Mounting method for temperature transmitter thermosensors of electric cooker

A technology of temperature sensors and heat-sensitive elements, which is applied to parts of thermometers, thermometers, instruments, etc., can solve the problems of increased waste of resources, fragile magnetic steel, and waste of manpower, and achieve high product reliability, stable positioning, and universal use good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 with Figure 7 , The method for installing a thermal element of an electric rice cooker temperature sensor provided by the present invention includes the following steps:

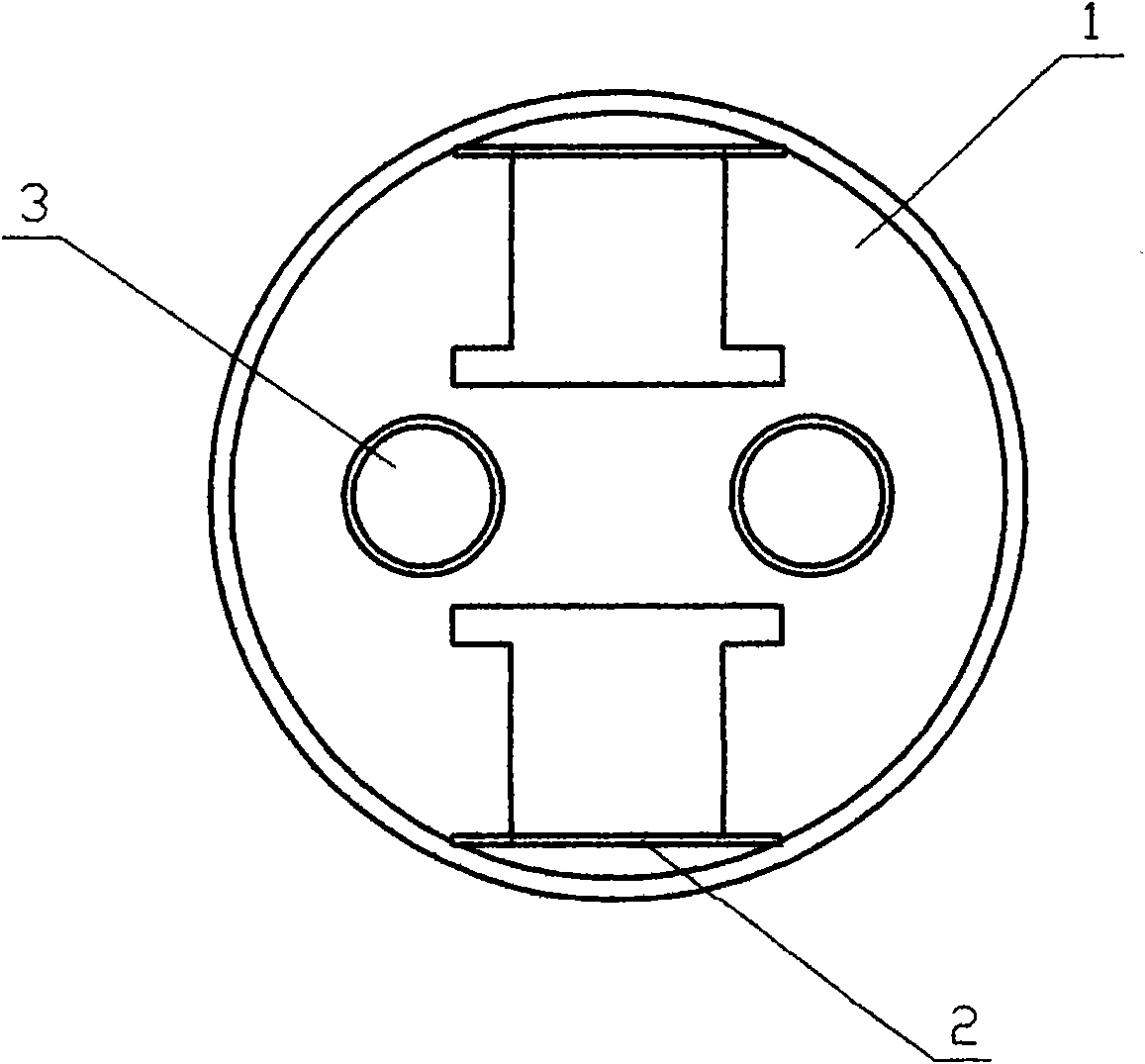

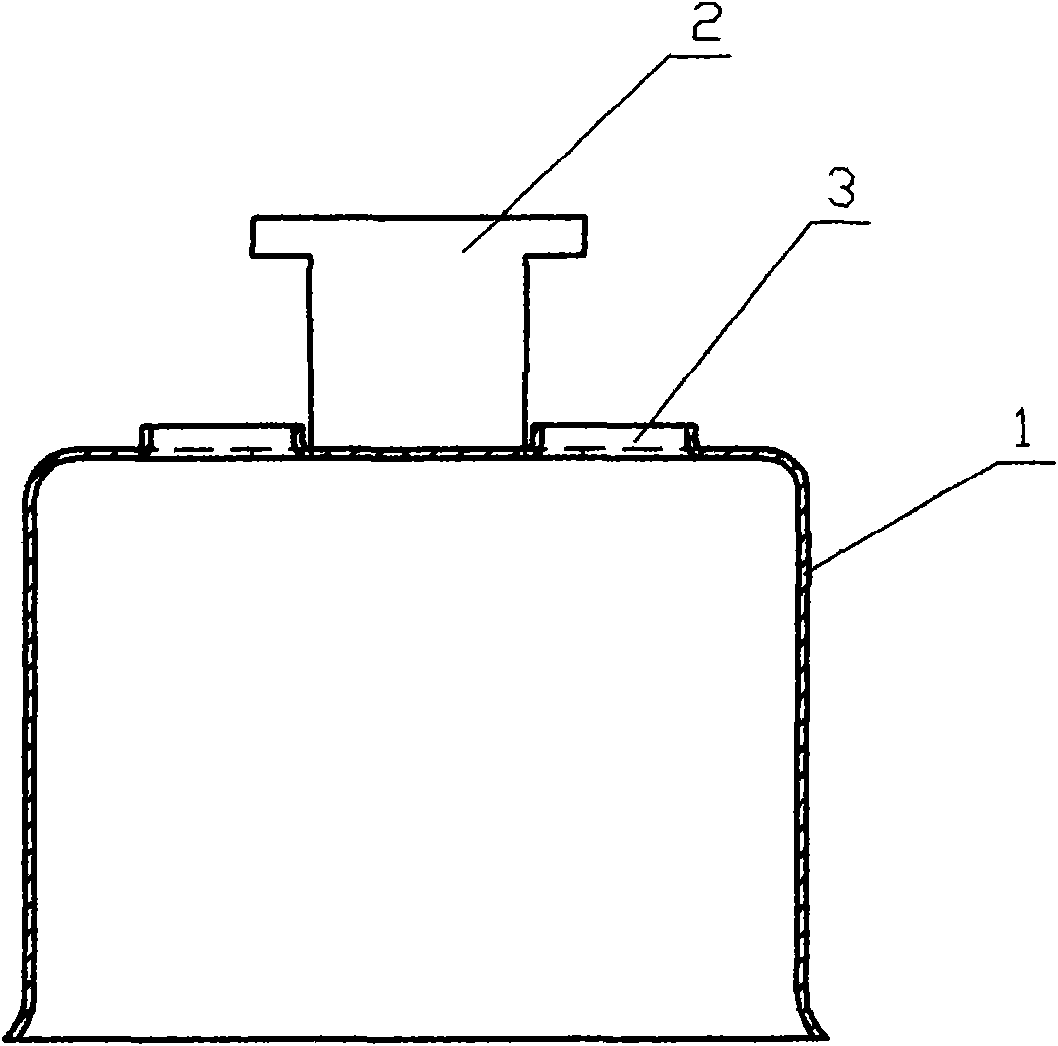

[0026] Before the inner shell 1 of the magnetic steel temperature limiter is flushed to the bottom, two T-shaped guide feet 2 are punched symmetrically at the bottom, and then two flanging holes 3 for positioning and fixing the lead wires are punched out to obtain the inner shell 1. see figure 1 , figure 2 ;

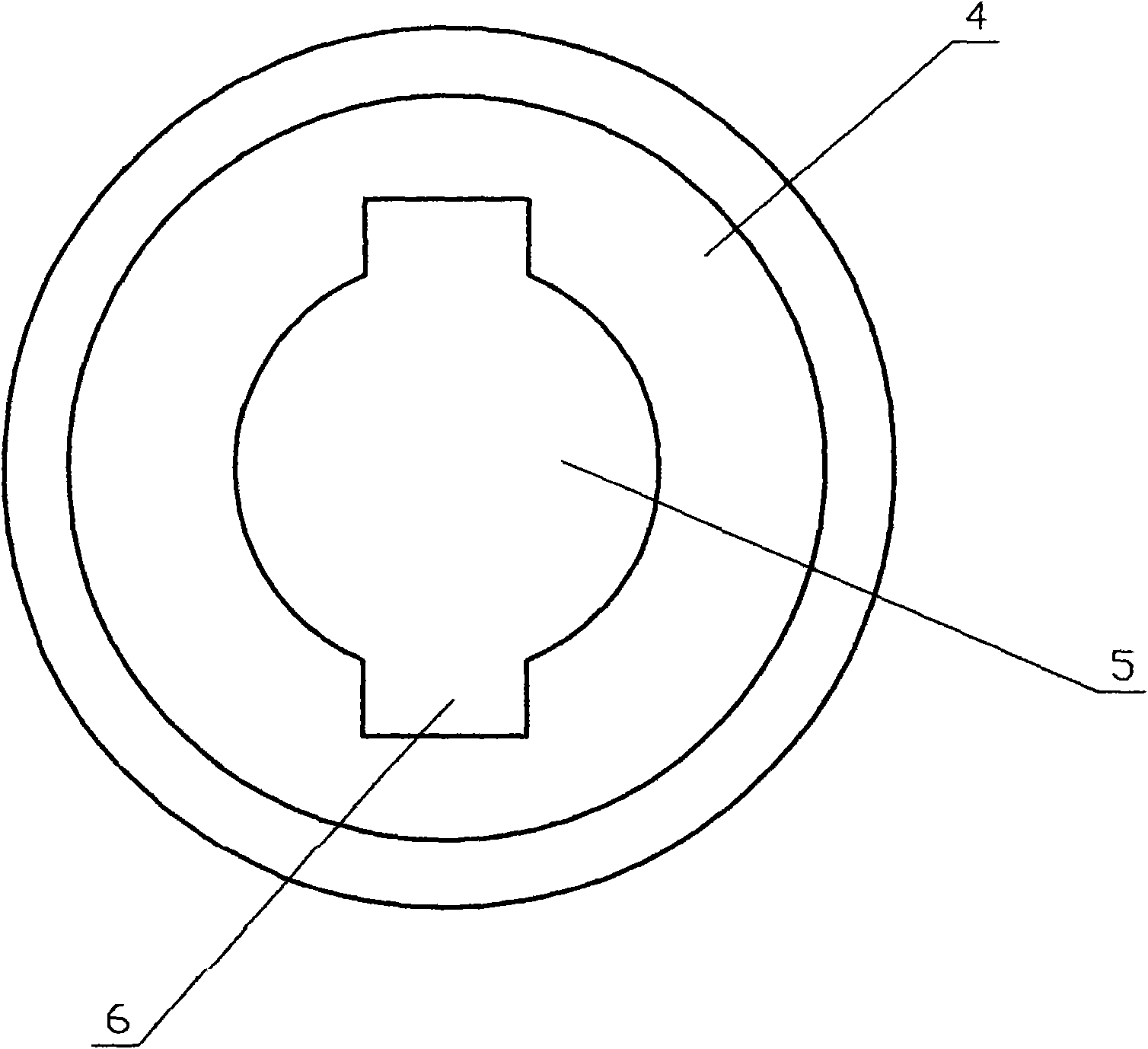

[0027] Before the bottom of the magnetic steel temperature limiter housing 4 is flushed, a round hole 5 is punched at the bottom and the round hole has two guide grooves 6 to obtain the housing 4, see image 3 ;

[0028] Process a pressing piece 7, the pressing piece is punched with two flanging openings 8, which are U-shaped or through holes, and a groove 9 is formed between the two flanging openings 8, see Figure 4 , ...

Embodiment 2

[0033] Refer to Figure 7 , The difference from Embodiment 1 is that the temperature control element 10 is a thermostat, which is an assembly drawing of a snap-type thermostat. The snap-type thermostat is used as a temperature control switch for an electric rice cooker, and its lead 11 is inserted through The pressing piece 7 does not need a flanging hole, and its function is to press the snap-type thermostat tightly, and the insert is tightened by the insulating sleeve. The remaining hardware such as the inner shell 1, the outer shell 4, etc. are the same as those in the first embodiment. The wrapped lead wire 11 passes through the flanged hole 3 of the inner shell 1 and is fixed, so there is no need to weld another positioning piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com