Cutter adjusting device

An adjustment device and tool technology, applied in the field of precision parts manufacturing, can solve the problems of easy movement of the tool position, time-consuming and difficult problems, and achieve the effect of convenient adjustment process and stable deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

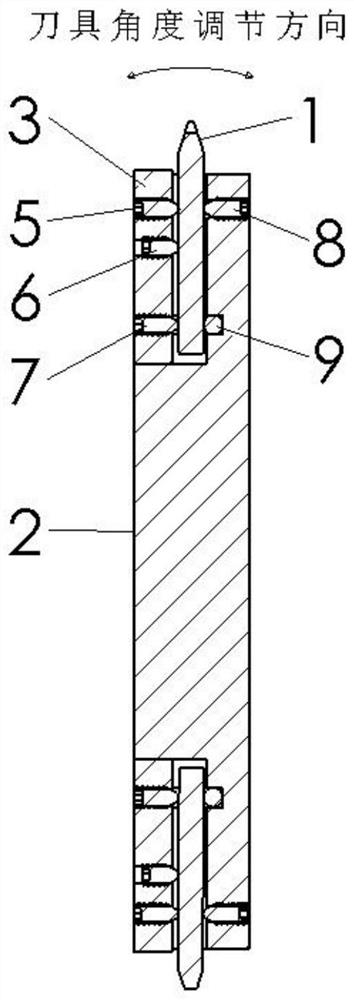

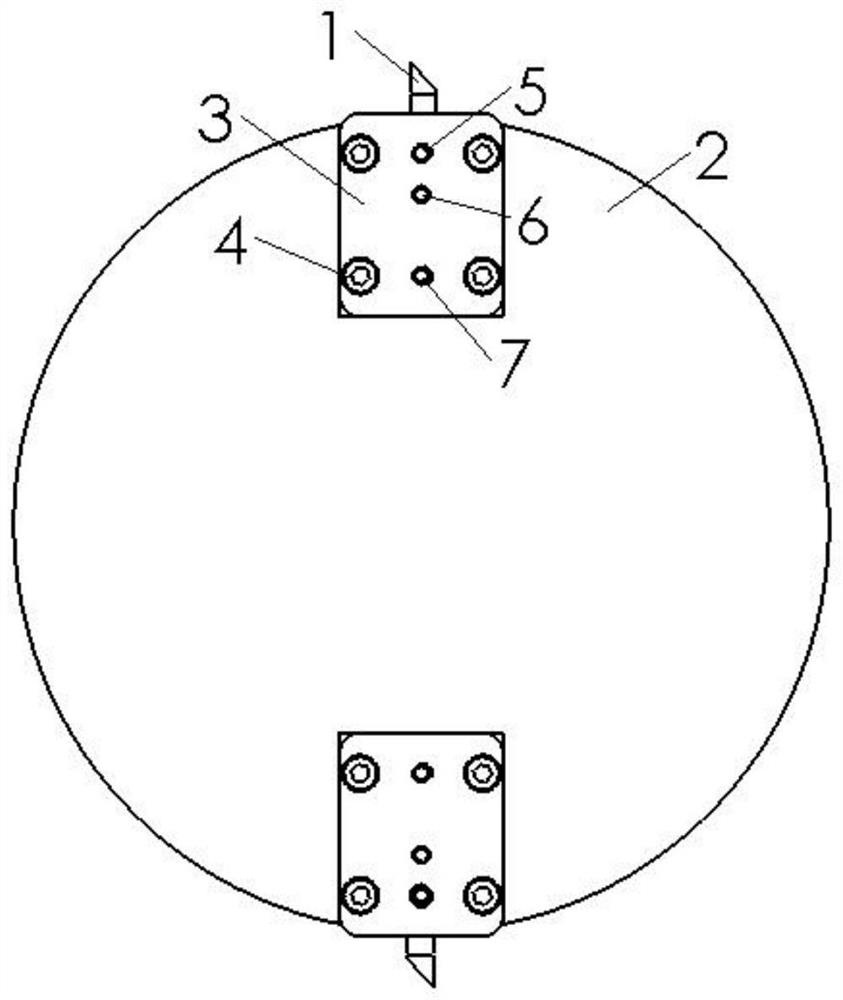

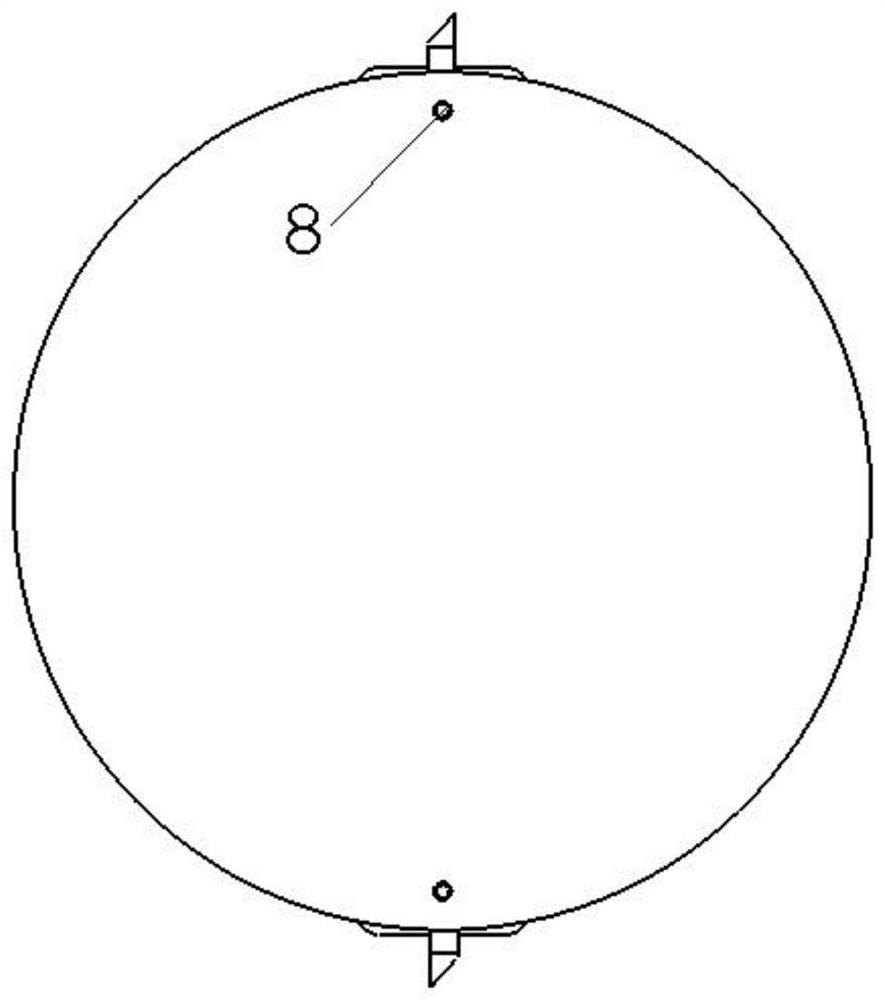

[0020] figure 1 It is a cross-sectional view of a tool adjusting device of the present invention, including: tool 1, tool holder 2, pressure block 3, fastening screw 4, fastening jack screw 5, elastic auxiliary jack screw 6, pre-tightened jack screw 7, positioning and adjusting jack Wire 8 and supporting cylinder 9.

[0021] Wherein, the installation angle of the cutter 1 needs to be adjusted precisely. Tool rest 2 is used for the installation of cutter 1 and other parts. The pressing block 3 is fixed on the tool holder 2 by fastening screws 4 . The fastening jackscrew 5, the elastic auxiliary jackscrew 6 and the pre-tightening jackscrew 7 are installed on the briquetting block 3 through the threaded holes. The support cylinder 9 is inserted into the tool mounting hole of the tool holder 2 by inlaying; the positioning adjustment jackscrew 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com