Ejector device with movable working nozzle

An ejector and nozzle technology, applied in the field of ejectors, can solve the problems of restricting the use of ejectors and failing to reach the ejection ratio, etc., so as to improve the ejection performance, increase the ejection ratio, and increase the ejection amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

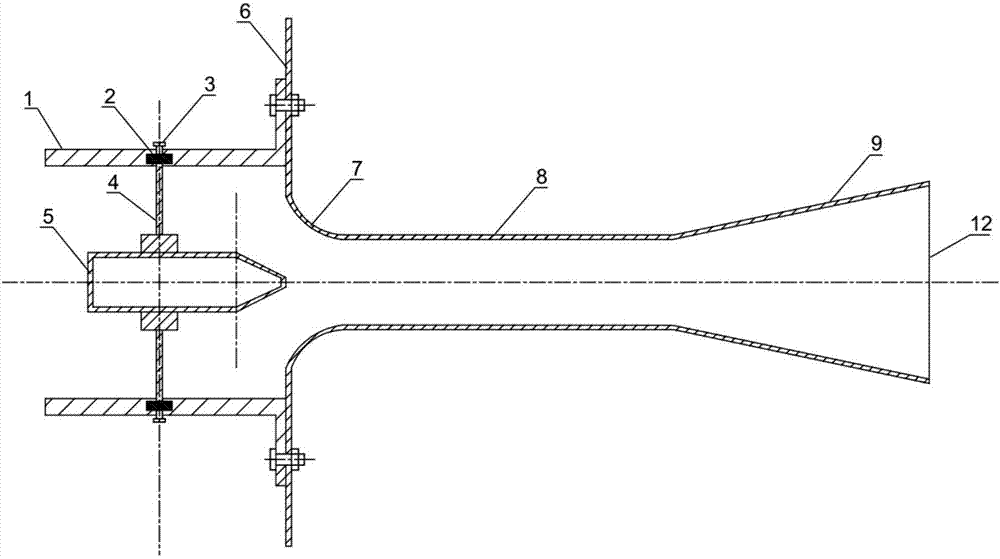

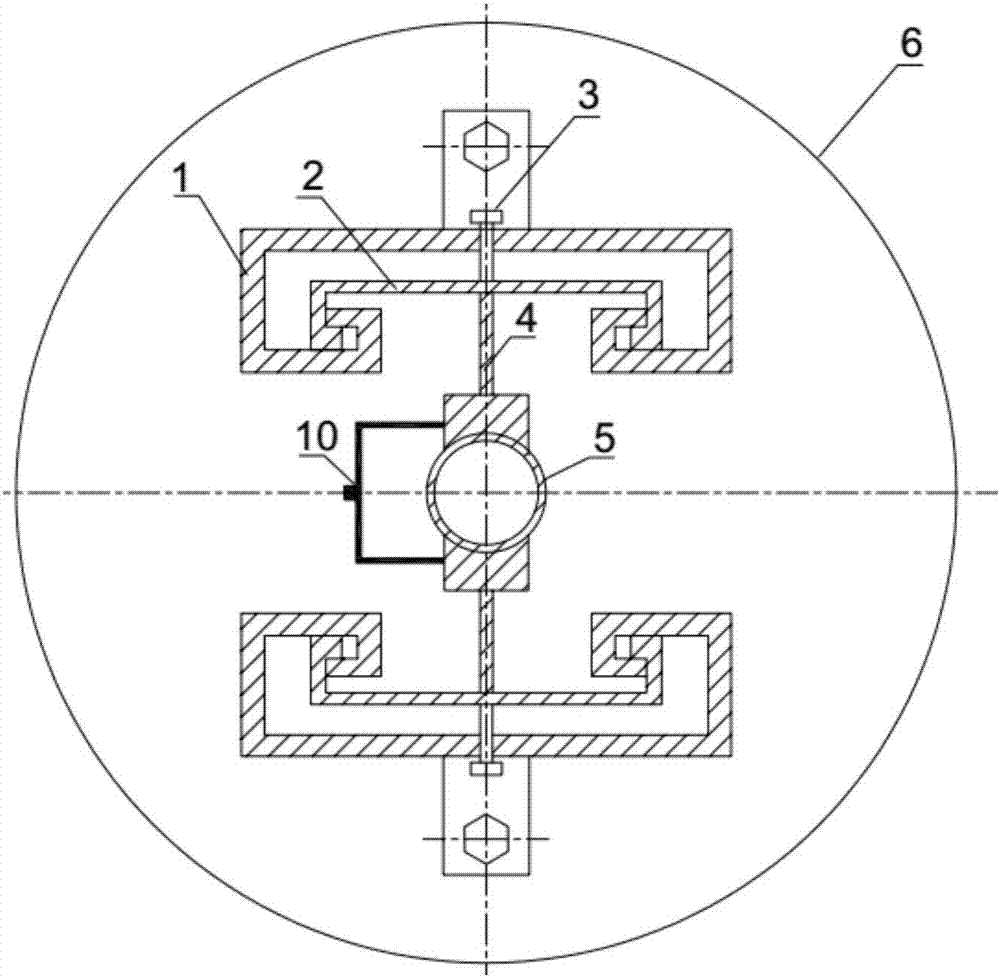

[0027] see figure 1 , the ejector device with movable working nozzle disclosed in the present invention includes a working nozzle 5 and an ejector main body 12, and the ejector main body 12 is composed of a shrinkage tube 7, a mixing tube 8 and a diffuser tube 9, and is characterized in that, The working nozzle 5 is connected to the welded disk 6 of the shrink tube 7 through a connecting piece, so that the working nozzle 5 can move horizontally along the central axis of the injector body 12 .

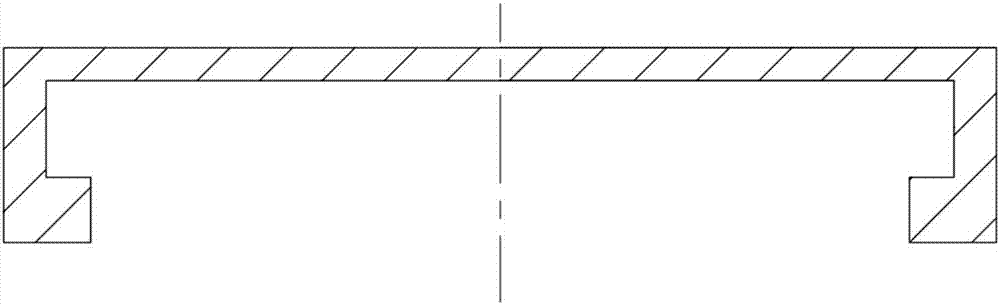

[0028] to combine figure 1 and figure 2 , the connecting piece includes a slideway 1 and a slider 2 capable of sliding in the slideway 1, the slideway 1 is fixedly connected with the disc 6 welded to the shrink tube 7, preferably, the slideway 1 is fixed on the guide with bolts On the injector body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com