industry

The invention discloses a cutting device used for iridescent printing paper, and relates to the field of paper processing equipment. The cutting device used for iridescent printing paper comprises anunwinding mechanism, a device body, a workbench, a guiding mechanism and a cutting mechanism. The unwinding mechanism is arranged on the left side of the device body. The workbench is arranged at thetop of the device body. At least one tensioning roller is arranged on the portion, between the unwinding mechanism and the workbench, of the device body. The guiding mechanism is arranged on the workbench. The cutting mechanism comprises a knife rest, a cutting knife and an air cylinder. Guiding grooves are formed in the two sides of the knife rest. The cutting knife is slidably connected into theguiding grooves, and the top of the cutting knife is connected with an output rod of the air cylinder. The air cylinder is fixed to the top of the rack. According to the cutting device for iridescentprinting paper, paper can be carried to the position of the cutting knife under the effect of the guiding mechanism, the cutting knife is controlled by the air cylinder to move back and forth, and thus fixed-dimension cutting of the paper is achieved; the whole process is controlled through a PLC, and thus the automation degree is high; and compared with traditional manual cutting, both the precision and the efficiency are greatly improved.

Owner:安徽天艺纸业科技有限公司

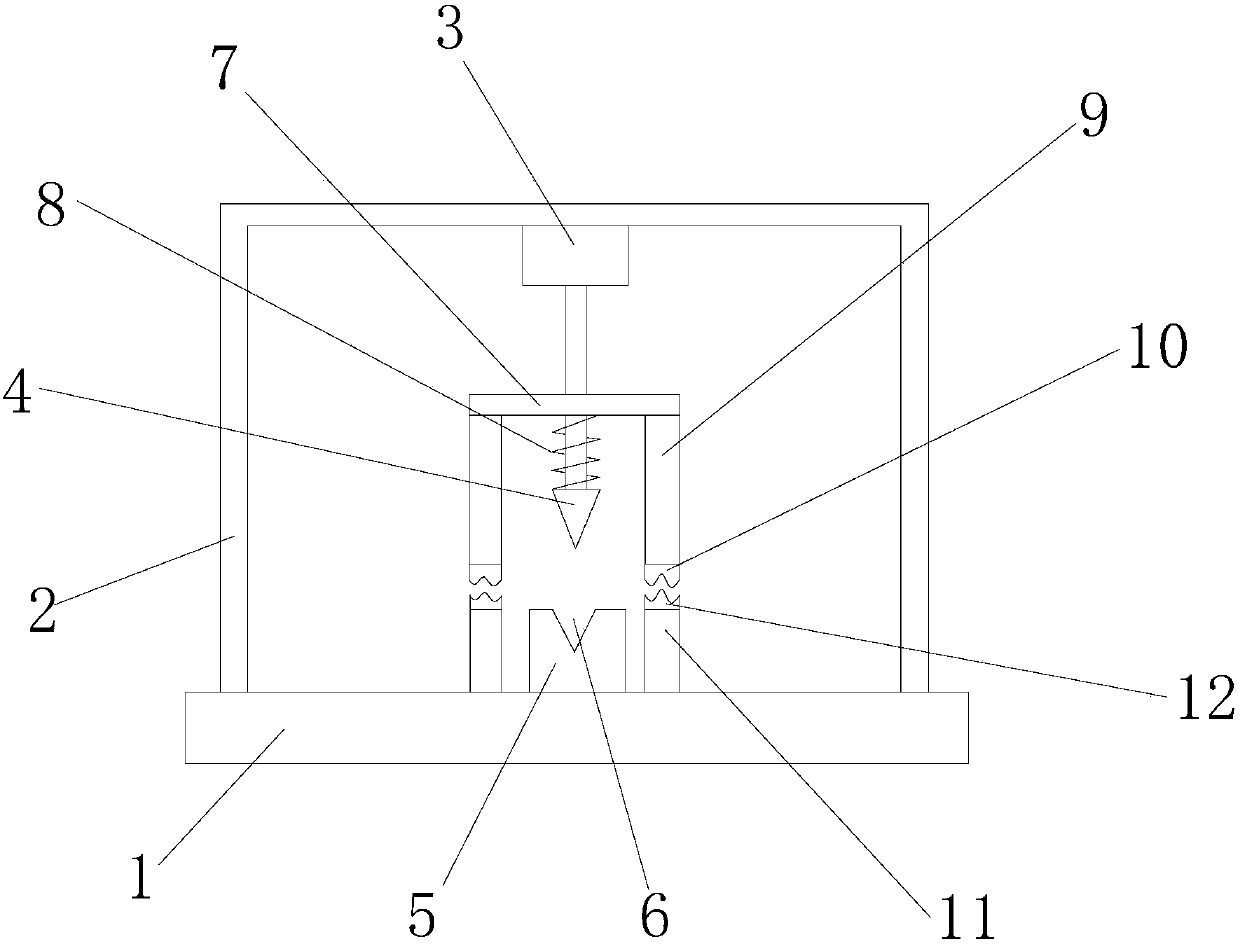

Yarn cutting device

The invention discloses a yarn cutter, which comprises a base, a frame, an air cylinder, a cutter, a knife seat, a knife groove, a mounting rod, a spring, a wire pressing plate, an upper rubber pad, a wire pressing seat and a lower rubber pad. The upper part of the base is fixedly equipped with a frame, the lower part of the frame is fixedly equipped with a cylinder, the lower end of the output shaft of the cylinder is fixedly equipped with a cutter, and a knife seat is arranged directly below the cutter, and the knife The upper surface of the seat is provided with a knife groove, and the outer side of the output shaft of the cylinder is slid to be provided with a mounting rod. There is a pressing board, the bottom of the pressing board is provided with an upper rubber pad, and a pressing seat fixed on the upper part of the base is provided directly below the pressing board, and a lower rubber pad is provided on the upper part of the pressing board , Compared with the prior art, the yarn can be cut quickly, the yarn rebound can be effectively prevented, the efficiency of yarn cutting is improved, and the textile processing is brought convenience.

Owner:新昌县绿松科技有限公司

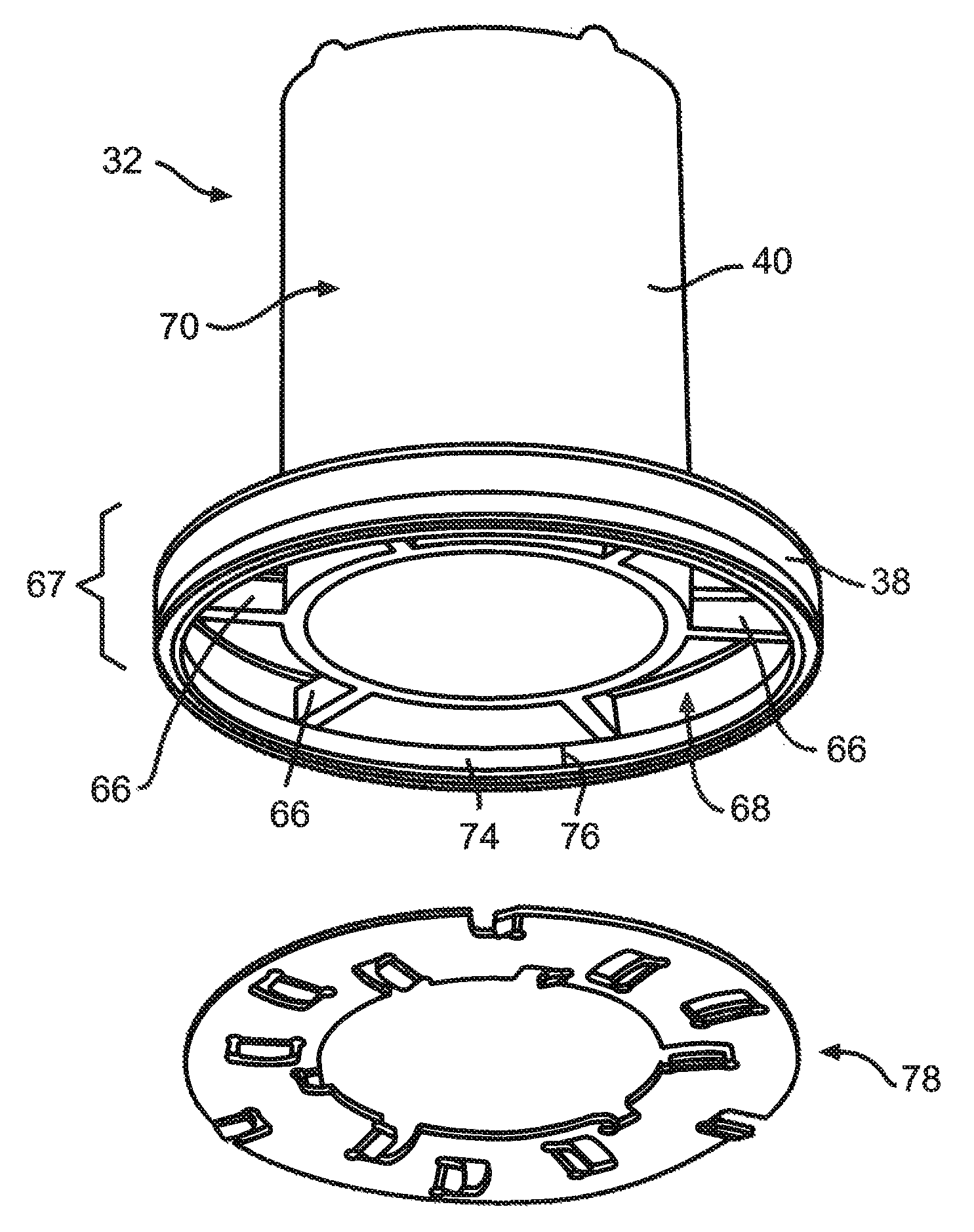

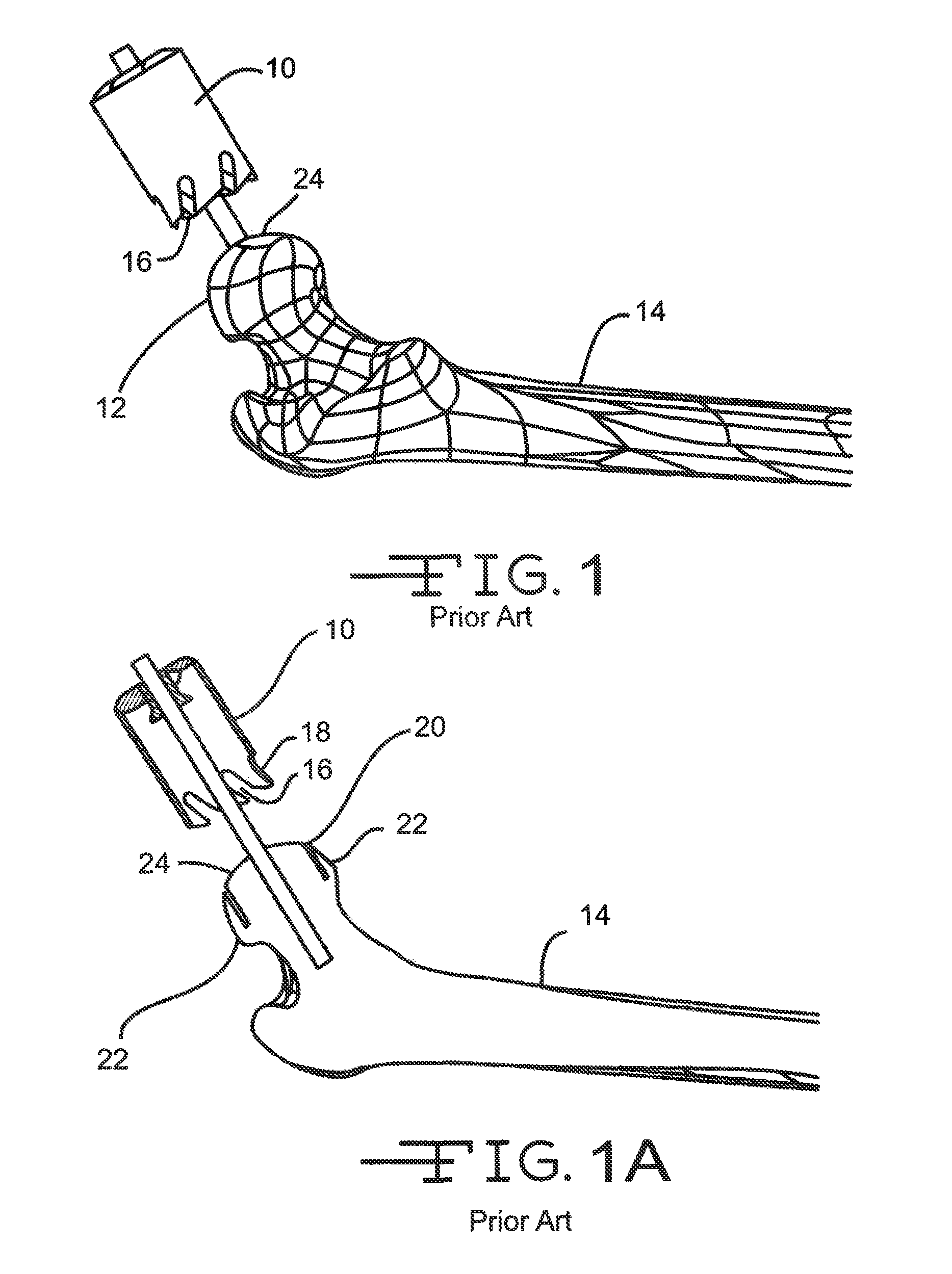

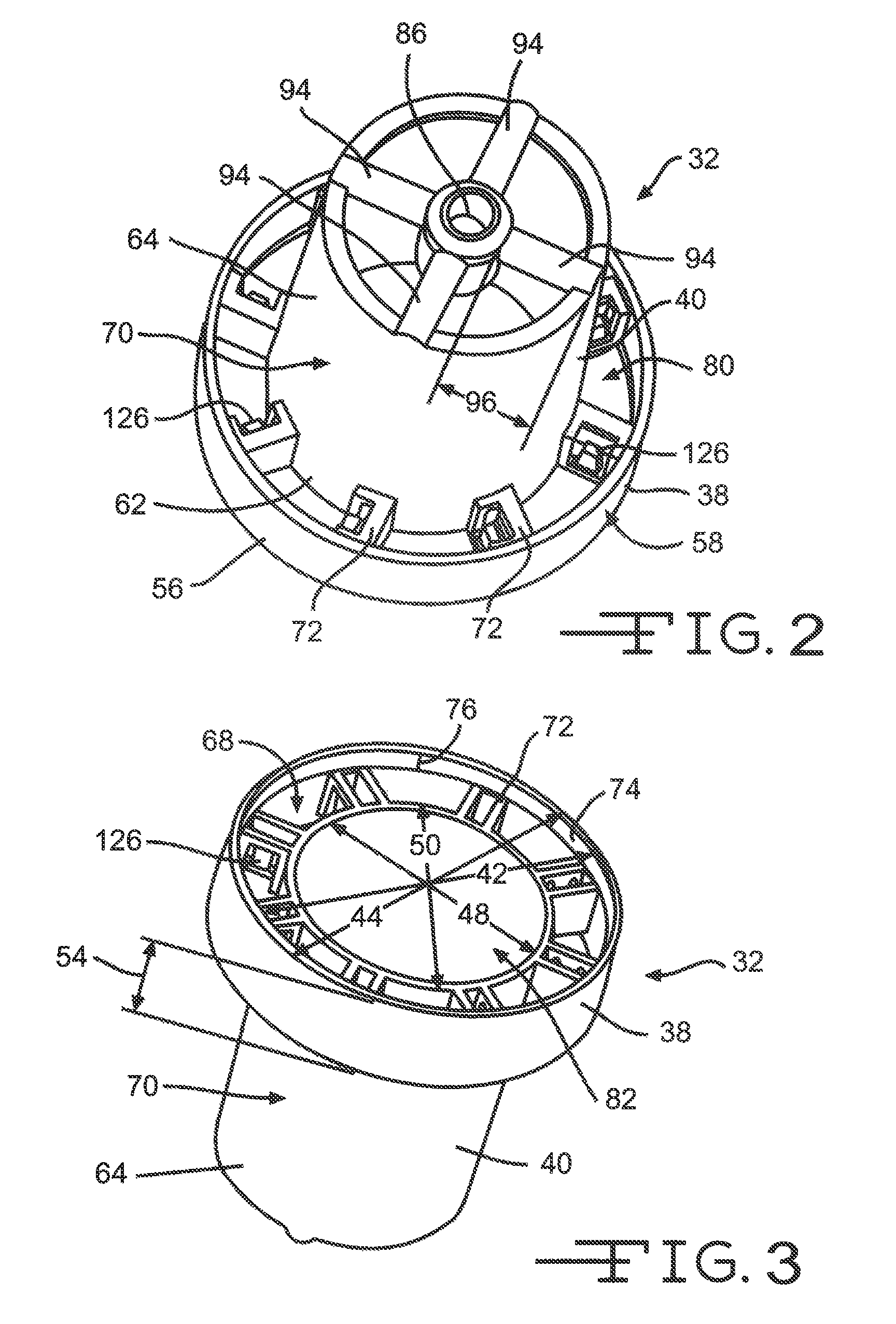

Disposable cylindrical cutter

ActiveUS8876825B2Avoid accidental damageAvoid overcuttingBone drill guidesConcentric cylinderMechanical engineering

A single use bone cutter comprised of two concentric cylinders and a series of insert blades or cutter disc is described. The cutter blades or cutter disc is preferably positioned at the distal end of the cutter. The bone cutter also comprises a guide rod that aids in the line of sight when using the cutter device.

Owner:WILSON GREATBATCH LTD

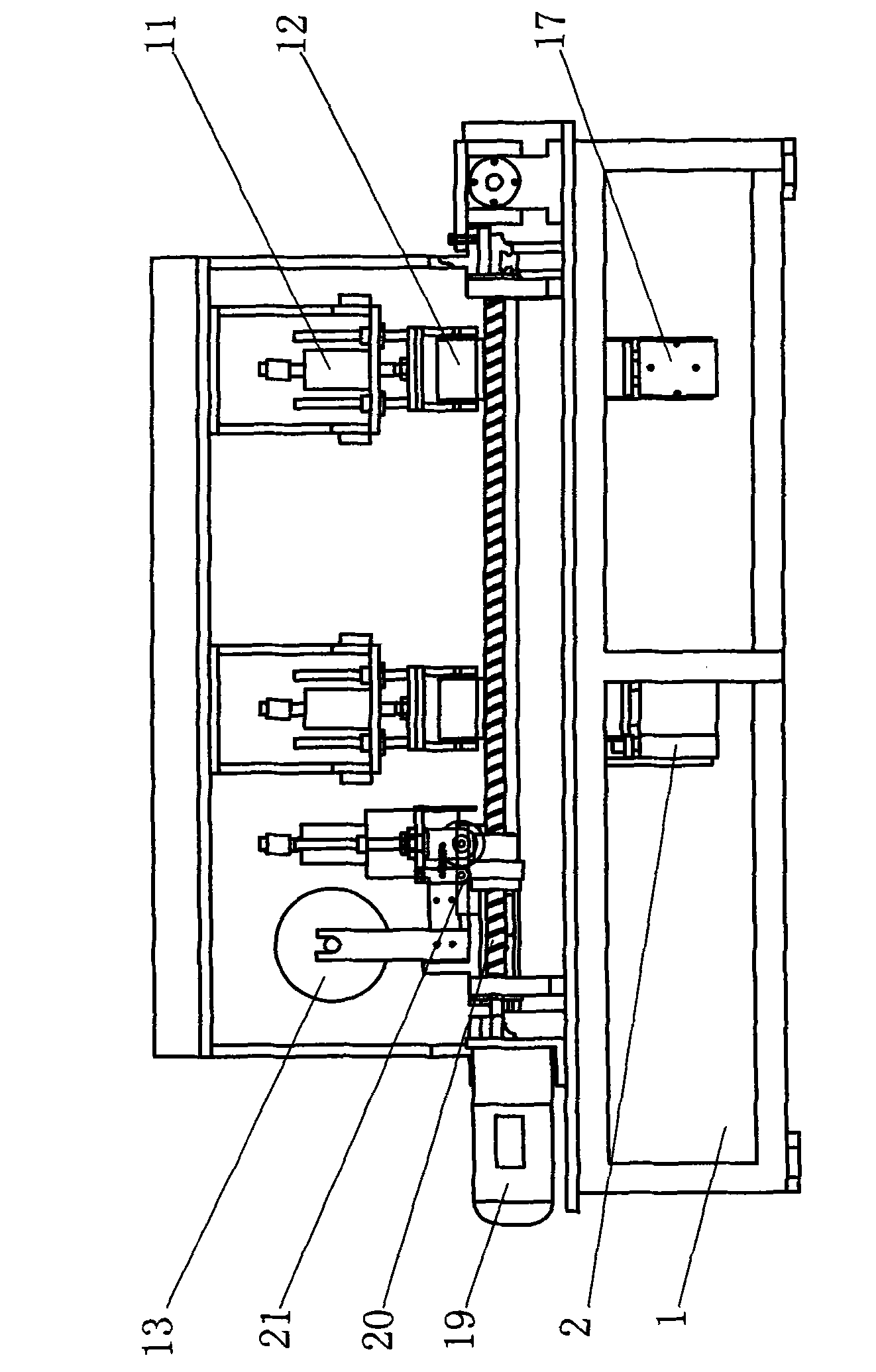

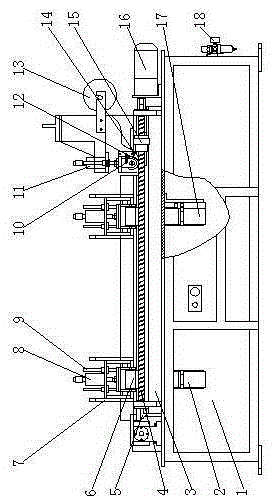

Hardware position processing lathe

InactiveCN102198676ARealize one-time processingEasy to fixWood mortising machinesWood slotting machinesEngineeringUltimate tensile strength

The invention relates to a hardware position processing lathe, which comprises a frame body and a bench arranged on the frame body, wherein the top of the bench is used for fixing a workpiece through a positioning and clamping device, wherein the positioning and clamping device is a door positioning and clamping element or a doorframe positioning and clamping element, a bench moving part is arranged below the bench, a lock cylinder cutter moving part and a locked groove cutter moving part are arranged on one side of the frame body, a hinge moving part is arranged on the other side of the frame body, a lock cylinder hole processing cutter is arranged on the lock cylinder cutter moving part, a locked groove processing cutter is arranged on the lock cylinder cutter moving part, and one or two or three hinge groove processing cutters are arranged on the hinge cutter moving part. The hardware position processing lathe is provided with the plurality of processing cutters, can realize once machine-shaping of positions of hardware such as a door lock and a door hinge and the like, has the advantages of low labour intensity, high production efficiency and stable quality of quantity production, can be used for processing the position of the hardware of the door and processing the position of the hardware of the doorframe, and has multiple purposes.

Owner:QIDONG LONGSHENG PRECISION MACHINERY

Self-adaptive glass cutting machine

PendingCN108483889AEasy to collect and storeAchieve separationGlass severing apparatusCutting forceSelf adaptive

The invention relates to the technical field of glass processing, in particular to a self-adaptive glass cutting machine. The self-adaptive glass cutting machine comprises a glass input mechanism anda pressing positioning mechanism, wherein the glass input mechanism is used for conveying glass to a cutting mechanism to be cut; a cutter head body and rotating shaft in a cutter head are respectively provided with through holes penetrating the cutter head body and the rotating shaft along corresponding axes, the cutter head body can be vertically movably arranged on a cutter head seat through anair pump; during the cutting, the cutter head seat is provided with the air pump, a cylinder cutter cuts the surface of the glass under the action of the air pump, the direct contact between the cylinder cutter and the glass is flexible contact, that is to say, the contact between the cylindrical cutter and the glass is similar to elastic contact; the cutter head itself can adjust the cutting force when encountering an uneven position so as not to break the cutter head, and the problems in the prior art are solved that the contact between the cutter head and the glass is rigid, the cutter head is damaged during cutting, the cutter head breaks, and the glass cracks.

Owner:ANHUI YINRUI GLASS MACHINERY

Bag breaking device of garbage bag

PendingCN110697181AAvoid affecting the bag breaking effectIncrease flexibilitySolid waste disposalBags openingElectric machineStructural engineering

Owner:GUANGZHOU UNIVERSITY

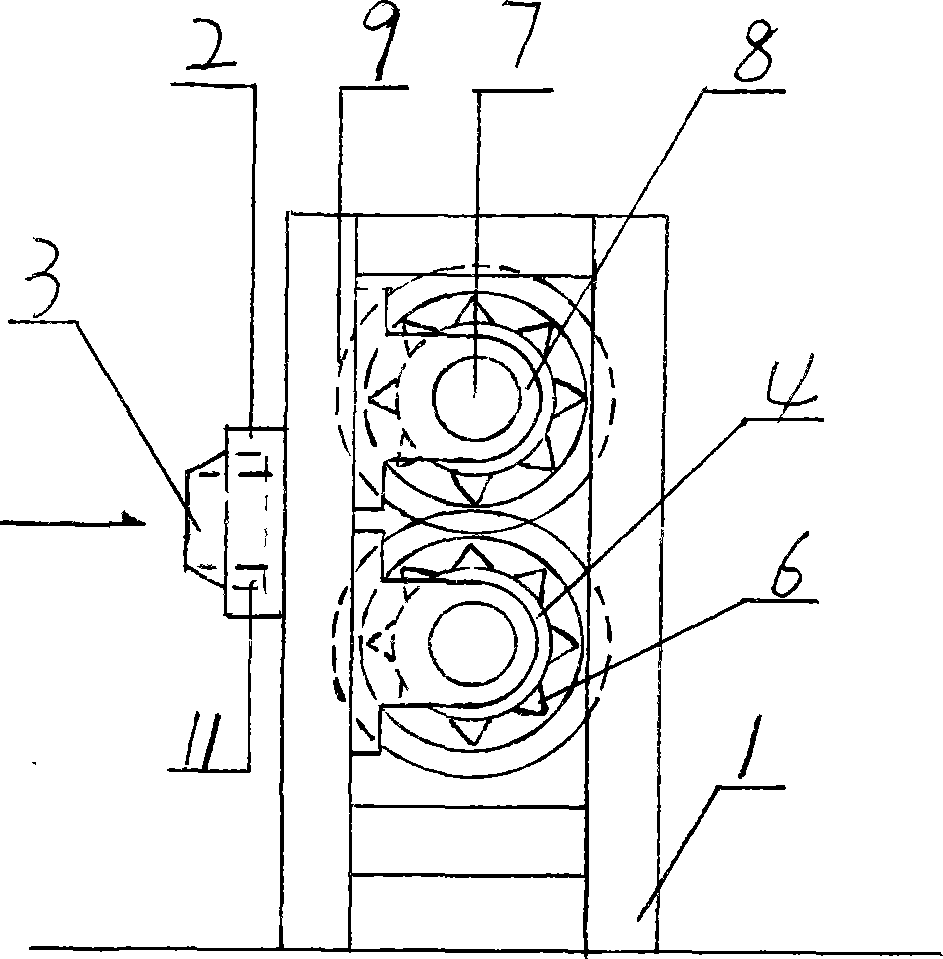

Belt conveyer

ActiveCN103979288AExtended service lifeImprove job stabilityConveyorsCleaningVertical vibrationKnife blades

The invention discloses a belt conveyer. The belt conveyer comprises a frame and a conveying belt; the frame is provided with a main roller, a driven roller and a support cylinder; the conveying belt sleeves the main roller and the driven roller; the rotating shaft of the main roller penetrates one end of the support cylinder and is rotatably arranged inside bearings and connected with a cylinder cutter, which is parallel to the rotating shaft, through a linkage mechanism. The belt conveyer also comprises a V-shaped blade which is fixed onto the support cylinder through a connecting rod, the V-shaped blade is in an arc shape matched with the outer surface of the main roller, the cross section of the V-shaped blade is provided with a wheel, and when in work, the wheel is in contact with the conveying belt on the main roller; the driven roller is provided with a tensioning mechanism. When the main roller fails and leads to vertical vibration of the conveying belt, the wheel mounted on the cross section of the V-shaped blade is in contact with the conveying belt, so that damage to the V-shaped blade due to too much contact between the V-shaped blade and the conveying surface of the conveying belt can be effectively avoided, and further the service life of the conveying belt can be prolonged.

Owner:承德光大输送机有限公司

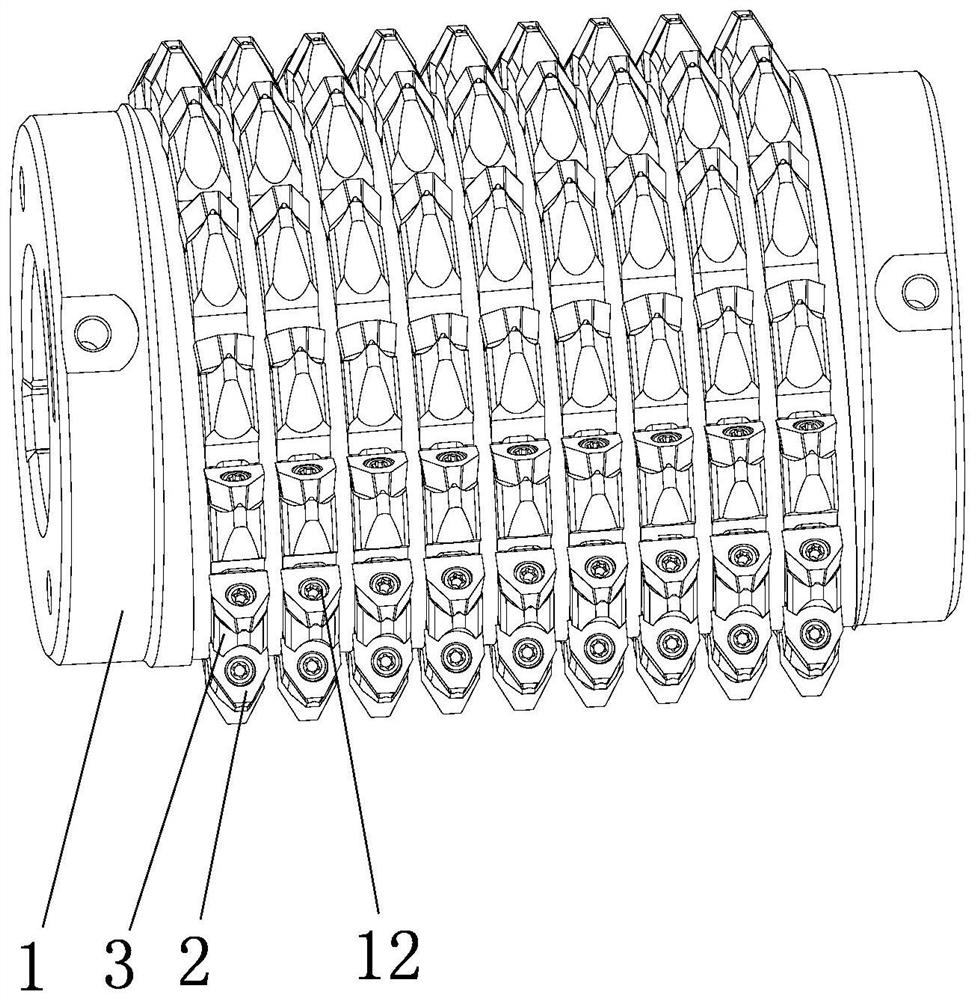

Spline hob with indexable blades

PendingCN112958819AImprove work performancePrecise positioningMilling cuttersStructural engineeringKnife blades

The invention provides a spline hob with indexable blades, and belongs to the technical field of cutters. The spline hob solves the problems that a hob body and blades of an existing spline hob are integrally formed, the blades can be damaged easily after the spline hob is used for a period of time, and the whole spline hob needs to be replaced. The spline hob with the indexable blades comprises a cylindrical hob body and a plurality of blades installed on the hob body. A plurality of circles of blade mounting base units distributed at intervals are arranged on the peripheral wall of the cylindrical hob body, and each circle of blade mounting base unit is composed of a plurality of blade mounting base bodies distributed on the peripheral wall of the cylindrical hob body in a surrounding mode. Blade mounting grooves for positioning and mounting the corresponding blades are formed in the blade mounting base bodies, V-shaped grooves are formed in the bottoms of the blades from front to back, and positioning convex steps positioned and embedded into the V-shaped grooves are arranged on the groove walls of the blade mounting grooves. The spline hob has the advantages that the blades and the hob body are arranged in a split mode, and the blades are convenient to replace.

Owner:美戈利(浙江)科技有限公司

Machining tool for eccentric ring groove and machining method

The invention discloses a machining tool for an eccentric ring groove and a machining method, and belongs to the field of machining. When the eccentric ring groove in the end surface of a rotating body part is machined, a cylindrical cutter handle is rotated around the axis of the cylindrical cutter handle while the cylindrical cutter handle is fed in the axial direction of the cylindrical cutterhandle. A blade can directly carry out feeding and rotating on the end surface of the rotating body part, and the roughly-machined eccentric ring groove is obtained in the end surface of the rotatingbody part. A first sliding block is controlled to slide along a linear sliding groove in a connecting plate so that the cylindrical cutter handle can rotate around the axis of the cylindrical cutter handle, and the blade successively performs finish machining on the inner wall and the outer wall of the roughly-machined eccentric ring groove, and the eccentric ring groove is obtained. A cutter clamp extends out of a joint in the axial direction of the cylindrical cutter handle, and the blade extends out of the cutter clamp, so that the joint and the cutter clamp do not affect the machining of the end surface of the rotating body part by the blade. The cutting speed of the blade is the rotating line speed of the blade, the rotating line speed of the blade is greater than the rotating line speed of the cylindrical cutter handle, and the machining efficiency of the eccentric ring groove is greatly improved.

Owner:WUHAN MARINE MACHINERY PLANT

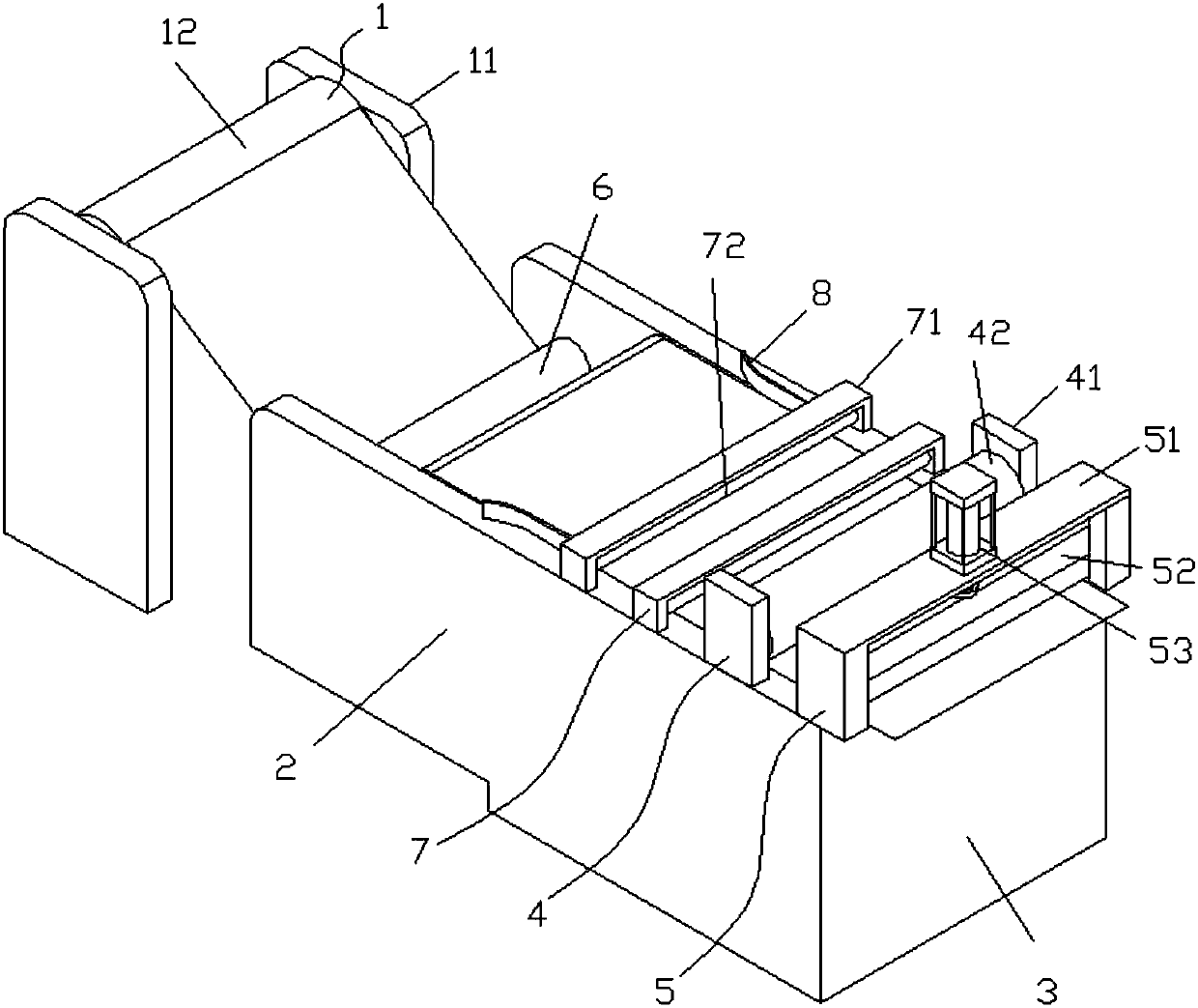

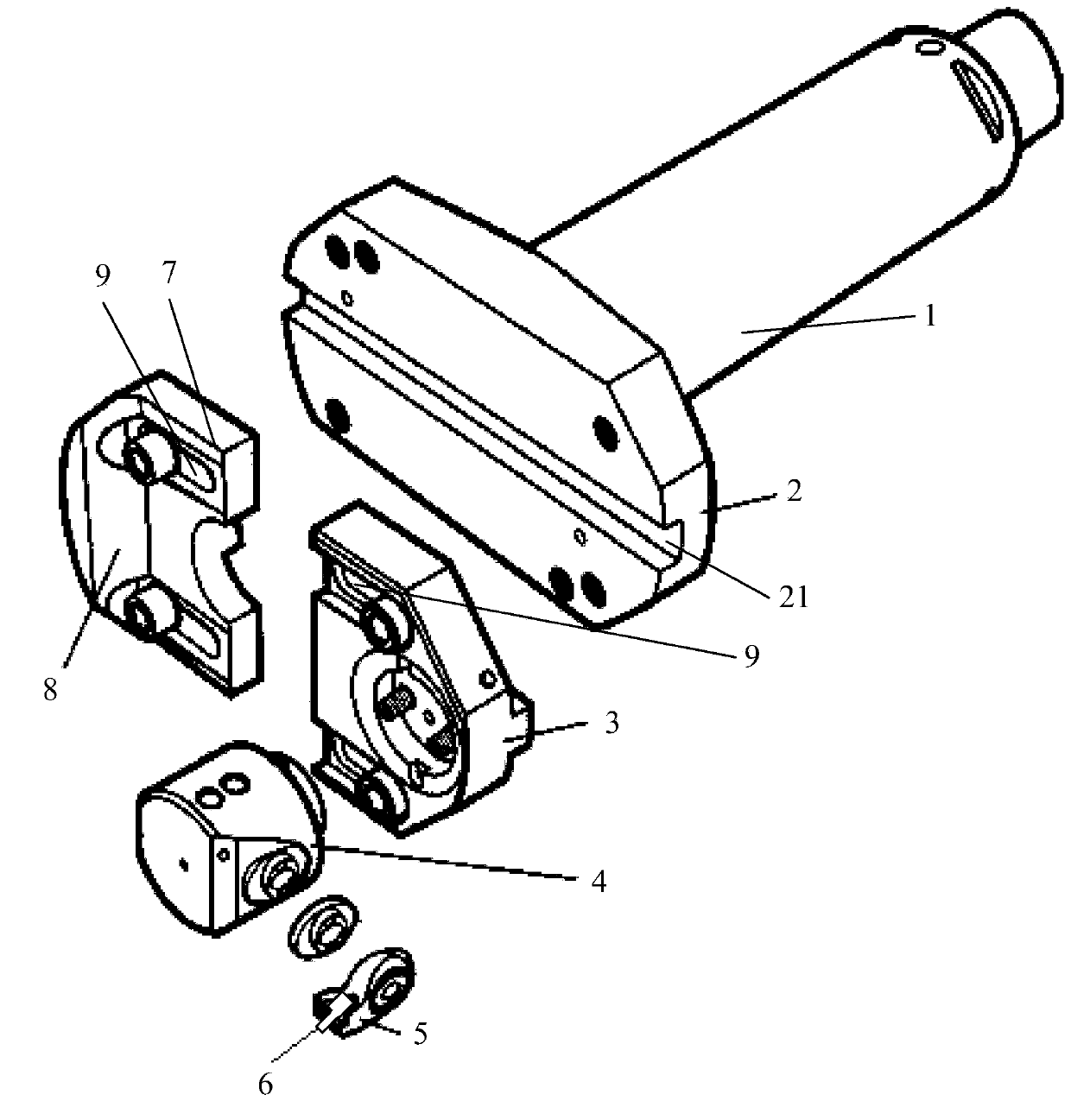

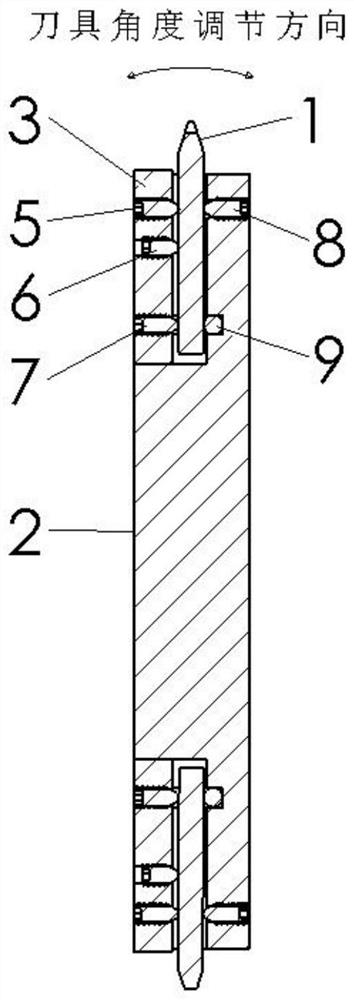

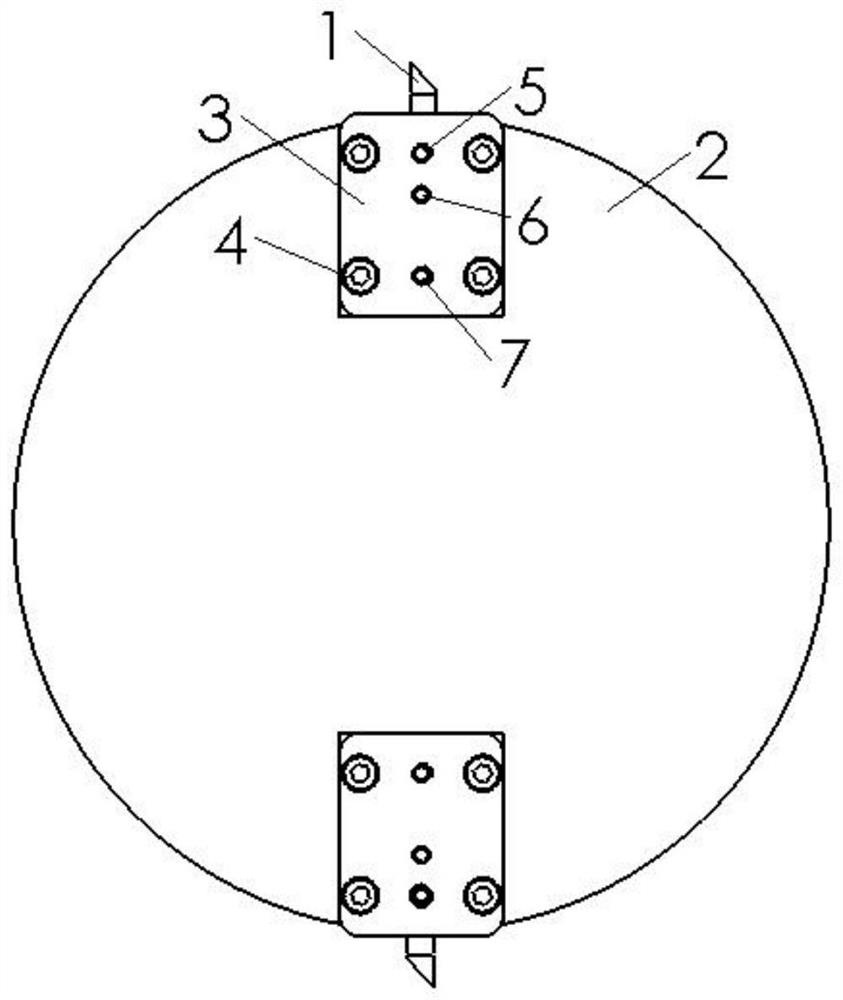

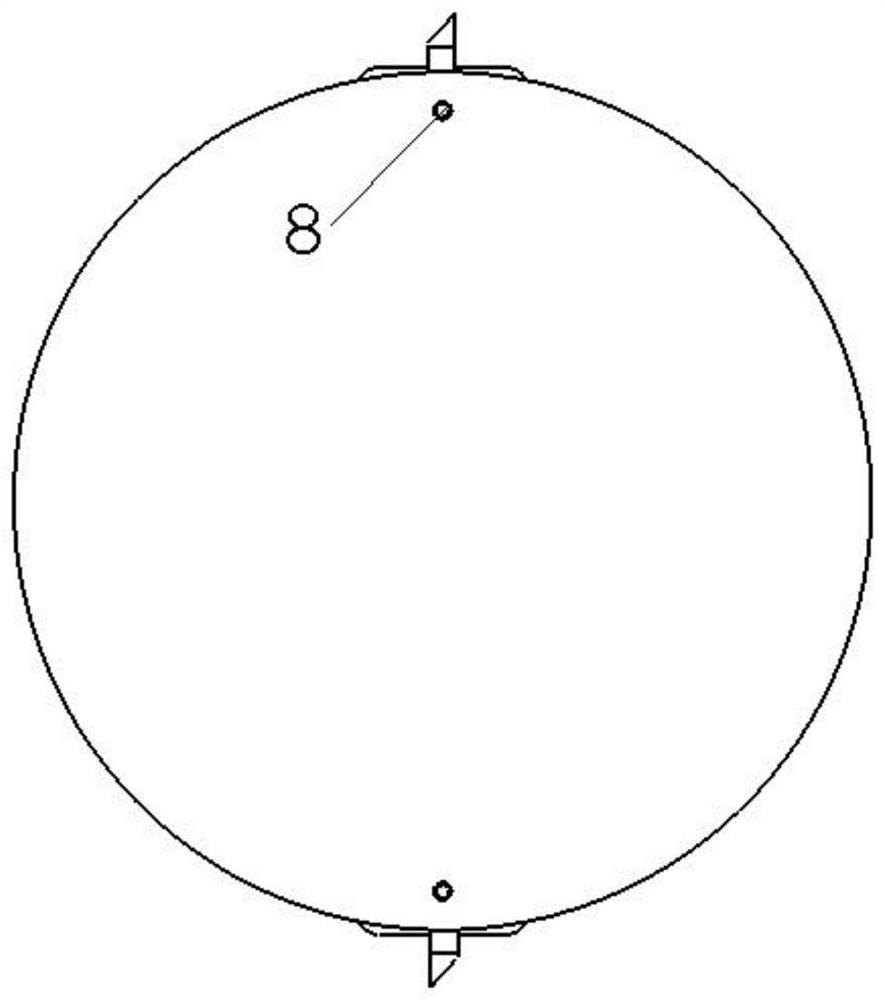

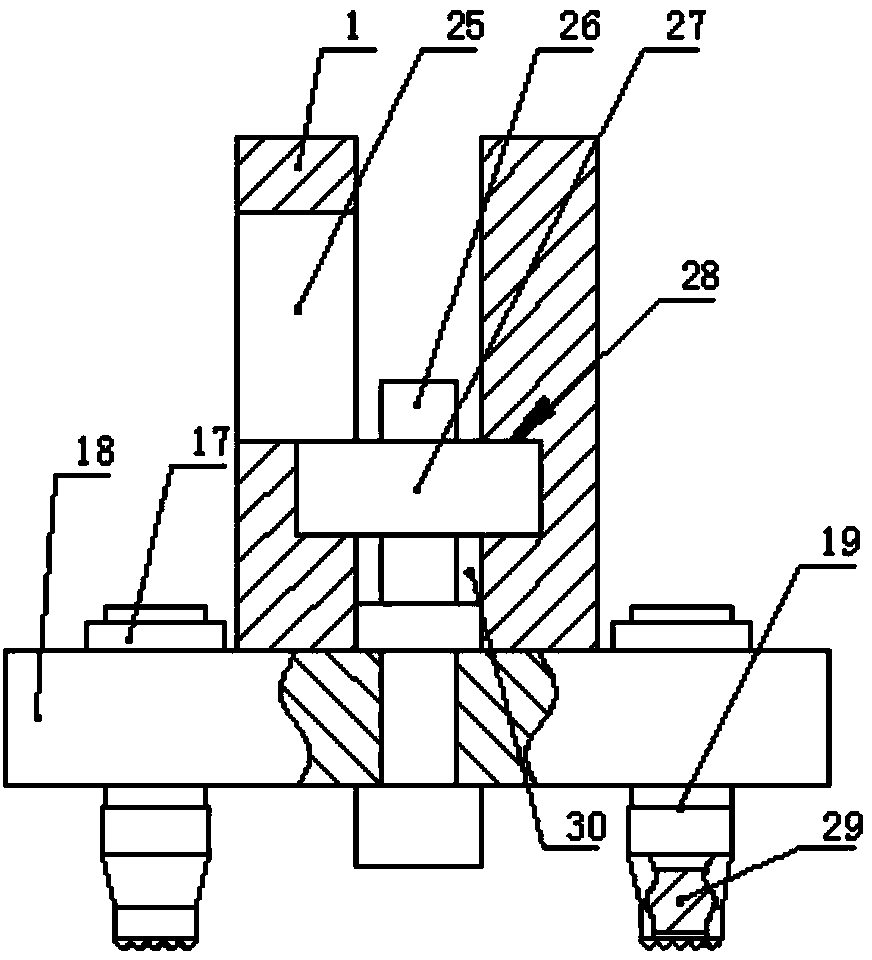

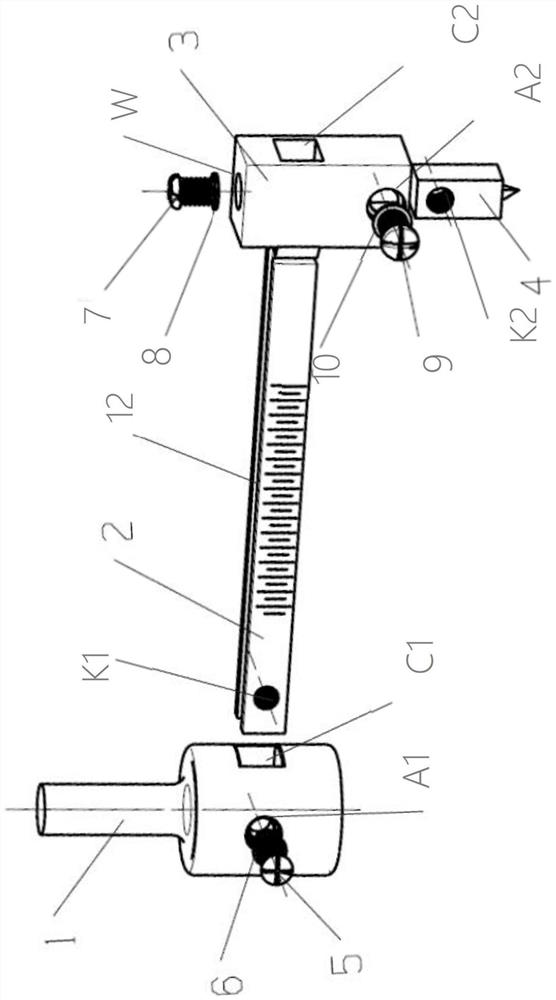

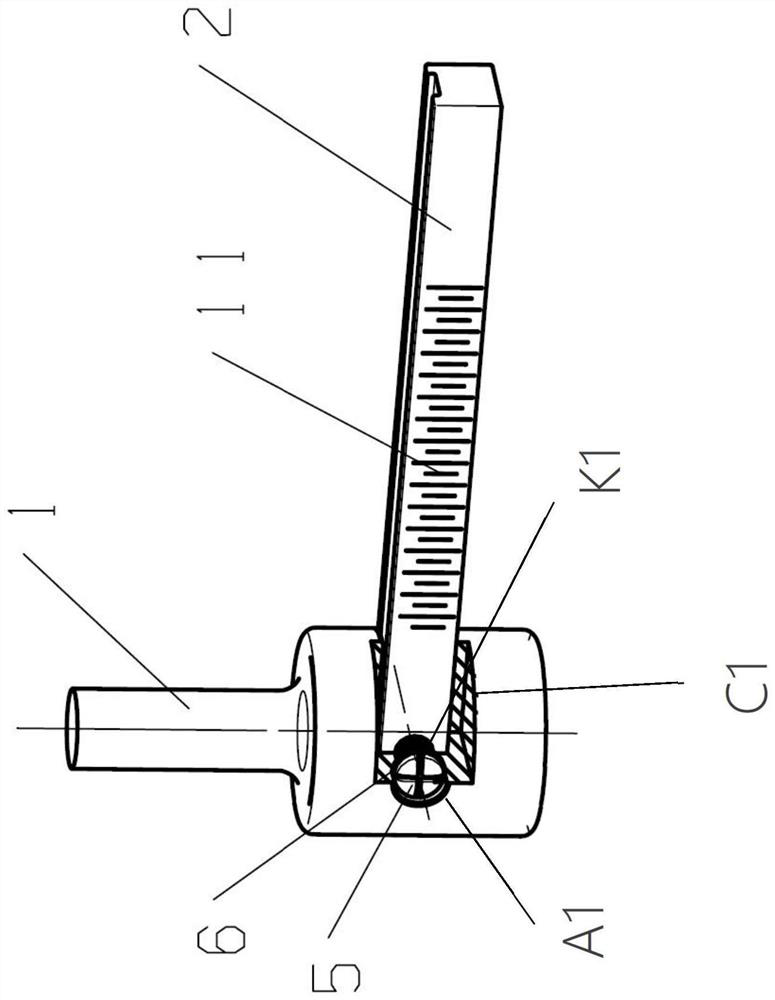

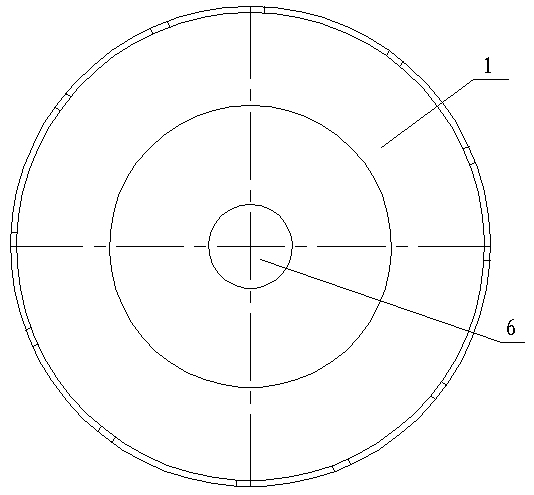

Cutter adjusting device

ActiveCN114227295AAvoid attitude deflection in other directionsWon't moveMeasurement/indication equipmentsPositioning apparatusJackscrewMachine tool

The invention discloses a tool adjusting device which comprises a tool (1), a tool rest (2), a pressing block (3), a fastening screw (4), a fastening jackscrew (5), an elastic auxiliary jackscrew (6), a pre-tightening jackscrew (7), a positioning adjusting jackscrew (8) and a supporting cylinder (9). The tool (1) is fixed on the tool rest (2) through the pressing block (3), the fastening screw (4) and the fastening jackscrew (5), and the installation angle of the tool (1) can be precisely adjusted through the elastic auxiliary jackscrew (6), the fastening screw (4) and the positioning adjusting jackscrew (8). According to the cutter adjusting device, the mounting angle of the cutter (1) on a precision machine tool can be precisely and conveniently adjusted.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI +1

Antiskid stop device for automobile

InactiveCN107117140AEasy to insertIncrease resistanceBraking element arrangementsManufacturing technologyRoad surface

The invention relates to the technical field of automobile machinery manufacturing, in particular to an antiskid stop device for an automobile. The antiskid stop device is characterized in that the stop device which directly makes contact with the ground to achieve the stopping purpose is composed of a brake cylinder body, a telescopic rod and a strip-shaped plate type brake knife; a brake port is formed in the upper end of the brake cylinder body; the telescopic rod is arranged in the brake cylinder body; a brake push plate is arranged at the upper end of the telescopic rod; the telescopic rod is matched with an outlet of the lower end of the brake cylinder body and extends out of the brake cylinder body; the strip-shaped plate type brake knife is arranged at the lower end, extending out of the brake cylinder body, of the telescopic rod; a retraction spring is arranged on a groove cavity formed among the brake push plate at the rear end of the telescopic rod, the telescopic rod and the cylinder body; the upper end of the spring abuts against the brake push plate, and the lower end of the spring abuts against the lower end inside the cylinder body to realize the retraction effect of the spring; and the advantage that on ice snow covered pavement in winter, the automobile directly makes contact with the ice snow covered pavement in an embedded mode through automobile body protruding parts, so that the problems that tires slip when making contact with the ice snow covered pavement, thus braking is difficult, braking sideslips, and climbing is difficult are solved is achieved.

Owner:秦书民

A belt conveyor

ActiveCN103979288BExtended service lifeImprove job stabilityConveyorsCleaningVertical vibrationEngineering

The invention discloses a belt conveyer. The belt conveyer comprises a frame and a conveying belt; the frame is provided with a main roller, a driven roller and a support cylinder; the conveying belt sleeves the main roller and the driven roller; the rotating shaft of the main roller penetrates one end of the support cylinder and is rotatably arranged inside bearings and connected with a cylinder cutter, which is parallel to the rotating shaft, through a linkage mechanism. The belt conveyer also comprises a V-shaped blade which is fixed onto the support cylinder through a connecting rod, the V-shaped blade is in an arc shape matched with the outer surface of the main roller, the cross section of the V-shaped blade is provided with a wheel, and when in work, the wheel is in contact with the conveying belt on the main roller; the driven roller is provided with a tensioning mechanism. When the main roller fails and leads to vertical vibration of the conveying belt, the wheel mounted on the cross section of the V-shaped blade is in contact with the conveying belt, so that damage to the V-shaped blade due to too much contact between the V-shaped blade and the conveying surface of the conveying belt can be effectively avoided, and further the service life of the conveying belt can be prolonged.

Owner:承德光大输送机有限公司

Production equipment with acute angle passivation function for crescent child and mother parts

InactiveCN112372416AWith sharp angle blunting functionGuaranteed smoothnessEdge grinding machinesConveyorsAcute angleGear wheel

The invention discloses production equipment with an acute angle passivation function for crescent child and mother parts. The production equipment comprises a chassis, wherein a material placing plate is arranged at the left upper side of the chassis; a material pushing plate is arranged at the right side of a material pushing rod; a conveyor belt is arranged at the right side of a material storage bin; a full gear is arranged below the conveyor belt; a first motor is arranged at the right side of a half gear; a cylinder cutter is arranged above a drilling mechanism; a hydraulic rod is arranged above a second motor; a first mechanical arm is arranged at the right side of the hydraulic rod; a suction disc is arranged below a connecting rod; a second mechanical arm is arranged at the rightside of the first mechanical arm; a positioner is arranged at the left end of a grinding machine; a material placing plate is arranged at the right side of the second mechanical arm; and a pushing plate is arranged behind a groove. Compared with existing common pendant production equipment, the production equipment with the acute angle passivation function for crescent child and mother parts can be used for carrying out passivation treatment on sharp parts of products, so that harm to a wearer is avoided, and therefore, processing efficiency and product.

Owner:东莞市帕特慕可科技有限公司

Ink printing grooving machine with punching device

The invention relates to an ink printing grooving machine with a punching device. The punching device coaxially coats on a seaming roller beside a cutter base, and comprises a mounting disc, a base and cylinder cutters; the mounting disc coats on the outer edge of the seaming roller; the base is transversely mounted at the outer edge of the mounting disc; two cylinder cutters are symmetrically mounted at the two sides of the base; and a sleeve aligned to the cylinder cutters coats at the outer edge of a secondary roller below the seaming roller. The punching device is added in an existing ink printing grooving machine structure, that is, the mounting disc coats beside the cutter base on the seaming roller, and then the base is fixed on the outer edge of the mounting disc, so that the cylinder cutters mounted at the two sides of the base are aligned to paper boxes to be processed; and when the paper boxes pass through the cutter base with high speed, the seaming processing of an upper cover and a lower cover is synchronously finished, and the cylinder cutters synchronously finish the processing of through holes in the paper boxes.

Owner:天津市蓟县再杨纸箱厂

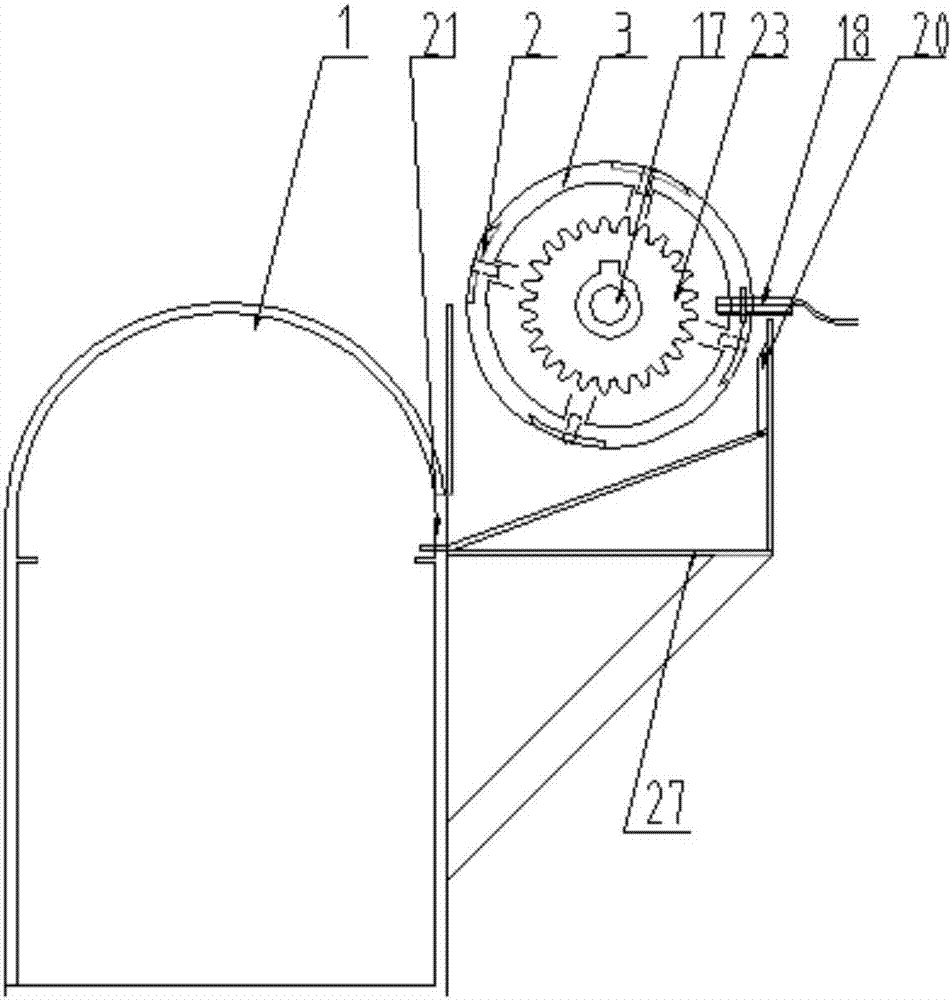

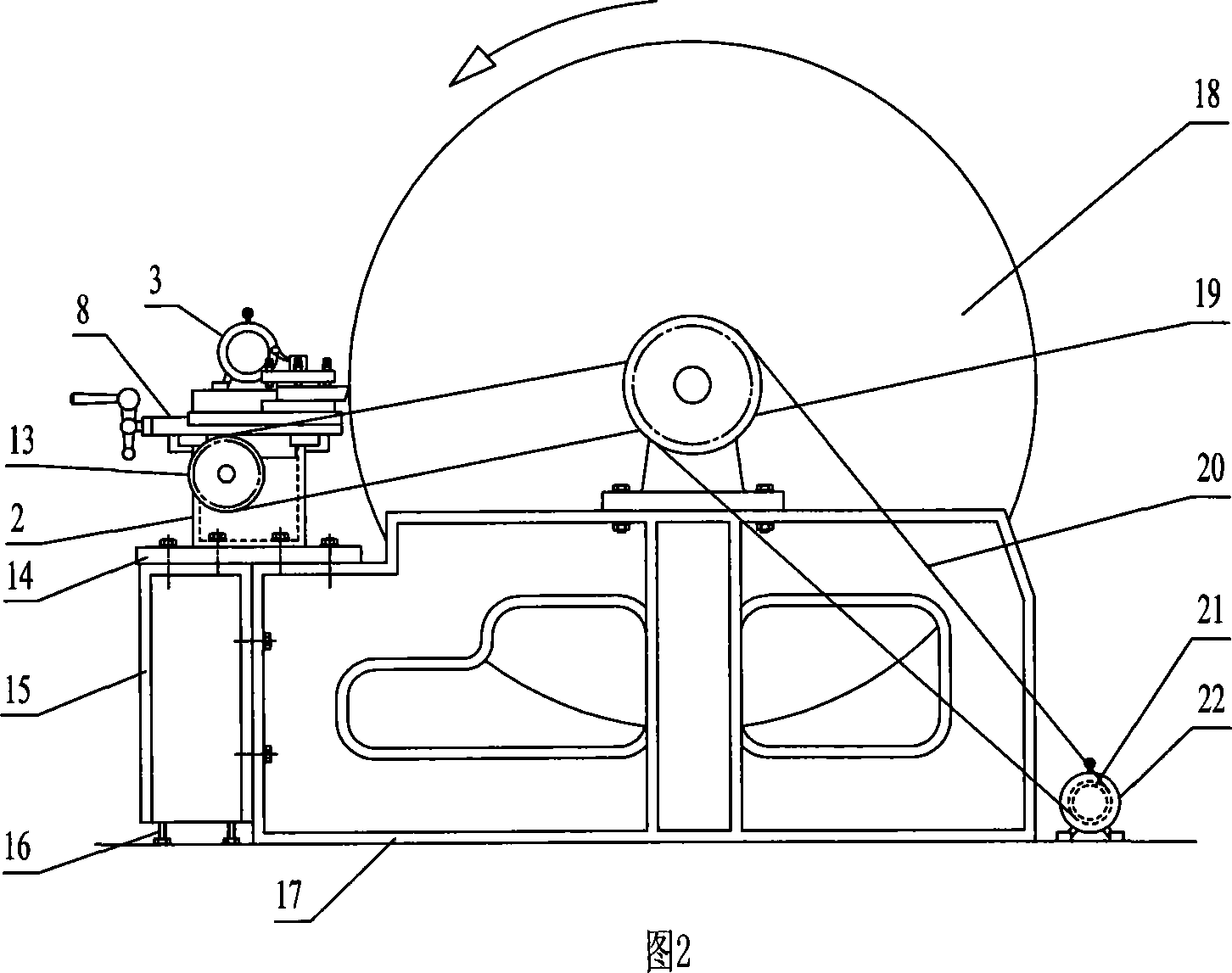

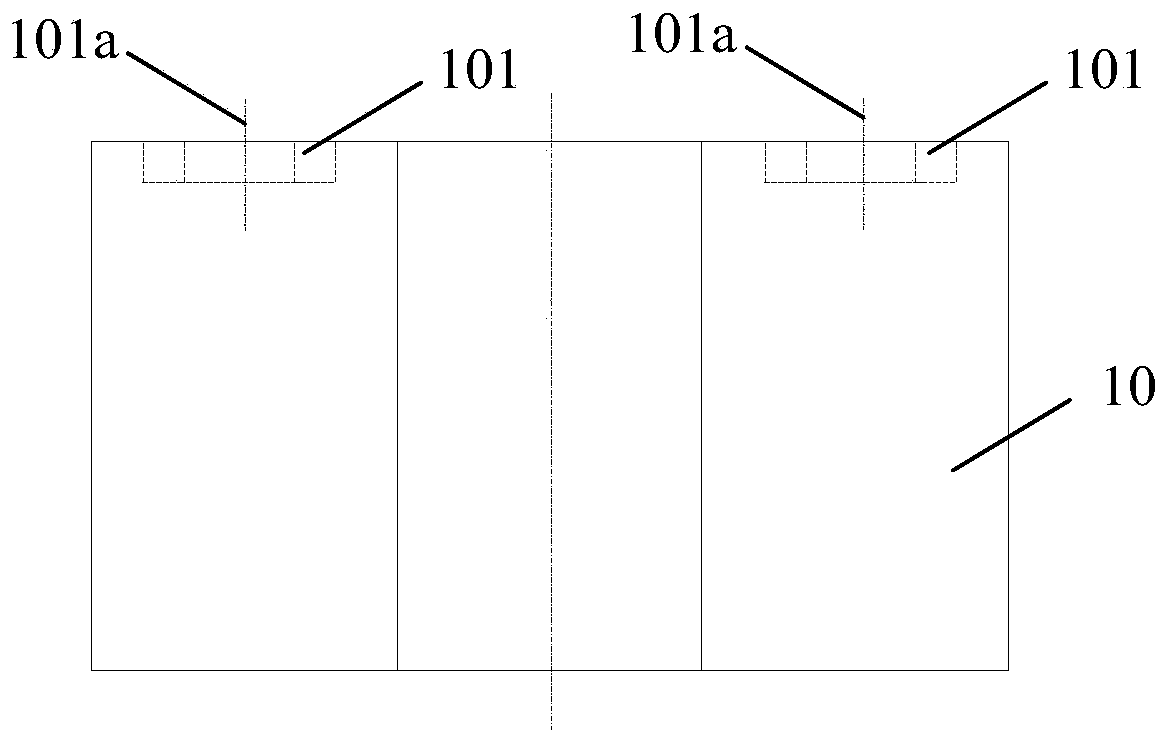

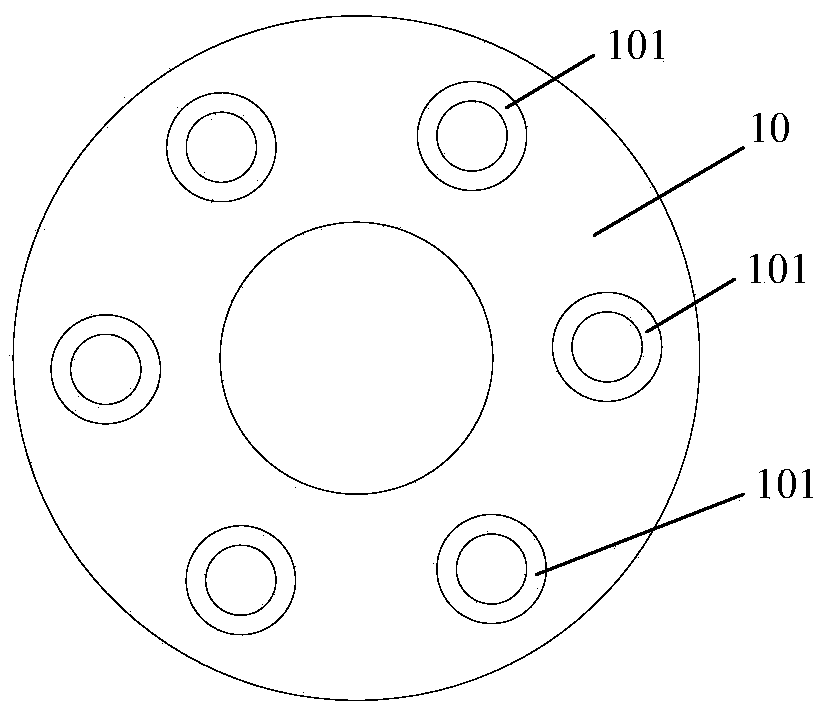

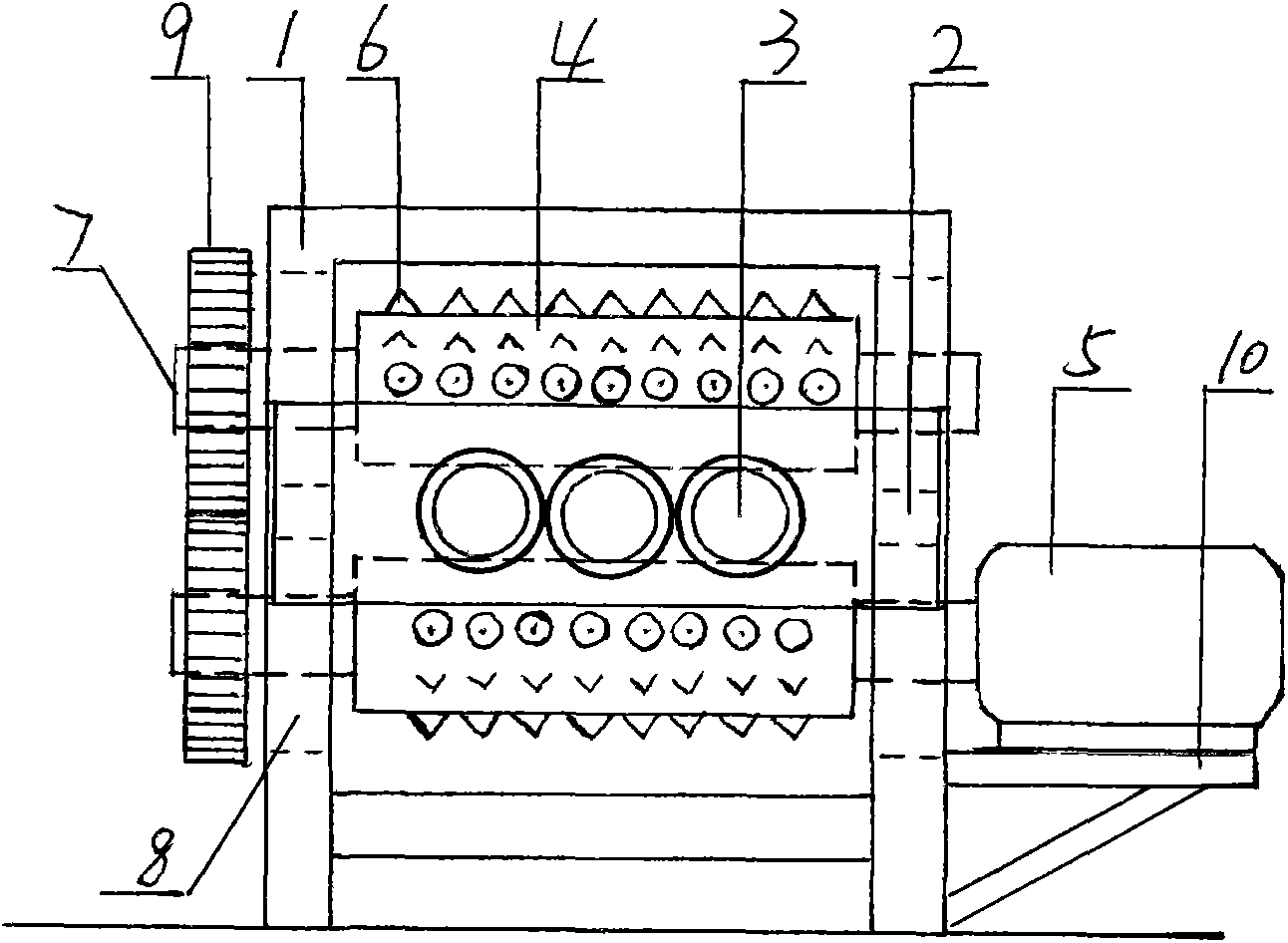

Roller type phragmites communis unhairing machine

InactiveCN103815529AImprove processing qualityImprove processing efficiencyFood treatmentPulp and paper industryRoot hair

A roller type phragmites communis unhairing machine structurally comprises a support, a cutter rest, cylinder cutters, two rollers and motors, wherein the two rollers are arranged on the inner side of the support, phragmites communis can enter a gap between the rollers, and shaft heads at two ends of the rollers are fixed on the support through bearing seats. Two identical meshed gears and the motors are arranged on the two shaft heads on sides of the rollers, and the motors can drive the upper roller and the lower roller to rotate in opposite directions through the gears. A row of cylinder cutters are arranged in front of the gap between the rollers. When the roller type phragmites communis unhairing machine is used, phragmites communis is inserted into each of the cylinder cutters and dragged to move forwards by the rotating rollers, and root hair on the phragmites communis is cut off by cutting edges when touching the cylinder cutters. Therefore, the roller type phragmites communis unhairing machine is convenient and practical.

Owner:冯莉莉

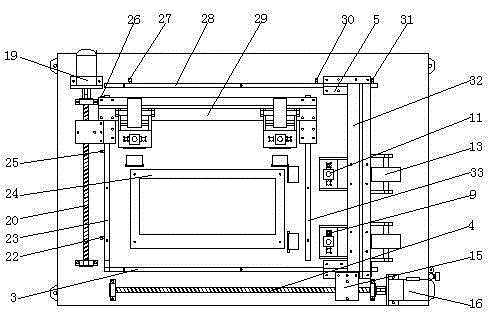

Four-side film covering machine

InactiveCN106553427AEasy to useBeautiful processingLaminationLamination apparatusEngineeringMechanical engineering

A four-side film covering machine is characterized in that a mold, a front guide rail, a rear guide rail, a left guide rail and a right guide rail are arranged on a bottom box; guide rail slide blocks are installed on the guide rails; a transverse push rod is installed between the slide block of the front guide rail and the slide block of the rear guide rail; a longitudinal push rod is installed between the slide block of the left guide rail and the slide block of the right guide rail; a front-back film covering roll stand is installed on the lower portion of the transverse push rod; a left-right film covering roll stand is installed on the upper portion of the longitudinal push rod; a transverse lead screw is arranged outside the front guide rail; a longitudinal lead screw is arranged outside the left guide rail; lead screw nuts are arranged on the transverse lead screw and the longitudinal lead screw; the transverse push rod is connected with the nut of the transverse lead screw; the longitudinal push rod is connected with the nut of the longitudinal lead screw; motors are arranged on the transverse lead screw and the longitudinal lead screw; and a longitudinal cylinder cutter and a transverse cylinder cutter are arranged on the upper portion of the interior of the bottom box. The four-side film covering machine solves the problem that because a film covering machine conducts full closing on surfaces of objects, materials are wasted, and the four-side film covering machine is particularly suitable for covering objects, such as plastic and paper pieces, with plastic thin films.

Owner:周建设

Wedge-shaped chopper for strip bonding and machining method of wedge-shaped chopper

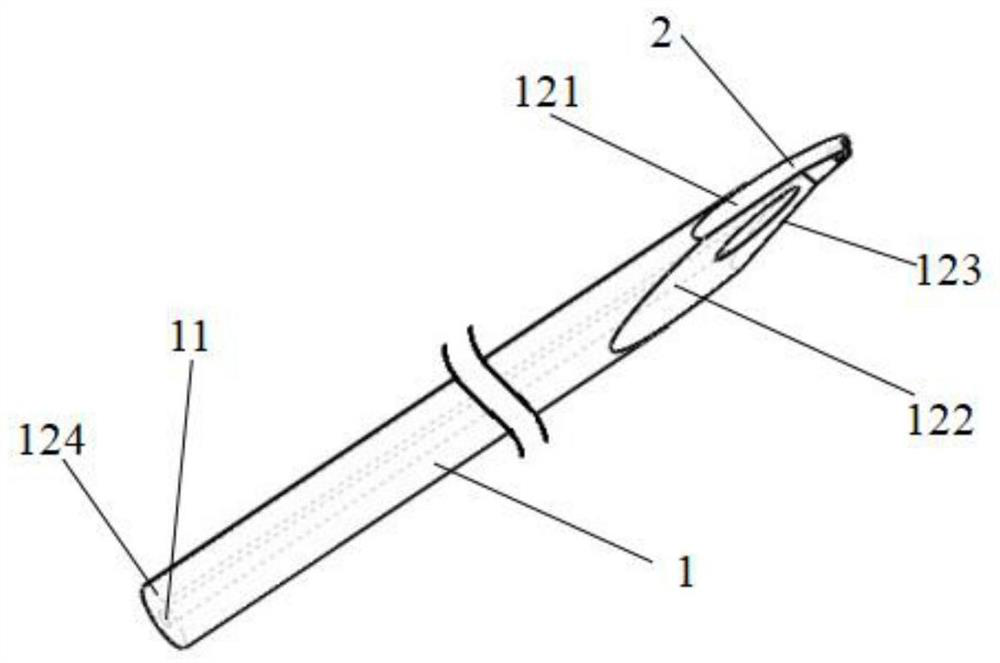

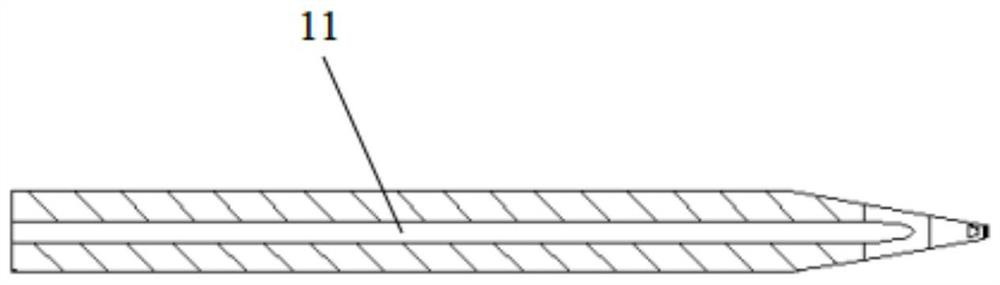

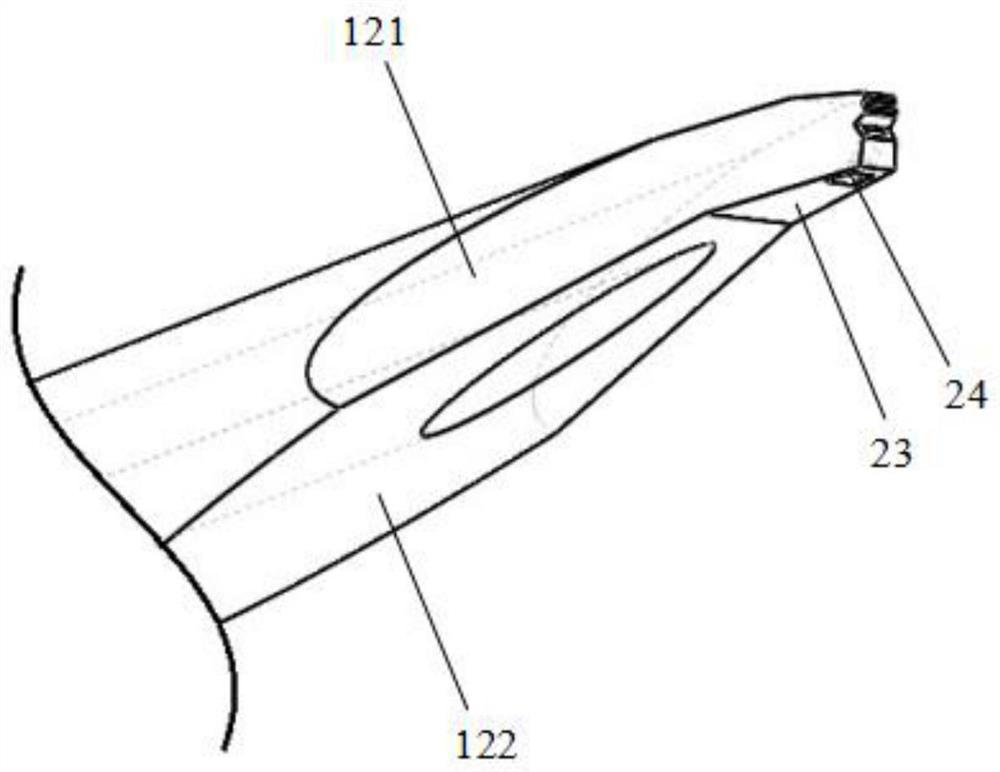

PendingCN112786470APerforation smoothlyNo vibrationSolid-state devicesSemiconductor/solid-state device manufacturingTool bitLead bonding

The invention discloses a wedge-shaped chopper for strip bonding and a machining method of the wedge-shaped chopper. The wedge-shaped chopper is of an integrated structure and comprises a chopper handle and a chopper head, the chopper handle is a flat notch type cylinder, the chopper head is of a wedge-shaped structure, and the transition from the chopper handle to the chopper head is realized through a first diagonal plane, a second diagonal plane, a third diagonal plane and a flat notch plane. A through straight lead round hole is formed in the center of the cutter handle, a through inclined lead square hole is formed in the cutter head, and the cutter head comprises a first diagonal plane, a plane, a third diagonal plane, a fourth diagonal plane and an end face. The end face comprises a front fillet face, a bonding face, a rear fillet face, a groove and a first inclined face, and the groove is formed in the bonding face. The wedge-shaped chopper for strip bonding and the machining method of the wedge-shaped chopper are suitable for hot ultrasonic wedge-shaped welding bonding of narrow-spacing, high-density, deep-cavity and multi-cavity strips, and the requirements that strip perforation is smooth, ultrasonic transmission is free of vibration, the bonding strength meets the use requirement and the service life is long are met. And a key tool guarantee is provided for lead bonding of microwave device and microwave chip assembly.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Slicing and chopping machine for household crops

InactiveCN102729276BSave spaceReduce the number of motorsCuttersMetal working apparatusCylinder cutterCrop

The invention discloses a slicing and chopping machine for household crops. The slicing and chopping machine mainly comprises a motor, a transmission part, an automatic conveying and automatic adjusting device and a slicing and chopping cylinder cutter. The slicing and chopping machine is ingenious and compact in design, reasonable in spatial arrangement, practical and efficient, safe and reliable, and low in cost, can realize the slicing and chopping of different crops, has automatic conveying and automatic adjusting functions, and is suitable for processing semi-finished products of the crops and chopping stalks of the crops, thus being capable of greatly promoting the development of the breeding industry, and having very wide application and generalization prospects.

Owner:GUANGXI UNIV

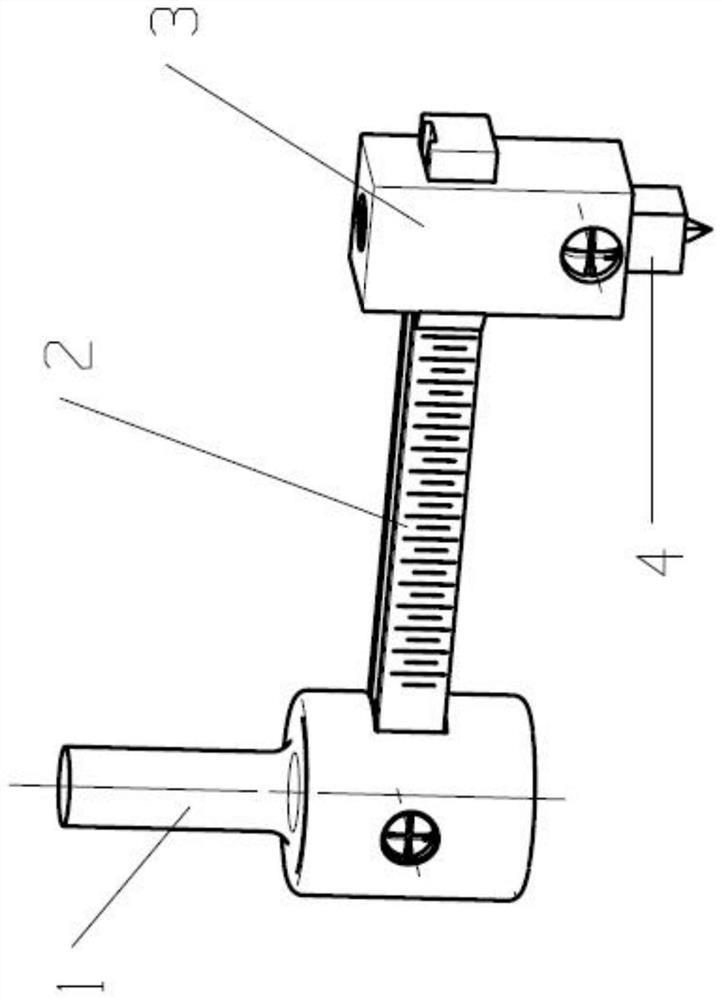

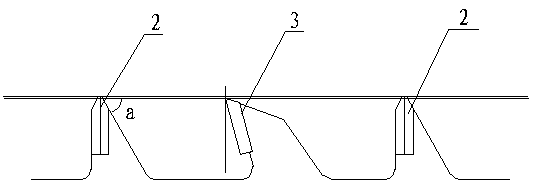

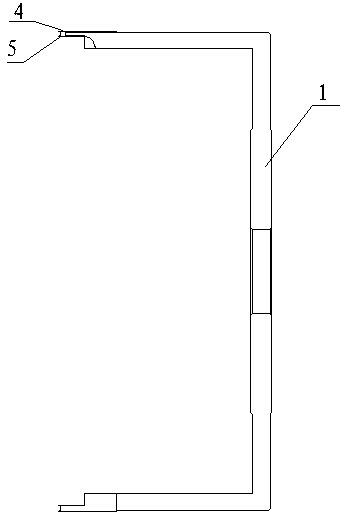

Scriber device for non-metal sheet blanking

The invention discloses a scriber device for non-metal sheet blanking. The scriber device comprises a cylindrical knife handle, a cuboid scale, a cuboid vernier and a scriber, wherein a first clamping groove is formed in the cylindrical knife handle; the cuboid scale is arranged in the first clamping groove; the cuboid vernier is movably assembled on the cuboid scale; the scriber is arranged at the bottom of the cuboid vernier; and the cuboid vernier slides to drive the scriber to reciprocate on the cuboid scale. The scriber device is simple in structure and convenient to operate, and it can be guaranteed that the surface of a machined non-metal sheet is smooth and uniform. Meanwhile, substances harmful to a human body are not likely to be generated, and the non-metal sheet can be machined and blanked into a circle with the needed diameter.

Owner:SHANXI JIANGHUAI HEAVY IND

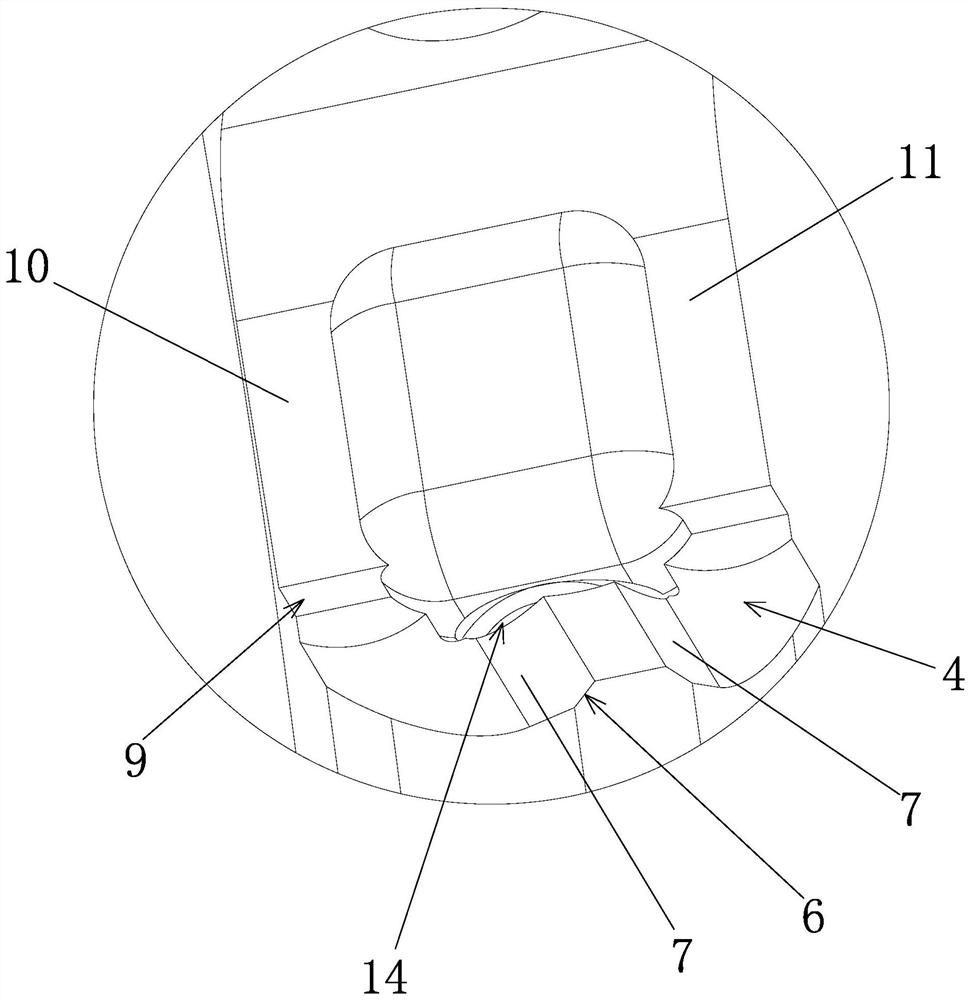

Double-groove cylinder cutter

A double-groove cylinder cutter comprises a first cutter body and a second cutter body. The second cutter body is mounted on the inner side of the first cutter body, a first cutter flat edge and a first cutter rough guide edge are uniformly distributed on the circumference of the first cutter body at intervals, a first cutter left rough guide edge and a first cutter right rough guide edge are arranged on the first cutter rough guide edge, a second cutter flat edge and a second cutter rough guide edge are uniformly distributed on the circumference of the second cutter body at intervals, and a second cutter left rough guide edge and a second cutter right rough guide edge are arranged on the second cutter rough guide edge. According to the single cylinder cutter, a rough guide edge structureis additionally arranged, cork materials can be machined, so that machined surfaces are brighter and cleaner, cutting is easier, burrs are avoided, late machining repair cost is omitted, the cutter islonger in service life, two circular grooves can be simultaneously machined, and working efficiency is improved.

Owner:大连金河精密工具有限公司

Manufacture and application method of roller type phragmites communis unhairing machine

ActiveCN103815530AImprove processing qualityImprove processing efficiencyFood treatmentPulp and paper industryRoot hair

The invention provides a manufacture and application method of a roller type phragmites communis unhairing machine. The roller type phragmites communis unhairing machine structurally comprises a support, a cutter rest, cylinder cutters, two rollers and motors, wherein the two rollers are arranged on the inner side of the support, phragmites communis can enter a gap between the rollers, and shaft heads at two ends of the rollers are fixed on the support through bearing seats. Two identical meshed gears and the motors are arranged on the two shaft heads on sides of the rollers, and the motors can drive the upper roller and the lower roller to rotate in opposite directions through the gears. A row of cylinder cutters are arranged in front of the gap between the rollers. When the roller type phragmites communis unhairing machine is used, phragmites communis is inserted into each of the cylinder cutters and dragged to move forwards by the rotating rollers, and root hair on the phragmites communis is cut off by cutting edges when touching the cylinder cutters. Therefore, the roller type phragmites communis unhairing machine is convenient and practical.

Owner:NANTONG HONGFENG NEW ENERGY MACHINERY

Plant feed crusher

InactiveCN104383994AEasy to crushImprove crushing effectFeeding-stuffGrain treatmentsMotor driveEngineering

The present invention provides a plant feed crusher, which comprises a box body and a material feeding table, wherein a crushing chamber and a cutting chamber are arranged in the box body, one side of the cutting chamber is provided with the material feeding table, the height of the material feeding table is 1 / 2 of the height of the box body, one side of the cutting chamber is provided with a material inlet, the material inlet is positioned above the material feeding table, a material pressing table is arranged above the material inlet, the left side and the right side of the material inlet are provided with sliding ways, the material pressing table and the sliding way are slidably connected, the material feeding table and the box body are fixedly connected, one side of the crushing chamber is provided with a material outlet, 5-8 cm height different exists between the material outlet and the material inlet, a cylinder cutter is arranged in the crushing chamber, the cylinder cutter and the crushing chamber form a shaft connection, a reamer is arranged in the cutting chamber, the reamer and the cutting chamber form a shaft connection, the side surface of the box body is provided with a cylinder cutter motor and a reamer motor, the cylinder cutter motor drives the cylinder cutter to rotate, the reamer motor drives the reamer to rotate, and the rotation directions of the cylinder cutter and the reamer are opposite. The plant feed crusher has characteristics of simple structure, easy use, accident occurrence rate reducing, easy rod-like feed crushing, and good crushing effect.

Owner:孙桂芝

A safety separation device for small composite solid rocket motor case and grain

A safety separating device for a shell and a grain of a small-sized composite solid rocket engine comprises an upper sealing seat and a lower sealing seat which are mounted at the upper end and the lower end of an engine shell to be processed in a sealing mode. A liquid inlet is formed in the upper sealing seat, and a liquid inlet valve used for regulating the flow quantity of sense reducing liquid entering the engine shell to be processed is connected to the liquid inlet. A liquid outlet is formed in the lower sealing seat, and a liquid outlet valve used for regulating the flow quantity of sense reducing liquid flowing out of the engine shell to be processed is connected to the liquid outlet. A cylinder cutter used for cutting the grain in the engine shell to be processed is arranged in the upper sealing seat, and is of a cylindrical structure with the closed upper end and a cutting edge at the lower end. A push rod used for pushing the cylinder cutter to cut the grain downwards penetrates through the upper sealing seat to be connected with the cylinder cutter. The position, making contact with the upper sealing seat, of the push rod is dynamically sealed. The safety separating device has the advantages of being safe, high in efficiency, small in equipment investment and suitable for recovery processing of small-sized scrapped solid rocket engines.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com