Movable limiting type clothes drying machine

A technology for clothes drying machines and drying rods, which is applied to clothes lines, washing devices, textiles, and paper making, etc., can solve the problem that the upper travel limit detection switch is not accurate enough, affects the normal use of the electric clothes drying machine, and the rise cannot be truly in place. and other problems to achieve the effect of solving unstable work performance, tight occlusion, and uniform force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

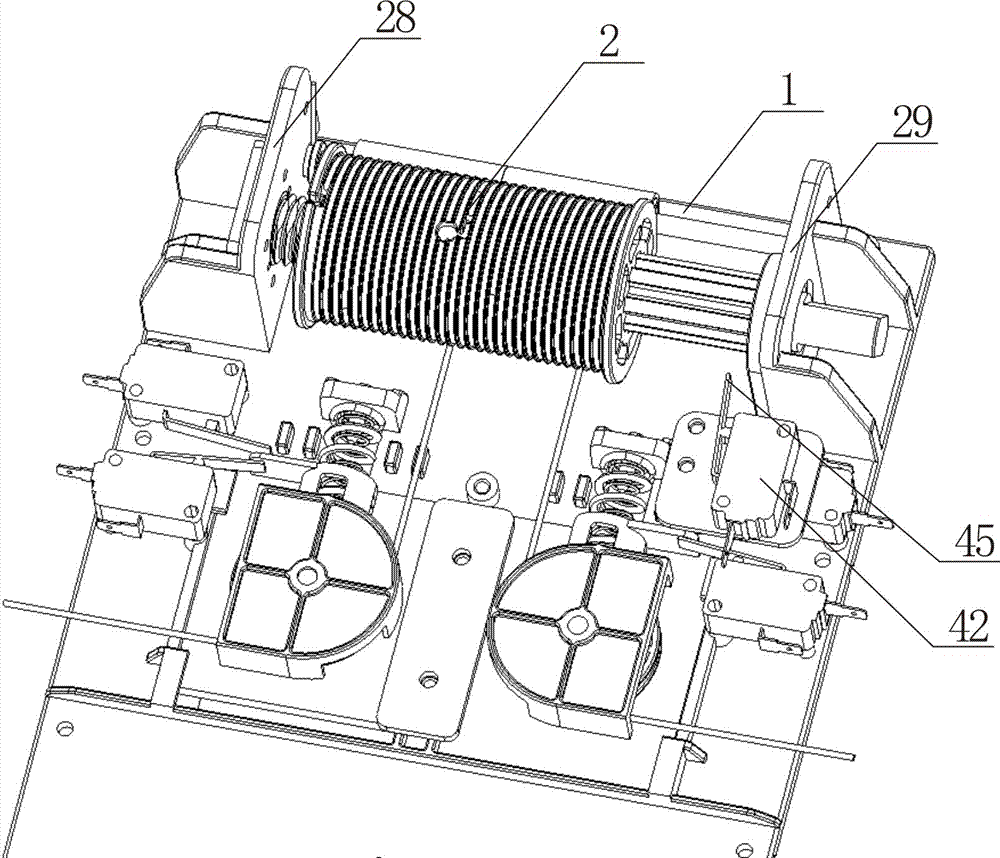

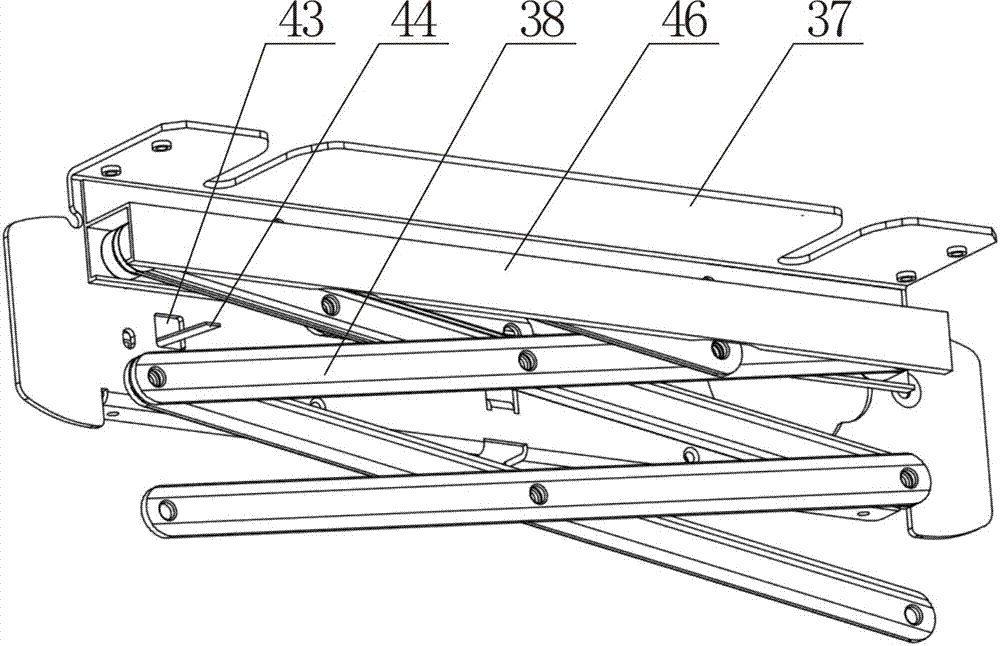

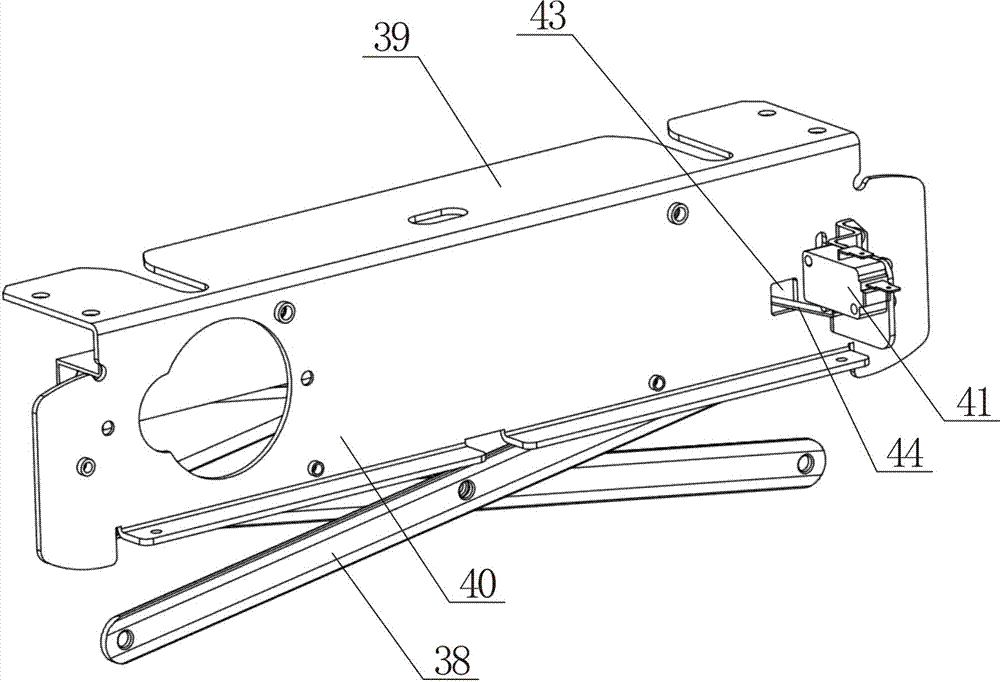

[0032] Such as figure 1 , 2 . As shown in 3, the mobile limit type clothes dryer includes a transmission support plate 1, a wire reel 2, an L-shaped mounting plate 37 and a scissor type telescopic frame 38, and the wire reel 2 is installed on the installation frame 28 of the transmission support plate 1 And on the mounting frame 29, the L-shaped mounting plate 37 includes a top panel 39 and a side panel 40, the upper end of the scissors-type telescopic frame 38 is installed in the slide rail 46 on the side panel 40, and the lower end of the scissors-type telescopic frame 38 is installed The clothes rail, the hanging rope 12 on the reel 2 drives the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com