Wedge-shaped chopper for strip bonding and machining method of wedge-shaped chopper

A wedge-shaped, chopper technology, applied in the direction of electrical components, electrical solid devices, semiconductor/solid device manufacturing, etc., to achieve consistent bonding strength, smooth perforation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

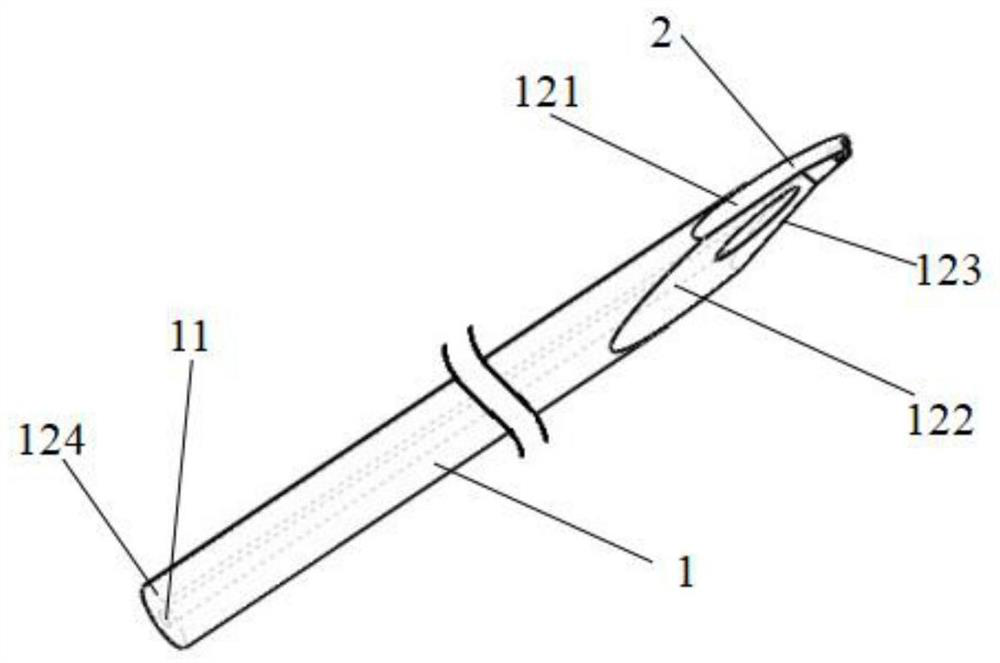

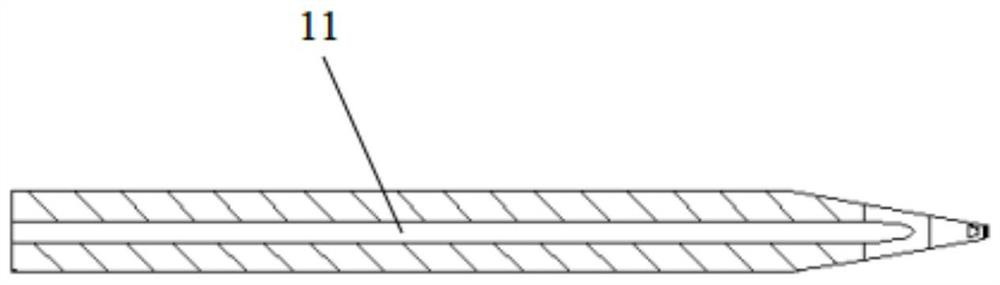

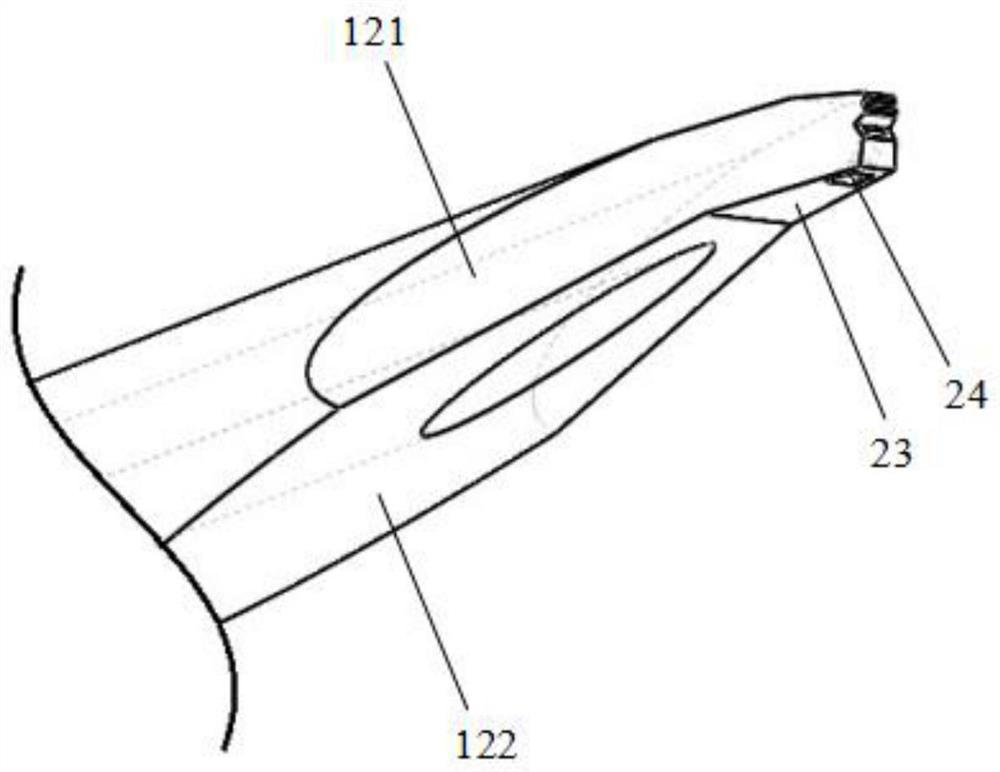

Embodiment 1

[0052] A wedge-shaped riving knife with an overall structure for strip bonding, with a length of 12mm, including two parts: a handle 1 and a head 2. The cutting surface 123 and the flat notch surface 124 make a transition, the angle between the first beveled surface 121, the second beveled surface 122, and the third beveled surface 123 is consistent with the knife handle 1, and the angle is 2°; the knife handle 1 is a flat notched cylinder , the shank diameter is 1.5mm, the shank diameter tolerance is ≤±5μm, the radial length of the flat notch is 1.3mm, and the radial length tolerance of the flat notch is (-0.01, 0); the center of the shank 1 is provided with a straight lead circle through The hole 11 has a diameter of 0.20 mm, dimensional tolerance ≤ ± 5 μm, concentricity ≤ ± 5 μm, surface roughness ≤ 1.0 μm; the cutter head 2 is a wedge-shaped structure, consisting of a first beveled surface 121, a plane 23, and a third beveled surface 123 , the fourth chamfered surface 21 a...

Embodiment 2

[0056] A wedge-shaped riving knife with an overall structure for strip bonding, with a length of 40mm, including two parts: a handle 1 and a head 2. The handle 1 and the head 2 pass through a first inclined plane 121, a second inclined plane 122, and a third The cutting surface 123 is transitioned to the flat notch surface 124, and the angle between the first beveled surface 121, the second beveled surface 122, and the third beveled surface 123 is consistent with the knife handle 1, and the included angle is 30°; the knife handle 1 is a flat notched cylinder , the shank diameter is 2.5mm, the shank diameter tolerance is ≤±5μm, the radial length of the flat notch is 2.3mm, and the radial length tolerance of the flat notch is (-0.01, 0); the center of the shank 1 is provided with a straight lead circle The hole 11 has a diameter of 0.55 mm, dimensional tolerance ≤ ± 5 μm, concentricity ≤ ± 5 μm, surface roughness ≤ 1.0 μm; the cutter head 2 is a wedge-shaped structure, composed o...

Embodiment 3

[0060] A wedge-shaped riving knife with an overall structure for strip bonding, with a length of 19.05mm, including two parts: a handle 1 and a cutter head 2. The beveled surface 123 and the flat notch surface 124 make a transition, and the first beveled surface 121, the second beveled surface 122, and the third beveled surface 123 are consistent with the included angle of the knife handle 1, and the included angle is 10°; the knife handle 1 is a flat notch type Cylindrical, shank diameter is 1.586mm, shank diameter tolerance ≤±5μm, flat notch radial length is 1.5mm, flat notch radial length tolerance is (-0.01, 0); shank 1 center is provided with a through straight lead The round hole 11 has a diameter of 0.45 mm, a dimensional tolerance of ≤±5 μm, a concentricity of ≤±5 μm, and a surface roughness of ≤1.0 μm; the cutter head 2 is a wedge-shaped structure, composed of a first beveled surface 121, a plane 23, and a third beveled surface 123. The fourth beveled surface 21 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Radial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com