High-corrosion-resistance nickel-copper alloy seamless pipe and manufacturing method thereof

A technology of nickel-copper alloy and manufacturing method, applied in the field of seamless pipes, can solve the problems such as the oxide scale is not easily washed off, the deformation is difficult, and the deformation resistance is large, so as to ensure the quality of the inner surface, the corrosion inhibition effect, and the stress good condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

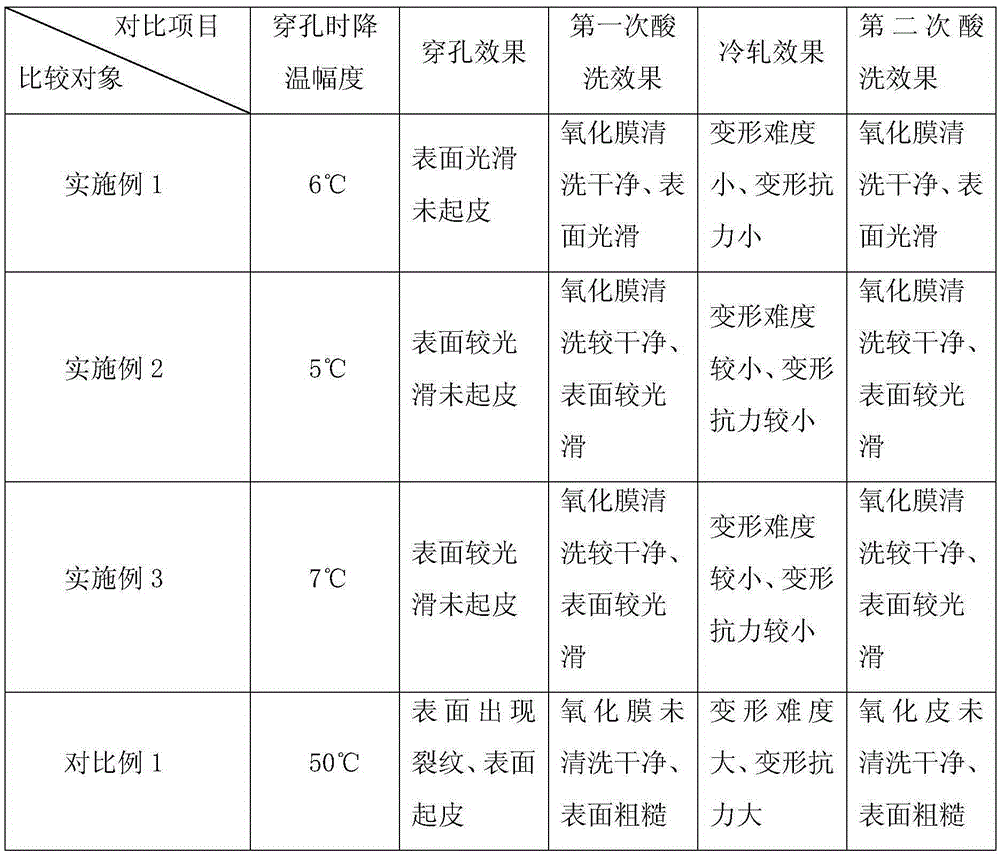

Embodiment 1

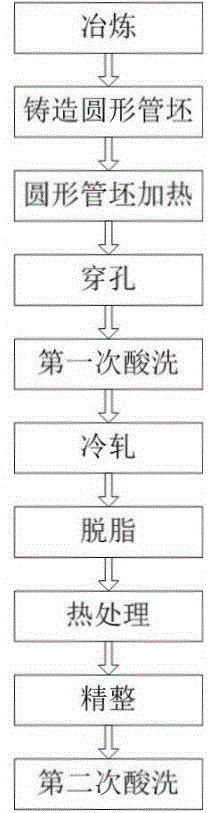

[0044] A method for manufacturing a high-corrosion-resistant nickel-copper alloy seamless pipe, comprising the steps of:

[0045] Step 1, smelting, its chemical composition is calculated by weight percentage: Ni≥60, Cu35-37, Fe≤2, Mn≤1, C<0.4, Si<0.3, S<0.015, Pb<0.01, Bi<0.15, Sn<0.22, Sb<0.13, the balance is unavoidable trace elements. .

[0046] Step 2, casting a circular tube blank.

[0047] Step 3: Heating the circular tube blank.

[0048] From the heating furnace used to heat the round tube blank in the step 3 to the piercer for piercing the circular tube blank in the step 4, a heat preservation channel for the circular tube blank to pass is set to ensure that the circular tube blank The temperature drop between the heating and the piercing machine is less than 10 degrees.

[0049] Step 4. Piercing. The temperature range is controlled at 651°C-898°C. The piercing plug used is equipped with a lubricant injection device, which can continuously spray the lubricant from ...

Embodiment 2

[0058] A method for manufacturing a high-corrosion-resistant nickel-copper alloy seamless pipe, comprising the steps of:

[0059] Step 1, smelting, its chemical composition is calculated by weight percentage: Ni≥60, Cu35-37, Fe≤2, Mn≤1, C<0.4, Si<0.3, S<0.015, Pb<0.01, Bi<0.15, Sn<0.22, Sb<0.13, the balance is unavoidable trace elements. .

[0060] Step 2, casting a circular tube blank.

[0061] Step 3: Heating the circular tube blank.

[0062] From the heating furnace used to heat the round tube blank in the step 3 to the piercer for piercing the circular tube blank in the step 4, a heat preservation channel for the circular tube blank to pass is set to ensure that the circular tube blank The temperature drop between the heating and the piercing machine is less than 10 degrees.

[0063] Step 4. Piercing. The temperature range is controlled at 651°C-898°C. The piercing plug used is equipped with a lubricant injection device, which can continuously spray the lubricant from ...

Embodiment 3

[0072] A method for manufacturing a high-corrosion-resistant nickel-copper alloy seamless pipe, comprising the steps of:

[0073] Step 1, smelting, its chemical composition is calculated by weight percentage: Ni≥60, Cu35-37, Fe≤2, Mn≤1, C<0.4, Si<0.3, S<0.015, Pb<0.01, Bi<0.15, Sn<0.22, Sb<0.13, the balance is unavoidable trace elements. .

[0074] Step 2, casting a circular tube blank.

[0075] Step 3: Heating the circular tube blank.

[0076] From the heating furnace used to heat the round tube blank in the step 3 to the piercer for piercing the circular tube blank in the step 4, a heat preservation channel for the circular tube blank to pass is set to ensure that the circular tube blank The temperature drop between the heating and the piercing machine is less than 10 degrees.

[0077] Step 4. Piercing. The temperature range is controlled at 651°C-898°C. The piercing plug used is equipped with a lubricant injection device, which can continuously spray the lubricant from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com