Patents

Literature

46results about How to "Reduce hydrogen embrittlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

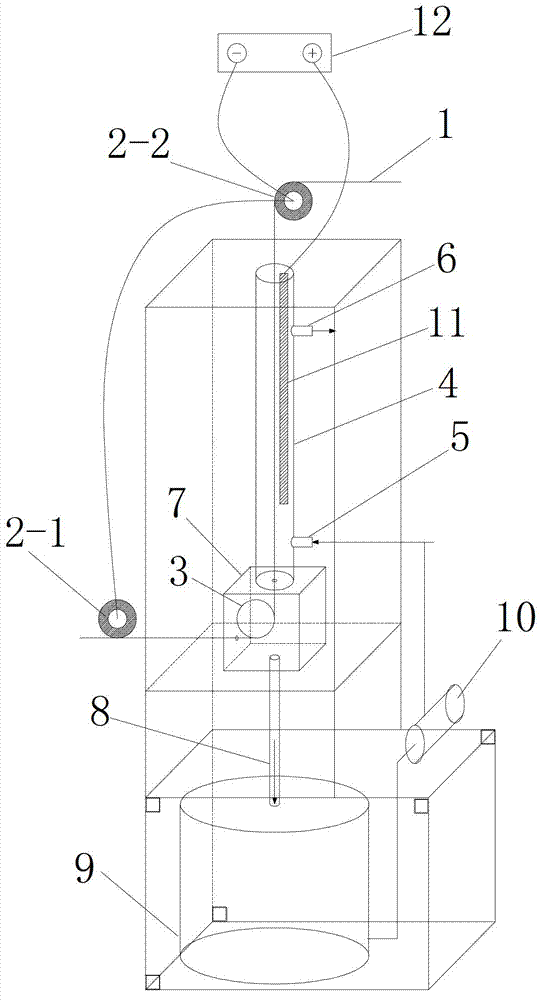

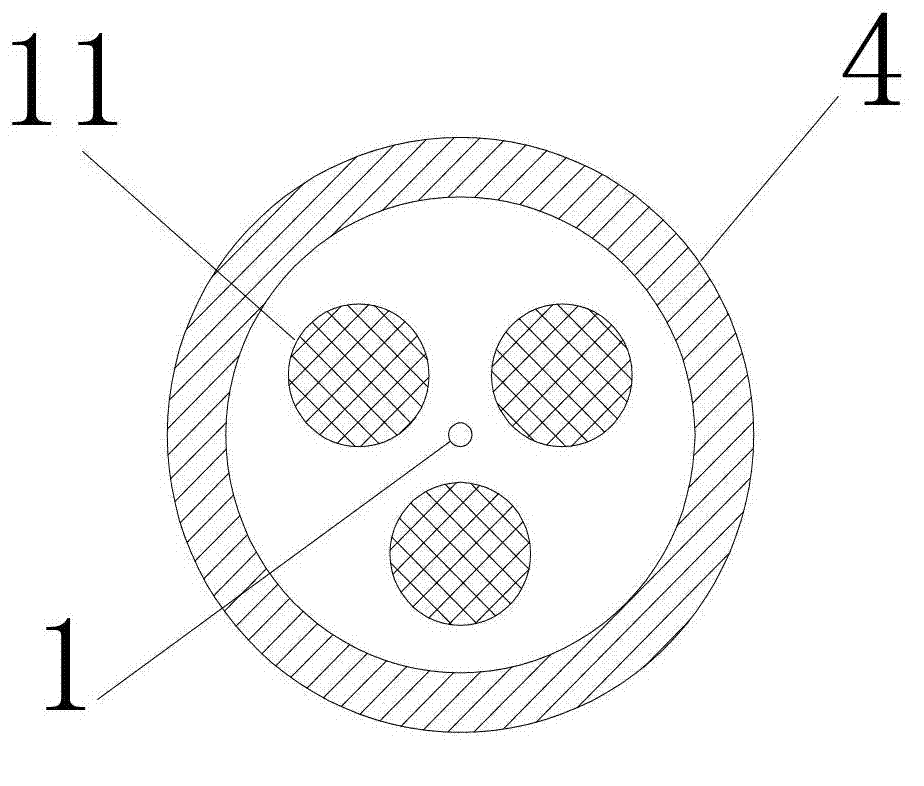

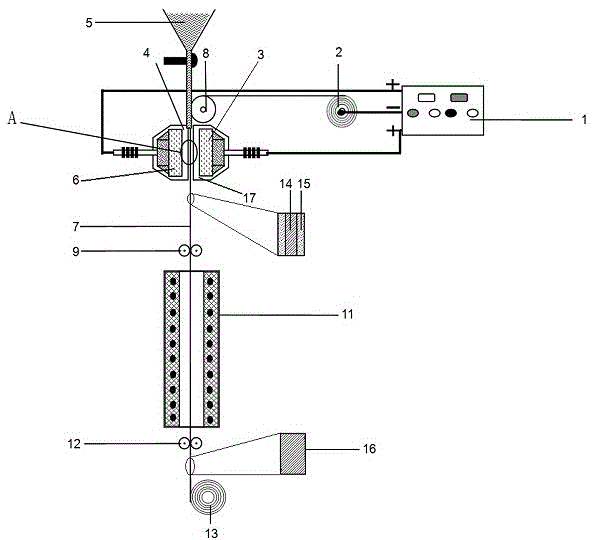

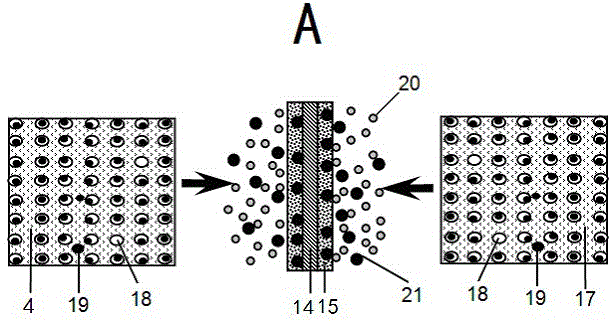

Electroplated diamond wire saw sand-applying device

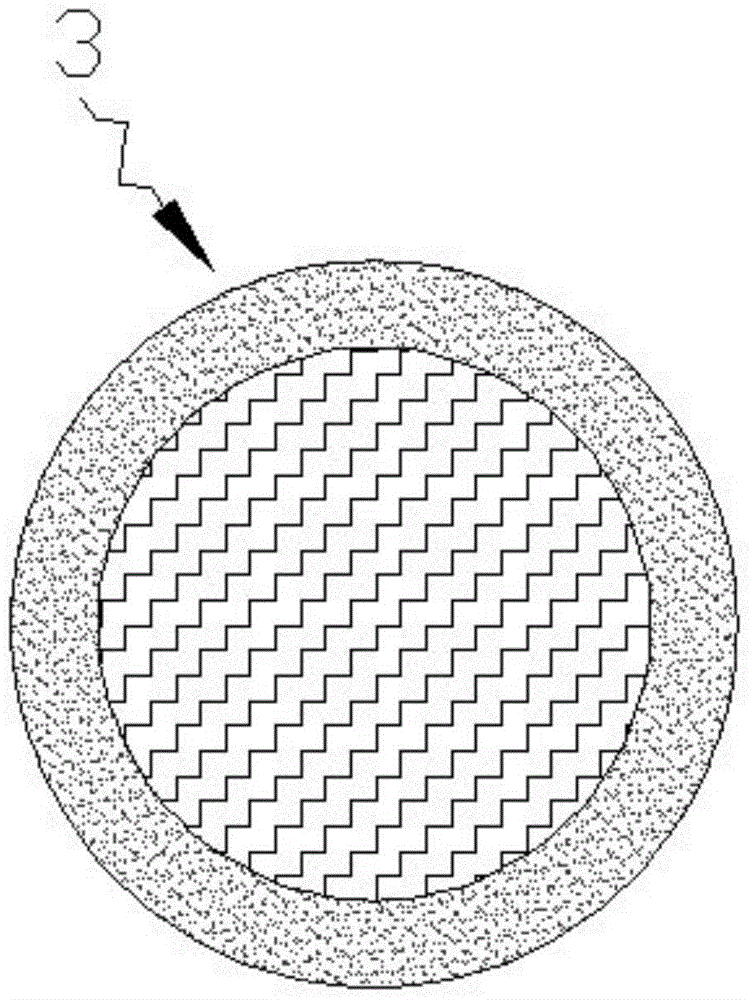

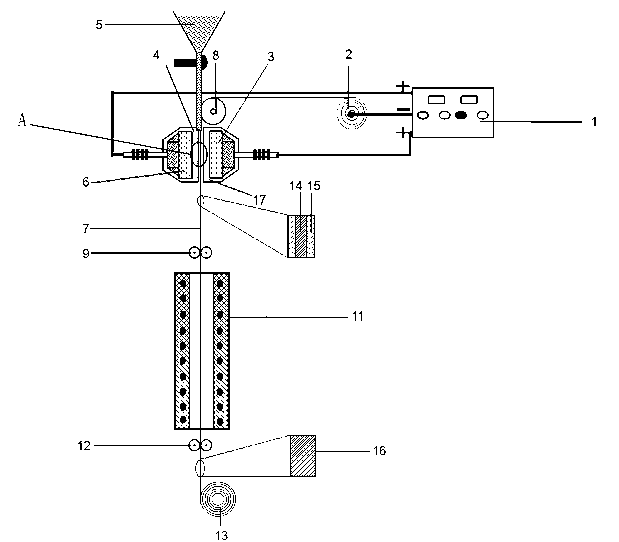

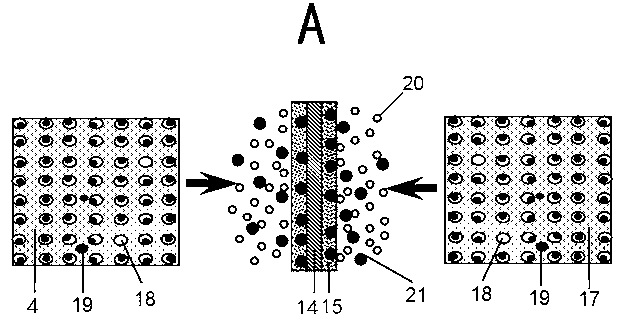

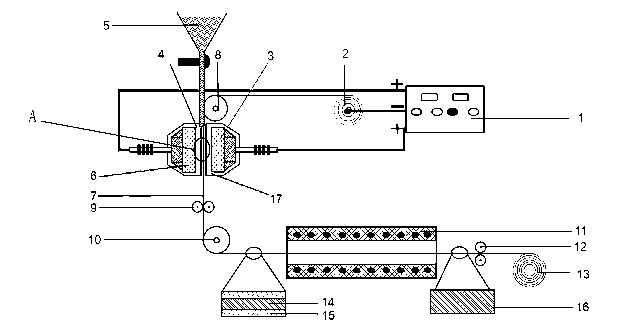

The invention discloses an electroplated diamond wire saw sand-applying device. The device sequentially comprises the components, from top to bottom: a vertical tubular sand-applying sub tank, a liquid-returning box, and a plating solution master tank. A guide wheel is fixed in the liquid-returning box. A core wire is sequentially wound on a wire-feeding conductive wheel on the bottom of the vertical tubular sand-applying sub tank and the guide wheel. The core wire then penetrates the vertical tubular sand-applying sub tank, and is finally wound on a wire-discharging conductive wheel on the top of the vertical tubular sand-applying sub tank. The wire-feeding conductive wheel and the wire-discharging conductive wheel are connected in parallel, and are then connected to the negative electrode of an electroplating power supply. Metal anodes are arranged around the core wire in the vertical tubular sand-applying sub tank. The metal anodes are connected with positive electrodes of the electroplating power supply. Through a water pump above the plating solution, the plating solution is lifted from the plating solution master tank into the vertical tubular sand-applying sub tank. With the device provided by the invention, sand-application of produced diamond wire is uniform and good. During the production process, current density is high, efficiency is high, internal stresses of the plating and the substrate are small, plating solution application amount is low, and wire breakage probability is low.

Owner:无锡超亚环保设备有限公司

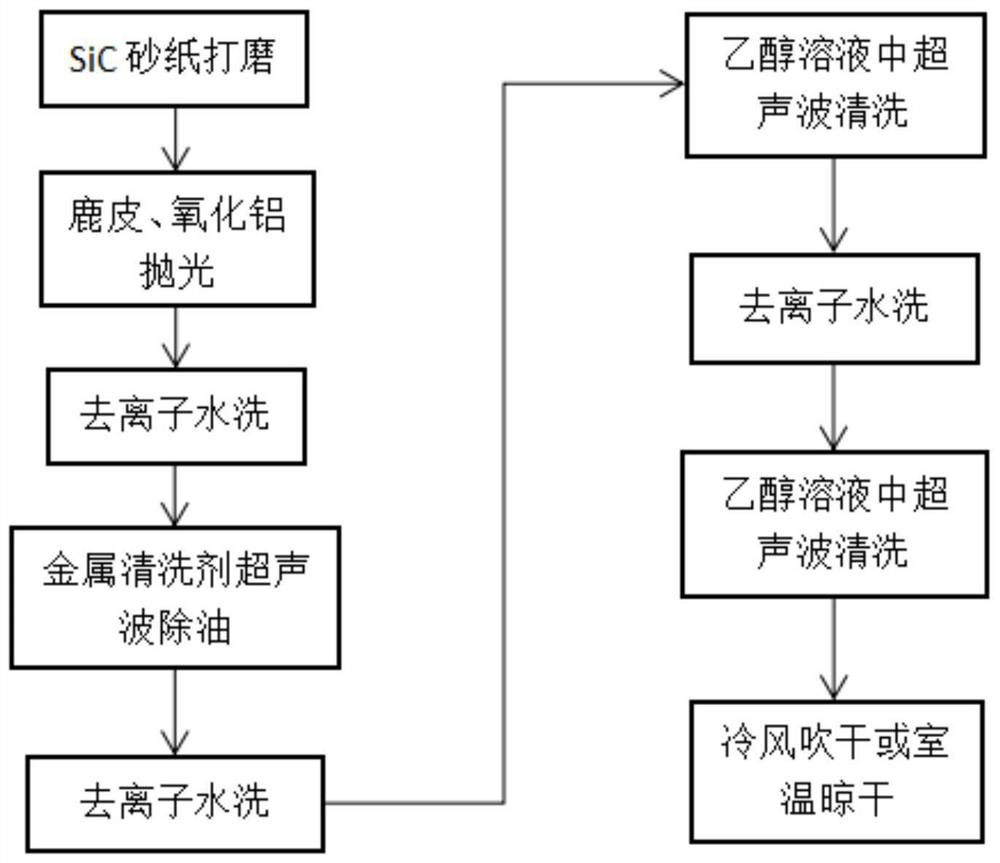

Method for double-pulse electrodeposition of nanocrystalline nickel-cobalt alloy

InactiveCN102260891AUniform crystallizationCrystal fineMaterial nanotechnologyPhotography auxillary processesElectroplatingNickel ions

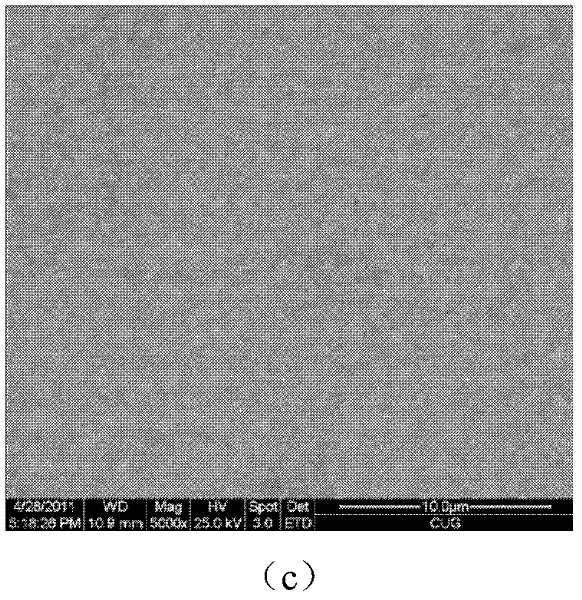

The invention relates to a method for electrodepositing a nanocrystalline nickel-cobalt alloy by double-pulse. The method for electrodepositing the nanocrystalline nickel-cobalt alloy by double-pulse is characterized by comprising the following processing steps: in a plating solution with a pH value of 5-6, a nickel ion concentration of 0.68-0.95 mol / L and a cobalt ion concentration of 1.9*10<-2>to 3.8*10<-2> mol / L, taking a soluble nickel plate after the soluble nickel plate is subjected to surface treating as a anode, taking an iron sheet after the iron sheet is subjected to surface treating as a cathode and electroplating a nanocrystalline nickel-cobalt alloy layer by using double-pulse electrodepositing technology, wherein the time for electrodepositing is 15-20 min, the positive-going pulse current density is 1.0-2.0 A / dm<2>, the positive-going duty ratio is 60-80%, the working time of the positive-going pulse is 50-100 ms and the positive-going cycle is 40-60 ms; and the negative-going pulse current density is 0.1-0.2 A / dm<2>, the negative-going duty ratio is 60-80%, the working time of the negative-going pulse is 10-20 ms, the negative-going cycle is 1-2 ms and the workingtime of the positive-going pulse is 5-10 times of that of the negative-going pulse. The nickel-cobalt alloy coating prepared by the method has the advantages of smooth surface, compact structure, fine and even crystal, good smoothness, no crack and excellent corrosion resistance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Wear-resistant worpiece and manufacturing method of wear-resistant coating thereof

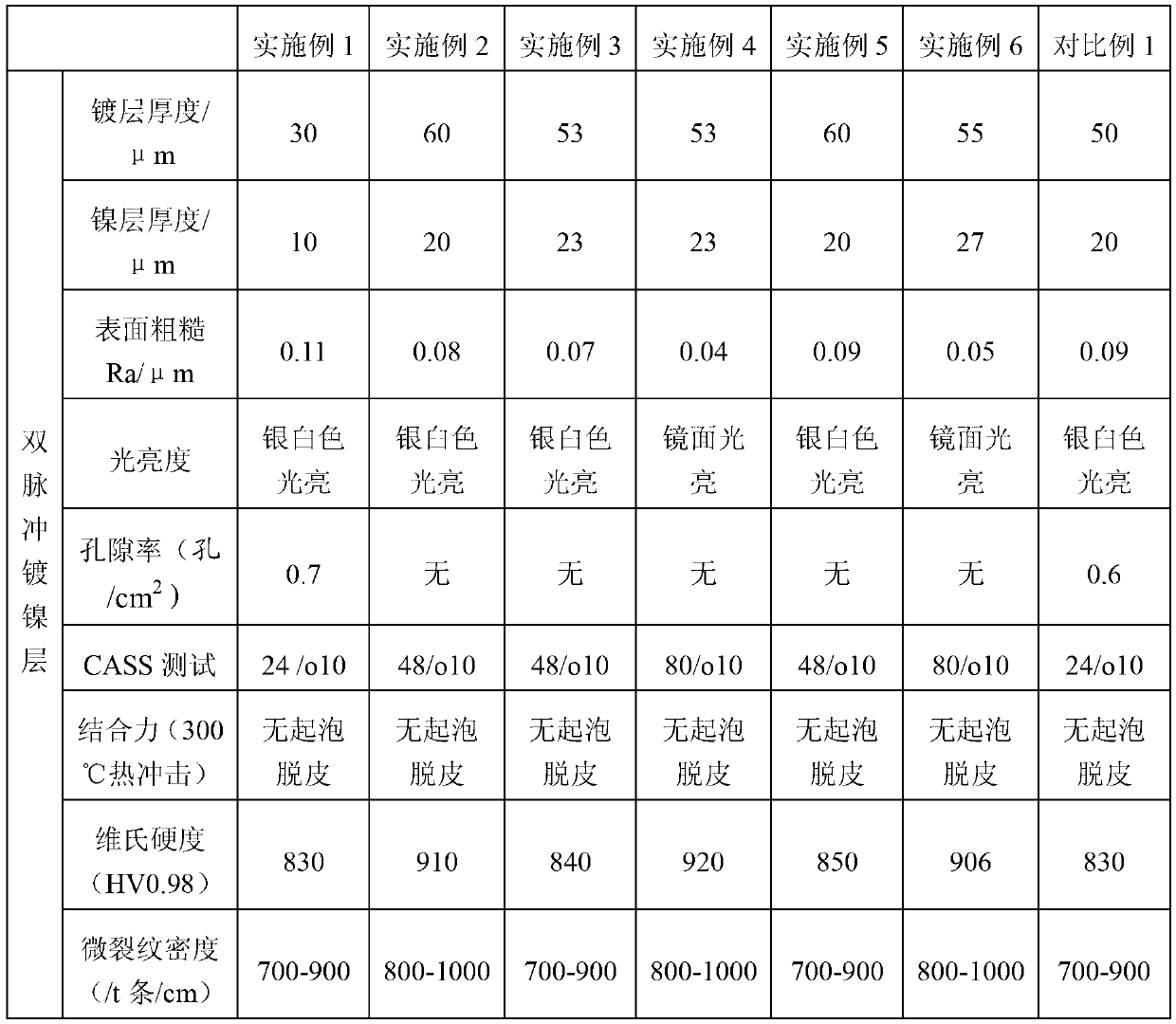

The invention discloses a wear-resistant workpiece and a manufacturing method of a wear-resistant coating thereof. The preparation method of the wear-resistant coating comprises the following steps: forming a preparation piece according to the structure of a required wear-resistant workpiece; coating nickel on the surface of the preparation piece through a double-pulse method, thus forming a nickel-coated transition piece; and coating a hard chromium layer on the surface of the nickel-coated transition piece, thus forming the wear-resistant coating on the surface of the preparation piece. For the manufacturing method of the wear-resistant workpiece, a step of coating nickel on the surface of the workpiece through a double-pulse nickel coating method is added; and the double-pulse nickel coating method is characterized in that the magnitude of current or voltage is regulated by an external control means, the current is additionally controlled by controlling the pulse switch-on time, the pulse switch-off time, the pulse duty factor, the pulse current density and the like, and corresponding variables are changed to respectively achieve the effects of increasing the cathode current density, inhibiting the generation of side reaction, reducing the impurity content in the coating, improving the current distribution and the like, thus improving the quality of the coated nickel layer and prolonging the service life of the wear-resistant workpiece.

Owner:HUNAN TELI HYDRAULIC +1

Cutting wire for one-way wire traveling of low magnesia and manufacturing method thereof

ActiveCN104690381APerformance is not degradedLow tensile strengthElectrical-based machining electrodesManganeseOxygen

The invention discloses a cutting wire for one-way wire traveling of low magnesia and a manufacturing method thereof. The core comprises the following materials: 75-85 percent of copper, 0.0005-0.50 percent of magnesium, 0.001-0.03 percent of boron, 0.0005-0.02 percent of RE, 0.05-1.0 percent of other elements, less than 0.5 weight percent of inevitable impurities and the balance of zinc, wherein the other elements are at least two of titanium, iron, silicon, nickel, manganese, aluminum, tin and phosphorus. The surface layer comprises the following materials: 35-45 percent of copper, 0.0005-3.0 percent of oxygen, 0.0005-0.25 percent of manganese, 0.005-0.01 percent of RE, less than 0.5 percent of inevitable impurities and the balance of zinc. The core is subjected to upward continuous casting smelting, plastic processing and re-crystallization annealing, the surface layer is thermally treated, and a master blank is generated; the master blank is subjected to continuous drawing and continuous annealing processing to generate the cutting wire. A material piece of which the thickness is greater than 80 mm can be cut by the cutting wire, and the straightness, the dimensional accuracy, the surface smoothness and the cutting speed are high.

Owner:NINGBO BODE HIGHTECH CO LTD

Copper plating bath for coating copper and method for surface copper plating permanent magnetic material using the same

ActiveCN101372740AImprove bindingDense depositionLiquid/solution decomposition chemical coatingCopper coatingCopper plating

The invention relates to copper plating solution for copper coating, which comprises the following compositions: 0.03 to 0.5 mol / l of copper sulphate, 0.10 to 0.3 mol / l of sulphate and 0.1 to 0.7 mol / l of a complexing agent, and the PH value is regulated to 6.5 to 8.0. In the invention, surface copper coating is carried out on a permanent-magnet material which is pre-treated by the copper plating solution so as to obtain a copper coating with evenness, stability and strong bonding force of the copper coating, and the surface of the permanent-magnet material has excellent corrosion resistance.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

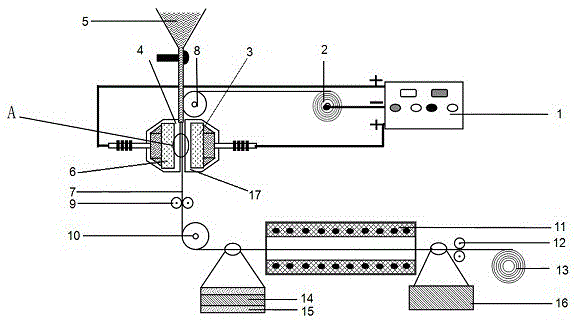

Method for preparing high-silicon steel ribbon through using electric brush composite plating method and continuous silicon steel ribbon preparing device

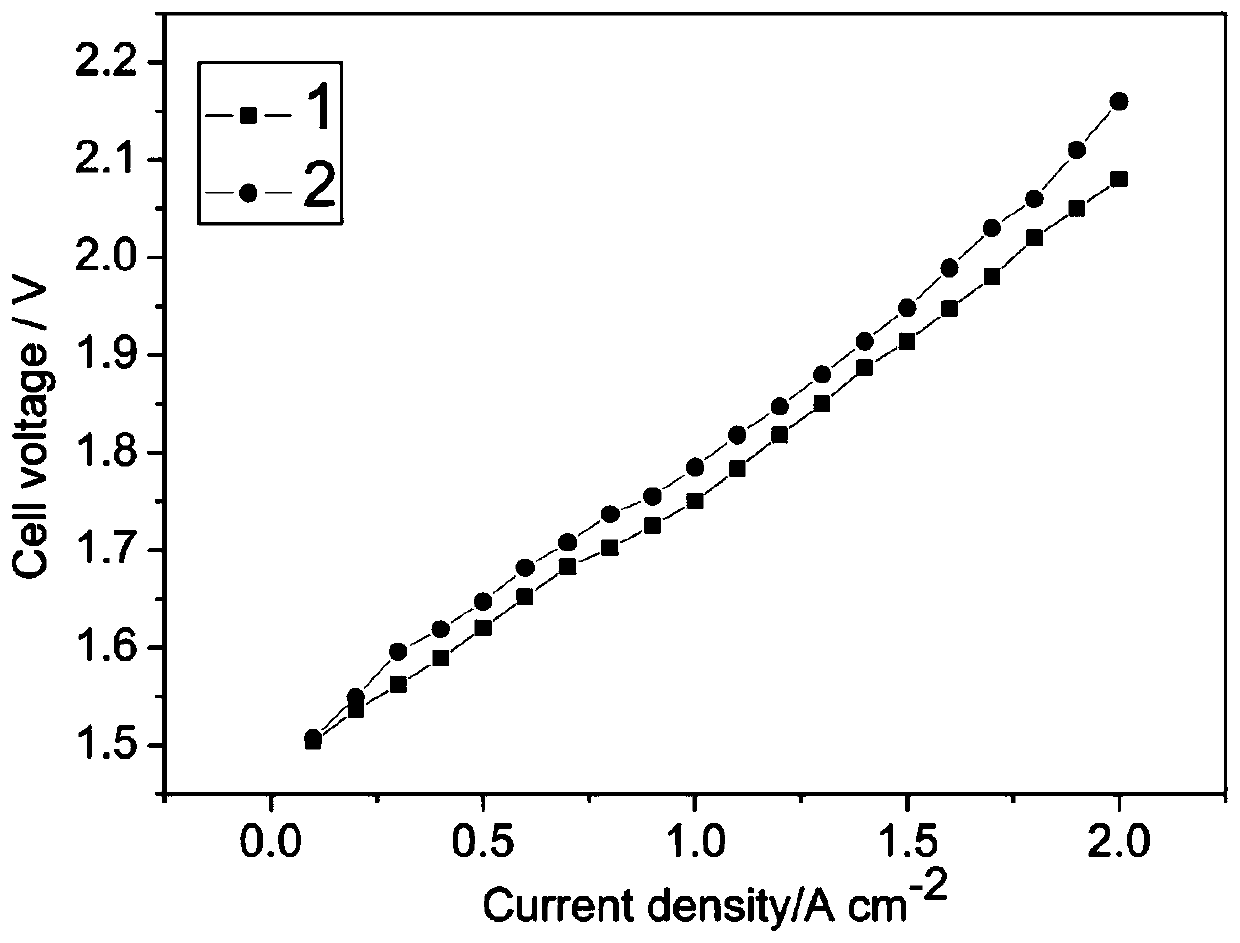

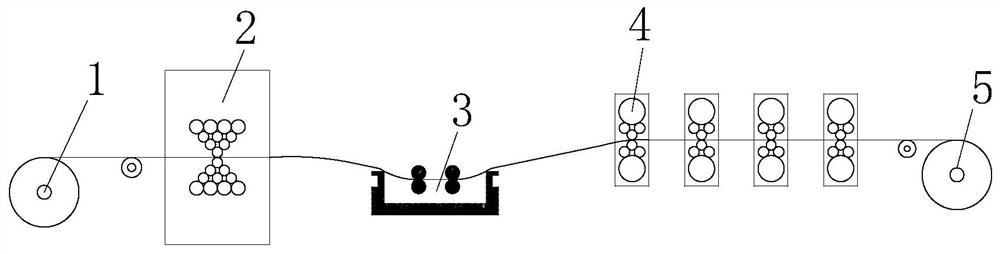

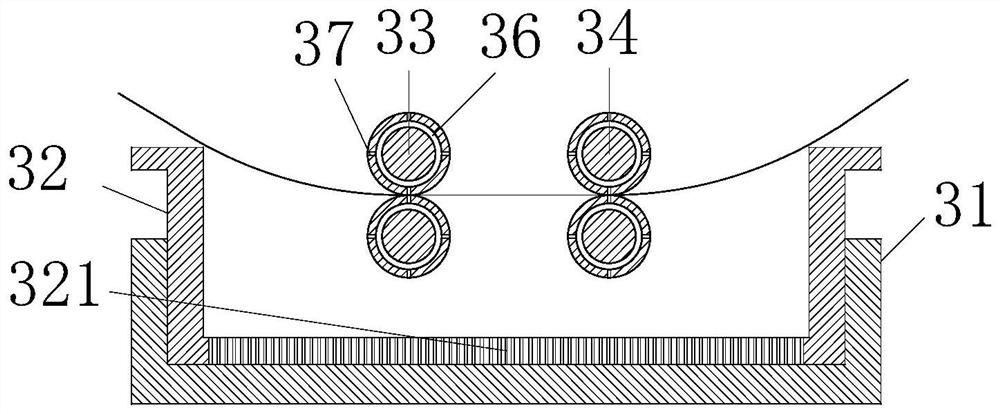

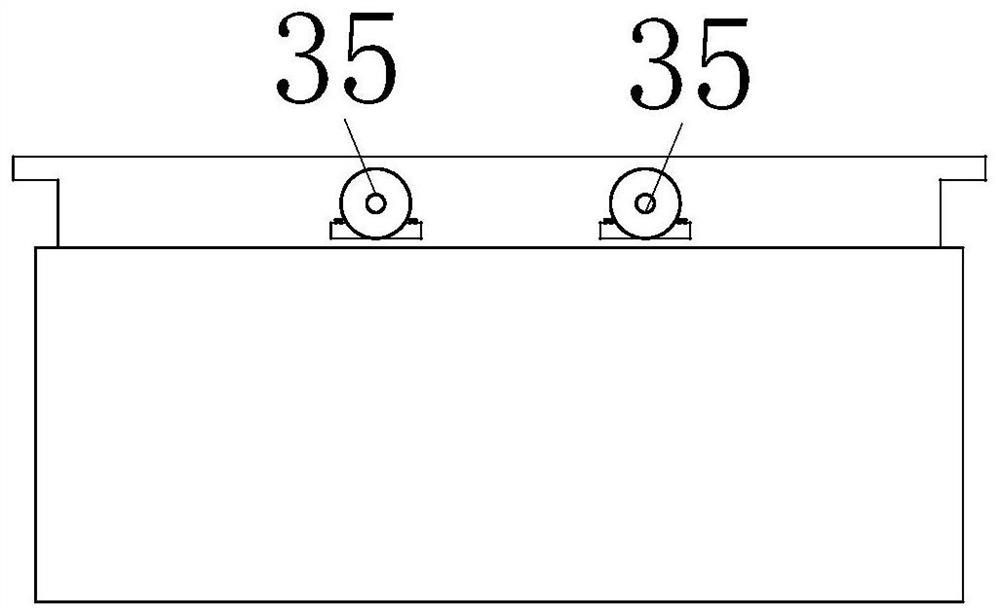

ActiveCN103320842AAvoid adverse effectsHigh cell voltageElectrolytic coatingsCarbon steelSilicon particle

The invention discloses a method for preparing a high-silicon steel ribbon through using an electric brush composite plating method. The method is characterized in that a pure iron ribbon, a low-carbon steel ribbon or a low-silicon steel ribbon is used as a cathode plating piece ribbon, an electric brush plating anode plate is used as an anode, a layer of iron-silicon iron particle composite plating layer is coated on the cathode plating piece ribbon through using an electric brush composite silicon plating process, a composite plating layer steel ribbon adopting a steel-ribbon substrate as a core part is formed, then the uniform dispersion heat treatment is carried out, silicon-contained particles in the iron-silicon iron particle composite plating layer are uniformly dispersed into the steel ribbon substrate of the core part, and the high-silicon steel ribbon can be continuously prepared. The invention also discloses a continuous silicon steel ribbon preparing device which comprises an unreeling guide device, a conveying device, an electroplating device, a dispersion heat treatment device and a rolling device. The high-silicon plating layer is electrically plated on the cathode plating piece ribbon, then the high-silicon steel ribbon with an excellent magnetic conduction performance is obtained through using a heat treatment process, the simplicity in operation can be realized, characteristics such as high efficiency and continuity in preparation can be achieved, and the preparation cost also can be greatly reduced.

Owner:SHANGHAI UNIV

Method for removing hydrogen in high strength steel electroplated by zinc-nickel alloy

The invention relates to a method for removing hydrogen in high strength steel electroplated by zinc-nickel alloy, including the following steps: 1) zinc nickel alloy coated high strength steel parts are sequentially cleaned by water and soaked by alcohol; 2) parts after being cleaned are placed into a vacuum furnace to be subject to heat treatment, so that hydrogen atom on coating surface is overflown; 3) parts after hydrogen removal are placed into citric acid-boric acid mixed aqueous solution to be activated; 4) parts after coating activation treatment are subject to zinc nickel alloy electroplating again; 5) parts after composite electroplating are placed into chromic anhydride-sodium chloride mixed aqueous solution to be passivated; 6) parts after passivation treatment are cleaned by water and dried by blowing, thus obtaining the finished product conforming to the requirements. The method can be utilized to effectively remove hydrogen penetrated into base metal in electroplated by zinc-nickel alloy process, hydrogen embrittlement is reduced, and passivation coating with good protective properties can be generated on the surface of alloy coating, and meanwhile the technological method of the invention is simple and production cost is low.

Owner:湖北三江航天红林探控有限公司

Nickel copper phosphorus plating bath for permanent magnet material and permanent magnet material surface treatment method thereof

InactiveCN101724833AReduce hydrogen embrittlementLiquid/solution decomposition chemical coatingElectroless nickelCopper plating

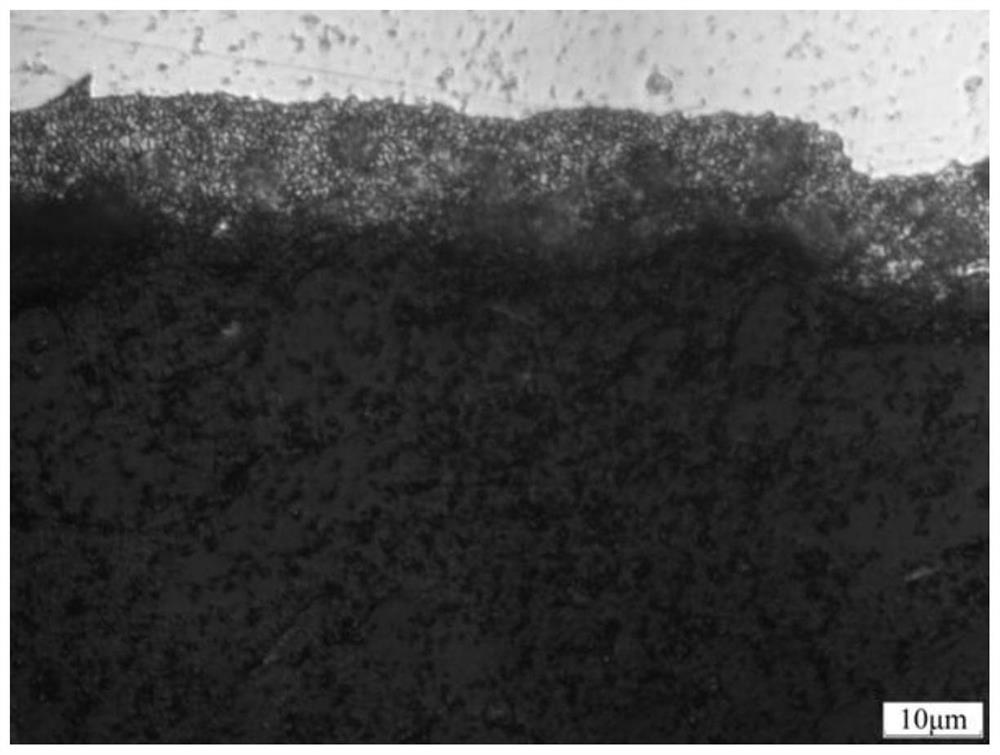

The invention relates to an electroless nickel copper phosphorus alloy plating bath. The copper plating bath contains the eletroless nickel copper phosphorus alloy plating bath, including 15-28g / L of NiSO4 6H2O, 15-25g / L of NaH2PO2 H2O, 0.5-10g / L of CuSO4 5H2O and 30-60g / L of complexing agent. The invention adopts the copper plating bath for carrying out surface nickel copper phosphorus alloy plating on the pre-treated permanent magnet material, so as to obtain uniform and stable coating film, and the surface thereof has favourable anti-corrosion performance, the coating film is in amorphous state nano structure, no obvious crystal boundary is existed, grain size is 3.8-10 nanometer, and the thickness of the coating film is 5-20 nanometer.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Method for electroplating high-strength corrosion-proof cadmium-tin-titanium alloy on 304 or 316 L stainless steel surface

The invention provides a method for electroplating a protective plating layer of high-strength corrosion-proof cadmium-tin-titanium alloy on a 304 or 316 L stainless steel surface. The corrosion resistance of a plating layer is 6 to 7 times higher than that of a cadmium-plated layer, and the plating layer is uniform and fine and can be matched with cadmium-plated cyanide; after surface pre-treatment and in advanced cadmium-plating, the binding force of a cadmium-tin-titanium alloy plating layer is far more than that of the same kind of cadmium-tin plated alloy and the cadmium-plated layer; the cadmium-tin-titanium plating layer is porous, so that the hydrogen is beneficial for escaping; the cadmium-tin-titanium plating layer has good paintability, weldability, formability and low-hydrogen embrittlement; the whole preparation process is simple, cyanogen-free electroplating is achieved, and the preparation process is safe and environmentally-friendly.

Owner:无锡市恒利弘实业有限公司

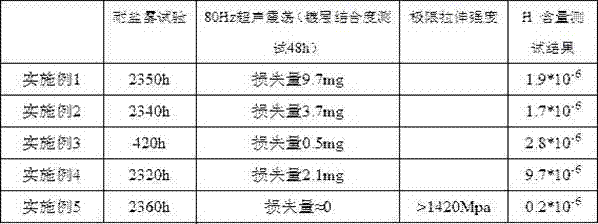

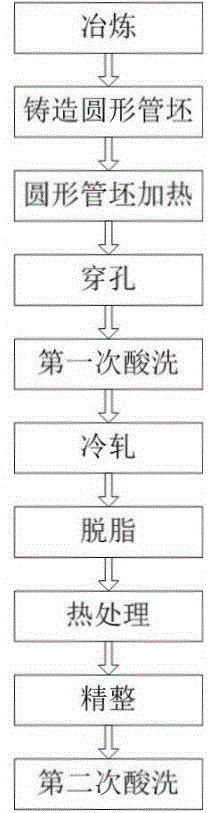

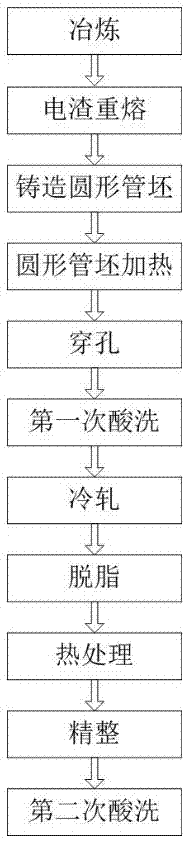

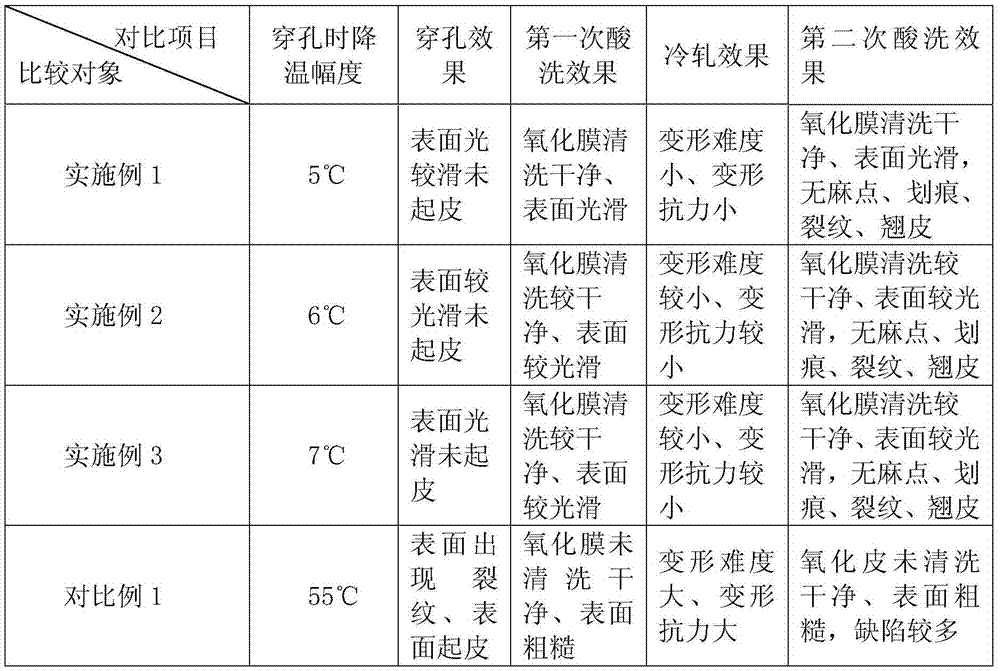

High-corrosion-resistance nickel-copper alloy seamless pipe and manufacturing method thereof

The invention discloses a high-corrosion-resistance nickel-copper alloy seamless pipe. Chemical components of the high-corrosion-resistance nickel-copper alloy seamless pipe comprise, by weight, 60% of Ni or more, 35%-37% of Cu, 2% of Fe or less, 1% of Mn or less, C smaller than 0.4%, Si smaller than 0.3%, S smaller than 0.015%, Pb smaller than 0.01%, Bi smaller than 0.15%, Sn smaller than 0.22%, Sb smaller than 0.13% and the balance inevitable micro elements. A manufacturing method of the high-corrosion-resistance nickel-copper alloy seamless pipe comprises the following steps of smelting, casting of a round pipe blank, heating of the round pipe blank, perforating, the first time of acid pickling, cold rolling, degreasing, heat treatment, finishing and the second time of acid pickling. The manufactured high-corrosion-resistance nickel-copper alloy seamless pipe is smooth in surface, free of cracks, good in surface quality, high in size precision and excellent in corrosion resistance. The manufacturing method is short in procedure, easy and convenient to operate, high in efficiency and yield and low in cost, pickling waste water concentration and treatment cost.

Owner:HUZHOU HUATE STAINLESS STEEL TUBES MFG

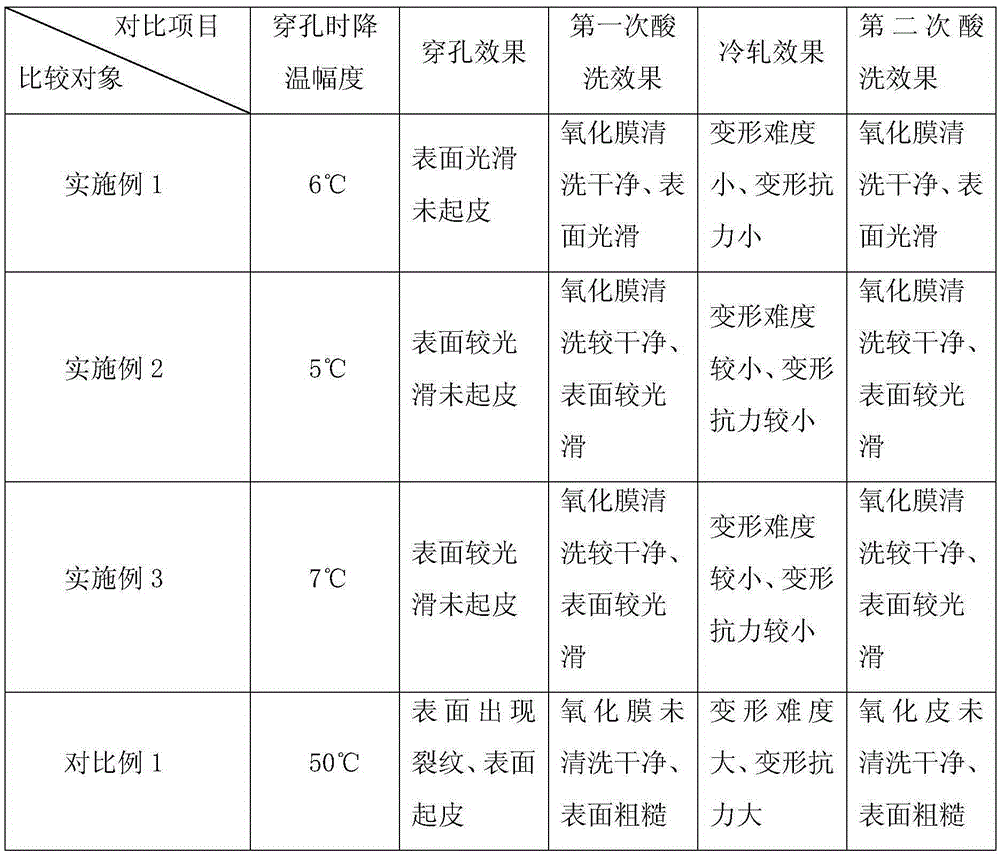

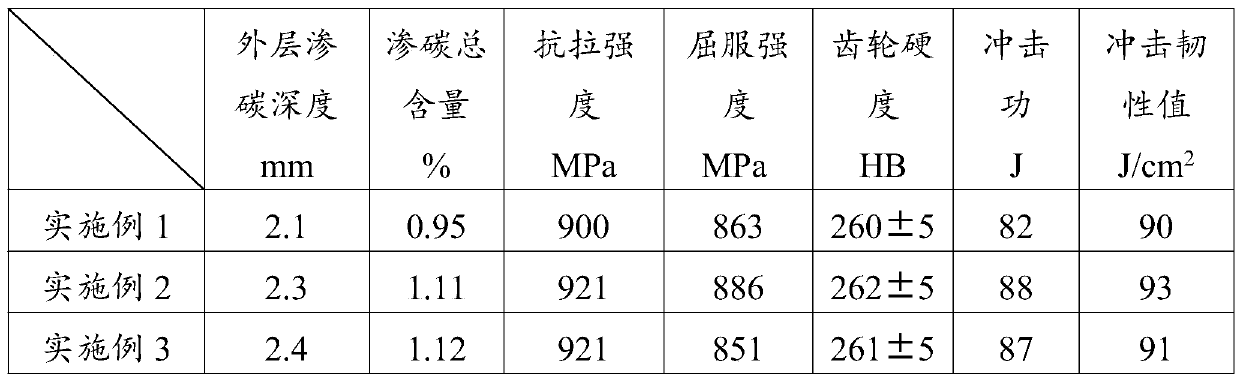

Heat treatment process of high-wear-resistance antirust gear steel

InactiveCN111549206AReduced tendency to crackAvoid layeringHot-dipping/immersion processesSolid state diffusion coatingTemperingGear wheel

The invention discloses a heat treatment process of high-wear-resistance antirust gear steel. The heat treatment process comprises the following steps of carrying out hot die forging on a gear blank by using a medium alloy steel raw material; carrying out heating pretreatment on the gear blank; carrying out sub-temperature secondary normalizing; refining a tissue structure; periodically supplyingoxygen into a normalizing furnace at a constant speed during secondary normalizing heating of the gear blank; and carrying out sufficient pyrolysis combustion dehydrogenation. According to the heat treatment process, crystalline grains of the gear blank are refined through sub-temperature secondary normalizing, so that the cracking tendency of a steel part is reduced; the oxygen is supplied for sufficient pyrolysis combustion dehydrogenation, so that the hydrogen embrittlement phenomenon is reduced; the structure is uniformly strengthened through quenching and tempering treatment, so that theinternal structure is uniform and compact, the heat conduction and dissipation performance is improved, and steel structure layering is avoided; dirt on the surface of steel is removed through shot blasting treatment, so that the bonding strength between a workpiece and a protective coating is improved, the wear-resisting and rust-preventing effects are achieved through cooperation with a hot galvanizing layer, and the surface organization structure of the rough gear is strengthened; and overall carburizing and outer side quenching layer carbonitriding are combined, so that the overall performance of the gear steel is improved.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

Preparation method for low-hydrogen fragile zinc-nickel alloy electroplated layer

The invention relates to a preparation method for a low-hydrogen fragile zinc-nickel alloy electroplated layer. The preparation method is characterized in that a process for an electroplated zinc-nickel alloy coating is as follows: 70-80g / L of ZnCl2, 100-120g / L of NiCl2.6H2O, 30-40g / L of KCl, 190-210g / L of NH4Cl, 20-30g / L of H3BO3, 0.5-1g / L of 2-mercapto benzimidazole cyclohexylamine salt, 0.5-1g / L of benzimidazole, 0.5-1g / L of citric acid and 0.5-1g / L of oxalic acid. The current density is 1.5A / dm<2>-2.7A / dm<2>; the temperature is 30-40 DEG C; the pH (Potential of Hydrogen) value is 5-6.5. According to the method, seepage hydrogen of high-strength in the electroplating process can be effectively reduced, and the obtained zinc-nickel electroplated layer has low hydrogen fragility and a good protection performance.

Owner:WUXI SANZHOU COLD ROLLED SILICON STEEL

Method for treating surface of high-strength fastener

InactiveCN112126958AAvoid crackingAvoid damage phenomenonLiquid surface applicatorsMetallic material coating processesChromate and dichromateHydrogen embrittlement

The invention discloses a method for treating the surface of a high-strength fastener, relates to the field of methods for treating the surfaces of fasteners in the field of fasteners, and aims to solve the problem that a fastener is cracked or damaged due to the fact that hydrogen embrittlement is easily generated in the treatment process of an existing treatment method. The method comprises thefollowing steps: step 1. degreasing; step 2. removing oxide skin by laser; step 3. performing electroplating treatment; step 4. performing hydrogen embrittlement reduction processing; step 5. performing chromate passivation treatment; step 6. performing drying treatment; step 7. coating grease; and step 8. taking out and draining.

Owner:苏州汇铭源工业零部件有限公司

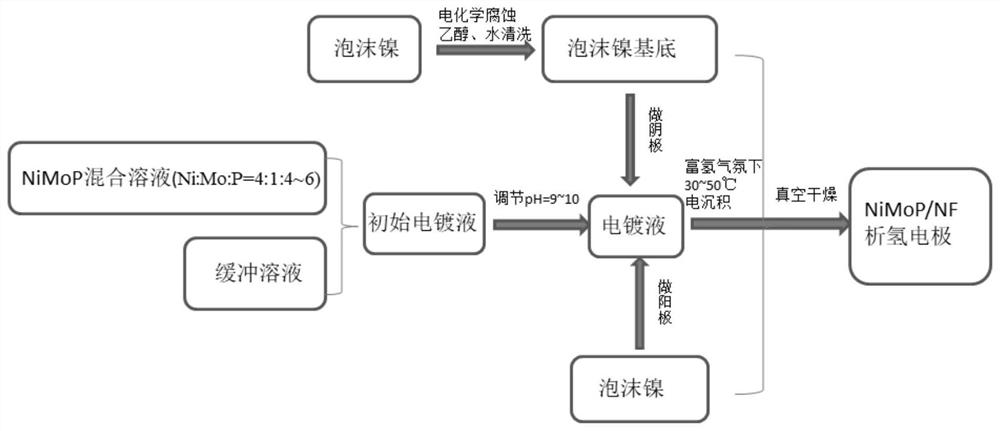

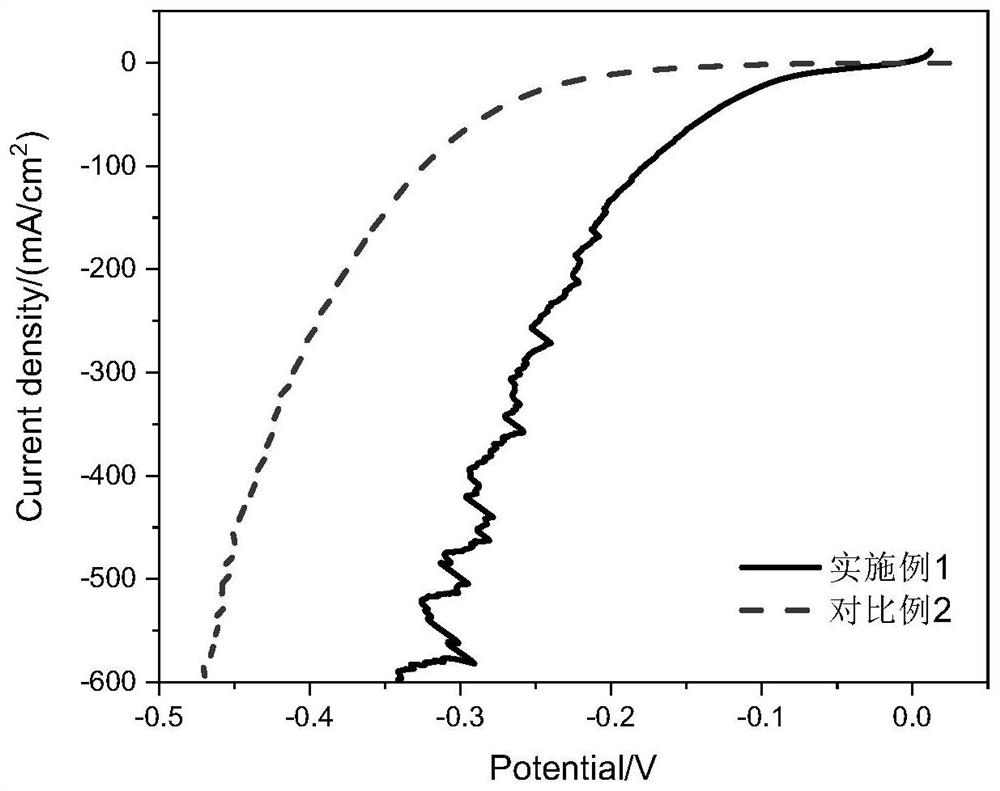

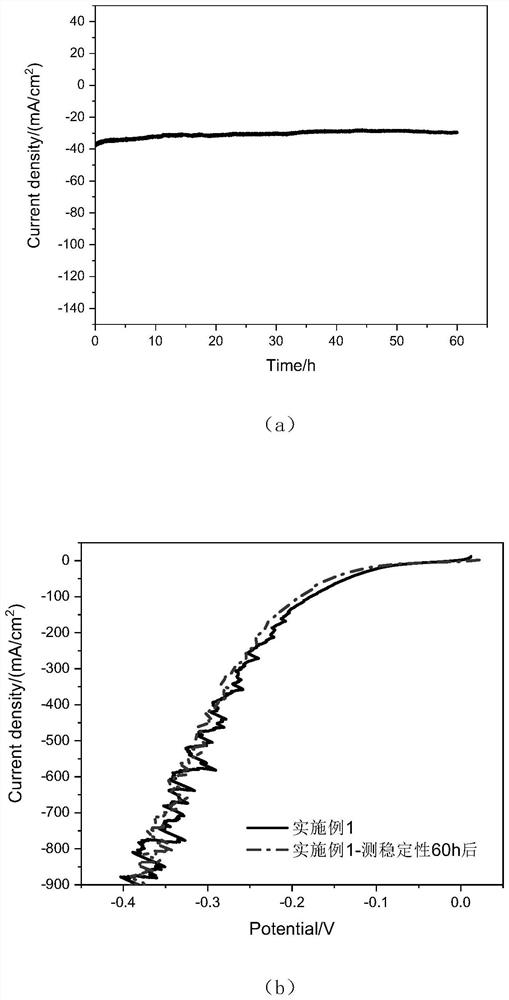

Preparation method of NiMoP electrode for hydrogen evolution by alkaline electrolysis of water

The invention discloses a preparation method of a NiMoP electrode for hydrogen evolution by alkaline electrolysis of water, which comprises the following steps: (1) placing foamed nickel in a strong acid solution for electrochemical corrosion, then taking out the foamed nickel, and cleaning the foamed nickel with ethanol and deionized water in sequence to obtain the foamed nickel after electrochemical corrosion; (2) selecting a nickel salt, a molybdenum salt and a phosphor salt to prepare a NiMoP mixed solution, then adding a buffer agent, and then adjusting the pH value of the solution to 9-10 by using an inorganic base to obtain an electroplating solution; (3) transferring the electroplating solution prepared in the step (2) into an electroplating bath, and carrying out electro-deposition in a hydrogen-rich atmosphere by taking foamed nickel as an anode and taking the foamed nickel subjected to electrochemical corrosion as a cathode; and (4) after the electro-deposition reaction is finished, cleaning the electrode with deionized water, and performing vacuum drying at room temperature to obtain the NiMoP / NF hydrogen evolution electrode. The finally prepared NiMoP / NF hydrogen evolution electrode has excellent HER performance, and has long-time stability in a three-electrode system and a simulated industrial electrolytic cell.

Owner:QINGDAO CHUANGQI XINNENG CATALYSIS TECH CO LTD

Copper-nickel alloy seamless tube and manufacturing method thereof

ActiveCN105441720AReduce dosageReduce corrosionMandrelsMetal rolling arrangementsChemical compositionTrace element

The invention discloses a copper-nickel alloy seamless tube and a manufacturing method. The copper-nickel alloy seamless tube comprises, by weight, more than 63% of Ni, 28%-34% of Cu, 0-2.5% of Fe, 0-2% of Mn, less than 3% of C, less than 0.5% of Si, less than 0.024% of S, and the balance inevitable trace elements. The manufacturing method includes the following steps of smelting, electroslag remelting, round pipe billet casting, round pipe billet heating, perforating, the first time of acid pickling, cold rolling, degreasing, thermal treatment, finishing and the second time of acid pickling. The manufactured copper-nickel alloy seamless tube is free of the appearance defects of pitting, scratches, cracks, peeling and the like, and the inner surface and the outer surface of the seamless tube are bright; according to the manufacturing method, the process is short, operation is simple and convenient, efficiency is high, the percent of pass is high, and cost is low.

Owner:HUZHOU HUATE STAINLESS STEEL TUBES MFG

Method for preparing high-silicon silicon steel thin strip by electric brush composite plating method and continuous preparation device for silicon steel strip

ActiveCN103320842BReduce adverse effectsSolve the problem of fragmentationElectrolytic coatingsFerrosiliconBrush

The invention discloses a method for preparing a high-silicon silicon steel strip by an electric brush composite plating method. A pure iron strip, a low-carbon steel strip or a low-silicon silicon steel strip is used as a cathode plated strip, and an anode plate is plated by an electric brush. As the anode, a layer of iron-iron-silicon particle composite coating is covered on the cathodic plating thin strip through the brush composite silicon plating process to form a composite coated steel strip with the core as the steel strip matrix, and then perform uniform diffusion heat treatment to make the iron - The silicon-containing particles in the composite coating of ferrosilicon particles are uniformly diffused into the steel strip matrix at the core, thereby continuously preparing high-silicon steel thin strips. The invention also discloses a silicon steel strip continuous preparation device, which includes an unwinding guiding device, a conveying device, an electroplating device, a diffusion heat treatment device and a winding device. In the invention, the high-silicon silicon steel strip with excellent magnetic properties is obtained by electroplating the high-silicon coating on the cathode-plated thin strip, and then undergoing a heat treatment process. The method is simple to operate, has the characteristics of high efficiency and continuous preparation, and can greatly reduce the preparation cost.

Owner:SHANGHAI UNIV

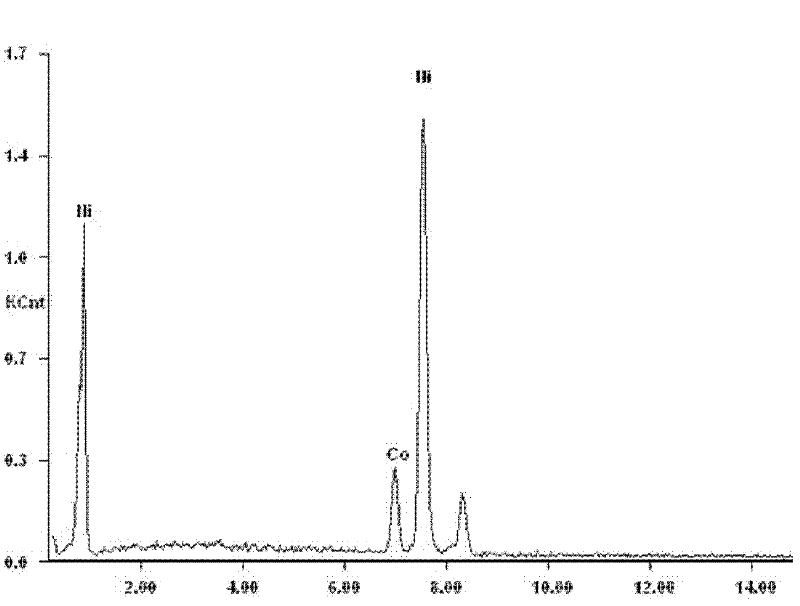

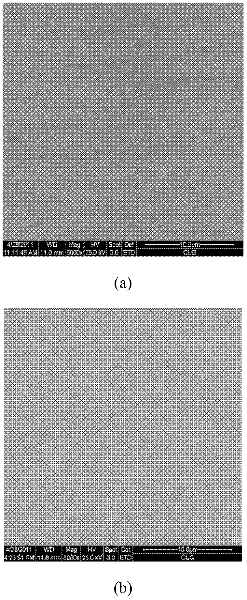

Nano zinc-cobalt alloy coating based on double-pulse electrodeposition and preparation method of nano zinc-cobalt alloy coating

The invention discloses a nano zinc-cobalt alloy coating based on double-pulse electrodeposition and a preparation method of the nano zinc-cobalt alloy coating. According to the preparation method ofthe nano zinc-cobalt alloy coating based on double-pulse electrodeposition, a zinc plate is used as an anode, a low-carbon steel sheet is used as a cathode, and a nano zinc-cobalt alloy coating is electroplated in a plating solution through a double-pulse electrodeposition process, wherein the pH value of the plating solution is 4-5. the concentration of zinc ions is 0.64 mol / L-0.70 mol / L, the concentration of cobalt ions is 0.1 mol / L-0.16 mol / L, the electrodeposition time is 20 min, the forward current density is 1.5 A / dm<2>-3.0 A / dm<2>, the forward duty ratio is 30%-70%, the forward period is 30 ms-70 ms, the reverse current density is 0.2 A / dm<2>-0.4 A / dm<2>, the reverse duty ratio is 30%-70%, the forward working time is 100 ms, the reverse working time is 12 ms, and the reverse periodis 1 ms. The surface of the nano zinc-cobalt alloy coating prepared with the preparation method of the nano zinc-cobalt alloy coating based on double-pulse electrodeposition is bright and smooth, crystals are uniform and dense, the binding force of the nano zinc-cobalt alloy coating and a base material is good, and excellent anti-corrosion performance is achieved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Nano easy-welding high-hardness wear-resistant corrosion-resistant decorative alloy catalytic liquid and preparation method thereof

InactiveCN110079794AStrong corrosion resistanceImprove corrosion resistanceLiquid/solution decomposition chemical coatingRare-earth elementWear resistant

The invention discloses a nano, easy-to-weld, high-hardness, wear-resistant, corrosion-resistant and decorative alloy catalytic liquid and a preparation method thereof. The nano, easy-to-weld, high-hardness, wear-resistant, corrosion-resistant and decorative alloy catalytic liquid is compounded by nickel, zinc, rare earth elements and the like as basic raw materials, a lubricating, easy-to-weld, high-hardness, wear-resistant, corrosion-resistant, bright-thickness and accurate-thickness nano-alloy layer can be obtained on the surface of metal by high-temperature catalysis, and the nano easy-to-weld, high-hardness, wear-resistant, corrosion-resistant and decorative alloy catalytic liquid has an appearance decoration effect on the premise of high hardness, high wear resistance, high corrosionresistance and the like, the compact conversion alloy layer formed by catalysis can be stable in a severe environment, and the appearance of the alloy layer can be kept unchanged for a long year.

Owner:深圳市长裕环保有限公司

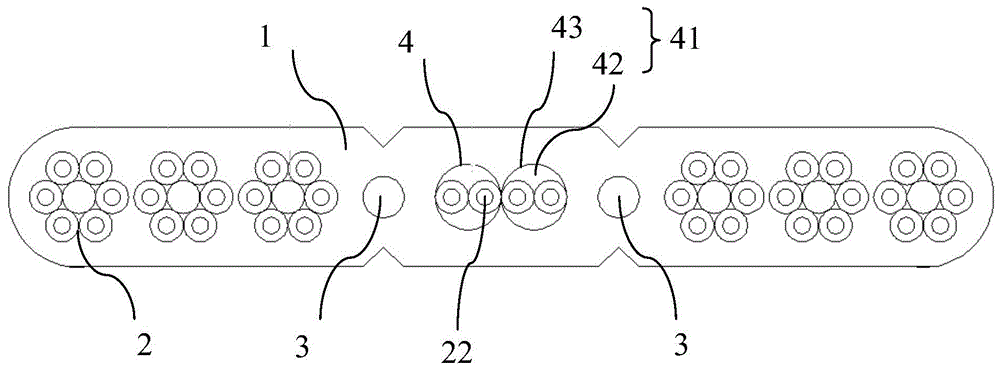

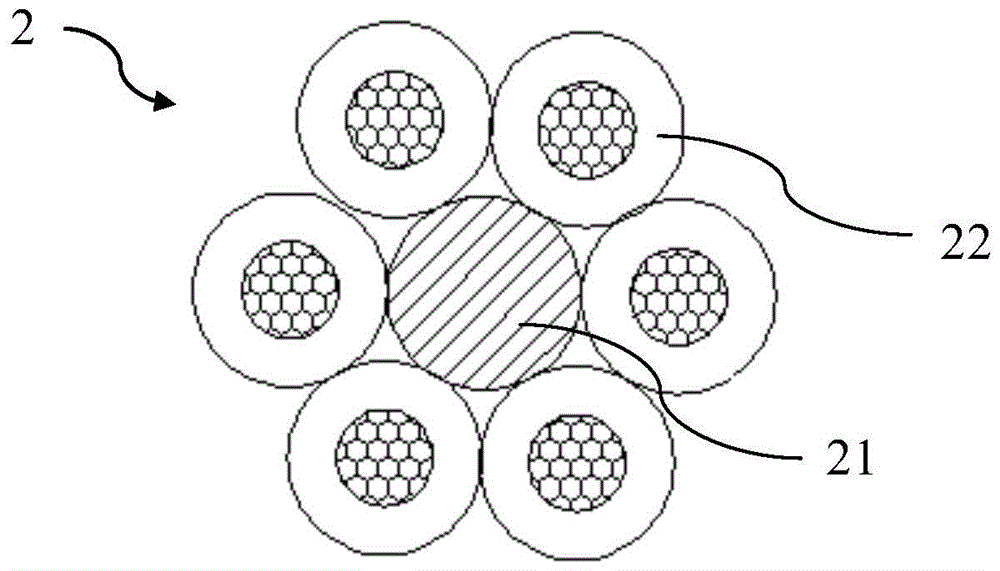

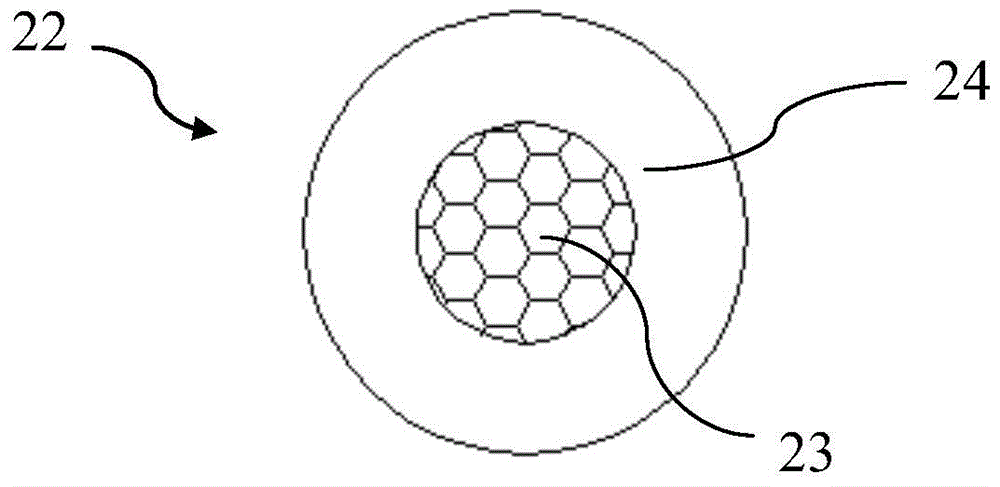

A flat combined drag chain cable and its preparation method

ActiveCN105448412BGuaranteed stabilityExtended service lifeNon-insulated conductorsPlastic/resin/waxes insulatorsInsulation layerLeft direction

The present invention discloses a flat combination drag chain cable and a preparation method thereof. The flat combination drag chain cable comprises a plurality of wire cores, and at least one steel wire embedded among a plurality of the wire cores; protective layers coat the wire cores and the steel wire; the wire cores are formed by twisting a plurality of insulation core wires and at least one adhesive tape; the insulation core wires include a group of conductors, formed by kinking a plurality of conductors, and an insulation layer coating outside the group of conductors; the conductors are formed by bunch stranding of a plurality of copper wires, the diameter of each wire of the copper wires is less than 0.2mm, and the twisting direction of the bunch stranding of a plurality of copper wires is the left direction. The flat combination drag chain cable provided by the invention has high anti-bending capability and is not able to break after more than million of times of back-and-forth bending motions, so that the physical property and the electrical property of the cable are not influenced.

Owner:ANHUI LIANJIAXIANG SPECIAL CABLE

Acid-washing corrosion-inhibiting fog inhibitor and preparation method thereof

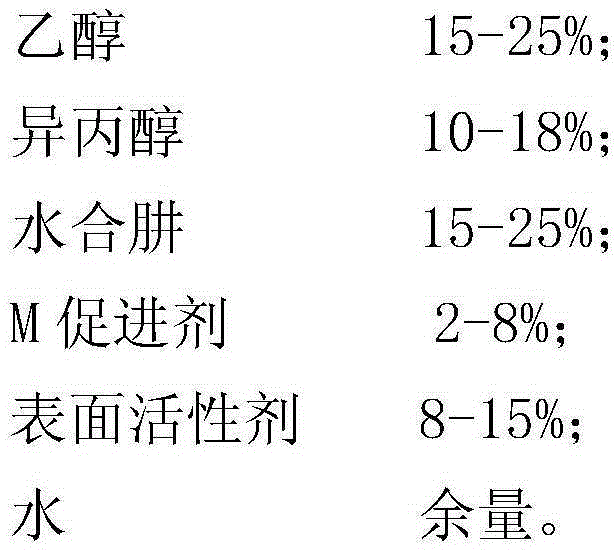

InactiveCN103436898AHigh corrosion inhibition rateGood corrosion inhibitionOther chemical processesAcid washingSURFACTANT BLEND

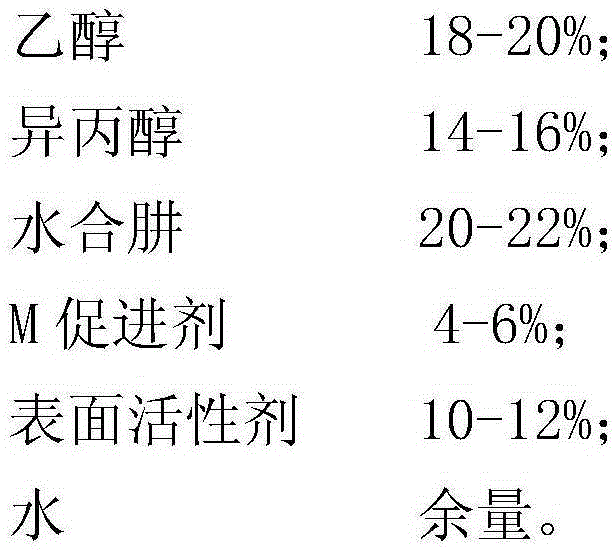

The invention discloses an acid-washing corrosion-inhibiting fog inhibitor which comprises the following components by weight: 15-25% of ethanol, 10-18% of isopropanol, 15-25% of hydrazine hydrate, 2-8% of an M promoter, 8-15% of a surfactant and the balance water. The preparation method of the acid-washing corrosion-inhibiting fog inhibitor comprises: adding the components into a reaction vessel according to priority and stirring to obtain the acid-washing corrosion-inhibiting fog inhibitor. The acid-washing corrosion-inhibiting fog inhibitor provided by the invention has corrosion inhibition rate of 98.5% or more and fog inhibition rate of 90% or more.

Owner:武汉亿强科技开发股份有限公司

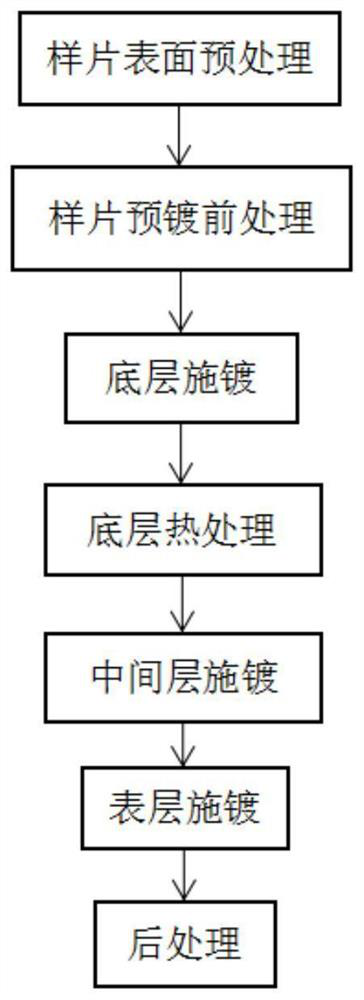

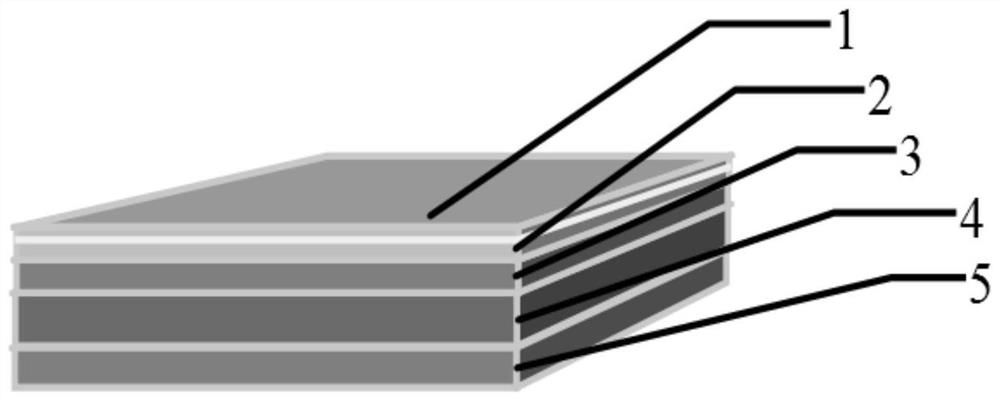

Ni-P-PFA-SiO2 nano composite coating and preparation method thereof

ActiveCN114016009AEfficient removalFacilitate chemical reactionsLiquid/solution decomposition chemical coatingSurface engineeringMetal

The invention discloses a Ni-P-PFA-SiO2 nano composite coating and a preparation method thereof, which belong to the technical field of metal surface engineering. According to the Ni-P-PFA-SiO2 nano composite coating, a Ni-P coating serves as a bottom layer, then the Ni-P-SiO2 coating, the Ni-P-PTE-SiO2 coating and the Ni-P-PFA-SiO2 coating are sequentially plated, surface dirt is removed by conducting alkali washing, electric alkali washing and acid washing on a base material in the preparation process, the binding force of the coatings is improved by adopting a method of conducting layered plating for four times, the porosity of the coatings is effectively reduced, the microstructure of the plating layer is changed, so that the hardness performance of the plating layer is more excellent, the preparation method is environment-friendly, the plating solution can be reused, and the method is scientific, reasonable, high in applicability and good in anti-corrosion effect. By adopting the method, the service life of the steel article can be prolonged, and the cost is saved.

Owner:NORTHEAST DIANLI UNIVERSITY

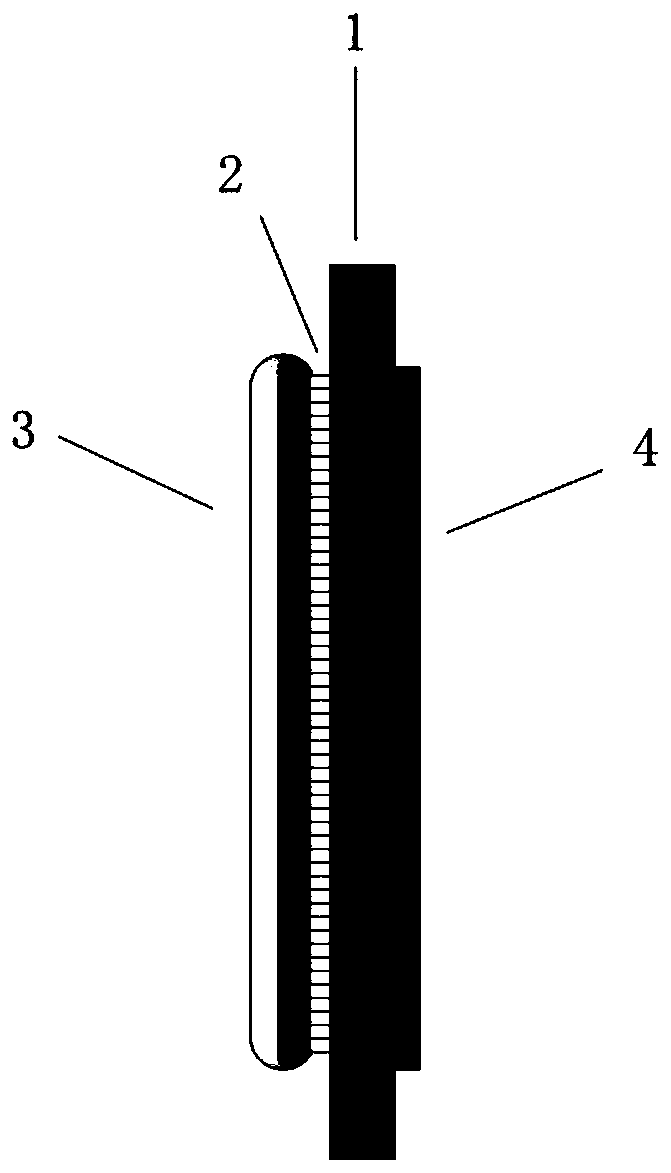

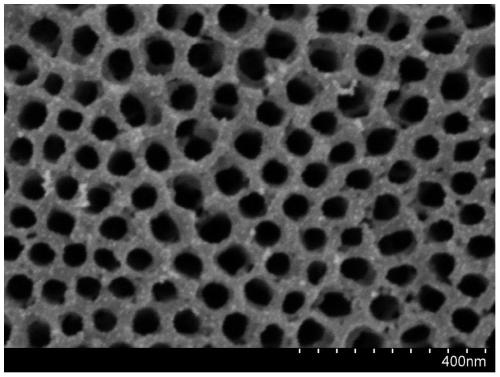

A titanium-based hydrogen evolution electrode for solid polymer water electrolyzer and preparation method thereof

ActiveCN107858701BSimple structureReduce usageMaterial nanotechnologySurface reaction electrolytic coatingTio2 nanotubeTitanium oxide

The invention discloses a titanium-based hydrogen evolution electrode used for a solid polymer water electrolyzing device and a preparing method of the titanium-based hydrogen evolution electrode. Thetitanium-based hydrogen evolution electrode is obtained in the manner that a perpendicularly-oriented titanium oxide nanotube array layer is prepared on the surface of a porous titanium base body, then precious metal nano particles are loaded on the surface of the titanium oxide nanotube array layer to form a catalyst layer, and finally the surface of the catalyst layer is coated with an ionic conducting polymer. The electrode has the functions of a current collector in the water electrolyzing device and the catalyst layer and can be used for replacing a carbon-supported platinum catalyst layer in a traditional solid polymer water electrolyzing device to be directly used for the hydrogen evolution reaction, the hydrogen evolution catalytic performance similar to that of a traditional carbon-supported platinum cathode can be obtained, the titanium-based hydrogen evolution electrode further has the beneficial effects of being low in cost and simple in process on the basis that the electrolytic efficiency of the solid polymer water electrolyzing device is ensured, and good application prospects and market value are achieved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Ferritic stainless steel cold-rolled strip steel production device

PendingCN114043366AAvoid damageQuality improvementGrinding drivesGrinding machinesElectric machineryStrip steel

The invention belongs to the technical field of strip steel production and processing, and particularly relates to a ferritic stainless steel cold-rolled strip steel production device, which comprises an uncoiler, a straightening machine, a pickling machine, a rolling mill and a coiler, and the pickling machine comprises a pickling tank, an inner tank, first grinding rollers, second grinding rollers and a motor; the pickling tank is fixedly connected to the ground; the inner tank is arranged in the pickling tank and slides on the inner wall of the pickling tank; first grinding rollers and second grinding rollers are arranged in the inner tank, the first grinding rollers and the second grinding rollers are rotationally connected with the inner tank, the number of the first grinding rollers is two, and the number of the second grinding rollers is two; the first grinding rollers and the second grinding rollers are vertically arranged in the inner tank; the motor is fixedly connected to the outer side of the inner tank; a pickling solution in the tank is used for pickling the polished strip steel, and the two modes of polishing and pickling are combined, so that the pickling quality and efficiency are improved, the strip steel is protected, the strip steel is prevented from being damaged due to excessive polishing, and the production and processing quality of the strip steel is improved.

Owner:孟祥平

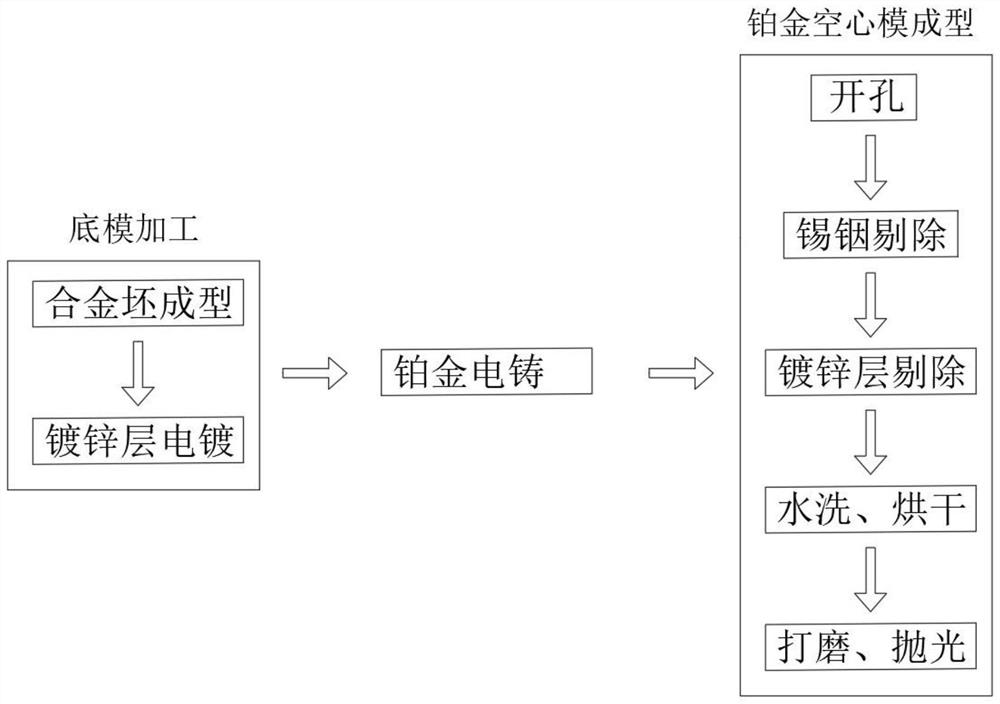

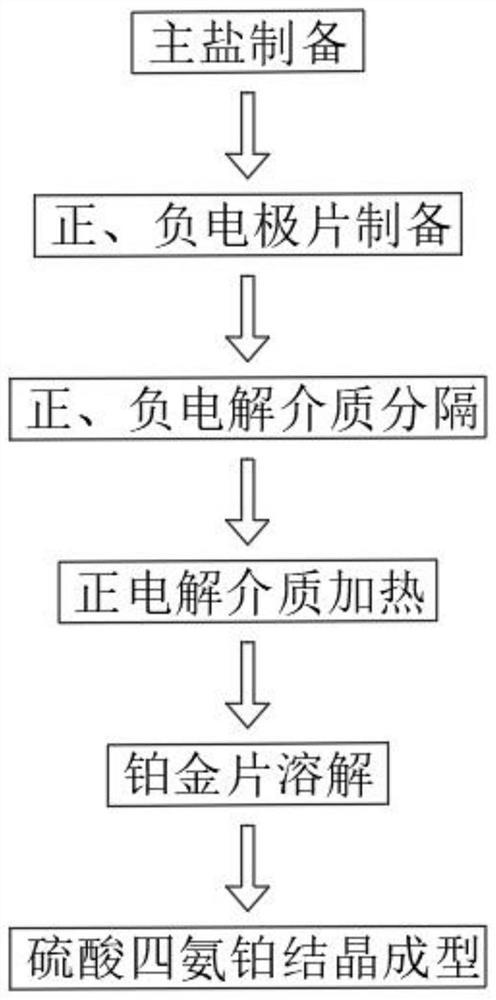

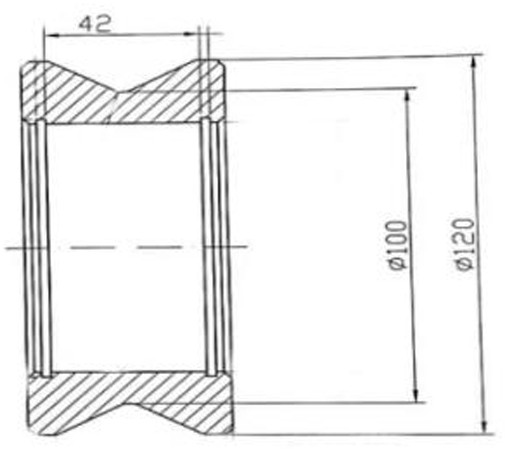

Novel process for electroforming jewelry by using platinum

InactiveCN113430608ASolve the problem of brittle crackingReduce hydrogen embrittlementJewelleryElectroforming processesPlatinumPotassium sodium tartrate

The invention discloses a novel process for electroforming jewelry by using platinum, and relates to the technical field of jewelry machining. The process comprises the following steps that a bottom die is machined; platinum electroforming is conducted, specifically, tetraammine platinum sulfate is used as main salt, potassium sodium tartrate tetrahydrate is used as conducting salt, an electroforming solution is formed, the surface of the bottom die is electroplated with a platinum plating layer of 100 microns-500 microns in the electroforming solution, and a rough workpiece is formed; and platinum hollow die forming is conducted, specifically, the bottom die of a rough workpiece is removed, the rough workpiece is ground and polished, and the jewelry is formed. According to the process, the platinum plating layer with the thickness of 100 microns-500 microns can be electroformed through cooperation of all the steps, the probability of the hydrogen embrittlement phenomenon of the electroformed platinum plating layer is low, and the problem that the platinum plating layer is prone to brittle cracking due to the hydrogen embrittlement phenomenon when the platinum plating layer with the thickness of 100 microns or above is electroplated is solved.

Owner:深圳市永达锐国际科技有限公司

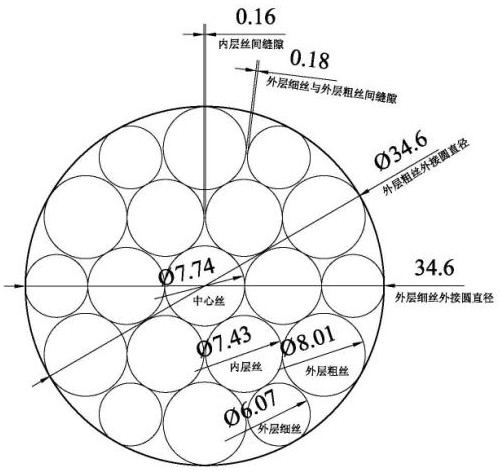

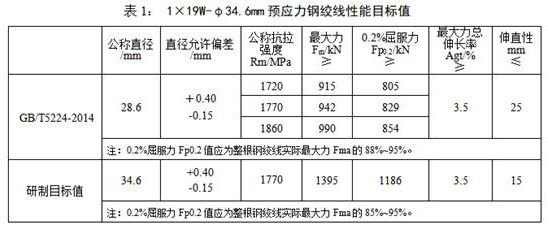

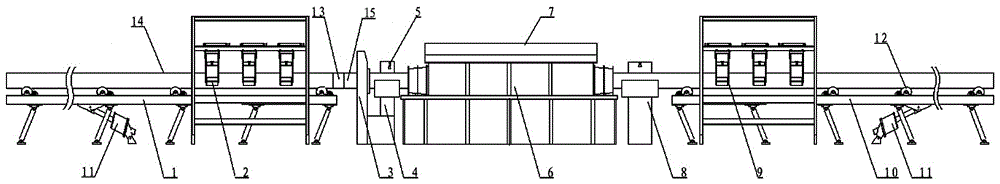

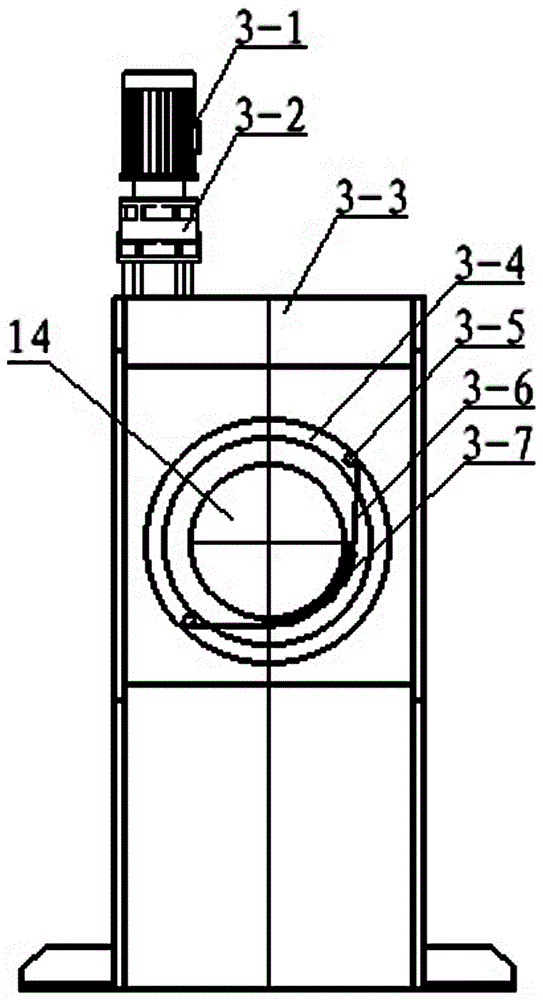

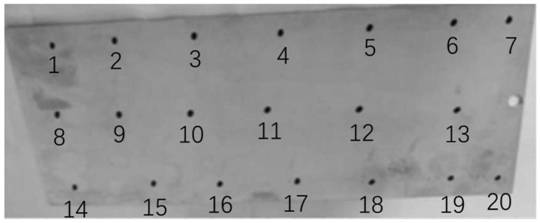

A kind of super-large diameter steel strand for mine anchor cable and its manufacturing method

ActiveCN114561821BReduce manufacturing costIncrease productivityFurnace typesMetallic material coating processesWire rodProduct inspection

The invention relates to a super-large-diameter steel strand for a mine anchor cable and a manufacturing method thereof. The steel strand adopts a 1×19-wire Waringon structure, 19 wires are twisted at one time, and the twist distance is 13.5 times. The diameter of the wire is 7.74mm, the diameter of the outer thick wire is 8.01mm, the diameter of the outer thin wire is 6.07mm, the diameter of the inner wire is 7.43mm, the nominal diameter of the steel strand is 34.6mm, and the upper deviation of the nominal diameter is +0.40 mm, the lower deviation of the nominal diameter is ‑0.15mm; the manufacturing method includes: selection of wire rods → inspection, testing → pickling, phosphating → inspection → drawing → semi-finished product inspection, testing → stranding → stabilization treatment → layer winding → Finished product inspection and testing → packaging → storage. The invention makes the measured diameter of the twisted steel strand reach 34.8mm through four kinds of diameters of wires, and the structure of the steel strand is tight and not loose, which meets the size requirement of the super-large diameter steel strand.

Owner:天津市新天钢中兴盛达有限公司 +3

Method for removing hydrogen by electroplating zinc-nickel alloy on high-strength steel

The invention relates to a method for removing hydrogen in high strength steel electroplated by zinc-nickel alloy, including the following steps: 1) zinc nickel alloy coated high strength steel parts are sequentially cleaned by water and soaked by alcohol; 2) parts after being cleaned are placed into a vacuum furnace to be subject to heat treatment, so that hydrogen atom on coating surface is overflown; 3) parts after hydrogen removal are placed into citric acid-boric acid mixed aqueous solution to be activated; 4) parts after coating activation treatment are subject to zinc nickel alloy electroplating again; 5) parts after composite electroplating are placed into chromic anhydride-sodium chloride mixed aqueous solution to be passivated; 6) parts after passivation treatment are cleaned by water and dried by blowing, thus obtaining the finished product conforming to the requirements. The method can be utilized to effectively remove hydrogen penetrated into base metal in electroplated by zinc-nickel alloy process, hydrogen embrittlement is reduced, and passivation coating with good protective properties can be generated on the surface of alloy coating, and meanwhile the technological method of the invention is simple and production cost is low.

Owner:湖北三江航天红林探控有限公司

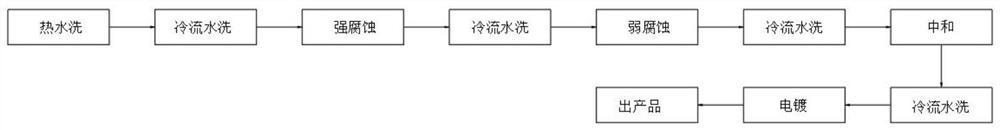

Continuous chrome plating device and method for large rods

ActiveCN105239139BEfficient removalImprove bindingElectrolysis componentsHydraulic cylinderOrganic solvent

Owner:CSIC ZHONGNAN EQUIP

Preparation method of stamping part

PendingCN114657613ADecreased cold bending performanceImprove corrosion resistanceElectroplatingMaterials science

The invention discloses a manufacturing method of a stamping part. The manufacturing method comprises the following steps that a blank is stamped to form a preformed part; the preformed part is placed in an acid electroplating solution to be electroplated for the first time; and placing the preformed part subjected to the first electroplating in an alkaline electroplating solution for second electroplating. According to the scheme, it can be guaranteed that the preformed part has high corrosion resistance and good cold bending performance, meanwhile, the thickness of a plating layer on the surface of the preformed part can be uniform through the method, and the welding performance of the preformed part in the later procedure is not affected.

Owner:SUZHOU PRESSLER ADVANCED FORMING TECHNOLOGIES CO LTD

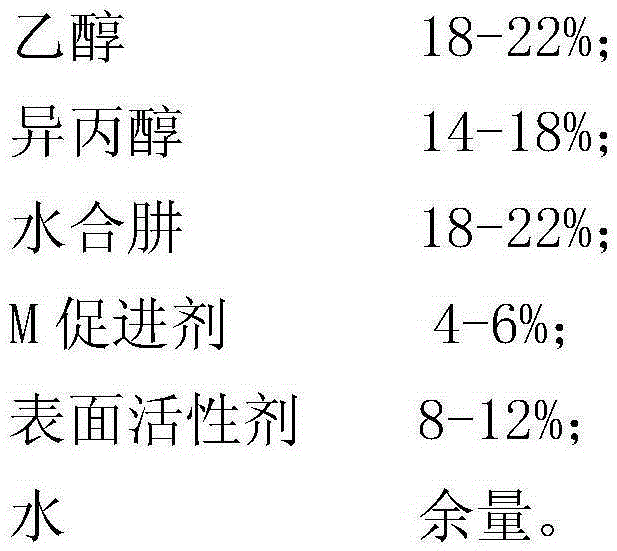

A kind of pickling anti-corrosion anti-fogging agent and preparation method thereof

InactiveCN103436898BHigh corrosion inhibition rateGood corrosion inhibitionOther chemical processesHydrazine compoundAcid washing

Owner:武汉亿强科技开发股份有限公司

Preparation method of porous alloy electrode and application thereof

ActiveCN113699547AReduce hydrogen evolution overpotentialEvenly distributedWater/sewage treatment by irradiationElectrolytic inorganic material coatingElectrolysisPtru catalyst

The invention discloses a preparation method of a porous alloy electrode, which is characterized in that a Ni-Cu-La-P porous alloy electrode is prepared by adopting a dealloying method, loading nano gamma-Fe2O3 on the porous alloy electrode by adopting a dispensing method, and then loading a photocatalyst on the surface of the electrode by adopting an electro-deposition method; the prepared porous alloy electrode is applied to treatment of organic wastewater containing micro-plastics and reduction of hydrogen evolution overpotential under the illumination condition, the hydrogen evolution overpotential of a water electrolysis cathode can be obviously reduced, the micro-plastics and organic pollutants in water can be removed, the removal rate is 90% or above, the preparation process is simple and easy to operate, the electrode is convenient to use, and the method is suitable for industrial production and market popularization and application.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com